Mathematical Modelling and Fluidic Thrust Vectoring Control of a Delta Wing UAV

Abstract

1. Introduction

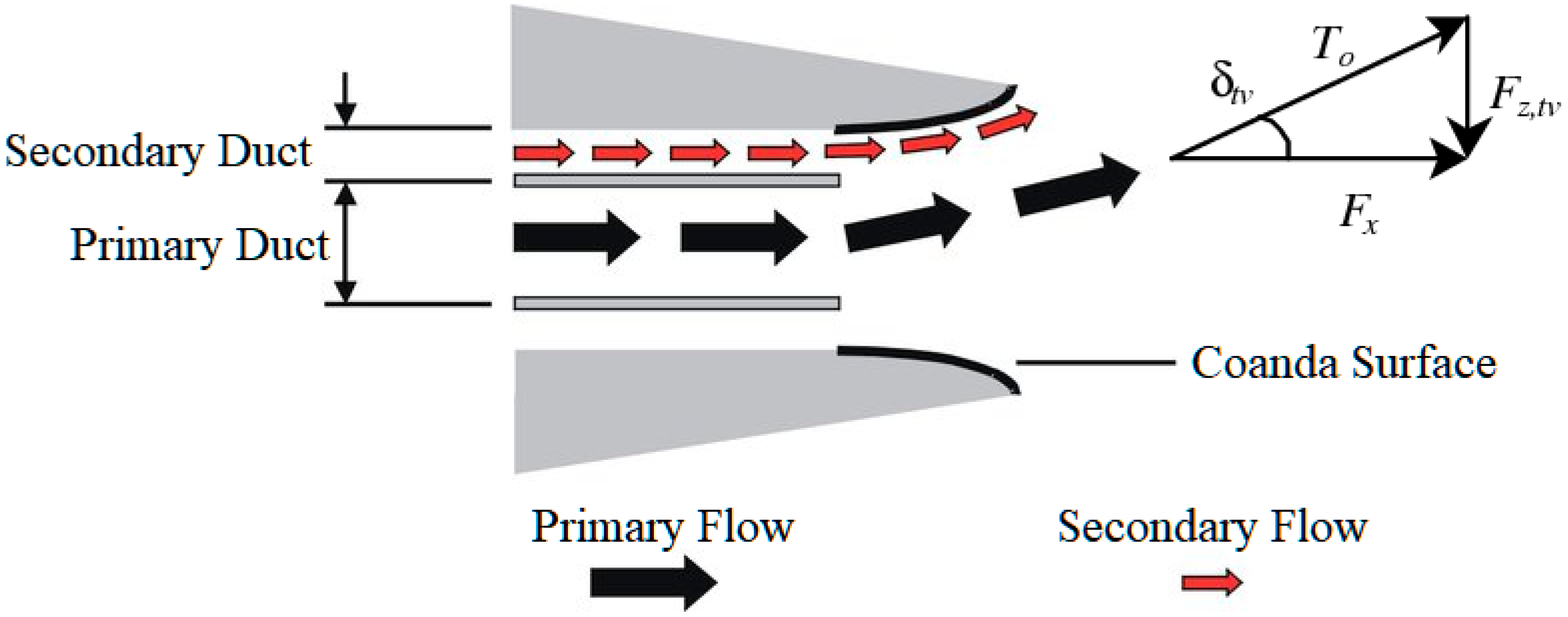

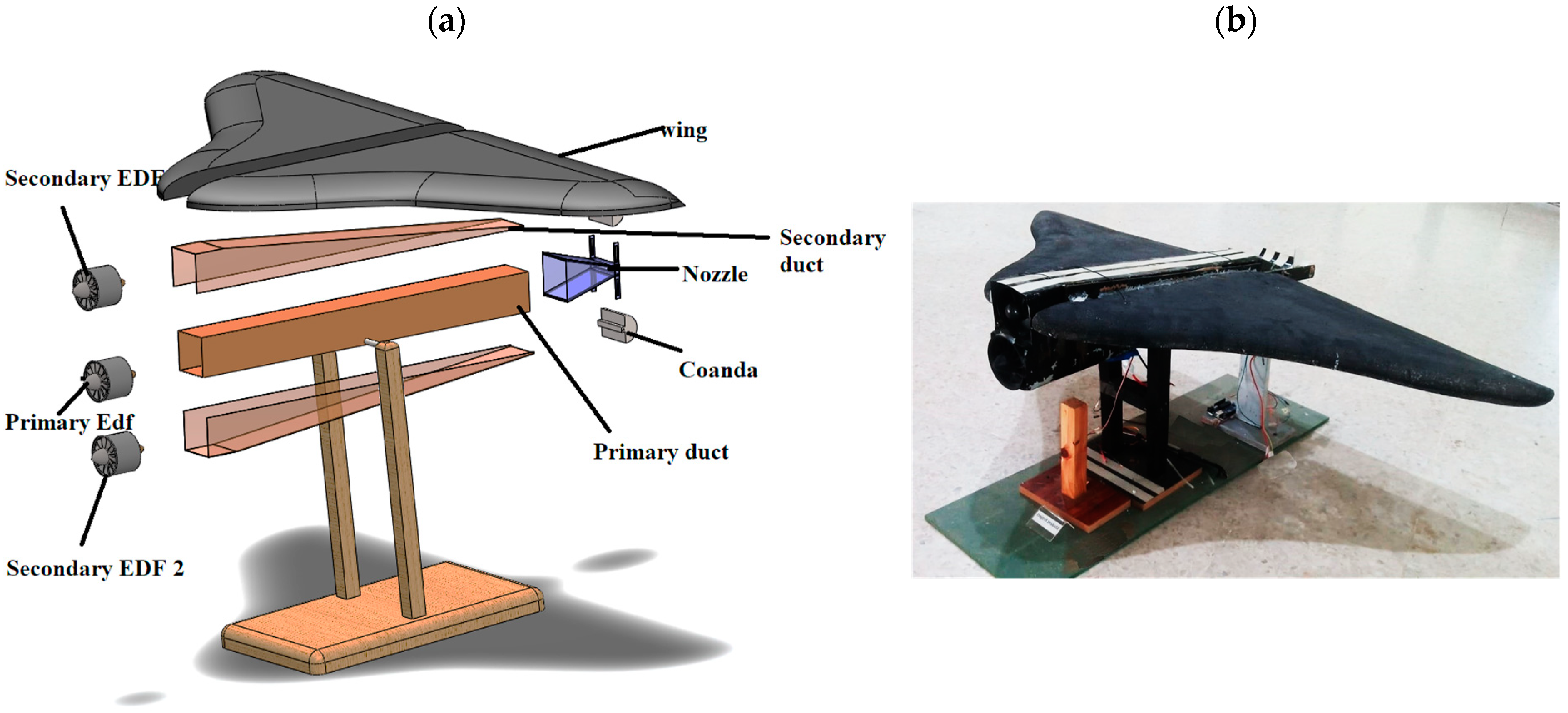

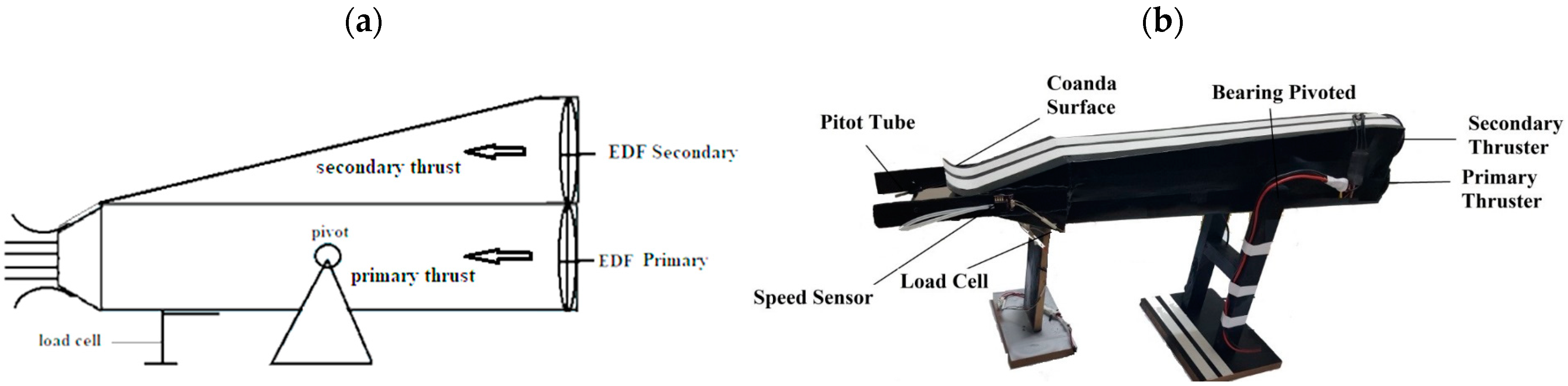

2. Experimental Setup

2.1. Experimentation

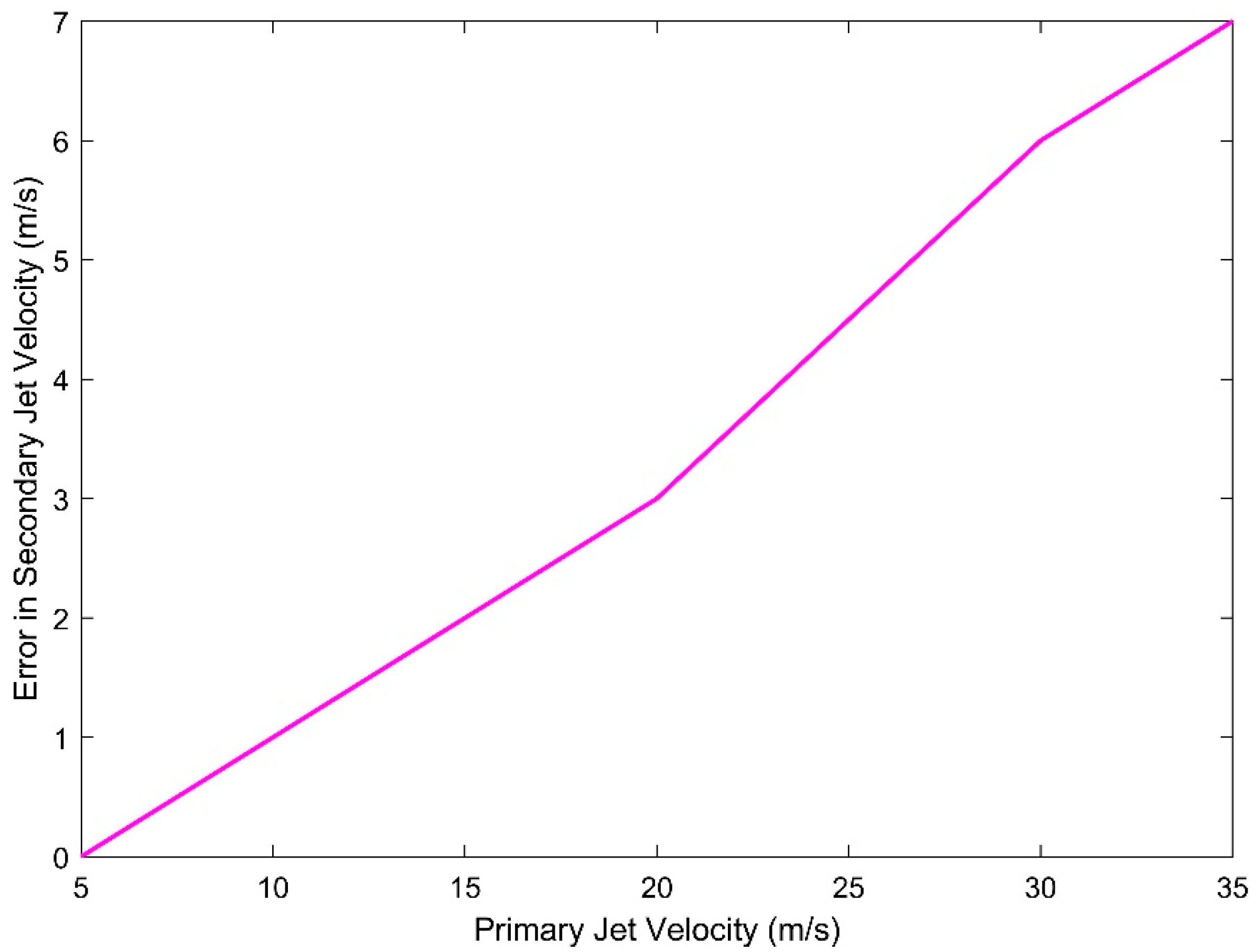

2.1.1. Velocity and Thrust Force Measurement

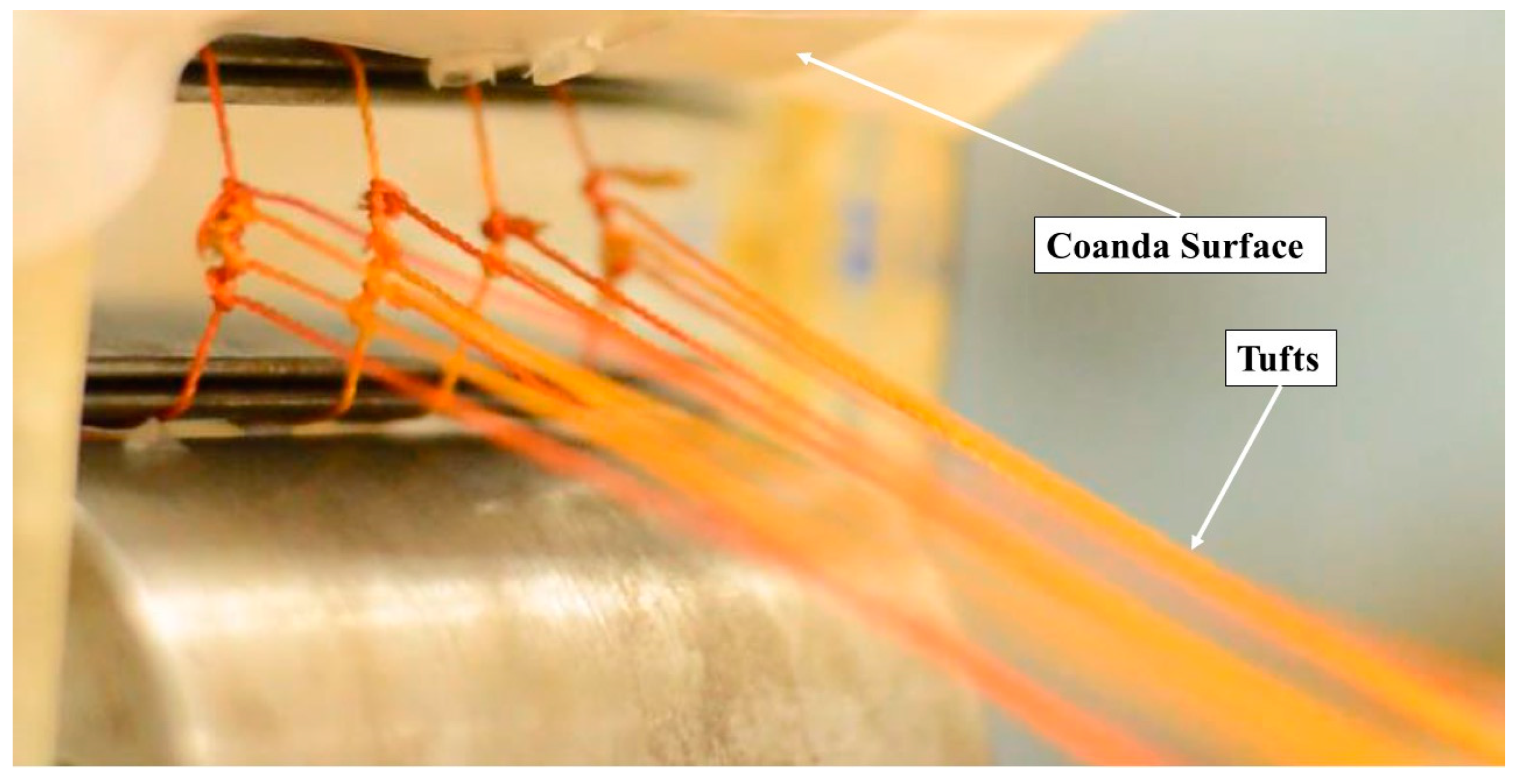

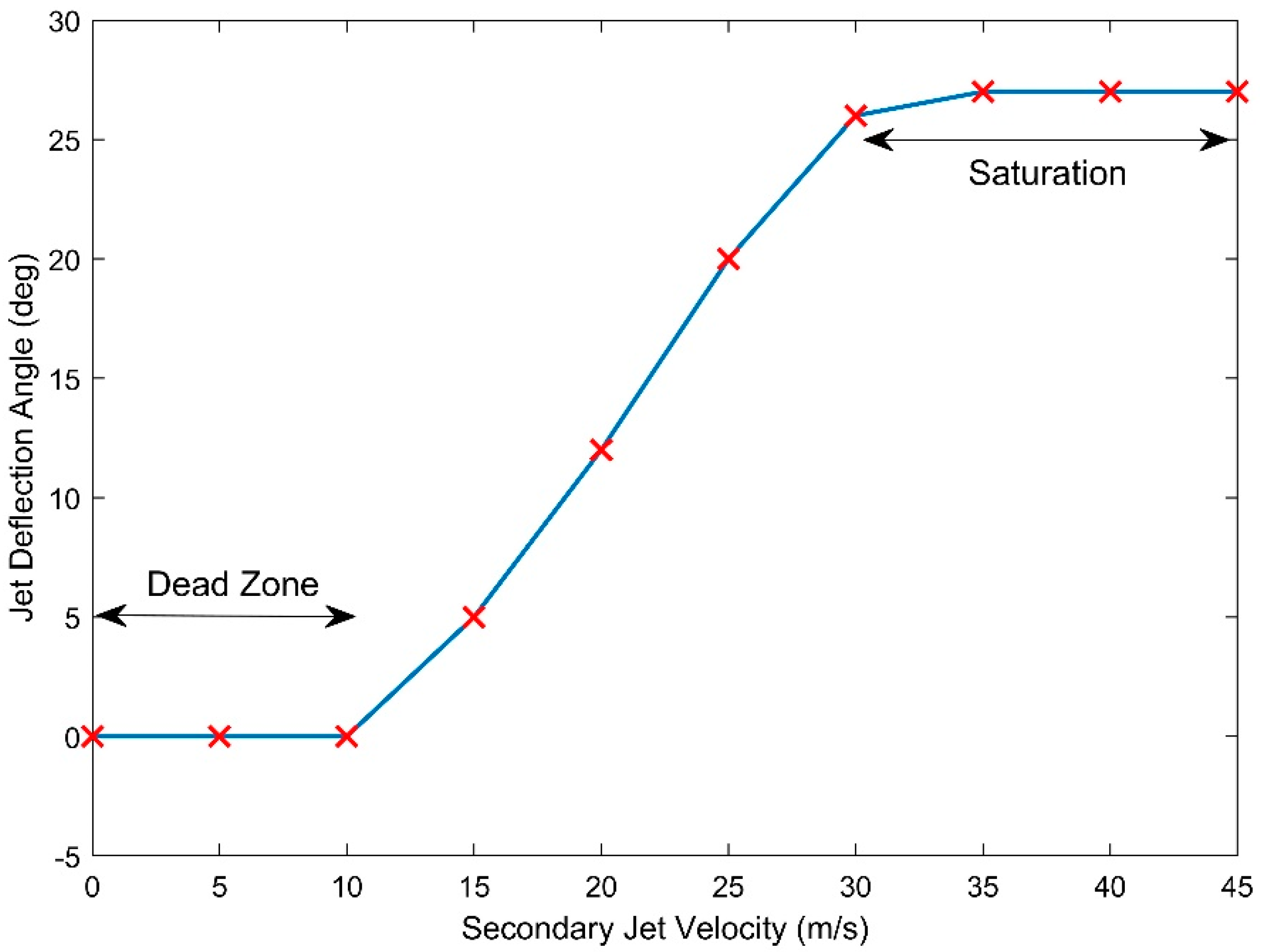

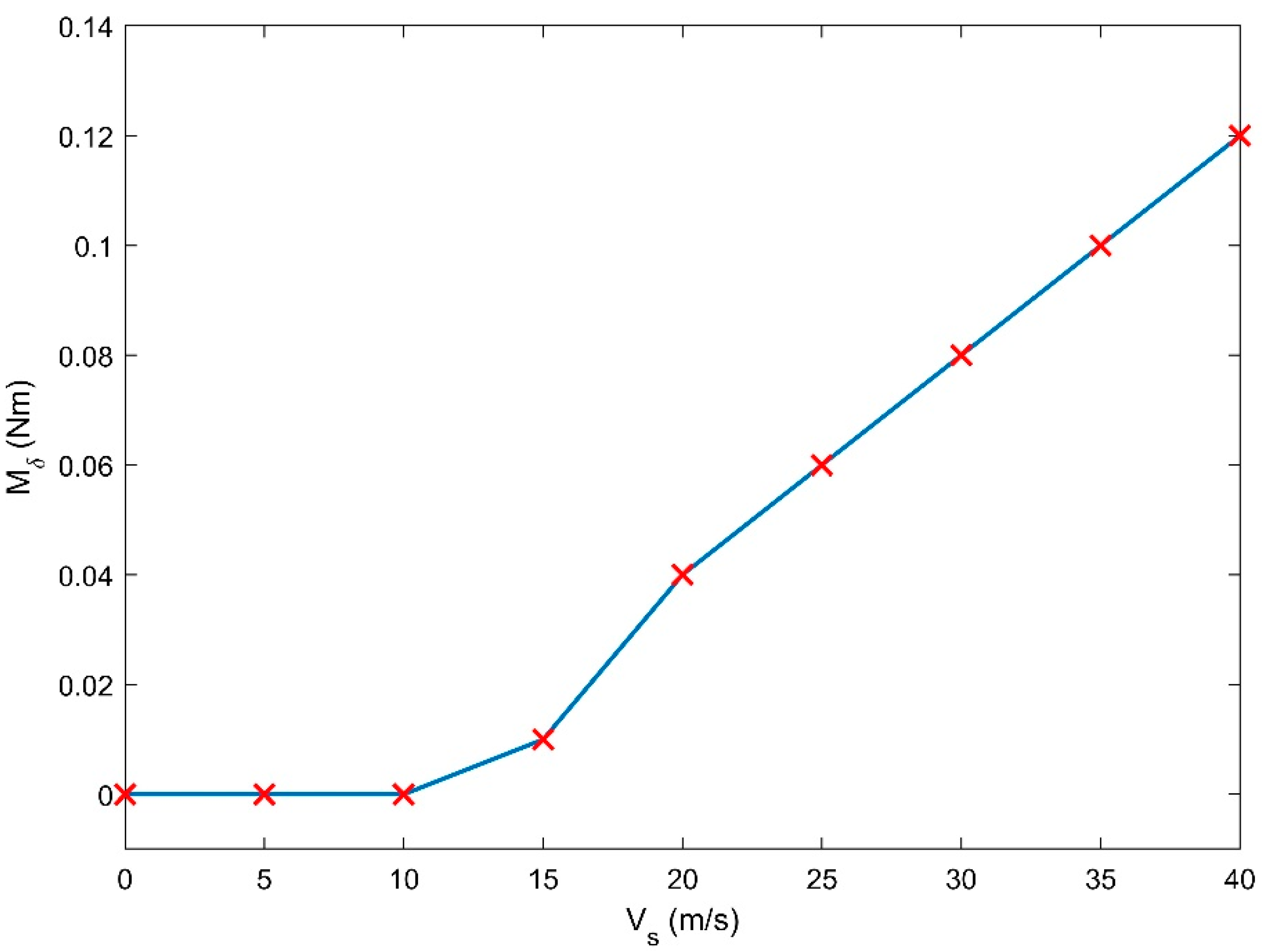

2.1.2. Experimental Measurement of Jet Deflection Angle

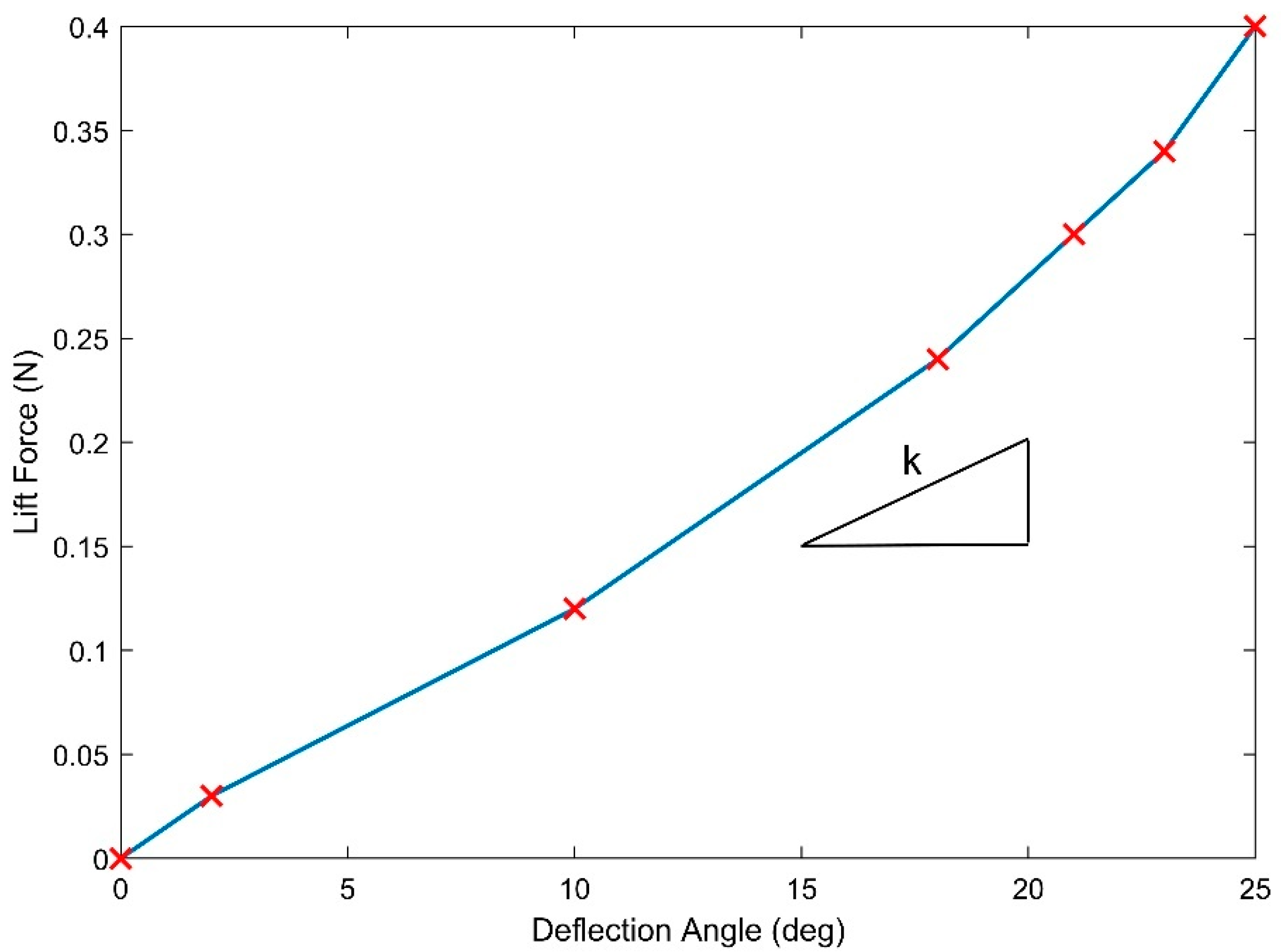

3. Dynamic Modelling

4. Controller Design

4.1. Benchmark Controller Design

4.1.1. Selection of Control Paradigm

4.1.2. Multi-Parameter Root Contour Method

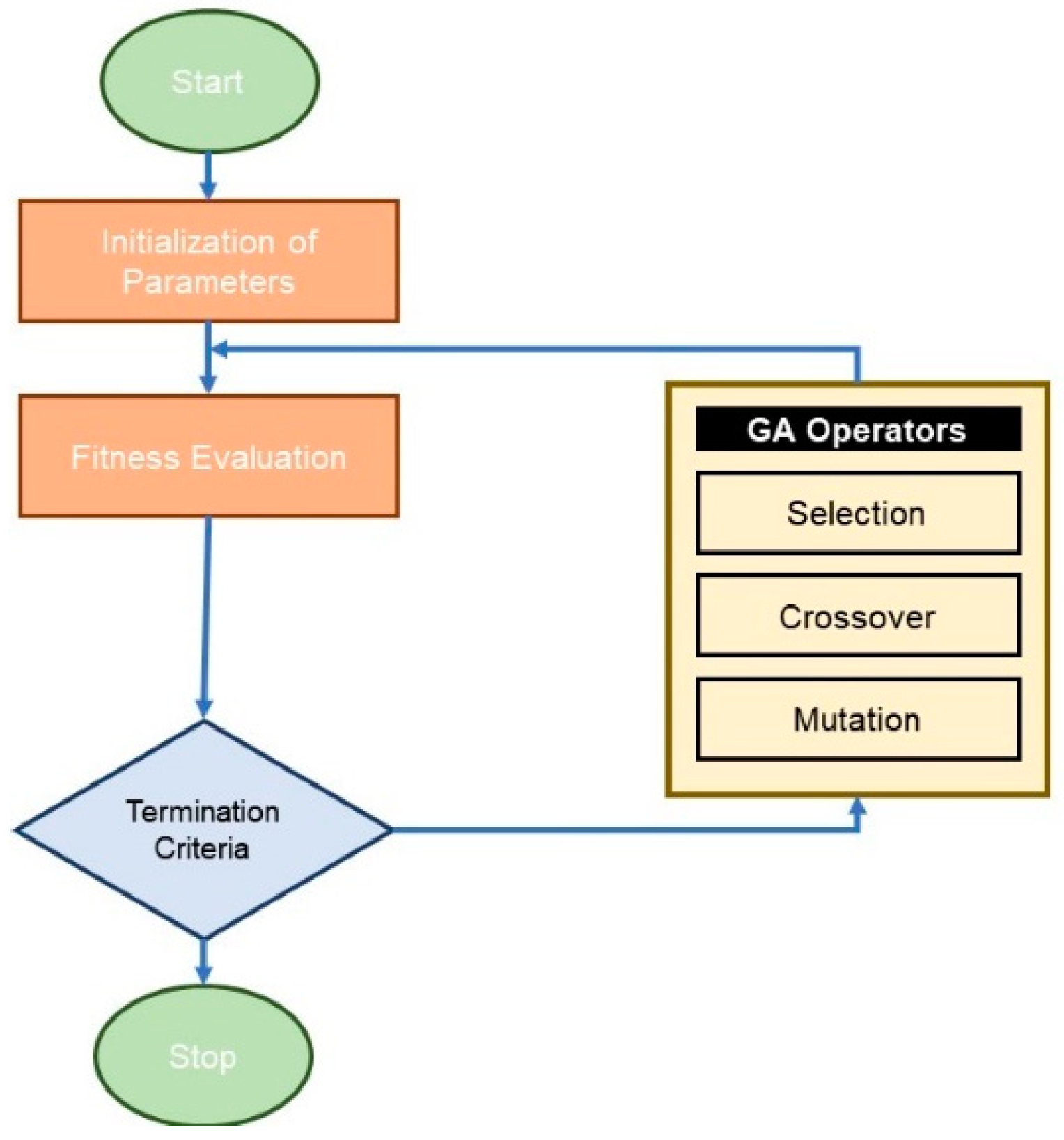

4.2. Genetic Algorithm (GA) Optimization

- The starting population is defined either randomly or heuristically.

- The fitness value of each population member is calculated.

- A selection probability proportional to the fitness rating is assigned to each member.

- Desired individuals are selected from the current generation to produce offspring for the next generation.

- Steps 1 to 4 are repeated, and the objective function is evaluated for each chromosome (member) of the new generation until a satisfactory solution is found.

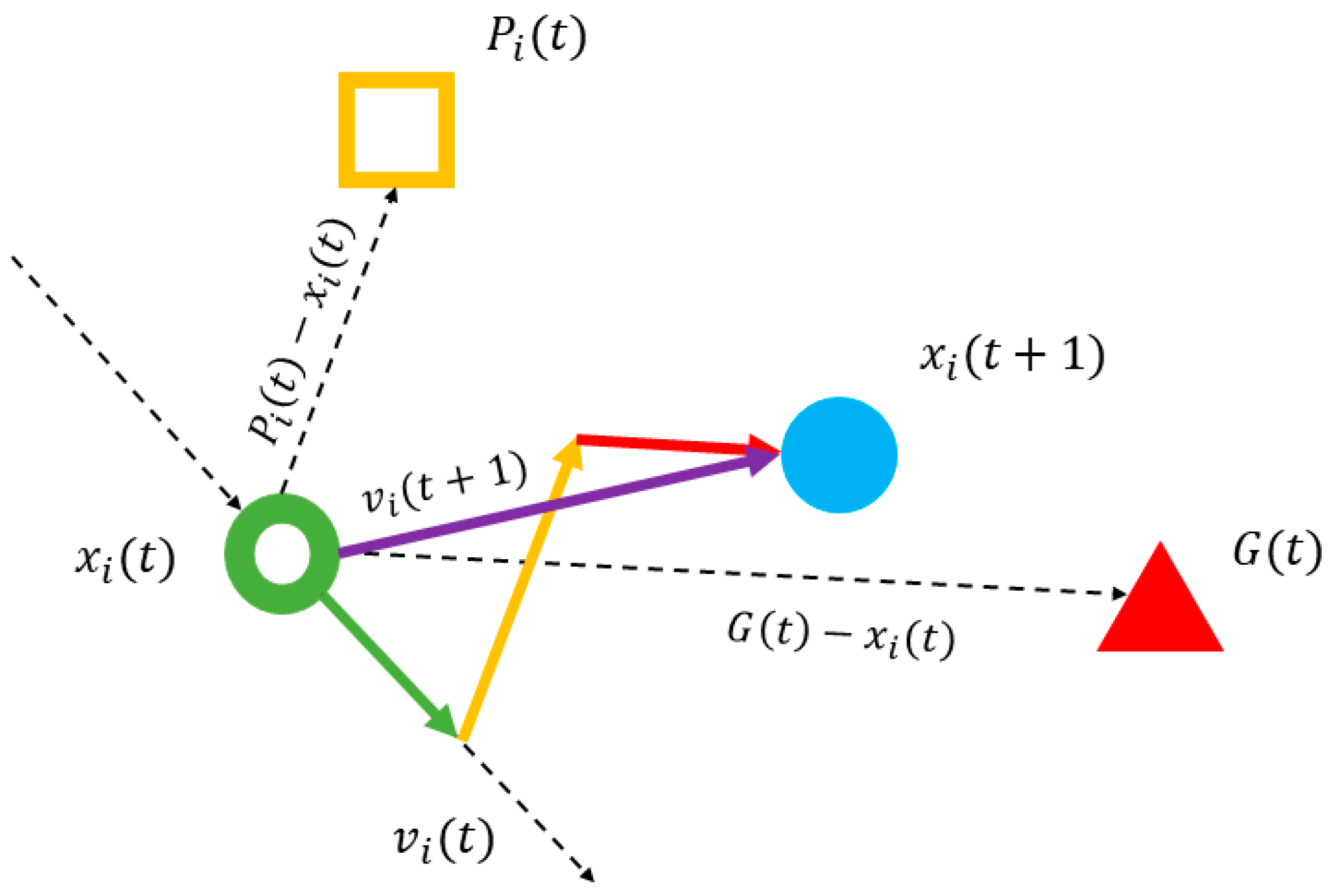

4.3. Particle Swarm Optimization (PSO)

- PSO employs velocity and location update equations that generate a new swarm of particles, allowing for significant differences between the new particles and existing ones.

- Compared to solutions generated by the GA, PSO maintains a higher density of candidate solutions within the solution space.

- Each solution in the population is influenced by the best particle’s experience in the swarm, facilitating rapid convergence.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Symbol | Description |

|---|---|

| Mass moment of inertia in pitch plane | |

| Pitch angle | |

| Pitching moment or stability derivative due to pitch rate | |

| Pitching moment due to angle of attack | |

| Angular acceleration in pitch | |

| Pitch angular velocity | |

| Jet deflection angle | |

| Distance between c.g. and exhaust nozzle | |

| Lift curve slope | |

| Dynamic pressure | |

| Effective planform area | |

| Lift curve slope of a 2D infinite flat plate | |

| Primary flow velocity | |

| Aerodynamic gain | |

| Lift force | |

| AR | Aspect ratio |

References

- Gal-Or, B. Vectored Propulsion, Supermaneuverability and Robot Aircraft; Springer: Berlin/Heidelberg, Germany, 1990. [Google Scholar]

- Gal-Or, B. Fundamental concepts of vectored propulsion. J. Propuls. Power 1990, 6, 747–757. [Google Scholar] [CrossRef]

- Alcorn, C.; Croom, M.; Francis, M.; Ross, H. The X-31 aircraft: Advances in aircraft agility and performance. Prog. Aerosp. Sci. 1996, 32, 377–413. [Google Scholar] [CrossRef]

- Bowers, A.H.; Pahle, J.W. Thrust Vectoring on the NASA F-18 High Alpha Research Vehicle; NASA: Washington, DC, USA, 1996.

- Vickers, J. Propulsion Analysis of the F-16 Multiaxis Thrust Vectoring Aircraft; NASA: Washington, DC, USA, 1994.

- Ahmad, S.M.; Siddique, S.M.; Yousaf, M.S.; Tariq, M.; Khan, M.I.; Alam, M.A. Computational and experimental investigation of fluidic thrust vectoring actuator. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 315. [Google Scholar] [CrossRef]

- Crowther, W.J.; Wilde, P.I.A.; Gill, K.; Michie, S.M. Towards Integrated design of fluidic flight controls for a flapless aircraft. Aeronaut. J. 2009, 113, 699–713. [Google Scholar] [CrossRef]

- Sekar, T.C.; Kushari, A.; Mody, B.; Uthup, B. Fluidic thrust vectoring using transverse jet injection in a converging nozzle with aft-deck. Exp. Therm. Fluid Sci. 2017, 86, 189–203. [Google Scholar] [CrossRef]

- Shi, N.-X.; Gu, Y.-S.; Zhou, Y.-H.; Wang, L.-X.; Feng, C.; Li, L.-K. Mechanism of hysteresis and uncontrolled deflection in jet vectoring control based on Coanda effect. Phys. Fluids 2022, 34, 084107. [Google Scholar] [CrossRef]

- Cen, Z.; Smith, T.; Stewart, P.; Stewart, J. Integrated flight/thrust vectoring control for jet-powered unmanned aerial vehicles with ACHEON propulsion. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 1057–1075. [Google Scholar] [CrossRef]

- Mangin, B.; Chpoun, A.; Jacquin, L. Experimental and numerical study of the fluidic thrust vectoring of a two-dimensional supersonic nozzle. In Proceedings of the 24th AIAA Applied Aerodynamics Conference, San Francisco, CA, USA, 5–8 June 2006. [Google Scholar]

- Mason, M.; Crowther, W. Fluidic Thrust Vectoring for Low Observable Air Vehicles. In Proceedings of the 2nd AIAA Flow Control Conference, Portland, OR, USA, 28 June–1 July 2004. [Google Scholar]

- Fielding, J.P.; Mills, A.; Smith, H. Design and manufacture of the DEMON unmanned air vehicle demonstrator vehicle. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2009, 224, 365–372. [Google Scholar] [CrossRef]

- Das, A.K.; Acharyya, K.; Mankodi, T.K.; Saha, U.K. Fluidic Thrust Vector Control of Aerospace Vehicles: State-of-the-Art Review and Future Prospects. J. Fluids Eng. 2023, 145, 080801. [Google Scholar] [CrossRef]

- Saghafi, F.; Banazadeh, A. Co-flow fluidic thrust vectoring requirements for longitudinal and lateral trim purposes. In Proceedings of the 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Sacramento, CA, USA, 9–12 July 2006; p. 4980. [Google Scholar]

- Wu, K.; Jin, Y.; Kim, H.D. Study on the Fluidic Thrust Vector Control Using Co-Flow Concept. Korean Soc. Propuls. Eng. Conf. Proc. 2017, 48, 675–678. [Google Scholar]

- Forliti, D.J.; Diaz-Guardamino, I.E. Exploring Mechanisms of Fluidic Thrust Vectoring Using a Transverse Jet and Suction. AIAA J. 2009, 47, 2329–2337. [Google Scholar] [CrossRef]

- Maruyama, Y.; Sakata, M.; Takahashi, Y. Performance analyses of fluidic thrust vector control system using dual throat nozzle. AIAA J. 2022, 60, 1730–1744. [Google Scholar] [CrossRef]

- Ferlauto, M.; Marsilio, R. Numerical Investigation of the Dynamic Characteristics of a Dual-Throat-Nozzle for Fluidic Thrust-Vectoring. AIAA J. 2017, 55, 86–98. [Google Scholar] [CrossRef]

- Wen, X.; Zhou, K.; Liu, P.; Zhu, H.; Wang, Q.; Liu, Y. Schlieren Visualization of Coflow Fluidic Thrust Vectoring Using Sweeping Jets. AIAA J. 2022, 60, 435–444. [Google Scholar] [CrossRef]

- Gu, D.-W.; Natesan, K.; Postlethwaite, I. Modelling and robust control of fluidic thrust vectoring and circulation control for unmanned air vehicles. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2008, 222, 333–345. [Google Scholar] [CrossRef]

- Kikkawa, H.; Uchiyama, K. Attitude Control of a Fixed-Wing UAV Using Thrust Vectoring System; IEEE: Piscataway, NJ, USA, 2017; pp. 264–269. [Google Scholar]

- Warsop, C.; Crowther, W. NATO AVT-239 task group: Flight demonstration of fluidic flight controls on the MAGMA subscale demonstrator aircraft. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019; p. 282. [Google Scholar]

- Nelson, R.C.; Pelletier, A. The unsteady aerodynamics of slender wings and aircraft undergoing large amplitude maneuvers. Prog. Aerosp. Sci. 2003, 39, 185–248. [Google Scholar] [CrossRef]

- Polhamus, E.C. A Concept of the Vortex Lift of Sharp-Edge Delta Wings Based on a Leading-Edge-Suction Analogy; NASA: Washington, DC, USA, 1966.

- Vaitheeswaran, S.M.; Gowthami, T.S.; Prasad, S.; Yathirajam, B. Monostatic radar cross section of flying wing delta planforms. Eng. Sci. Technol. Int. J. 2017, 20, 467–481. [Google Scholar] [CrossRef]

- Lyddon, J.; Nguyen, M.; Quackenbush, J.; Schadegg, T.; Takahashi, T.T. Optimum Design of a Fuel Efficient Mid-Size Business Jet. In Proceedings of the 10th AIAA Multidisciplinary Design Optimization Conference, National Harbor, MD, USA, 13–17 January 2014; p. 1337. [Google Scholar]

- Ahmad, S. Flight dynamics, parametric modelling and real-time control of a 1-DOF Tailplane. Math. Comput. Model. Dyn. Syst. 2013, 19, 220–237. [Google Scholar] [CrossRef]

- Khan, Y.M.; Ahmad, S.M.; Ali, M.; Khan, M. Flight dynamics and parametric modeling of a 2-DOF lab aircraft. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 233, 2923–2931. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, Z. Aerodynamic Design, Analysis and Validation of a Small Blended-Wing-Body Unmanned Aerial Vehicle. Aerospace 2022, 9, 36. [Google Scholar] [CrossRef]

- Min, B.-M.; Shin, S.-S.; Shim, H.-C.; Tahk, M.-J. Modeling and Autopilot Design of Blended Wing-Body UAV. Int. J. Aeronaut. Space Sci. 2008, 9, 121–128. [Google Scholar] [CrossRef]

- Lim, S.; Yook, Y.; Heo, J.P.; Im, C.G.; Ryu, K.H.; Sung, S.W. A new PID controller design using differential operator for the integrating process. Comput. Chem. Eng. 2023, 170, 108105. [Google Scholar] [CrossRef]

- Golnaraghi, F.; Kuo, B.C. Automatic Control Systems; McGraw-Hill Education: New York, NY, USA, 2017. [Google Scholar]

- Mirjalili, S.; Mirjalili, S. Genetic algorithm. In Evolutionary Algorithms and Neural Networks: Theory and Applications; Springer: Cham, Switzerland, 2019; pp. 43–55. [Google Scholar]

- Kachitvichyanukul, V. Comparison of three evolutionary algorithms: GA, PSO, and DE. Ind. Eng. Manag. Syst. 2012, 11, 215–223. [Google Scholar] [CrossRef]

- Pratchayaborirak, T.; Kachitvichyanukul, V. A two-stage PSO algorithm for job shop scheduling problem. Int. J. Manag. Sci. Eng. Manag. 2011, 6, 83–92. [Google Scholar] [CrossRef]

- Lambora, A.; Gupta, K.; Chopra, K. Genetic Algorithm—A Literature Review; IEEE: Piscataway, NJ, USA, 2019; pp. 380–384. [Google Scholar]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef]

- Eberhart, R.C.; Shi, Y.; Kennedy, J. Swarm Intelligence; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Ratnaweera, A.; Halgamuge, S.; Watson, H. Self-Organizing Hierarchical Particle Swarm Optimizer with Time-Varying Acceleration Coefficients. IEEE Trans. Evol. Comput. 2004, 8, 240–255. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Gain Bounds | 0–1000 |

| Initial Population Size | 50 |

| Stopping Criteria | 300 Generations |

| Creation Function | Uniform |

| Selection Function | Stochastic Selection Function |

| Crossover | Intermediate |

| Mutation | Adaptive Feasible |

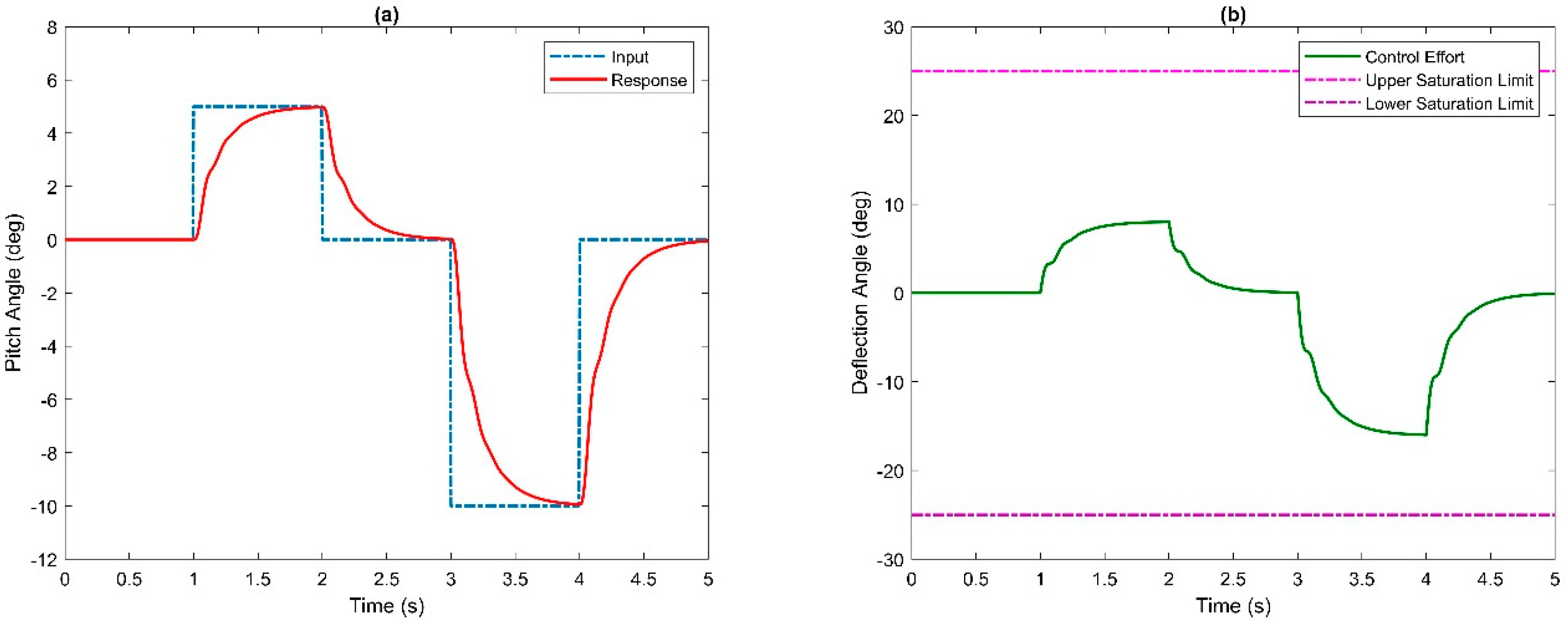

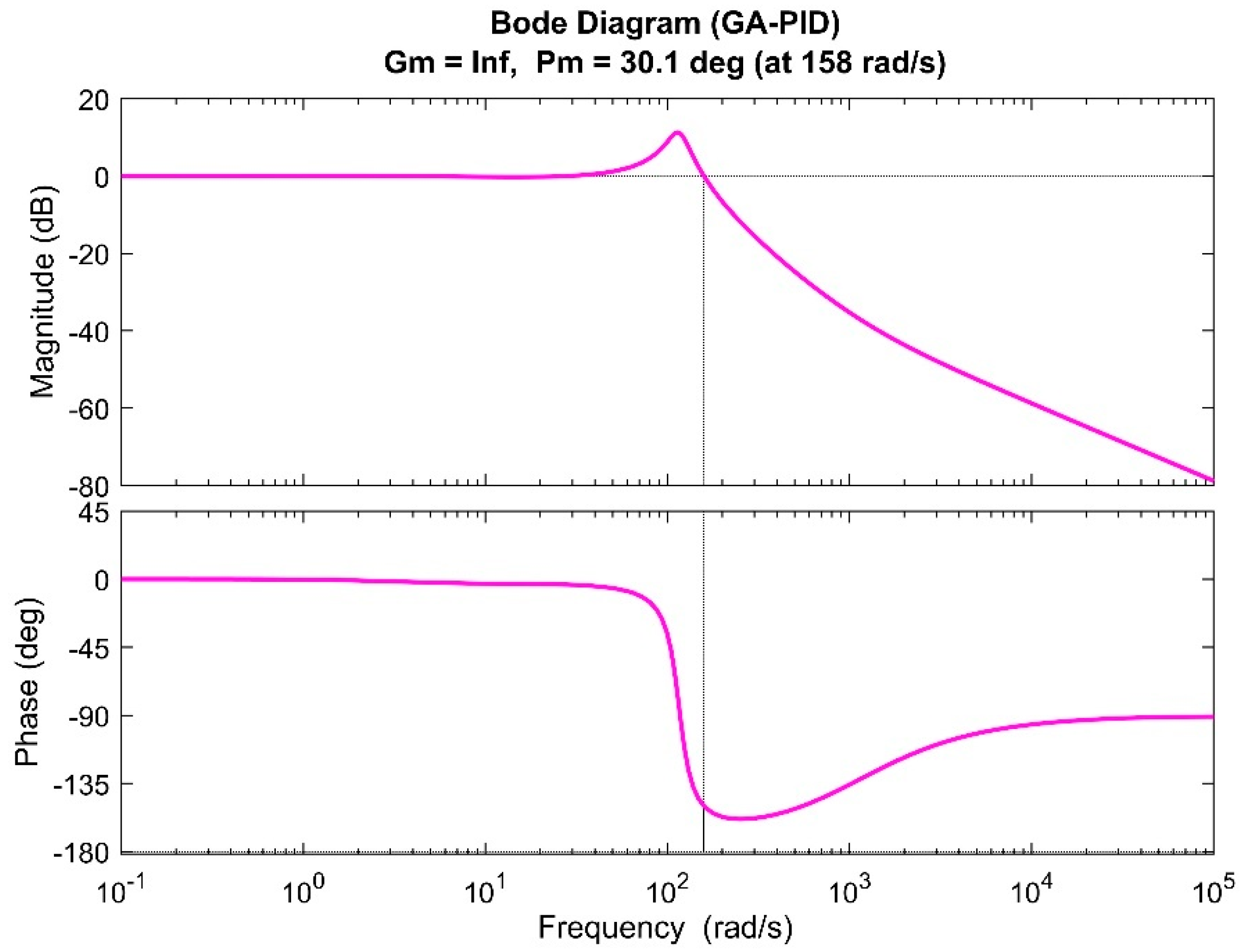

| PM | ||||||||

|---|---|---|---|---|---|---|---|---|

| PID | 175 | 825 | 13 | 0.485 | 2.33 | 1.039 | 0 | 179° |

| GA-PID | 110 | 981 | 0.1 | 0.390 | 1.923 | 0.749 | 0 | 30.1° |

| PSO-PID | 26 | 900 | 0.9 | 0.328 | 1.273 | 0.610 | 0 | 173° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanveer, A.; Ahmad, S.M. Mathematical Modelling and Fluidic Thrust Vectoring Control of a Delta Wing UAV. Aerospace 2023, 10, 563. https://doi.org/10.3390/aerospace10060563

Tanveer A, Ahmad SM. Mathematical Modelling and Fluidic Thrust Vectoring Control of a Delta Wing UAV. Aerospace. 2023; 10(6):563. https://doi.org/10.3390/aerospace10060563

Chicago/Turabian StyleTanveer, Ahsan, and Sarvat Mushtaq Ahmad. 2023. "Mathematical Modelling and Fluidic Thrust Vectoring Control of a Delta Wing UAV" Aerospace 10, no. 6: 563. https://doi.org/10.3390/aerospace10060563

APA StyleTanveer, A., & Ahmad, S. M. (2023). Mathematical Modelling and Fluidic Thrust Vectoring Control of a Delta Wing UAV. Aerospace, 10(6), 563. https://doi.org/10.3390/aerospace10060563