Evolution of Rotating Internal Channel for Heat Transfer Enhancement in a Gas Turbine Blade

Abstract

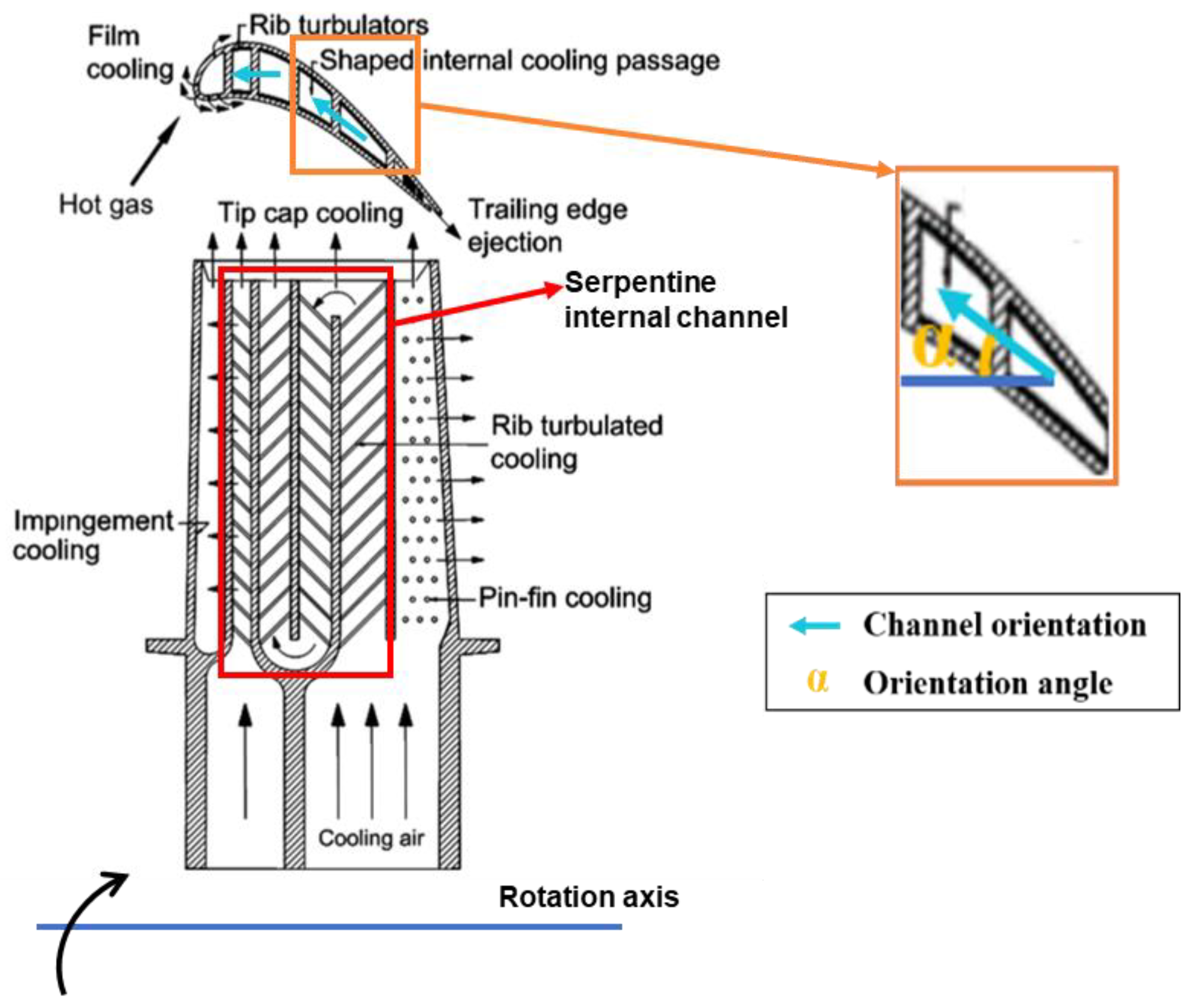

1. Introduction

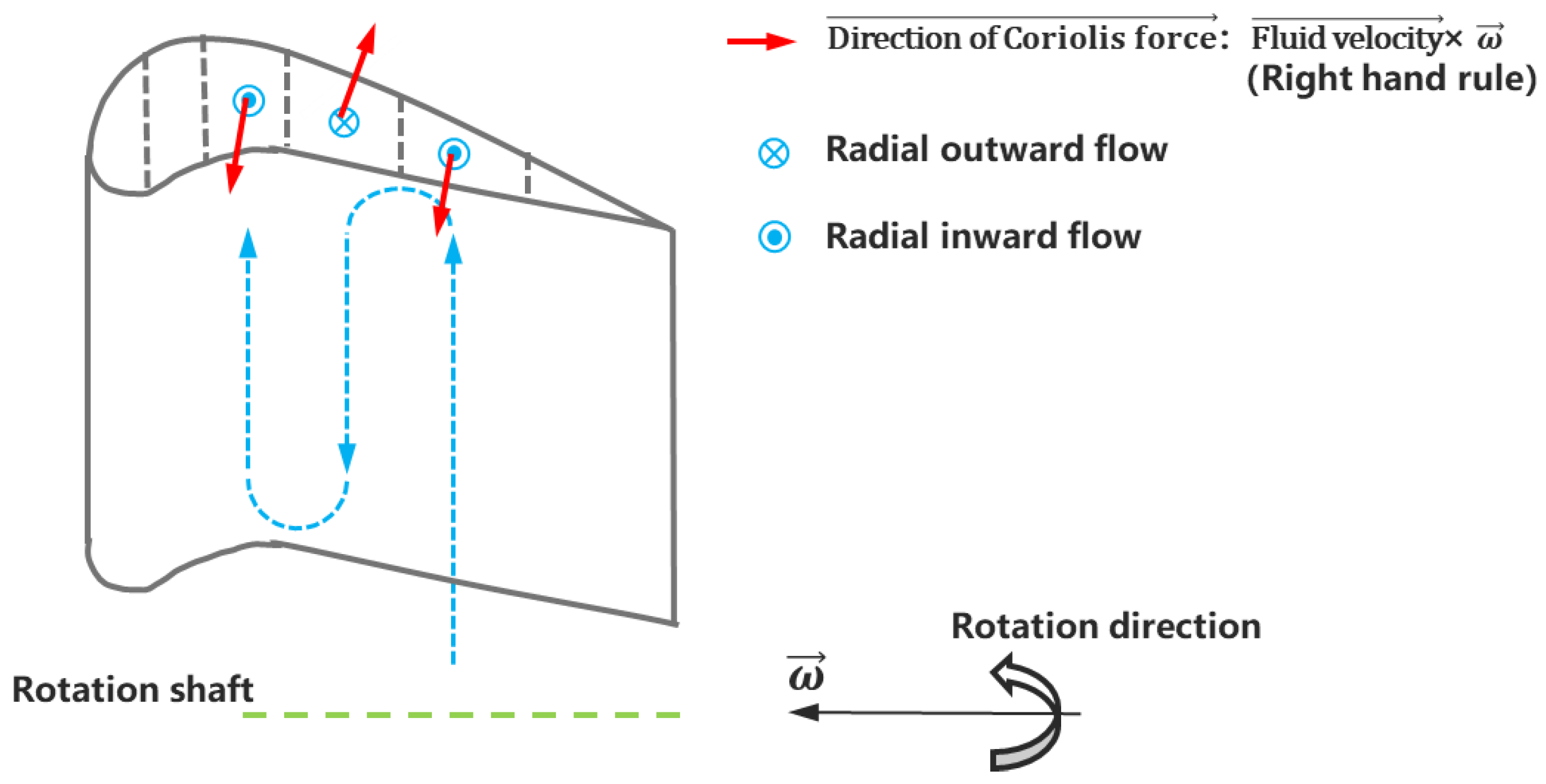

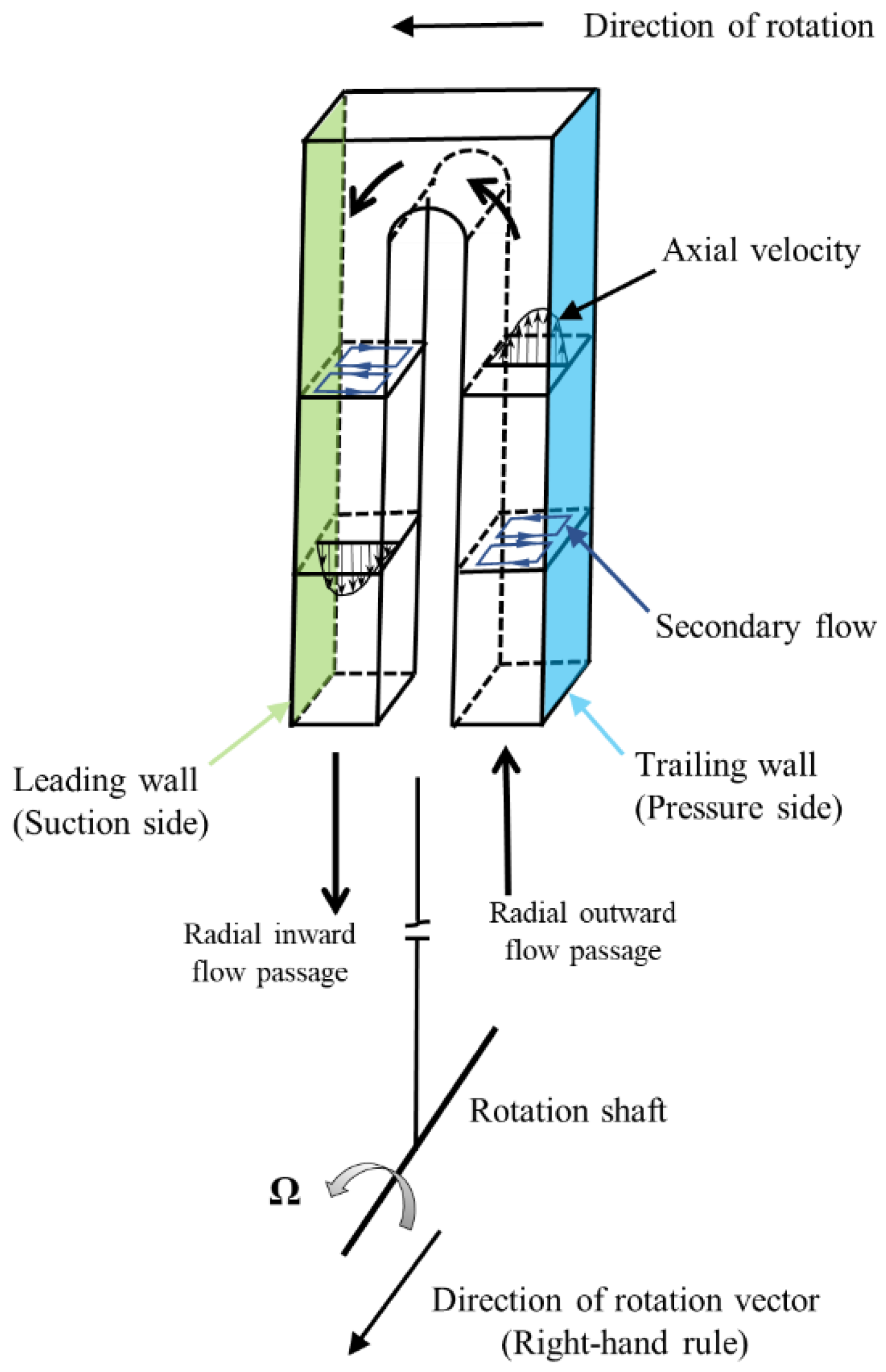

2. Influence of Coriolis Force

2.1. Mechanisms of Coriolis Force Effect on Heat Transfer

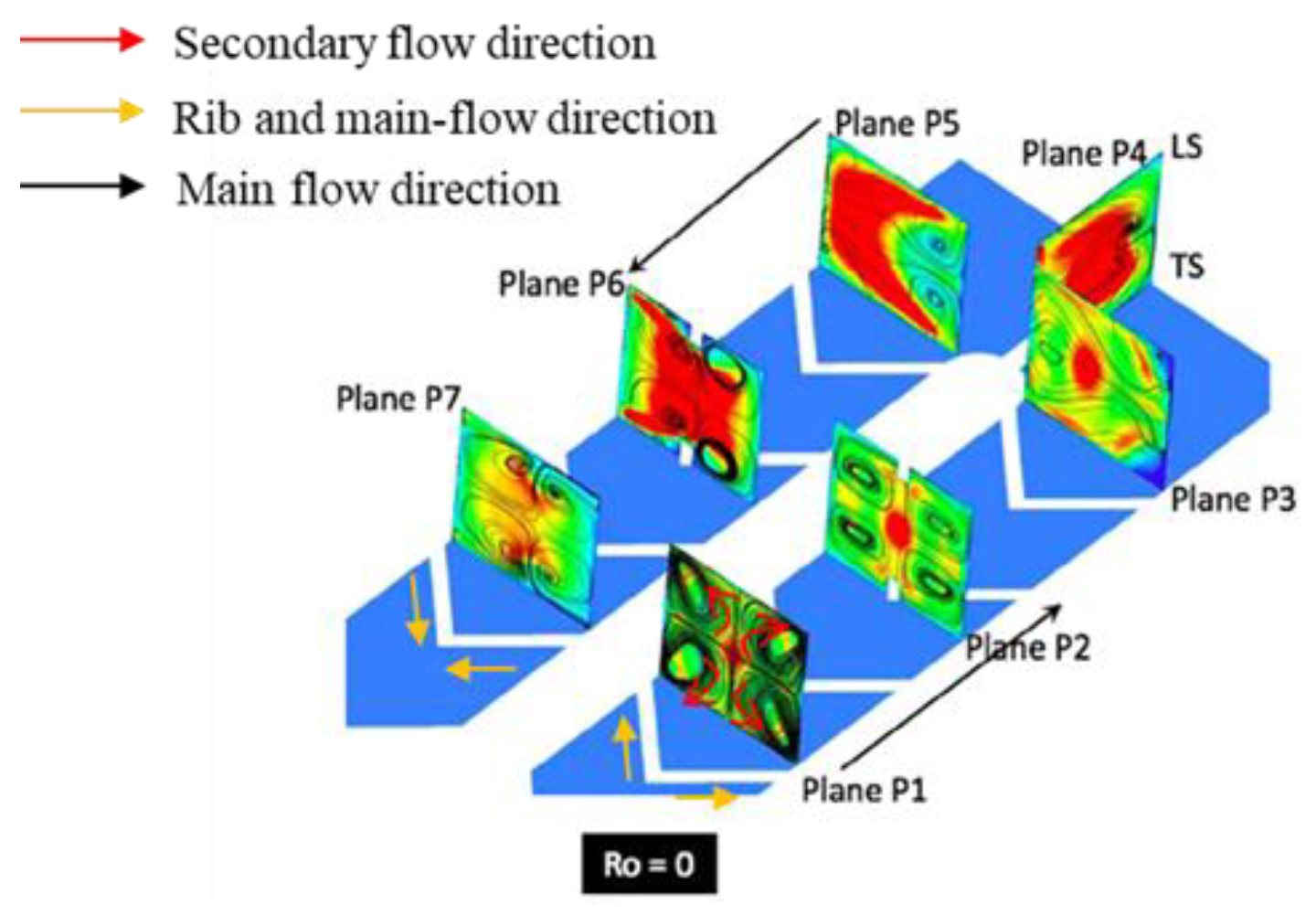

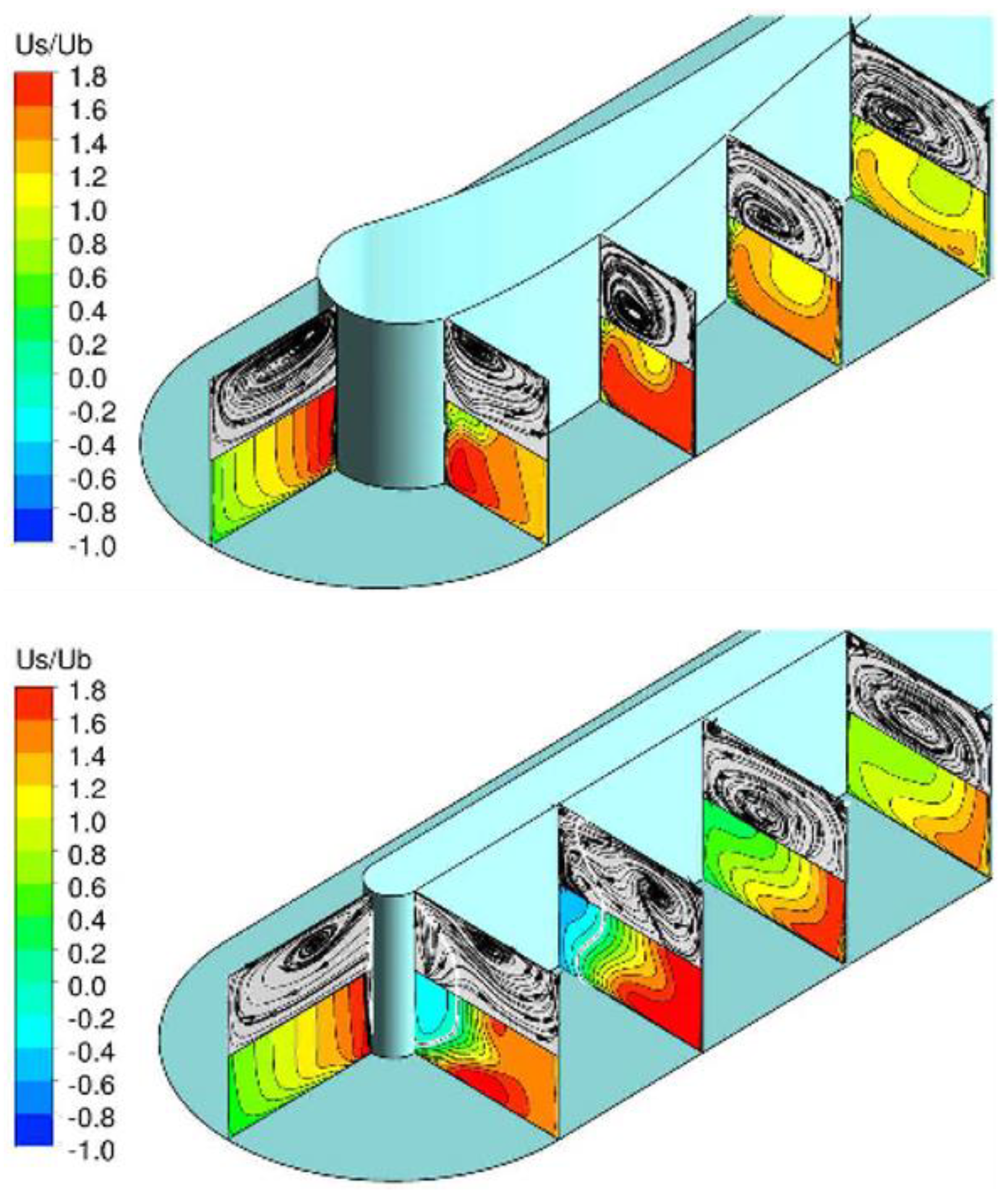

2.2. Interaction Mechanisms of Coriolis Force and Turbulators on Flow Pattern

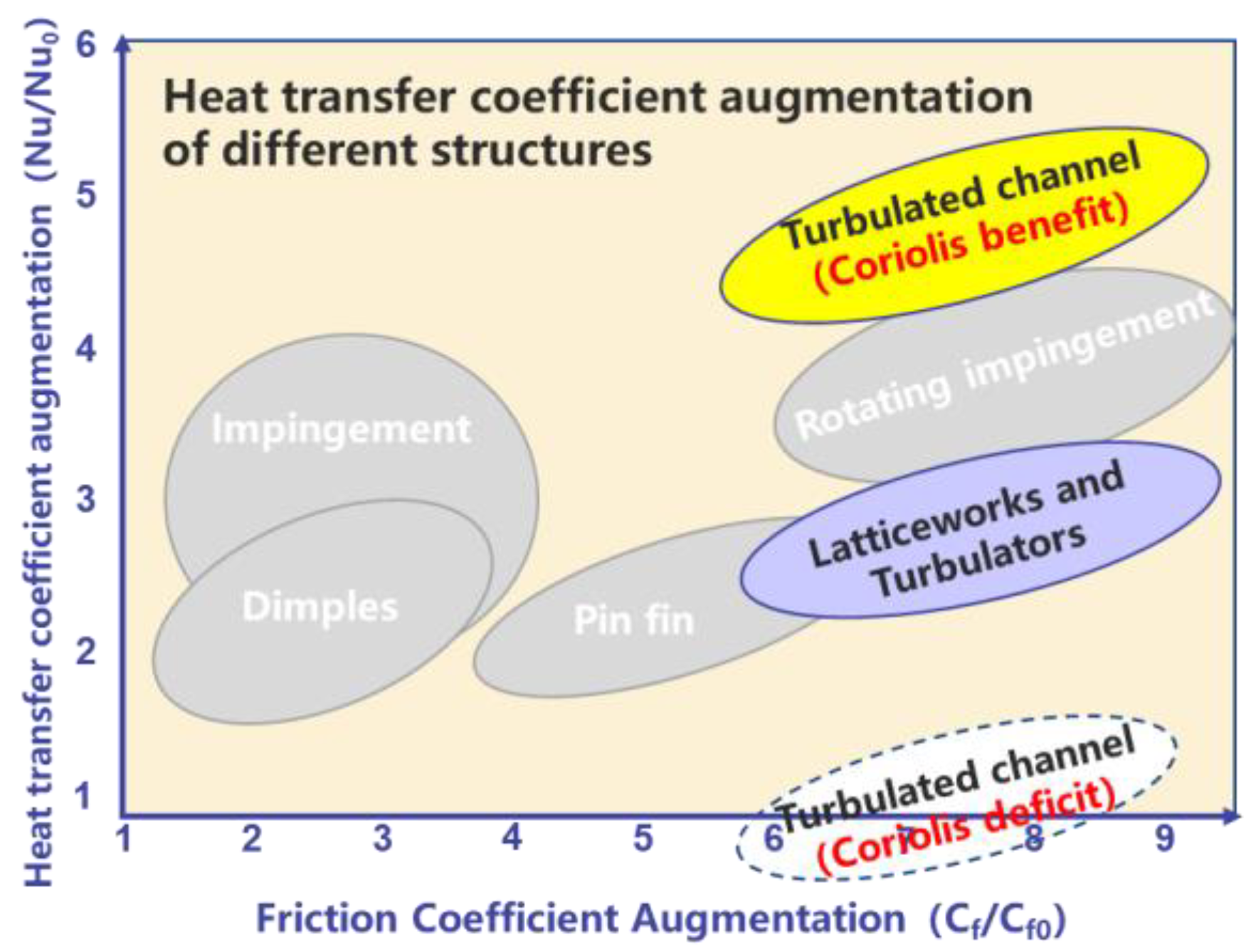

3. Utilization of Coriolis Force

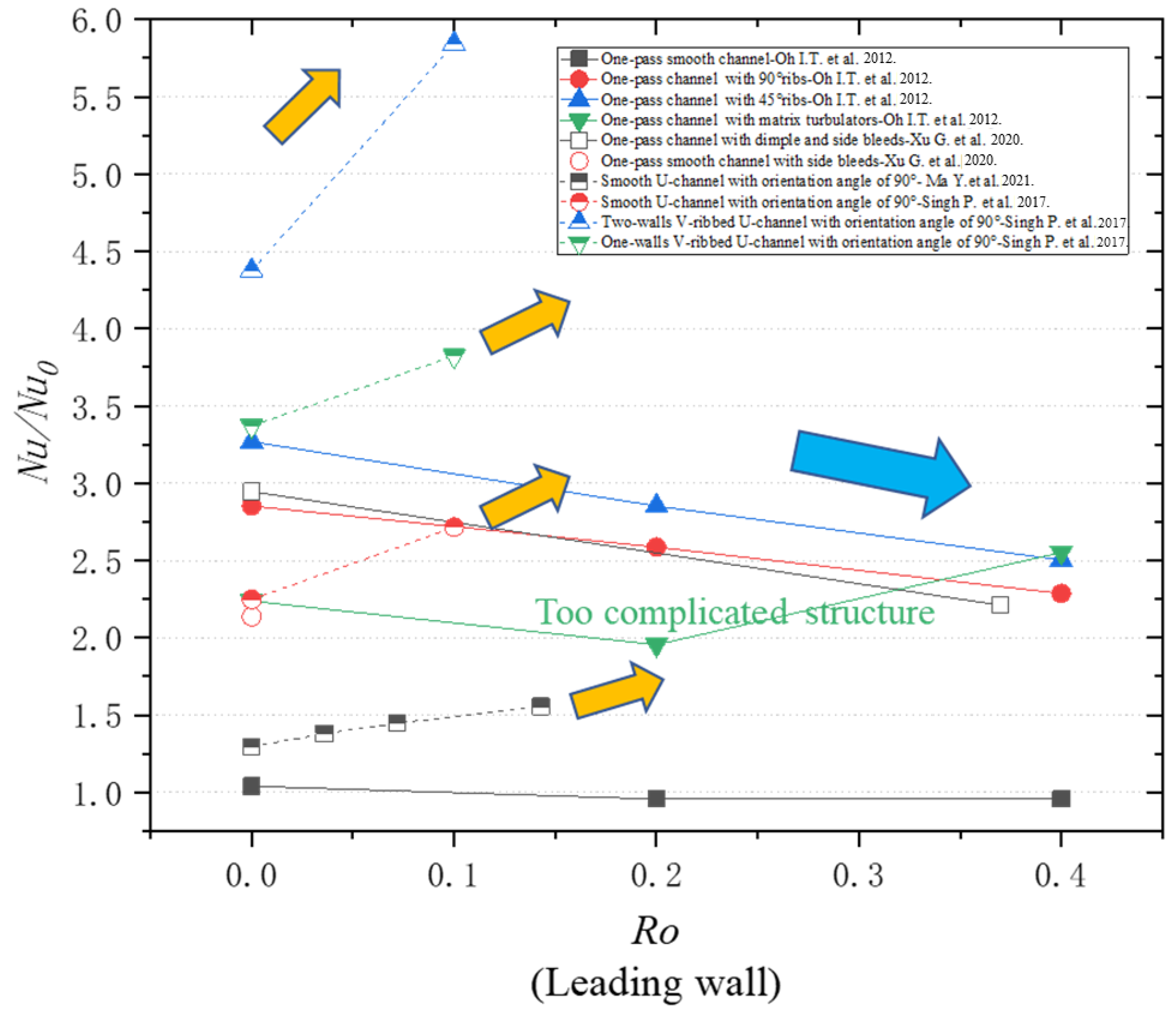

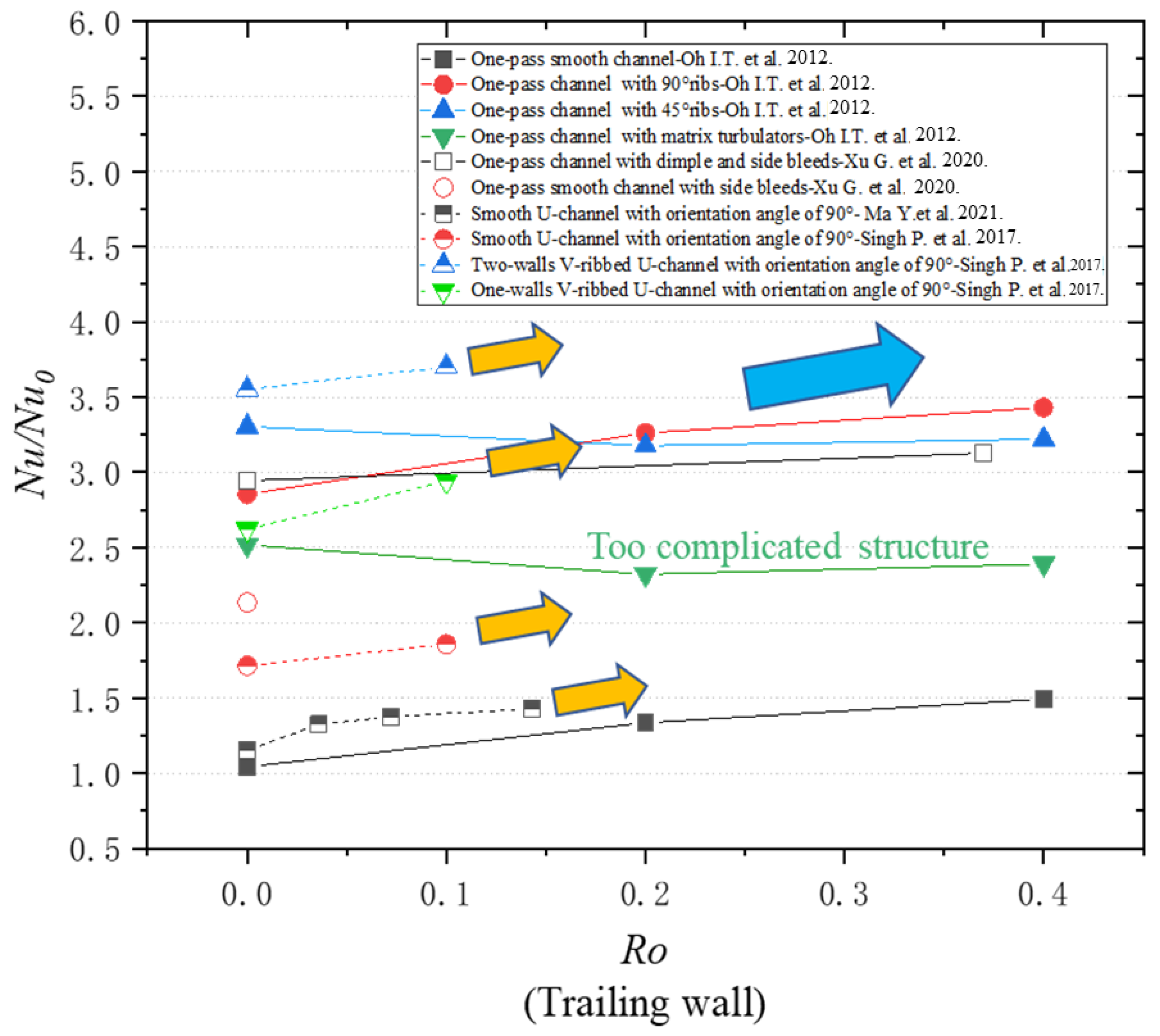

3.1. Weakening the Coriolis Force’s Negative Heat Transfer Effect

3.2. Utilizing the Coriolis Force’s Positive Heat Transfer Effect

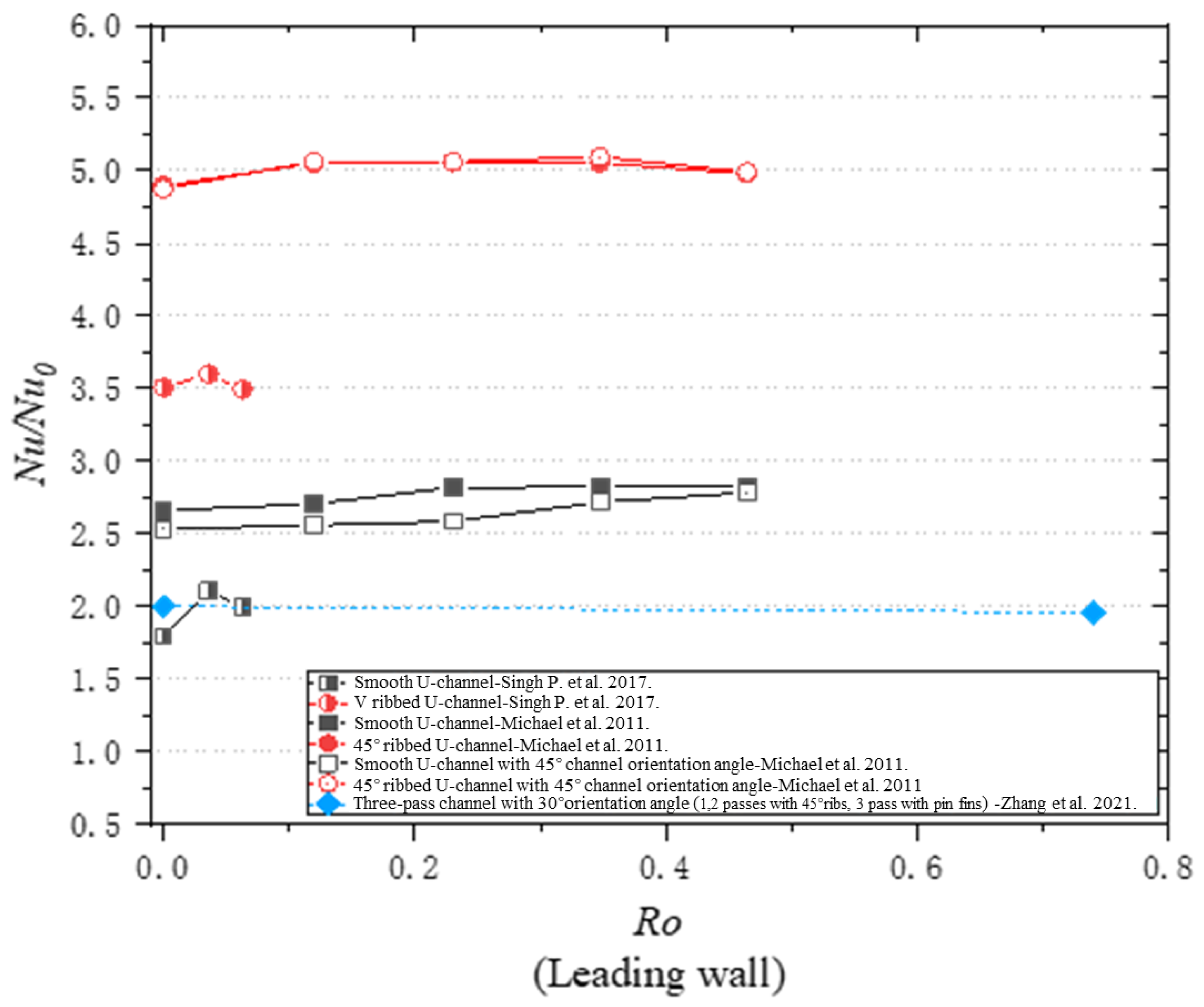

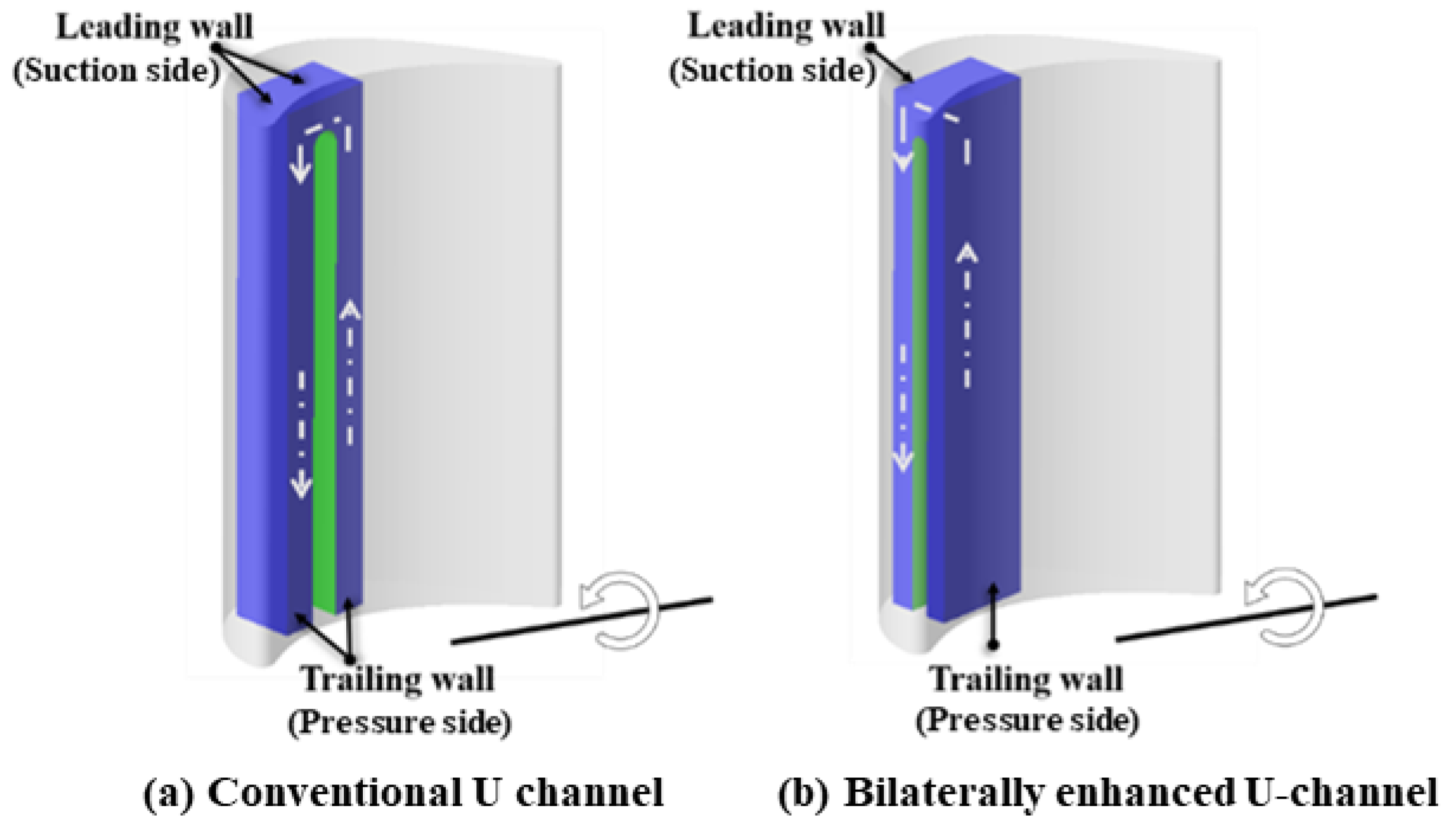

3.2.1. Principle of Heat Transfer Augmentation and Study State

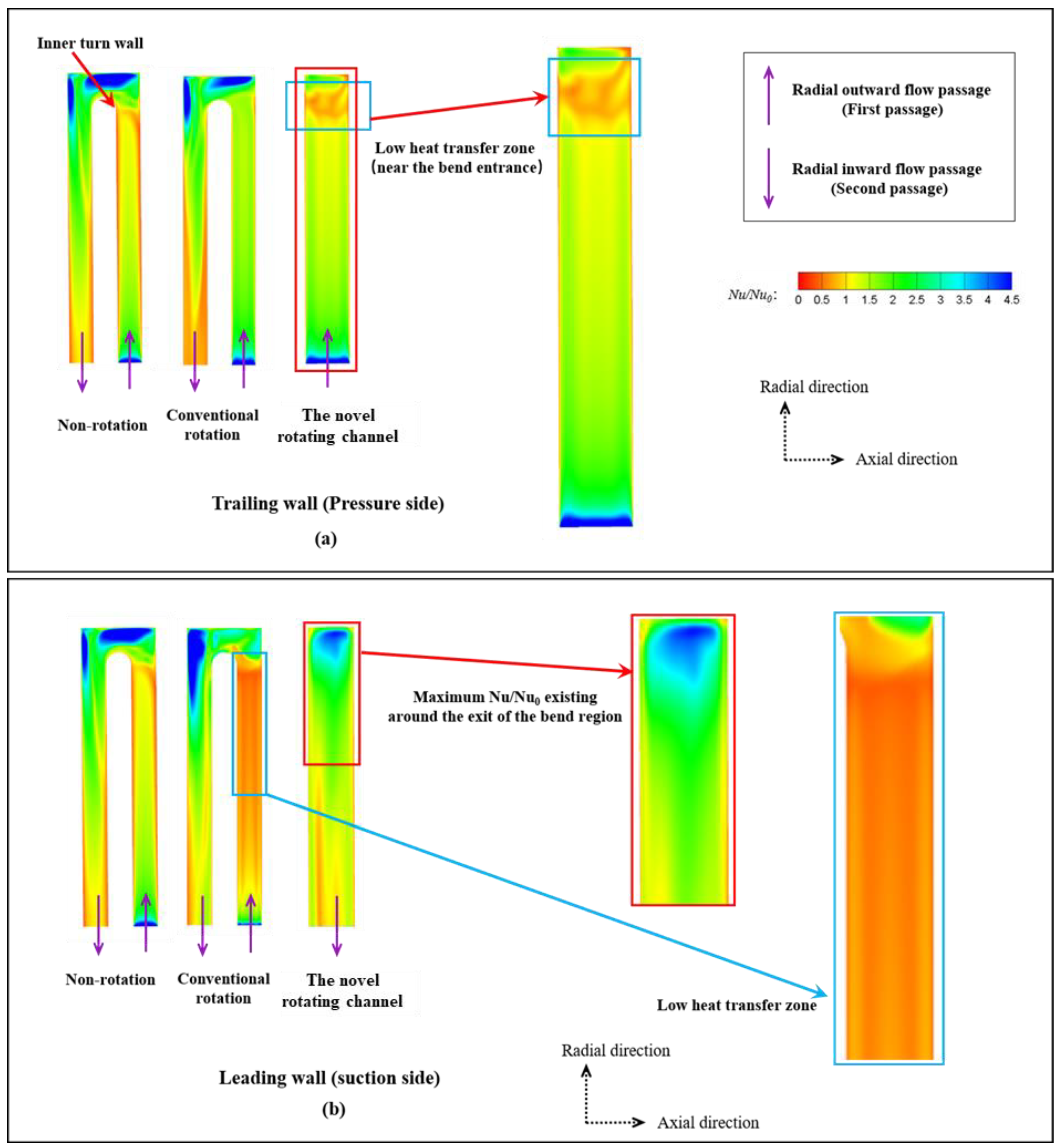

3.2.2. Heat Transfer Characteristics on Suction and Pressure Sides Compared with Conventional Rotating Channel

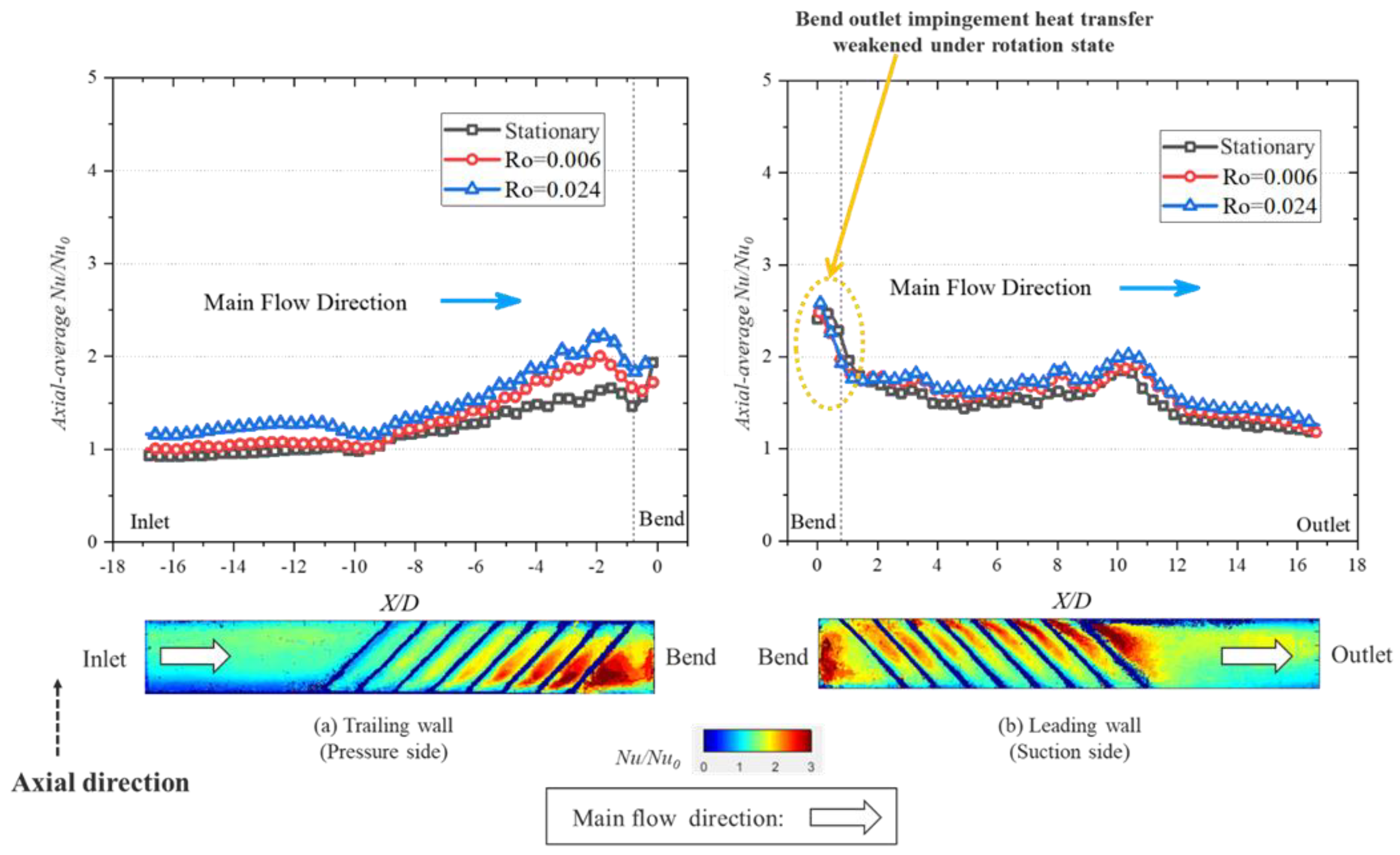

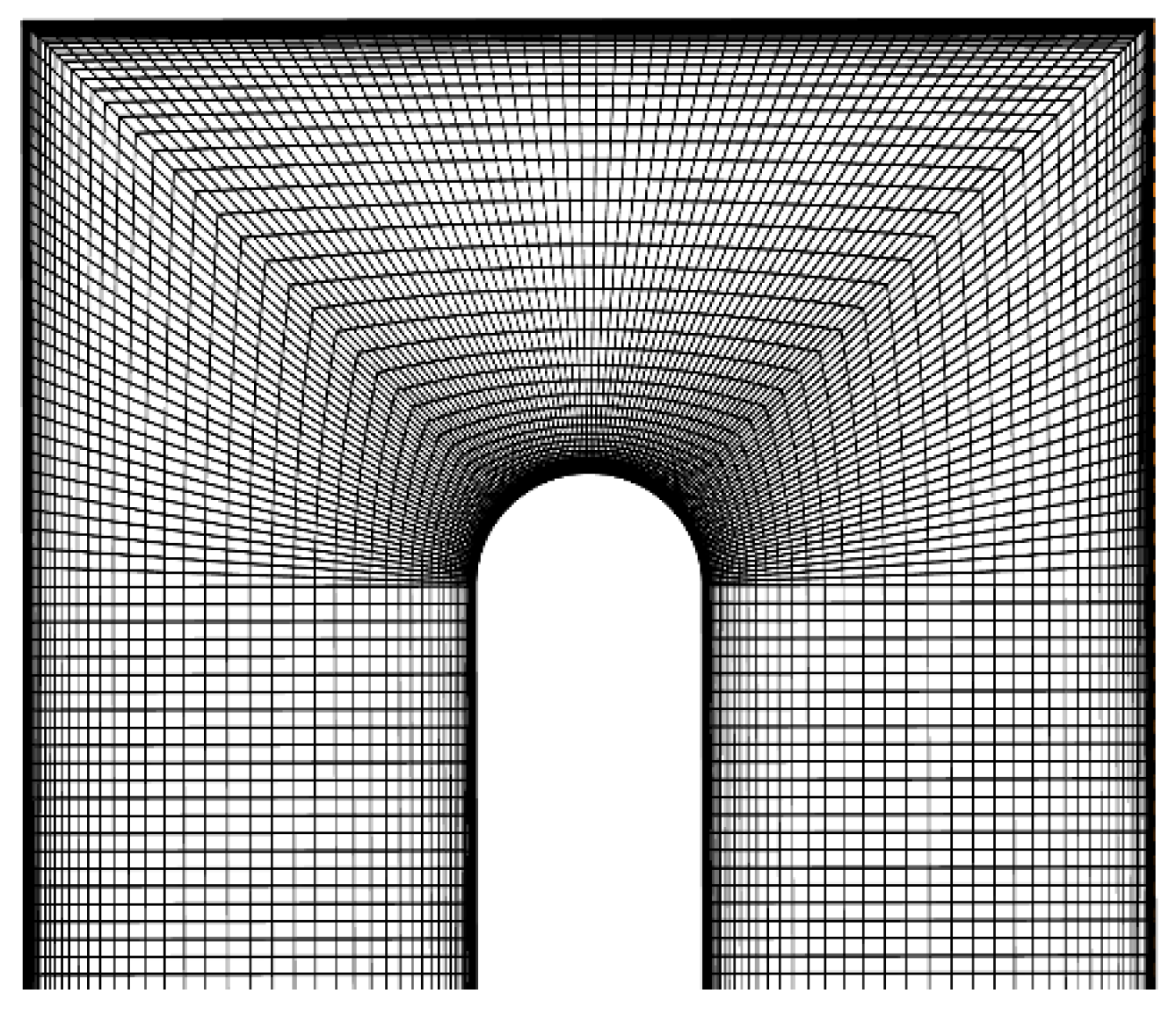

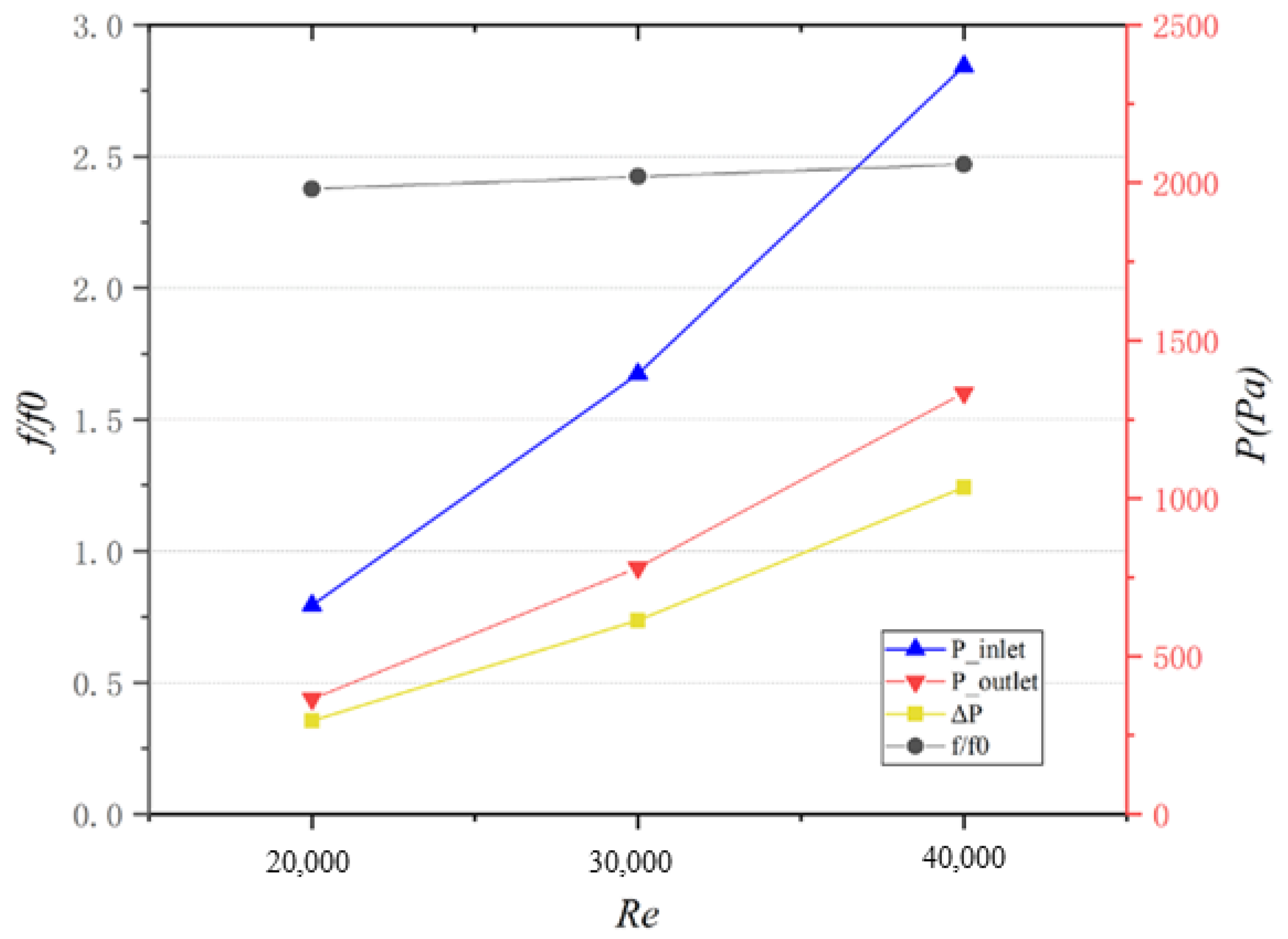

4. Reynolds Number Effect on Bilaterally Enhanced U-Channel

5. Conclusions

- For a conventional rotating channel, the trailing wall of the radial outward flow path and the leading wall of the radial inward flow path possess higher heat transfer performance, while the opposite walls perform lower heat transfer. This is because the leading or trailing wall with the Coriolis force pointing at it has Coriolis-induced secondary flow flushing and thus obtains heat transfer augmentation, but the opposite wall has the secondary flow leaving and thus leads to a heat transfer deficit.

- Coriolis-induced secondary flow can interact with the rib-induced secondary flow, leading to heat transfer enchantment or weakened secondary flow. This is because when the circulation directions of the two-type secondary flows are the same, the secondary flow can be enhanced and thus improve heat transfer ability. However, as the circulation directions are opposite, the secondary flow is weakened by each other and can even disappear.

- The channel orientation angle can weaken the strength of the Coriolis force applied on the trailing or leading wall. The reason for this is that there is a component Coriolis force applied on the wall when a channel orientation angle exists and the component Coriolis force is smaller, thus the strength of the Coriolis-induced secondary flow is smaller, leading to the Coriolis force effect being weakened.

- A novel rotating U-channel with a channel orientation angle of 90° (called a bilaterally enhanced U-channel) can utilize the Coriolis force positive heat transfer effect on the leading and the trailing walls at the same time. This is because, according to the right-hand rule, when the main flow goes from the pass near the pressure side and then enters the pass near the suction side, the direction of the Coriolis force can simultaneously point to the leading and trailing walls, causing heat transfer enhancement on both the pressure and the suction sides.

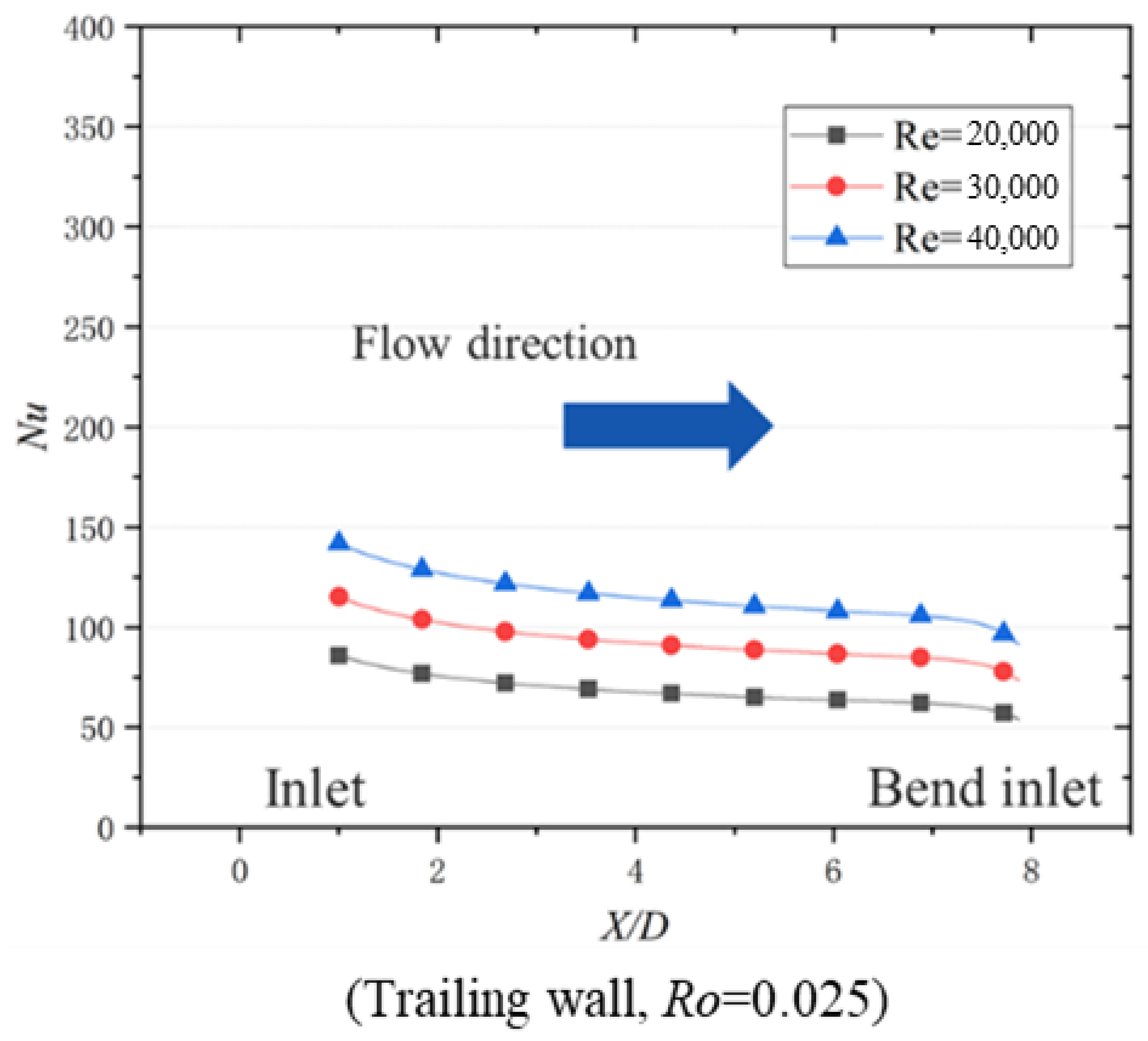

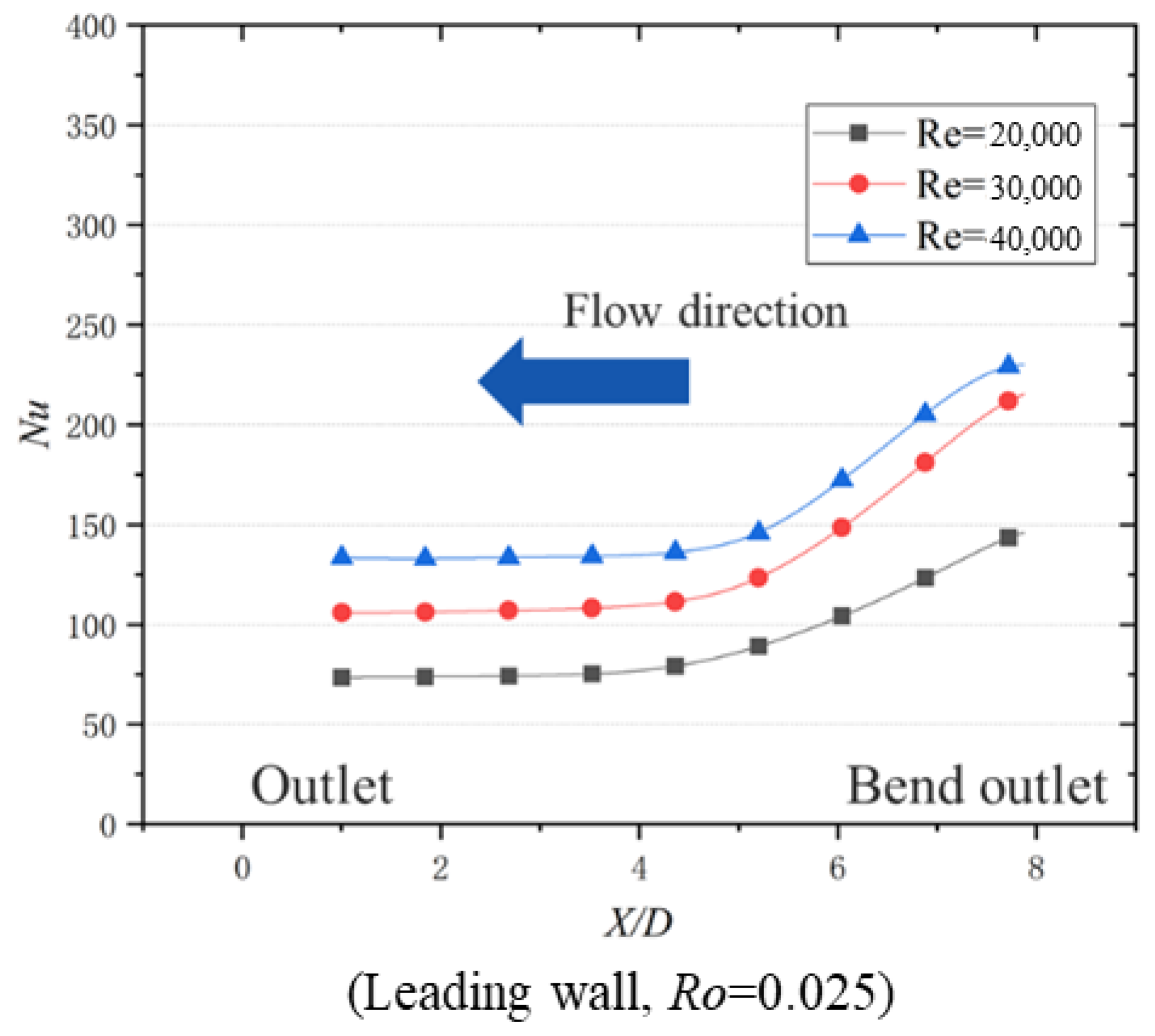

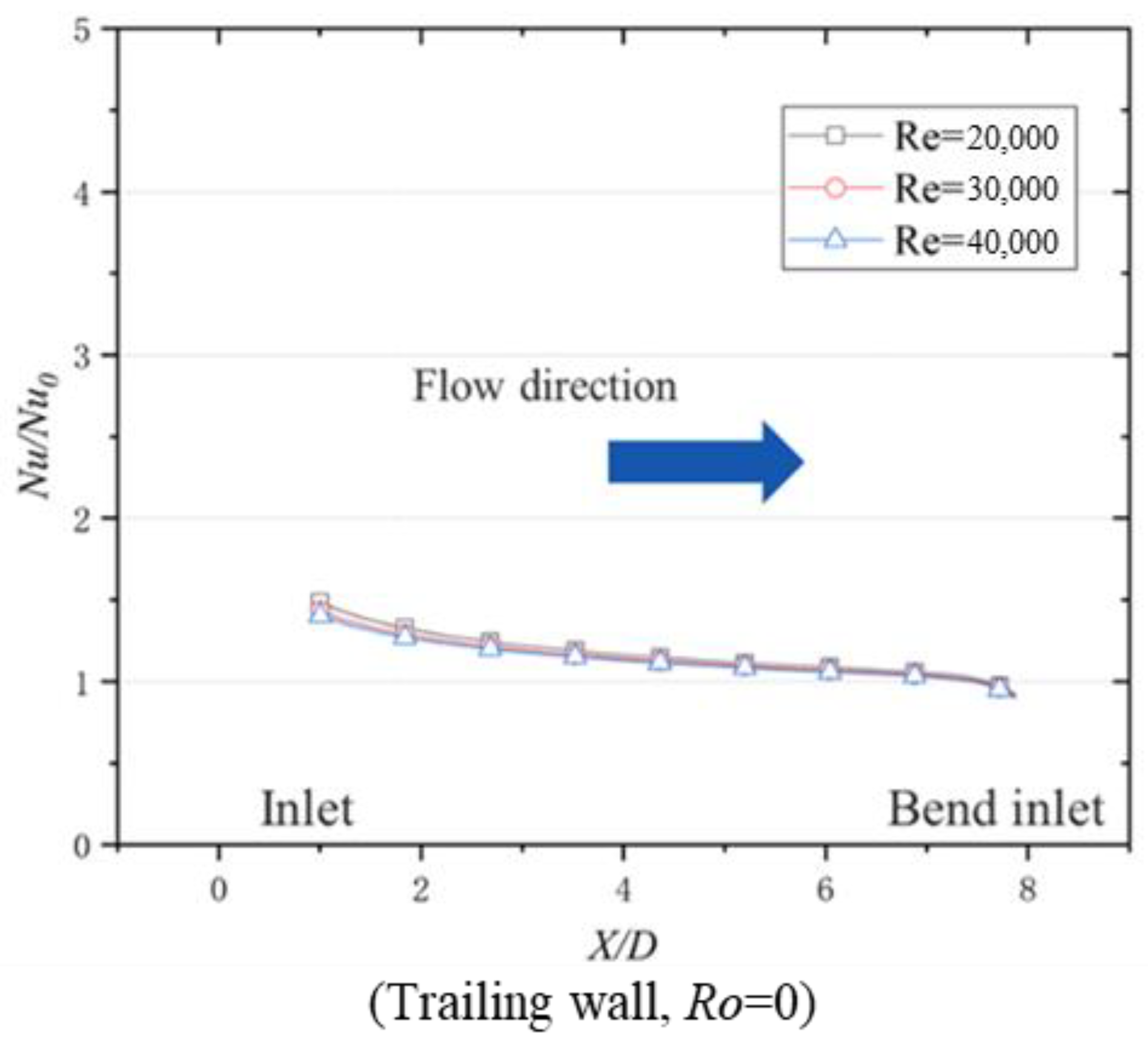

- Based on the non-dimensional equations for a bilaterally enhanced U-channel with incompressible and viscous flow, Re and Ro are vital non-dimensional numbers that influence the performance of a bilaterally enhanced U-channel. Combined with the research results, Ro is good for the heat transfer of bilaterally enhanced U-channels on both the leading and the trailing walls. At the same Ro, Re positively affects the Nu on the leading and the trailing walls of a Coriolis-utilization rotating smooth U-channel but plays a negligible role on Nu/Nu0.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Nu | local Nusselt number |

| Nu0 | Nusselt number from the Dittus–Boelter correlation |

| Nu/Nu0 | Nusselt number ratio |

| f | friction factor standing for pressure loss in a pipe |

| f0 | friction factor obtained by fully-developed turbulent flow in a smooth duct |

| f/f0 | friction factor ratio |

| Re | Reynolds number |

| Ro | Rotation number |

| Buo | Buoyancy parameter |

| h | heat transfer coefficient |

| Dh | hydraulic diameter |

| thermal conductivity | |

| Prandtl Number | |

| outlet pressure | |

| inlet pressure | |

| inlet bulk velocity | |

| air density | |

| channel length from the inlet to outlet | |

| fluid kinematic viscosity | |

| rotation speed | |

| LES | large eddy simulation |

| AR | aspect ratio |

References

- Acharya, S.; Kanani, Y. Chapter Three—Advances in Film Cooling Heat Transfer. Adv. Heat Transf. 2017, 49, 91–156. [Google Scholar]

- Han, J.C. Turbine Blade Cooling Studies at Texas A&M University: 1980–2004. J. Thermophys. Heat Transf. 2006, 20, 161–187. [Google Scholar]

- Fedorov, R.V.; Kovalnogov, V.N.; Zolotov, A.N. Development and study of technical solutions for turbine blades cooling. In Proceedings of the International Conference of Numerical Analysis and Applied Mathematics (ICNAAM), Thessaloniki, Greece, 25–30 September 2018; Available online: https://pubs.aip.org/aip/acp/article/1978/1/470024/772457/Development-and-study-of-technical-solutions-for (accessed on 14 July 2024).

- Smirnov, E.; Panov, D.; Ris, V. Goryachev V. Towards DES in CFD-based optimization: The case of a sharp U-bend with/without rotation. J. Mech. Sci. Technol. 2020, 34, 1557–1566. [Google Scholar] [CrossRef]

- Borello, D.; Salvagni, A.; Hanjali, K. Effects of rotation on flow in an asymmetric rib-roughened duct: LES study. Int. J. Heat Fluid Flow 2015, 55, 104–119. [Google Scholar] [CrossRef]

- Shevchenko, I.; Kindra, V.; Bychkov, N. A Numerical Study of Heat and Mass Transfer in a Narrowing Channel with Pin Fin-Dimple Arrays. In Proceedings of the International Multi-Conference on Industrial Engineering and Modern Technologies, Vladivostok, Russia, 3–4 October 2018; Available online: https://ieeexplore.ieee.org/document/8602582 (accessed on 2 July 2024).

- Kolesova, E.G.; Zhornik, M.N.; Kolesova, A.A. The experimental study of heat transfer in the channels of the vortex matrices of gas turbine blades. In Proceedings of the Heat and Mass Transfer and Hydrodynamics in Swirling Flows (HMTHSF-2019), Rybinsk, Russia, 16–18 October 2019; Available online: https://pubs.aip.org/aip/acp/article/2211/1/070005/995960/The-experimental-study-of-heat-transfer-in-the (accessed on 12 July 2024).

- Baybuzenko, I.N. Local Heat Transfer and Friction Measurements in Ribbed Channel at High Reynolds Numbers. In Proceedings of the ASME Turbo Expo 2021: Turbomachinery Technical Conference and Exposition, Online, 7–11 June 2021; Available online: https://asmedigitalcollection.asme.org/GT/proceedings/GT2021/84980/V05BT13A001/1120074 (accessed on 21 July 2024).

- Sokolov, N.P.; Polishchuk, V.G.; Andreev, K.D.; Rassokhin, V.A.; Zabelin, N.A. Heat transfer and pressure drop in rectangular channels with crossing fins (a Review). Therm. Eng. 2015, 62, 423–433. [Google Scholar] [CrossRef]

- Saxer-Felici, H.; Naik, S.; Gritsch, M.; Sedlov, A. Heat Transfer Enhancement for a Turbine Blade Leading Edge Passage Using Various Turbulator Geometries. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Dusseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Ris, V.V.; Galaev, S.A.; Levchenya, A.M.; Pisarevskii, I.B. Numerical Investigation of a Developed Turbulent Flow and Heat Transfer in a Rectangular Channel with Single-Sided Internal Ribs. Therm. Eng. 2021, 71, 167–175. [Google Scholar] [CrossRef]

- Naik, S.; Retzko, S.; Gritsch, M.; Sedlov, A. Impact of Turbulator Design on the Heat Transfer in a High Aspect Ratio Triangular Passage of a Turbine Blade. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, Dusseldorf, Germany, 16–20 June 2014; Available online: https://www.semanticscholar.org/paper/Impact-of-Turbulator-Design-on-the-Heat-Transfer-in-Naik-Retzko/cda3a285c57fcd4a652d718067dbb892578d6322 (accessed on 26 June 2024).

- Han, J.; Dutta, S. Recent Developments in Turbine Blade Internal Cooling. Ann. N. Y. Acad. Sci. 2001, 934, 162–178. [Google Scholar] [CrossRef]

- Ligrani, P.; Blaskovich, T.; Oliveira, M. Comparison of Heat Transfer Augmentation Techniques. AIAA J. 2003, 41, 337–362. [Google Scholar] [CrossRef]

- Han, J. Recent Studies in Turbine Blade Cooling. Int. J. Rotating Mach. 2004, 10, 443–457. [Google Scholar]

- Wright, L.; Han, J. Heat Transfer Enhancement for Turbine Blade Internal Cooling. J. Enhanc. Heat Transf. 2014, 21, 111–140. [Google Scholar] [CrossRef]

- Ligrani, P. Heat Transfer Augmentation Technologies for Internal Cooling of Turbine Components of Gas Turbine Engines. Int. J. Rotating Mach. 2013, 2013, 275653. [Google Scholar] [CrossRef]

- Bunker, R. Evolution of Turbine Cooling. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar] [CrossRef]

- Ekkad, S.V.; Singh, P. Detailed Heat Transfer Measurements for Rotating Turbulent Flows in Gas Turbine Systems. Energies 2020, 14, 39. [Google Scholar] [CrossRef]

- Du, W.; Luo, L.; Jiao, Y.; Songtao, W. Heat transfer in the trailing region of gas turbines—A state-of-the-art review. Appl. Therm. Eng. 2021, 199, 117614. [Google Scholar] [CrossRef]

- Yeranee, K.; Yu, R. A review of recent studies on rotating internal cooling for gas turbine blades. Chin. J. Aeronaut. 2021, 34, 85–113. [Google Scholar] [CrossRef]

- Wagner, R.E.; Velkoff, H.R. Measurements of Secondary Flows in a Rotating Duct. J. Eng. Gas Turbines Power 1972, 94, 261–270. [Google Scholar] [CrossRef]

- Johnston, J.P.; Halleent, R.M.; Lezius, D.K. Effects of spanwise rotation on the structure of two-dimensional fully developed turbulent channel flow. J. Fluid Mech. 1972, 56, 533–557. [Google Scholar] [CrossRef]

- Moon, I.M. Effects of Coriolis Force on the Turbulent Boundary Layer in Rotating Fluid Machines. Undergraduate Thesis, Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge, MA, USA, 1964. [Google Scholar]

- Ito, H.; Nanbu, I.C. Flow in Rotating Straight Pipes of Circular Cross Section, ASME Preprint 70-WA/FE-13, December 1970. Available online: https://asmedigitalcollection.asme.org/fluidsengineering/article/93/3/383/395774/Flow-in-Rotating-Straight-Pipes-of-Circular-Cross (accessed on 12 July 2024).

- Morris, W.D.; Ayhan, T. Observations on the influence of rotation on heat transfer in the coolant channels of gas turbine rotor blades. Proc. Inst. Mech. Eng. 1979, 193, 303–311. [Google Scholar] [CrossRef]

- Metzger, D.E.; Stan, R.L. Entry Region Heat Transfer in Rotating Radial Tubes. J. Energy 1977, 1, 297–300. [Google Scholar] [CrossRef]

- El-Masri, M.A.; Louis, J.F. On the Design of High-Temperature Gas Turbine Blade Water-Cooling Channels. J. Eng. Gas Turbines Power 1978, 100, 586–591. [Google Scholar] [CrossRef]

- Amosd, J. Fluid Cooled Turbine Rotor Blade Has Insert with Coolant Passageways and Also Has Bifurcated Roots. US3902820-A, 2 September 1975. [Google Scholar]

- Electric Power Research Institute. Advanced Cooled-Engine Shell/Spar Turbine Vanes and Blades. Available online: https://www.epri.com/research/products/AP-4751 (accessed on 2 July 2024).

- Slitenko, A.F. Gas-turbine rotor cooling systems. Power Eng.—J. Acad. Sci. USSR 1986, 24, 155–159. [Google Scholar]

- Mudawar, I.A. Boiling Heat Transfer in Rotating Channels with Reference to Gas Turbine Blade Cooling. Doctoral Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 1984. [Google Scholar]

- Shrestha, S.; Prasad, A.; Ricklick, M. Internal Cooling of Rotating and Non-Rotating Channels with Rib Turbulators. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Yonghui, X.; Qi, J.; Di, Z.; Zhongyang, S.; Wei, J. Review on Research of Heat Transfer Performance for Gas Turbine Blade Cooling Channel. Proc. Chin. Soc. Electr. Eng. 2017, 6, 1711–1720. [Google Scholar]

- Xu, T.; Shi, D.B.; Zhang, D. Flow and Heat Transfer Characteristics of the Turbine Blade Variable Cross-Section Internal Cooling Channel with Turning Vane. Appl. Sci. 2023, 13, 1446. [Google Scholar] [CrossRef]

- Amano, R.S.; Beyhaghi, S. Heat Transfer in a Rotating Two-pass Square Channel Representing Internal Cooling of Gas Turbine Blades. In Proceedings of the Aiaa Aerospace Sciences Meeting, Turbine Cooling, AIAA 2016-0655, San Diego, CA, USA, 4–8 January 2016. [Google Scholar]

- Lorenzon, A.; Casarsa, L. Validation of the Transient Liquid Crystal Thermography Technique for Heat Transfer Measurements on a Rotating Cooling Passage. Energies 2020, 13, 4759. [Google Scholar] [CrossRef]

- Saravani, M.S.; Amano, R.S. Heat Transfer Enhancement in Stationary and Rotating Internal Cooling Channels using Angled Ribs. In Proceedings of the 2019 AIAA Science and Technology Forum and Exposition, San Diego, CA, USA, 7–11 January 2019. [Google Scholar]

- Fang, Y. Effects of High Buoyancy Parameter on Flow and Heat Transfer of Two-Pass Smooth/Ribbed Channels. Energies 2021, 15, 148. [Google Scholar] [CrossRef]

- Liang, C.; Rao, Y.; Chen, J.; Luo, X. Experimental and Numerical Study of the Turbulent Flow and Heat Transfer in a Wedge-Shaped Channel with Guiding Pin Fin Arrays Under Rotating Conditions. J. Turbomach. 2022, 144, 071007. [Google Scholar] [CrossRef]

- Shi, D.; Xu, T.; Chen, Z.; Zhang, D.; Xie, Y. The effect of dimple/protrusion arrangements on the comprehensive thermal performance of variable cross-section rotating channels for gas turbine blades. Int. J. Therm. Sci. 2024, 196, 108733. [Google Scholar] [CrossRef]

- Chia, K.C.; Huang, S.C.; Liu, Y.H. Experimental Investigation of Heat Transfer on the Internal Tip Wall in a Rotating Two-Pass Rectangular Channel. J. Therm. Sci. Eng. Appl. 2021, 13, 011025. [Google Scholar] [CrossRef]

- Zhang, D.W.; Li, H.W.; Tian, Y.T. Effects of a high Reynolds number and rotation on the leading-edge heat transfer of a ribbed cooling channel with a cross-section consisting of a semicircle and a rectangle. Int. J. Heat Mass Transf. 2022, 188, 122646. [Google Scholar] [CrossRef]

- Zhu, F.; Jing, Q.; Xie, Y.; Zhang, D. Numerical investigation on flow and heat transfer characteristics of U-shaped channels with side-wall column ribs. Int. Commun. Heat Mass Transf. 2022, 137, 106221. [Google Scholar] [CrossRef]

- Chen, I.L.; Sahin, I.; Wright, L.M.; Han, J.-C.; Krewinkel, R. Heat transfer in a rotating, blade-shaped, two-pass cooling channel with a variable aspect ratio. J. Turbomach.-Trans. ASME 2022, 144, 021011. [Google Scholar] [CrossRef]

- Ren, M.; Li, X.; Ren, J.; Jiang, H. Numerical Study on Local Heat Transfer in a Rotating Cooling Channel. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Pattanaprates, N.; Juntasaro, E.; Juntasaro, V. Numerical Investigation on the Modified Bend Geometry of a Rotating Multipass Internal Cooling Passage in a Gas Turbine Blade. J. Therm. Sci. Eng. Appl. 2018, 10, 061003. [Google Scholar] [CrossRef]

- Chang, S.W.; Chen, C.A.; Lu, Y.E. Experimental study of heat-transfer and pressure-drop performances of a rotating two-pass channel with composite stepped skew ribs and internal effusion. Int. J. Heat Mass Transf. 2023, 212, 124308. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, Y.; Yang, L.; Yan, L.; Luan, Y. Flow and Heat Transfer Performance of Channels with 45 Degree Ribs in Staggered Array. J. Appl. Fluid Mech. 2021, 14, 1535–1546. [Google Scholar]

- Ahn, J. Large Eddy Simulation of Flow and Heat Transfer in a Ribbed Channel for the Internal Cooling Passage of a Gas Turbine Blade: A Review. Energies 2023, 16, 3656. [Google Scholar] [CrossRef]

- Shi, D.; Jing, Q.; Gao, T.; Zhang, D.; Xie, Y. Flow and heat transfer mechanism of U-shaped channel considering variable cross-section and rotating effects. Int. Commun. Heat Mass Transf. 2021, 129, 105701. [Google Scholar] [CrossRef]

- Pouyaei, P.; Kayhani, M.H.; Norouzi, M.; Bahambari, A.B.; Kim, M.; Kim, K.C. Effect of a curved turning vane on the heat transfer and fluid flow of four-pass internal cooling channels of gas turbine blades. Proc. Inst. Mech. Eng. Part G-J. Aerosp. Eng. 2023, 237, 3726–3742. [Google Scholar] [CrossRef]

- Yang, S.F.; Wu, H.W.; Han, J.C.; Zhang, L.; Moon, H.-K. Heat transfer in a smooth rotating multi-passage channel with hub turning vane and trailing-edge slot ejection. Int. J. Heat Mass Transf. 2017, 109, 1–15. [Google Scholar] [CrossRef]

- Son, S.Y.; Kihm, K.D.; Han, J.C. PIV flow measurements for heat transfer characterization in two-pass square channels with smooth and 90° ribbed wall. Int. J. Heat Mass Transf. 2002, 45, 4809–4822. [Google Scholar] [CrossRef]

- Hosseinalipour, S.M.; Shahbazian, H.R.; Sunden, B. Experimental investigations and correlation development of convective heat transfer in a rotating smooth channel. Exp. Therm. Fluid Sci. 2018, 94, 316–328. [Google Scholar] [CrossRef]

- Qiu, L.; Deng, H.; Sun, J.; Tao, Z.; Tian, S. Pressure drop and heat transfer in rotating smooth square U-duct under high rotation numbers. Int. J. Heat Mass Transf. 2013, 66, 543–552. [Google Scholar] [CrossRef]

- Deng, H.; Qiu, L.; Tao, Z.; Tain, S. Heat transfer study in rotating smooth square U-duct at high rotation numbers. Int. J. Heat Mass Transf. 2013, 66, 733–744. [Google Scholar] [CrossRef]

- Li, H.; You, R.; Deng, H.; Tao, Z.; Zhu, J. Heat transfer investigation in a rotating U-turn smooth channel with irregular cross-section. Int. J. Heat Mass Transf. 2016, 96, 267–277. [Google Scholar] [CrossRef]

- Tao, Z.; Qiu, L.; Deng, H. Heat transfer in a rotating smooth wedge-shaped channel with lateral fluid extraction. Appl. Therm. Eng. 2015, 87, 47–55. [Google Scholar] [CrossRef]

- Hoseinalipour, S.M.; Shahbazian, H.; Sunden, B.A. Influences of secondary flow induced by Coriolis forces and angled ribs on heat transfer in a rotating channel. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 388–417. [Google Scholar] [CrossRef]

- Duchaine, F.; Gicquel LY, M.; Grosnickel, T.; Koupper, C. Large-Eddy Simulation of the Flow Developing in Static and Rotating Ribbed Channels. J. Turbomach. 2020, 142, 041003. [Google Scholar] [CrossRef]

- Hosseinalipour, S.M.; Shahbazian, H.; Sunden, B. Coriolis and buoyancy effects on heat transfer in viewpoint of field synergy principle and secondary flow intensity for maximization of internal cooling. Heat Mass Transf. 2021, 57, 1467–1483. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Tian, Y.; You, R.; Zhang, D.; Wu, A. Heat transfer in a rotating lateral outflow trapezoidal channel with pin fins under high rotation numbers and Reynolds numbers. Appl. Therm. Eng. 2022, 213, 118725. [Google Scholar] [CrossRef]

- Chen, I.L.; Sahin, I.; Wright, L.M.; Han, J.-C.; Krewinkel, R. Heat Transfer in a Rotating, Two-Pass, Variable Aspect Ratio Cooling Channel with Profiled V-Shaped Ribs. J. Turbomach. 2021, 143, 081013. [Google Scholar] [CrossRef]

- Ahn, J.; Choi, H.; Lee, J.S. Large eddy simulation of flow and heat transfer in a rotating ribbed channel. Int. J. Heat Mass Transf. 2007, 50, 4937–4947. [Google Scholar] [CrossRef]

- Saravani, M.S.; Dipasquale, N.J.; Beyhaghi, S.; Amano, R.S. Heat Transfer in Internal Cooling Channels of Gas Turbine Blades: Buoyancy and Density Ratio Effects. J. Energy Resour. Technol. 2019, 141, 112001. [Google Scholar] [CrossRef]

- Beyhaghi, S.; Saravani, M.S.; Morrison, M. Computational and Experimental Investigation of Heat Transfer in Stationary and Rotating Internal Cooling Ducts with High Rotation Numbers. In Proceedings of the 15th International Energy Conversion Engineering Conference, Atlanta, GA, USA, 11 July 2017. [Google Scholar]

- Deng, H.; Tao, Z.; Xu, G. Prediction of turbulent flow and heat transfer within rotating smooth U-shaped passage. J. Beijing Univ. Aeronaut. Astronaut. 2003, 29, 205–209. [Google Scholar]

- Ma, Y.; Cheng, Y.P.; Xie, J.; Zhou, Z.; Xu, J. Numerical investigation of internal cooling enhancement with Coriolis force in rotating gas turbine blades. J. Enhanc. Heat Transf. 2021, 28, 19–38. [Google Scholar] [CrossRef]

- Chang, S.W.; Cai, W.L.; Shen, H.D.; Yu, K.C. Uncoupling Coriolis Force and Rotating Buoyancy Effects on Full-Field Heat Transfer Properties of a Rotating Channel. J. Vis. Exp. 2018, 140, e57630. [Google Scholar]

- Chang, S.W.; Huang, S.W. Aerothermal performance of a rotating two-pass furrowed channel roughened by angled ribs. Appl. Therm. Eng. 2021, 199, 117613. [Google Scholar] [CrossRef]

- Sahin, I.; Chen, I.L.; Wright, L.M.; Han, L.C.; Xu, H.; Fox, M. Heat Transfer in Rotating, Trailing-Edge, Converging Channels With Smooth Walls and Pin-Fins. J. Turbomach. 2021, 143, 1–36. [Google Scholar] [CrossRef]

- Flynt, G.A.; Webster, R.S.; Sreenivas, K. Computation of heat transfer in turbine rotor blade cooling channels with angled rib turbulators. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, San Jose, CA, USA, 14–17 July 2013. [Google Scholar]

- Chang, S.W.; Liou, T.M.; Po, Y. Coriolis and rotating buoyancy effect on detailed heat transfer distributions in a two-pass square channel roughened by 45° ribs at high rotation numbers. Int. J. Heat Mass Transf. 2010, 53, 1349–1363. [Google Scholar] [CrossRef]

- Chen, W. Experimental and Numerical Study of the Mechanism of Internal Cooling in Gas Turbine Blade. Ph.D. Thesis, Tsinghua University, Beijing, China, 2011. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CDFD&dbname=CDFD1214&filename=1013023958.nh&uniplatform=NZKPT&v=lut-saoAeW4s5BdP4VxUFM5_7vE3g7qZjkevxfSo9DLgD7kMVdDK35bPPmDtXpfw (accessed on 1 July 2024).

- Singh, P.; Li, W.; Ekkad, S.V.; Ren, J. A new cooling design for rib roughened two-pass channel having positive effects of rotation on heat transfer enhancement on both pressure and suction side internal walls of a gas turbine blade. Int. J. Heat Mass Transf. 2017, 115, 6–20. [Google Scholar] [CrossRef]

- Bunker, R.S.; Dees, J.E.; Palafox, P. Impingement Cooling in Gas Turbines: Design, Applications, and Limitations. Impingement Jet Cool. Gas Turbines 2014, 25, 1. [Google Scholar]

- Al-Qahtani, M.; Jang, Y.J.; Chen, H.C.; Han, J.C. Flow and heat transfer in rotating two-pass rectangular channels (AR=2) by Reynolds stress turbulence model. Int. J. Heat Mass Transf. 2002, 45, 1823–1838. [Google Scholar] [CrossRef]

- Liou, T.M.; Chang, S.W.; Hung, J.H.; Chiou, S.F. High rotation number heat transfer of a 45° rib-roughened rectangular duct with two channel orientations. Int. J. Heat Mass Transf. 2007, 50, 4063–4078. [Google Scholar] [CrossRef]

- Kim, S.; Choi, E.Y.; Kwak, J.S. Effect of Channel Orientation on the Distribution of the Heat Transfer Coefficient in Smooth and Dimpled Rotating Rectangular Channels. In Proceedings of the ASME 2010 International Mechanical Engineering Congress and Exposition. Volume 7: Fluid Flow, Heat Transfer and Thermal Systems, Parts A and B, Vancouver, BC, Canada, 12–18 November 2012; pp. 1611–1621. Available online: https://gasturbinespower.asmedigitalcollection.asme.org/IMECE/proceedings/IMECE2010/44441/1611/339650 (accessed on 25 July 2024).

- Parsons, J.A.; Han, J.C.; Zhang, Y. Effect of model orientation and wall heating condition on local heat transfer in a rotating two-pass square channel with rib turbulators. Int. J. Heat Mass Transf. 1995, 38, 1151–1159. [Google Scholar] [CrossRef]

- Guo, X.; Xu, H.; Li, X.; Ren, J. Flow and heat transfer characteristics of Coriolis-utilization rotating rectangular smooth cooling U-channel. Appl. Therm. Eng. 2022, 211, 118420. [Google Scholar]

- Han, A. Effect of rotation on heat transfer in two-pass square channels with five different orientations of 45° angled rib turbulators. Int. J. Heat Mass Transf. 2003, 46, 653–669. [Google Scholar]

- Li, Y.; Chen, J.; Liu, T.; Deng, H.; Xue, S. Heat transfer characteristics in a rotating AR=4:1 channel with different channel orientations at high rotation numbers. Propuls. Power Res. 2021, 10, 130–142. [Google Scholar] [CrossRef]

- Li, Y.; Deng, H.; Xu, G.; Qiu, L.; Tian, S. Effect of Channel Orientation on Heat Transfer in Rotating Smooth Square U-Duct at High Rotation Number. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference & Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Li, Y.; Deng, H.; Xu, G.; Tian, S. Heat transfer investigation in rotating smooth square U-duct with different wall temperature ratios and channel orientations. Int. J. Heat Mass Transf. 2015, 89, 10–23. [Google Scholar] [CrossRef]

- Dutta, S.; Han, J.C. Local Heat Transfer in Rotating Smooth and Ribbed Two-Pass Square Channels With Three Channel Orientations. J. Heat Transf. 1996, 118, 578–584. [Google Scholar] [CrossRef]

- Tafti, D.; Dowd, C.; Tan, X. High Reynold Number LES of a Rotating Two-Pass Ribbed Duct. Aerospace 2018, 5, 124. [Google Scholar] [CrossRef]

- Guo, X.X.; Wang, S.Y.; Li, X.Y.; Ren, J. Aerothermodynamic features of Coriolis-applied U channel. Int. J. Therm. Sci. 2024, 197, 108815. [Google Scholar] [CrossRef]

- Oh, I.T.; Kim, K.M.; Dong, H.L.; Park, J.S.; Cho, H.H. Local Heat/Mass Transfer and Friction Loss Measurement in a Rotating Matrix Cooling Channel. J. Heat Transf. 2012, 134, 011901.1–011901.9. [Google Scholar]

- Xu, G.; Chen, Y.; Wen, J. Heat transfer in a rotating rectangular channel (AR = 4) with dimples and sidewall bleeds. Int. J. Heat Mass Transf. 2020, 150, 119118.1–119118.14. [Google Scholar] [CrossRef]

- Huh, M.; Lei, J.; Han, J.C. Influence of Channel Orientation on Heat Transfer in a Two-Pass Smooth and Ribbed Rectangular Channel (AR = 2:1) Under Large Rotation Numbers. J. Turbomach. 2012, 134, 011022. [Google Scholar] [CrossRef]

- Zhang, B.L.; Zhu, H.R.; Liu, C.L.; Yao, C.Y. Experimental Study of Outflow Effects in a Rotating Turbulated Channel. J. Turbomach. 2021, 143, 071009. [Google Scholar] [CrossRef]

- Guo, X.X.; Li, X.Y.; Ren, J. Heat transfer and flow features of a Bifacial-enhanced U channel. Appl. Therm. Eng. 2024, 245, 122812. [Google Scholar] [CrossRef]

- Lezius, D.K.; Johnston, J.P. Roll-Cell Instabilities in Rotating Laminar and Turbulent Channel Flows. J. Fluid Mech. 1976, 77, 153–174. [Google Scholar] [CrossRef]

- Singh, P.; Ekkad, S. Experimental investigation of rotating rib roughened two-pass square duct with two different channel orientations. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, GT2017-64225, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Li, X.; Ren, J. Evolution of Rotating Internal Channel for Heat Transfer Enhancement in a Gas Turbine Blade. Aerospace 2024, 11, 836. https://doi.org/10.3390/aerospace11100836

Guo X, Li X, Ren J. Evolution of Rotating Internal Channel for Heat Transfer Enhancement in a Gas Turbine Blade. Aerospace. 2024; 11(10):836. https://doi.org/10.3390/aerospace11100836

Chicago/Turabian StyleGuo, Xinxin, Xueying Li, and Jing Ren. 2024. "Evolution of Rotating Internal Channel for Heat Transfer Enhancement in a Gas Turbine Blade" Aerospace 11, no. 10: 836. https://doi.org/10.3390/aerospace11100836

APA StyleGuo, X., Li, X., & Ren, J. (2024). Evolution of Rotating Internal Channel for Heat Transfer Enhancement in a Gas Turbine Blade. Aerospace, 11(10), 836. https://doi.org/10.3390/aerospace11100836