Experimental Investigation of a Swirling-Oxidizer-Flow-Type Hybrid Rocket Engine Using Low-Melting-Point Thermoplastic Fuel and Oxygen

Abstract

:1. Introduction

2. Experimental Setup and Conditions

2.1. Experimental Setup

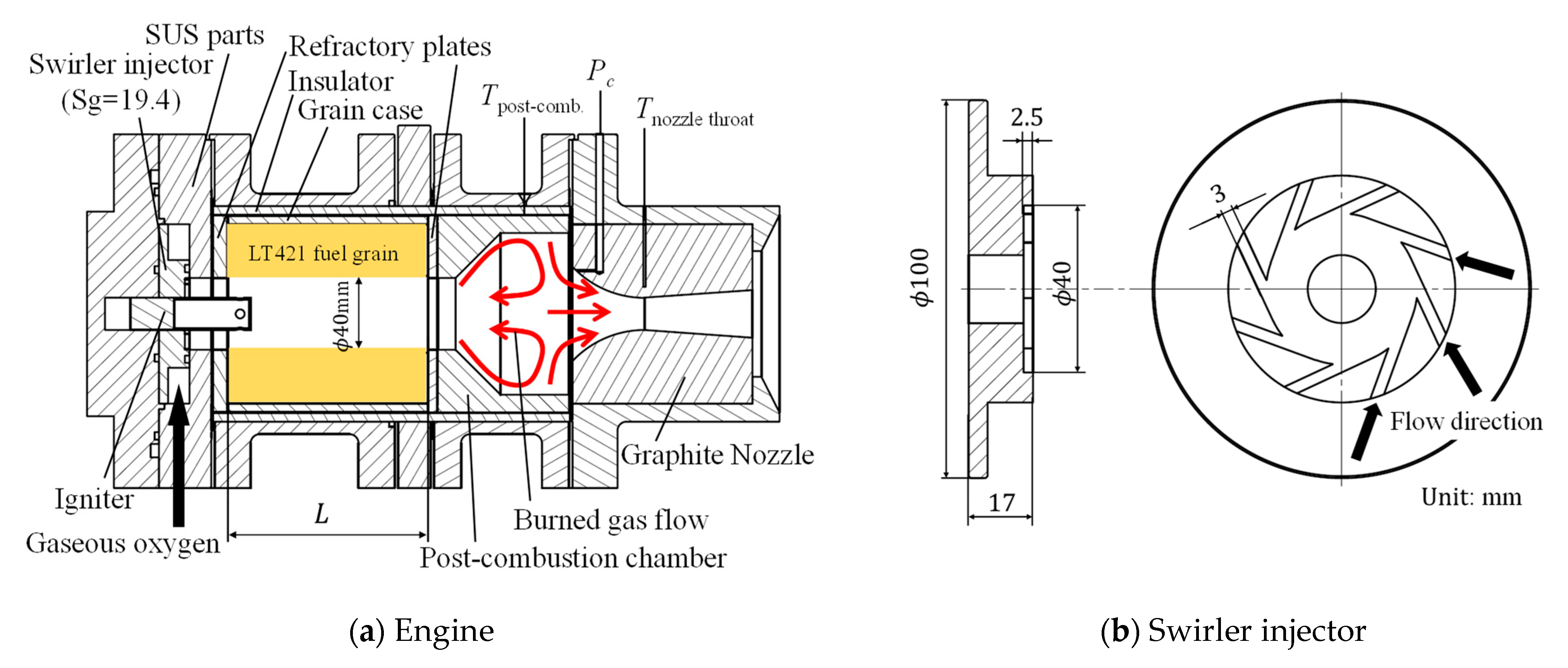

2.1.1. Hybrid Rocket Engine

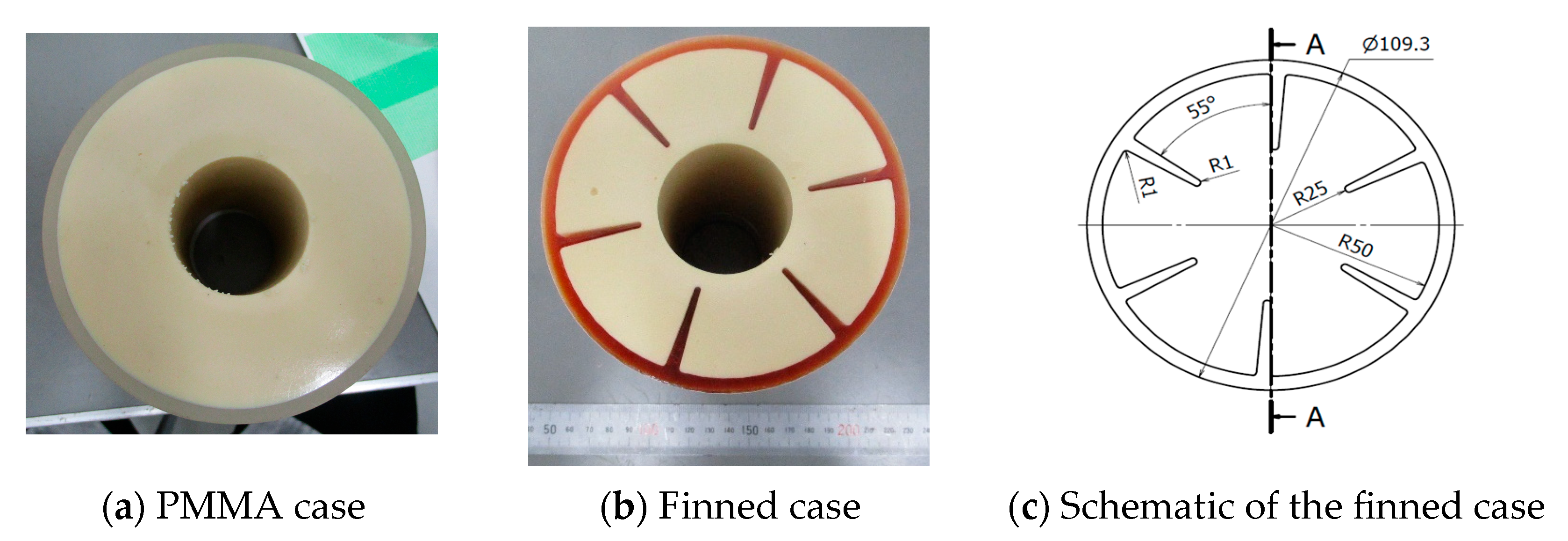

2.1.2. Fuel Grain Fabrication

2.1.3. Engine Test Facility

2.2. Data Analysis and Experimental Condition

2.2.1. Setting Targets for Equivalence Ratios

2.2.2. Regression Rate and Oxidizer Mass Flux

2.2.3. Experimental Conditions

2.2.4. Data Analysis

3. Experimental Results and Discussion

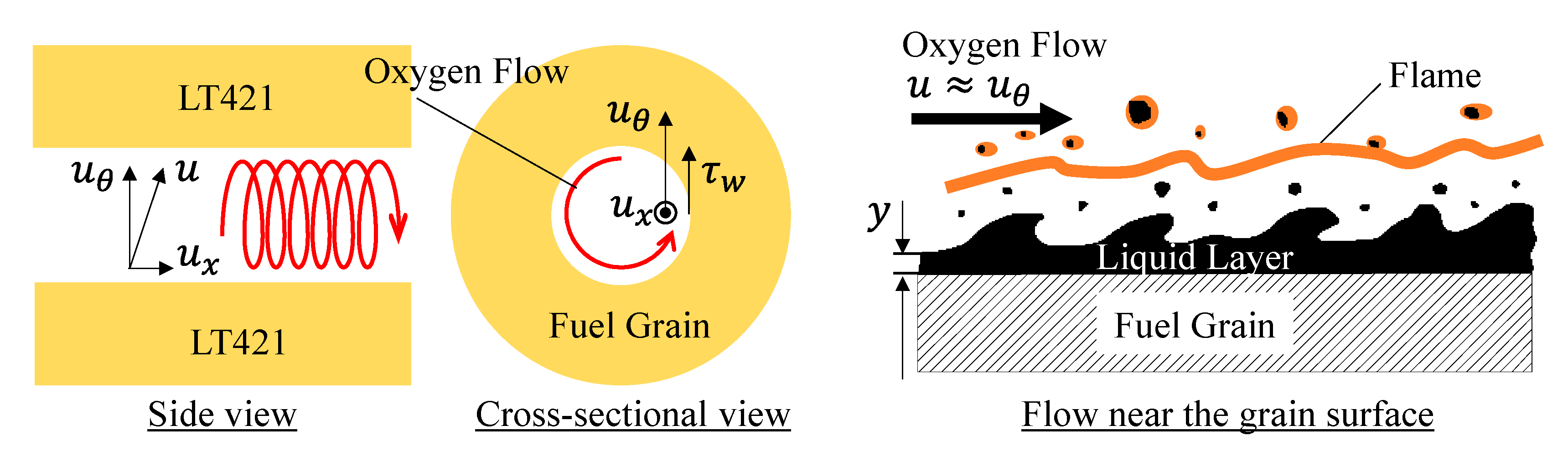

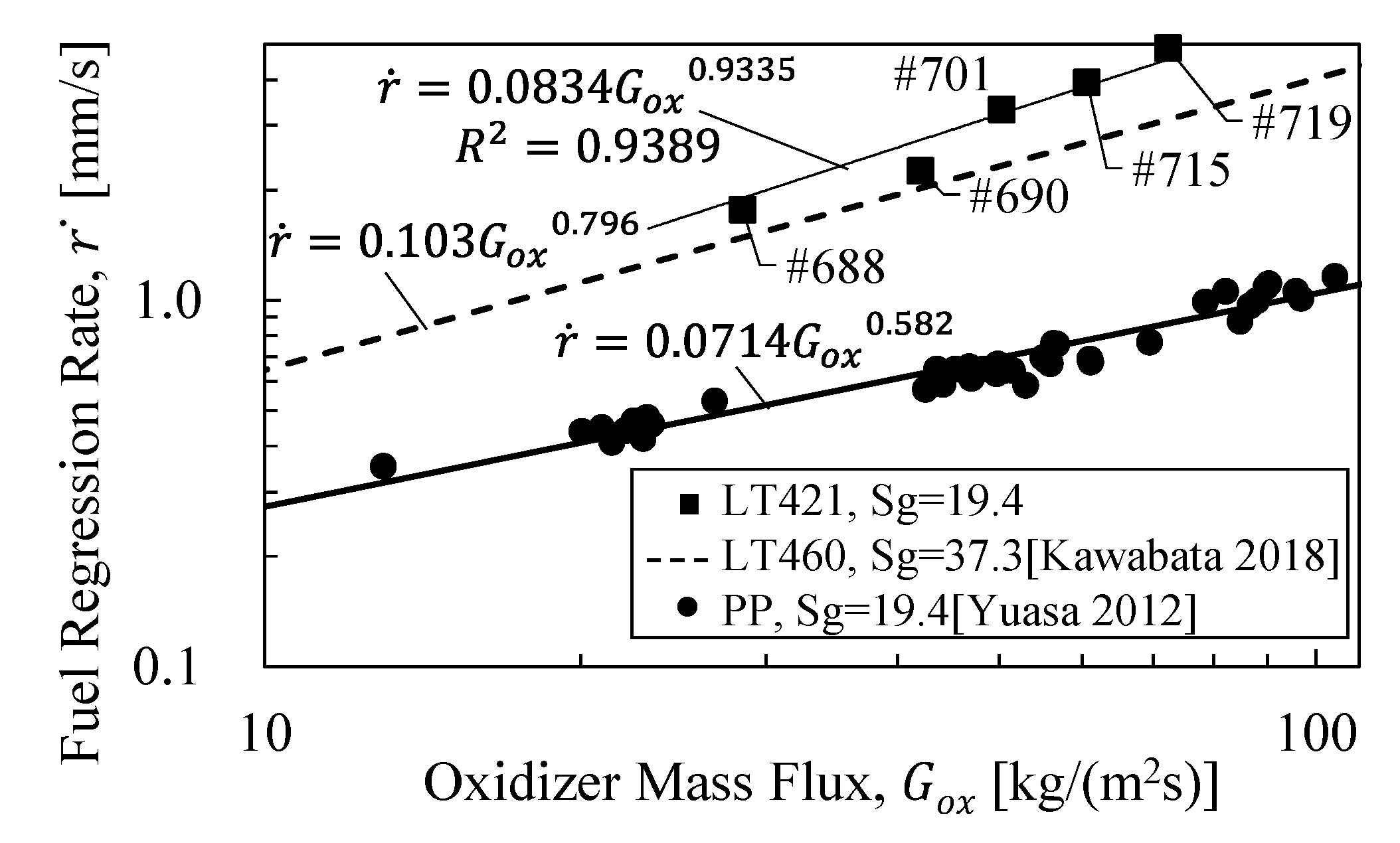

3.1. Effect of Oxygen Mass Flow Rate on Fuel Regression Rate

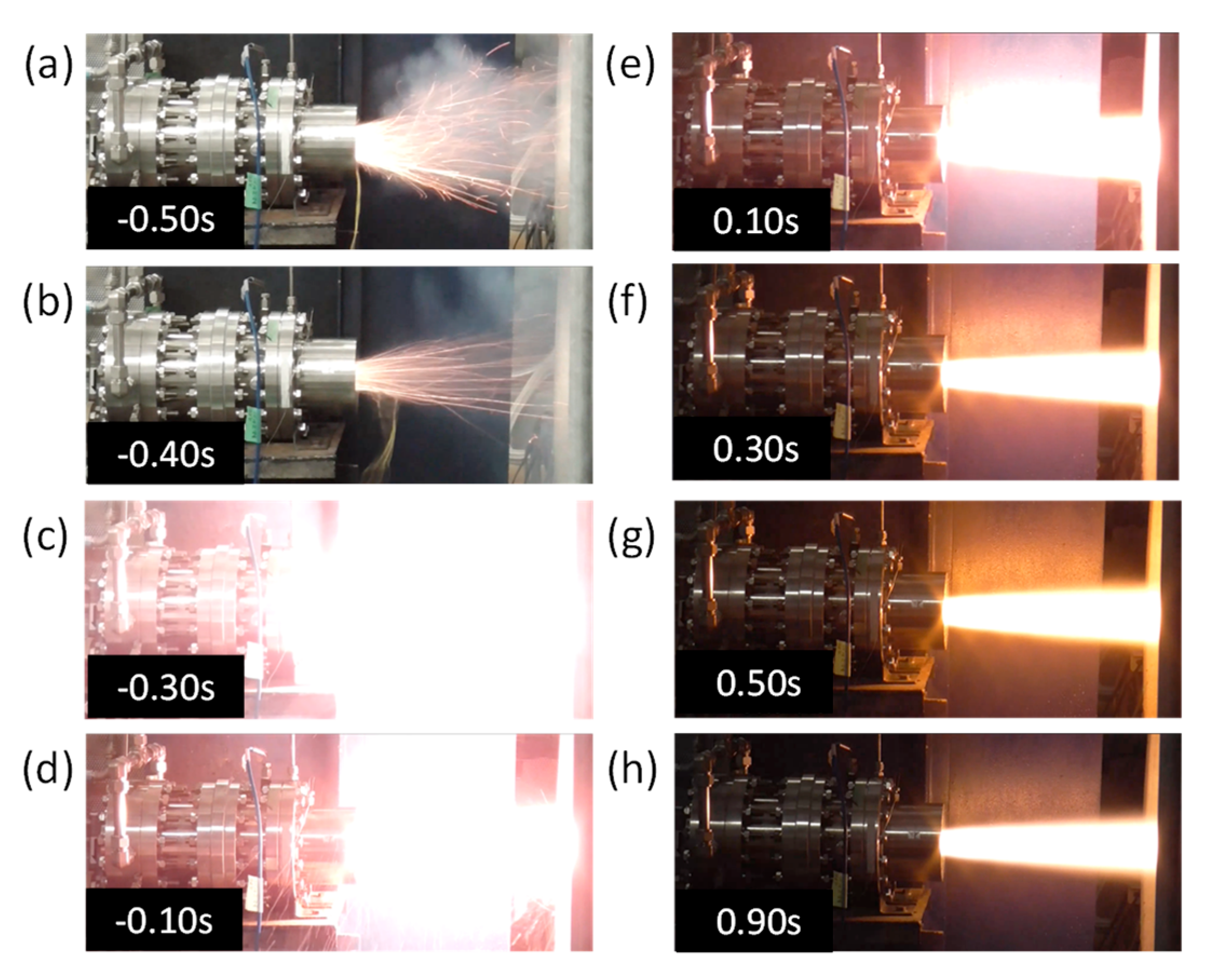

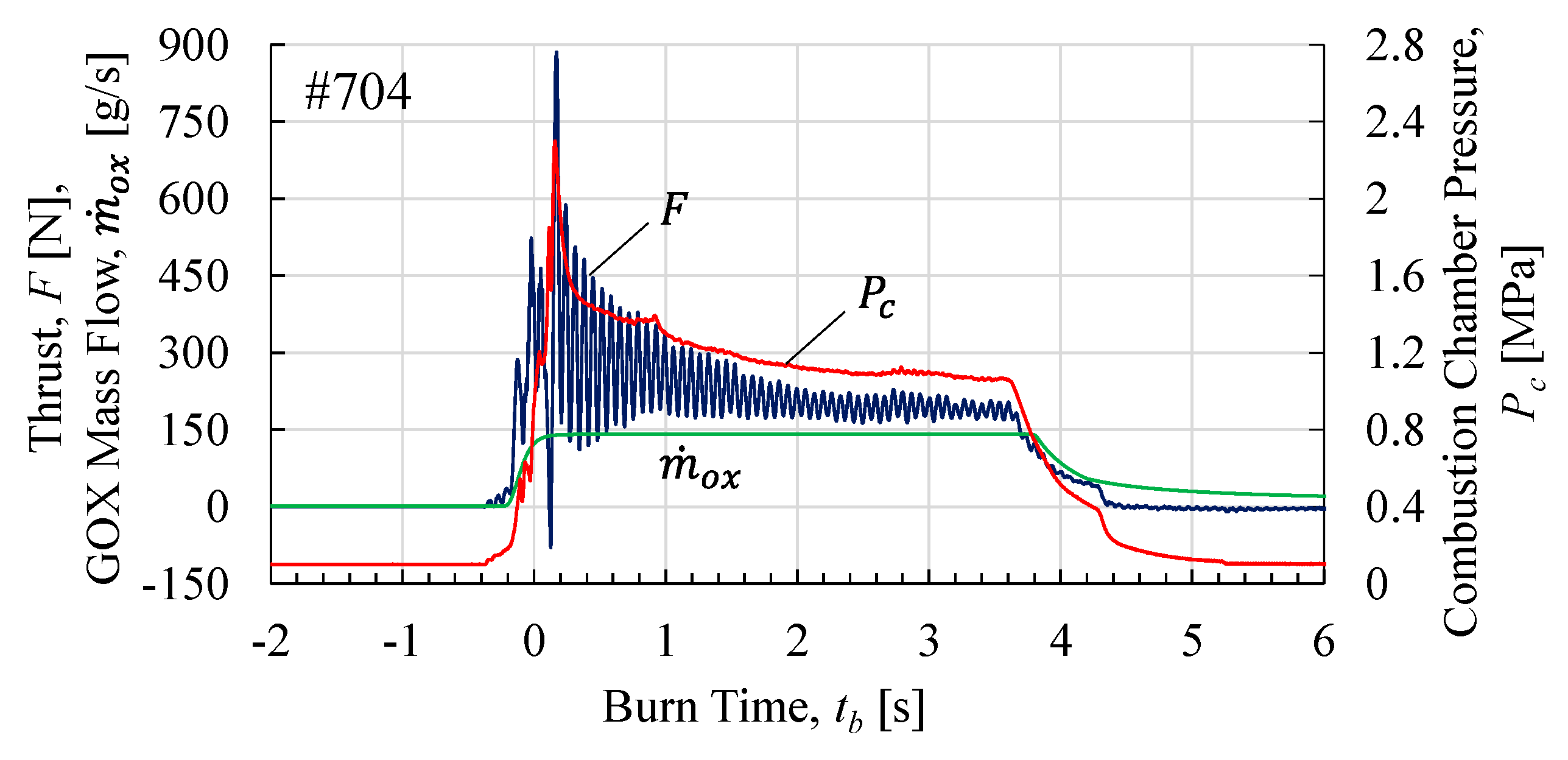

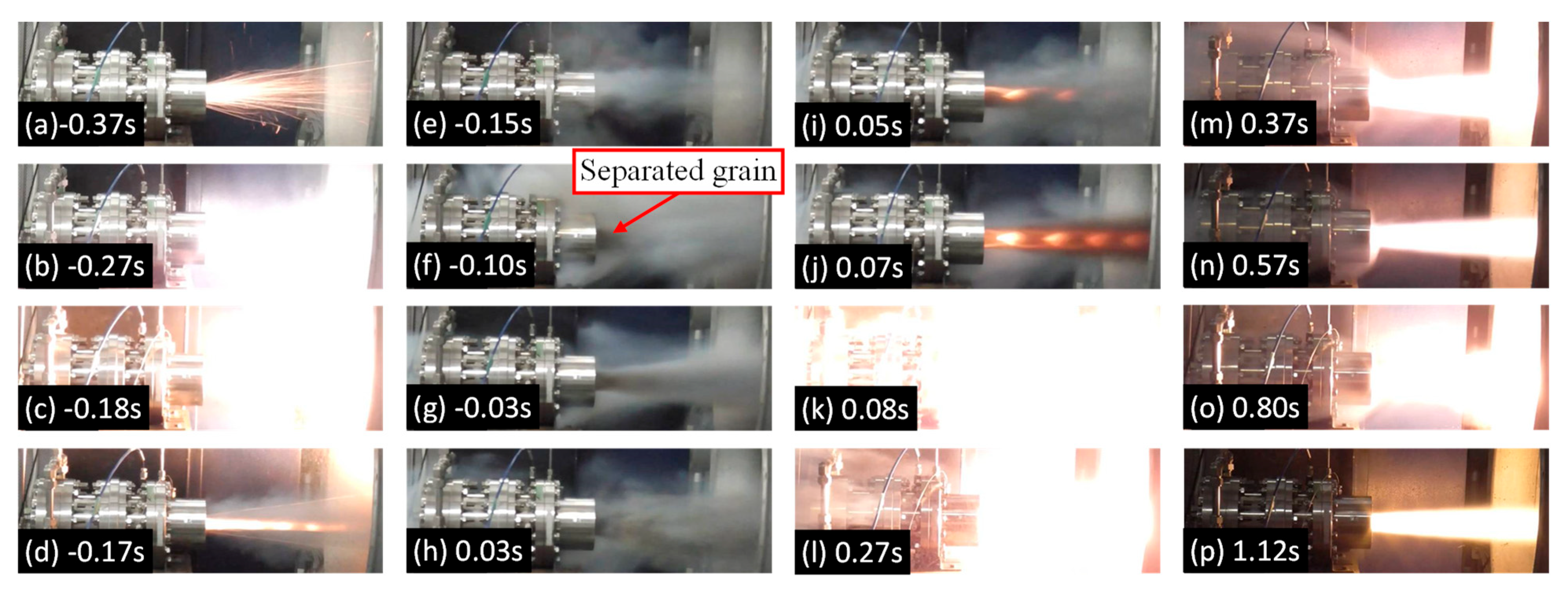

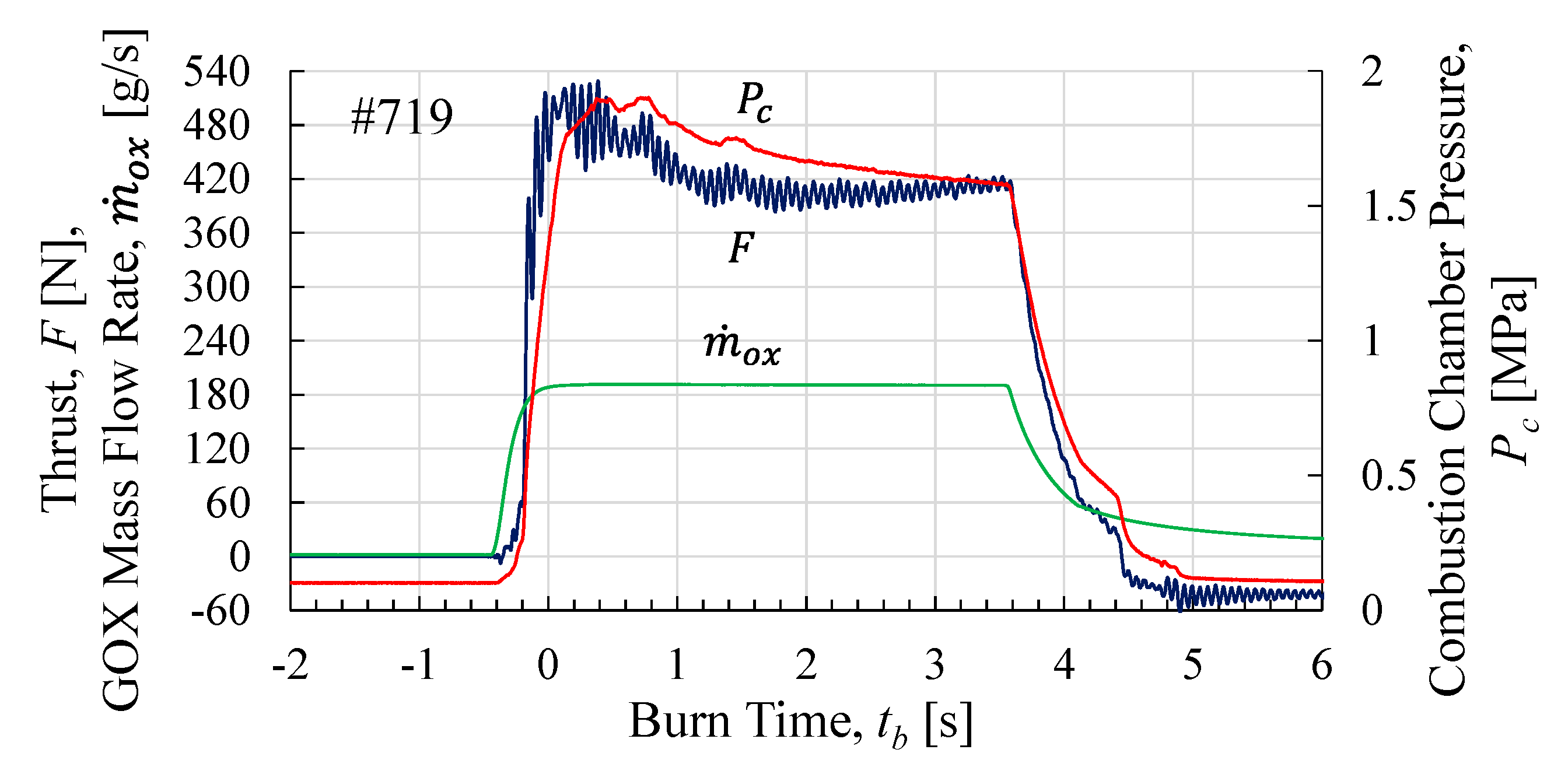

3.1.1. Typical Combustion Condition

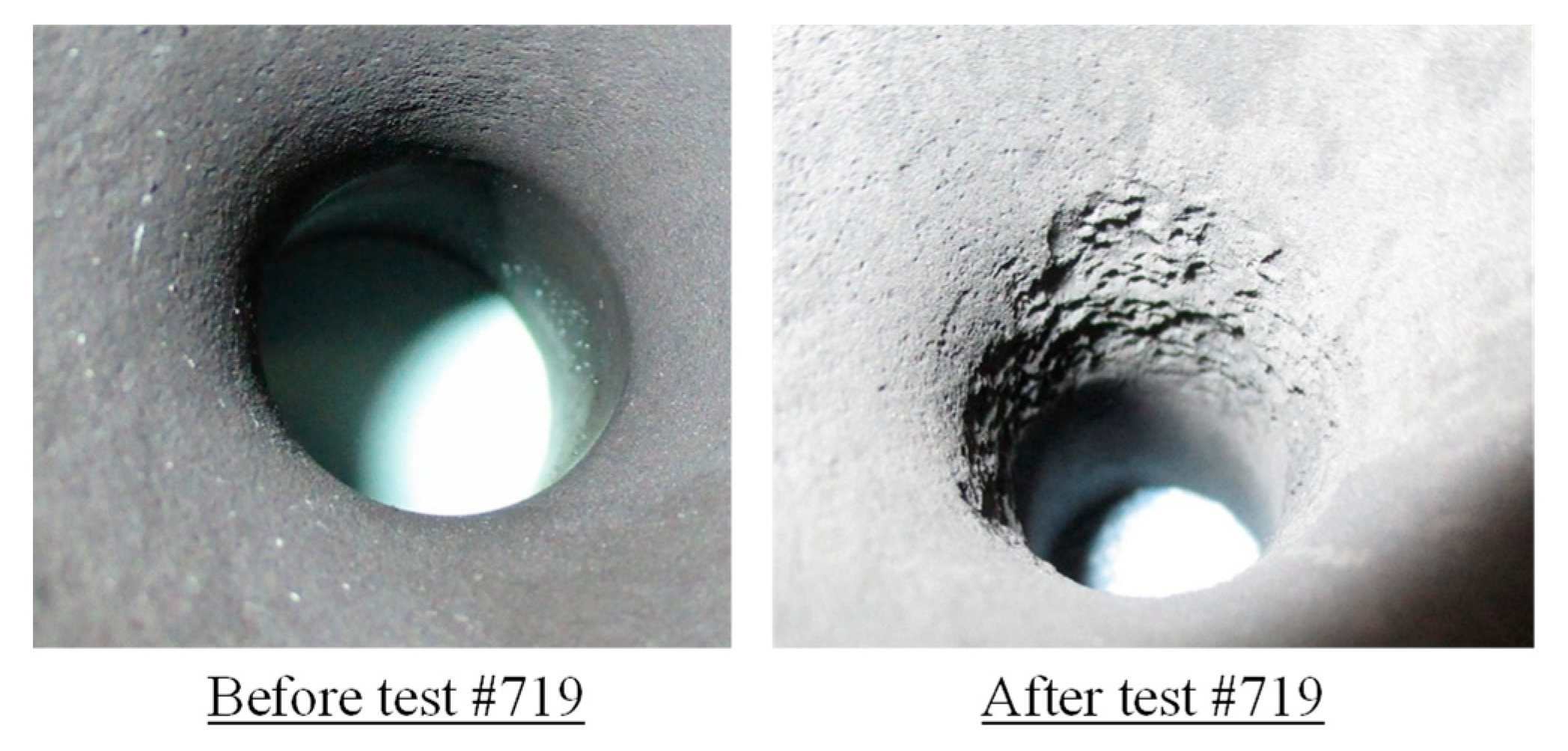

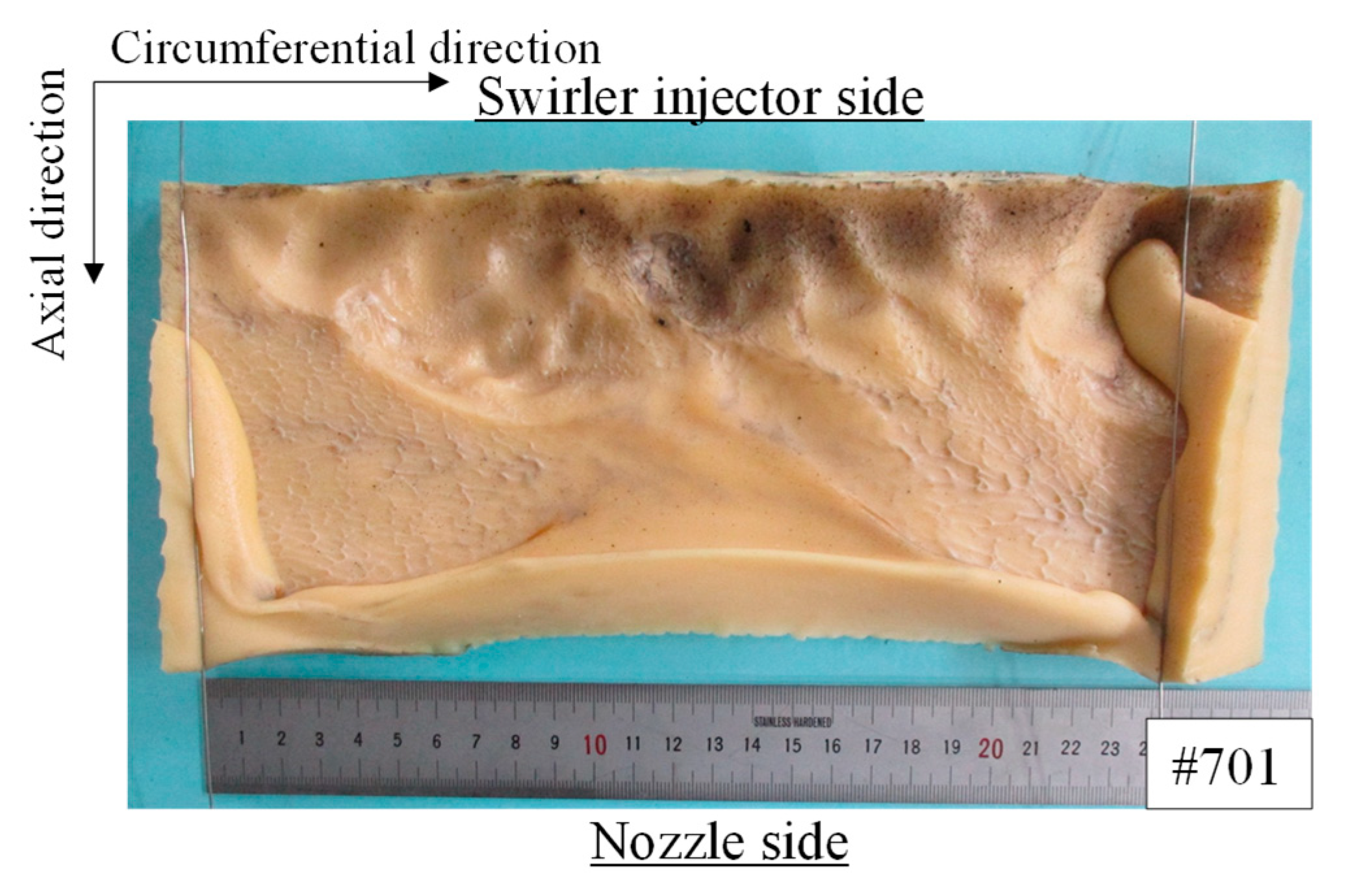

3.1.2. Fuel Grain Separation by Shear Force of Swirling Flow

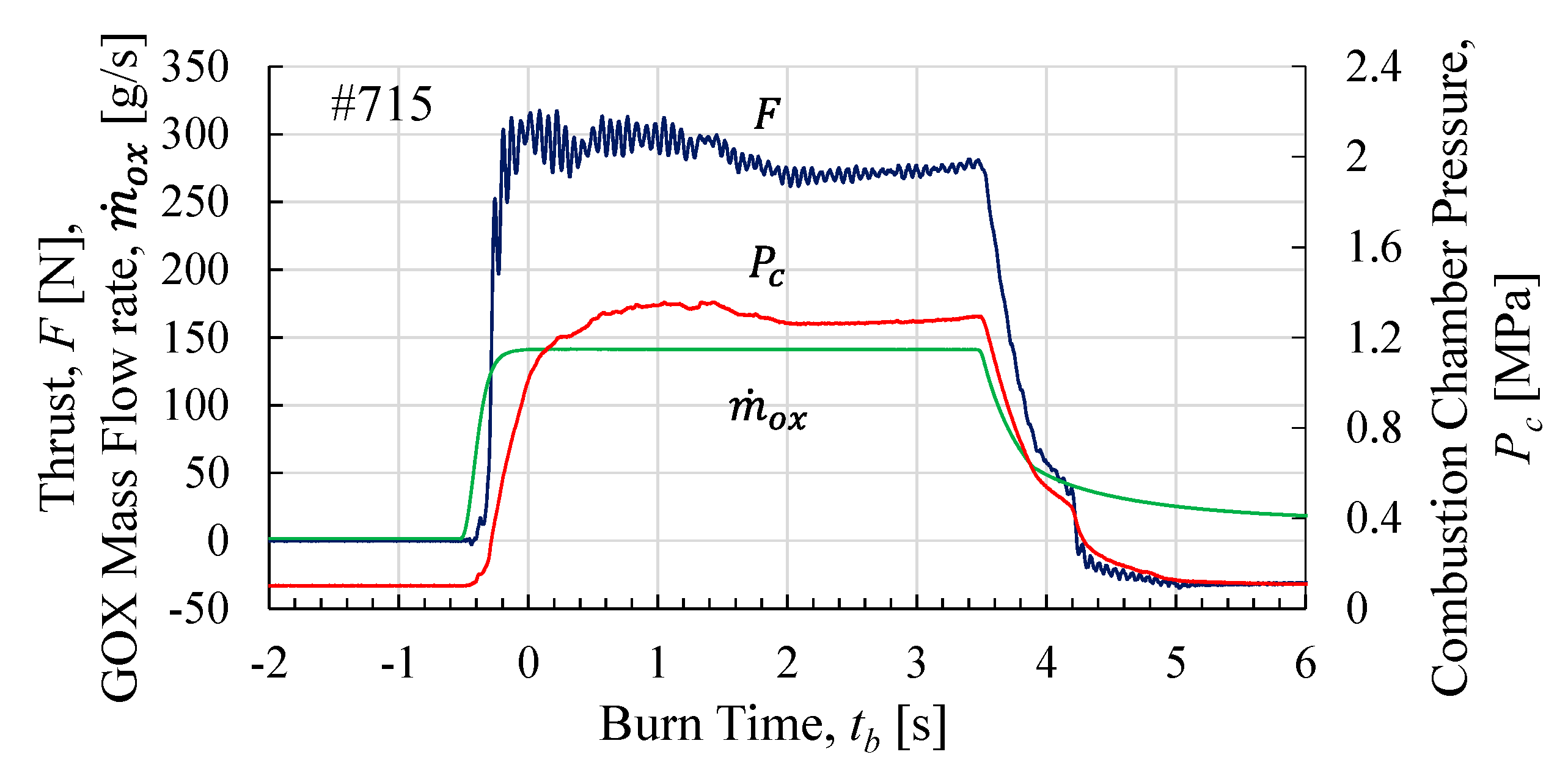

3.1.3. Combustion Condition with Finned Case

3.1.4. Time-Averaged Engine Performance and Fuel Regression Rate Correlation

3.2. Effect of Burn Time on Fuel Regression Rate

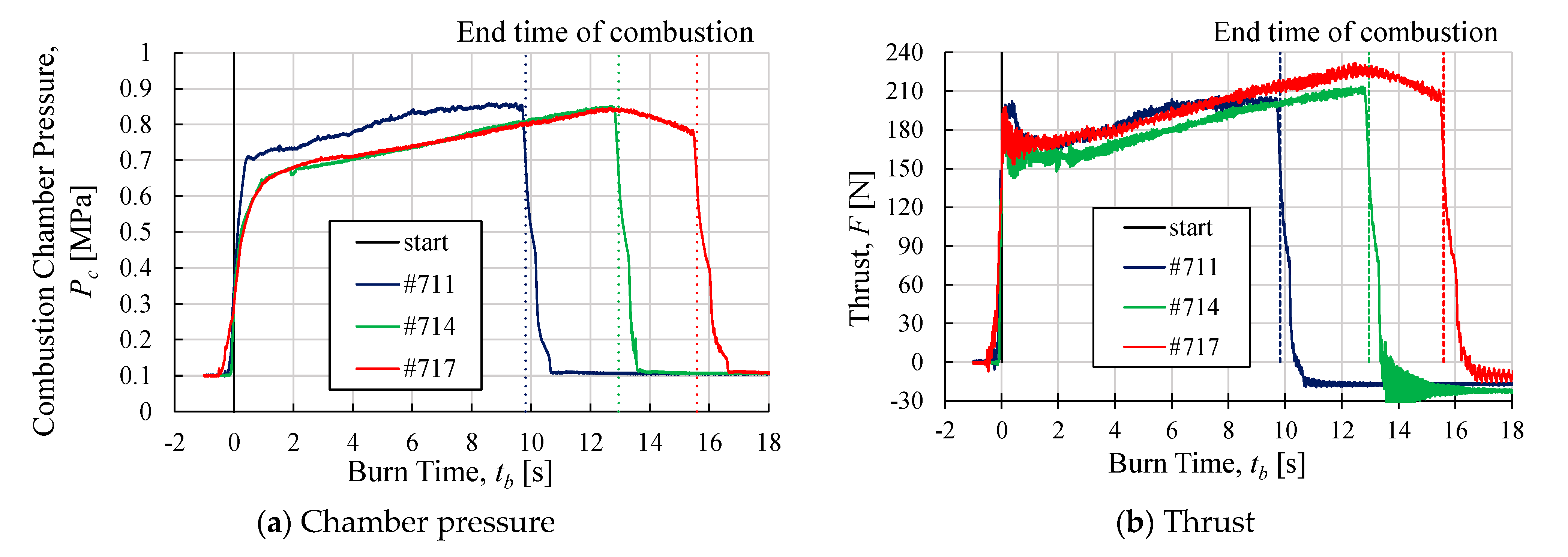

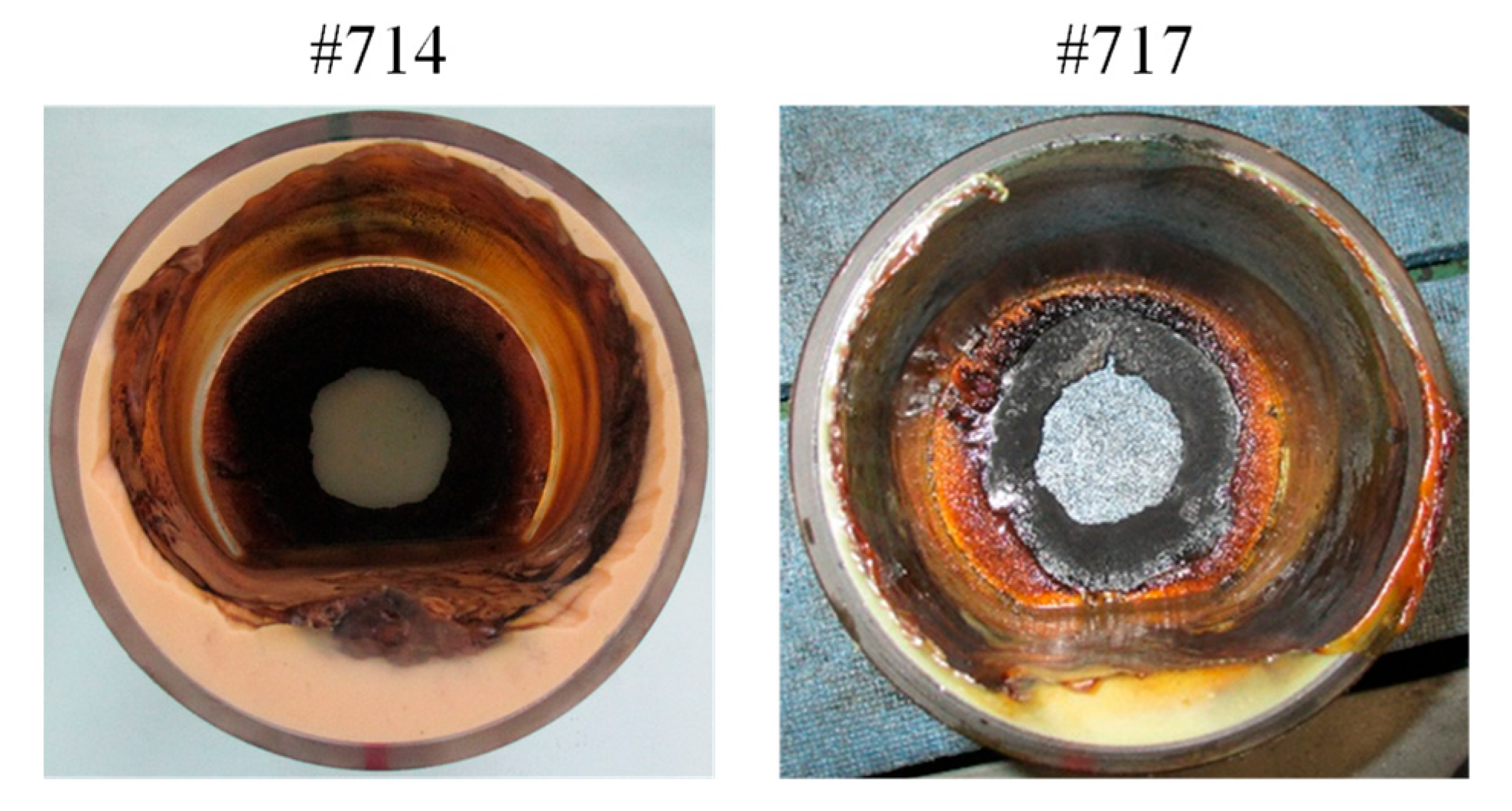

3.2.1. Combustion Conditions and Fuel Regression Rate

3.2.2. Effect of Burn Time on Wall Temperatures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| area of circle with swirler exit diameter | |

| cross-sectional area of swirler slit | |

| nozzle throat area | |

| C* | characteristic exhaust velocity |

| flow coefficient | |

| d | grain port diameter |

| time-averaged grain port diameter | |

| initial grain port diameter | |

| final grain port diameter | |

| nozzle throat diameter | |

| E | relative error |

| oxidizer mass flux | |

| Isp | specific impulse |

| axial flux of angular momentum | |

| axial flux of the axial thrust | |

| L | length of fuel grain |

| axial distance of flow-development region | |

| fuel mass flow rate | |

| oxidizer mass flow rate | |

| propellant mass flow rate | |

| molar mass of burned gas | |

| number of swirler slit | |

| static pressure of fluid | |

| combustion chamber pressure | |

| orifice upstream pressure | |

| R | final to initial grain port diameter ratio |

| universal gas constant | |

| gas constant of oxygen | |

| radius | |

| radius of swirler slit exit | |

| time-averaged fuel regression rate | |

| fuel regression rate in grain leading-edge region | |

| fuel regression rate in grain rear edge-region | |

| swirl number | |

| geometrical swirl number | |

| total surface area of grain port and post-combustion chamber | |

| burn time | |

| burned gas temperature at combustion chamber | |

| orifice upstream temperature | |

| absolute flow velocity | |

| axial flow velocity | |

| tangential flow velocity | |

| width of swirler slit | |

| burned mass of fuel grain | |

| axial distance along fuel grain port | |

| thickness of molten fuel layer | |

| C* efficiency | |

| specific heat ratio | |

| density of fluid | |

| density of burned gas | |

| density of fuel grain | |

| equivalence ratio | |

| viscosity coefficient | |

| viscosity coefficient of oxygen | |

| shear stress | |

| Subscripts | |

| exp | experimental |

| th | theoretical |

References

- Kuo, K.K.; Chiaverini, M.J. Challenges of Hybrid Rocket Propulsion in the 21st Century. In Fundamentals of Hybrid Rocket Combustion and Propulsion; Chaiverini, M.J., Kuo, K.K., Eds.; Progress in Astronautics and Aeronautics; AIAA: Reston, VA, USA, 2007; pp. 593–638, NASA RP-1311. [Google Scholar]

- Takahashi, A.; Shimada, T. Essentially Non-explosive propulsion Paving a Way for Fail-Safe Space Transportation. Transact. Jpn. Soc. Aeronaut. Space Sci. Space Technol. Jpn. 2018, 16, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Virgin Galactic. Available online: https://www.virgingalactic.com/ (accessed on 2 May 2023).

- Yuasa, S.; Yamamoto, K.; Hachiya, H.; Kitagawa, K.; Oowada, Y. Development of a Small Sounding Hybrid Rocket with a Swirling-Oxidizer-Type Engine. In Proceedings of the 37th AIAA Joint Propulsion Conference and Exhibit, Salt Lake City, UT, USA, 8–11 July 2001. AIAA Paper 2001-3537. [Google Scholar] [CrossRef]

- Karabeyoglu, A.; Zilliac, G.; Castellucci, P.; Urbanczyk, P.; Inalhan, G.; Cantwell, B. Flight Demonstration of the High Burning Rate Hydrocarbon-Based Hybrid Rocket Fuels. In Proceedings of the 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Huntsville, AL, USA, 20–23 July 2003. AIAA Paper 2003-5196. [Google Scholar] [CrossRef]

- Kobald, M.; Schmierer, C.; Fischer, U.; Tomilin, K.; Petrarolo, A. A Record Flight of the Hybrid Sounding Rocket HEROS 3. Transact. Jpn. Soc. Aeronaut. Space Sci. Space Technol. Jpn. 2018, 16, 312–317. [Google Scholar] [CrossRef] [Green Version]

- Gilmour Space Technologies. Available online: https://www.gspace.com/ (accessed on 2 May 2023).

- TiSPACE. Available online: https://www.tispace.com/ (accessed on 2 May 2023).

- HyImpulse Technologies. Available online: https://www.hyimpulse.de/en/ (accessed on 2 May 2023).

- MJOLNIR SPACEWORKS. Available online: https://www.mjolnir-sw.com/ (accessed on 2 May 2023).

- Letara. Available online: https://www.letara.space/ (accessed on 2 May 2023).

- Kamps, L.; Hirai, S.; Nagata, H. Hybrid Rockets as Post-Boost Stages and Kick Motors. Aerospace 2021, 8, 253. [Google Scholar] [CrossRef]

- Mazzetti, A.; Merotto, L.; Pinarello, G. Paraffin-based Hybrid Rocket Engines Applications: A Review and a Market Perspective. Acta Astronaut. 2016, 126, 286–297. [Google Scholar] [CrossRef]

- Knuth, W.H.; Chiaverini, M.J.; Sauer, J.A.; Gramer, D.J. Solid-Fuel Regression Rate Behavior of Vortex Hybrid Rocket Engines. J. Propuls. Power 2002, 18, 600–609. [Google Scholar] [CrossRef]

- Yuasa, S.; Shimada, O.; Imamura, T.; Tamura, T.; Yamamoto, K. A Technique for Improving the Performance of Hybrid Rocket Engines. In Proceedings of the 35th AIAA Joint Propulsion Conference and Exhibit, Los Angeles, CA, USA, 20–24 June 1999. AIAA Paper 1999-2322. [Google Scholar] [CrossRef]

- Nagata, H.; Okada, K.; San’da, T.; Akiba, R.; Satori, S.; Kudo, I. New Fuel Configurations for Advanced Hybrid Rockets. In Proceedings of the 49th International Astronautical Congress, Melbourne, VIC, Australia, 28 September–2 October 1998. Paper IAF-98-S.3.09. [Google Scholar]

- Carrick, P.; Larson, C. Lab Scale Test and Evaluation of Cryogenic Solid Hybrid Rocket Fuels. In Proceedings of the 31st AIAA Joint Propulsion Conference and Exhibit, San Diego, CA, USA, 10–12 July 1995. AIAA Paper 1995-2948. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A.; Altman, D.; Cantwell, B.J. Combustion of Liquefying Hybrid Propellants, Part 1: General Theory. J. Propuls. Power 2002, 18, 610–620. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A.; Cantwell, B.J. Combustion of Liquefying Hybrid Propellants, Part 2: Stability of Liquid Films. J. Propuls. Power 2002, 18, 621–630. [Google Scholar] [CrossRef]

- Galfetti, L.; Merotto, L.; Boiocchi, M.; Maggi, F.; DeLuca, L.T. Experimental Investigation of paraffin-based Fuels for Hybrid Rocket Propulsion. Proc. Prog. Propuls. Phys. 2013, 4, 59–74. [Google Scholar] [CrossRef] [Green Version]

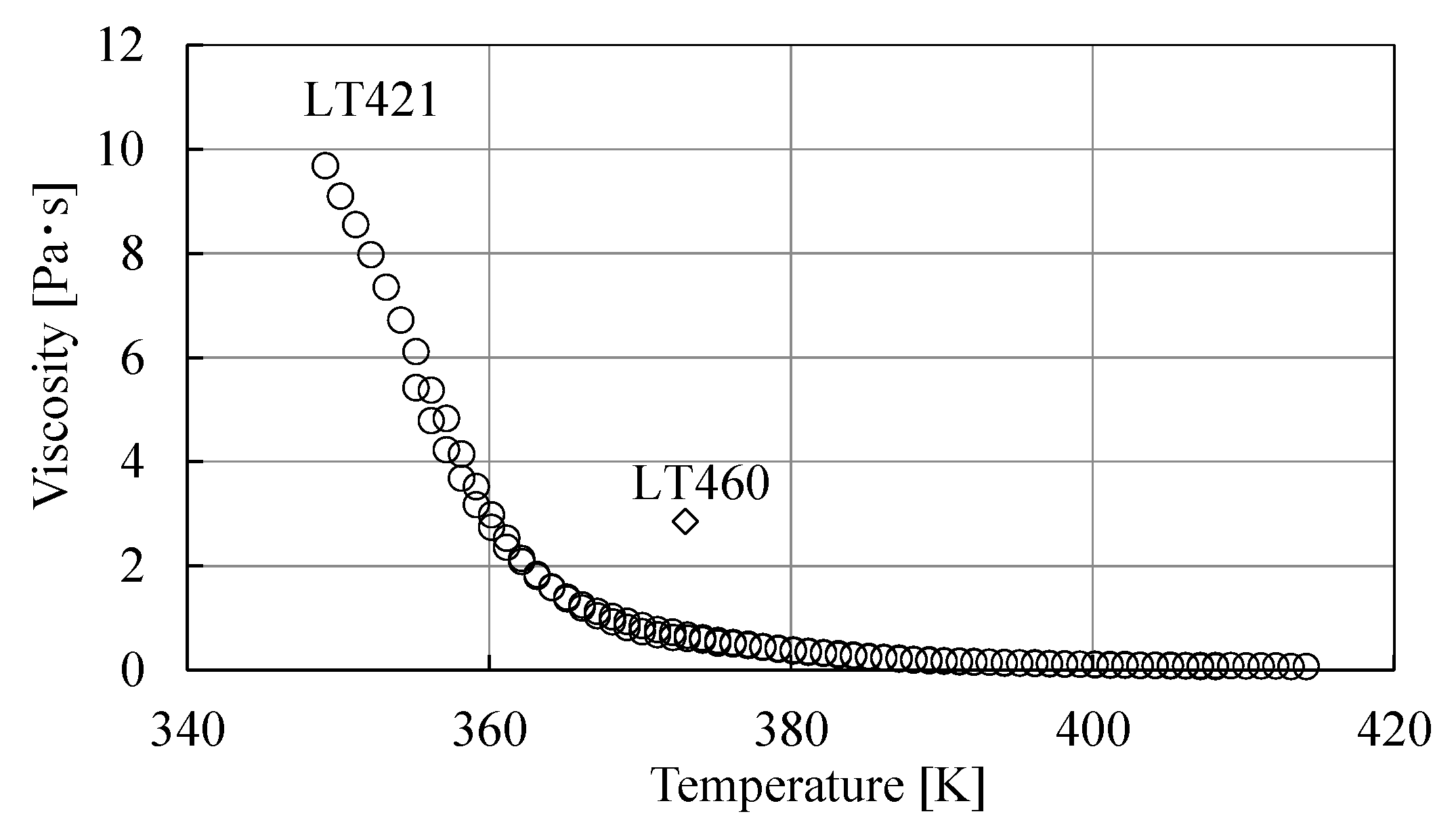

- Kobald, M.; Schmierer, C.; Ciezki, K.H.; Schlechtriem, S.; Toson, E.; De Luca, L.T. Viscosity and Regression Rate of Liquefying Hybrid Rocket Fuels. J. Propuls. Power 2017, 33, 1245–1251. [Google Scholar] [CrossRef]

- Kim, S.; Moon, H.; Kim, J.; Cho, J. Evaluation of Paraffin–Polyethylene Blends as Novel Solid Fuel for Hybrid Rockets. J. Propuls. Power 2015, 31, 1750–1760. [Google Scholar] [CrossRef]

- Kumar, R.; Ramakrishna, P.A. Studies on EVA-Based Wax Fuel for Launch Vehicle Applications. Propellants Explos. Pyrotech. 2016, 41, 295–303. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, S.; Zhang, W.; Shen, R.; DeLuca, L.T.; Ye, Y. Mechanical Modifications of Paraffin-based Fuels and the Effects on Combustion Performance. Propellants Explos. Pyrotech. 2017, 42, 1268–1277. [Google Scholar] [CrossRef]

- Ishigaki, T.; Nakagawa, I. Improving Physical Properties of Wax-Based Fuels and Its Effect on Regression Rate. J. Propuls. Power 2020, 36, 123–128. [Google Scholar] [CrossRef]

- Veale, K.; Adali, S.; Pitot, J.; Brooks, M. A review of the performance and structural considerations of paraffin wax hybrid rocket fuels with additives. Acta Astronaut. 2017, 141, 196–208. [Google Scholar] [CrossRef]

- Oztan, C.; Coverstone, V. Utilization of additive manufacturing in hybrid rocket technology: A review. Acta Astronaut. 2021, 180, 130–140. [Google Scholar] [CrossRef]

- Bisin, R.; Paravan, C.; Alberti, S.; Galfetti, L. A new strategy for the reinforcement of paraffin-based fuels based on cellular structures: The armored grain—Mechanical characterization. Acta. Astronaut. 2020, 176, 494–509. [Google Scholar] [CrossRef]

- Bisin, R.; Paravan, C. A new strategy for the reinforcement of paraffin-based fuels based on cellular structures: The armored grain—Ballistic characterization. Acta. Astronaut. 2023, 206, 284–298. [Google Scholar] [CrossRef]

- Lin, X.; Qu, D.; Chen, X.; Wang, Z.; Luo, J.; Meng, D. Three-dimensional printed metal-nested composite fuel grains with superior mechanical and combustion properties. Virtual Phys. Prototyp. 2022, 17, 437–450. [Google Scholar] [CrossRef]

- Sakurai, T.; Oishige, Y.; Saito, K. Fuel Regression Behavior of Swirling-Injection End-Burning Hybrid Rocket Engine. J. Fluid Sci. Technol. 2019, 14, JFST0025. [Google Scholar] [CrossRef] [Green Version]

- Wada, Y.; Jikei, M.; Kato, R.; Kato, N.; Hori, K. Application of Low Melting Point Thermoplastics to Hybrid Rocket Fuel. Transact. Jpn. Soc. Aeronaut. Space Sci. Space Technol. Jpn. 2012, ists28, Pa_1–Pa_5. [Google Scholar] [CrossRef] [Green Version]

- Wada, Y.; Kawabata, Y.; Kato, R.; Kato, N.; Hori, K. Observation of Combustion Behavior of Low Melting Temperature Fuel for a Hybrid Rocket Using Double Slab Motor. Int. J. Energetic Mater. Chem. Propuls. 2016, 15, 351–369. [Google Scholar] [CrossRef]

- Kawabata, Y.; Banno, A.; Wada, Y.; Ozawa, K.; Shimada, T.; Kato, N.; Hori, K.; Nagase, R. Experimental Investigation of Fuel Regression Rate of Low-Melting-Point Thermoplastic Fuels in the Altering-Intensity Swirling-Oxidizer-Flow-Type Hybrid Rocket Engine. Transact. Jpn. Soc. Aeronaut. Space Sci. Space Technol. Jpn. 2018, 16, 267–273. [Google Scholar] [CrossRef]

- Gordon, S.; McBride, B. Computer Program for Calculation of Complex Chemical Equilibrium Compositions and Applications; National Aeronautics and Space Administration: Cleveland, OH, USA, 1994. [Google Scholar]

- Wada, Y.; Kato, R.; Kato, N.; Hori, K. Small Rocket Launch Experiment using Low Melting Point Thermoplastic Fuel/N2O Hybrid Rocket. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, San Jose, CA, USA, 14–17 July 2013. AIAA Paper 2013-4050. [Google Scholar] [CrossRef]

- Banno, A.; Wada, Y.; Mishima, Y.; Tsugoshi, T.; Kato, N.; Hori, K.; Nagase, R. Pyrolysis Behavior of a Paraffin-based Thermoplastic Polymer used in Hybrid Rocket Fuel. Int. J. Energetic Mater. Chem. Propuls. 2019, 18, 341–354. [Google Scholar] [CrossRef]

- Oishi, T.; Tokyo Metropolitan University, Hino, Tokyo, Japan; Kato, N.; Katazen Corp., Obu, Aichi, Japan. Personal communication, 2021.

- Beer, J.M.; Chigier, N.A. Combustion Aerodynamics; Reprint; Robert E. Krieger Publishing Company: Malabar, FL, USA, 1983; pp. 109–115. [Google Scholar]

- Saito, D.; Yuasa, S.; Hirata, K.; Sakurai, T.; Shiraishi, N. Combustion Characteristics of Paraffin-Fueled Swirling Oxidizer-Flow-Type Hybrid Rocket Engines. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Atlanta, GA, USA, 30 July–1 August 2012. AIAA Paper 2012-3904. [Google Scholar] [CrossRef]

- Yuasa, S.; Ide, T.; Masugi, M.; Sakurai, T.; Shiraishi, N.; Shimada, T. Visualization and Emission Spectra of Flames in Combustion Chamber of Swirling-Oxidizer-Flow-Type Hybrid Rocket Engines. J. Therm. Sci. Technol. 2011, 6, 268–277. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Lin, X.; Wang, Z.; Wu, K.; Luo, J.; Fang, S.; Zhang, C.; Li, F.; Yu, X. Effects of swirl injection on the combustion of a novel composite hybrid rocket fuel grain. Acta Astronaut. 2022, 199, 174–182. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A.; Cantwell, B.J.; Zilliac, G. Development of Scalable Space-Time Averaged Regression Rate Expressions for Hybrid Rockets. J. Propuls. Power 2007, 23, 737–747. [Google Scholar] [CrossRef]

- Yuasa, S.; Shiraishi, N.; Sakamoto, M.; Sezaki, C.; Hirata, K.; Sakurai, T. Evaluation Method of C* Efficiency of Swirling-Oxidizer-Flow-Type Hybrid Rocket Engines. J. Jpn. Soc. Aeronaut. 2011, 59, 97–101. (In Japanese) [Google Scholar] [CrossRef] [Green Version]

- Merotto, L.; Boiocchi, M.; Milova, P.; Monzani, M.R.; Galfetti, L. Development of an Experimental Lab-scale Set Up for Transient Combustion Investigation in Hybrid Rockets. In Proceedings of the 63rd International Astronautical Congress, Naples, Italy, 1–5 October 2012. Paper IAC-12-C4.2.25. [Google Scholar]

- Bellomo, N.; Barato, F.; Faenza, M.; Lazzarin, M.; Bettella, A.; Pavarin, D. Numerical and Experimental Investigation of Unidirectional Vortex Injection in Hybrid Rocket Engines. J. Propuls. Power 2013, 29, 1097–1113. [Google Scholar] [CrossRef]

- Kitagawa, K.; Sakurazawa, T.; Yuasa, S. Combustion Experiment to Evaluate a LOX Vaporization Nozzle for a Swirling-Oxidizer-Flow-Type Hybrid Rocket Engine with a 1500N-Thrust. Space Technol. Jpn. JSASS 2007, 6, 47–54. (In Japanese) [Google Scholar] [CrossRef] [Green Version]

- Yuasa, S.; Shiraishi, N.; Hirata, K. Controlling Parameters for Fuel Regression Rate of Swirling-oxidizer-flow-type Hybrid Rocket Engine. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Atlanta, GA, USA, 30 July–1 August 2012. AIAA Paper 2012-4106. [Google Scholar] [CrossRef]

- Sakurai, T.; Yuasa, S.; Ando, H.; Kitagawa, K.; Shimada, T. Performance and Regression Rate Characteristics of 5-kN Swirling-Oxidizer-Flow-Type Hybrid Rocket Engine. J. Propuls. Power 2017, 33, 891–901. [Google Scholar] [CrossRef]

- Matsui, K.; Tsuji, H.; Makino, A. The Effects of Water Vapor Concentration on the Rate of Combustion of an Artificial Graphite in Humid Air Flow. Combust. Flame. 1983, 50, 107–118. [Google Scholar] [CrossRef]

- Acharya, R.; Kuo, K.K. Effect of Chamber Pressure and Propellant Composition on Erosion Rate of Graphite Rocket Nozzle. J. Propuls. Power 2007, 23, 1242–1254. [Google Scholar] [CrossRef]

- Kamps, L.; Hirai, S.; Sakurai, K.; Viscor, T.; Saito, Y.; Guan, R.; Isochi, H.; Adachi, N.; Itoh, M.; Nagata, H. Investigation of Graphite Nozzle Erosion in Hybrid Rockets Using Oxygen/High-Density Polyethylene. J. Propuls. Power 2020, 36, 423–434. [Google Scholar] [CrossRef]

- Solyman, W.S.E.; Nagiub, H.M.; Alian, N.A.; Shaker, N.O.; Kandil, U.F. Synthesis and characterization of phenol/formaldehyde nanocomposites: Studying the effect of incorporating reactive rubber nanoparticles or Cloisite-30B nanoclay on the mechanical properties, morphology and thermal stability. J. Radiat. Res. Appl. Sci. 2016, 10, 72–79. [Google Scholar] [CrossRef] [Green Version]

| Sample No. | LT421 | LT462 | LT464 | LT460 | |

|---|---|---|---|---|---|

| Composition | Styrene series resin [%] | 8 | 9 | 11 | 13 |

| Low melting resin [%] | 13 | 33 | 32 | 31 | |

| Liquefacient (fatty acid) [%] | 4 | 0 | 3 | 6 | |

| Paraffin oil [%] | 75 | 57 | 53 | 49 | |

| Element ratio | C [%] | 35 | 36 | 36 | 36 |

| H [%] | 65 | 63 | 63 | 63 | |

| O [%] | 0.4 | 0.6 | 1 | 1 | |

| Physical property | Specific gravity | 0.89 | 0.92 | 0.92 | 0.92 |

| Mechanical property | Yang’s modulus [kPa] | 37.7 | 169.3 | 267.7 | 617.7 |

| Maximum stress [MPa] | 0.09 | 0.26 | 0.41 | 0.58 | |

| Maximum strain [%] | 378.8 | 319.4 | 344.0 | 300.2 | |

| Fuel | LT421 | Paraffin Wax (FT0070) | PE | PP | HTPB |

|---|---|---|---|---|---|

| Isp [s] | 257.3 | 289.6 | 290.2 | 286.7 | 287.0 |

| O/F, mass | 3.02 | 2.46 | 2.44 | 2.44 | 2.08 |

| 3.1. Firing Tests Varying Oxygen Mass Flow Rate | ||||||||

|---|---|---|---|---|---|---|---|---|

| Exp. No. | L | Nozzle | Grain Case | Refractory Plate | ||||

| (g/s) | (s) | (mm) | (-) | (mm) | (-) | (-) | Leading-Edge Side | |

| #688 | 50 | 4 | 50 | C1M | 12 | 1.28 | PMMA | Graphite |

| #690 | 85 | 4 | 111 | C1M | 12 | 1.28 | PMMA | Bakelite |

| #698 | 115 | 4 | 111 | C4M | 18 | 1.17 | PMMA | Bakelite |

| #701 | 115 | 4 | 111 | C4M | 18 | 1.17 | PMMA | Bakelite |

| #704 | 150 | 4 | 111 | C4M | 18 | 1.34 | PMMA | Graphite |

| #707 | 115 | 4 | 111 | C1M | 12 | 1.46 | PMMA | Bakelite |

| #715 | 150 | 4 | 111 | C1Mr-3 * | 18 | 1.34 | Finned | Graphite |

| #719 | 200 | 4 | 111 | C1Mr-5 * | 18 | 1.29 | Finned | Graphite |

| 3.2. Firing Tests Varying Burn Time | ||||||||

| #711 | 80 | 10 | 91.4 | C1Mr-1 * | 18 | - | PMMA | Bakelite |

| #714 | 80 | 13 | 91.4 | C1Mr-2 * | 18 | - | PMMA | Graphite |

| #717 | 80 | 16 | 91.4 | C1Mr-4 * | 18 | - | PMMA | Graphite |

| Exp. No. | F | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (g/s) | (g/s) | (mm) | (kg/(m2s)) | (s) | (-) | (MPa) | (N) | (mm/s) | (-) | |

| #688 | 48.9 ± 0.6 | 11.3 | 53.46 | 28.5 ± 2.4 | 3.78 | 0.77 | 0.775 | 84 | 1.77 ± 0.08 | 0.97 |

| #690 | 77.8 ± 1.0 | 34.1 | 57.03 | 42.1 ± 3.4 | 3.78 | 1.46 | 1.524 | 176 | 2.26 ± 0.10 | 0.99 |

| #698 | 107.9 ± 1.3 | Grain separation | – | – | – | – | – | – | – | |

| #701 | 107.0 ± 1.3 | 53.8 | 64.10 | 50.3 ± 3.8 | 3.64 | 1.67 | 0.977 | 229 | 3.32 ± 0.13 | 1.07 |

| #704 | 140.8 ± 1.8 | Grain separation | – | – | – | – | – | – | – | |

| #707 | 111.9 ± 1.4 | Grain separation | – | – | – | – | – | – | – | |

| #715 | 140.3 ± 1.8 | 62.8 | 68.58 | 62.8 ± 4.6 | 3.63 | 1.49 | 1.274 | 281 | 3.93 ± 0.15 | 1.04 |

| #719 | 190.3 ± 2.4 | 82.8 | 75.69 | 72.4 ± 5.1 | 3.66 | 1.45 | 1.698 | 425 | 4.88 ± 0.18 | 1.11 |

| Exp. No. | L | |||

|---|---|---|---|---|

| (g/s) | (Pa·s) | (mm) | (mm) | |

| #688 | 48.9 ± 0.6 | 2.015 × 10−5 | 76.8 | 50 |

| #690 | 77.8 ± 1.0 | 2.031 × 10−5 | 86.1 | 111 |

| #701 | 107.0 ± 1.3 | 2.020 × 10−5 | 93.4 | 111 |

| #715 | 140.3 ± 1.8 | 2.026 × 10−5 | 99.9 | 111 |

| #719 | 190.3 ± 2.4 | 2.034 × 10−5 | 107.7 | 111 |

| Exp. No. | F | Tc,th | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| [g/s] | [g/s] | [mm] | [kg/(m2s)] | [s] | [-] | [MPa] | [N] | [mm/s] | [-] | [K] | |

| #711 | 75.2 ± 0.9 | 38.4 | 86.59 | 23.9 ± 1.6 | 9.82 | 1.70 | 0.787 | 188 | 2.37 ± 0.08 | 1.24 | 2223 |

| #714 | 82.8 ± 1.0 | 33.1 | 91.19 | 24.5 ± 1.6 | 12.95 | 1.33 | 0.739 | 183 | 1.98 ± 0.06 | 1.02 | 3006 |

| #717 | 82.5 ± 1.0 | 32.7 | 97.88 | 22.1 ± 1.4 | 15.59 | 1.32 | 0.750 | 199 | 1.86 ± 0.06 | 1.04 | 3018 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oishi, T.; Tamari, M.; Sakurai, T. Experimental Investigation of a Swirling-Oxidizer-Flow-Type Hybrid Rocket Engine Using Low-Melting-Point Thermoplastic Fuel and Oxygen. Aerospace 2023, 10, 713. https://doi.org/10.3390/aerospace10080713

Oishi T, Tamari M, Sakurai T. Experimental Investigation of a Swirling-Oxidizer-Flow-Type Hybrid Rocket Engine Using Low-Melting-Point Thermoplastic Fuel and Oxygen. Aerospace. 2023; 10(8):713. https://doi.org/10.3390/aerospace10080713

Chicago/Turabian StyleOishi, Tsuyoshi, Mitsuru Tamari, and Takashi Sakurai. 2023. "Experimental Investigation of a Swirling-Oxidizer-Flow-Type Hybrid Rocket Engine Using Low-Melting-Point Thermoplastic Fuel and Oxygen" Aerospace 10, no. 8: 713. https://doi.org/10.3390/aerospace10080713

APA StyleOishi, T., Tamari, M., & Sakurai, T. (2023). Experimental Investigation of a Swirling-Oxidizer-Flow-Type Hybrid Rocket Engine Using Low-Melting-Point Thermoplastic Fuel and Oxygen. Aerospace, 10(8), 713. https://doi.org/10.3390/aerospace10080713