Performance of Additively Manufactured Fuels for Hybrid Rockets

Abstract

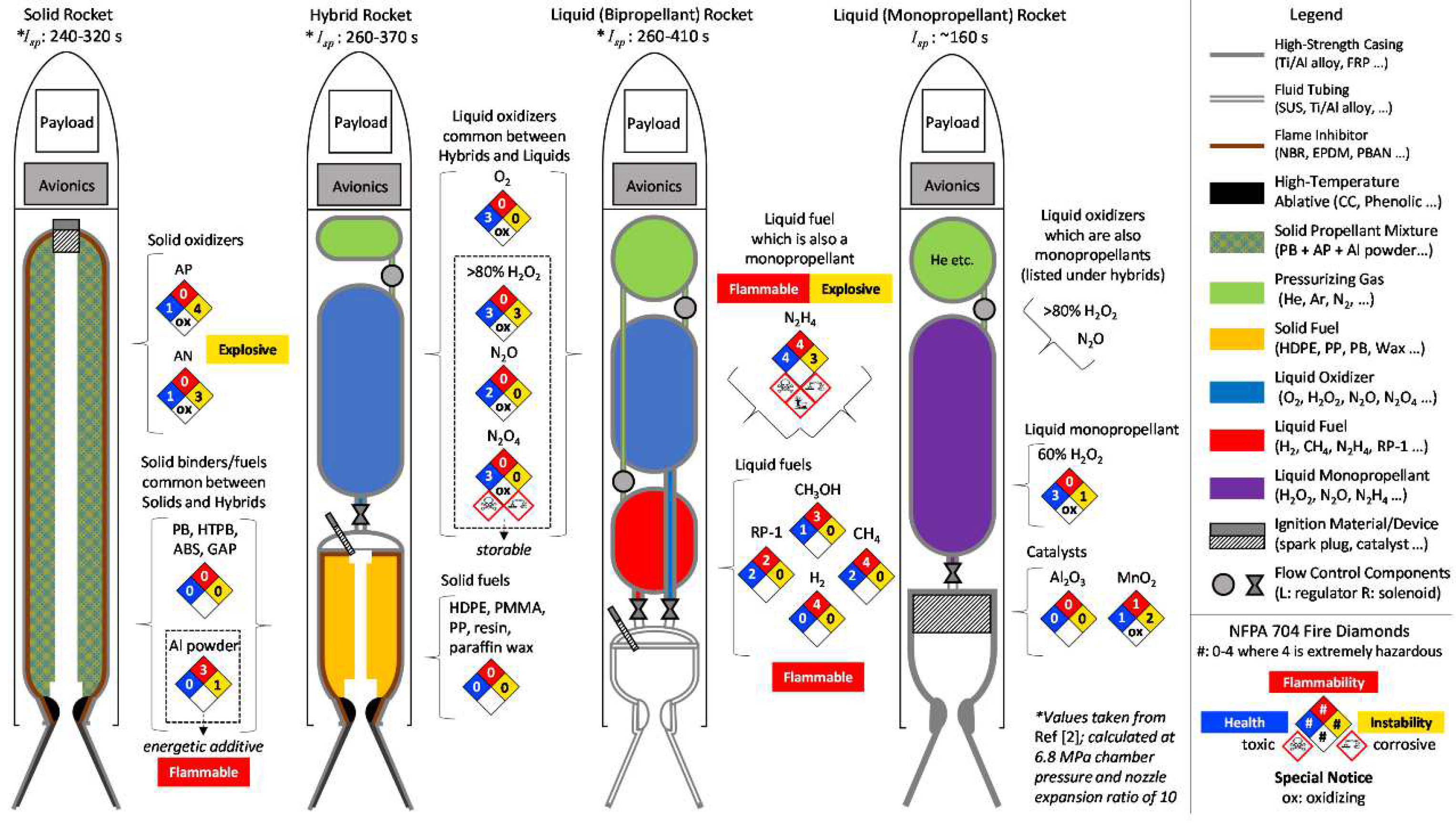

:1. Introduction

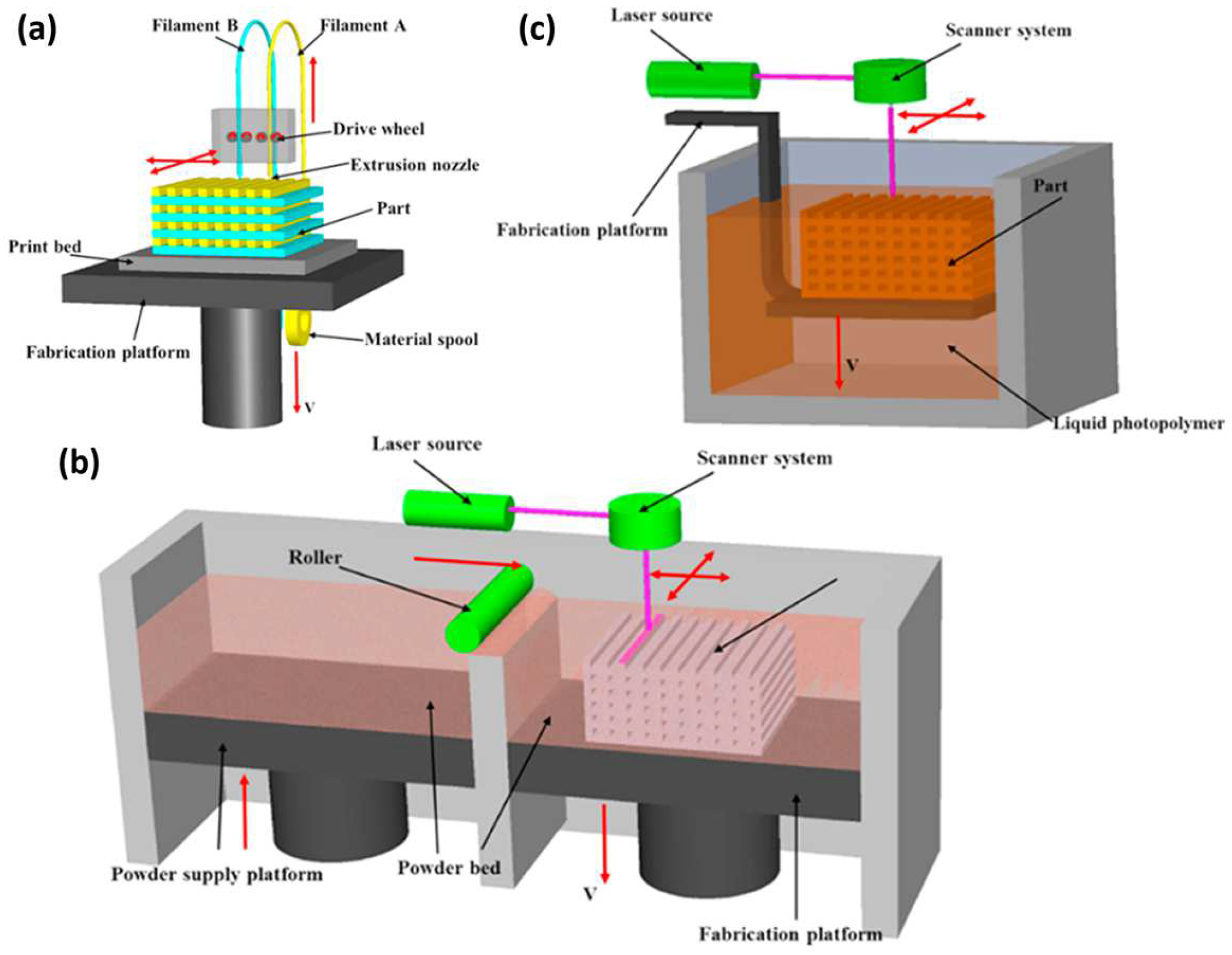

1.1. Introduction to Additive Manufacturing

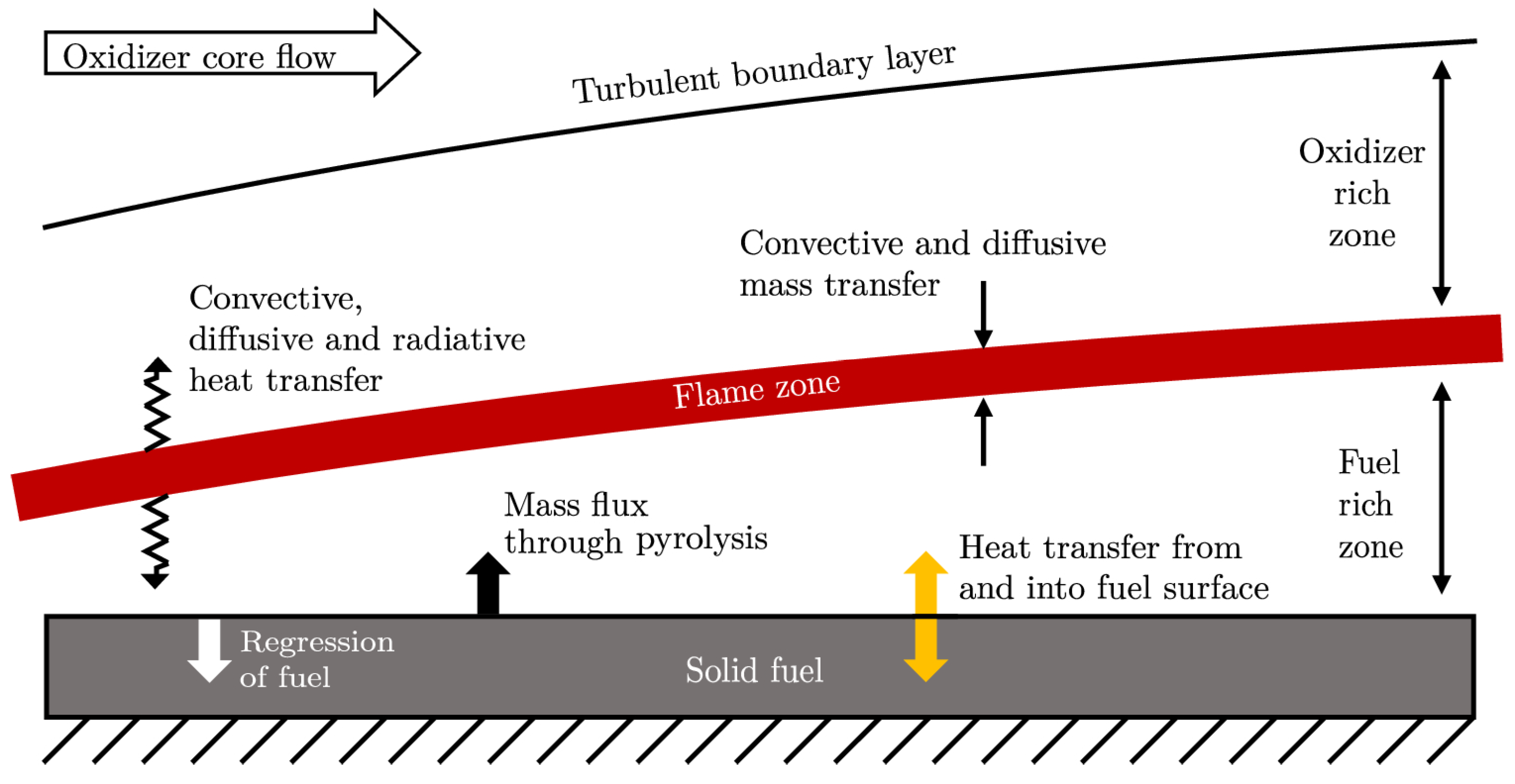

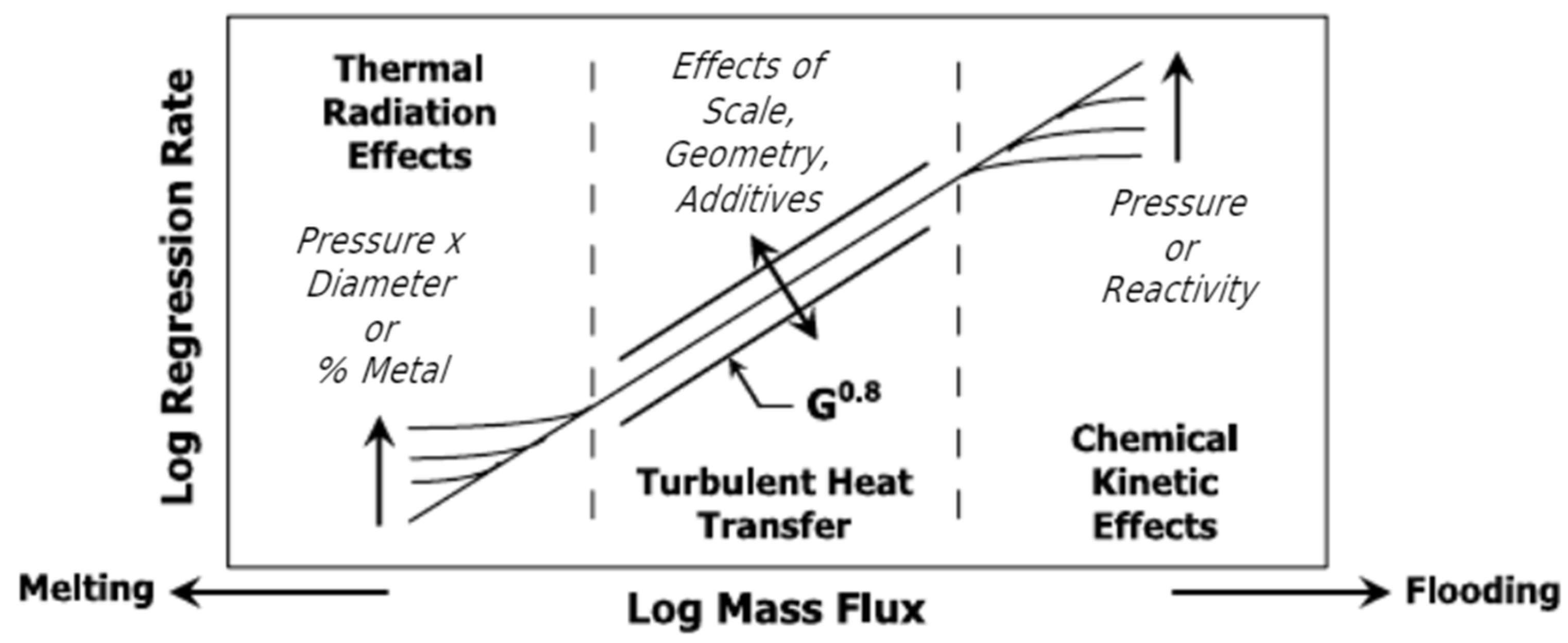

1.2. Ballistic Performance

1.3. Outline of Present Work

2. Literature Review of Additive Manufacturing in Hybrid Rockets

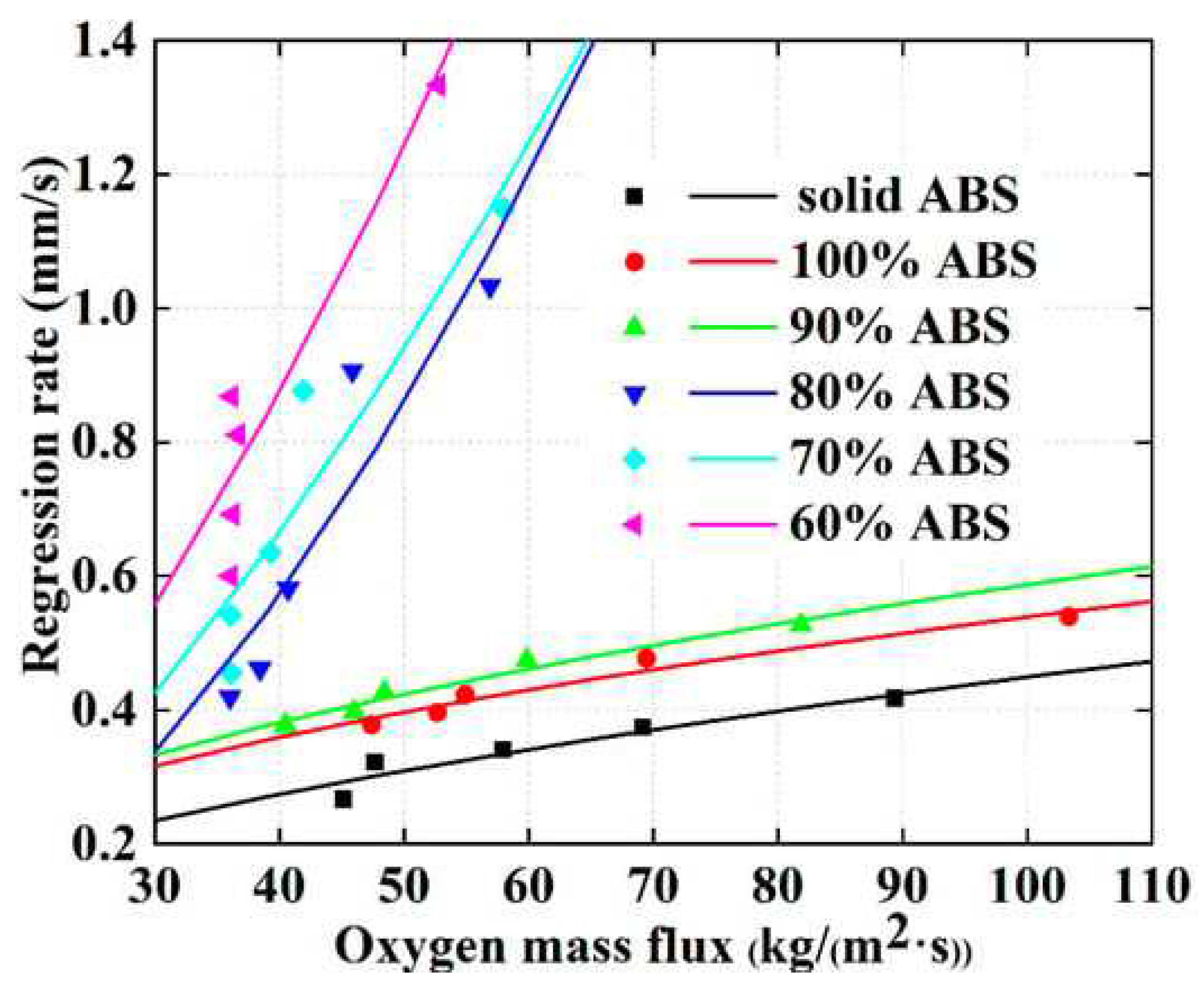

2.1. Comparison of Printed Fuels

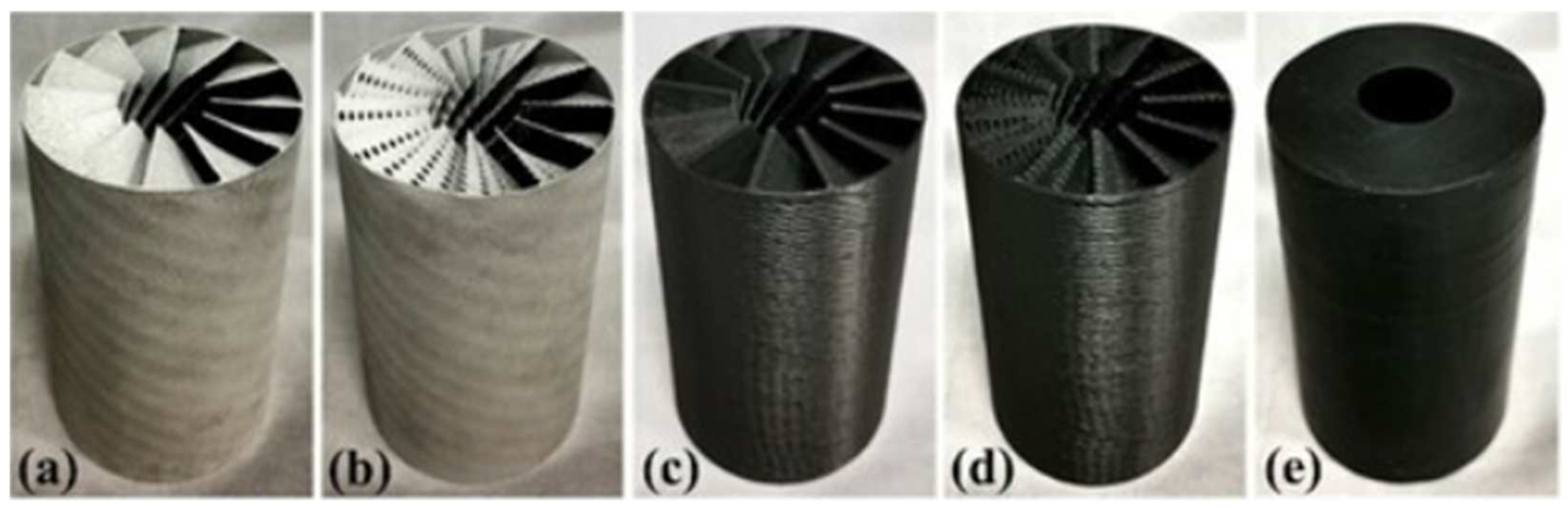

2.2. Complex Combustion Port Geometries

2.2.1. Helical Ports

2.2.2. Swirling Ports

2.2.3. Complex Combustion Port Geometries Summary

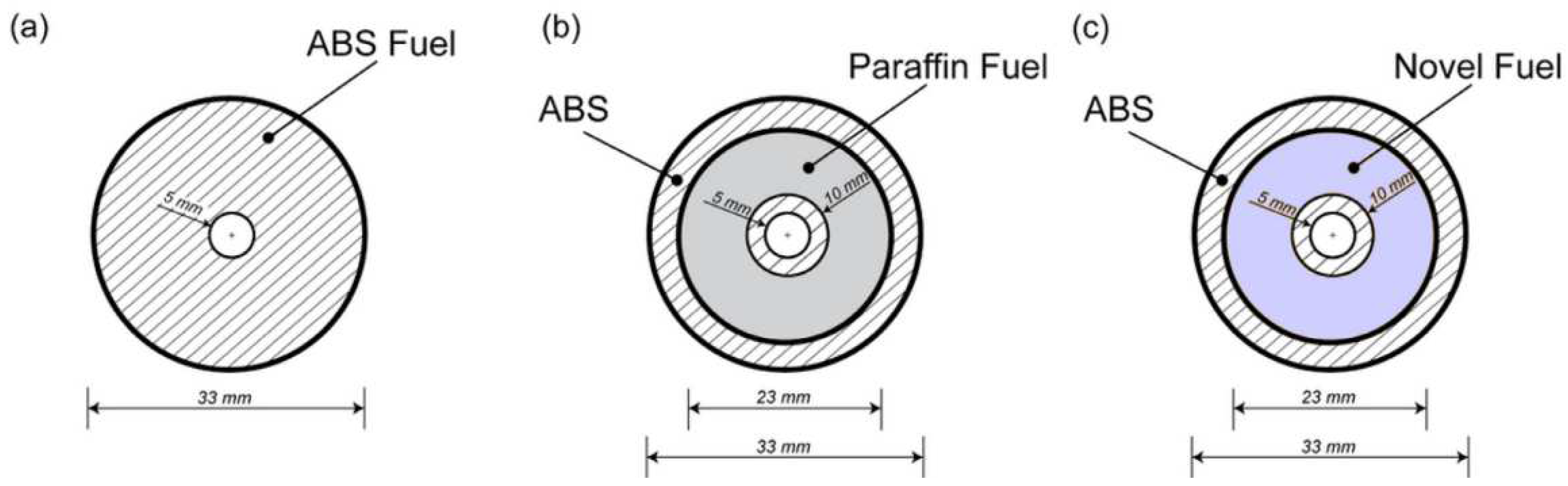

2.3. Multi-Fuel Printed Systems

2.3.1. Paraffin Additives

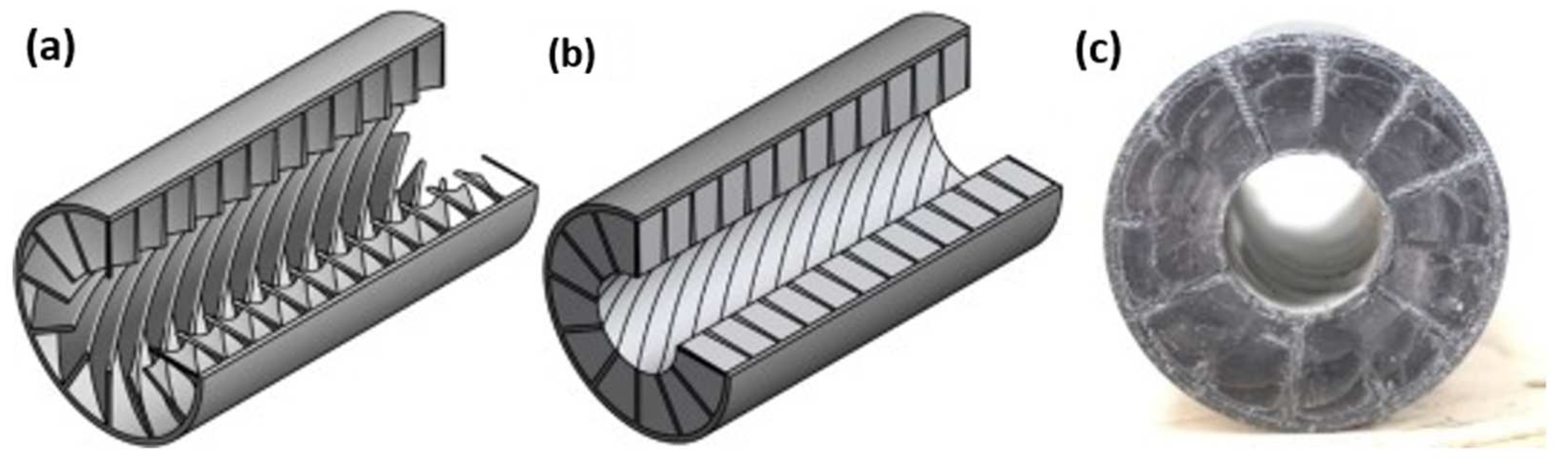

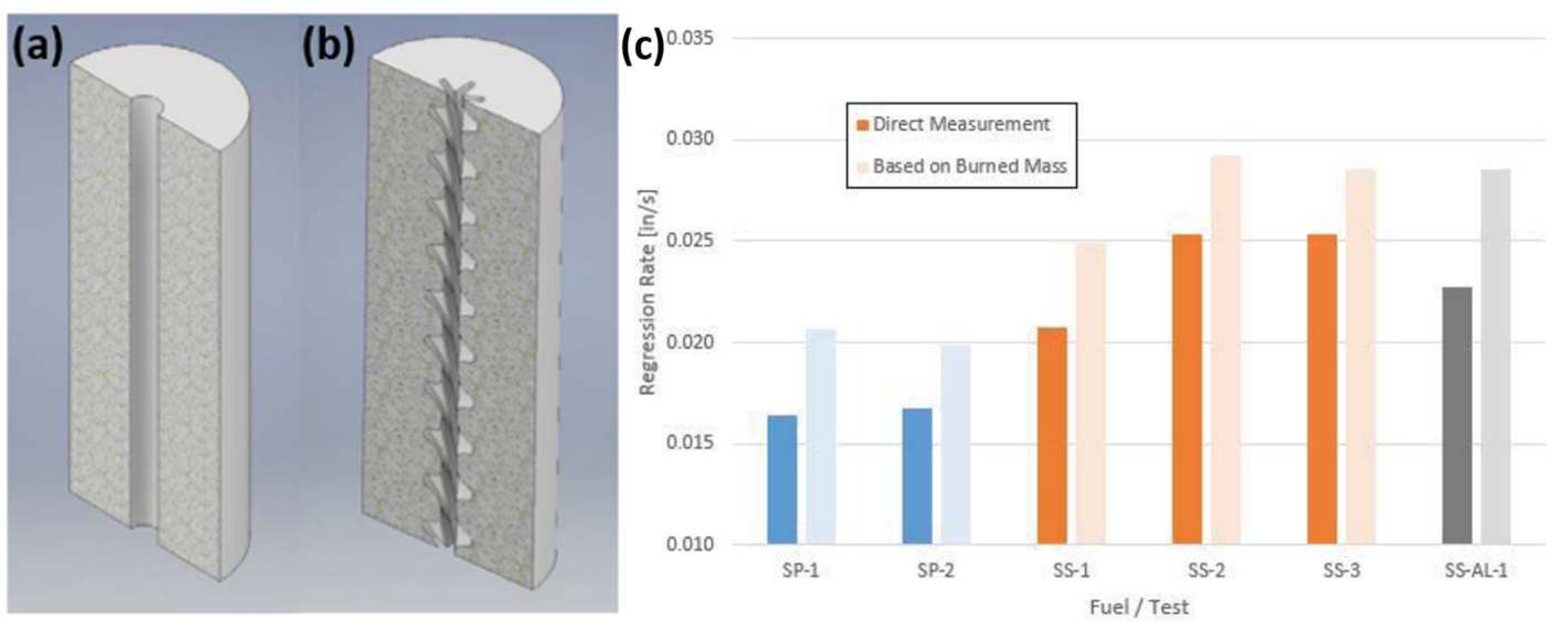

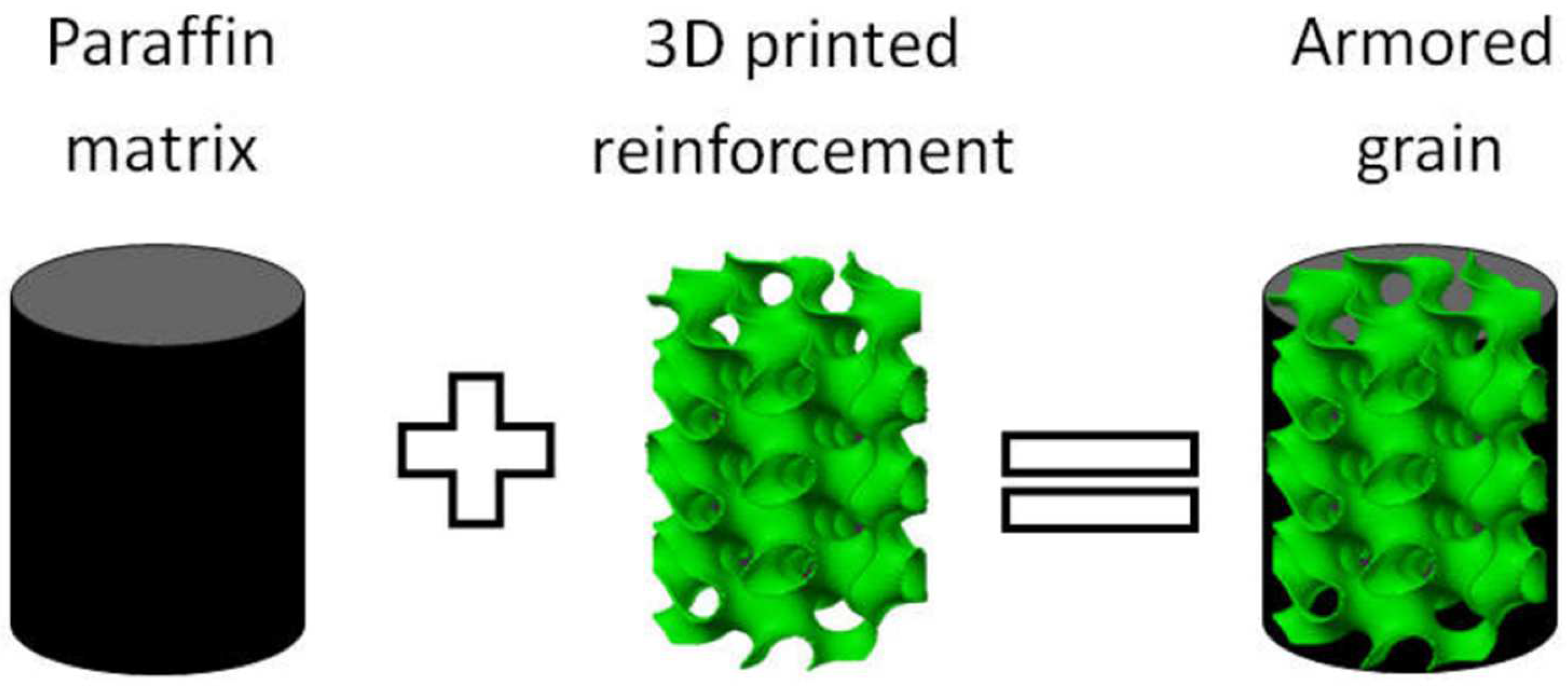

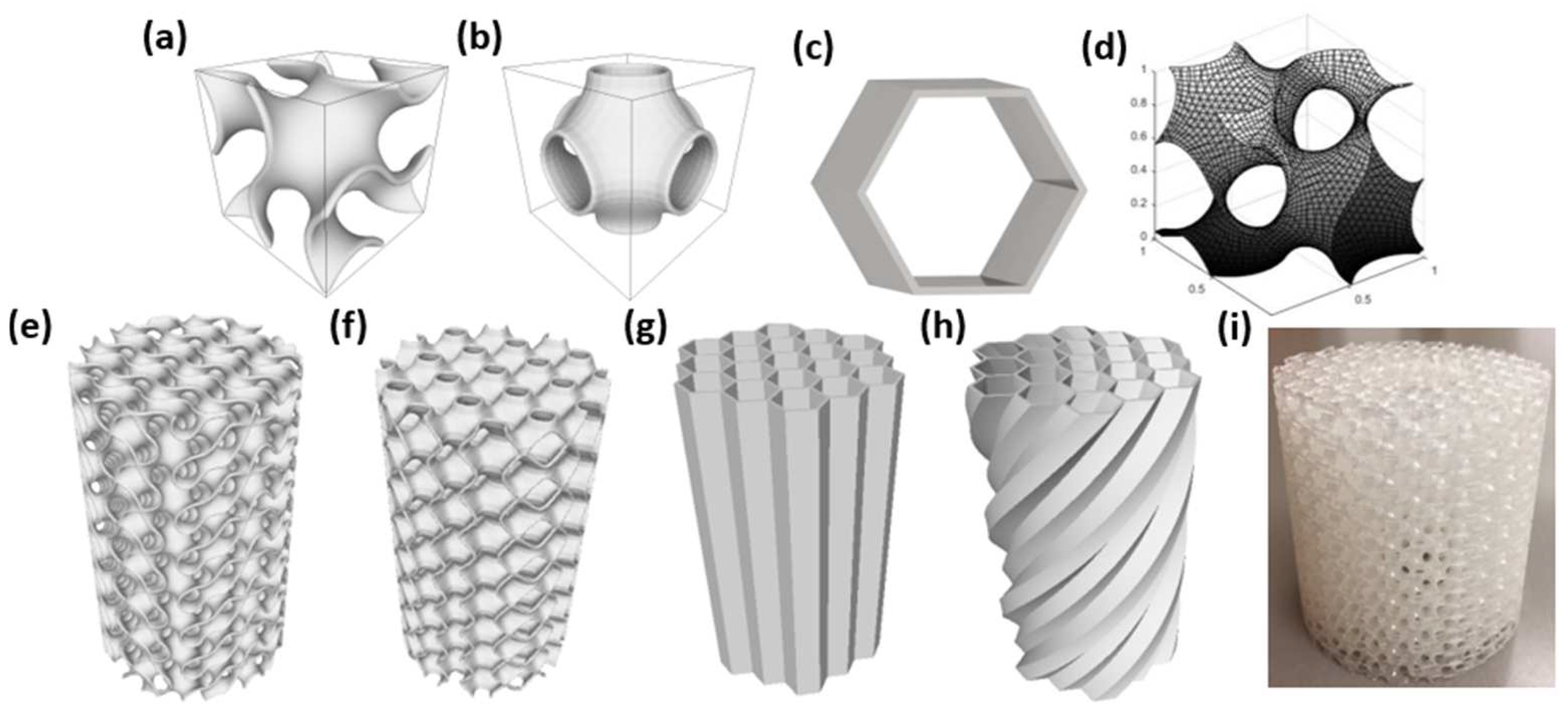

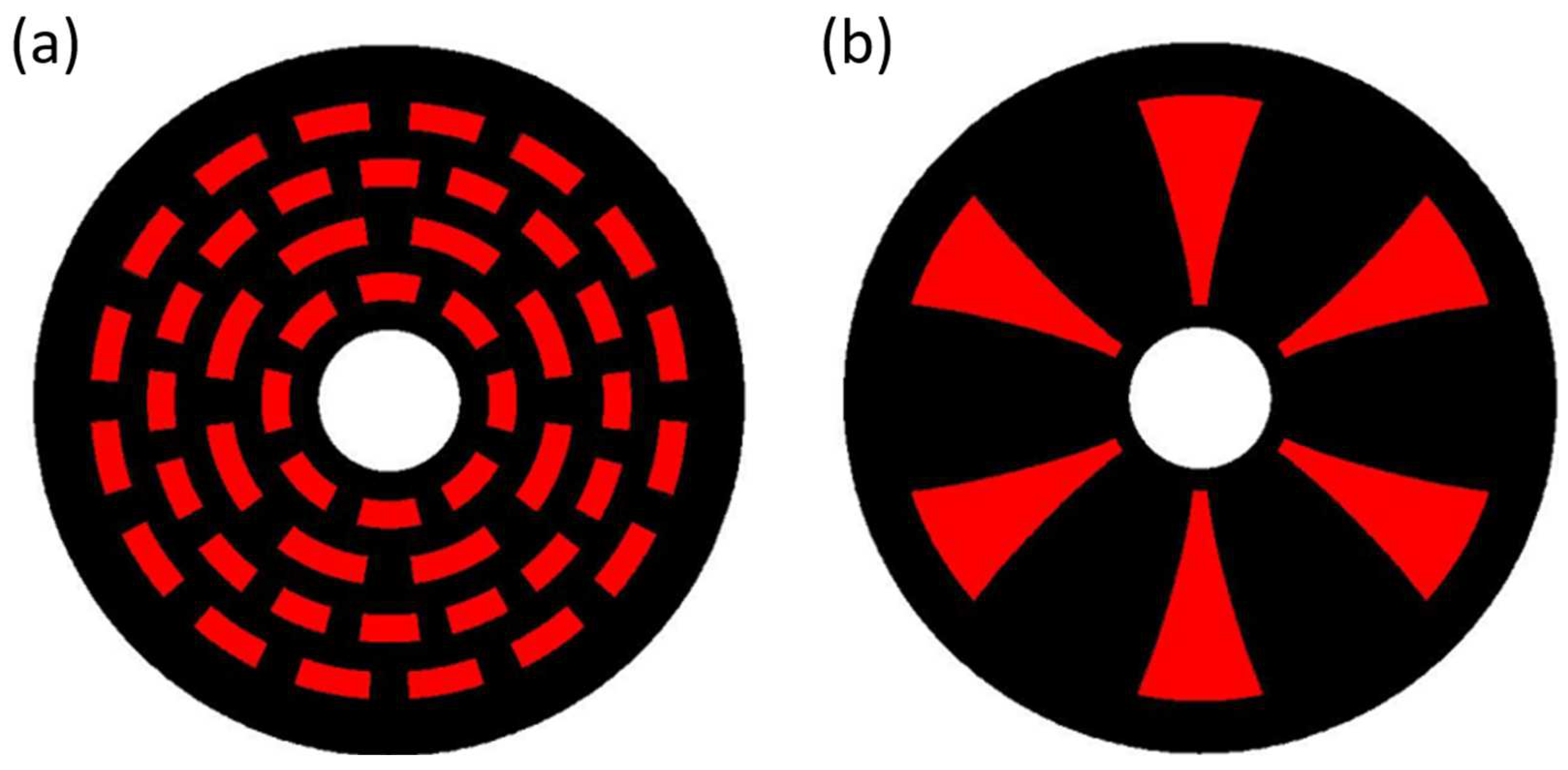

2.3.2. Embedded Structures

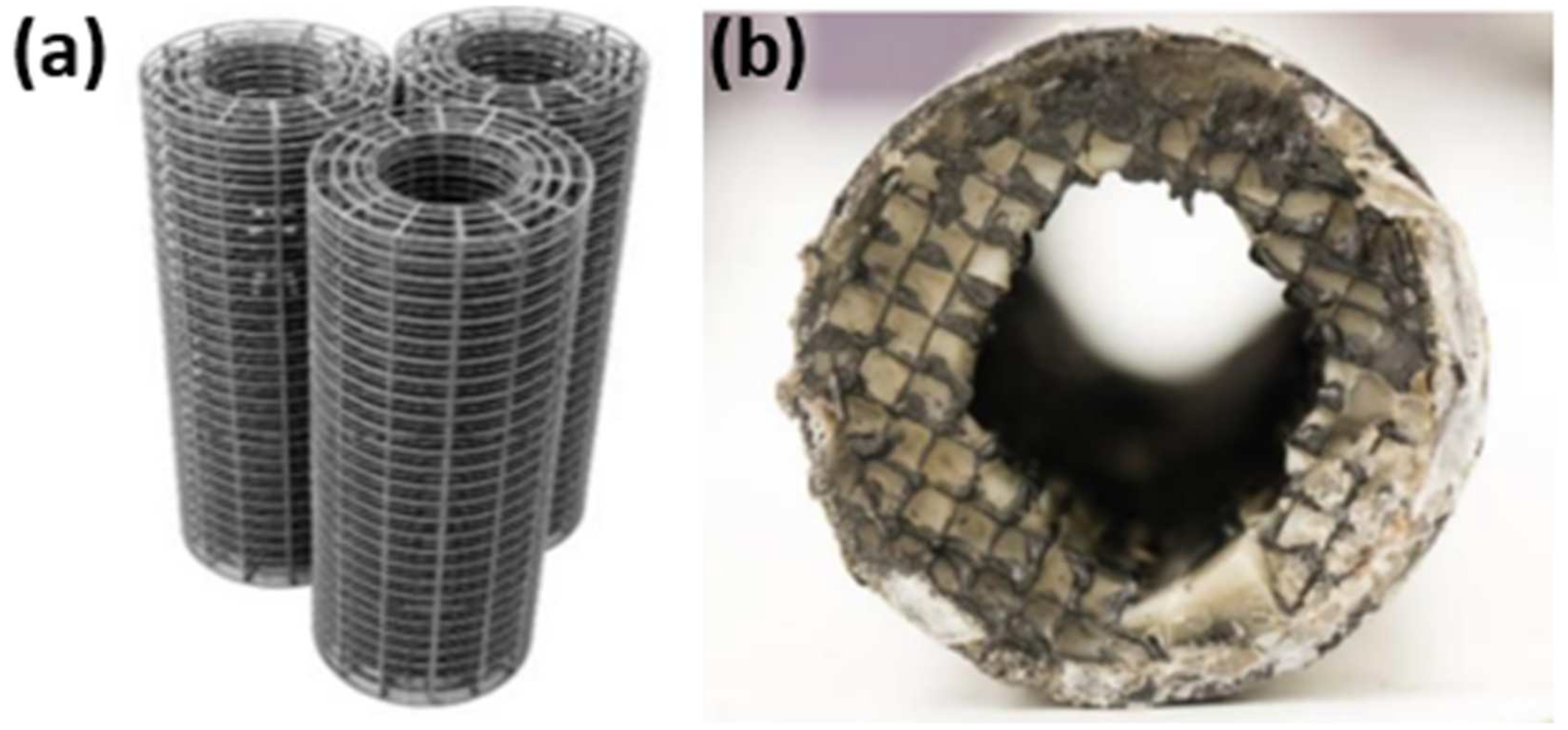

2.3.3. Matrices

2.3.4. Flow Modifiers

2.3.5. Metallic Additives

2.3.6. Summary

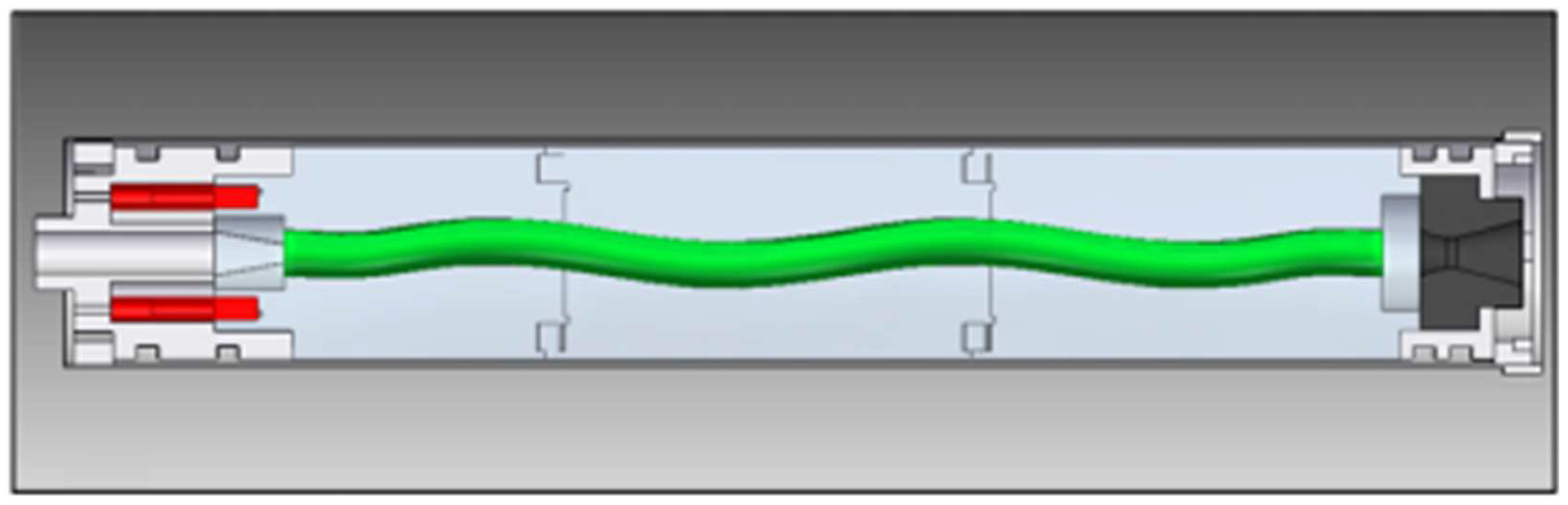

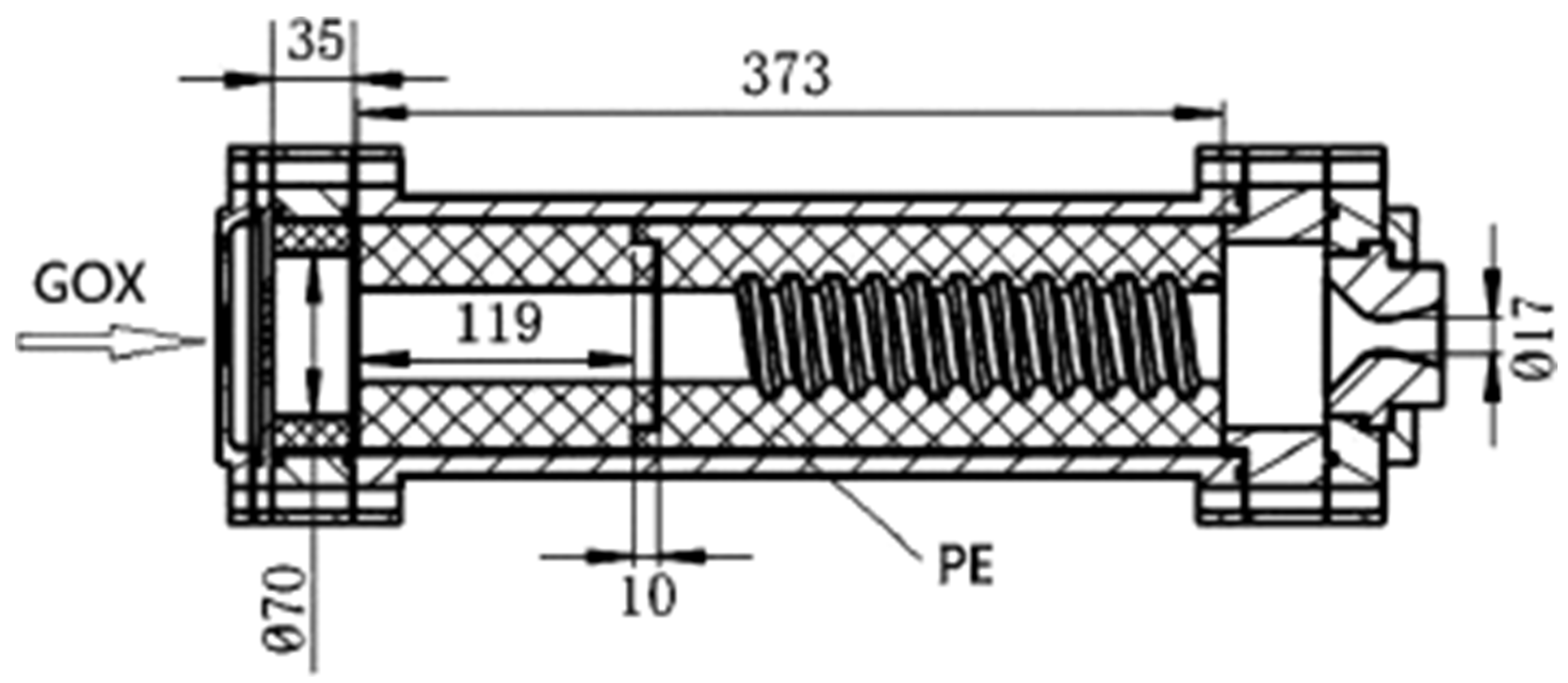

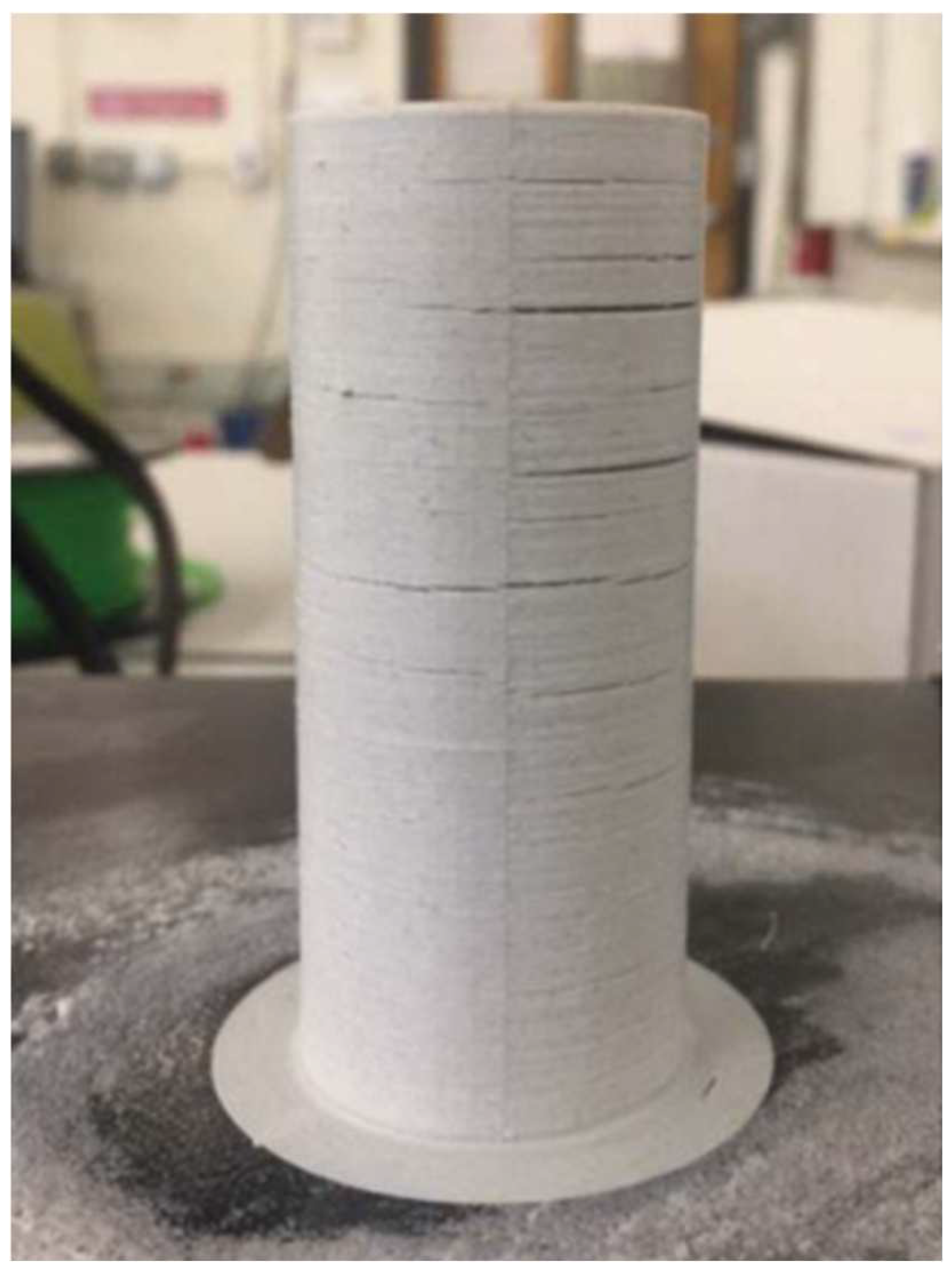

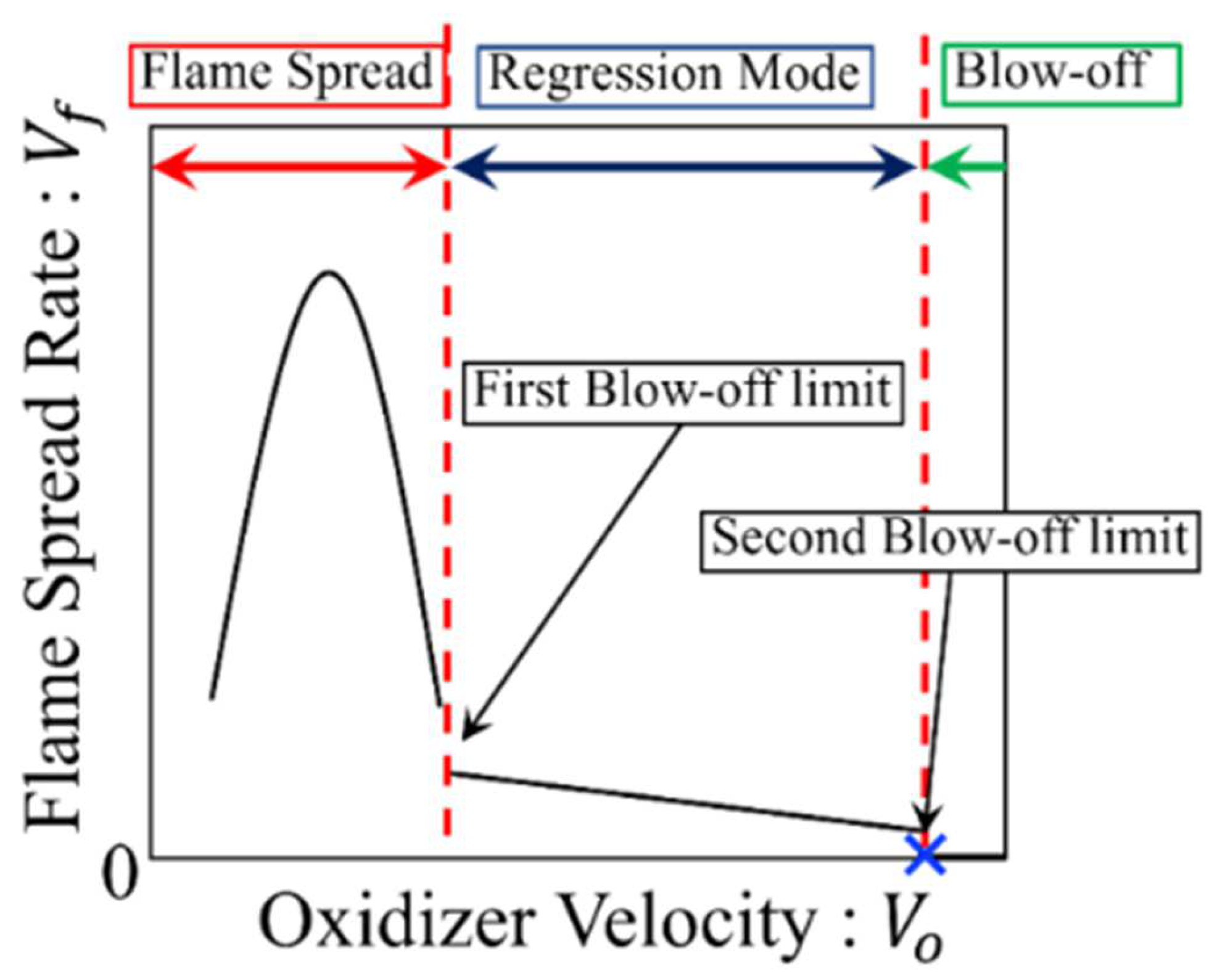

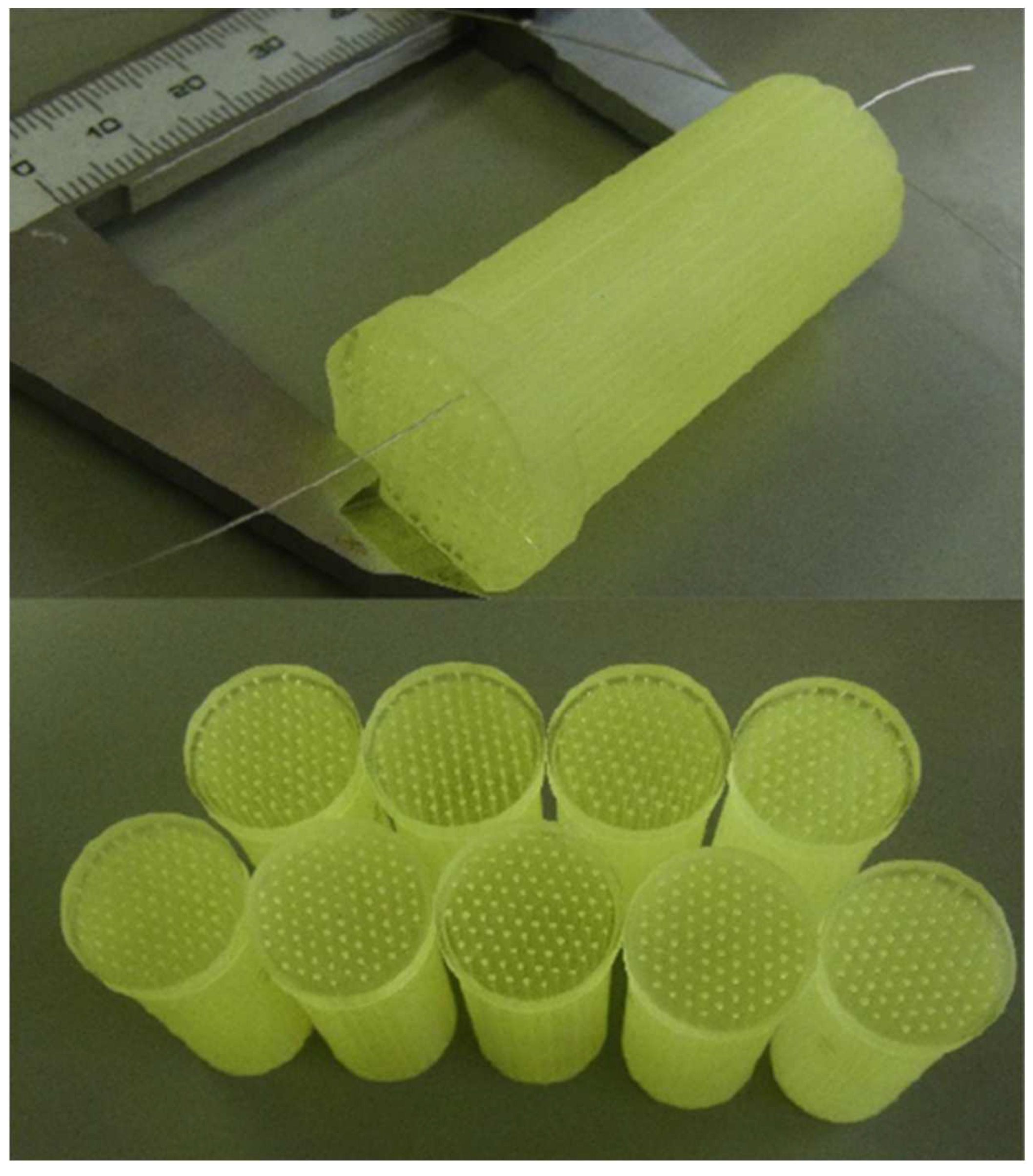

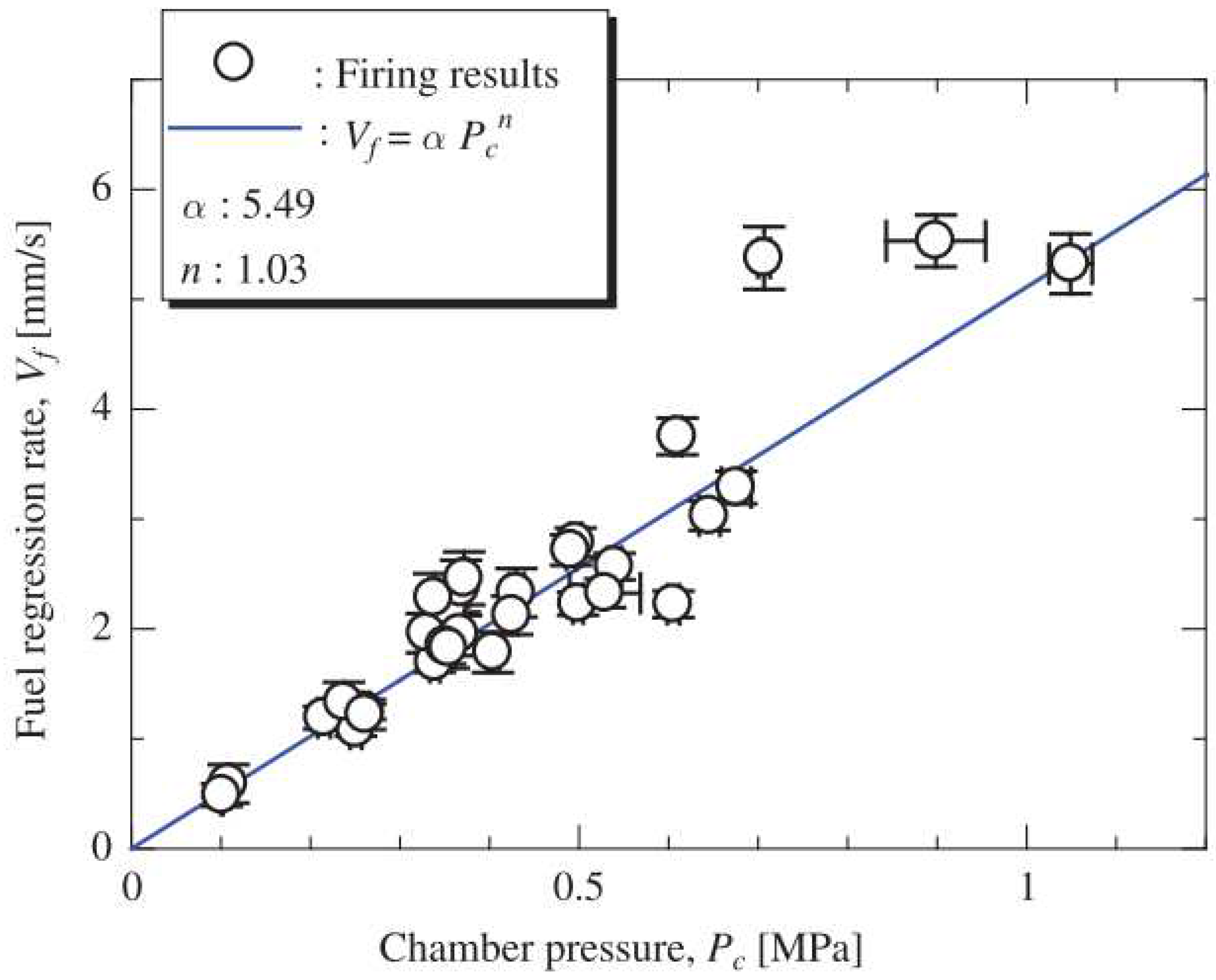

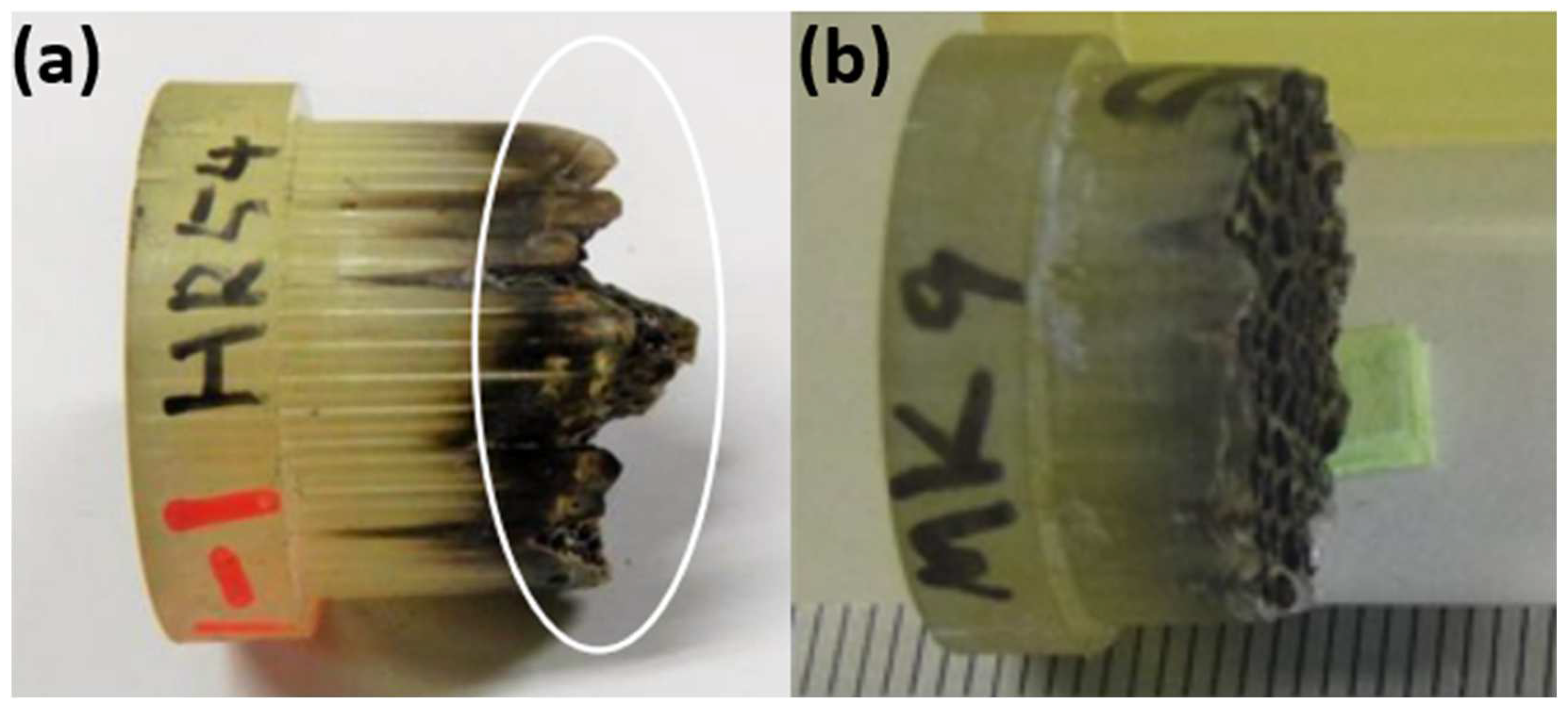

2.4. Axial-Injection End-Burning Hybrids

2.5. Literature Review Summary

3. Theoretical Performance Analysis

3.1. Fuel and Oxidizer Property Estimations

3.2. Chemical Equilibrium Analysis Computations

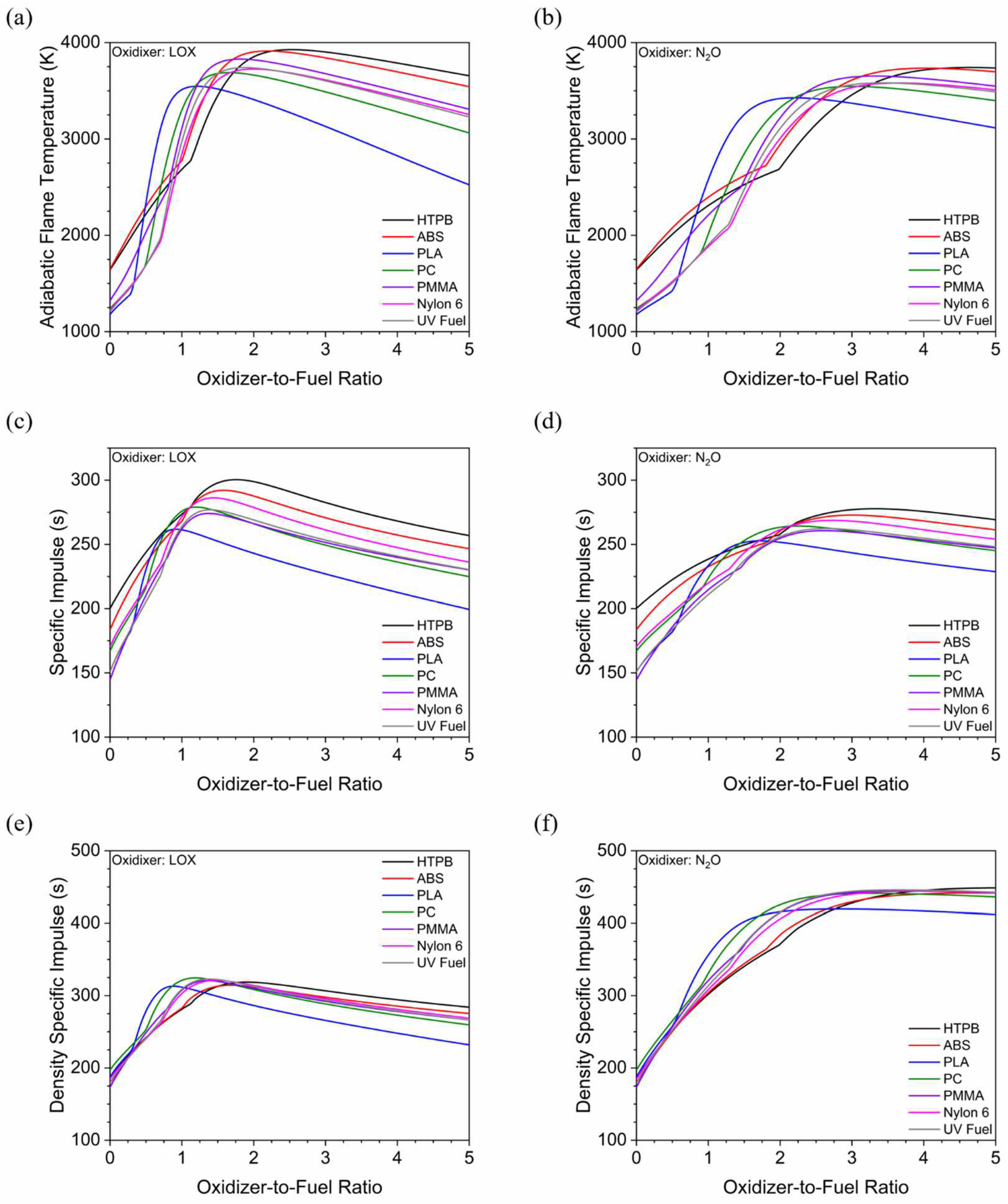

3.2.1. Baseline Fuels

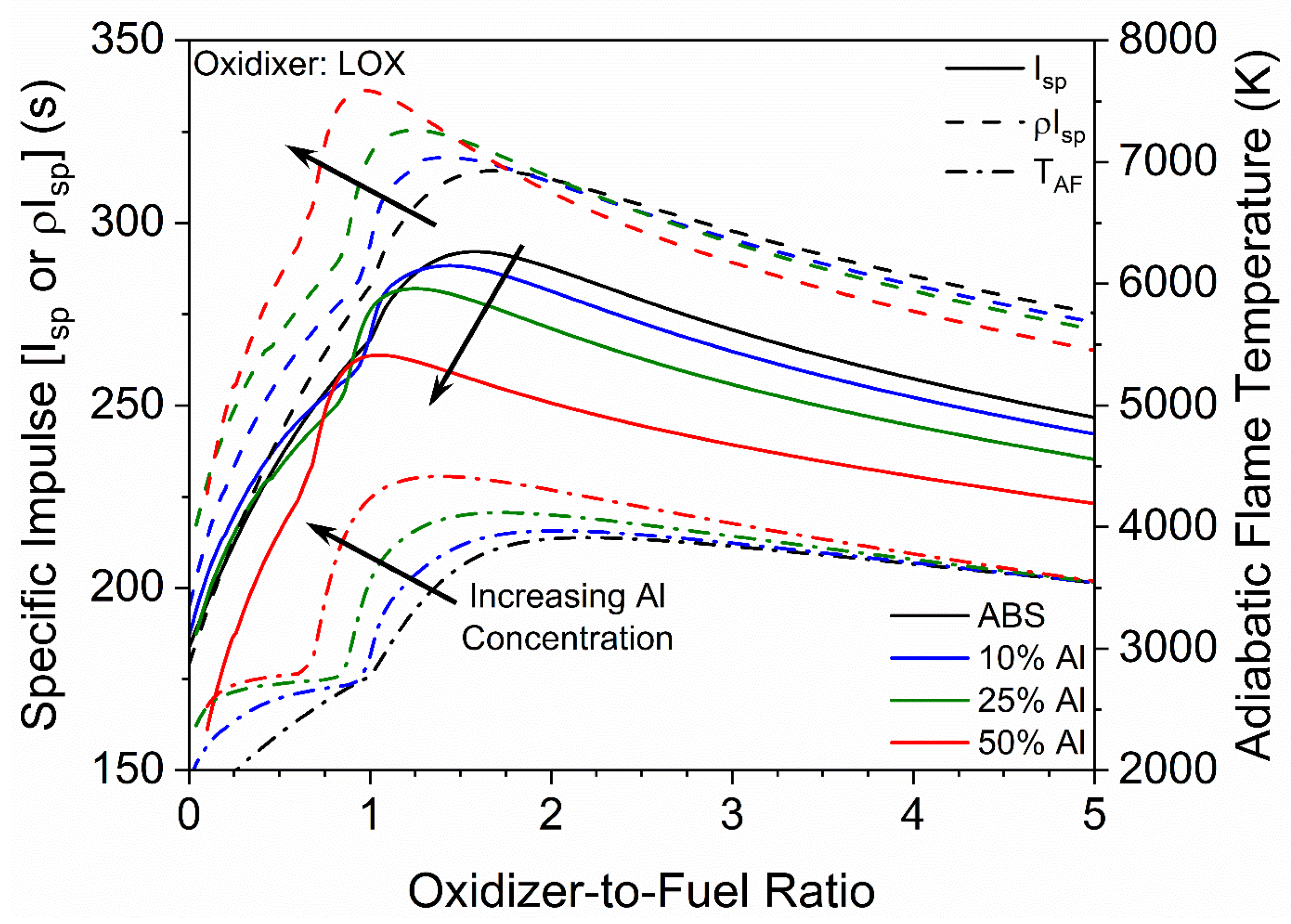

3.2.2. Inclusion of Metallic Additives

3.3. Summary

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kuo, K.; Chiaverini, M. Fundamentals of Hybrid Rocket Combustion and Propulsion; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2007; Volume 218. [Google Scholar]

- Kamps, L.; Hirai, S.; Nagata, H. Hybrid Rockets as Post-Boost Stages and Kick Motors. Aerospace 2021, 8, 253. [Google Scholar] [CrossRef]

- Oztan, C.; Coverstone, V. Utilization of additive manufacturing in hybrid rocket technology: A review. Acta Astronaut. 2021, 180, 130–140. [Google Scholar] [CrossRef]

- Bhuvanesh, K.M.; Sathiya, P. Methods and materials for additive manufacturing: A critical review on advancements and challenges. Thin-Walled Struct. 2021, 159, 107228. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; David, H. Additive manufacturing (3D printing): A review of materials, methods, applications, and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Sood, A.K.; Odhar, R.K.; Mahapatra, S.S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Glaser, C.; Hijkema, J.; Anthoine, J. Evaluation of Regression Rate Enhancing Concepts and Techniques for Hybrid Rocket Engines. Aerotec. Missili Spaz. 2022, 101, 267–292. [Google Scholar] [CrossRef]

- Marxman, G.A.; Wooldridge, C.E. Fundamentals of Hybrid Boundary-Layer Combustion. Heterog. Combust. 1964, 15, 485–522. [Google Scholar]

- Sutton, G.; Biblarz, O. Rocket Propulsion Elements, 8th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Chiaverini, M. Review of solid-fuel regression rate behavior in classical and nonclassical hybrid rocket motors. In Fundamentals of Hybrid Rocket Combustion and Propulsion; Kuo, K., Ed.; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2007; Volume 218, pp. 37–126. [Google Scholar]

- Ozawa, K.; Han-wei, W.; Yoshino, T.; Tsuboi, N. Time-resolved fuel regression measurement function of a hybrid rocket solid fuel integrated by multi-material additive manufacturing. Acta Astronaut. 2021, 187, 89–100. [Google Scholar] [CrossRef]

- Thomas, J.C.; Petersen, E.L.; DeSain, J.D.; Brady, B.B. Enhancement of Regression Rates in Hybrid Rockets with HTPB Fuel Grains by Metallic Additives. In Proceedings of the AIAA Propulsion and Energy 2015 Forum, Orlando, FL, USA, 27–29 July 2015. [Google Scholar]

- DeLuca, L.; Galfetti, L.; Maggi, F.; Colombo, G.; Paravan, C.; Reina, A.; Tadini, P.; Sossi, A.; Duranti, E. Time-Resolved Burning of Solid Fuels for Hybrid Rocket Propulsion. Prog. Propul. Phys. 2011, 2, 341–362. [Google Scholar]

- Whitmore, S.A.; Peterson, Z.W.; Eilers, S.D. Comparing Hydroxyl Terminated Polybutadiene and Acrylonitrile Butadiene Styrene as Hybrid Rocket Fuels. J. Propuls. Power 2013, 29, 582–592. [Google Scholar] [CrossRef]

- Grefen, B.; Becker, J.; Linke, S.; Stoll, E. Design, Production and Evaluation of 3D-Printed Mold Geometries for a Hybrid Rocket Engine. Aerospace 2021, 8, 220. [Google Scholar] [CrossRef]

- Walker, S.D. High Regression Rate Hybrid Rocket Fuel Grains with Helical Port Structures. Master’s Thesis, Utah State University, Logan, UT, USA, 2015. [Google Scholar]

- Whitmore, S.A.; Merkley, S.L.; Tonc, L.; Mathias, S.D. Survey of Selected Additively Manufactured Propellants for Arc Ignition of Hybrid Rockets. J. Propuls. Power 2016, 32, 1494–1504. [Google Scholar] [CrossRef]

- Yu, X.; Yu, H.; Zhang, W.; DeLuca, L.; Shen, R. Effect of Penetrative Combustion on Regression Rate of 3D Printed Hybrid Rocket Fuel. Aerospace 2022, 9, 696. [Google Scholar] [CrossRef]

- McFarland, M.; Antunes, E. Small-Scale Static Fire Tests of 3D Printing Hybrid Rocket Fuel Grains Produced from Different Materials. Aerospace 2019, 6, 81. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Li, F.; Yu, X. Combustion performance of a novel hybrid rocket fuel grain with a nested helical structure. Aerosp. Sci. Technol. 2020, 97, 105613. [Google Scholar] [CrossRef]

- Zdybal, D.; Pabarcius, L.; Laczewski, A.; Wyciszkiewicz, B.; Zwolak, A.; Slawecki, P.; Wyzlinski, M. Investigation of FDM-printed open-framework-reinforced helical PEWAX grains as a robust, high regression hybrid rocket fuel. In Proceedings of the AIAA Scitech 2021 Forum, Virtual Event, 11–21 January 2021. [Google Scholar]

- Tian, H.; Li, Y.; Li, C.; Sun, X. Regression rate characteristics of hybrid rocket motor with helical grain. Aerosp. Sci. Technol. 2017, 68, 90–103. [Google Scholar] [CrossRef]

- Armold, D.M. Formulation and Characterization of Paraffin-Based Solid Fuels Containing Swirl Inducing Grain Geometry and/or Energetic Additives. Master’s Thesis, The Pennsylvania State University, State College, PA, USA, 2014. [Google Scholar]

- Yenawine, A.W. Hybrid Rocket Engines: Development of Composite Fuels with Complex 3D Printed Ports. Master’s Thesis, University of Miami, Miami, FL, USA, 2019. [Google Scholar]

- McKnight, B.R.; Boyer, E.J.; Nardozzo, P.K.; Cortopassi, A. Design and Testing of an Additively Manufactured Advanced Hybrid Rocket Motor Propulsion Unit for CubeSats (PUC). In Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference, Orlando, FL, USA, 27–29 July 2015. [Google Scholar]

- Young, G.; Connell, T.L., Jr.; Fennell, K.; Possehl, S.; Baier, M. Examining Port Geometry/Solid Loading for Additively Manufactured Fuels in Hybrid Rockets. J. Propuls. Power 2021, 37, 305–313. [Google Scholar] [CrossRef]

- Connell, T.L., Jr.; Young, G.; Beckett, K.; Gumm, C.; Gonzalez, D.; Baier, M. Enhanced Solid Fuel Regression in a Hybrid Rocket Employing Additively Manufactured Fuels Exhibiting Novel Fuel Grain Port Geometries. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar]

- Karabeyoglu, M.A.; Altman, D.; Cantwell, B.J. Combustion of Liquefying Hybrid Propellants: Part 1, General Theory. J. Propuls. Power 2002, 18, 610–620. [Google Scholar] [CrossRef]

- Karabeyoglu, A.; Zilliac, G.; Cantwell, B.J.; DeZilwa, S.; Castellucci, P. Scale-Up Tests of High Regression Rate Paraffin-Based Hybrid Rocket Fuels. J. Propuls. Power 2004, 20, 1037–1045. [Google Scholar] [CrossRef]

- Armold, D.M.; Boyer, E.J.; McKnight, B.; Kuo, K.; Desain, J.; Brady, B.B.; Fuller, J.; Curtiss, T.J. Testing of Hybrid Rocket Fuel Grains at Elevated Temperatures with Swirl Patterns Fabricated Using Rapid Prototyping Technology. In Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014. [Google Scholar]

- Mengu, D.; Kumar, R. Development of EVA-SEBS based wax fuel for hybrid rocket applications. Acta. Astronaut. 2018, 152, 325–334. [Google Scholar] [CrossRef]

- Veale, K.; Adali, S.; Pitot, J.; Brooks, M. A review of the performance and structural considerations of paraffin wax hybrid rocket fuels with additives. Acta. Astronaut. 2017, 141, 196–208. [Google Scholar] [CrossRef]

- Nakagawa, I.; Hikone, S. Study on the Regression Rate of Paraffin-Based Hybrid Rocket Fuels. J. Propuls. Power 2011, 27, 1276–1279. [Google Scholar] [CrossRef]

- Ishigaki, T.; Nakagawa, I. Improving Physical Properties of Wax-Based Fuels and Its Effect on Regression Rate. J. Propuls. Power 2020, 36, 123–128. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, S.; Zhang, W.; Shen, R.; DeLuca, L.T.; Ye, Y. Mechanical Modifications of Paraffin-based Fuels and the Effects on Combustion Performance. Propellants Explos. Pyrotech. 2017, 42, 1268–1277. [Google Scholar] [CrossRef]

- Kumar, R.; Ramakrishna, P.A. Studies on EVA-Based Wax Fuel for Launch Vehicle Applications. Propellants Explos. Pyrotech. 2016, 41, 295–303. [Google Scholar] [CrossRef]

- Galfetti, L.; Merotto, L.; Boiocchi, M.; Maggi, F.; DeLuca, L. Ballistic and rheological characterization of paraffin-based fuels for hybrid rocket propulsion. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011. [Google Scholar]

- Bisin, R.; Paravan, C.; Verga, A.; Galfetti, L. An Innovative Strategy for Paraffin-based Fuels Reinforcement: Part II, Ballistic Characterization. In Proceedings of the 8th European Conference for Aeronautics and Aerospace Sciences (EUCASS), Madrid, Spain, 1–4 July 2019. [Google Scholar]

- Bisin, R.; Paravan, C.; Alberti, S.; Galfetti, L. A new strategy for the reinforcement of paraffin-based fuels based on cellular structures: The armored grain–Mechanical characterization. Acta. Astronaut. 2020, 176, 494–509. [Google Scholar] [CrossRef]

- Bisin, R.; Paravan, C.; Verga, A.; Galfetti, L. Towards High-Performing Paraffin-based Fuels Exploiting the Armored Grain Concept. In Proceedings of the 9th European Conference for Aeronautics and Space Sciences (EUCASS), Lille, France, 27 June–1 July 2022. [Google Scholar]

- Bisin, R.; Paravan, C.; Parolini, S.; Galfetti, L. Impact of 3D-printing on the Mechanical Reinforcement and the Ballistic Response of Paraffin-based Fuels: The Armored Grain. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual Event, 24–28 August 2020. [Google Scholar]

- Bisin, R.; Paravan, C.; Alberti, S.; Galfetti, L. An Innovative Strategy for Paraffin-based Fuels Reinforcement: Part I, Mechanical and Pre-Burning Characterization. In Proceedings of the 8th European Conference for Aeronautics and Aerospace Sciences (EUCASS), Madrid, Spain, 1–4 July 2019. [Google Scholar]

- Hill, C.; McDougall, C.C.; Messinger, T.; Johansen, C.T. Modification of Paraffin-based Hybrid Rocket Fuels Using Structural Lattices. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Hill, C.; Johansen, C.T. Evaluation of Lattice-Augmented Hybrid Rocket Fuels on a Slab Burner. In Proceedings of the AIAA Propulsion and Energy 2021 Forum, Virtual Event, 9–11 August 2021. [Google Scholar]

- Lin, X.; Qu, D.; Chen, X.; Wang, Z.; Luo, J.; Meng, D.; Liu, G.; Zhang, K.; Li, F.; Wu, X. Three-dimensional printed metal-nested composite fuel grains with superior mechanical and combustion properties. Virtual Phys. Prototy. 2022, 17, 437–450. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, Z.; Wang, W.; Wang, N. Combustion characteristics of skeleton polymer reinforced paraffin-wax fuel grain for applications in hybrid rocket motors. Combust. Flame 2022, 241, 112055. [Google Scholar] [CrossRef]

- Lai, K.; Soria, J.; Atkinson, C. ABS Infill Structures for Enhancing the Performance of Paraffin Fuel Grains in Hybrid Rocket Engines; Technical Report LTRAC-TR 2022.1; Monash University: Melbourne, Australia, 2022. [Google Scholar]

- Meier, J.; Reynolds, J.; Whalen, S.; Patel, J.; Bortner, M.J.; Young, G. Improved Hybrid Rocket Performance by Additively Manufactured Gel-Infused Solid Fuels. J. Propuls. Power 2023, 39, 97–105. [Google Scholar] [CrossRef]

- Oztan, C.; Ginzburg, E.; Akin, M.; Zhou, Y.; Leblanc, R.M.; Coverstone, V. 3D printed ABS/paraffin hybrid rocket fuels with carbon dots for superior combustion performance. Combust. Flame 2021, 225, 428–434. [Google Scholar] [CrossRef]

- Strategies for 3D Printing Advanced Hybrid Rocket Fuel Grains and Hybrid-Like Liquid Rocket Motors. Available online: https://www.slideshare.net/JerryFuller3/strategies-for-3d-printing-advanced-hybrid-rocket-fuel-grains-and-hybridlike-liquid-rocket-motorsadditive-innovationfuller (accessed on 20 February 2023).

- McCulley, J.; Bath, A.; Whitmore, S. Design and Testing of FDM Manufactured Paraffin-ABS Hybrid Rocket Motors. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Atlanta, GA, USA, 30 July–1 August 2012. [Google Scholar]

- Aarant, T.; Bass, J.; Grizzel, T.; Holladay, S.; McVey, M.; Putthoff, W.; Shaw, A.; Tarle, P.; Nickel, R.; Littlel, C.; et al. The Development of a Powder-Filled, Abs Matric for Use as Fuel In A Hybrid Rocket Motor. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Holladay, S.; Aarant, T.; Bass, J.; Grizzel, T.; McVey, M.; Putthoff, W.; Shaw, A.; Littel, C.; Lyne, J.E. Hybrid Rocket Engine Design Utilizing a Polymer Matrix Encapsulating Pulverized Fuel. Undergraduate Thesis, University of Tennessee, Knoxville, TN, USA, 2019. [Google Scholar]

- Barnhill, B.; Darling, S.; Springer, A.; Todd, A.; Whaley, S. Design and Development of Hybrid Rocket for Spaceport America Cup; University of Tennessee: Knoxville, TN, USA, 2019. [Google Scholar]

- Bettella, A.; Lazzarin, M.; Bellomo, N.; Barato, F.; Pavarin, D.; Grosse, M. Testing and CFD Simulation of Diaphragm Hybrid Rocket Motors. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011. [Google Scholar]

- Doran, E.; Dyer, J.; Lohner, K.; Dunn, Z.; Cantwell, B.; Zilliac, G. Nitrous Oxide Hybrid Rocket Motor Fuel Regression Rate Characterization. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, OH, USA, 8–11 July 2007. [Google Scholar]

- Whitmore, S.A.; Olsen, K.C.; Forster, P.; Oztan, C.Y.; Coverstone, V.L. Test and Evaluation of Copper-Enhanced, 3-D Printed ABS Hybrid Rocket Fuels. In Proceedings of the AIAA Propulsion and Energy 2021 Forum, Virtual Event, 9–11 August 2021. [Google Scholar]

- Okutani, Y.; Saito, Y.; Kimino, M.; Tsuji, A.; Soeda, K.; Nagata, H. Investigation of Regression Rate under High-Pressure in Axial-Injection End-Burning Hybrid Rockets. In Proceedings of the 2018 Joint Propulsion Conference, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar]

- Saito, Y.; Yokoi, T.; Totani, T.; Wakita, M.; Nagata, H. Fuel Regression Characteristics of a Novel Axial-Injection End-Burning Hybrid Rocket. J. Propuls. Power 2018, 34, 247–259. [Google Scholar] [CrossRef]

- Matsuoka, T.; Murakami, S.; Nagata, H. Transition characteristics of combustion modes for flame spread in solid fuel tube. Combust. Flame 2012, 159, 2466–2473. [Google Scholar] [CrossRef]

- Fukada, M.; Suzuki, S.; Hayasaka, H.; Maebayashi, H.; Mungyu, S.; Leung, Y.A.M.; Nagata, H. Necessary Condition of Regression Mode in Axial-Injection End-burning Hybrid Rockets. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023. [Google Scholar]

- Saito, Y.; Kimino, M.; Tsuji, A.; Okutani, Y.; Soeda, K.; Nagata, H. High Pressure Fuel Regression Fuel regression characteristics Characteristics of Axial-Injection End-Burning Hybrid Rockets. J. Propuls. Power 2019, 35, 328–341. [Google Scholar] [CrossRef]

- Nagata, H.; Teraki, H.; Saito, Y.; Kanai, R.; Yasukochi, H.; Wakita, M.; Totani, T. Verification Firings of End-Burning Type Hybrid Rockets. J. Propuls. Power 2017, 33, 1473–1477. [Google Scholar] [CrossRef]

- Okuda, R.; Komizu, K.; Tsuji, A.; Miwa, T.; Fukada, M.; Kamps, L.; Nagata, H. Fuel Regression Characteristics of Axial-Injection End-Burning Hybrid Rocket Using Nitrous Oxide. J. Propuls. Power 2022, 38, 759–770. [Google Scholar] [CrossRef]

- Hitt, M.A.; Agnew, J.F. Printed Axial-Injection, End-Burning Hybrid Fuel Grain Study. J. Spacecr. Rockets 2021, 58, 1552–1556. [Google Scholar] [CrossRef]

- Hitt, M.A. Preliminary Additively Manufactured Axial-Injection, End-Burning Hybrid Rocket Motor Regression Rate Study. In Proceedings of the 2018 Joint Propulsion Conference, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar]

- Hitt, M.A. Additively Manufactured Axial-Injection, End-Burning Hybrid Motor Regression Rate Study. J. Propuls. Power 2020, 36, 485–487. [Google Scholar] [CrossRef]

- Hirai, S.; Kamps, L.; Nobuhara, Y.; Nagata, H. Demonstration of Axial-Injection End-Burning Hybrid Rocket using FDM 3D Printer. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023. [Google Scholar]

- Gordon, S.; McBride, B.J. Computer Program for Calculation of Complex Chemical Equilibrium Compositions and Applications. Part I: Analysis; NASA Reference Publication 1311–1: Cleveland, OH, USA, 1994.

- Gordon, S.; McBride, B.J. Computer Program for Calculation of Complex Chemical Equilibrium Compositions and Applications. Part II: Users Manual and Program Description; NASA Reference Publication 1311–2: Cleveland, OH, USA, 1996.

- Thomas, J.C.; Peterson, E.L. HTPB Heat of Formation: Literature Survey, Group Additive Estimations, and Theoretical Effects. AIAA J. 2022, 60, 1269–1282. [Google Scholar] [CrossRef]

- Ahn, B.; Huh, J.; Bhosale, V.K.; Kwon, S. Three-Dimensionally Printed Polylactic Acid as Solid Fuel for Hydrogen Peroxide Hybrid Rockets. J. Propuls. Power 2021, 29, 582–592. [Google Scholar] [CrossRef]

- Zheng, W.R.; Li, S.F.; Chow, W.K. Review on Chemical Reactions of Burning Poly(methyl methacrylate) PMMA. J. Fire Sci. 2002, 20, 401–433. [Google Scholar] [CrossRef]

- Joshi, R.M.; Zwolinski, B.J. Heats of Combustion Studies on Polymers. Macromolecules 1968, 1, 25–30. [Google Scholar] [CrossRef]

- Herps, H.H.T. Modelling and Comparative Assessment of Polyamide-6 Manufacturing towards a Sustainable Chemical Industry. Ph.D. Thesis, Utrecht University, Utrecht, The Netherlands, 2020. [Google Scholar]

- Lyon, R.E. Solid-State Thermochemistry of Flaming Combustion; DOT/FAA/AR-99/56, ADA367981; Office of Aviation: Washington, DC, USA, 1999.

- Walters, R.N.; Hackett, S.M.; Lyon, R.E. Heats of Combustion of High Temperature Polymers. Fire Mater. 2000, 24, 209–252. [Google Scholar] [CrossRef]

- Walters, R.N. Molar Group Contributions to the Heat of Combustion. Fire Mater. 2002, 26, 103–145. [Google Scholar] [CrossRef]

- Walters, R.N.; Lyon, R.E. Molar Group Contributions to Polymer Flammability. J. Appl. Polym. Sci. 2003, 87, 548–563. [Google Scholar] [CrossRef]

- Heister, S.; Wernimont, E. Chapter 11: Hydrogen Peroxide, Hydroxyl Ammonium Nitrate, and Other Storable Oxidizers. In Fundamentals of Hybrid Rocket Combustion and Propulsion; Kuo, K.K., Chiaverini, M., Eds.; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2007; Volume 218, pp. 457–488. [Google Scholar]

| Reference | Geometry | Fuel | Oxidizer | Key Results |

|---|---|---|---|---|

| Walker [19] | Helical Port | ABS | GOX | Over 200% increase in RR Lower O/F ratios Shorter pitch length caused higher RR |

| Wang et al. [23] | Nested Helical Structure | ABS + Paraffin w/ additives | GOX | 20% increase in RR Slight increase in CE |

| Zdybal et al. [24] | Helical Port | Polyamide-12 + PEWAX w/ EVA | GOX | Up to 26.7% increase in RR Up to 34% decrease in CE Shorter pitch length caused higher RR |

| Tian et al. [25] | Helical Port | Polyethylene | GOX | Decreased thread pitch increased RR by 40% Increased groove depth increased RR by 15–20% Increased groove width increased RR by 10% |

| Armold [26] | Six-pointed Star-Swirl Port | Acrylic | GOX | 1/8 tpi: 60% increase in RR 1/4 tpi: 180% increase in RR 1/2 tpi: 250% increase in RR |

| Yenawine [27] | Star-Swirl Port 1/2 tpi | ABS | GOX | 36% increase in RR 6.4% decrease in CE |

| McKnight et al. [28] | Star-Swirl Port 1/2 tpi | ABS (natural, white, black) and Windform XT 2.0 | GOX | All materials increased in RR ABS decreased in CE Windform XT 2.0 increased in CE |

| Young et al. [29] | Straight Elliptical Port | PMMA | GOX | No significant change in RR or CE |

| Young et al. [29] | Swirl-Elliptical Port | PMMA | GOX | 35% increase in RR 10% increase in CE |

| Connell et al. [30] | Ramped Protrusion Port | PC or PMMA | GOX | 32–36% decrease in RR No significant change to CE |

| Connell et al. [30] | Swirled-Slotted Port | PC or PMMA | GOX | −13% to +43% change in RR 0.6–6.6% increase in CE Expansion region: 21% increase in RR, 9% increase in CE Pockets: 8% decrease in RR, 7.4% increase in CE |

| Connell et al. [30] | Swirl-Ellipse Port | PC or PMMA | GOX | 64–116% increase in RR 1.8–9.9% increase in CE |

| Fuel | Molecular Weight | Density | Heat of Formation | |||||

|---|---|---|---|---|---|---|---|---|

| Theoretical | Literature | |||||||

| Name | Formula | (g/mol) | (kg/m3) | (kJ/mol) | (kJ/kg) | (kJ/mol) | (kJ/kg) | Reference |

| Hydroxyl-Terminated Polybutadiene (HTPB) | (C4H6)n | 54 | 930 | 209 | 3867 | 342 | 6321 | Thomas and Petersen, 2022 [74] |

| Acrylonitrile Butadiene Styrene (ABS) (43/50/7) | (C3.85H4.85N0.43)n | 57 | 975 | 198 | 3463 | 63 | 1096 | Whitmore et al., 2013 [17] |

| Polylactic Acid (PLA) | (C3H4O2)n | 72 | 1240 | −259 | −3595 | −302 | −4194 | Ahn et al., 2021 [75] |

| Poly(Methyl Methacrylate) (PMMA) | (C5H8O2)n | 100 | 1180 | −172 | −1715 | −622 | −6212 | Zeng et al., 2002 [76] |

| Polycarbonate (PC) | (C16H14O3)n | 254 | 1200 | 27 | 108 | −103 | −406 | Joshi and Zwolinski, 1968 [77] |

| Nylon 6 | (C6H11ON)n | 113 | 1084 | −5 | −43 | −272 | −13 | Herps, 2020 [78] |

| UV-Curable Fuel a | (C16.09H20.61O3.97)n | 277 | 1191 | - | - | −297 | −1070 | Okuda et al., 2022 [67] |

| Maximum Theoretical Performance Parameter | |||||

|---|---|---|---|---|---|

| Fuel | Oxidizer | (K) | (m/s) | (s) | (s) |

| HTPB | LOX | 3927 | 1874 | 300 | 319 |

| ABS | LOX | 3913 | 1822 | 292 | 314 |

| PLA | LOX | 3547 | 1611 | 262 | 313 |

| PMMA | LOX | 3689 | 1724 | 279 | 324 |

| PC | LOX | 3829 | 1702 | 274 | 321 |

| Nylon 6 | LOX | 3726 | 1773 | 286 | 321 |

| UV Fuel | LOX | 3741 | 1715 | 277 | 323 |

| HTPB | N2O | 3742 | 1737 | 278 | 449 |

| ABS | N2O | 3735 | 1706 | 273 | 442 |

| PLA | N2O | 3427 | 1564 | 253 | 419 |

| PMMA | N2O | 3546 | 1642 | 264 | 441 |

| PC | N2O | 3653 | 1626 | 261 | 444 |

| Nylon 6 | N2O | 3581 | 1672 | 269 | 444 |

| UV Fuel | N2O | 3582 | 1632 | 262 | 446 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, C.; Thomas, J.C. Performance of Additively Manufactured Fuels for Hybrid Rockets. Aerospace 2023, 10, 500. https://doi.org/10.3390/aerospace10060500

Nguyen C, Thomas JC. Performance of Additively Manufactured Fuels for Hybrid Rockets. Aerospace. 2023; 10(6):500. https://doi.org/10.3390/aerospace10060500

Chicago/Turabian StyleNguyen, Calvin, and James C. Thomas. 2023. "Performance of Additively Manufactured Fuels for Hybrid Rockets" Aerospace 10, no. 6: 500. https://doi.org/10.3390/aerospace10060500

APA StyleNguyen, C., & Thomas, J. C. (2023). Performance of Additively Manufactured Fuels for Hybrid Rockets. Aerospace, 10(6), 500. https://doi.org/10.3390/aerospace10060500