Lean Demonstration of On-Board Thermal Anomaly Detection Using Machine Learning

Abstract

:1. Introduction

1.1. Skykraft’s Hosted Payload Programme

- Low-cost hosting.

- Well defined interfaces described in an interface control document [10].

- Provision of interface test software and test jig.

- Expert advice.

1.2. The uni.lu/SnT AI4Space Skykard

- Develop and test a payload development approach.

- Demonstrate an on-board anomaly-detection algorithm using machine learning.

- Develop a proof-of-concept for a versatile thermal anomaly-detection system.

1.2.1. Anomaly Detection

- Out-of-range anomalies: an anomalous behavior causes high heating. The excessive temperature endangers the hardware. A measured temperature value exceeds a defined permissible maximum value. Such a situation is often addressed using embedded sensors and simple comparative analysis.

- Within-range anomalies: An anomalous behavior causes a minor heating, thus a minor increase in temperature. The measured values remain within range. The pattern of temperature measurement is, however, anomalous [18]. Such complex anomalies can only be detected by high-fidelity algorithms or human intervention. Detecting those helps the understanding of emerging satellite health issues and can thus serve predictive maintenance [19] applications.

1.2.2. Why Artificial Intelligence?

1.3. Available Project Development Methodologies

- Phasing of projects.

- The extent to which projects are carried out iteratively.

- How technical models are used to develop the product.

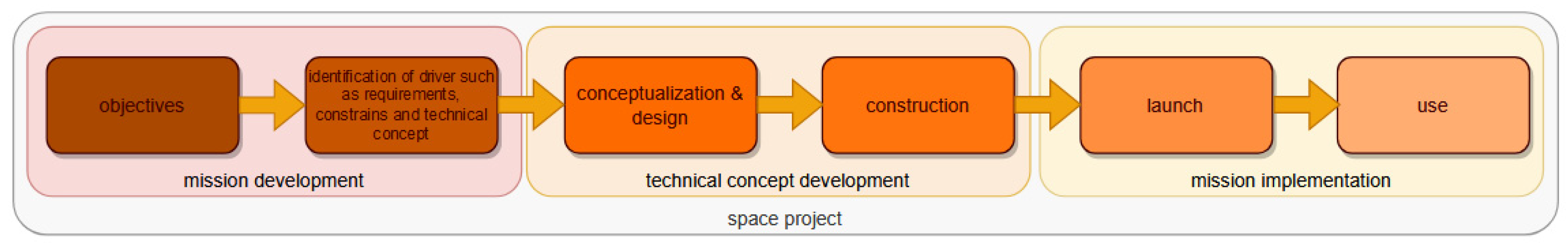

1.3.1. Phases of Space Projects

- Mission development.

- Technical concept development.

- Mission implementation.

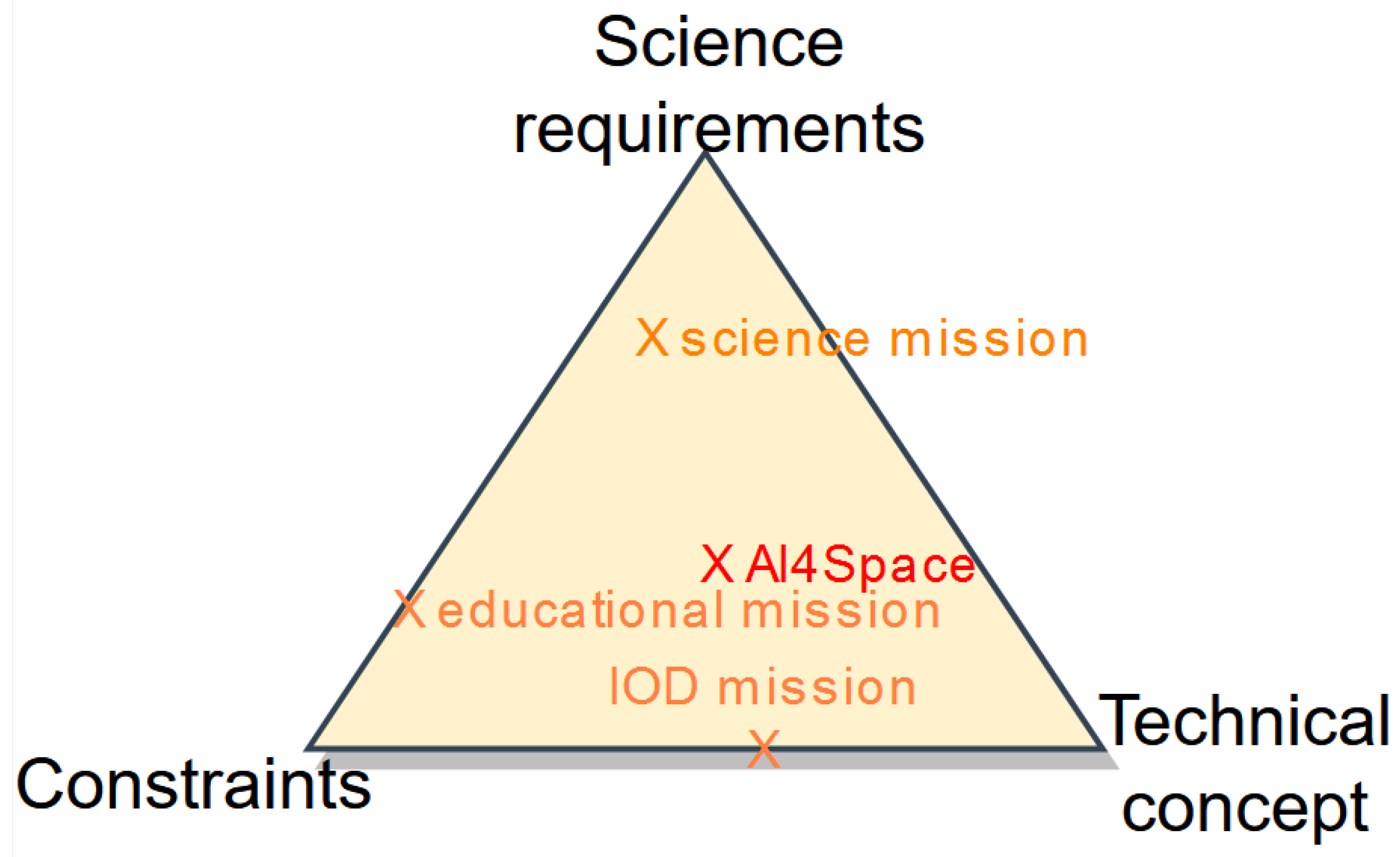

1.3.2. Mission Development

- Scientific requirements. For instance, flagship scientific missions always need the development of beyond-the-state-of-the-art sensors to achieve their groundbreaking objective. The requirement and the consequently needed development govern the mission.

- Constraints, such as a budget envelope, are formulated for most, if not for all, missions. For some, however, the compliance to constraints is dominating over other aspects [28]. Constraints are often defined by the sponsor of a mission, such as a space agency. Educational missions are often constraint-driven. Those often do not have an inherent scientific objective, but their goal is to train students.

- Some missions are being dictated a concept, which then takes precedence of other potential drivers. This is in particular the case for CubeSat [29] and satellite bus in-orbit demonstration missions.

1.3.3. Technical Concept Development

- Conceptualization and design.

- Construction, which can be further subdivided into:

- (a)

- Manufacturing, that is, the assembly of the spacecraft from its parts; and

- (b)

- Verification, that is, the check whether the design requirements are met.

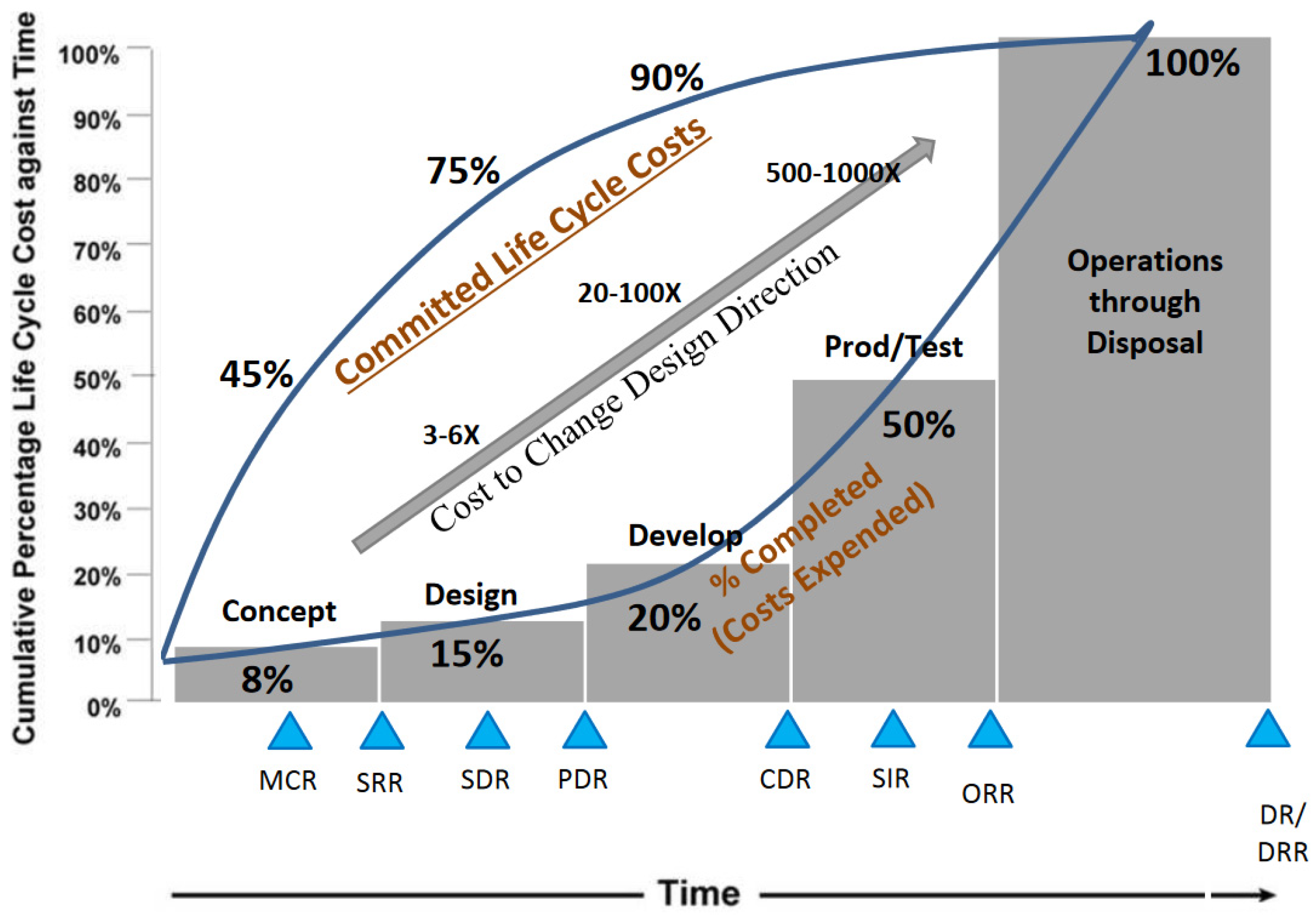

1.3.4. Methods of Space Project Development

- Lifecycle management, i.e., the time-wise implementation.

- Model management, i.e., the use of descriptive models to advance design and construction.

- Waterfall, being the successive, prespecified progression from initiation to the end. In each step, a new aspect is addressed leading to the final product.

- Project drivers;

- Need or interest in innovation;

- Background knowledge;

- Available facilities;

- Complexity of the project;

- Accepted exposure to construction or concept risk.

- Model-based approach [33]. A central repository is used to list, maintain, and verify requirements, interfaces, and results of analyses, usually in a formal or semi-formal way. The approach is efficient for very large projects during the mission development and conceptualization phase but is of limited utility for later project phases.

- Domain-specific models. Here, the development is based on a number of computer and physical models such as a computer-aided-design (CAD) model. This approach is often coupled with the waterfall approach and may be used until operations. Technical domain-specific models can be used to simulate and verify subsystem-specific requirements.

1.4. Outline of the Manuscript

2. Our Methodology

2.1. AI4Space Project Analysis

- defines scientific requirements,

- was given a rough timeline and interface definition as constraint,

- was given envelope information on dimensions, power consumption, and material use describing the technical concept.

- having relatively low system-engineering complexity,

- not employing radiofrequency equipment,

- not employing mechanisms,

- not responsible for power generation or storage,

- needing flight hardware quality.

2.2. Our Lean Management Approach and Hybrid Waterfall-Iterative Approach

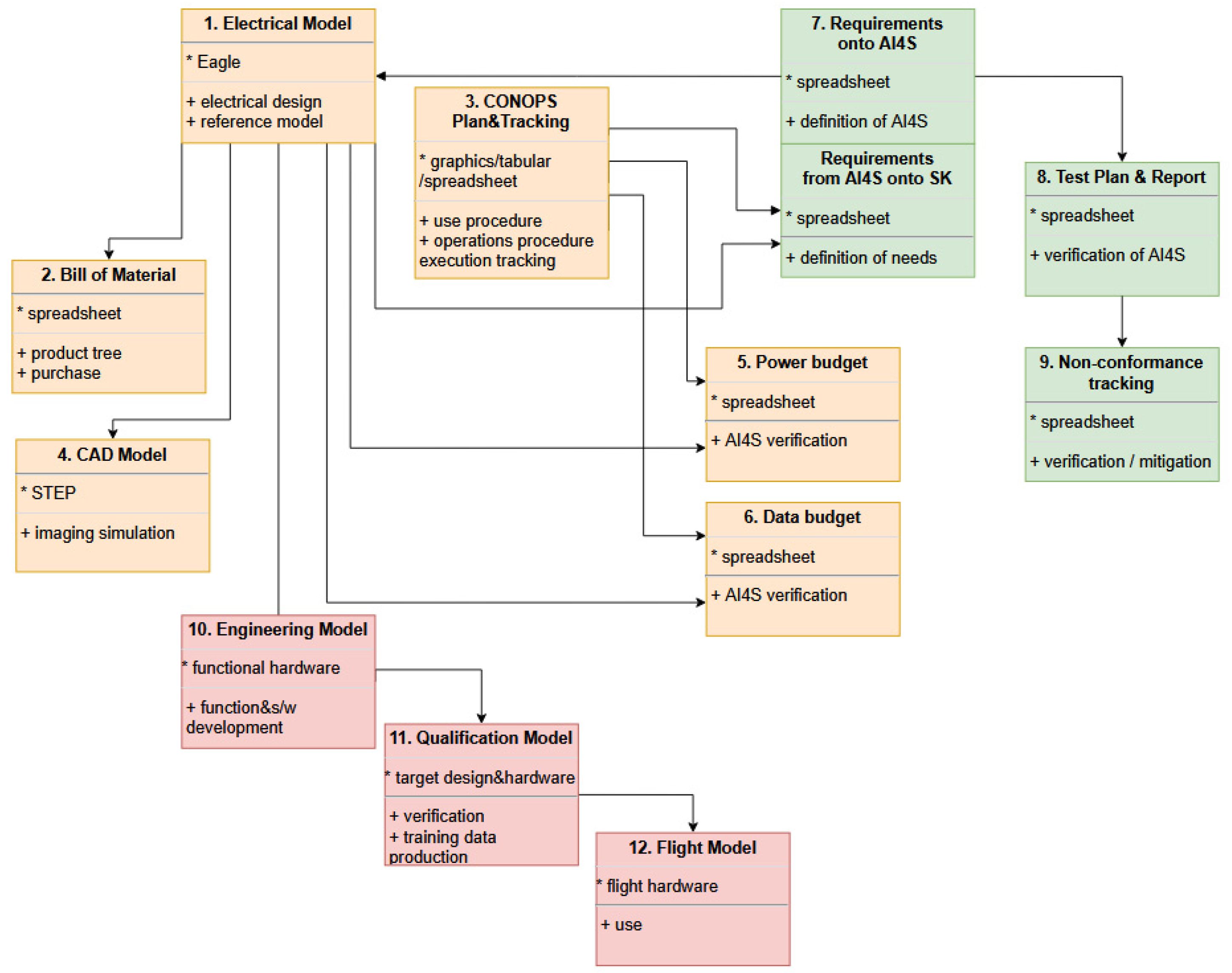

2.3. Our Domain-Specific-Models Approach

- Technical models,

- Management models,

- Software model.

- Virtual models.

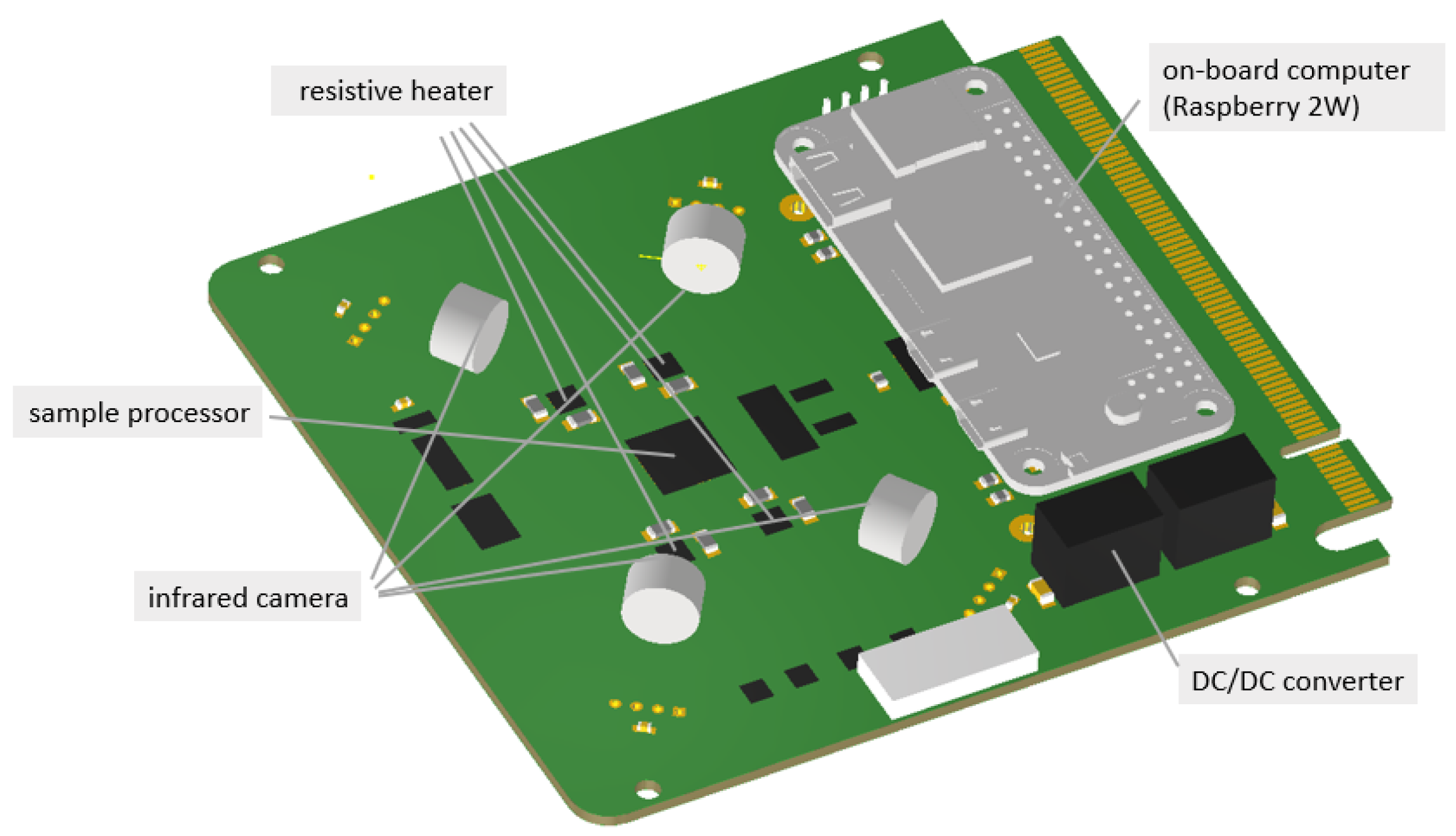

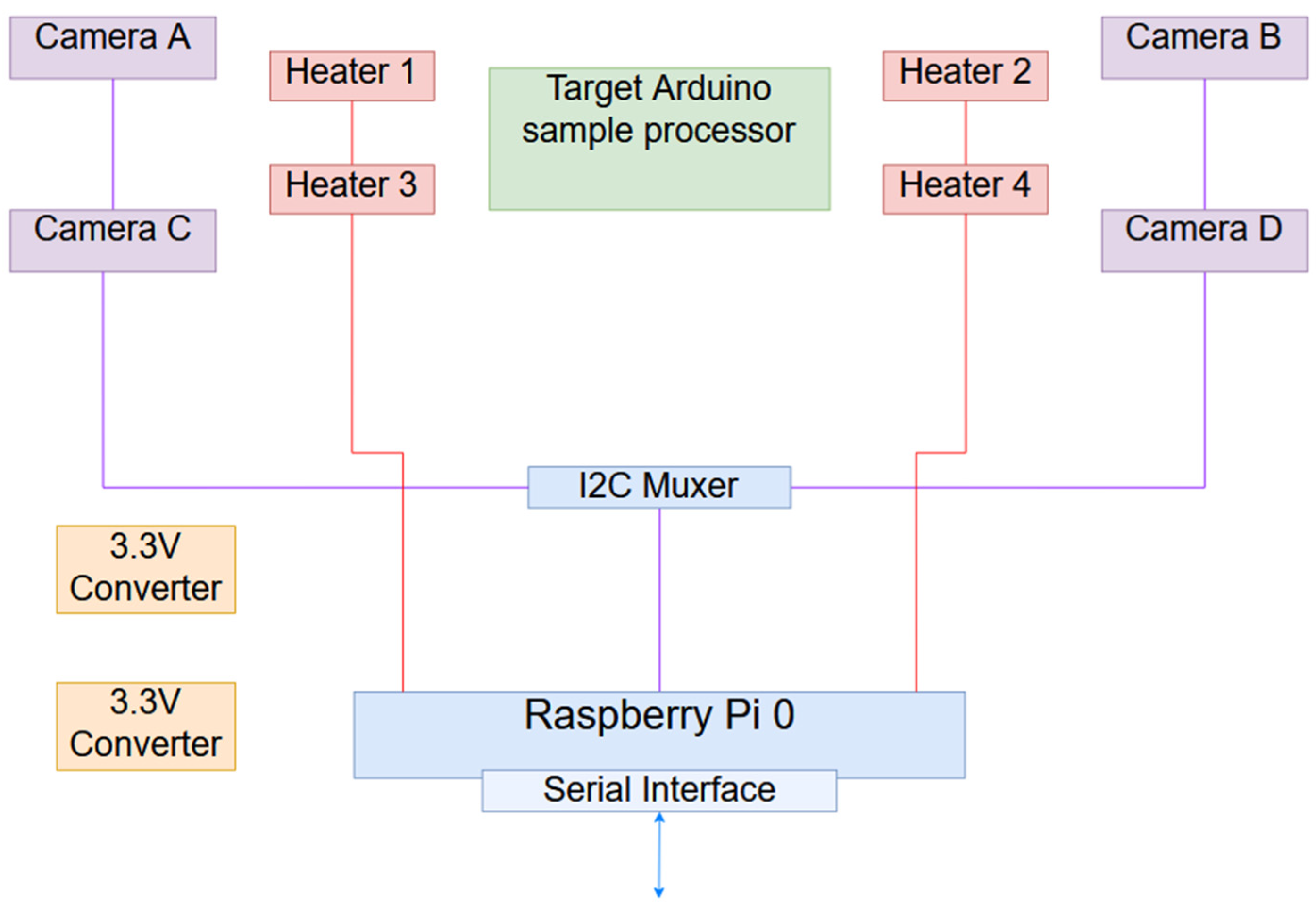

- The electrical model (ElM, reference) implemented in Autodesk Eagle served to design the electrical function and as reference for all further technical models.

- The bill-of-materials (BOM) served as a simplified product tree and for the purchase of the components.

- The CONOPS plan and CONCOPS tracking were implemented as a graphic and spreadsheet.

- A computer-aided-design (CAD) model served to understand the view of the four infrared cameras.

- Power budget.

- Data budget.

- Requirement list containing:

- ▪

- requirement imposed on our product by the host satellite, and

- ▪

- requirement onto the host spacecraft and its operations.

- Test procedure and report served to track tests carried out.

- Non-conformance tracking served to list any unexpected incidents. For each item, a history of the discovery and investigative action is kept, as well as the conclusion

- Physical Models.

- 10.

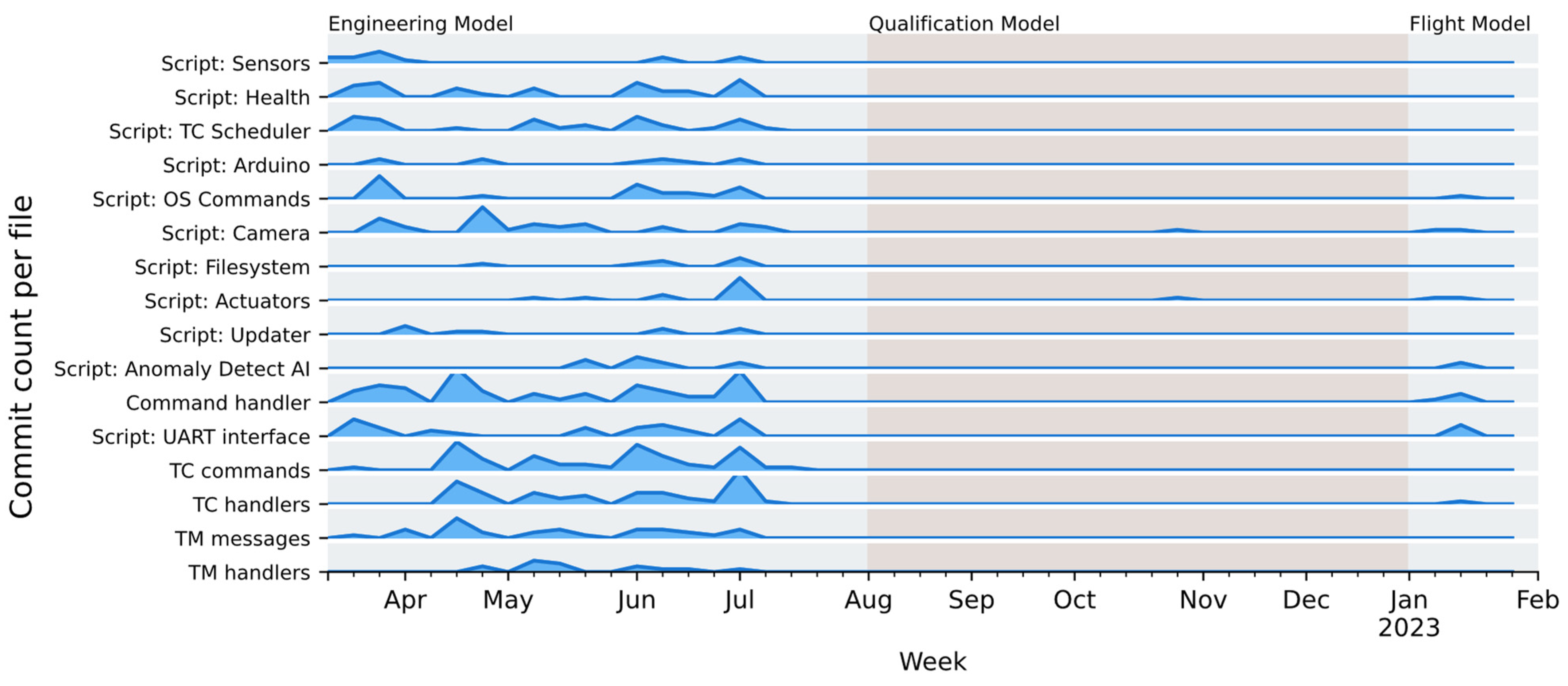

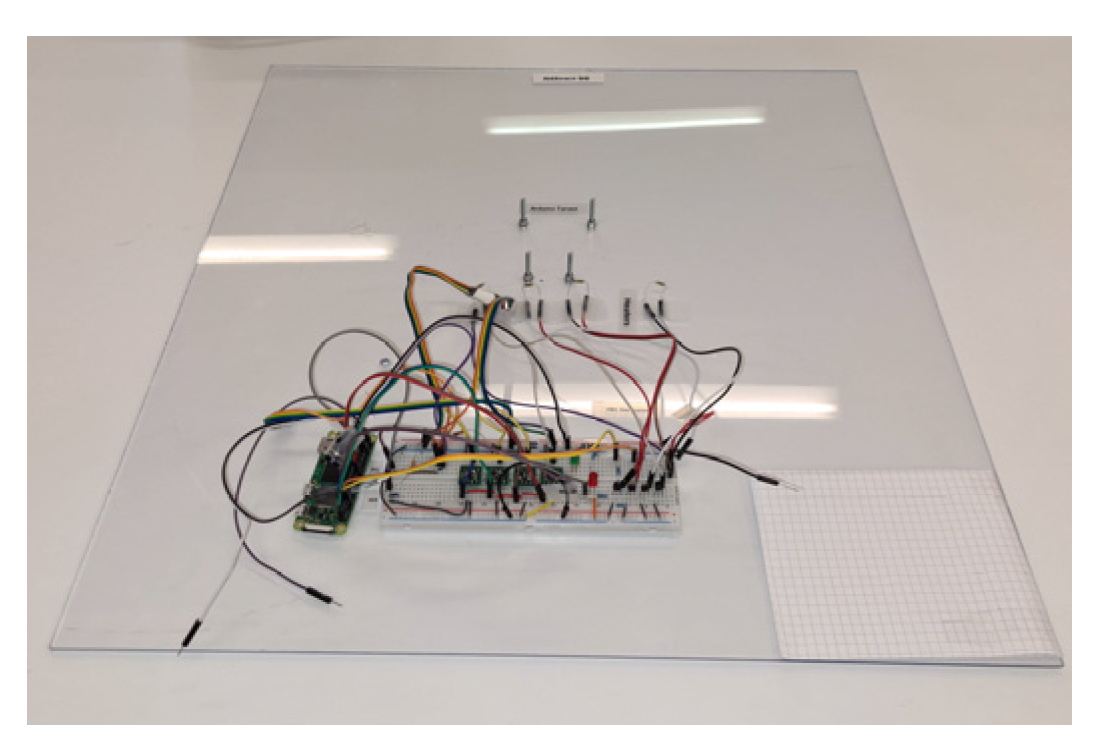

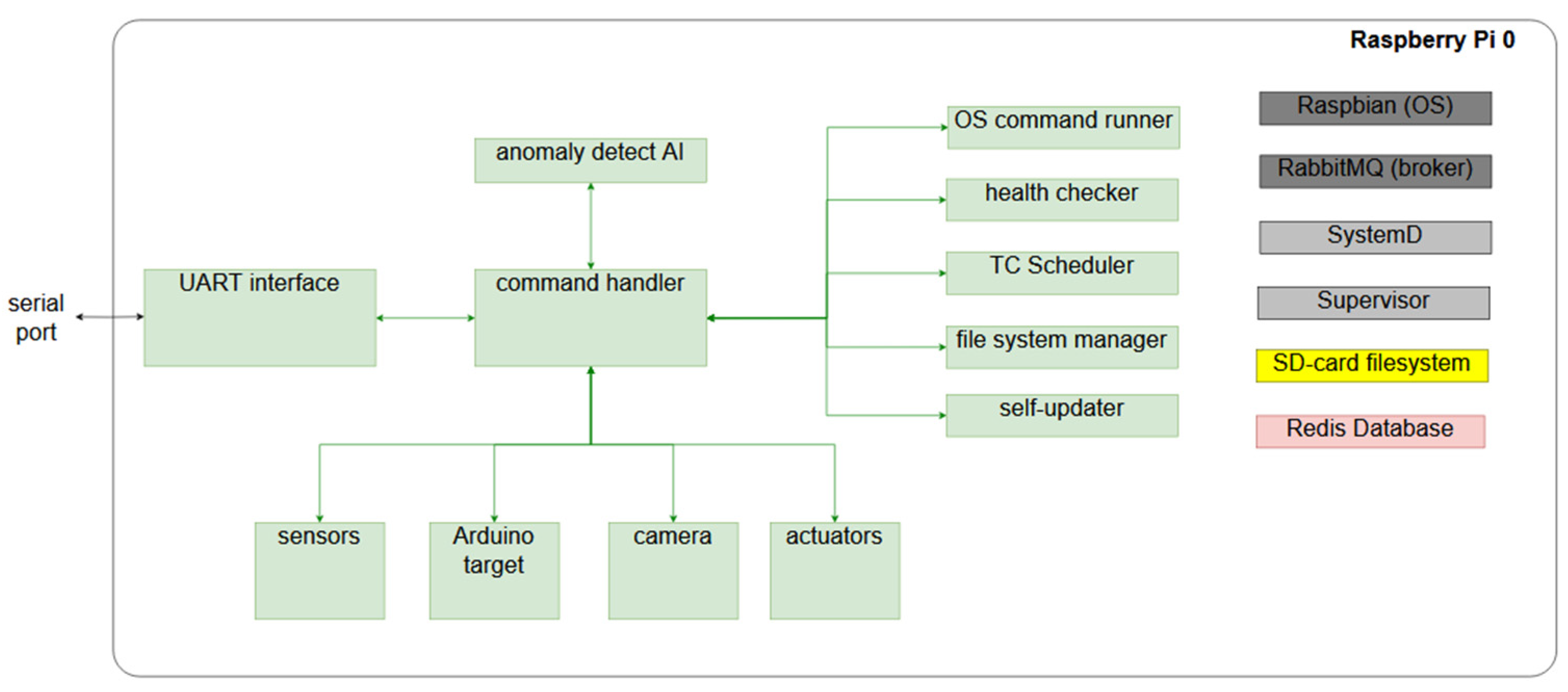

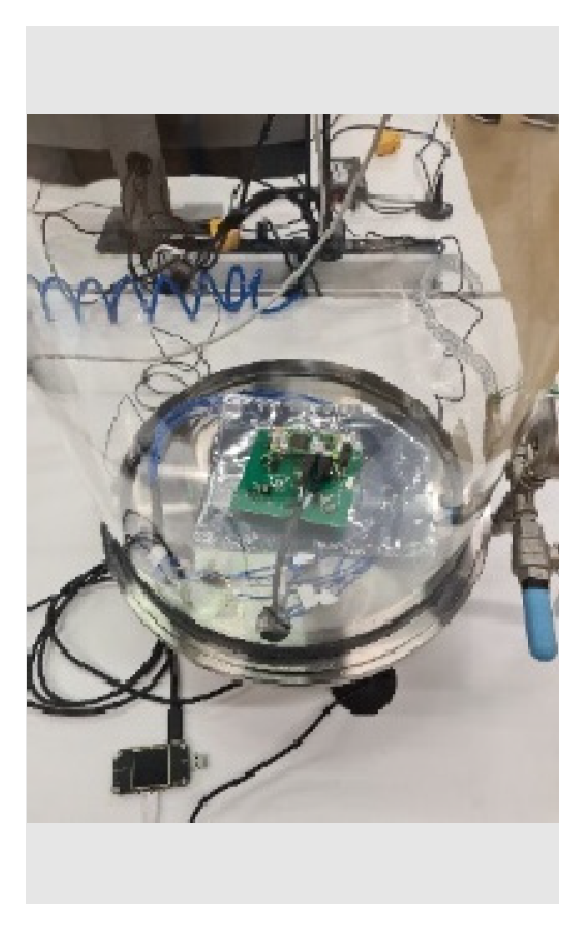

- The engineering model (EM), here implemented as a flat-sat, served to develop the main functions and the software interface. To this end, it also featured a host satellite on-board computer simulator

- 11.

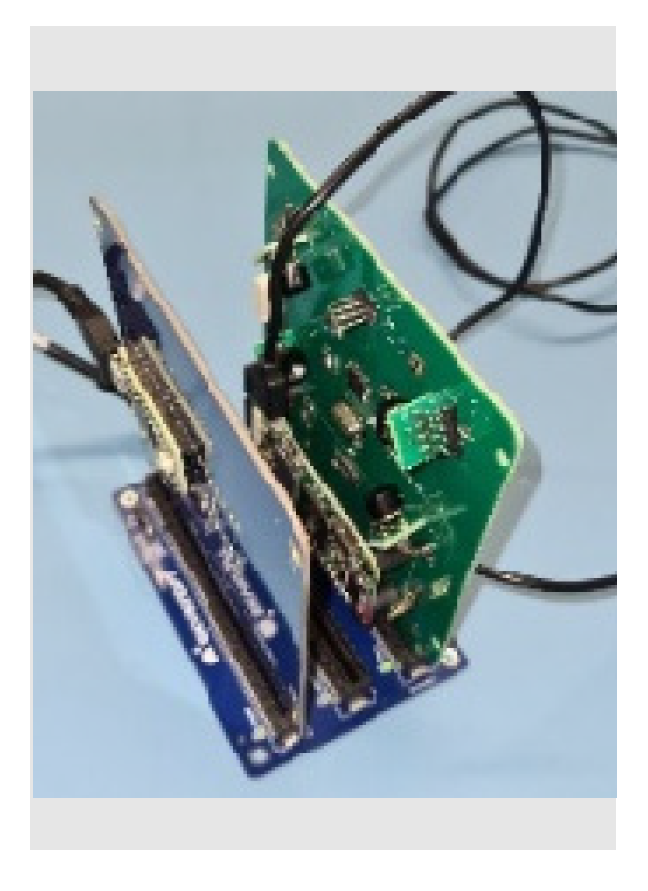

- The qualification model (QM) served to test the manufacturing and initial image acquisition.

- 12.

- The flight model (FM) is the final product, which was launched and operated.

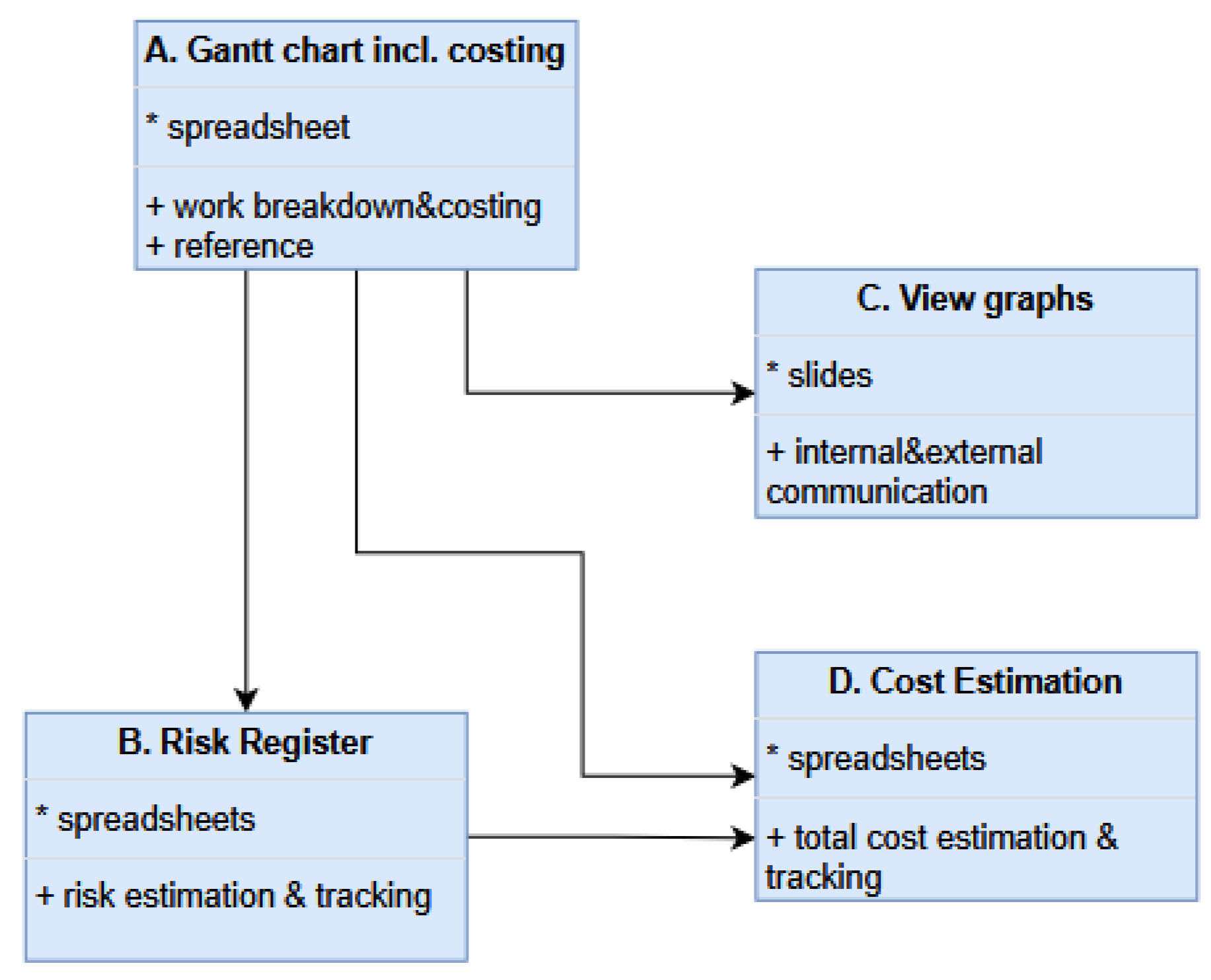

- A.

- Gantt chart (reference) served to break down the work into tasks and to identify logical dependencies. It also contained an estimate for the cost of each task.

- B.

- Risk register served to list the risk and the mitigation action. It also contained an estimate for the cost of each risk.

- C.

- Viewgraphs.

- D.

- Total cost estimate is the sum of task-cost and risk-cost.

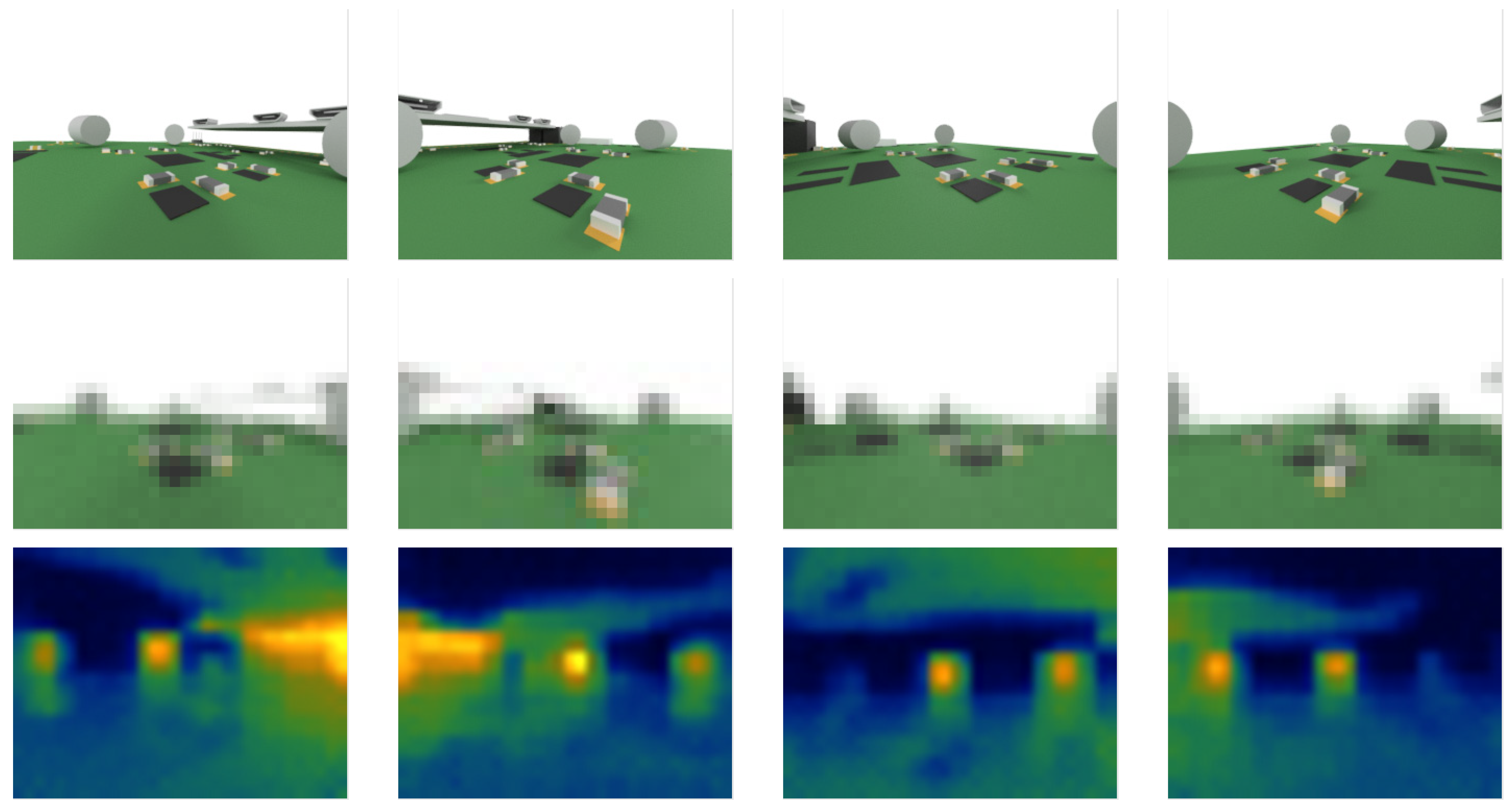

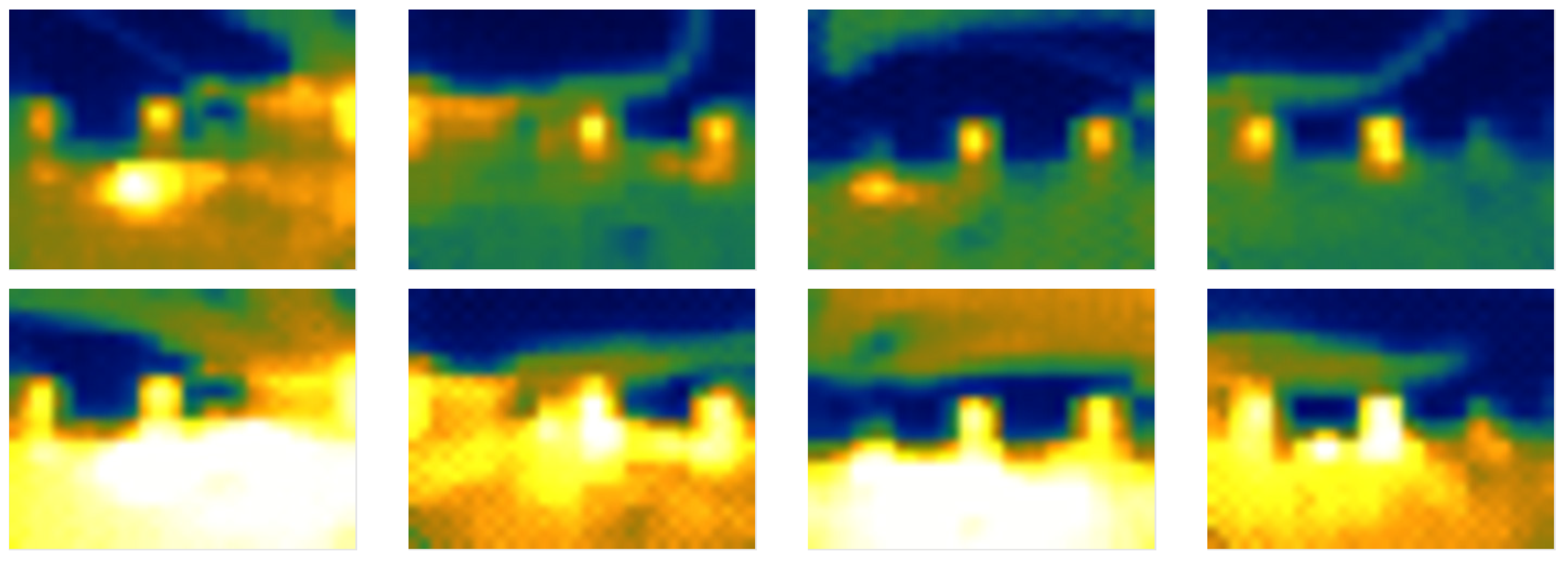

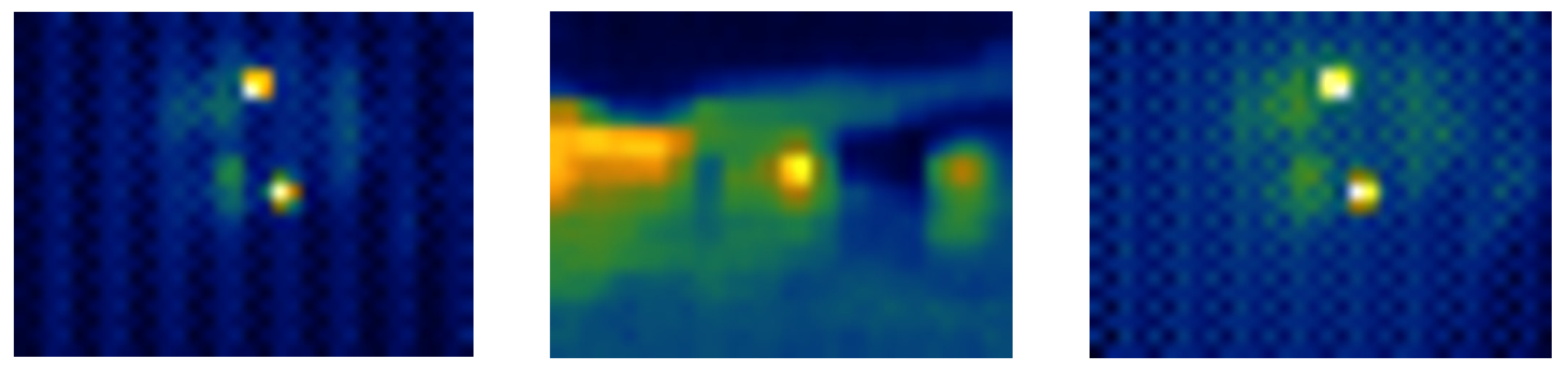

2.4. Functional Testing and ML-Training

2.5. ML Training and Testing

2.6. Omission of Engineering Models and Reduced Verification

- Such analysis-type verification was not requested and a verification-by-inspection and similarity to the established Skykard design was successful.

- We had reduced the importance of the science-driver, that is, the accuracy of our temperature measurement.

- Such modeling for the purpose of experiment outcome prediction can be done a posteriori.

- No thermal environment, that is, the temperature of the hosting satellite, necessary for accurate thermal simulations of the AI4Space Skykard, is available.

3. Concept-of-Operations

- Reference infrared imagery where no heater is switched on, representing the nominal situation.

- Imagery with one heater switched on, representing an anomaly.

- Imagery with a further realistic heat source to verify robustness against false anomaly detection.

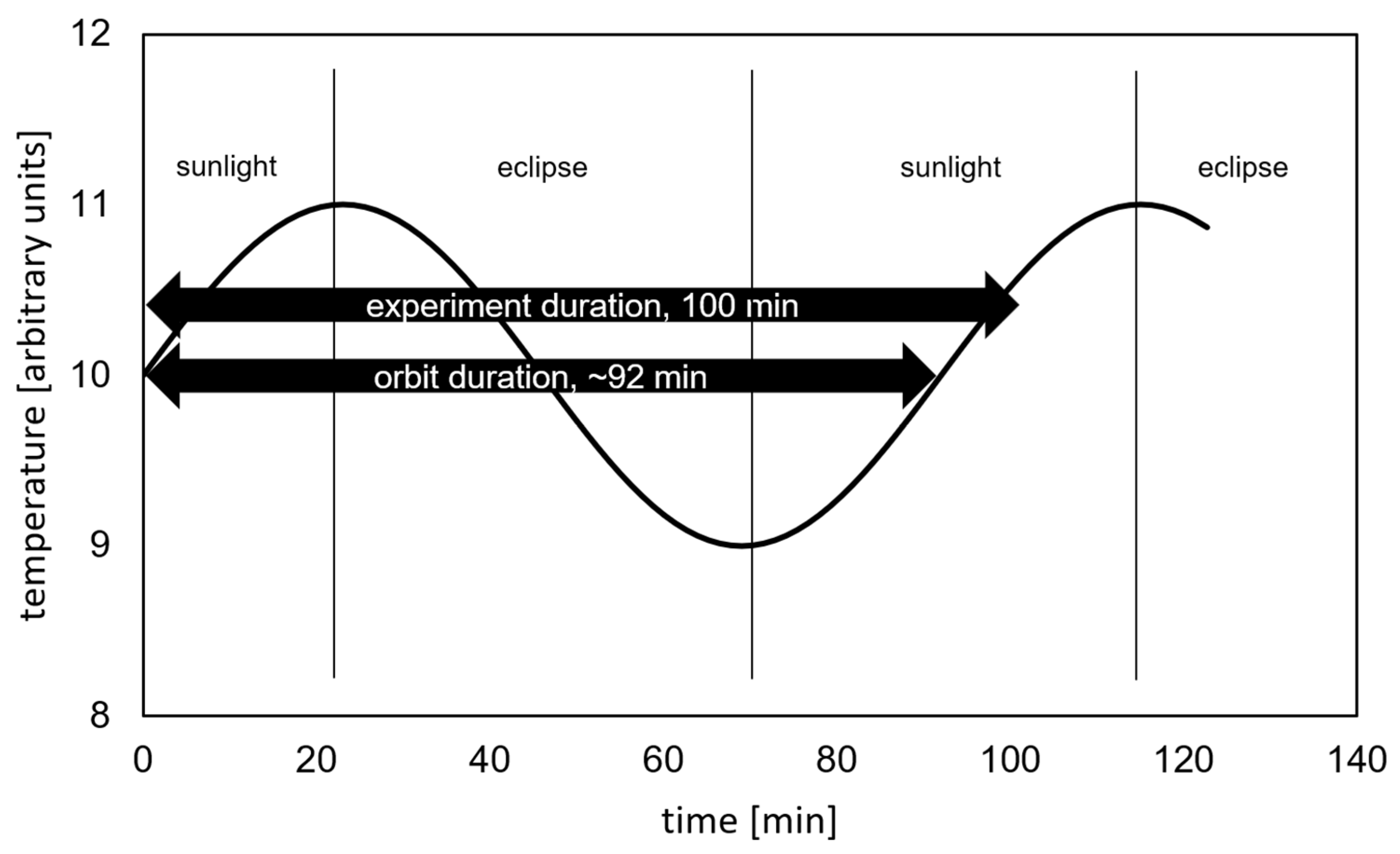

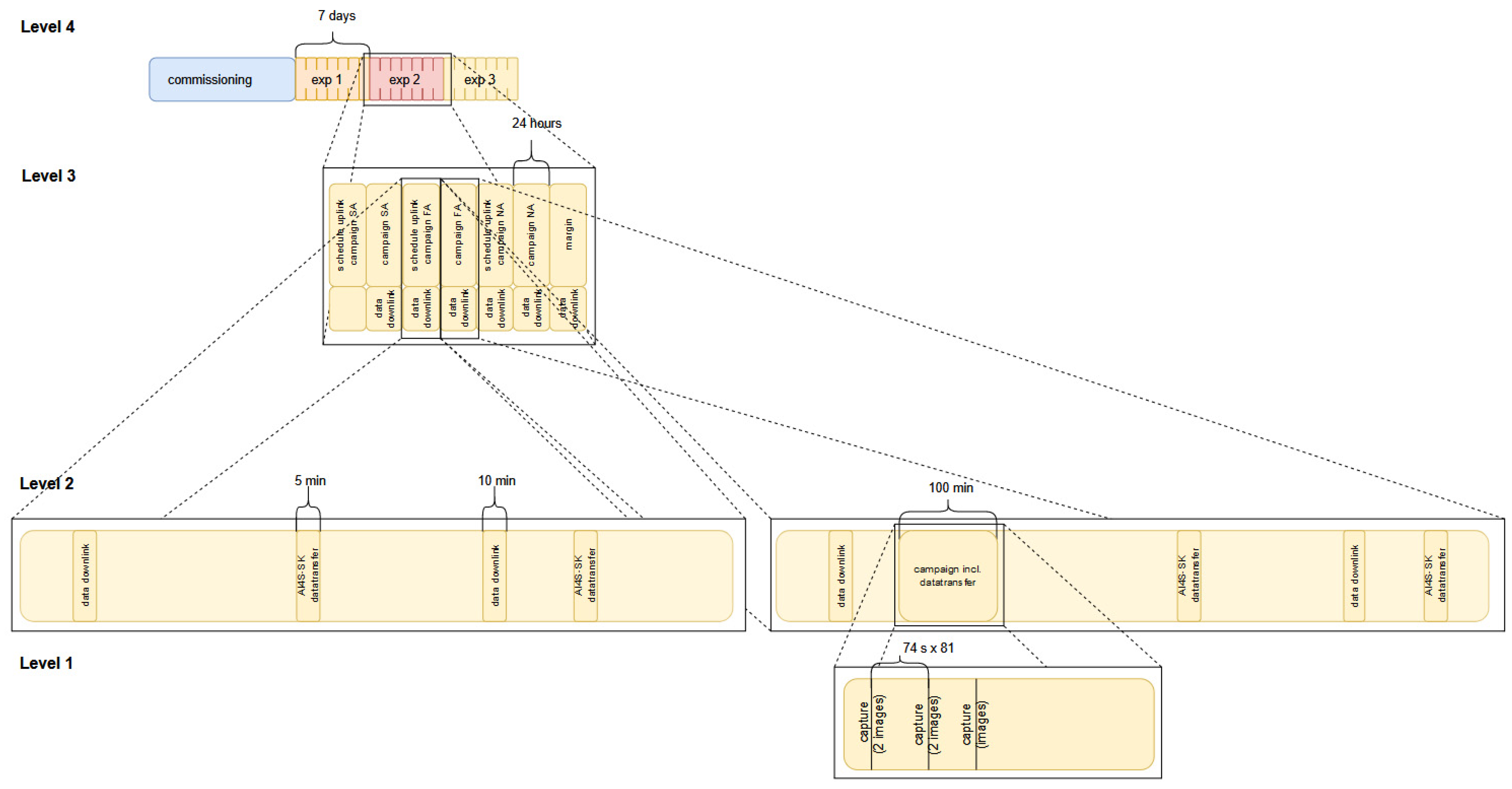

- Our CONOPS was drafted in four levels:

- Level 4: entire mission.

- Level 3: experiment lasting 1 calendar week.

- Level 2: one day encompassing experiment schedule execution and/or data downlink.

- Level 1: experiment schedule details containing imagery taking, AI operations, and data transfer to host satellite.

4. Results

4.1. Succesful Payload Integration and In-Orbit Commissioning

4.2. Mishaps

- (a)

- Loose link between electrical model and bill-of-material

- (b)

- Loss of sample-processor functionality

- (c)

- Host satellite AI4Space payload communication

5. Conclusions

- A rigorous implementation of the model tree is essential to ensure full consistency throughout the entire project. Therefore, the derivation from the model needs to be well-described and meticulously implemented.

- A comprehensive interface description, either in document format or in emulators, is crucial to preventing engineering flaws. Identifying and addressing gaps in the interface definition through a thorough analysis of provided interface control requirements is imperative, as it mitigates the discovery of costly issues at later stages.

6. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Honoré-Livermore, E. Integrating Agile Systems Engineering and Project Management in Small Satellites Development. Ph.D Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2022. [Google Scholar]

- Tsiga, Z.D.; Emes, M.; Smith, A. Critical Success Factors for Projects in the Space Sector. J. Mod. Proj. Manag. 2016, 3, 56–63. [Google Scholar]

- Hoffman, E.; Boyle, J.; Rogers, E. REAL Knowledge and the James Webb Space Telescope: Success and Failure Coexisting in NASA. In Successes and Failures of Knowledge Management; Liebowitz, J., Ed.; Morgan Kaufmann: Boston, MA, USA, 2016; pp. 35–58. ISBN 978-0-12-805187-0. [Google Scholar]

- Hetey, L.; Neefs, E.; Thomas, I.; Zender, J.; Vandaele, A.-C.; Berkenbosch, S.; Ristic, B.; Bonnewijn, S.; Delanoye, S.; Leese, M.; et al. Development of a Knowledge Management System for the NOMAD Instrument Onboard the ExoMars TGO Spacecraft. Aircr. Eng. Aerosp. Technol. 2020, 92, 81–92. [Google Scholar] [CrossRef]

- Basha, N.S.; Kwasa, B.J.; Bloebaum, C. Study of Cost Overrun and Delays of Department of Defense (DoD)’s Space Acquisition Program. In Proceedings of the 39th International Annual Conference of the American Society for Engineering Management, Coeur d’Alene, ID, USA, 17–20 October 2018; pp. 625–633. [Google Scholar]

- Thoemel, J.; Muylaert, J.M.; Ratti, F.; Gavira, J. In-Flight Testing of Critical Technologies and Experimentation of Aerothermodynamic Phenomena. In Proceedings of the 16th AIAA/DLR/DGLR International Space Planes and Hypersonic Systems and Technologies Conference, Bremen, Germany, 19 October 2009. [Google Scholar]

- Del Vecchio, A.; Marino, G.; Gardi, R.; Vigliotti, A.; Thoemel, J.; Ratti, F.; Izquierdo, J.G. Mechanical and Thermal Qualification/Acceptance Activities of the Experiments and Payloads for the Expert—Esa Experimental Re-Entry Vehicle. In Proceedings of the 17th AIAA International Space Planes and Hypersonic Systems and Technologies Conference 2011, San Francisco, CA, USA, 11 April 2011. [Google Scholar]

- Del Vecchio, A.; De Stefano Fumo, M.; Gardi, R.; Marino, G.; Thoemel, J.; Izquierdo, J.G. EXPERT—The ESA Experimental Re-Entry Vehicle: Overview of the Experiments and Payloads Qualified and Ready for the Flight. In Proceedings of the International Astronautical Congress, IAC, Naples, Italy, 1–5 October 2012; American Institute of Aeronautics and Astronautics: Reston, VA, USA; San Antonio, TX, USA, 2012; Volume 8, pp. 6726–6738. [Google Scholar]

- Thoemel, J.; Tirtey, S.; Birjmohan, S.; Fletcher, D.; Chazot, O. Design of a Catalysis In-Flight Experiment. In Proceedings of the Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7 January 2008. [Google Scholar]

- Diggle, B.; Gibbs, A. Skyride Interface Control Document (SK-B3-PL-ICD-0001) V1.3; Skykraft Pty Ltd.: Reid, Australia, 2022. [Google Scholar]

- Kaveh Azar The History of Power Dissipation. Available online: https://www.electronics-cooling.com/2000/01/the-history-of-power-dissipation/ (accessed on 19 February 2024).

- Gutiérrez, O.; Prieto, M.; Sánchez-Reyes, A.; Gómez, A. TID Characterization of COTS Parts Using Radiotherapy Linear Accelerators. IEICE Electron. Express 2019, 16, 1–6. [Google Scholar] [CrossRef]

- Sinclair, D.; Dyer, J. Radiation Effects and COTS Parts in SmallSats. In Proceedings of the 27th Annual AIAA/USU Conference on Small Satellites; Utah State University: Logan, UT, USA, 2013; Volume 2. [Google Scholar]

- Underwood, C.I.; Oldfield, M.K. Observed Radiation-Induced Degradation of Commercial-off-the-Shelf (COTS) Devices Operating in Low-Earth Orbit. IEEE Trans. Nucl. Sci. 1998, 45, 2737–2744. [Google Scholar] [CrossRef]

- Laib dit Leksir, Y.; Mansour, M.; Moussaoui, A. Localization of Thermal Anomalies in Electrical Equipment Using Infrared Thermography and Support Vector Machine. Infrared Phys. Technol. 2018, 89, 120–128. [Google Scholar] [CrossRef]

- Mendes, M.A.; Tonini, L.G.R.; Muniz, P.R.; Donadel, C.B. Thermographic Analysis of Parallelly Cables: A Method to Avoid Misdiagnosis. Appl. Therm. Eng. 2016, 104, 231–236. [Google Scholar] [CrossRef]

- Fuertes, S.; Picart, G.; Tourneret, J.-Y.; Chaari, L.; Ferrari, A.; Richard, C. Improving Spacecraft Health Monitoring with Automatic Anomaly Detection Techniques. In Proceedings of the 14th International Conference on Space Operations, Daejeon, Republic of Korea, 16–20 May 2016; p. 2430. [Google Scholar]

- Horne, R.; Mauw, S.; Mizera, A.; Stemper, A.; Thoemel, J. Anomaly Detection Using Deep Learning Respecting the Resources on Board a CubeSat. J. Aerosp. Inf. Syst. 2023, 1–14. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.A.M.N.; Vita, R.; Francisco, R.d.P.; Basto, J.P.; Alcalá, S.G.S. A Systematic Literature Review of Machine Learning Methods Applied to Predictive Maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Chapelle, O.; Haffner, P.; Vapnik, V.N. Support Vector Machines for Histogram-Based Image Classification. IEEE Trans. Neural Netw. 1999, 10, 1055–1064. [Google Scholar] [CrossRef] [PubMed]

- Hsu, S.-C.; Chen, I.-C.; Huang, C.-L. Image Classification Using Naive Bayes Classifier with Pairwise Local Observations. J. Inf. Sci. Eng. 2017, 33, 1177–1193. [Google Scholar]

- Khodadadzadeh, M.; Li, J.; Plaza, A.; Bioucas-Dias, J.M. A Subspace-Based Multinomial Logistic Regression for Hyperspectral Image Classification. IEEE Geosci. Remote Sens. Lett. 2014, 11, 2105–2109. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet Classification with Deep Convolutional Neural Networks. In Proceedings of the Advances in Neural Information Processing Systems, Lake Tahoe, NV, USA, 3–6 December 2012; Pereira, F., Burges, C.J., Bottou, L., Weinberger, K.Q., Eds.; Curran Associates, Inc.: New York, NY, USA, 2012; Volume 25. [Google Scholar]

- Rawat, W.; Wang, Z. Deep Convolutional Neural Networks for Image Classification: A Comprehensive Review. Neural Comput. 2017, 29, 2352–2449. [Google Scholar] [CrossRef] [PubMed]

- Pinto, J.K.; Kharbanda, O.P. Lessons for an Accidental Profession. Bus. Horiz. 1995, 38, 41–50. [Google Scholar] [CrossRef]

- Space Project Management. Project Planning and Implementation; ECSS-M-ST-10C Rev. 1 2009; ECSS: Noordwijk, The Netherlands, 2009.

- Hirshhorn, S.; Voos, L.; Bromley, L. NASA Systems Engineering Handbook; National Aeronautics and Space Administration: Washington, DC, USA, 2017.

- Chicarro, A.; Martin, P.; Trautner, R. The Mars Express Mission: An Overview. In Mars Express: The Scientific Payload; Andrew Wilson, Scientific Coordination: Noordwijk, The Netherlands, 2004; Volume 1240, pp. 3–13. ISBN 92-9092-556-6. [Google Scholar]

- Moore, C.; Caspi, A.; Woods, T.N.; Mason, J. The Miniature X-ray Solar Spectrometer (MinXSS) CubeSat: Instrument Characterization Techniques, Instrument Capabilities and Solar Science Objectives. AAS Sol. Phys. Div. Abstr. 2016, 47, 301–302. [Google Scholar]

- Beck, K.; Beedle, M.; van Bennekum, A.; Cockburn, A.; Cunningham, W.; Fowler, M.; Grenning, J.; Highsmith, J.; Hunt, A.; Jeffries, R.; et al. Agile Manifesto. Available online: http://agilemanifesto.org/ (accessed on 8 July 2023).

- Ebert, C.; Kirschke-Biller, F. Agile Systems Engineering. IEEE Softw. 2021, 38, 7–15. [Google Scholar] [CrossRef]

- Munakata, R. Cubesat Design Specification Rev. 13. Available online: https://static1.squarespace.com/static/5418c831e4b0fa4ecac1bacd/t/56e9b62337013b6c063a655a/1458157095454/cds_rev13_final2.pdf (accessed on 23 February 2024).

- Fischer, P.M.; Lüdtke, D.; Lange, C.; Roshani, F.C.; Dannemann, F.; Gerndt, A. Implementing Model-Based System Engineering for the Whole Lifecycle of a Spacecraft. CEAS Space J. 2017, 9, 351–365. [Google Scholar] [CrossRef]

- Raspberry Pi Ltd. (Trading) Product Brief (Raspberry Pi Zero 2 W). Available online: https://datasheets.raspberrypi.com/rpizero2/raspberry-pi-zero-2-w-product-brief.pdf (accessed on 22 November 2023).

- Melexis Datasheet (MLX90640 32 × 24 IR Array). Available online: https://www.melexis.com/en/product/MLX90640/Far-Infrared-Thermal-Sensor-Array (accessed on 22 November 2023).

- Van Rossum, G.; Drake, F.L. Python 3 Reference Manual, Scotts Valley; CreateSpace: Scotts Valley, CA, USA, 2009; ISBN 978-1-4414-1269-0. [Google Scholar]

- Rabbit MQ. Available online: https://www.rabbitmq.com (accessed on 19 February 2024).

- Python Construct Library. Available online: https://construct.readthedocs.io/en/latest/ (accessed on 19 February 2024).

- Robot Framework. Available online: https://robotframework.org/ (accessed on 19 February 2024).

- Sandler, M.; Howard, A.; Zhu, M.; Zhmoginov, A.; Chen, L.-C. MobileNetV2: Inverted Residuals and Linear Bottlenecks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, UT, USA, 18–23 June 2018. [Google Scholar]

| Anomaly | Not Anomaly | Uncertain | |

|---|---|---|---|

| Anomaly | 87.9% | 11.6% | 0.5% |

| Not anomaly | 1.2% | 98% | 0.8% |

| F1 score | 0.93 | 0.90 |

| Metric | Value |

|---|---|

| Area under ROC Curve | 0.93 |

| Weighted average precision | 0.93 |

| Weighted average recall | 0.92 |

| Weighted average F1 score | 0.92 |

| Requirement | Value |

|---|---|

| Data rate | 2 × 64 kbyte/downlink pass over Australia |

| Frequency downlink passes | 2/day |

| Experiment duration | Max 60 min/day |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thoemel, J.; Kanavouras, K.; Sachidanand, M.; Hein, A.; Ortiz del Castillo, M.; Pauly, L.; Rathinam, A.; Aouada, D. Lean Demonstration of On-Board Thermal Anomaly Detection Using Machine Learning. Aerospace 2024, 11, 523. https://doi.org/10.3390/aerospace11070523

Thoemel J, Kanavouras K, Sachidanand M, Hein A, Ortiz del Castillo M, Pauly L, Rathinam A, Aouada D. Lean Demonstration of On-Board Thermal Anomaly Detection Using Machine Learning. Aerospace. 2024; 11(7):523. https://doi.org/10.3390/aerospace11070523

Chicago/Turabian StyleThoemel, Jan, Konstantinos Kanavouras, Maanasa Sachidanand, Andreas Hein, Miguel Ortiz del Castillo, Leo Pauly, Arunkumar Rathinam, and Djamila Aouada. 2024. "Lean Demonstration of On-Board Thermal Anomaly Detection Using Machine Learning" Aerospace 11, no. 7: 523. https://doi.org/10.3390/aerospace11070523