Aerodynamic Optimization Framework for a Three-Dimensional Nacelle Based on Deep Manifold Learning-Assisted Geometric Multiple Dimensionality Reduction

Abstract

1. Introduction

- (a)

- To address the difficulty of keeping balance between efficiency and accuracy of 3D nacelle parametric methods, the proposed method combines the traditional CST method with an auto-encoder to achieve a high-fidelity and efficient multiple dimensionality reduction of 3D nacelle geometry;

- (b)

- To address the lack of an efficient multi-objective optimization design method in direct 3D nacelle design, a novel aerodynamic design framework is developed based on a genetic algorithm and the proposed geometric dimensionality reduction method;

- (c)

- Taking the laminar flow area and drag coefficient as design objectives, Pareto front curves are given under different drag divergence constraints. The geometric distribution and the surface isentropic Mach number distribution of 3D nacelles with different aerodynamic performance are analyzed to provide experience for the subsequent aerodynamic design of a 3D nacelle.

2. CFD Validation and Mesh Analysis

3. Geometric Multiple Dimensionality Reduction Based on Deep Manifold Learning

3.1. The Concept of Deep Manifold Learning

3.2. Autoencoders (AE)

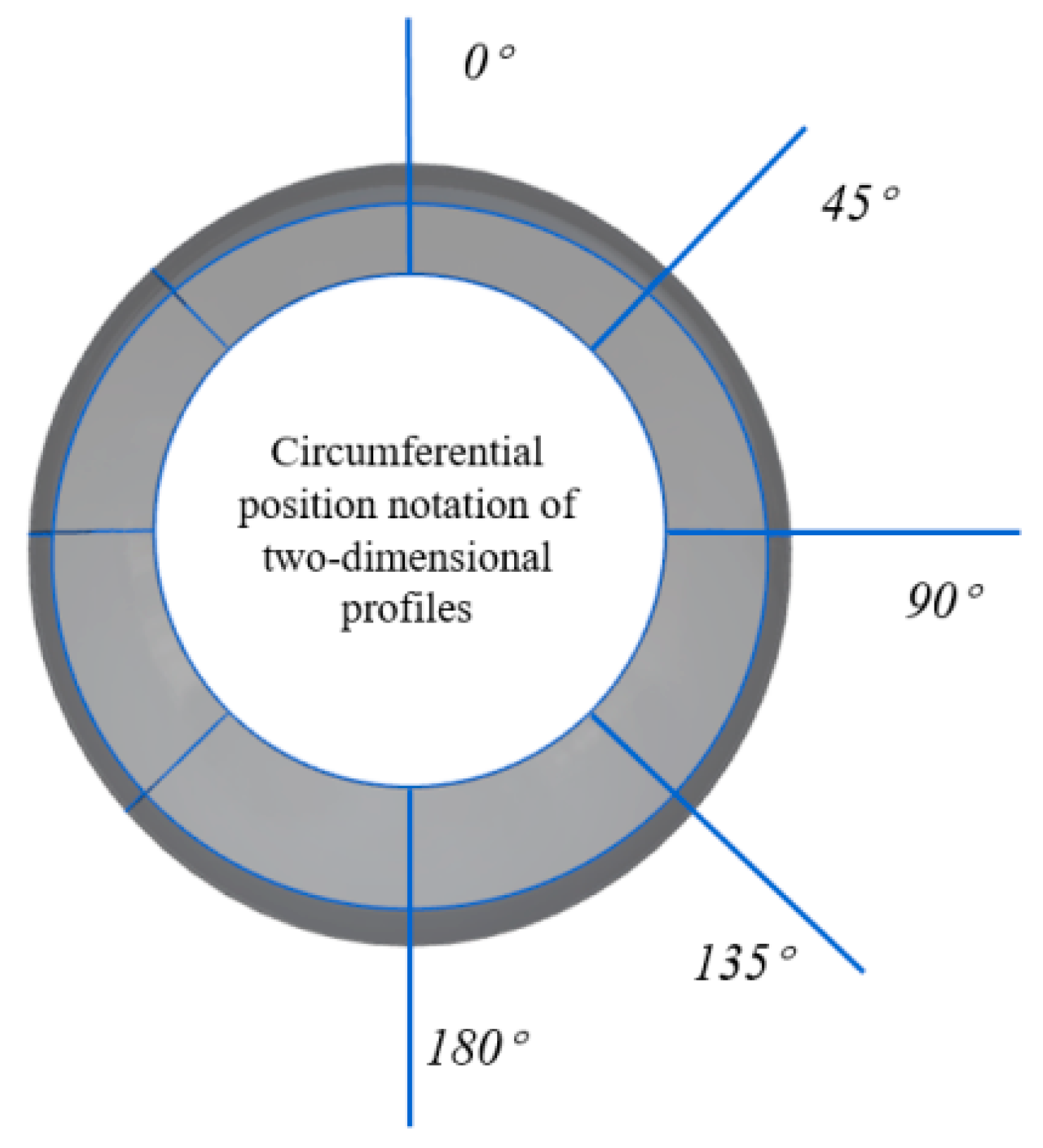

3.3. Geometric Multiple Dimensionality Reduction of Three-Dimensional Nacelle

3.4. Geometric Multiple Dimensionality Reduction Method Verification

4. Aerodynamic Optimization of Three-Dimensional Nacelle

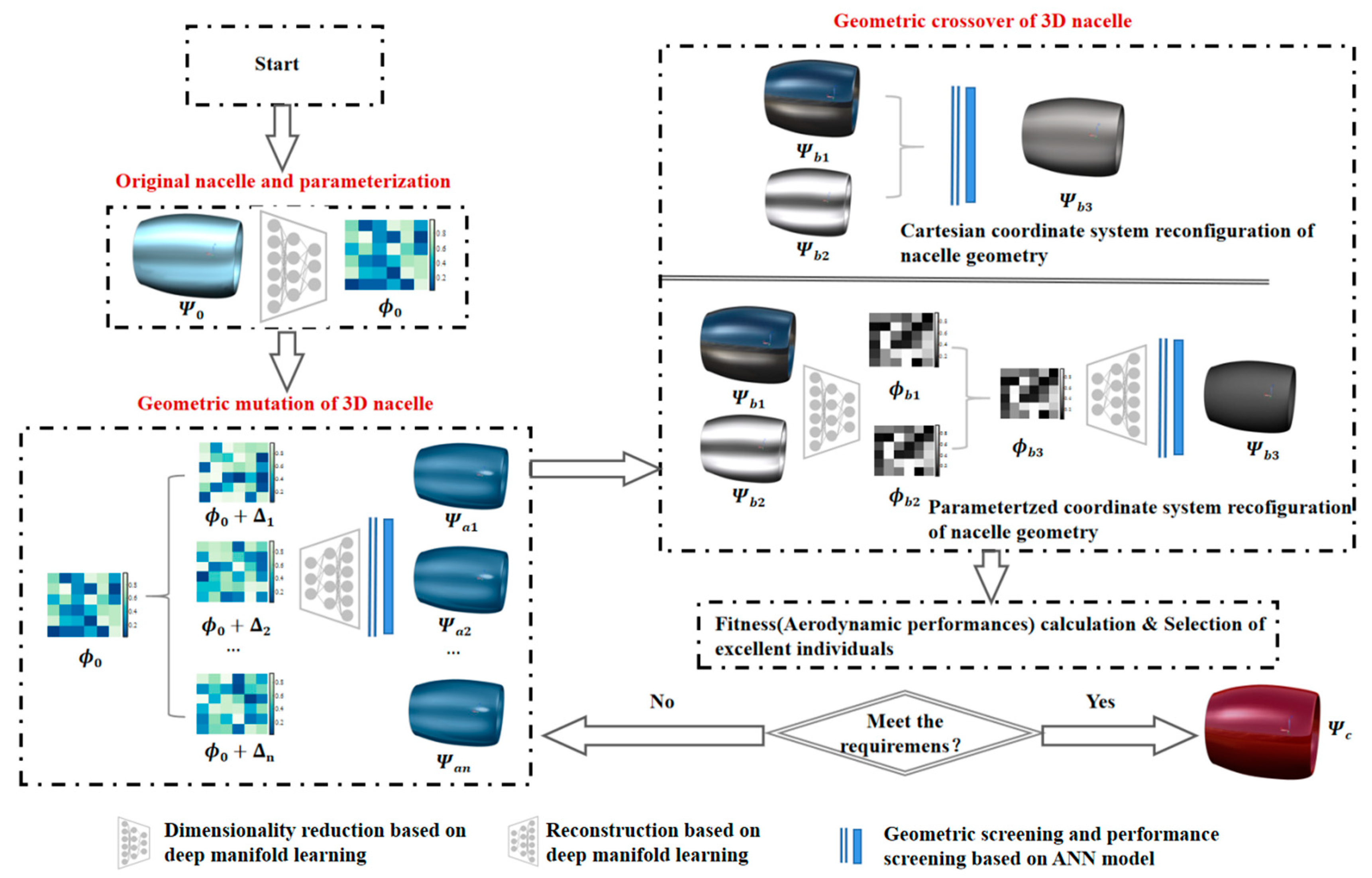

4.1. D Nacelle Aerodynamic Optimization Framework Based on Deep Manifold Learning

| Algorithm 1 3D Nacelle Aerodynamic Optimization Framework |

| 1: I = 0; //Evolutionary population generation; 2: Initialize ; //Initializing the population; 3: = MDRd (); //Multiple dimensionality reduction; 4: while (not Terminate-Condition) do //If the termination condition is not met, the loop { 5: I ++; //loop; 6: //Mutation; 7: = Mutation (); //Disturb to obtain new nacelle parameters; 8: screening(MDRc ()); //Acquisition of new nacelle configurations by mutation, and geometric and performance screening, MDRc: Multiple dimensionality reconfiguration; 9: Fitness (); //Select excellent individuals from the existing population; 10: // Crossover; 11: = MDRd ();// MDRd: Multiple dimensionality reduction; 12: screening ([Crossover (), MDRc (Crossover ())])// Acquisition of new nacelle configurations by crossover, and geometric and performance screening, MDRc: Multiple dimensionality reconfiguration; 13: Fitness (); Select excellent individuals from the existing population; } 14: end while 15: return |

4.2. Dynamic Training and Assisted Optimization of ANN Model for Aerodynamic Performance Evaluation

4.3. Optimization Problem Description

4.4. Optimal Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Robinson, M.; MacManus, D.G.; Christie, R.; Sheaf, C.; Grech, N. Nacelle design for ultra-high bypass ratio engines with CFD based optimisation. Aerosp. Sci. Technol. 2020, 113, 106191. [Google Scholar] [CrossRef]

- Kim, H.; Lee, M. Flow simulation of a supersonic airplane with installed engine nacelle. Aerosp. Sci. Technol. 2021, 117, 106900. [Google Scholar] [CrossRef]

- Wang, C.; Wang, S.; Wang, L.; Cao, C.; Sun, G.; Li, C.; Yang, Y. Framework of nacelle inverse design method based on improved generative adversarial networks. Aerosp. Sci. Technol. 2022, 121, 107365. [Google Scholar] [CrossRef]

- Tejero, F.; Christie, R.; MacManus, D.; Sheaf, C. Non-axisymmetric aero-engine nacelle design by surrogate-based methods. Aerosp. Sci. Technol. 2021, 117, 106890. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, M.; Hu, X. Optimal shape design and transition uncertainty analysis of transonic axisymmetric natural laminar flow nacelle at high Reynolds number. Aerosp. Sci. Technol. 2022, 121, 107345. [Google Scholar] [CrossRef]

- Yao, Y.; Ma, D.; Yang, M.; Zhang, L.; Guo, Y. Adaptive-surrogate-based robust optimization of transonic natural laminar flow nacelle. Chin. J. Aeronaut. 2021, 34, 36–52. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, Y.; Li, S.; Chen, H. Transonic Nacelle Aerodynamic Optimization Based on Hybrid Genetic Algorithm. In Proceedings of the 17th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar]

- Li, S.; Zhong, Y. A Turbofan-Engine Nacelle Shape Design and Optimization Method for Natural Laminar Flow Control. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, Seoul, Republic of Korea, 13–17 June 2016. [Google Scholar]

- Zhong, Y.; Li, S. A 3D Shape Design and Optimization Method for Natural Laminar Flow Nacelle. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Hicks, R.; Henne, P. Wing design by numerical optimization. J. Aircraft 1977, 5, 407–412. [Google Scholar]

- He, W.; Liu, X. Improved aerofoil parameterisation based on class/shape function transformation. Aeronaut. J. 2019, 123, 310–339. [Google Scholar] [CrossRef]

- Vuruskan, A.; Hosder, S. Impact of Turbulence Models and Shape Parameterization on Robust Aerodynamic Shape Optimi-zation. J. Aircraft. 2019, 56, 1099–1115. [Google Scholar] [CrossRef]

- Wang, S.; Sun, G.; Li, C. Natural Laminar Flow Optimization of Transonic Nacelle Based on Differential Evolution Algorithm. J. Aerosp. Eng. 2019, 32, 06019001. [Google Scholar] [CrossRef]

- Wang, S.; Sun, G.; Chen, W.; Zhong, Y. Database self-expansion based on artificial neural network: An approach in aircraft design. Aerosp. Sci. Technol. 2017, 72, 77–83. [Google Scholar] [CrossRef]

- Wang, S.; Cao, C.; Wang, C.; Wang, L.; Sun, G. A Nacelle Inlet Design Approach with More Three-Dimensional Geometric Con-sideration. Aerosp. Sci. Technol. 2021, 112, 106621. [Google Scholar] [CrossRef]

- Li, J.; Gao, Z.; Huang, J.; Zhao, K. Aerodynamic design optimization of nacelle/pylon position on an aircraft. Chin. J. Aeronaut. 2013, 26, 850–857. [Google Scholar] [CrossRef]

- He, X.; Bai, J.; Li, L.; Yang, T.; Zhang, Y. CYFFD Parameterization Method for Cylindrical Components of Aircrafts. J. Northwest. Polytech. Univ. 2018, 36, 1027–1036. [Google Scholar] [CrossRef]

- Wang, X.; Wang, S.; Tao, J.; Sun, G.; Mao, J. A PCA–ANN-based inverse design model of stall lift robustness for high-lift device. Aerosp. Sci. Technol. 2018, 81, 272–283. [Google Scholar] [CrossRef]

- Kingma, D.; Welling, M. Auto-Encoding Variational Bayes. arXiv 2014, arXiv:1312.6114v11. [Google Scholar]

- Goodfellow, I.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative Adversarial Nets. In Proceedings of the 28th Conference on Neural Information Processing Systems (NIPS), Montreal, QC, Canada, 7–12 December 2014; pp. 2672–2680. [Google Scholar]

- Chen, W.; Chiu, K.; Fuge, M.D. Airfoil Design Parameterization and Optimization Using Bézier Generative Adversarial Networks. AIAA J. 2020, 58, 4723–4735. [Google Scholar] [CrossRef]

- Du, X.; He, P.; Martins, J.R. Rapid airfoil design optimization via neural networks-based parameterization and surrogate modeling. Aerosp. Sci. Technol. 2021, 113, 106701. [Google Scholar] [CrossRef]

- Agarwal, D.; Marques, S.; Robinson, T. Aerodynamic Shape Optimisation Using Parametric CAD and Discrete Ad-joint. Aerospace 2022, 9, 743. [Google Scholar] [CrossRef]

- Yao, W.; Marques, S.; Robinson, T.; Armstrong, C.; Sun, L. A reduced-order model for gradient-based aerodynamic shape op-timisation. Aerosp. Sci. Technol. 2020, 106, 106120. [Google Scholar] [CrossRef]

- Faust, G.K.; Mungur, P. Nacelle Design; General Electric Company: Cleveland, OH, USA, 1987; pp. 17–20. [Google Scholar]

- Yufei, Z.; Haixin, C.; Song, F.; Miao, Z.; Meihong, Z. Drag prediction method of powered-on civil aircraft based on thrust drag bookkeeping. Chin. J. Aeronaut. 2015, 11, 1023–1033. [Google Scholar]

- Wu, H.; Liu, X.; An, W.; Lyu, H. A generative deep learning framework for airfoil flow field prediction with sparse data. Chin. J. Aeronaut. 2022, 35, 470–484. [Google Scholar] [CrossRef]

- Sun, X.; Cao, W.; Liu, Y.; Zhu, L.; Zhang, W. High Reynolds number airfoil turbulence modeling method based on machine learning technique. Comput. Fluids 2022, 236, 105298. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, W.; Sun, X.; Liu, Y.; Yuan, X. Turbulence closure for high Reynolds number airfoil flows by deep neural networks. Aerosp. Sci. Technol. 2021, 110, 106452. [Google Scholar] [CrossRef]

- Wu, H.; Liu, X.; An, W.; Chen, S.; Lyu, H. A deep learning approach for efficiently and accurately evaluating the flow field of supercritical airfoils. Comput. Fluids 2020, 198, 104393. [Google Scholar] [CrossRef]

- Harsanyi, J.C.; Chang, C.I. Hyperspectral image classification and dimensionality reduction: An orthogonal subspace projection approach. IEEE Trans. Geosci. Remote Sens. 1994, 32, 779–785. [Google Scholar] [CrossRef]

- Cheng, X.; Chen, Y.R.; Tao, Y.; Wang, C.Y.; Kim, M.S.; Lefcourt, A.M. A novel integrated PCA and FLD method on hyperspectral image feature extraction for cucumber chilling damage inspection. Trans. ASAE 2004, 47, 1313. [Google Scholar] [CrossRef]

- Bandos, T.V.; Bruzzone, L.; Camps-Valls, G. Classification of hyperspectral images with regularized linear discriminant analysis. IEEE Trans. Geosci. Remote Sens. 2009, 47, 862–873. [Google Scholar] [CrossRef]

- Ma, L.; Crawford, M.M.; Tian, J. Local manifold learning-based k-nearest-neighbor for hyperspectral image classification. IEEE Trans. Geosci. Remote Sens. 2010, 48, 4099–4109. [Google Scholar] [CrossRef]

- Bourlard, H.; Kamp, Y. Auto-association by multilayer perceptrons and singular value decomposition. Biol. Cybern. 1988, 59, 291–294. [Google Scholar] [CrossRef]

- Omata, N.; Shirayama, S. A novel method of low-dimensional representation for temporal behavior of flow fields using deep autoencoder. AIP Adv. 2019, 9, 015006. [Google Scholar] [CrossRef]

- He, X.; He, Q.; Chen, J.-S. Deep autoencoders for physics-constrained data-driven nonlinear materials modeling. Comput. Methods Appl. Mech. Eng. 2021, 385, 114034. [Google Scholar] [CrossRef]

- Christie, R.; Heidebrecht, A.; Macmanus, D. An Automated Approach to Nacelle Parameterization Using Intuitive Class Shape Transformation Curves. J. Eng. Gas Turbines Power 2017, 139, 062601. [Google Scholar] [CrossRef]

- Cao, F.; Hu, X.; Zhang, M.; Tang, Z. Transonic natural laminar flow nacelle optimization design at high Reynolds number. J. Aerosp. Power 2021, 36, 1729–1739. [Google Scholar]

| Mesh a | Mesh b | Mesh c | Mesh d | |

|---|---|---|---|---|

| Total number of grid nodes | 3,281,700 | 5,506,500 | 7,918,200 | 10,105,400 |

| Drag coefficient | 0.002885 | 0.002721 | 0.002710 | 0.002687 |

| Layer | Output Dimension | Network | |

|---|---|---|---|

| encoder | Dense Block (1) | 128 | (128-Linear, ReLU) × 4 |

| Dense Block (2) | 64 | (64-Linear, ReLU) × 4 | |

| Dense Block (3) | 16 | (16-Linear, ReLU) × 4 | |

| Encoder Output | 16 | 16-Linear, Tanh | |

| decoder | Dense Block (4) | 16 | (16-Linear, ReLU) × 4 |

| Dense Block (5) | 64 | (64-Linear, ReLU) × 4 | |

| Dense Block (6) | 128 | (128-Linear, ReLU) × 4 | |

| Block (1) | 228 | 228-Linear |

| Process | Output Dimension |

|---|---|

| Data point of 3D nacelle | 38 × 163 |

| Axial dimensionality reduction by CST | 38 × 6 |

| Secondary dimensionality reduction by AE | 16 |

| Traditional Typical Sections Parametric Method | Parametric Method Based on MDR | |

|---|---|---|

| Average geometry error | 0.003002 | 0.000038 |

| Average isentropic Ma error | 0.009058 | 0.000170 |

| Traditional Typical Sections Parametric Method | Parametric Method Based on MDR | ||

|---|---|---|---|

| Average Drag coefficient | 0.002812 | 0.002908 | 0.0002816 |

| Relative error | / | 3.4139% | 0.01422% |

|

Average Drag Coefficient () | Laminar Flow Ratio () | Suction Spike Strength () | |

|---|---|---|---|

| Opt1 | 0.002135 | 0.265165 | 1.535550 |

| Opt2 | 0.002557 | 0.360348 | 1.384353 |

| Opt3 | 0.002228 | 0.194124 | 1.374854 |

| Opt4 | 0.002584 | 0.291058 | 1.631023 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Wang, L.; Cao, C.; Sun, G.; Huang, Y.; Zhou, S. Aerodynamic Optimization Framework for a Three-Dimensional Nacelle Based on Deep Manifold Learning-Assisted Geometric Multiple Dimensionality Reduction. Aerospace 2023, 10, 573. https://doi.org/10.3390/aerospace10070573

Wang C, Wang L, Cao C, Sun G, Huang Y, Zhou S. Aerodynamic Optimization Framework for a Three-Dimensional Nacelle Based on Deep Manifold Learning-Assisted Geometric Multiple Dimensionality Reduction. Aerospace. 2023; 10(7):573. https://doi.org/10.3390/aerospace10070573

Chicago/Turabian StyleWang, Cong, Liyue Wang, Chen Cao, Gang Sun, Yufeng Huang, and Sili Zhou. 2023. "Aerodynamic Optimization Framework for a Three-Dimensional Nacelle Based on Deep Manifold Learning-Assisted Geometric Multiple Dimensionality Reduction" Aerospace 10, no. 7: 573. https://doi.org/10.3390/aerospace10070573

APA StyleWang, C., Wang, L., Cao, C., Sun, G., Huang, Y., & Zhou, S. (2023). Aerodynamic Optimization Framework for a Three-Dimensional Nacelle Based on Deep Manifold Learning-Assisted Geometric Multiple Dimensionality Reduction. Aerospace, 10(7), 573. https://doi.org/10.3390/aerospace10070573