1. Introduction

An autogyro, also known as a autogiro, is a type of aircraft that generates lift through both the rotation of a rotor and propulsion from an engine [

1,

2,

3]. Its structure is simpler than that of a helicopter, with no need for complex transmission systems, control mechanisms, and it has a mechanically simpler and more reliable collective control system. This makes equipment more reliable and reduces maintenance costs, as well as having other economic advantages [

4].

The appearance of an autogyro is very similar to that of a helicopter, with both having a large-diameter rotor on top that provides lift and aerodynamic torque for the aircraft. However, there are some noticeable differences. The rotor of a helicopter has a complex structure, is driven by an engine, and provides forward flight power, and achieving pitch and roll attitudes requires complex cyclic blade pitch changes. The rotor of an autogyro has a simple and reliable structure and is driven by airflow, while forward flight power is provided by the propeller, and achieving pitch and roll attitudes just requires tilting the rotor disc [

5,

6].

In the early twentieth century, many physicists studied the automatic rotation principle of rotors. The results that they obtained showed that under certain conditions, when a rotorcraft descends at an appropriate attack angle or flies horizontally, its rotor can rotate automatically. After that, there were a number of attempts to construct rotorcraft, but these did not have the capabilities of sustained and controlled flight. In the 1930s and 1940s, Juan de Cierva from Spain developed the first successful autogyro aircraft, the C-4 autogyro [

7,

8,

9,

10]. Because of its small size, simple structure, and low requirements for runway takeoff and landing, the success of the first autogyro has attracted widespread attention from society. Subsequently, many companies have invested in research on autogyros. Harold Pitcairn from America established the Pitcairn-Cierva Autogiro Company, which produced the PCA-2 autogyro with a flying speed of up to 190 km/h and a flying altitude of 5613 m. In 1953, the Bensen Aircraft Corporation produced the Bensen Gyrocopter, which had a simple structure, was easy to assemble, and required only a few dozen horsepower for takeoff and landing. Groen Brothers Aviation and Carter Aviation Technologies, two famous American rotorcraft companies, have been mainly dedicated to developing potential applications of rotorcraft [

11]. In particular, the Carter Aviation Technologies’ CarterCopter, developed in 1998, combines the advantages of fixed-wing aircraft, tiltrotor aircraft, and helicopters. It can take off and land vertically, while also being capable of fast flight. At the beginning of the twenty-first century, AutoGyro from Germany became the world’s largest producer of autogyros, with its MTOsport autogyro having a long endurance time and being widely used, for example, in agriculture for plant protection and detection [

12]. In addition, some research has been conducted on large jet-engine-based rotorcraft and unmanned rotorcraft, and this has yielded significant results [

13,

14,

15,

16,

17].

China’s research on rotorcraft started later than that in Europe and America, with fewer achievements having been made so far. In recent years, however, Chinese enthusiasts have begun their own journey in developing rotorcraft and have played an important role in promoting research on autogyros.

Dynamic modeling is a prerequisite for flight control design and simulation, but owing to the complex aerodynamic characteristics of rotors, it is difficult to establish a high-confidence mathematical model for autogyros. Therefore, accurate rotor modeling is particularly important. The main methods for modeling rotor dynamics include momentum theory, blade element theory, vortex theory, wind tunnel experiments, and computational fluid dynamics (CFD) calculations, as well as some other methods [

18].

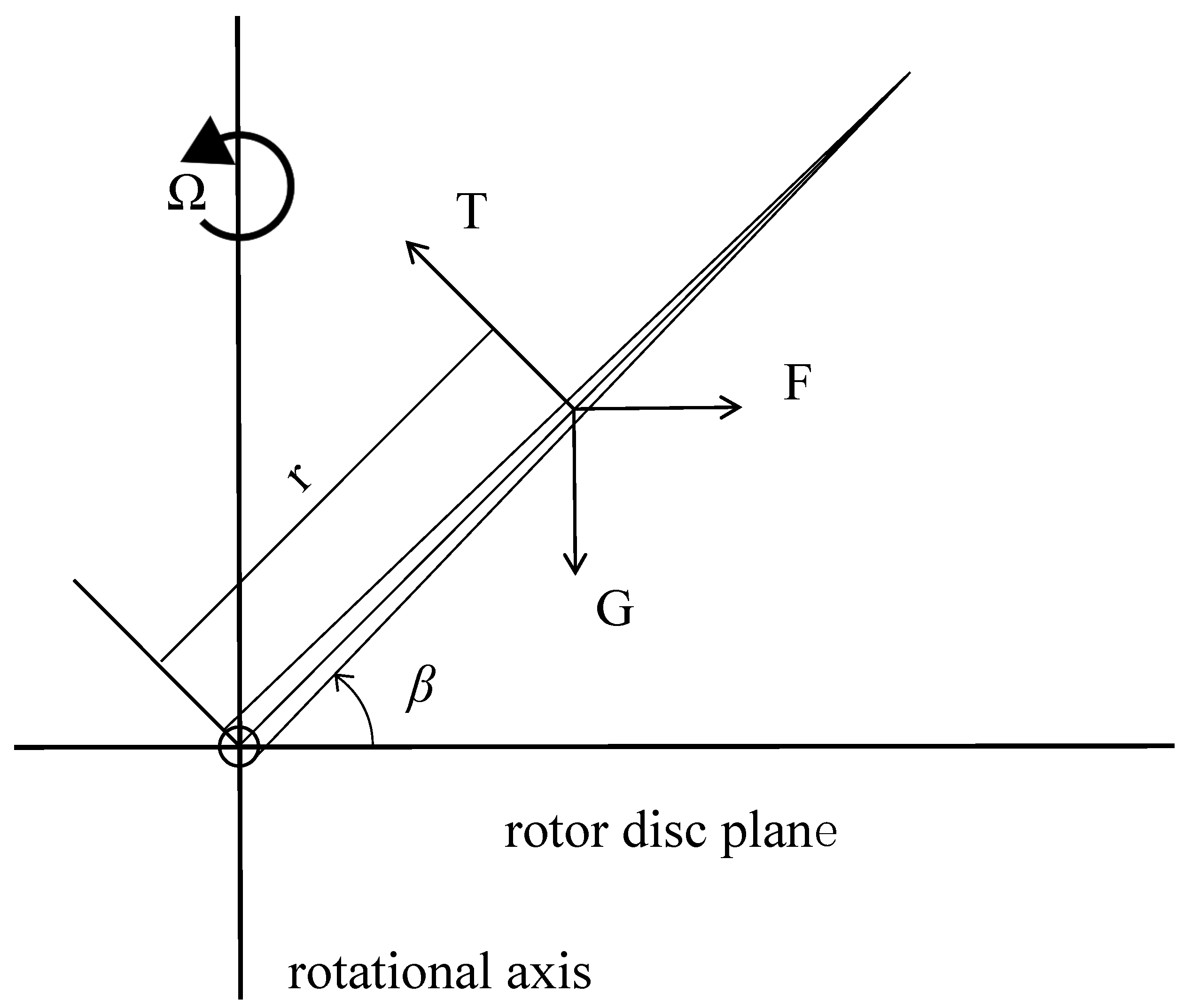

At the end of the nineteenth century, Drzewiecki proposed the blade element theory for rotors, in which a rotor blade is considered as being composed of an infinite number of small blade elements [

18,

19]. The force and torque on a single blade or even the entire rotor can be obtained through radial integration. The advantage of this theory is its high accuracy, but it is complex to calculate and difficult to implement. In the early twentieth century, Glauert used momentum theory to model rotors in forward flight [

20,

21,

22,

23,

24]. Momentum theory assumes uniform inflow and treats a rotor as an infinitely thin disc to study its effect on airflow using basic fluid dynamical laws. The advantage of momentum theory is its simplicity and efficiency in calculation, but because of the assumption of uniform induced velocity, it has reduced accuracy and a limited range of applicability. The results of wind tunnel experiments often differ significantly from actual flight data owing to the non-steady-state and nonlinear characteristics of rotor aircraft, as well as to the effects of wind tunnel size and interference from tunnel walls when using scaled models. CFD calculations are typically used for component analysis only, and so parameters calculated by CFD may differ significantly from their actual values for rotor aircraft with unsteady aerodynamic characteristics [

18,

20,

21,

22,

23,

24,

25]. Currently, system identification is considered an effective method for establishing dynamic models for rotating wing aircraft. Glasgow University has developed a model based on system identification techniques [

26]. However, modeling of rotorcraft dynamics based on system identification requires real helicopter flight data as a basis. If we want to study the effects on flight performance resulting from changes in the rotor parameters, this method has certain limitations.

Liu Peng and his team from Nanjing University of Aeronautics and Astronautics have conducted highly reliable modeling of helicopters based on FlightGear software [

27]. The rotor part of an autogyro has almost identical dynamic characteristics to that of a helicopter, and the YASim dynamics library in FlightGear software has high confidence in modeling the rotor part. Therefore, the study described here is based on this library, taking account of the characteristics of autogyro rotors for secondary development, and adopting a simplification of traditional blade element theory to achieve greater accuracy in modeling autogyro rotor models.

Unlike a helicopter, which can directly drive its rotor to achieve the necessary rotation speed and lift for takeoff, an autogyro must use a different method. Typically, an autogyro uses its engine to drive the rotor for pre-rotation. After a certain rotation speed has been reached, the engine is disconnected from the rotor and used to drive the propeller for taxiing, which leads the autogyro to enter a spin state and increases the lift for takeoff. An autogyro has a simple rotor collective control system. As a result, the autogyro can obtain sufficient lift during the pre-selection stage by changing the collective angle and achieve vertical takeoff in a similar way to a helicopter. This takeoff method is called “jump-takeoff”, which is different from the takeoff methods of helicopters and fixed-wing aircraft and is based on the unique performance characteristics of autogyros [

16].

Although the traditional takeoff method of an autogyro requires only a short distance of runway compared with fixed-wing aircraft, the autogyro still needs to taxi for tens to hundreds of meters before taking off, which imposes some requirements for the takeoff site and runway. However, with jump-takeoff, it is possible to achieve almost vertical takeoff in place like a helicopter, which greatly reduces the takeoff distance of an autogyro and further reduces its requirements in terms of takeoff site and runway. This increases the range of possible takeoff and landing sites for autogyros, opening up broader application prospects. Therefore, research on jump-takeoff for autogyros has great significance for engineering development and practical applications.

However, to date, there have been few studies of jump-takeoff of rotary-wing aircraft. In this article, accurate mathematical modeling based on YASim is conducted for a certain model of autogyro, design simulation solutions for the jump-takeoff of an autogyro are performed, the effects of different rotor parameters on jump-takeoff performance are examined, and guidance is provided for further optimization of jump-takeoff performance and for the design of rotor parameters. A complete jump-takeoff–climb–cruise mission is designed to verify the feasibility of jump-takeoff, lay the foundation for subsequent jump-takeoff experiments, and accumulate experience.

The remainder of this article is structured as follows. In

Section 2, the mathematical model of the autogyro is briefly introduced. In Section

3, a simulation platform for the autogyro is constructed, on which verification validation and accreditation (VV&A) [

28] are performed. In Section

4, the jump-takeoff conditions are explored and the jump-takeoff performance is studied. In Section

5, the jump-takeoff performance is optimized. In Section

6, a complete jump-takeoff–climb–cruise mission is implemented on the simulation platform based on optimized parameters. In Section

7, the main contributions of this study are summarized and conclusions are presented.

5. Performance Optimization for Jump Takeoff

Based on the analysis of the jump-takeoff performance in Section

4, and considering the performance of the transmission mechanism between the engine and rotor as well as the maximum collective angle jump-takeoff limit, a pre-rotation speed of 400 rpm and a collective angle of 10° were determined for jump-takeoff. According to the conclusion in Section

4 and the analysis in

Section 3.4, we will optimize the jump-takeoff performance. There are two main aspects of optimization. On one hand, we need to generate more lift during the jump-takeoff process to increase the jump-takeoff height of the autogyro. On the other hand, we need to reduce the rotation speed decay rate. To achieve these two points, we will explore and optimize the jump-takeoff performance by changing two rotor parameters: rotor diameter and blade tip weighting. The method of adding weights to the tip of rotor blades is called blade tip weighting. As we known, tip weight weighting can increase the rotational inertia of the rotor.

A high-inertia rotor can store a large amount of energy that can be transformed into the initial take-off force, and it can store more energy to bring about greater jump-takeoff performance. Furthermore, it can also provide greater centrifugal force, which prevents instability caused by blade bending during rotation [

36,

38,

39].

For convenience in the modeling and simulation calculations in this article, the added weight block at the blade tip is considered as mass point, and its rotational inertia is thus obtained as

where

is the added mass at the blade tip and

R is the radius of the rotor. When there is no additional weight attached to the end of the rotor blade, the rotational inertia of the blade is

where

M is the mass of a single blade and

l is the diameter of the rotor plane. Therefore, the rotational inertia of the rotor blade with additional weight added to its tip is

Based on the weight of the rotor blade itself, the maximum blade tip weighting setting should not exceed 65% of the weight of the rotor blade. The range of variation of the rotor diameter should be within 6% of the diameter. Therefore, the diameter was varied from 8 m to 9 m in increments of 0.25 m, and the blade tip weighting was varied from 0 kg to 10 kg in increments of 2.5 kg. Jump-takeoff flight experiments were conducted for different combinations of rotor parameters, and the results are shown in

Table 10. The variations in jump-takeoff height obtained from the data in

Table 10 are plotted in three dimensions in

Figure 21.

As can be seen from

Figure 21 and

Table 10, overall, the jump-takeoff height increases with increasing blade tip weighting and rotor diameter. However, when the blade tip weighting is small, the sensitivity of the jump-takeoff height to changes in rotor diameter is low. Similarly, when the rotor diameter is small, the sensitivity of the jump-takeoff height to changes in tip weight is low. Further analysis reveals that within the area enclosed by two curves representing a fixed rotor diameter of 8.5 m with varying tip weight and a fixed blade tip weighting of 5 kg with varying rotor diameter, the maximum jump-takeoff height is generally optimized within a range of 10 m or less. Beyond this range, there is a high sensitivity of the maximum jump-takeoff height to both rotor diameter and blade tip weighting, and even slight increases in either parameter can significantly change the maximum jump-takeoff height.

From

Figure 22, it can be seen that there are significant differences in the rotation speed decay for different blade tip weighting and rotor diameters. The smaller the rotor diameter and the heavier the blade tip weighting, the slower the rotation speed decays. On the basis of the results obtained in

Section 4.2, we chose the initial state speed decay rate at different parameter values to represent the overall speed decay rate of the process. By fitting a polynomial function to the curve of rotation speed decay, we can differentiate at the initial state point to obtain an initial rate of decay for each combination of rotor parameters, as shown in

Table 11. The variations in rotation speed decay rate obtained from the data in

Table 11 are plotted in three dimensions in

Figure 23.

The plot in

Figure 23 is projected onto the rotor diameter–decay rate and blade tip weighting–decay rate planes in

Figure 24 and

Figure 25, respectively. From

Figure 24, it can be seen that the rotation speed decay rate is minimally affected by changes in rotor diameter, and so the effect of diameter variations on the decay rate can henceforth be ignored. However, from

Figure 25, it can be seen that the speed decay rate is greatly affected by changes in the blade tip weighting: as this weight increases, the speed decay rate decreases with a logarithmic trend, corresponding to better jump-takeoff performance. Once the blade tip weighting has exceeded 8 kg, the curve tends to flatten out, with a slope approaching zero, and the sensitivity to further increases in blade tip weighting becomes small. We select a value for the speed decay rate of 0.707 of its converged value as the optimal design value, i.e., a value of 60 rev/min/s, and at this value we draw a plane parallel to the blade tip weighting–rotor diameter plane and intersecting with the original surface as shown in

Figure 23. We thereby obtain an appropriate range for selecting blade tip weightings between 4.5 kg and 6.3 kg.

According to the above results, when the rotor diameter is greater than or equal to 8.5 m and the blade tip weighting is greater than or equal to 5 kg, a significant optimization of maximum jump-takeoff height can be achieved. The blade tip weighting needs to be within the range of 4.5 kg to 6.3 kg for better optimization and to improve the cost-effectiveness of the speed decay rate. Considering the weights of the blades themselves and the strength of the rotor structure, neither the blade tip weighting nor the rotor diameter can be too large. Therefore, a rotor diameter of 8.5 m and a blade tip weighting of 5 kg were selected as optimized values.

6. Jump-Takeoff and Cruise in Nominal State

This article takes a certain autogyro with a takeoff weight of 450 kg (excluding blade tip weighting) as an example. Based on the data comparison and analysis of results presented above, the following rotor parameters and control variables were determined: an individual blade tip weighting of 5 kg, a pre-rotation speed of 400 rpm, a collective angle at jump-takeoff of 10°, a collective angle at cruising level flight of 2°, and a rotor diameter of 8.5 m.

At the beginning of the entire simulation, we started the engine for pre-rotation to achieve a rotation speed of 400 rpm. Then, we changed the collective angle at a rate of 20°/s to 10° while opening the throttle to achieve jump-takeoff. At the same time, we connected the attitude control to stabilize the aircraft. After reaching a specific jump-takeoff height, we lowered the collective angle to the value required for auto-rotation and connected the altitude and lateral controls. We set a specific jump-takeoff height of 10 m and controlled the autogyro to hover at an altitude of 10 m. Based on simulations and engineering experience, we needed to reserve a tolerance limit of 30% to end the jump-takeoff phase ahead of time. Therefore, the altitude and lateral controls were connected when a height of 7 m was reached, so that the autogyro could smoothly enter a hovering state at an altitude of 10 m. Then, we gradually increased the climb rate for a steady climbing process until a predetermined cruising altitude at 70 m was reached, at which the autogyro entered the cruise flight stage. The entire simulation process and flight mission diagram are shown, respectively, in

Figure 26 and

Figure 27.

Throughout this process, traditional inner-loop/outer-loop separation design control laws were adopted, with traditional PID being used for attitude angle control in both the vertical and horizontal directions. Outer-loop energy total control was used in the vertical direction, while trajectory control was used in the horizontal direction.

From

Figure 28 and

Figure 29, it can be seen that at the beginning of the simulation of the jump-takeoff, the rotation speed decreases rapidly. When the collective angle decreases to the angle required for auto-rotation, the rotation speed begins to increase until it stabilizes along with the height and maintains a stable auto-rotation.

After parameter optimization design, the autogyro can achieve a complete jump-takeoff and smoothly transition to the climb and level flight phases, verifying the feasibility of jump-takeoff flight.

7. Conclusions

In this article, high-confidence mathematical modeling of the autogyro designed by Xiamen University has been implemented, a jump-takeoff simulation on the autogyro has been designed and performed, and an in-depth study of its jump-takeoff performance has been conducted. A simplification of blade element theory has been proposed and discussed, and the principles of rotor self-rotation and conditions for jump-takeoff have been studied. The simplified blade element theory presented here enables simple calculations and is easily implemented while retaining high accuracy. Through the proposal of two indicators, namely, jump-takeoff height and rotation speed decay rate, this article has provided theoretical standards for studying jump-takeoff performance.

With regard to engineering applications, on the basis of the YASim dynamics library in FlightGear software, secondary development has been performed in this article to construct a simulation platform for autogyros, and jump-takeoff experiments have been designed and performed. The impact of changes in different control parameters on jump-takeoff performance has been studied. Simulation results show that the collective angle has a significant impact on the jump-takeoff height. On this basis, the optimization of jump-takeoff performance through changes in different rotor parameters has been investigated. It has been found that the optimization of the jump-takeoff height is greatly influenced by the rotor diameter. With the same blade tip weighting, by increasing the rotor diameter, the maximum jump-takeoff height can reach approximately 50 m. The optimization of the rotation speed decay rate is greatly influenced by blade tip weighting. With the same rotor diameter, by increasing blade tip weighting, the minimum rotation speed decay rate can reach approximately 40 rev/min/s. These two data can be observed from

Figure 21 and

Figure 23. On the basis of these optimized results, combined with engineering experience, we are able to obtain optimal design parameters for rotors. The work described in this article is significant for the future development and optimization of rotor modeling methods and the selection and design of rotor parameters, as well as for the implementation of autogyro jump-takeoff experiments.

In this article, relatively simple modeling was adopted for the behavior of the autogyro in lateral directions, and there are significant errors between the simulation results and flight data for roll angle, yaw angle, aileron, rudder, etc. In future work, we will aim to improve and extend the modeling of the autogyro to take a more detailed account of movement in lateral directions. Furthermore, it is known that for jump-takeoff, high-inertia rotors can store a greater amount of energy, provide greater lift, and reduce their rotational speed more slowly. Therefore, we will conduct further research on the landing of an autogyro equipped with a high-inertia rotor, with the aim of achieving ultra-short or even vertical landing by changing the collective angle.