3D Printer Selection for Aircraft Component Manufacturing Using a Nonlinear FGM and Dependency-Considered Fuzzy VIKOR Approach

Abstract

:1. Introduction

- Some existing methods are illustrated with numerical examples rather than real cases;

- As mentioned above, the performances of 3D printers in different aspects may be correlated, while existing methods assume that they are independent.

- The nFGM method is devised to derive the absolute priorities of criteria. In this way, the derivation accuracy can be enhanced without reducing efficiency;

- By considering the dependency between criteria, the defined reference points are reasonable and realizable, thereby improving the correctness of decision making.

2. 3D Printing Technologies for Manufacturing Aircraft Components

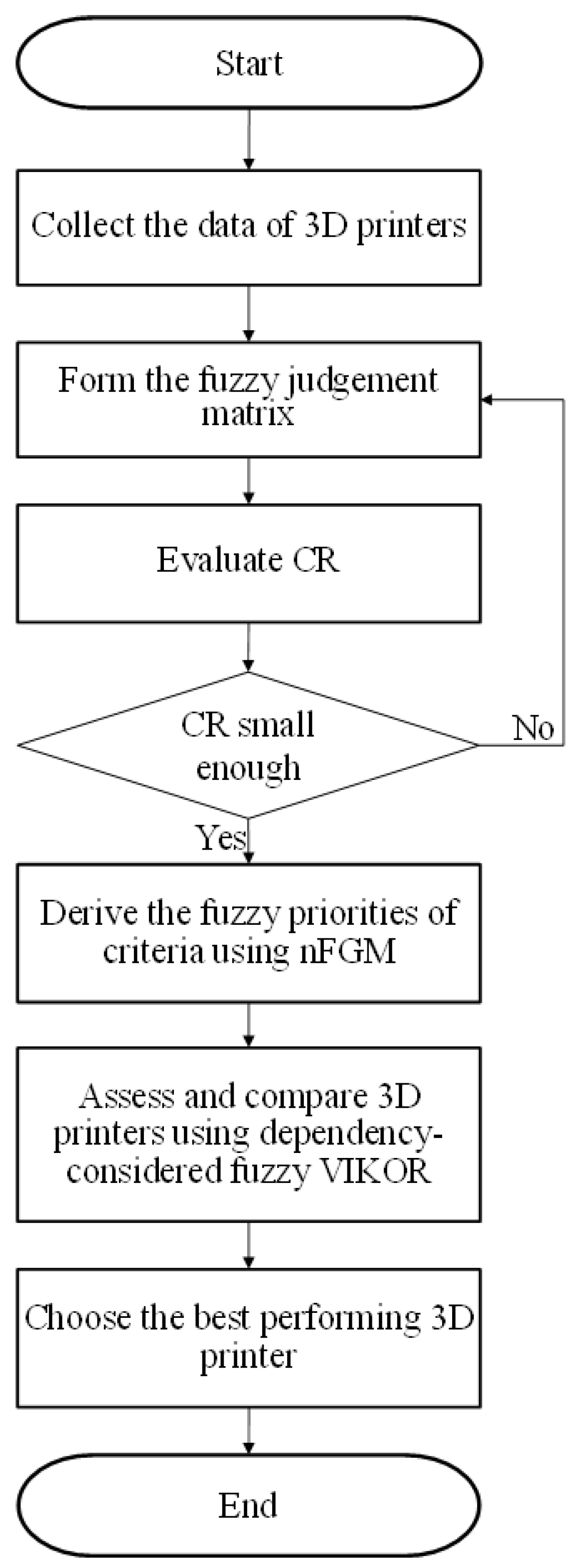

3. Methodology

- Step 1. Form the fuzzy pairwise comparison matrix and check its fuzzy consistency ratio;

- Step 2. Apply nFGM to derive the absolute priorities of criteria;

- Step 3. Apply the formulae of the criteria to assess the performances of each 3D printer;

- Step 4. Assess and compare 3D printers using dependency-considered fuzzy VIKOR;

- Step 5. Choose the 3D printer that surpasses the other alternatives.

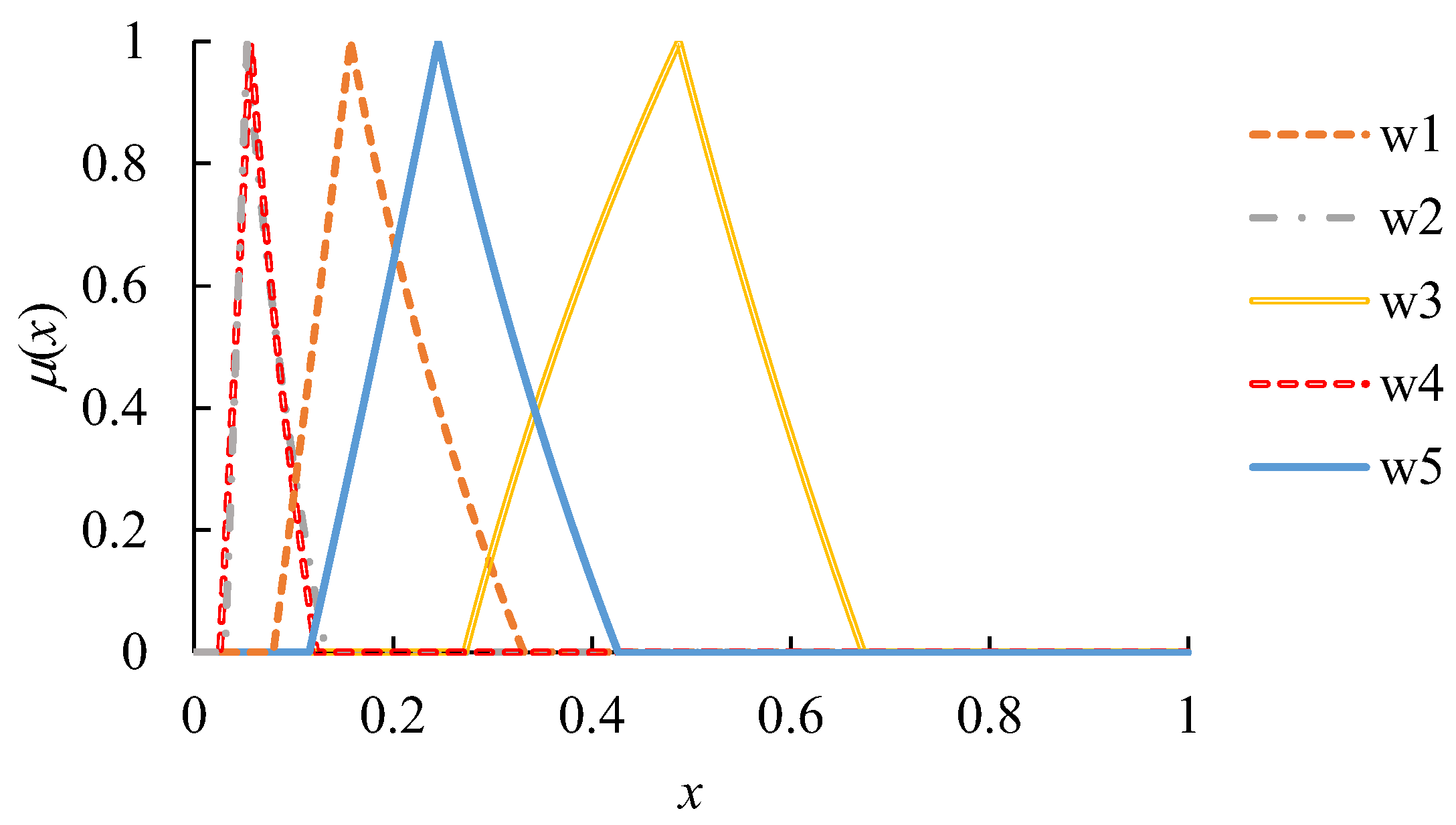

3.1. nFGM for Deriving the Fuzzy Priorities of Criteria

- xACO is based on the actual α cuts of a fuzzy priority, while nFGM is based on the estimated α cuts to save time;

- In xACO, the half-membership function of an absolute priority is approximated by a logarithmic function, while in nFGM, the half-membership function is approximated by either an exponential or a logarithmic function.

- Step 1. Approximate the α cuts of for α = 0, 0.5, and 1;

- Step 2. Conduct a crisp eigen analysis using the cores of matrix elements: The result is indicated with ;

- Step 3. Calibrate as [43]:where is the left (right) α cut of . is updated to the right-hand side of Equation (3);

- Step 4. Use the α cuts of for α = 0 and 1 to fit both types of functions as:or

- Step 5. Determine the function type using the α cuts of when α = 0.5:when , orwhen .

3.2. Dependency-Considered Fuzzy VIKOR for Assessing 3D Printers

- ∀ r ≠ q;

- or .

4. Case Study

4.1. Background

- Five attributes–the number of materials supported, the number of nozzles, the price, the resolution, and the speed, were comparable. However, other properties, such as the mechanical properties of 3D-printed aircraft parts (including consistency, yield stress, ultimate strength, fatigue, etc.) may be more important in practice, but it is difficult to compare the performances in these properties of 3D-printed aircraft parts manufactured by various 3D printers in practice. One possible way to solve this problem is to ask each 3D printer supplier to print samples and provide their measurement reports. However, this would not be a comparison on an equally fair basis, even if they follow the same standard;

- Except for price and resolution, if the other attributes were larger, then all the better.

4.2. Application of the Proposed Methodology

4.2.1. Comparing All 3D Printers

4.2.2. Comparing 3D Printers Using Different Materials

4.3. Discussion

- (1)

- The most important criterion for the decision maker’s selection of a suitable 3D printer was the price, followed by speed and the number of materials supported. In contrast, the number of nozzles was the least important criterion;

- (2)

- The 3D printer that most conformed to the subjective judgment of the decision maker was Stratasys Fortus 900mc, which had the largest number of nozzles and comparable speed, while the price was not the highest. However, only the second requirement was met. HP Jet Fusion 5200 and Concept Laser M2 Cusing came in second and third;

- (3)

- The superiority of the Stratasys Fortus 900mc over the other 3D printers became significant when the value of η exceeded 0.6, which meant that more emphasis was placed on the average performance rather than the worst performance.

- (4)

- Among 3D printers that apply the direct metal laser sintering (DMLS) technology, Concept Laser M2 Cusing was the best choice;

- (5)

- If the dependency between the two criteria was not considered, the ranks of 3D printers remained unchanged. However, the superiority of the Stratasys Fortus 900mc became less significant. As a result, η must be set to a value greater than 0.66 to satisfy both two requirements;

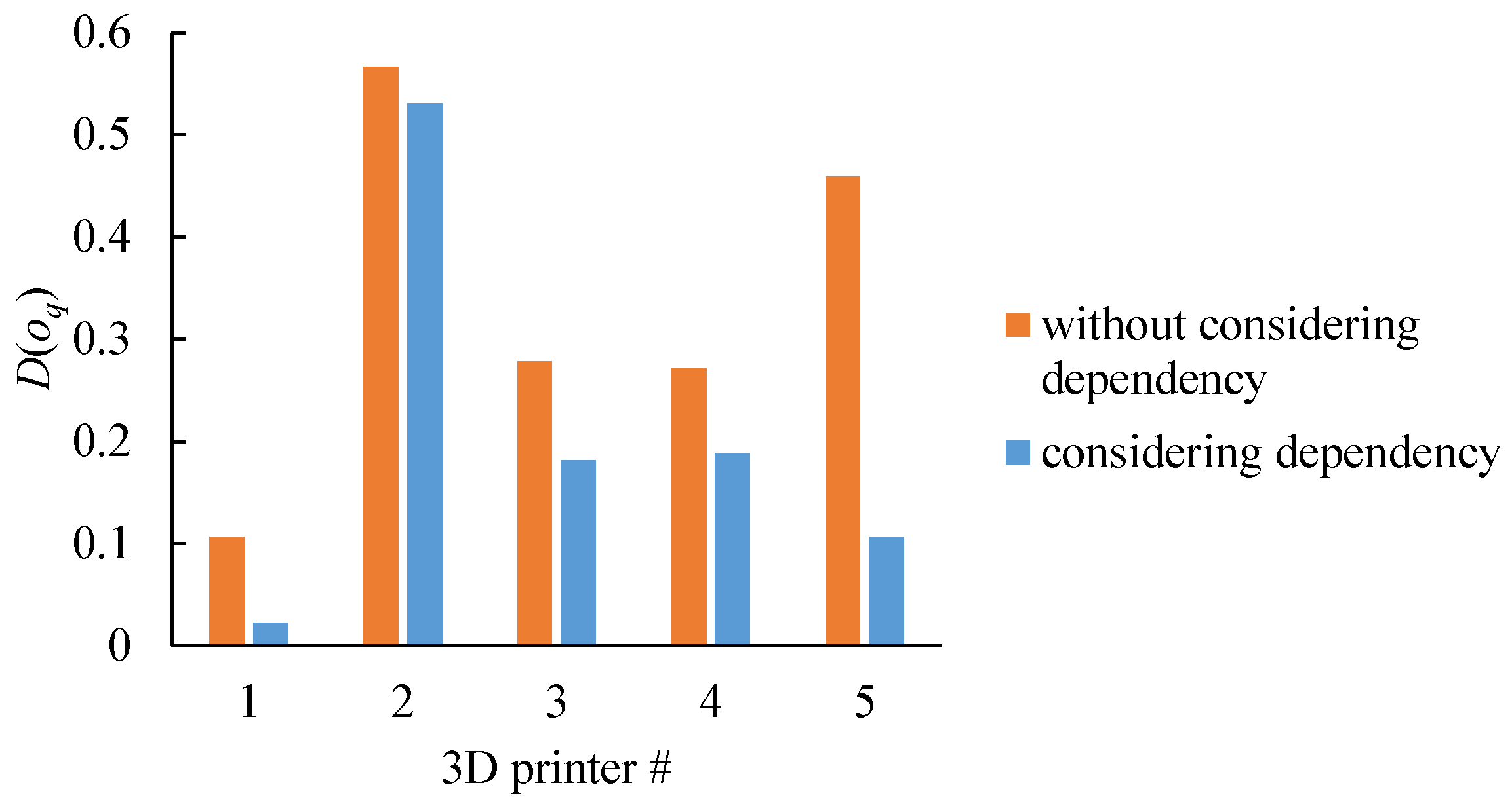

- (6)

- By considering the dependency between two attributes, 3D printers were compared with the closest reference points that were practically feasible. As a result, the distance between a 3D printer and its reference point was closer than that without considering the dependency, as shown in Figure 3.

- (7)

- The application results of four contrasting MCDM methods are reported in Table 14: FGM–fuzzy weighted average (FWA) [52,53,54], the ordered weighted average (OWA) [55,56,57], FGM–FTOPSIS [58,59,60,61,62,63], and FGM-fuzzy VIKOR [64,65,66,67]. Clearly, the same 3D printer, Stratasys Fortus 900mc, was chosen by all methods, showing the trustability of the experimental result using the proposed methodology. However, 3D printers ranked differently in various methods. Their unequal performances in deriving the absolute priorities accounted for such difference. Defining and comparing with practically feasible solutions also accounted for such differences. For example, the EOS M 400-4 was not as good as the HP Jet Fusion 5200 for speed, and the opposite was true for resolution. Therefore, the two 3D printers were compared to different reference points, whereas in existing methods, they were compared to the same reference point. This explains why their ranking results in the proposed methodology differ from those in existing methods.

- (8)

- Although the attributes of the 3D printers compared in this experiment were not specific to 3D printers for manufacturing aircraft components, the decision maker was from the aviation industry, so his judgment on the relative priorities of criteria was only applicable to 3D printers for manufacturing aircraft components, not general-purpose 3D printers. In addition, in previous studies such as Chen and Lin [57], the number of supported application types was critical for choosing a general-purpose 3D printer, but it was not considered in this study when choosing a suitable 3D printer for manufacturing aircraft components;

- (9)

- The ground truth of this case study is that the EOS M 290 was dominated by other 3D printers and, therefore, could not be selected, while other 3D printers could be recommended using different MCDM methods. In addition, 3D printers performed better in more criteria, such as Stratasys Fortus 900mc and EOS M 400-4, which are more likely to be selected. The experimental results also support these facts.

5. Conclusions

- (1)

- The criterion most critical to the selection of a suitable 3D printer for manufacturing aircraft components was the price, followed by the speed and the number of materials supported;

- (2)

- The best 3D printers using FDM, DMLS, and MJF were Stratasys Fortus 900mc, Concept Laser M2 Cusing, and HP Jet Fusion 5200V, respectively.

- (3)

- In total, Stratasys Fortus 900mc achieved the best overall performance with an advantage of 88% over the other compared 3D printers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.-C.; Chen, T.; Yeh, Y.-L. Advanced 3D printing technologies for the aircraft industry: A fuzzy systematic approach for assessing the critical factors. Int. J. Adv. Manuf. Technol. 2019, 105, 4059–4069. [Google Scholar] [CrossRef]

- Chung, K.-C.; Shu, M.-H.; Wang, Y.-C.; Huang, J.-C.; Lau, E.M. 3D printing technologies applied to the manufacturing of aircraft components. Mod. Phys. Lett. B 2020, 34, 2040018. [Google Scholar] [CrossRef]

- EOS, Additive Manufacturing for Aviation Locking Shaft for the Aircraft Door of an Airbus A350. Available online: https://www.eos.info/en/all-3d-printing-applications/aerospace-3d-printing/aircraft (accessed on 3 January 2023).

- Manda, V.R.; Kampurath, V.; Msrk, C. 3D printing and its effect on outsourcing: A study of the Indian aircraft industry. J. Aerosp. Technol. Manag. 2018, 10, e0718. [Google Scholar] [CrossRef]

- 3DSourced.com, 3D Printing in Aerospace: Everything You Need to Know. Available online: https://www.3dsourced.com/guides/3d-printing-in-aerospace-aircraft/ (accessed on 12 January 2023).

- Chen, T.-C.T.; Wang, Y.-C. AI applications to kaizen management. In Artificial Intelligence and Lean Manufacturing; Springer: Berlin/Heidelberg, Germany, 2022; pp. 37–53. [Google Scholar] [CrossRef]

- Shuaib, M.; Haleem, A.; Kumar, S.; Javaid, M. Impact of 3D Printing on the environment: A literature-based study. Sustain. Oper. Comput. 2021, 2, 57–63. [Google Scholar] [CrossRef]

- Chen, T.-C.T. Capacity planning for a ubiquitous manufacturing system based on three-dimensional printing. In 3D Printing and Ubiquitous Manufacturing; Springer: Berlin/Heidelberg, Germany, 2020; pp. 47–61. [Google Scholar] [CrossRef]

- Manners-Bell, J.; Lyon, K. The implications of 3D printing for the global logistics industry. Transp. Intell. 2012, 1, 1–5. [Google Scholar]

- Mavri, M. Redesigning a production chain based on 3D printing technology. Knowl. Process Manag. 2015, 22, 141–147. [Google Scholar] [CrossRef]

- Chen, T.-C.T.; Wang, Y.-C. AI applications to pull production, JIT, and production leveling. In Artificial Intelligence and Lean Manufacturing; Springer: Berlin/Heidelberg, Germany, 2022; pp. 55–74. [Google Scholar] [CrossRef]

- Wu, H.-C.; Chen, T.-C.T. Quality control issues in 3D-printing manufacturing: A review. Rapid Prototyp. J. 2018, 24, 607–614. [Google Scholar] [CrossRef]

- Chen, T.-C.T. Quality control in a 3D printing-based ubiquitous manufacturing system. In 3D Printing and Ubiquitous Manufacturing; Springer: Berlin/Heidelberg, Germany, 2020; pp. 83–95. [Google Scholar] [CrossRef]

- Lin, C.-W.; Chen, T. 3D printing technologies for enhancing the sustainability of an aircraft manufacturing or MRO company—A multi-expert partial consensus-FAHP analysis. Int. J. Adv. Manuf. Technol. 2019, 105, 4171–4180. [Google Scholar] [CrossRef]

- Chen, T.-C.T. Three-dimensional printing capacity planning. In 3D Printing and Ubiquitous Manufacturing; Springer: Berlin/Heidelberg, Germany, 2020; pp. 29–45. [Google Scholar] [CrossRef]

- Chiu, M.-C.; Chen, T.-C.T. A ubiquitous healthcare system of 3D printing facilities for making dentures: Application of type-II fuzzy logic. Digit. Health 2022, 8, 20552076221092540. [Google Scholar] [CrossRef]

- Roberson, D.; Espalin, D.; Wicker, R. 3D printer selection: A decision-making evaluation and ranking model. Virtual Phys. Prototyp. 2013, 8, 201–212. [Google Scholar] [CrossRef]

- Chen, T.-C.T.; Lin, Y.-C. A FAHP-FTOPSIS approach for bioprinter selection. Health Technol. 2020, 10, 1455–1467. [Google Scholar] [CrossRef]

- Prabhu, S.R.; Ilangkumaran, M. Decision making methodology for the selection of 3D printer under fuzzy environment. Int. J. Mater. Prod. Technol. 2019, 59, 239–252. [Google Scholar] [CrossRef]

- Prabhu, S.R.; Ilangkumaran, M. Selection of 3D printer based on FAHP integrated with GRA-TOPSIS. Int. J. Mater. Prod. Technol. 2019, 58, 155–177. [Google Scholar] [CrossRef]

- Lei, F.; Wei, G.; Shen, W.; Guo, Y. PDHL-EDAS method for multiple attribute group decision making and its application to 3D printer selection. Technol. Econ. Dev. Econ. 2022, 28, 179–200. [Google Scholar] [CrossRef]

- Brito, L.C.; Susto, G.A.; Brito, J.N.; Duarte, M.A. An explainable artificial intelligence approach for unsupervised fault detection and diagnosis in rotating machinery. Mech. Syst. Signal Process. 2022, 163, 108105. [Google Scholar] [CrossRef]

- Wu, H.-C.; Lin, Y.-C.; Chen, T.-C.T. Leisure agricultural park selection for traveler groups amid the COVID-19 pandemic. Agriculture 2022, 12, 111. [Google Scholar] [CrossRef]

- Chen, T.-C.T. Type-II fuzzy collaborative intelligence for assessing cloud manufacturing technology applications. Robot. Comput.-Integr. Manuf. 2022, 78, 102399. [Google Scholar] [CrossRef]

- Simchi, A.; Petzoldt, F.; Pohl, H. On the development of direct metal laser sintering for rapid tooling. J. Mater. Process. Technol. 2003, 141, 319–328. [Google Scholar] [CrossRef]

- Singh, R.; Rishab; Sidhu, J.S. On three-dimensional printing of 17-4 precipitation-hardenable stainless steel with direct metal laser sintering in aircraft structural applications. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 440–450. [Google Scholar] [CrossRef]

- Śliwa, R.E.; Bernaczek, J.; Budzik, G. The application of direct metal laser sintering (DMLS) of titanium alloy powder in fabricating components of aircraft structures. Key Eng. Mater. 2016, 687, 199–205. [Google Scholar] [CrossRef]

- Ferro, C.G.; Varetti, S.; De Pasquale, G.; Maggiore, P. Lattice structured impact absorber with embedded anti-icing system for aircraft wings fabricated with additive SLM process. Mater. Today Commun. 2018, 15, 185–189. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z.; Xu, P.; Liu, Z. Recent research and development status of laser cladding: A review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Liu, Q.; Janardhana, M.; Hinton, B.; Brandt, M.; Sharp, K. Laser cladding as a potential repair technology for damaged aircraft components. Int. J. Struct. Integr. 2011, 2, 314–331. [Google Scholar] [CrossRef]

- Song, M.; Wu, L.; Liu, J.; Hu, Y. Effects of laser cladding on crack resistance improvement for aluminum alloy used in aircraft skin. Opt. Laser Technol. 2021, 133, 106531. [Google Scholar] [CrossRef]

- Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal binder jetting additive manufacturing: A literature review. J. Manuf. Sci. Eng. 2020, 142, 090801. [Google Scholar] [CrossRef]

- Gupta, A.; Soni, V.; Shah, D.; Lakdawala, A. Generative design of main landing gear for a remote-controlled aircraft. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Tang, Y.; Mak, K.; Zhao, Y.F. A framework to reduce product environmental impact through design optimization for additive manufacturing. J. Clean. Prod. 2016, 137, 1560–1572. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S.; Christensen, A. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 2010, 3, 249–259. [Google Scholar] [CrossRef]

- Yılmaz, F. Mechanical Characterization of Additively Manufactured Ti-6Al-4V Aircraft Structural Components Produced by Electron Beam Melting. Master’s Thesis, Middle East Technical University, Ankara, Turkey, 2022. Available online: https://open.metu.edu.tr/bitstream/handle/11511/99449/index.pdf (accessed on 4 January 2023).

- Petrovic, V.; Niñerola, R. Powder recyclability in electron beam melting for aeronautical use. Aircr. Eng. Aerosp. Technol. Int. J. 2015, 87, 147–155. [Google Scholar] [CrossRef]

- Prikhna, T.O.; Grechanyuk, I.M.; Karpets, M.V.; Grechanyuk, M.I.; Bagliuk, G.A.; Grechanyuk, V.G.; Khomenko, O.V. Electron-beam and plasma oxidation-resistant and thermal-barrier coatings deposited on turbine blades using cast and powder Ni (Co) CrAlY (Si) alloys produced by electron-beam melting II. Structure and chemical and phase composition of cast CoCrAlY alloys. Powder Metall. Met. Ceram. 2022, 61, 230–237. [Google Scholar] [CrossRef]

- Budzik, G. Geometric accuracy of aircraft engine blade models constructed by means of the generative rapid prototyping methods FDM and SLA. Adv. Manuf. Sci. Technol. 2010, 34, 33–43. [Google Scholar]

- Nazir, A.; Ali, M.; Hsieh, C.H.; Jeng, J.Y. Investigation of stiffness and energy absorption of variable dimension helical springs fabricated using multijet fusion technology. Int. J. Adv. Manuf. Technol. 2020, 110, 2591–2602. [Google Scholar] [CrossRef]

- Klein, A. How Binder Jet 3D Printing for Metals Compares to Selective Laser Melting and Electron Beam Melting. Available online: https://www.exone.com/Admin/getmedia/d2e3e618-aa7c-457a-a019-fbef2b8063c2/Klein-English-Article-012020.pdf (accessed on 21 June 2023).

- 3DEXPERIENCE Make, DMLS vs. EBM: Differences and Comparison. Available online: https://www.3ds.com/make/solutions/blog/dmls-vs-ebm-differences-and-comparison (accessed on 21 June 2023).

- Chen, T.; Wang, Y.-C.; Wu, H.-C. Analyzing the impact of vaccine availability on alternative supplier selection amid the COVID-19 pandemic: A cFGM-FTOPSIS-FWI approach. Healthcare 2021, 9, 71. [Google Scholar] [CrossRef]

- Chen, T.; Lin, Y.-C.; Chiu, M.-C. Approximating alpha-cut operations approach for effective and efficient fuzzy analytic hierarchy process analysis. Appl. Soft Comput. 2019, 85, 105855. [Google Scholar] [CrossRef]

- Aragonés-Beltrán, P.; Chaparro-González, F.; Pastor-Ferrando, J.; Rodríguez-Pozo, F. An ANP-based approach for the selection of photovoltaic solar power plant investment projects. Renew. Sustain. Energy Rev. 2010, 14, 249–264. [Google Scholar] [CrossRef]

- Johnson, R.A.; Wichern, D.W. Applied Multivariate Statistical Analysis; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Wang, Y.-J.; Liu, L.-J.; Han, T.-C. Interval-valued fuzzy multi-criteria decision-making with dependent evaluation criteria for evaluating service performance of international container ports. J. Mar. Sci. Eng. 2022, 10, 991. [Google Scholar] [CrossRef]

- Mikhailov, L.; Singh, M.G. Fuzzy analytic network process and its application to the development of decision support systems. IEEE Trans. Syst. Man Cybern. Part C (Appl. Rev.) 2003, 33, 33–41. [Google Scholar] [CrossRef]

- Opricovic, S. Fuzzy VIKOR with an application to water resources planning. Expert Syst. Appl. 2011, 38, 12983–12990. [Google Scholar] [CrossRef]

- Van Broekhoven, E.; De Baets, B. Fast and accurate center of gravity defuzzification of fuzzy system outputs defined on trapezoidal fuzzy partitions. Fuzzy Sets Syst. 2006, 157, 904–918. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Chen, T.-C.T. An intelligent system for assisting personalized COVID-19 vaccination location selection: Taiwan as an example. Digit. Health 2022, 8, 20552076221109062. [Google Scholar] [CrossRef]

- Zheng, G.; Zhu, N.; Tian, Z.; Chen, Y.; Sun, B. Application of a trapezoidal fuzzy AHP method for work safety evaluation and early warning rating of hot and humid environments. Saf. Sci. 2012, 50, 228–239. [Google Scholar] [CrossRef]

- Wang, Y.C.; Chen, T.C.T. A partial-consensus posterior-aggregation FAHP method—Supplier selection problem as an example. Mathematics 2019, 7, 179. [Google Scholar] [CrossRef]

- Veerraju, N.; Prasannam, V.L.; Rallabandi, L.K. Defuzzification index for ranking of fuzzy numbers on the basis of geometric mean. Int. J. Intell. Syst. Appl. 2020, 12, 13–24. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wang, Y.C.; Chen, T.C.T.; Lin, H.F. Evaluating the suitability of a smart technology application for fall detection using a fuzzy collaborative intelligence approach. Mathematics 2019, 7, 1097. [Google Scholar] [CrossRef]

- Linares-Mustarós, S.; Ferrer-Comalat, J.C.; Corominas-Coll, D.; Merigó, J.M. The ordered weighted average in the theory of expertons. Int. J. Intell. Syst. 2019, 34, 345–365. [Google Scholar] [CrossRef]

- Chen, T.; Lin, C.W. Smart and automation technologies for ensuring the long-term operation of a factory amid the COVID-19 pandemic: An evolving fuzzy assessment approach. Int. J. Adv. Manuf. Technol. 2020, 111, 3545–3558. [Google Scholar] [CrossRef]

- Merigo, J.M.; Casanovas, M. The fuzzy generalized OWA operator and its application in strategic decision making. Cybern. Syst. Int. J. 2010, 41, 359–370. [Google Scholar] [CrossRef]

- Chen, T. Obtaining the optimal cache document replacement policy for the caching system of an EC website. Eur. J. Oper. Res. 2007, 181, 828–841. [Google Scholar] [CrossRef]

- Noori, A.; Bonakdari, H.; Hassaninia, M.; Morovati, K.; Khorshidi, I.; Noori, A.; Gharabaghi, B. A reliable GIS-based FAHP-FTOPSIS model to prioritize urban water supply management scenarios: A case study in semi-arid climate. Sustain. Cities Soc. 2022, 81, 103846. [Google Scholar] [CrossRef]

- Chen, T.; Chiu, M.C. Smart technologies for assisting the life quality of persons in a mobile environment: A review. J. Ambient Intell. Humaniz. Comput. 2018, 9, 319–327. [Google Scholar] [CrossRef]

- Yadav, R.; Lee, H.H. Ranking and selection of dental restorative composite materials using FAHP-FTOPSIS technique: An application of multi criteria decision making technique. J. Mech. Behav. Biomed. Mater. 2022, 132, 105298. [Google Scholar] [CrossRef]

- Chen, T.-C.T.; Wu, H.-C.; Hsu, K.-W. A fuzzy analytic hierarchy process-enhanced fuzzy geometric mean-fuzzy technique for order preference by similarity to ideal solution approach for suitable hotel recommendation amid the COVID-19 pandemic. Digit. Health 2022, 8, 20552076221084457. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Govindan, K.; Esmaeili, A.; Sabaghi, M. Application of fuzzy VIKOR for evaluation of green supply chain management practices. Ecol. Indic. 2015, 49, 188–203. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Chen, T.-C.T. Analyzing the impact of COVID-19 vaccination requirements on travelers’ selection of hotels using a fuzzy multi-criteria decision-making approach. Healthc. Anal. 2022, 2, 100064. [Google Scholar] [CrossRef]

- Shemshadi, A.; Shirazi, H.; Toreihi, M.; Tarokh, M.J. A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting. Expert Syst. Appl. 2011, 38, 12160–12167. [Google Scholar] [CrossRef]

- Chen, T.-C.T.; Lin, Y.-C. Diversified capacity planning of three-dimensional printing for a manufacturer. Robot. Comput.-Integr. Manuf. 2021, 67, 102052. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. A digital twin for rapid qualification of 3D printed metallic components. Appl. Mater. Today 2019, 14, 59–65. [Google Scholar] [CrossRef]

- Wu, H.C.; Chen, T.C.T.; Huang, C.H.; Shih, Y.C. Comparing built-in power banks for a smart backpack design using an auto-weighting fuzzy-weighted-intersection FAHP approach. Mathematics 2020, 8, 1759. [Google Scholar] [CrossRef]

- Smith, D.M.; Kapoor, Y.; Klinzing, G.R.; Procopio, A.T. Pharmaceutical 3D printing: Design and qualification of a single step print and fill capsule. Int. J. Pharm. 2018, 544, 21–30. [Google Scholar] [CrossRef]

- Wu, H.C.; Chen, T.; Huang, C.H. A piecewise linear FGM approach for efficient and accurate FAHP analysis: Smart backpack design as an example. Mathematics 2020, 8, 1319. [Google Scholar] [CrossRef]

| Method | Method for Deriving Criteria | Method for Evaluating Alternatives | Accuracy | Efficiency | Dependency between Criteria |

|---|---|---|---|---|---|

| Lin and Chen [14] | Fuzzy geometric mean (FGM)-Fuzzy intersection (FI) | FTOPSIS | Low | High | Not considered |

| Robertson et al. [17] | Subjective assignment | WA | Low | Very high | Not considered |

| Prabhu and Ilangkumaran [19] | FGM | Fuzzy VIKOR | Low | High | Not considered |

| Prabhu and Ilangkumaran [20] | Grey analysis | TOPSIS | Not comparable | Medium | Not considered |

| Lei et al. [21] | PDHL | EDAS | Low | High | Not considered |

| Chen [24] | Efficient approximating alpha-cut operations (xACO) | Type-II fuzzy VIKOR | High | Low | Not considered |

| The proposed methodology | nFGM | Dependency- considered fuzzy VIKOR | High | High | Considered |

| Method | Number of Crisp Eigen Analyses Required | Number of FGM Calculations Required | Shape of Membership Function | Efficiency | Accuracy |

|---|---|---|---|---|---|

| ACO | 0 | Nonlinear | Very low | Very high | |

| xACO | 0 | Nonlinear | Very low~Low | High~Very high | |

| FGM | 0 | 1 | Linear | Very high | Very low~Very high * |

| cFGM | 1 | 1 | Linear | High | Low~Very high * |

| cpFGM | 1 | 2λ − 1 | Piecewise linear | High | Moderate~Very high * |

| acFGM | 1 | 1 | Linear | High | Moderate~Very high * |

| nFGM | 1 | 1 | Nonlinear | High | High~Very high * |

| Parameter | ||||||||

|---|---|---|---|---|---|---|---|---|

| 11.43 | −12.38 | −4.49 | 6.26 | 1.47 | 3.72 | −1.34 | −1.48 | |

| 43.17 | −44.52 | −11.39 | 13.01 | 1.84 | 6.41 | −1.09 | −2.19 | |

| 3.17 | −4.16 | −3.01 | 5.90 | 1.72 | 2.23 | −3.10 | −1.23 | |

| 30.99 | −31.80 | −13.87 | 15.68 | 1.27 | 4.64 | −1.30 | −2.72 | |

| 6.44 | −7.23 | −3.93 | 6.03 | 1.33 | 2.87 | −1.81 | −1.54 |

| Fuzzy Priorities | Left | Right |

|---|---|---|

| Exponential | Logarithmic | |

| Exponential | Logarithmic | |

| Logarithmic | Logarithmic | |

| Exponential | Logarithmic | |

| Exponential | Logarithmic |

| 3D Printer | Stratasys Fortus 900mc I | EOS M 290 II | Concept Laser M2 Cusing III | EOS M 400-4 IV | HP Jet Fusion 5200 V |

|---|---|---|---|---|---|

| Number of materials supported | 7 | 5 | 4 | 2 | 5 |

| Number of nozzles | 1~4 | 1~2 | 1~2 | 4 | 2 |

| Price (USD) | 400,000~1,000,000 | 250,000~450,000 | 500,000~1,000,000 | 1,000,000 | 400,000 |

| Printing technology | FDM | DMLS | DMLS | DMLS | MJF |

| Resolution (mm) | 0.13 ~ 0.5 | 0.02 ~ 0.04 | 0.02 ~ 0.08 | 0.1 ~ | 0.08 ~ |

| Speed | 2230 cm3/h | 2.5 cm3/h | 2.5 cm3/h & nozzle | 100 g/h | 4500 cm3/h |

| Vendor | Stratasys | EOS | Concept Laser | EOS | HP |

| q | |||||

|---|---|---|---|---|---|

| 1 | (4, 5, 5) | (4, 5, 5) | (4, 5, 5) | (4, 5, 5) | (1.5, 2.5, 3.5) |

| 2 | (1.5, 2.5, 3.5) | (0, 0, 1) | (0, 0, 1) | (0, 0, 1) | (0, 0, 1) |

| 3 | (1.5, 2.5, 3.5) | (0, 0, 1) | (4, 5, 5) | (0, 0, 1) | (0, 0, 1) |

| 4 | (0, 0, 1) | (4, 5, 5) | (4, 5, 5) | (3, 4, 5) | (0, 0, 1) |

| 5 | (1.5, 2.5, 3.5) | (0, 0, 1) | (0, 0, 1) | (1.5, 2.5, 3.5) | (4, 5, 5) |

| Reference Point | i = 1 | i = 2 | i = 3 | i = 4 | i = 5 |

|---|---|---|---|---|---|

| (4, 5, 5) | (4, 5, 5) | (4, 5, 5) | (4, 5, 5) | (1.5, 2.5, 3.5) | |

| (4, 5, 5) | (4, 5, 5) | (0, 0, 1) | (4, 5, 5) | (4, 5, 5) |

| q | |

|---|---|

| 1 | (0, 0, 0.2) |

| 2 | (0.1, 0.5, 0.7) |

| 3 | (0.1, 0.5, 0.7) |

| 4 | (0.6, 1, 1) |

| 5 | (0.1, 0.5, 0.7) |

| q (3D Printer No.) | (Overall Performance) ( Cut) | Rank | |

|---|---|---|---|

| 1 | 0: [0, 0.105]; 0.1: [0, 0.102]; 0.2: [0, 0.097]; 0.3: [0, 0.091]; 0.4: [0, 0.083]; 0.5: [0, 0.074]; 0.6: [0, 0.063]; 0.7: [0, 0.05]; 0.8: [0, 0.035]; 0.9: [0, 0.019]; 1: [0,0] | 0.022 | 1 |

| 2 | 0: [0.19, 0.437]; 0.1: [0.22, 0.458]; 0.2: [0.252, 0.48]; 0.3: [0.288, 0.501]; 0.4: [0.328, 0.522]; 0.5: [0.37, 0.542]; 0.6: [0.417, 0.563]; 0.7: [0.467, 0.583]; 0.8: [0.521, 0.603]; 0.9: [0.58, 0.623]; 1: [0.643, 0.643] | 0.531 | 5 |

| 3 | 0: [0.036, 0.171]; 0.1: [0.046, 0.181]; 0.2: [0.057, 0.19]; 0.3: [0.072, 0.198]; 0.4: [0.088, 0.204]; 0.5: [0.106, 0.21]; 0.6: [0.125, 0.214]; 0.7: [0.146, 0.217]; 0.8: [0.168, 0.218]; 0.9: [0.192, 0.218]; 1: [0.217, 0.217] | 0.182 | 3 |

| 4 | 0: [0.054, 0.163]; 0.1: [0.065, 0.173]; 0.2: [0.078, 0.182]; 0.3: [0.093, 0.191]; 0.4: [0.108, 0.198]; 0.5: [0.125, 0.205]; 0.6: [0.142, 0.211]; 0.7: [0.161, 0.216]; 0.8: [0.181, 0.22]; 0.9: [0.202, 0.222]; 1: [0.224, 0.224] | 0.189 | 4 |

| 5 | 0: [0.024, 0.132]; 0.1: [0.029, 0.133]; 0.2: [0.035, 0.133]; 0.3: [0.042, 0.136]; 0.4: [0.05, 0.137]; 0.5: [0.059, 0.137]; 0.6: [0.069, 0.136]; 0.7: [0.081, 0.133]; 0.8: [0.093, 0.13]; 0.9: [0.106, 0.125]; 1: [0.119, 0.119] | 0.107 | 2 |

| Reference Point | i = 1 | i = 2 | i = 3 | i = 4 | i = 5 |

|---|---|---|---|---|---|

| (4, 5, 5) | (4, 5, 5) | (0, 0, 1) | (4, 5, 5) | (4, 5, 5) |

| q (3D Printer No.) | Rank | |

|---|---|---|

| 2 | 0.451 | 3 |

| 3 | 0.092 | 1 |

| 4 | 0.113 | 2 |

| Reference Point | i = 1 | i = 2 | i = 3 | i = 4 | i = 5 |

|---|---|---|---|---|---|

| (4, 5, 5) | (4, 5, 5) | (4, 5, 5) | (4, 5, 5) | (4, 5, 5) |

| q (3D Printer No.) | Rank | |

|---|---|---|

| 1 | 0.150 | 1 |

| 5 | 0.479 | 2 |

| q | Rank (FGM-FWA) | OWA | Rank (FGM-FTOPSIS) | Rank (FGM-Fuzzy VIKOR) | Rank (Proposed Methodology) |

|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 5 | 5 | 5 | 5 | 5 |

| 3 | 3 | 4 | 4 | 3 | 3 |

| 4 | 2 | 2 | 3 | 2 | 4 |

| 5 | 4 | 3 | 2 | 4 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-C.; Chen, T.-C.T.; Lin, Y.-C. 3D Printer Selection for Aircraft Component Manufacturing Using a Nonlinear FGM and Dependency-Considered Fuzzy VIKOR Approach. Aerospace 2023, 10, 591. https://doi.org/10.3390/aerospace10070591

Wang Y-C, Chen T-CT, Lin Y-C. 3D Printer Selection for Aircraft Component Manufacturing Using a Nonlinear FGM and Dependency-Considered Fuzzy VIKOR Approach. Aerospace. 2023; 10(7):591. https://doi.org/10.3390/aerospace10070591

Chicago/Turabian StyleWang, Yu-Cheng, Tin-Chih Toly Chen, and Yu-Cheng Lin. 2023. "3D Printer Selection for Aircraft Component Manufacturing Using a Nonlinear FGM and Dependency-Considered Fuzzy VIKOR Approach" Aerospace 10, no. 7: 591. https://doi.org/10.3390/aerospace10070591

APA StyleWang, Y.-C., Chen, T.-C. T., & Lin, Y.-C. (2023). 3D Printer Selection for Aircraft Component Manufacturing Using a Nonlinear FGM and Dependency-Considered Fuzzy VIKOR Approach. Aerospace, 10(7), 591. https://doi.org/10.3390/aerospace10070591