An Orchestration Method for Integrated Multi-Disciplinary Simulation in Digital Twin Applications

Abstract

:1. Introduction

2. Literature Review and Scope

- The INTEROP project [14] was funded by the European Commission, and it aimed specifically at developing a research community around systems and software interoperability. Their main result was to create a network of companies and universities all devoted to the definition of interoperability standards and create a homogeneous business environment. However, while the main goals of the project were achieved, it seems that the focus was not on the modelling techniques of the design process of products and how to interconnect these aspects.

- The ATHENA project [15,16] was focused on the creation of a collaborative platform and framework for large enterprises. It is a quite extensive project, which tackled the main aspects of enterprise interoperability. It was able to identify languages, frameworks and semantics related to interoperability. Nevertheless, similarly to INTEROP, it appears that an approach for successfully integrating models of different systems and/or from different tools is not explored and not applied in a practical industrial context.

- The CRESCENDO project [17] aimed at developing the BDA or Behavioural Digital Aircraft. Such a project encapsulated many physical disciplines and techniques, integrating multiple models and obtaining a collaborative framework usable by a multitude of companies and their respective partners. While it seems to cover very widely the aircraft design process, it seems that a very high focus was placed on the optimisation of the systems geometry and on automatising certain specific aspects of the simulations setup. Moreover, it appears that the multi-tool integration was not tackled, focusing, to a certain extent, on each design step in a compartmentalised manner.

- AGILE [18] and TIVA [19] are closely related to each other, and both were developed by DLR (German Aerospace Center). These projects developed a comprehensive framework for the design of an aircraft, including the introduction of many relevant tools, such as the CPACS format [20], for the management of aircraft data, and the RCE (Version 10.4; https://rcenvironment.de/, 2022) software [21], which is a tool for the creation of multi-disciplinary workflows. Their work revolved heavily around the definition of a collaborative design process, similarly to the CRESCENDO initiative. However, it is noticeable that it is mainly focused on the multi-disciplinary and multi-tool integration, without expanding on the techniques and methods for multi-systems interoperability.

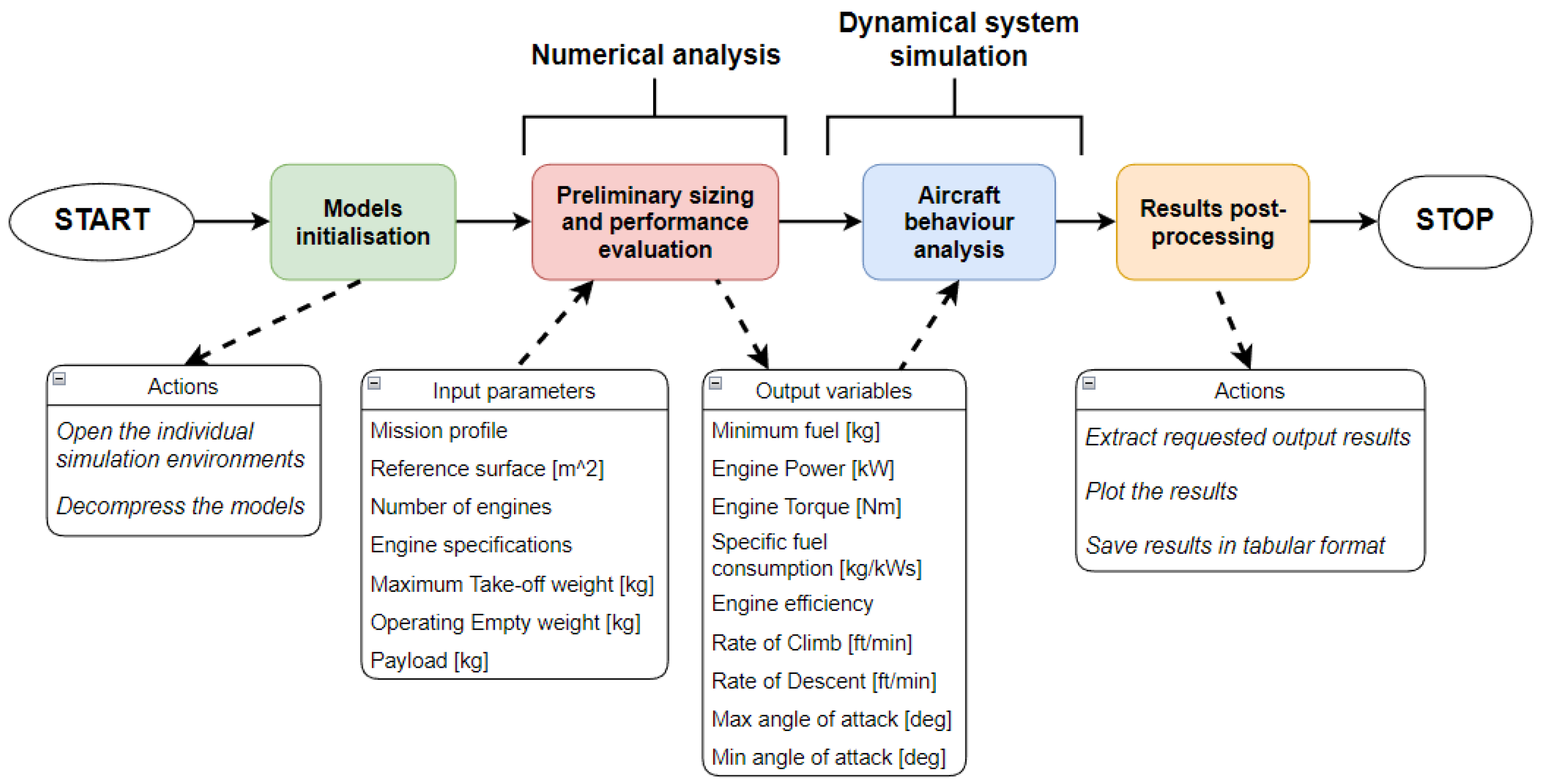

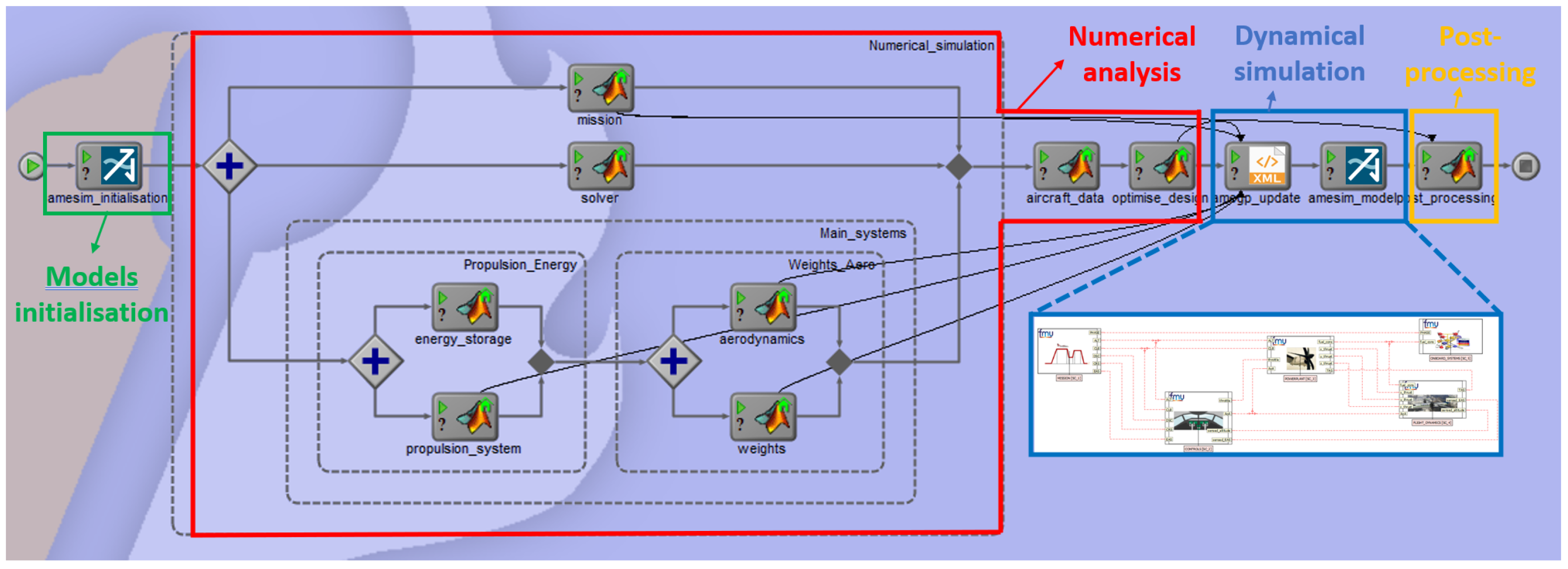

3. Approach Definition and Application

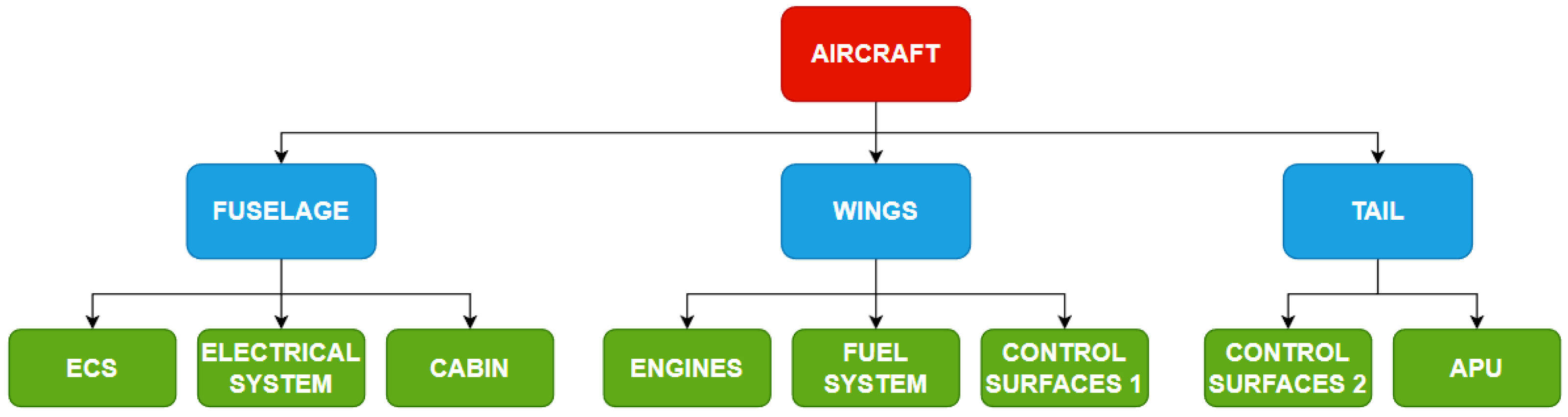

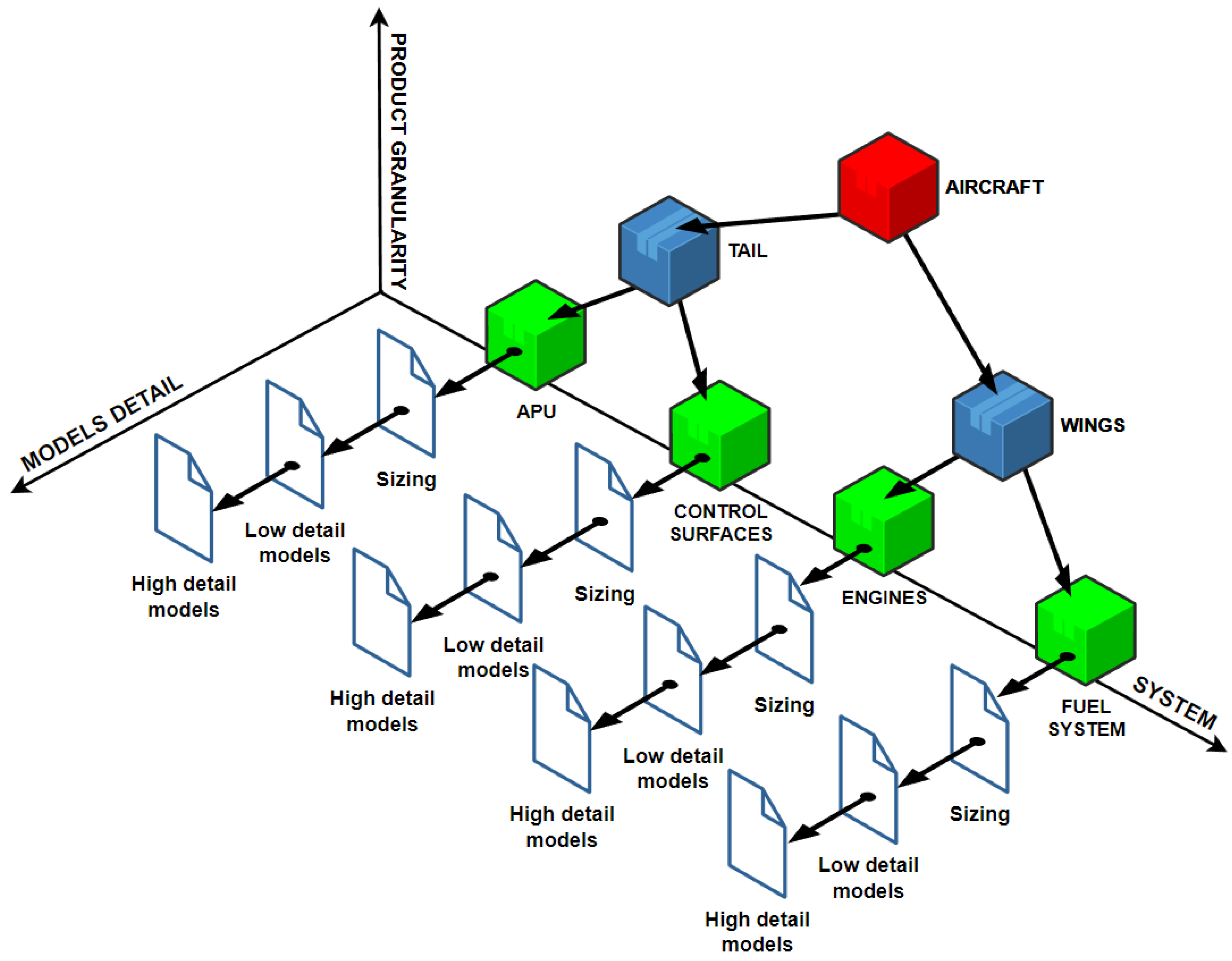

3.1. Multi-System Integration

- CLIMB, starting from a defined altitude;

- CRUISE, representing the majority of the mission;

- DESCENT, terminates at the starting altitude;

- Alternate CLIMB, immediately started after the DESCENT, shorter than CLIMB;

- Alternate CRUISE, much shorter then the CRUISE phase;

- Alternate DESCENT, ends, once again, at the starting altitude;

- LOITER, of similar length to Alternate CRUISE.

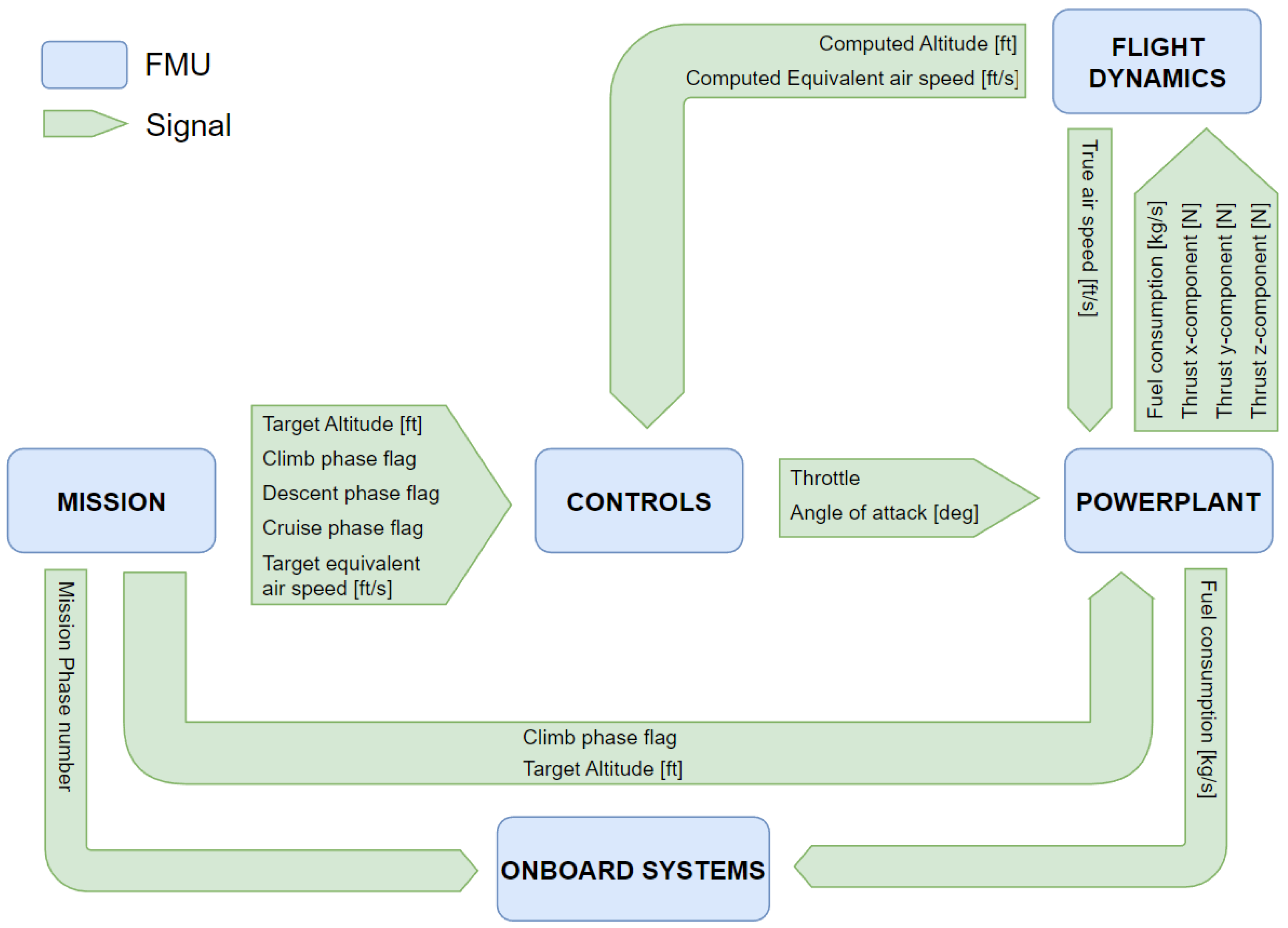

- MISSION, dedicated to the creation of the flight path previously described;

- CONTROLS, dedicated to the management of the behaviour of the aircraft;

- POWERPLANT, dedicated to the evaluation of the propulsion system performance;

- FLIGHT DYNAMICS, introduced previously;

- ON-BOARD SYSTEMS, dedicated to the simulation of various auxiliary systems.

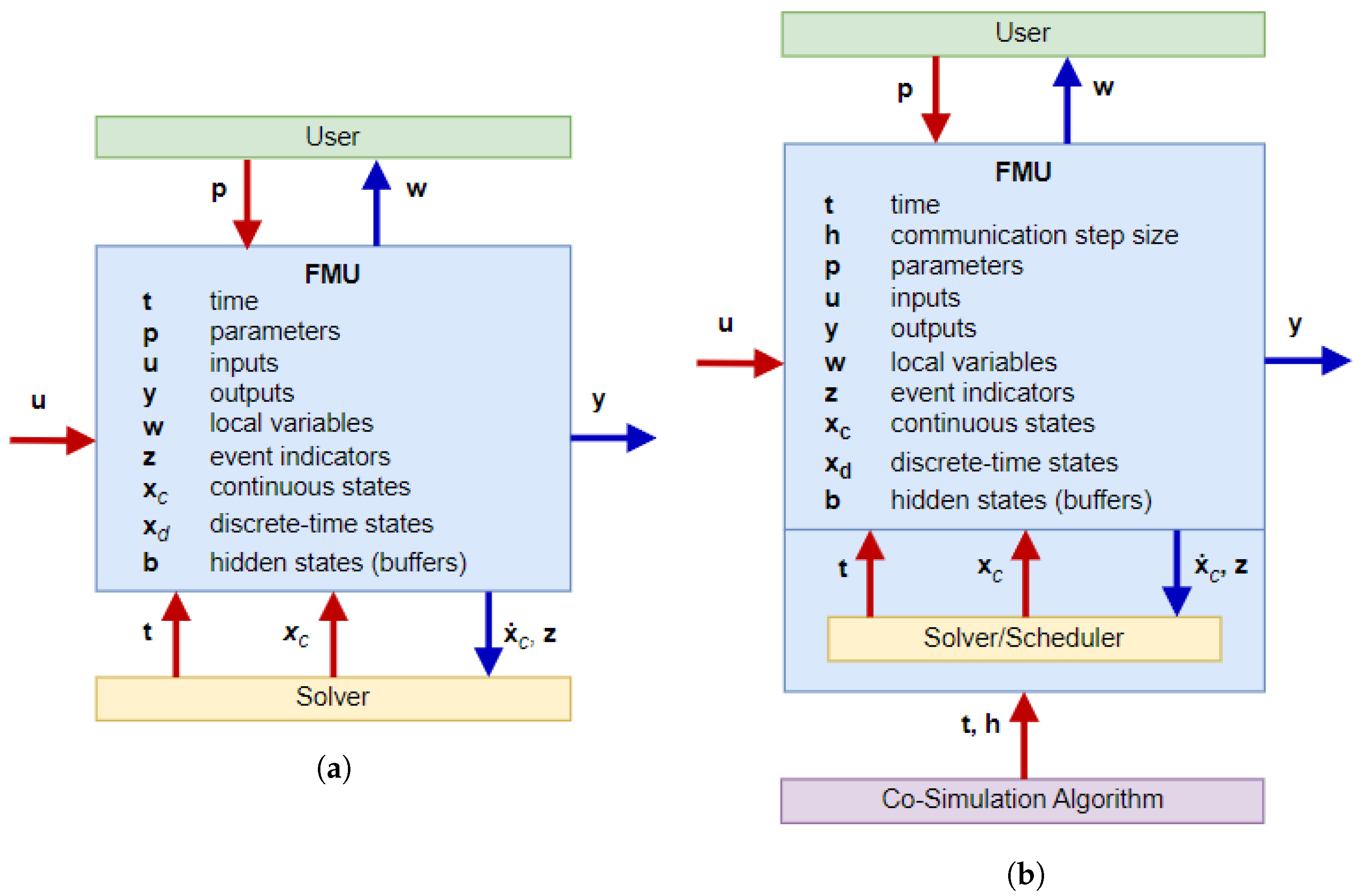

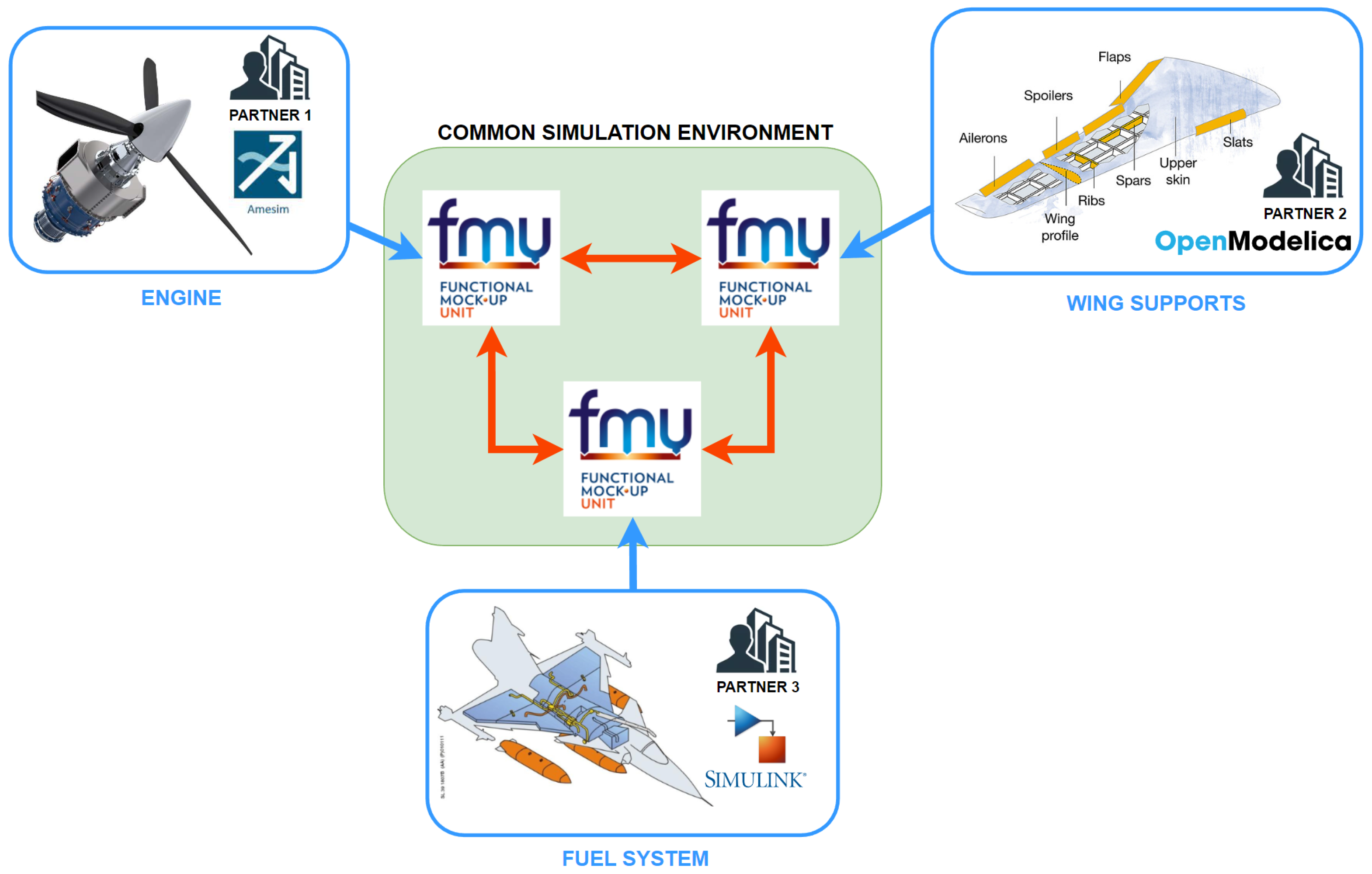

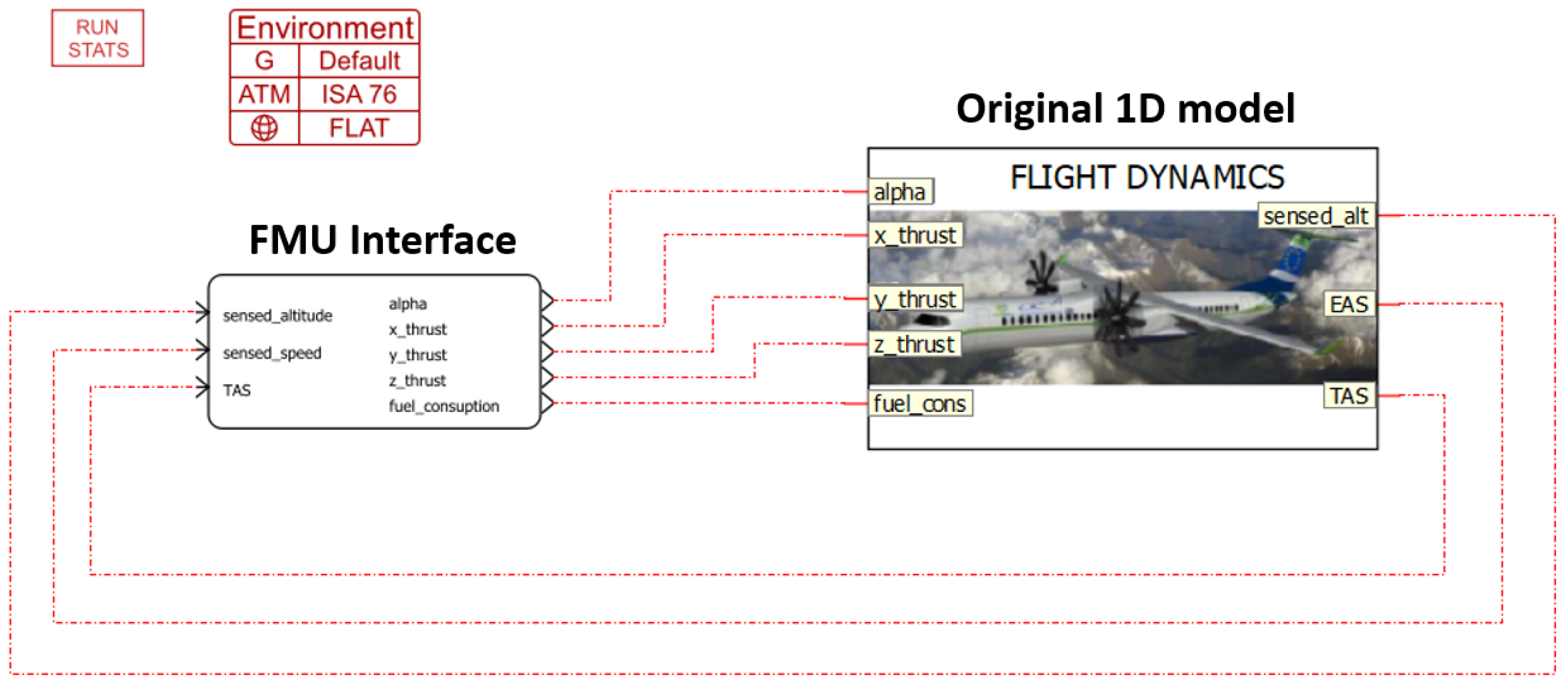

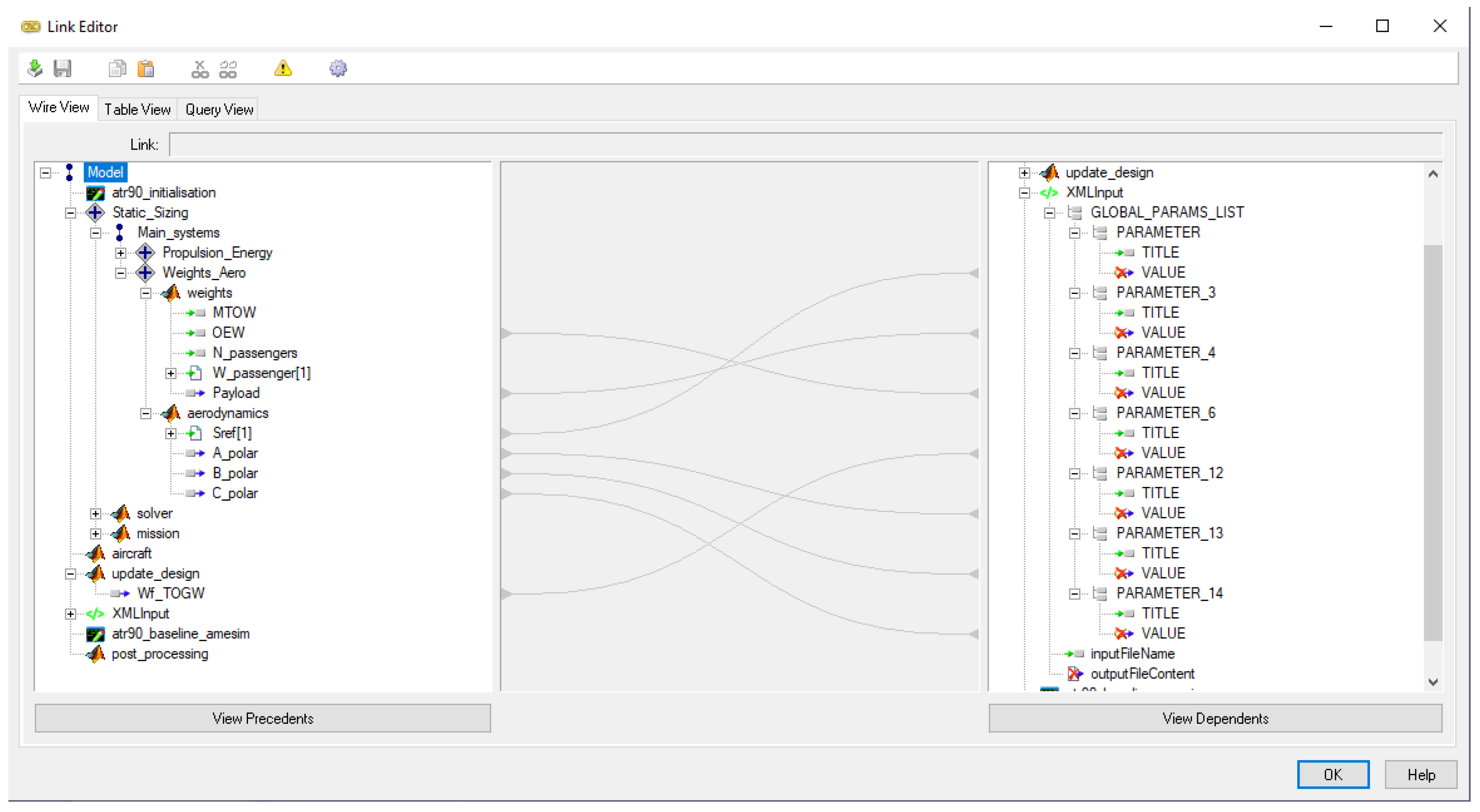

3.2. Multi-Tool Integration

4. Aircraft Test Case Results

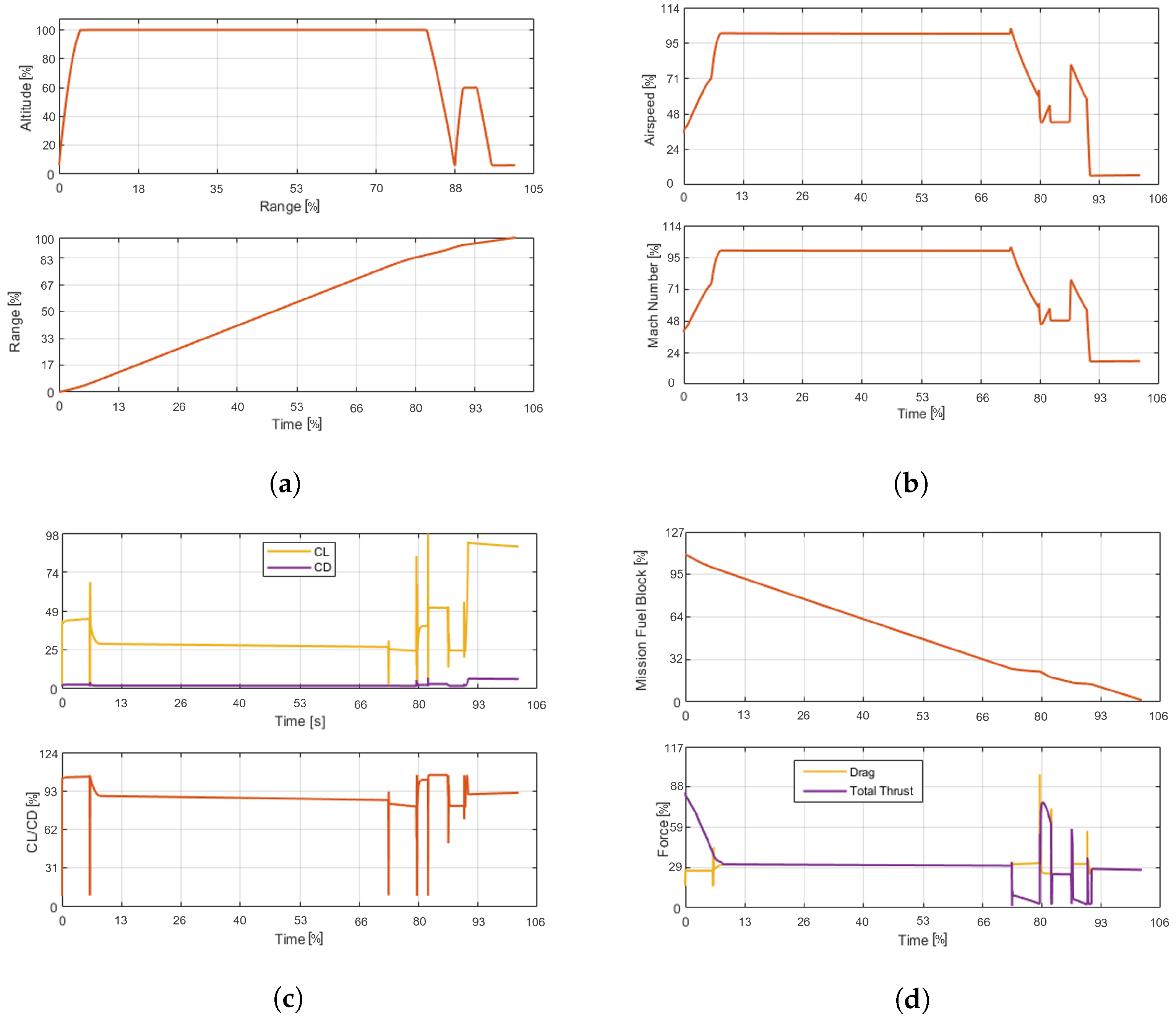

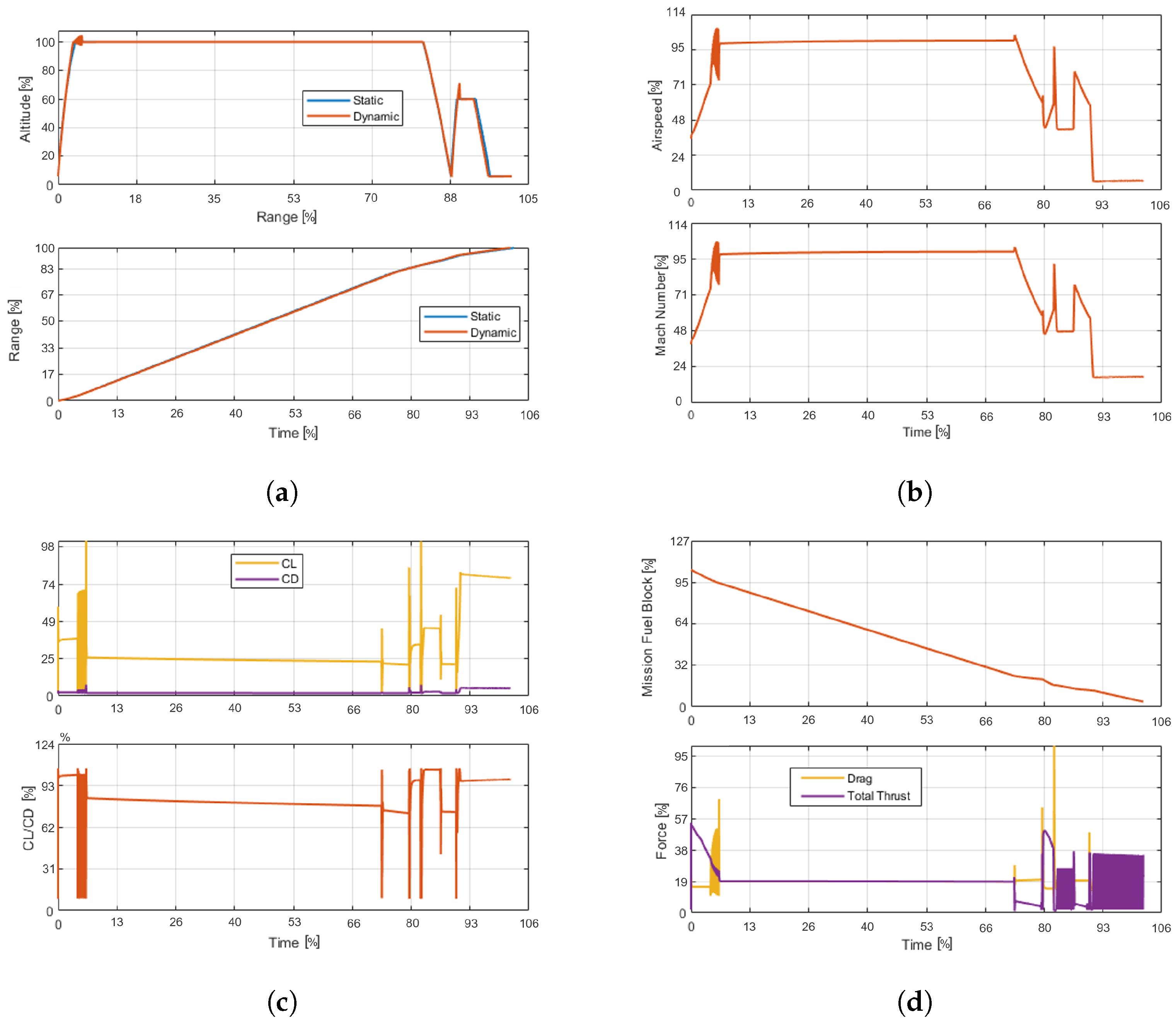

4.1. Reference Results

- the mission profile followed by the aircraft;

- the velocity/mach of the aircraft;

- the aerodynamic coefficients (lift and drag);

- the propulsion system characteristics, including the thrust and drag forces of the aircraft and the fuel remaining.

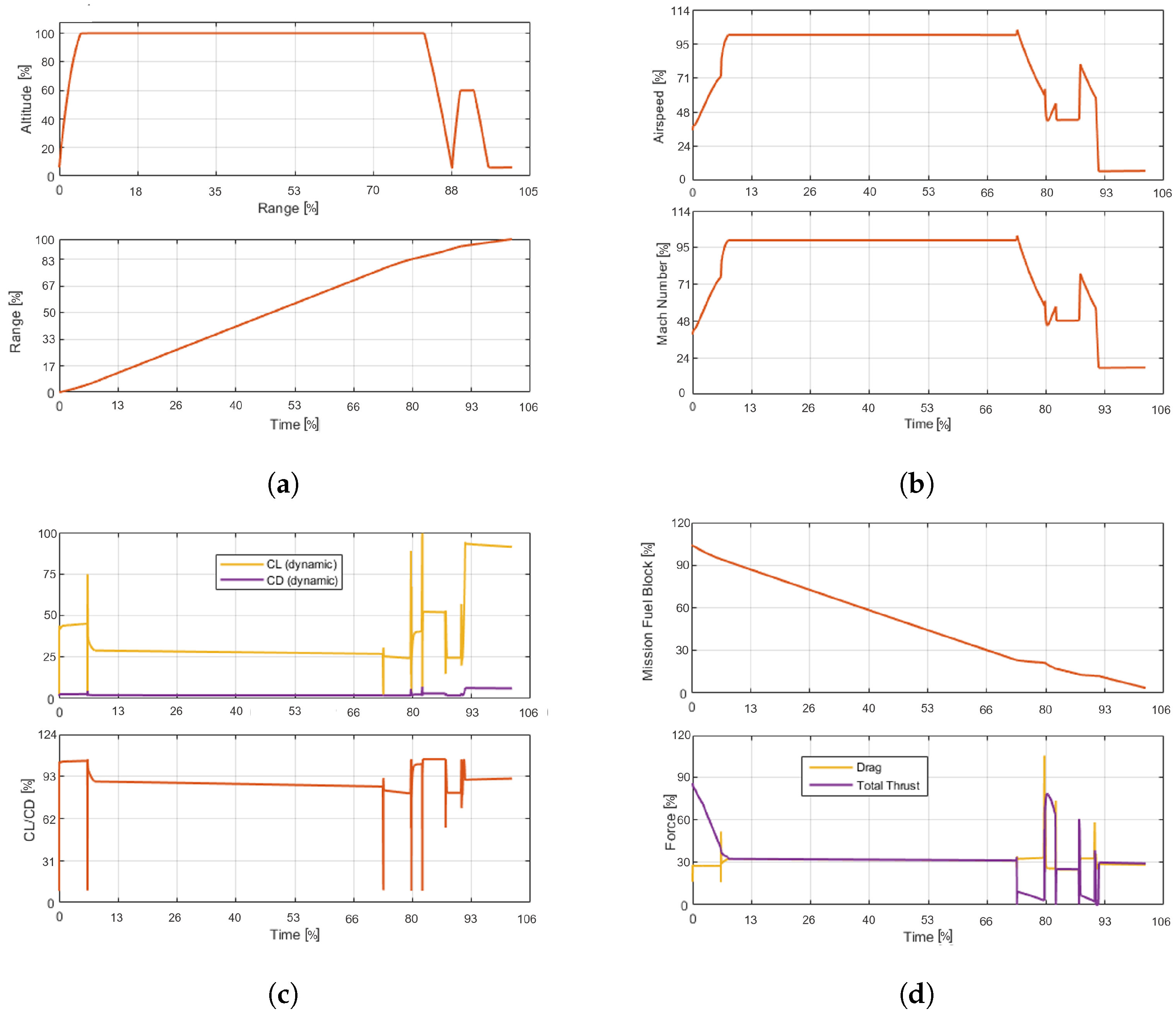

4.2. Multi-System Integration Results

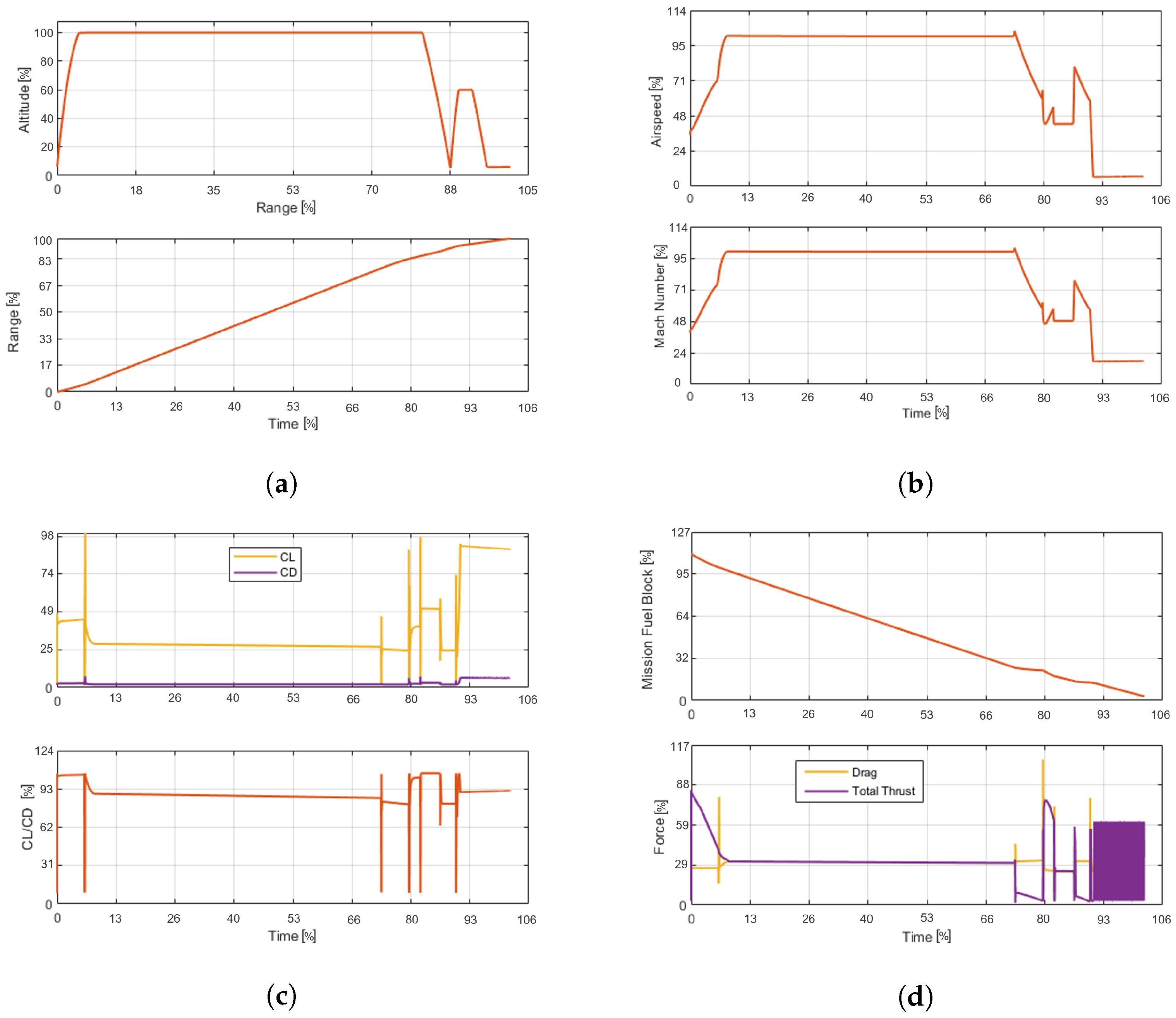

4.3. Multi-Tool Integration Results

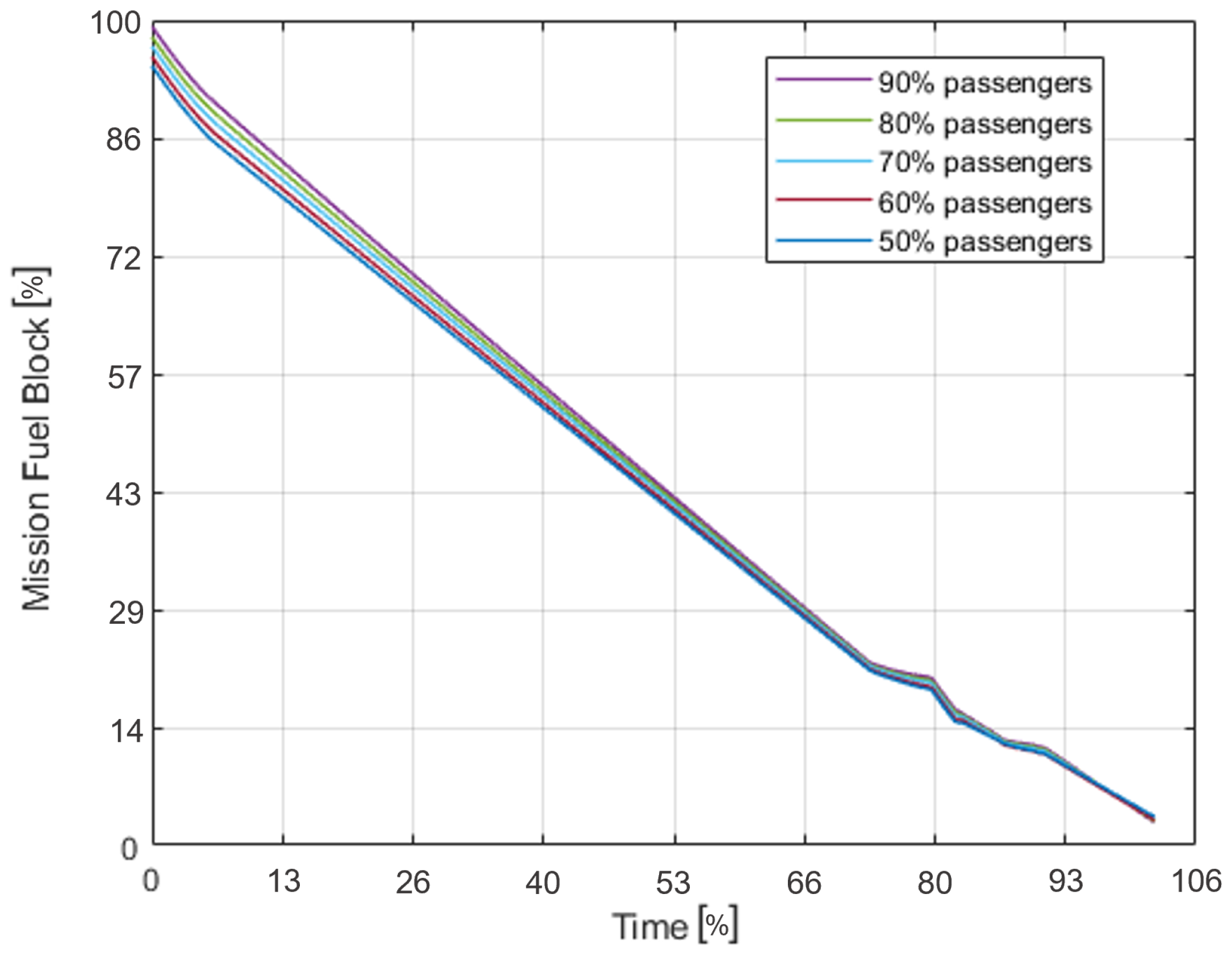

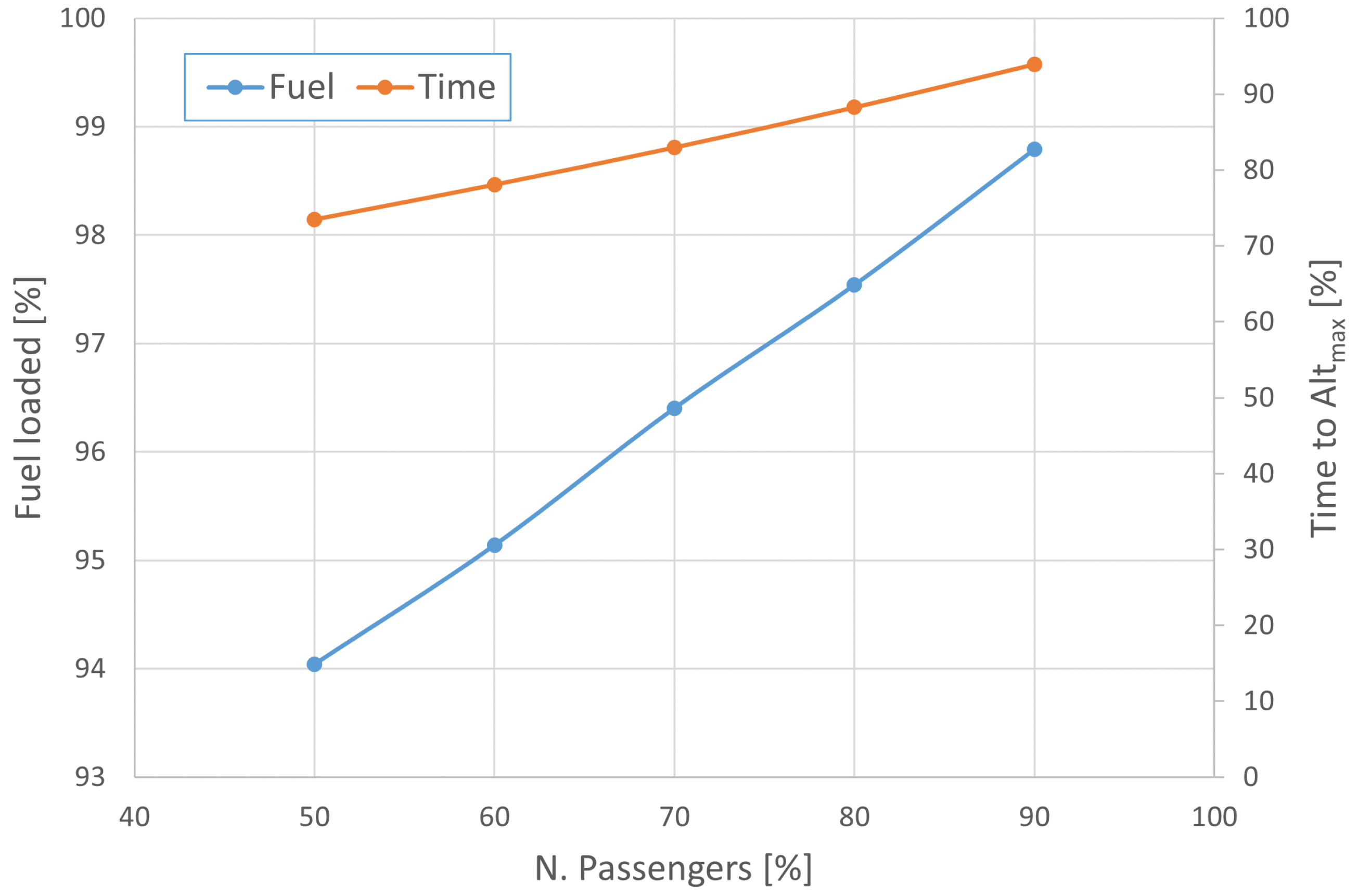

4.4. Sensitivity Analysis

5. Review of Process Performance

5.1. Multi-Systems Integration Performance

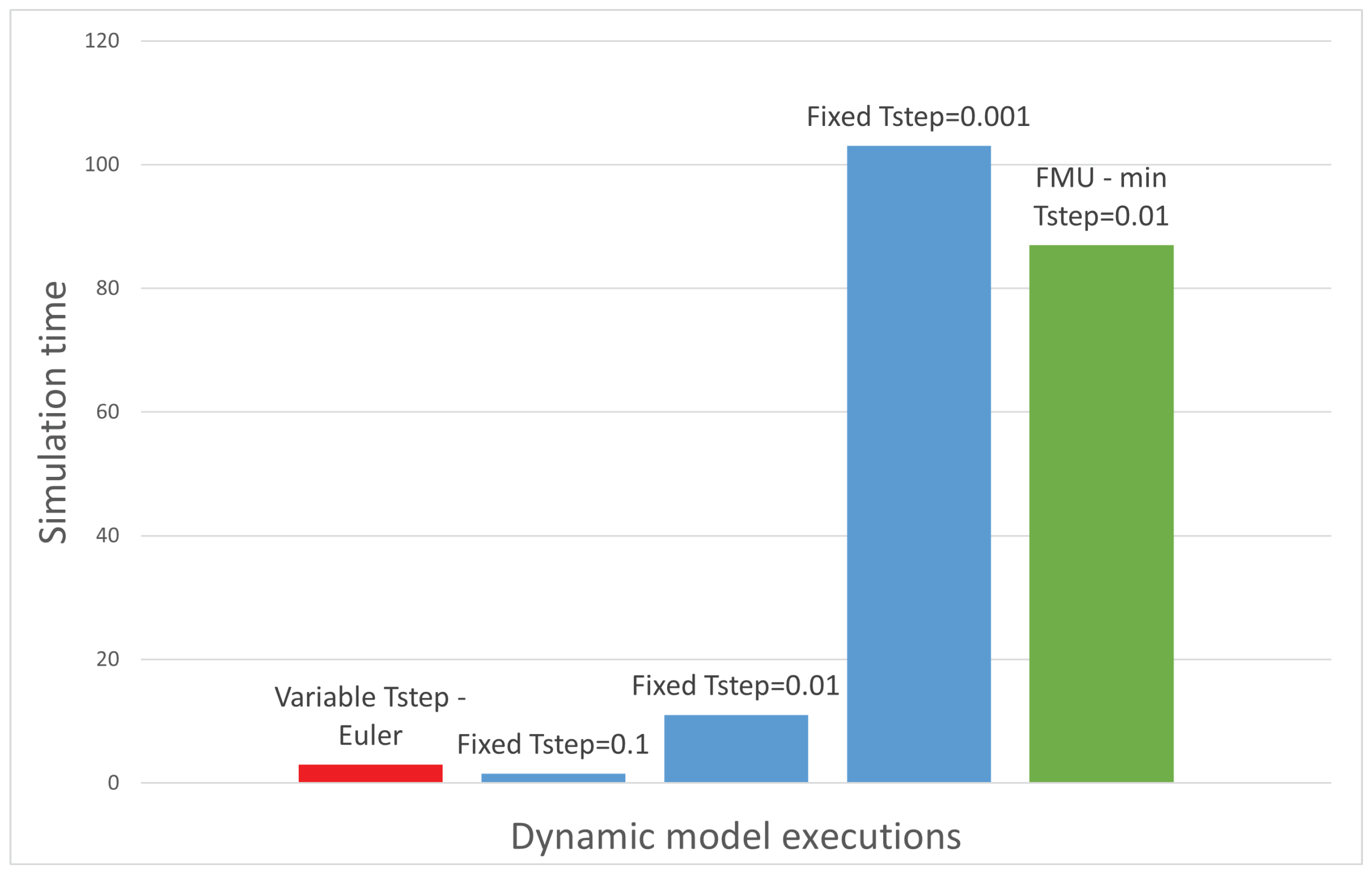

5.2. Multi-Tool Integration Performance

6. Conclusions and Next Steps

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MBSE | Model-Based Systems Engineering |

| PID | Proportional Integral Derivative |

| UNICADO | University Conceptual Aircraft Design and Optimization |

| TIVA | Technology Integration for the Virtual Aircraft |

| CPACS | Common Parametric Aircraft Configuration Schema |

| INTEROP | Interoperability research for networked enterprises applications and software |

| RCE | Remote Component Environment |

| DLR | Deutsches Zentrum für Luft- und Raumfahrt |

| AGILE | Aircraft 3rd Generation MDO for Innovative Collaboration |

| of Heterogeneous Teams of Experts | |

| CRESCENDO | Collaborative and Robust Engineering using Simulation |

| Capability Enabling Next Design Optimisation | |

| ATHENA | Advanced Technologies for Interoperability of Heterogeneous Enterprise |

| Networks and their Applications | |

| BDA | Behavioural Digital Aircraft |

| SE | Systems Engineering |

| RFLP | Requirements, Functional, Logical, Physical |

| FMU | Functional Mock-up Unit |

| CAD | Computer-Aided Design |

| FEM | Finite Element Method |

| CFD | Computational Fluid Dynamics |

| HPC | High-Performance Computing |

| AM | Arithmetic Mean |

| ME | Mean Error |

| MAPE | Mean Absolute Percentage Error |

| RMSE | Root Mean Square Error |

References

- McColl-Kennedy, J.; Schneider, U. Measuring customer satisfaction: Why, what and how. Total Qual. Manag. 2000, 11, 883–896. [Google Scholar] [CrossRef]

- Tundis, A.; Ferretto, D.; Garro, A.; Brusa, E.; Muhlhauser, M. Dependability assessment of a deicing system through the RAMSAS method. In Proceedings of the 2017 IEEE International Systems Engineering Symposium (ISSE), Vienna, Austria, 11–13 October 2017. [Google Scholar] [CrossRef]

- Asan, E.; Bilgen, S. Agility Problems in Traditional Systems Engineering—A Case Study. In Complex Systems Design & Management; Springer: Berlin/Heidelberg, Germany, 2013; pp. 53–71. [Google Scholar] [CrossRef]

- Brusa, E.; Calà, A.; Ferretto, D. Systems Engineering and Its Application to Industrial Product Development; Springer International Publishing: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Ramos, A.L.; Ferreira, J.V.; Barcelo, J. Model-Based Systems Engineering: An Emerging Approach for Modern Systems. IEEE Trans. Syst. Man, Cybern. Part C (Appl. Rev.) 2012, 42, 101–111. [Google Scholar] [CrossRef]

- Kleiner, S.; Kramer, C. Model Based Design with Systems Engineering Based on RFLP Using V6. In Lecture Notes in Production Engineering; Springer: Berlin/Heidelberg, Germany, 2013; pp. 93–102. [Google Scholar] [CrossRef]

- Pessa, C.; Cifaldi, M.; Brusa, E.; Ferretto, D.; Malgieri, K.M.; Viola, N. Integration of different MBSE approaches within the design of a control maintenance system applied to the aircraft fuel system. In Proceedings of the 2016 IEEE International Symposium on Systems Engineering (ISSE), Edinburgh, UK, 3–5 October 2016. [Google Scholar] [CrossRef]

- Brusa, E.G.M.; Morsut, S. Design and Structural Optimization of the Electric Arc Furnace Through a Mechatronic-Integrated Modeling Activity. IEEE/ASME Trans. Mechatron. 2015, 20, 1099–1107. [Google Scholar] [CrossRef]

- Biggs, G.; Juknevicius, T.; Armonas, A.; Post, K. Integrating Safety and Reliability Analysis into MBSE: Overview of the new proposed OMG standard. INCOSE Int. Symp. 2018, 28, 1322–1336. [Google Scholar] [CrossRef]

- Brusa, E.; Ferretto, D.; Cala, A. Integration of heterogeneous functional-vs-physical simulation within the industrial system design activity. In Proceedings of the 2015 IEEE International Symposium on Systems Engineering (ISSE), Rome, Italy, 28–30 September 2015. [Google Scholar] [CrossRef]

- Tomczyk, M.; van der Valk, H. Digital Twin Paradigm Shift: The Journey of the Digital Twin Definition. In Proceedings of the 24th International Conference on Enterprise Information Systems, Online, 25–27 April 2022. SCITEPRESS—Science and Technology Publications. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials. American Institute of Aeronautics and Astronautics, Honolulu, HI, USA, 3–26 April 2012. [Google Scholar] [CrossRef] [Green Version]

- Brusa, E. Digital Twin: Toward the Integration Between System Design and RAMS Assessment Through the Model-Based Systems Engineering. IEEE Syst. J. 2021, 15, 3549–3560. [Google Scholar] [CrossRef]

- Panetto, H.; Scannapieco, M.; Zelm, M. INTEROP NoE: Interoperability Research for Networked Enterprises Applications and Software. In On the Move to Meaningful Internet Systems 2004, Proceedings of the OTM 2004 Workshops: OTM Confederated International Workshops and Posters, GADA, JTRES, MIOS, WORM, WOSE, PhDS, and INTEROP 2004, Agia Napa, Cyprus, 25–29 October 2004; Meersman, R., Tari, Z., Corsaro, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; Volume 3292, LNCS; pp. 866–882. [Google Scholar]

- Ruggaber, R. ATHENA—Advanced Technologies for Interoperability of Heterogeneous Enterprise Networks and their Applications. In Technical Report Activities; SAP Research: Walldorf, Germany, 2003. [Google Scholar]

- Berre, A.J.; Elvesæter, B.; Figay, N.; Guglielmina, C.; Johnsen, S.G.; Karlsen, D.; Knothe, T.; Lippe, S. The ATHENA Interoperability Framework. In Enterprise Interoperability II; Springer: London, UK, 2007; pp. 569–580. [Google Scholar] [CrossRef] [Green Version]

- Coleman, P. The CRESCENDO project—Summary of a key European R&T initiative and key results. In Proceedings of the PDT Europe, The Hague, The Netherlands, 25–26 September 2012. [Google Scholar]

- Ciampa, P.D.; Nagel, B. AGILE Paradigm: The next generation collaborative MDO for the development of aeronautical systems. Prog. Aerosp. Sci. 2020, 119, 100643. [Google Scholar] [CrossRef]

- Bachmann, A.; Kunde, M.; Litz, M.; Schreiber, A. A Dynamic Data Integration Approach to Build Scientific Workflow Systems; Technical Report; German Aerospace Center: Cologne, Germany, 2003. [Google Scholar]

- Rizzi, A.; Zhang, M.; Nagel, B.; Boehnke, D.; Saquet, P. Towards a Unified Framework using CPACS for Geometry Management in Aircraft Design. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition. American Institute of Aeronautics and Astronautics, Nashville, TN, USA, 9–12 January 2012. [Google Scholar] [CrossRef] [Green Version]

- Boden, B.; Flink, J.; Först, N.; Mischke, R.; Schaffert, K.; Weinert, A.; Wohlan, A.; Schreiber, A. RCE: An Integration Environment for Engineering and Science. SoftwareX 2021, 15, 100759. [Google Scholar] [CrossRef]

- Weiand, P.; Buchwald, M.; Schwinn, D. Process Development for Integrated and Distributed Rotorcraft Design. Aerospace 2019, 6, 23. [Google Scholar] [CrossRef] [Green Version]

- Liersch, C.M.; Hepperle, M. A distributed toolbox for multidisciplinary preliminary aircraft design. CEAS Aeronaut. J. 2011, 2, 57–68. [Google Scholar] [CrossRef]

- Torrigiani, F.; Bussemaker, J.; Ciampa, P.; Fioriti, M.; Tomasella, F.; Aigner, B.; Rajpal, D.; Timmermans, H.; Savelyev, A.; Charbonnier, D. Design of the strut braced wing aircraft in the AGILE collaborative MDO framework. In Proceedings of the 31st Congress of the International Council of the Aeronautcal Sciences, Belo Horizonte, Brazil, 9–14 September 2018. [Google Scholar]

- Görtz, S.; Ilić, Č.; Abu-Zurayk, M.; Liepelt, R.; Jepsen, J.; Führer, T.; Becker, R.; Scherer, J.; Kier, T.; Siggel, M. Collaborative multi-level MDO process development and application to long-range transport aircraft. In Proceedings of the 30th Congress of the International Council of the Aeronautcal Sciences, Daejeon, Republic of Korea, 25–30 September 2016. [Google Scholar]

- Walther, J.N.; Gastaldi, A.A.; Maierl, R.; Jungo, A.; Zhang, M. Integration aspects of the collaborative aero-structural design of an unmanned aerial vehicle. CEAS Aeronaut. J. 2019, 11, 217–227. [Google Scholar] [CrossRef] [Green Version]

- Zimmnau, M.; Schültke, F.; Stumpf, E. UNICADO: Multidisciplinary analysis in conceptual aircraft design. CEAS Aeronaut. J. 2022, 14, 75–89. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L. Model of multidisciplinary simulation integration in helicopter rotor blade design process. Int. J. Comput. Integr. Manuf. 2013, 27, 229–241. [Google Scholar] [CrossRef]

- Errandonea, I.; Beltrán, S.; Arrizabalaga, S. Digital Twin for maintenance: A literature review. Comput. Ind. 2020, 123, 103316. [Google Scholar] [CrossRef]

- D’Amico, R.D.; Erkoyuncu, J.A.; Addepalli, S.; Penver, S. Cognitive digital twin: An approach to improve the maintenance management. CIRP J. Manuf. Sci. Technol. 2022, 38, 613–630. [Google Scholar] [CrossRef]

- Mahmoodian, M.; Shahrivar, F.; Setunge, S.; Mazaheri, S. Development of Digital Twin for Intelligent Maintenance of Civil Infrastructure. Sustainability 2022, 14, 8664. [Google Scholar] [CrossRef]

- Tao, F.; Xiao, B.; Qi, Q.; Cheng, J.; Ji, P. Digital twin modeling. J. Manuf. Syst. 2022, 64, 372–389. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Liu, Q.; Chen, X.; Zhang, D.; Leng, J. A Digital Twin-Based Approach for Designing and Multi-Objective Optimization of Hollow Glass Production Line. IEEE Access 2017, 5, 26901–26911. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2017, 94, 3563–3576. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Ariansyah, D.; Pardamean, B. Enhancing Interoperability of Digital Twin in the Maintenance phase of Lifecycle. In Proceedings of the 2022 6th International Conference on Information Technology, Information Systems and Electrical Engineering (ICITISEE), Xiamen, China, 21–23 October 2022. [Google Scholar] [CrossRef]

- Da Rocha, H.; Pereira, J.; Abrishambaf, R.; Santo, A.E. An Interoperable Digital Twin with the IEEE 1451 Standards. Sensors 2022, 22, 7590. [Google Scholar] [CrossRef] [PubMed]

- Bickford, J.; Bossuyt, D.L.V.; Beery, P.; Pollman, A. Operationalizing digital twins through model-based systems engineering methods. Syst. Eng. 2020, 23, 724–750. [Google Scholar] [CrossRef]

- Gudmundsson, S. Aircraft Structural Layout. In General Aviation Aircraft Design; Elsevier: Amsterdam, The Netherlands, 2022; pp. 113–146. [Google Scholar] [CrossRef]

- Junghanns, A.; Gomes, C.; Schulze, C.; Schuch, K.; Pierre, R.; Blaesken, M.; Zacharias, I.; Pillekeit, A.; Wernersson, K.; Sommer, T.; et al. The Functional Mock-up Interface 3.0—New Features Enabling New Applications. In Proceedings of the Linköping Electronic Conference Proceedings; Linköping University Electronic Press: Linköping, Sweden, 2021. [Google Scholar] [CrossRef]

- Available online: https://fmi-standard.org/docs/3.0/ (accessed on 10 November 2022).

- Popovici, K.; Mosterman, P. (Eds.) Real-Time Simulation Technologies: Principles, Methodologies, and Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Wikström, J. 3D Model of Fuel Tank for System Simulation: A Methodology for Combining CAD Models with Simulation Tools. Master’s Thesis, Department of Management and Engineering, Linköping University, Linköping, Sweden, 2011. Available online: http://liu.diva-portal.org/smash/get/diva2:448364/FULLTEXT01.pdf (accessed on 1 April 2023).

- Wing Image. Available online: https://www.airbus.com/en/newsroom/news/2017-01-wing-of-the-future (accessed on 1 April 2023).

- Engine Image. Available online: https://turb.aero/ (accessed on 1 April 2023).

- Gonzalez-Abad, J.; Garcia, A.L.; Kozlov, V. A container-based workflow for distributed training of deep learning algorithms in HPC clusters. In Proceedings of the Cluster Computing, Heidelberg, Germany, 6–9 September 2022. [Google Scholar] [CrossRef]

- Thummerer, T.; Stoljar, J.; Mikelsons, L. NeuralFMU: Presenting a Workflow for Integrating Hybrid NeuralODEs into Real-World Applications. Electronics 2022, 11, 3202. [Google Scholar] [CrossRef]

| Discipline/Analysis | Tools |

|---|---|

| Numerical sizing | MATLAB® (Version 9.12; MathWorks, 2022), Python (Version 3.10; https://www.python.org/, 2022) |

| Dynamical systems simulations | Simulink® (Version 10.5; MathWorks, 2022, Natick, MA, USA), AMEsim® (Version 2021.1; Siemens, 2021, Munich, Germany), Dymola® (Version 2022; Dassault Systèmes, 2022, Vélizy-Villacoublay, France) |

| CAD modelling | SolidWorks®(Version 2021; Dassault Systèmes, 2021), Siemens NX® (Version 12; Siemens, 2017), CATIA® (Version R21; Dassault Systèmes, 2011) |

| Vibro-acoustic simulations | SIMULIA® (Version 2021; Dassault Systèmes, 2021), ANSYS® (Version 2021R1; ANSYS Inc., 2021, Canonsburg, PA, USA) |

| FEM thermo-structural analysis | ANSYS® (Version 2021R1; ANSYS Inc., 2021), HyperMesh® (Version 2021; Altair, 2021, Troy, MI, US) |

| CFD simulations | STAR-CCM+® (Version 2021.1; Siemens, 2021), OpenFOAM (Version v2106; https://www.openfoam.com/, 2021) |

| Original Dynamic Model | Multi-Systems Simulation | |

|---|---|---|

| Simulation Time | ≈3 s | ≈87 s |

| Thrust-ME * | ref | % |

| Thrust-MAPE * | ref | % |

| Thrust-RMSE * | ref | % |

| Manual Execution of Design Process | Design Process with Multi-Tool Integration | |

|---|---|---|

| Simulation Time | ≈370 s | ≈480 s |

| Thrust-ME * | ref | % |

| Thrust-MAPE * | ref | % |

| Thrust-RMSE * | ref | % |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brusa, E.; Dagna, A.; Delprete, C.; Gentile, R. An Orchestration Method for Integrated Multi-Disciplinary Simulation in Digital Twin Applications. Aerospace 2023, 10, 601. https://doi.org/10.3390/aerospace10070601

Brusa E, Dagna A, Delprete C, Gentile R. An Orchestration Method for Integrated Multi-Disciplinary Simulation in Digital Twin Applications. Aerospace. 2023; 10(7):601. https://doi.org/10.3390/aerospace10070601

Chicago/Turabian StyleBrusa, Eugenio, Alberto Dagna, Cristiana Delprete, and Rocco Gentile. 2023. "An Orchestration Method for Integrated Multi-Disciplinary Simulation in Digital Twin Applications" Aerospace 10, no. 7: 601. https://doi.org/10.3390/aerospace10070601