Robust Flight Tether for In-Orbit Demonstrations of Coulomb Drag Propulsion

Abstract

:1. Introduction

1.1. Coulomb Drag and Propulsion

1.2. Electric Solar Wind Sail

1.3. Plasma Brake

1.4. In-Orbit Demonstrations with CubeSats

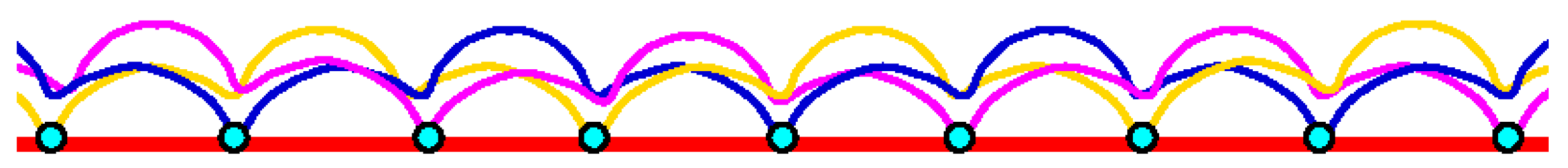

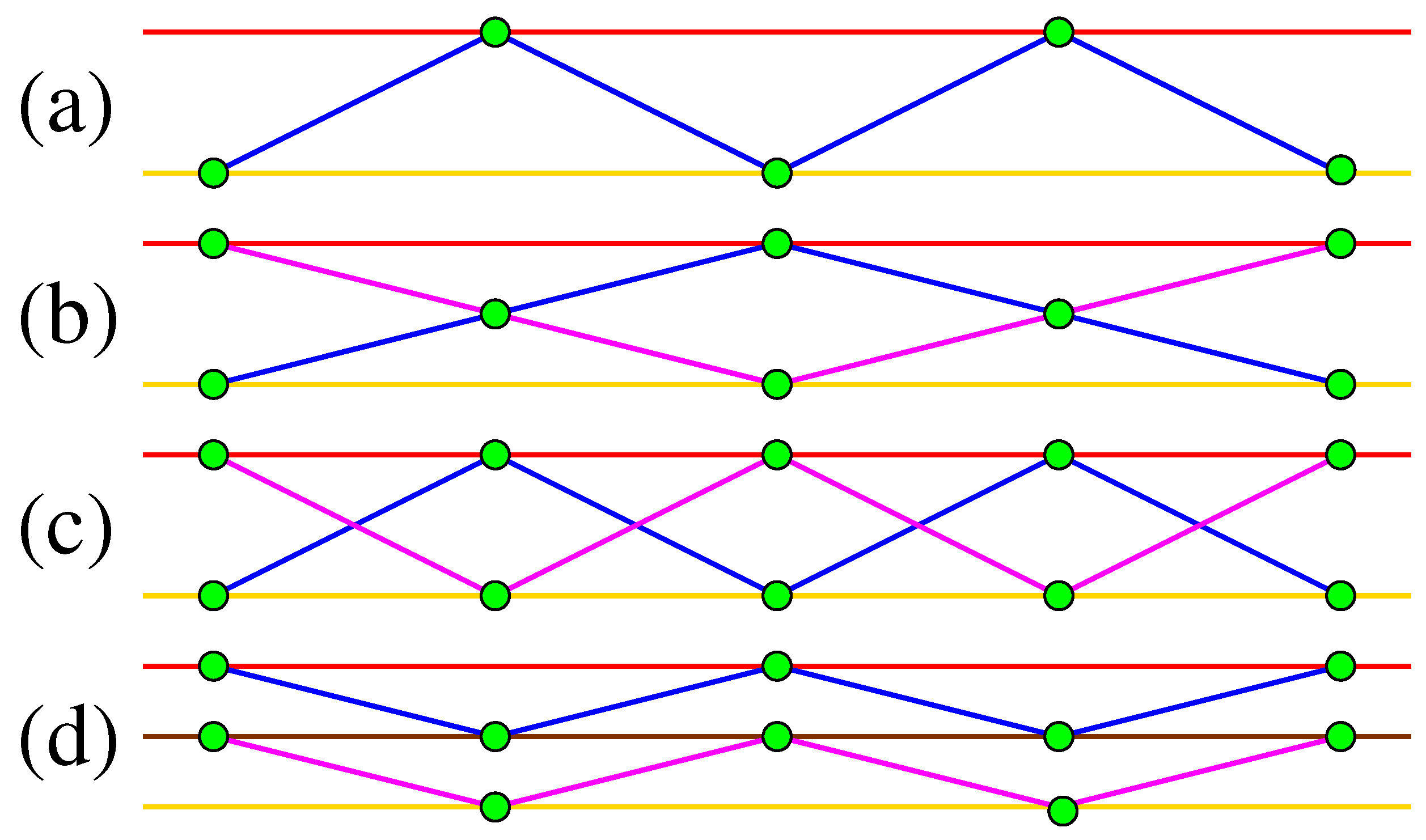

1.5. Tether Geometries and Bonding Methods

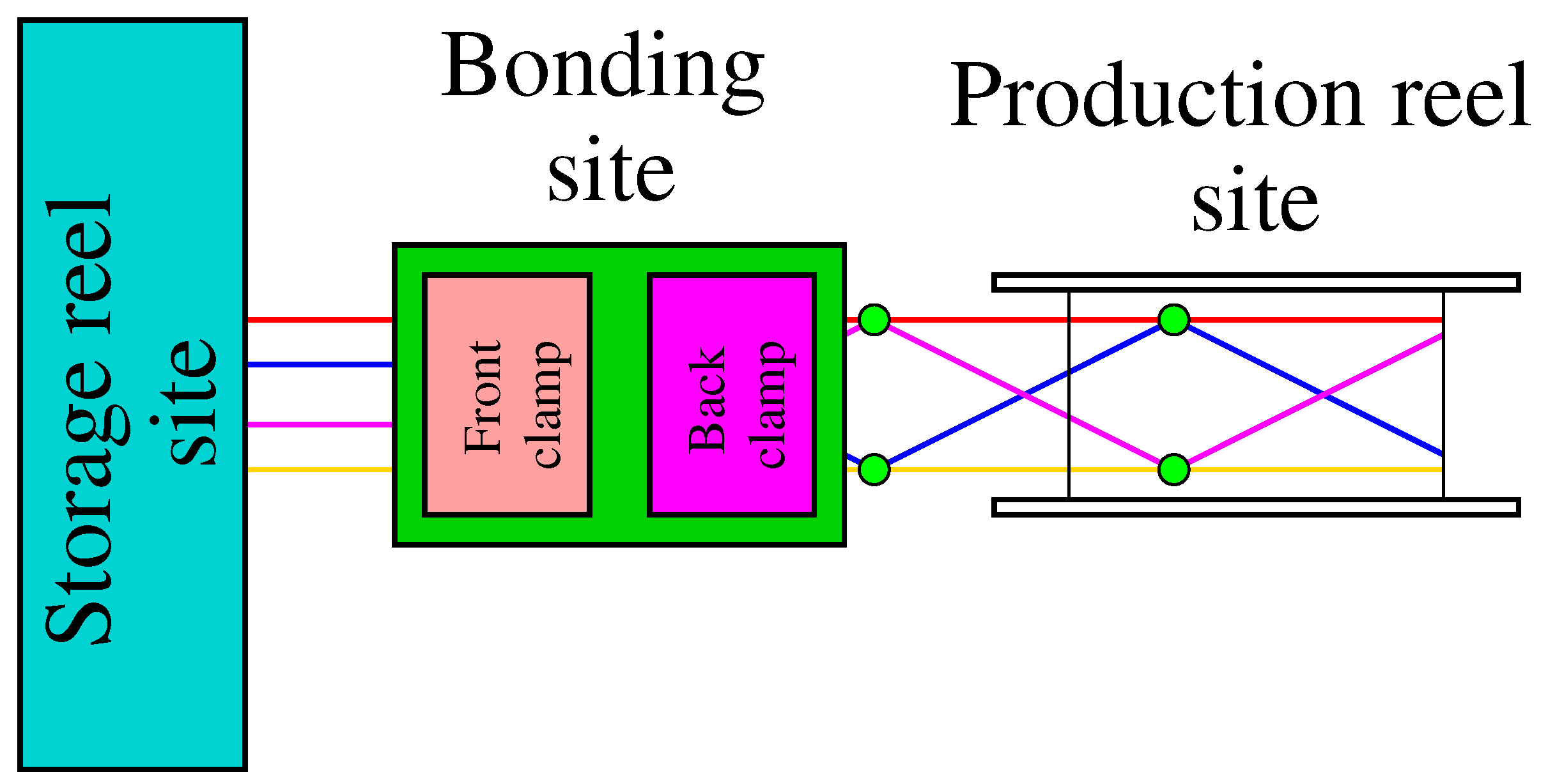

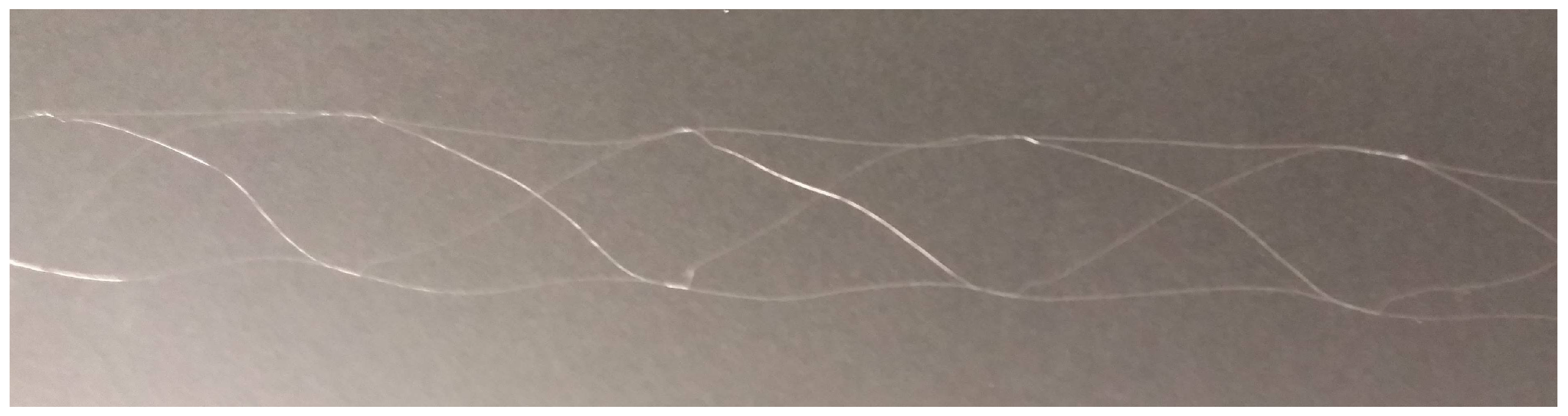

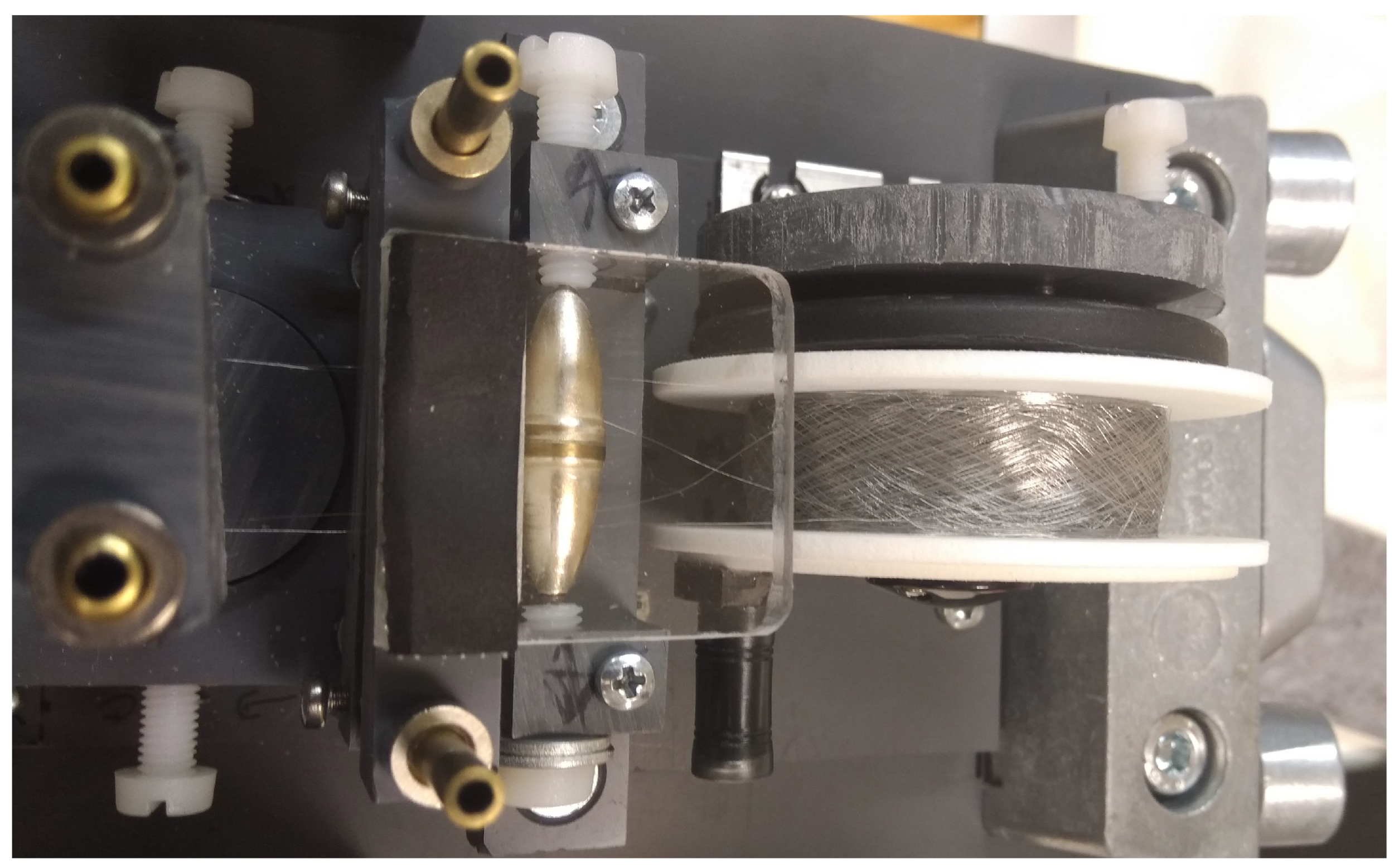

2. Tether Manufacturing

2.1. Wire Twisting

2.2. Bonding Process in General

2.3. Tether Geometries

3. Requirements and Implications

3.1. Space Environment

3.1.1. Redundancy for Micrometeoroids

3.2. Coulomb Drag Payload Integration and Flight Operations

3.2.1. Payload Integration

3.2.2. Deployment and Flight Dynamics

3.2.3. Electrical Power Consumption

3.3. Tether Manufacturing

3.3.1. Manual Mode

3.3.2. Tether Machine Parameters for Calibration

4. Results: Tether Type Selection, Testing, and Production

4.1. Tether Type Selection

4.2. Testing of the Produced Tether

4.2.1. Destructive Tests

4.2.2. Tether Production Tests

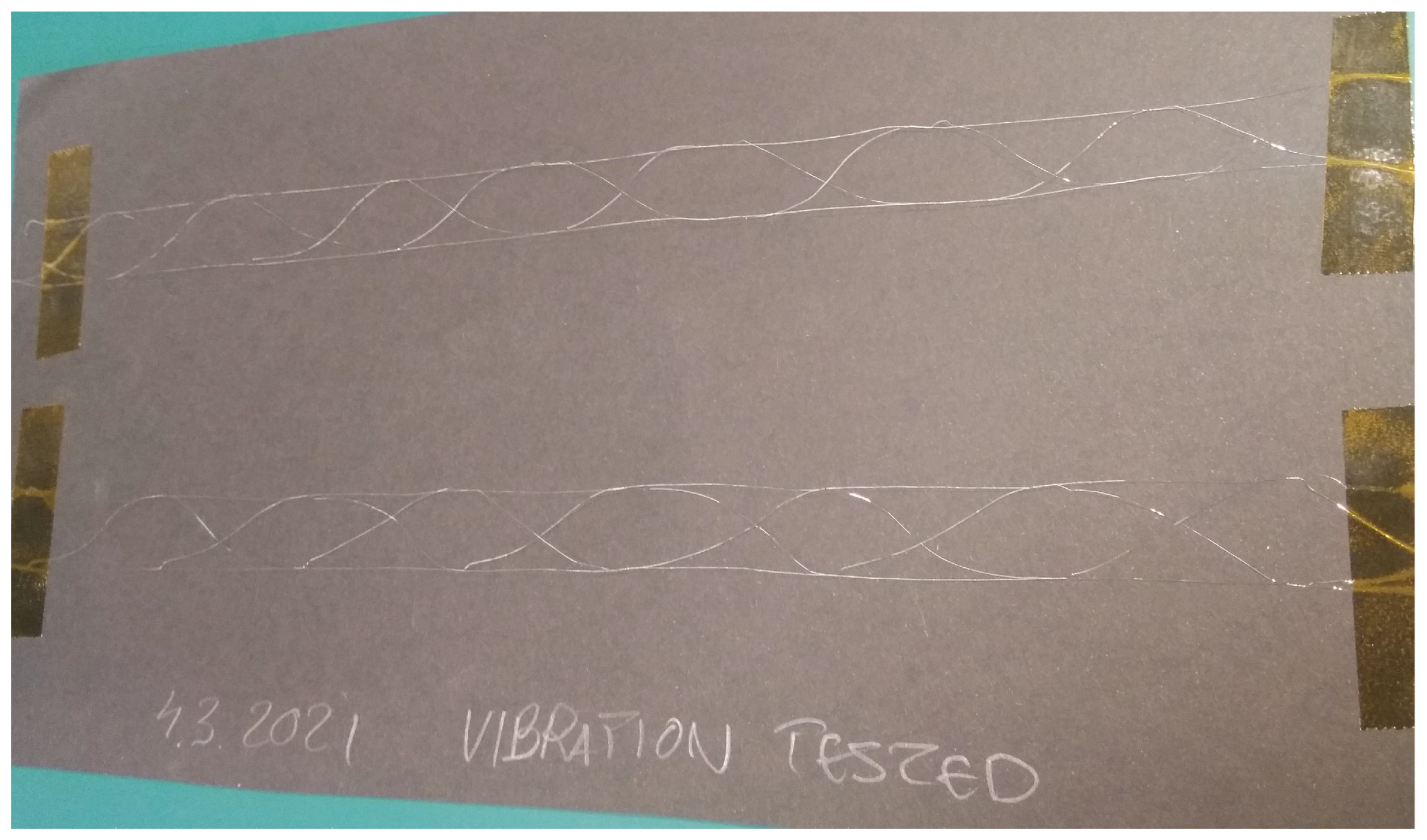

4.2.3. Vibration Test

4.2.4. Deployment Pull-Strength Tests

4.3. Production Reliability

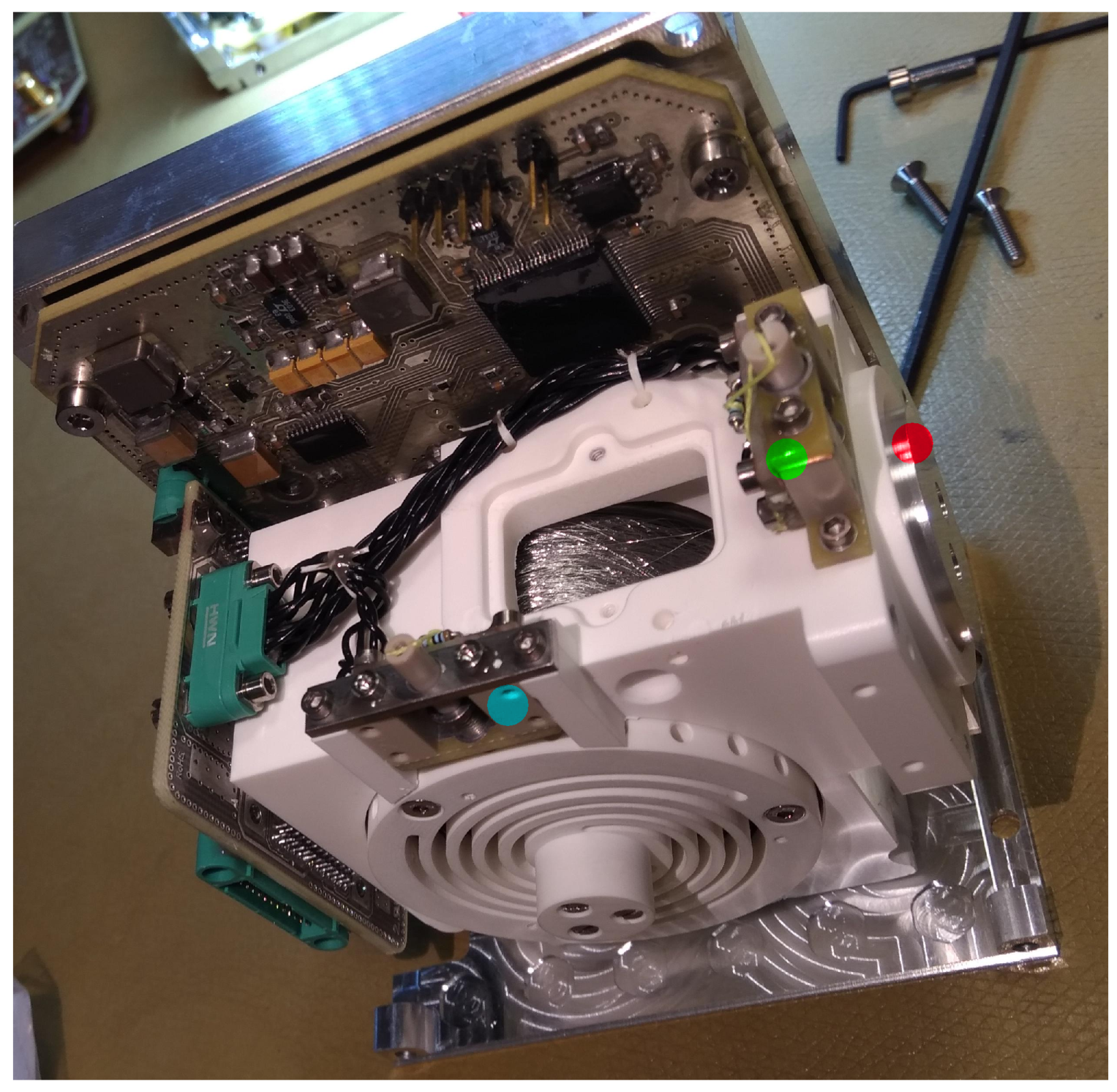

4.4. Payload Integration

4.5. Interfaces between Spacecraft

4.5.1. Mechanical Interface

4.5.2. Electrical Interface

5. Conclusions

5.1. Summary

5.2. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ESA | European Space Agency |

| LEO | Low-Earth Orbit |

References

- Janhunen, P. Electric sail for spacecraft propulsion. J. Propuls. Power 2004, 20, 763–764. [Google Scholar] [CrossRef]

- Janhunen, P. Simulation study of solar wind push on a charged wire: Basis of solar wind electric sail propulsion. Ann. Geophys. 2007, 25, 755–767. [Google Scholar] [CrossRef]

- Janhunen, P. On the feasibility of a negative polarity electric sail. Ann. Geophys. 2009, 27, 1439–1447. [Google Scholar] [CrossRef]

- Sanmartin, J.R.; Choiniere, E.; Gilchrist, B.E.; Ferry, J.-B.; Martinez-Sanchez, M. Bare-tether sheath and current: Comparison of asymtotic theory and kinetic simulations in stationary plasma. IEEE Trans. Plasma Phys. 2008, 36, 2851–2858. [Google Scholar] [CrossRef]

- Janhunen, P. Electrostatic plasma brake for deorbiting a satellite. J. Propuls. Power 2010, 26, 370–372. [Google Scholar] [CrossRef]

- Janhunen, P. The electric sail—A new propulsion method which may enable fast missions to the outer solar system. J. Br. Interplanet. Soc. 2008, 61, 322–325. [Google Scholar]

- Janhunen, P. Increased electric sail thrust through removal of trapped shielding electrons by orbit chaotisation due to spacecraft body. Ann. Geophys. 2009, 27, 3089–3100. [Google Scholar] [CrossRef]

- Mengali, G.; Quarta, A.; Janhunen, P. Electric sail performance analysis. J. Spacecr. Rocket. 2008, 45, 122–129. [Google Scholar] [CrossRef]

- Toivanen, P.; Janhunen, P. Spin plane control and thrust vectoring of electric solar wind sail by tether potential modulation. J. Propuls. Power 2013, 29, 178–185. [Google Scholar] [CrossRef]

- Toivanen, P.; Janhunen, P. Thrust vectoring of an electric solar wind sail with a realistic sail shape. Acta Astronaut. 2017, 131, 145–151. [Google Scholar] [CrossRef]

- Mengali, G.; Quarta, A. Non-Keplerian orbits for electric sails. Celest. Mech. Dyn. Astron. 2009, 109, 179–195. [Google Scholar] [CrossRef]

- Quarta, A.; Mengali, G. Electric sail mission analysis for outer solar system exploration. J. Guid. Control. Dyn. 2009, 27, 740–755. [Google Scholar] [CrossRef]

- Quarta, A.; Mengali, G. Electric sail missions to potentially hazardous asteroids. Acta Astronaut. 2010, 66, 1506–1519. [Google Scholar] [CrossRef]

- Merikallio, S.; Janhunen, P. Moving an asteroid with electric solar wind sail. Astrophys. Space Sci. Trans. 2010, 6, 41–48. [Google Scholar] [CrossRef]

- Quarta, A.; Mengali, G.; Janhunen, P. Electric sail for near-Earth asteroid sample return mission: Case 1998 KY26. J. Aerospace Eng. 2014, 27, 04014031-1–04014031-9. [Google Scholar] [CrossRef]

- Quarta, A.; Mengali, G.; Januhen, P. Electric sail option for cometary rendezvous. Acta Astronaut. 2016, 127, 684–692. [Google Scholar] [CrossRef]

- Slavinskis, A.; Janhunen, P.; Toivanen, P.; Muinonen, K.; Penttilä, A.; Granvik, M.; Kohout, T.; Gritsevich, M.; Pajusalu, M.; Sünter, I.; et al. Nanospacecraft fleet for multi-asteroid touring with electric solar wind sails. In Proceedings of the 2018 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2018. [Google Scholar]

- Janhunen, P.; Toivanen, P.; Envall, J. Electrostatic Tether Plasma Brake, ESA CleanSat Building Block 15 (BB15) Final Report, ESA CleanSat Project, 18 January 2017. Available online: https://www.electric-sailing.fi/papers/BB15-LSIversion-with-execsum.pdf (accessed on 31 October 2023).

- Iakubivskyi, I.; Janhunen, P.; Praks, J.; Allik, V.; Bussov, K.; Clayhills, B.; Dalbins, J.; Eenmäe, T.; Ehrpais, H.; Envall, J.; et al. Coulomb drag propulsion experiment of ESTCube-2 and FORESAIL-1. Acta Astronaut. 2020, 177, 771–783. [Google Scholar] [CrossRef]

- Lätt, S.; Slavinskis, A.; Ilbis, E.; Kvell, U.; Voormansik, K.; Kulu, E.; Pajusalu, M.; Kuuste, H.; Sünter, I.; Eenmäe, T.; et al. ESTCube-1 nanosatellite for electric solar wind sail in-orbit technology demonstration. Proc. Est. Acad. Sci. 2014, 63, 200–209. [Google Scholar] [CrossRef]

- Praks, J.; Rizwan Mughal, M.; Vainio, R.; Janhunen, P.; Envall, J.; Oleynik, P.; Näsilä, A.; Leppinen, H.; Niemelä, P.; Slavinskis, A.; et al. Aalto-1, multi-payload CubeSat: Design, integration and launch. Acta Astronaut. 2021, 187, 370–383. [Google Scholar] [CrossRef]

- Slavinskis, A.; Pajusalu, M.; Kuuste, H.; Ilbis, E.; Eenmäe, T.; Sünter, I.; Laizans, K.; Ehrpais, H.; Liias, P.; Kulu, E.; et al. ESTCube-1 in-orbit experience and lessons learned. IEEE Aerosp. Electron. Syst. Mag. 2015, 30, 13–22. [Google Scholar] [CrossRef]

- Rizwan Mughal, M.; Praks, J.; Vainio, R.; Janhunen, P.; Envall, J.; Näsilä, A.; Oleynik, P.; Niemelä, P.; Slavinskis, A.; Gieseler, J.; et al. Aalto-1 multi-payload CubeSat: In-orbit results and lessons learned. Acta Astronaut. 2021, 187, 557–568. [Google Scholar] [CrossRef]

- Hoyt, R.P.; Forward, R.L. Alternate Interconnection Hoytether Failure Resistant Multiline Tether. U.S. Patent No. 6286788, 11 September 2001. [Google Scholar]

- Seppänen, H.; Kiprich, S.; Kurppa, R.; Janhunen, P.; Hæggström, E. Wire-to-wire bonding of μ-diameter aluminum wires for the Electric Solar Wind Sail. Microelectron. Eng. 2011, 88, 3267–3269. [Google Scholar] [CrossRef]

- Seppänen, H.; Rauhala, T.; Kiprich, S.; Ukkonen, J.; Simonsson, M.; Kurppa, R.; Janhunen, P.; Hæggström, E. One kilometer (1 km) electric solar wind sail tether produced automatically. Rev. Sci. Instrum. 2013, 84, 095102. [Google Scholar] [CrossRef]

- Rauhala, T.; Seppänen, H.; Ukkonen, J.; Kiprich, S.; Maconi, G.; Janhunen, P.; Hæggström, E. Automatic 4-wire Heytether production for the electric solar wind sail. In Proceedings of the International Microelectronics Assembly and Packing Society Topical Workshop and Tabletop Exhibition on Wire Bonding, San Jose, CA, USA, 22–23 January 2013. [Google Scholar]

- Envall, J.; Toivanen, P.; Janhunen, P. Thin multi-wire Coulomb drag tether by diffusive bonding. In Proceedings of the Sixth International Conference of Tethers in Space, Madrid, Spain, 12–14 June 2019. [Google Scholar]

- Meteoroid and Debris Models—SPENVIS. Available online: https://www.spenvis.oma.be/help/background/metdeb/metdeb.html (accessed on 1 November 2023).

| Overall Environmental and Technical Drivers | Key Drivers for Tether Requirements | Tether Requirements | Key Drivers for Machine Design | Machine Requirements |

|---|---|---|---|---|

| Space environment (Section 3.1) | micrometeoroids (Section 3.1.1) | Number of wires | Number of wire storage reels | Size of the storage reel site |

| Tether width | Clamp dimensions | Size of the bonding site | ||

| 3-dimensionality | Tether geometry | Compliance with geometry | ||

| Thermal vacuum, atomic oxygen, ion sputtering, etc. | Any metallic alloy | Twist bonding | Twisting symmetry | |

| Carbon fibres, nano tubes, etc. | Not considered | Not considered | ||

| Coulomb drag payload integration and operations (Section 3.2) | Reel-to-reel rewinding (Section 3.2.1) | Suitable tether geometry | Compliance with the geometry | Storage reel interchanging |

| Tether deployment and flight dynamics (Section 3.2.2) | No cut wires | Curvature radii of the storage reels, wire guides, and production reel dimensions | Spatial size of the related sites | |

| No reverse tether layer overlapping | ||||

| Non-curliness | ||||

| Electrical power consumption and mass of the power system (Section 3.2.3) | Wire diameter | Wire pull strength | Functioning under the tensile strength | |

| Wire guide curvature radii | Spatial size of the wire guiding sites | |||

| Positioning | Twisting symmetry | |||

| Ohmic conductivity | Metallic alloy | Bond firmness | ||

| Carbon fibres, nano tubes, etc. | Not considered | |||

| Tether manufacturing (Section 3.3) | Research, technology developlment, and proof of concept | Selection of the tether geometry | Manual mode (Section 3.3.1) | Calibration, tuning, readiness for automatising, adequate production speed for tether of tens of metres |

| Strength of single twist bond | ||||

| Collective tether strength | ||||

| Tolerance to wire cuts in process | ||||

| Tether quality assurance | Long tethers | Automatic mode (Section 5.2) | Diagnostics for interrupts | |

| Large number of tether samples |

| Parameter | Description | Expected Effect | Under the Optimum | Over the Optimum |

|---|---|---|---|---|

| Twisting angle | Angle defined by the distance between the front clamp and the wire dispenser nozzles | Defines the plastic deformation and strength of the twisted bond | Angle too small leads to loose twist bonds and tether collapse under the deployment tension | Angle too large leads to wire cuts in twist bonding |

| Wire dispenser reel friction | Passive friction that defines the pulling strength of the wires at the dispenser nozzles | Defines the strength of the twisted bond | Friction too low leads to a weak twist bond and narrowing of the tether wound to the production reel | Friction too large leads to wire cuts and narrowing of the tether wound to the production reel |

| Wire dispenser pointing and alignment | Dispenser nozzle placement with respect to the twisting rotation axis | Symmetry of the wire pair plastic deformation | Asymmetry weakens the twist bond and causes narrowing of the tether | Asymmetry weakens the twist bond and causes narrowing of the tether |

| Clamping strength | Press force inserted to the twist bond at the front clamp | Strength of the twisted bond | Press force too small leads to a weak bond and causes narrowing of the tether | Press force too large leads to wire cuts |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toivanen, P.; Janhunen, P.; Kivekäs, J.; Mäkelä, M. Robust Flight Tether for In-Orbit Demonstrations of Coulomb Drag Propulsion. Aerospace 2024, 11, 62. https://doi.org/10.3390/aerospace11010062

Toivanen P, Janhunen P, Kivekäs J, Mäkelä M. Robust Flight Tether for In-Orbit Demonstrations of Coulomb Drag Propulsion. Aerospace. 2024; 11(1):62. https://doi.org/10.3390/aerospace11010062

Chicago/Turabian StyleToivanen, Petri, Pekka Janhunen, Jarmo Kivekäs, and Meri Mäkelä. 2024. "Robust Flight Tether for In-Orbit Demonstrations of Coulomb Drag Propulsion" Aerospace 11, no. 1: 62. https://doi.org/10.3390/aerospace11010062

APA StyleToivanen, P., Janhunen, P., Kivekäs, J., & Mäkelä, M. (2024). Robust Flight Tether for In-Orbit Demonstrations of Coulomb Drag Propulsion. Aerospace, 11(1), 62. https://doi.org/10.3390/aerospace11010062