A Sample Average Approximation Approach for Aircraft Product Configuration Optimization with Customer Order Uncertainty

Abstract

:1. Introduction

2. Literature Review

2.1. Uncertainty Management Approach

2.2. Production Configuration in Aircraft Manufacturing

2.3. Contributions of This Research

3. General-Configuration Aircraft Optimization Approach

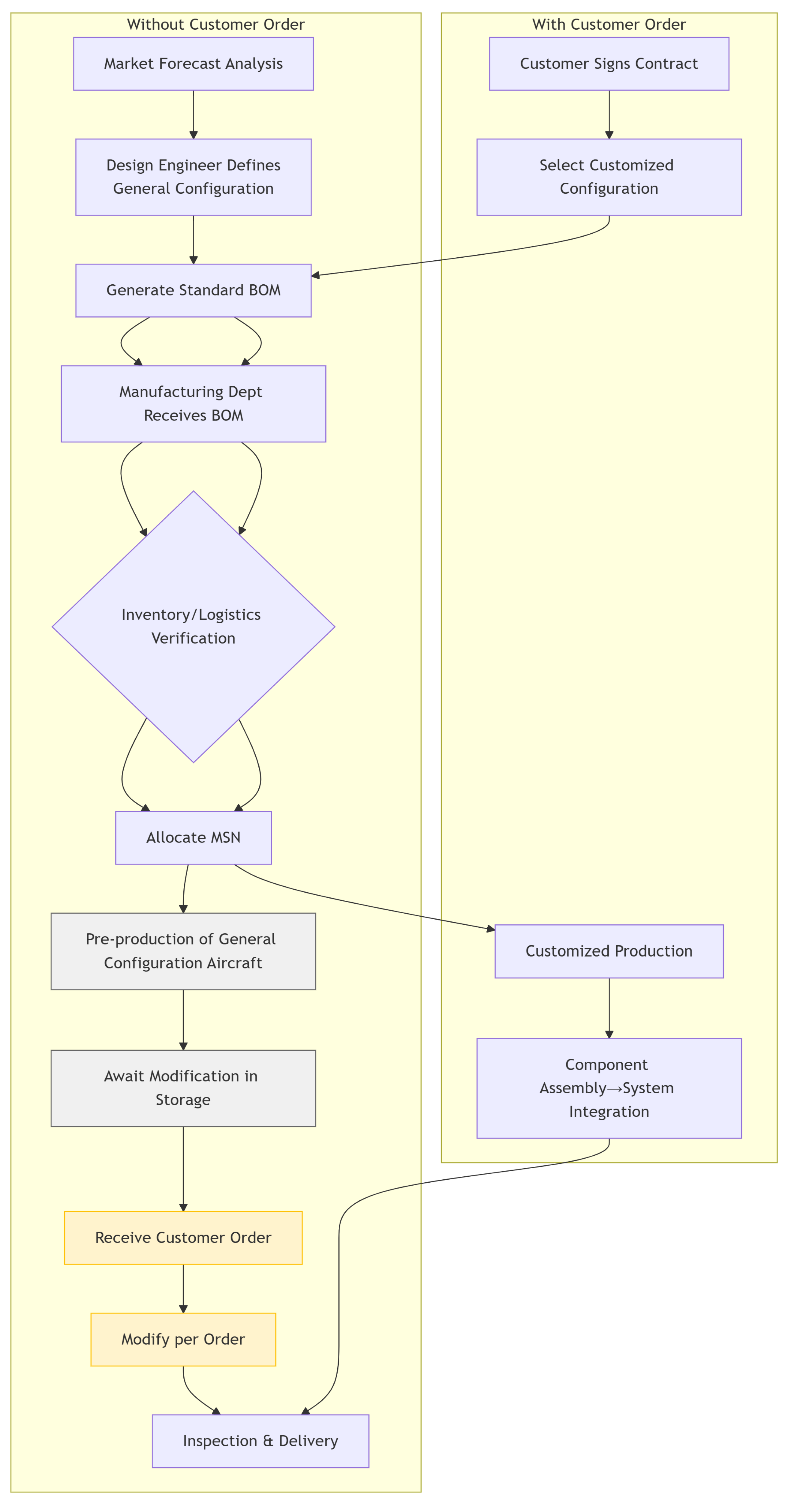

3.1. Problem Definition

3.2. Stochastic Optimization Model for GCA

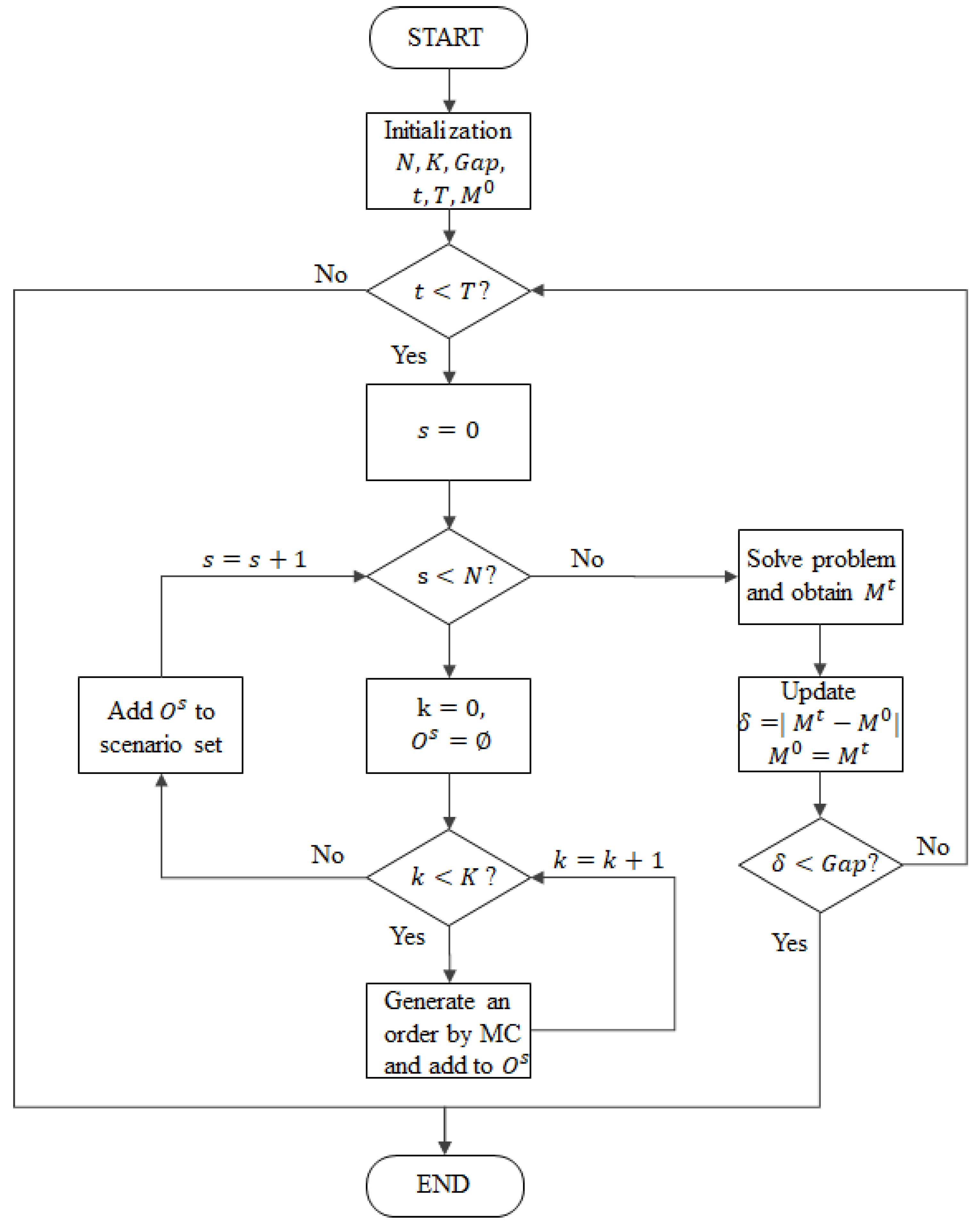

3.3. A Sample Average Approximate Approach

| Algorithm 1: The MC-based SAA approach. |

| START |

| 1. Initialize historical data set , sampling times N, number of orders K, converge gap , iteration time , initial objective . |

| 2. While Do |

| 3. Set , . |

| 4. For Do |

| 5. Generate scenario s, set , |

| 6. For Do |

| 7. Generate order k using Monte Carlo sampling in and add it to . Set . |

| 8. End for |

| 9. Add the scenario s with the orders to the objective Formula (10). Set . |

| 10. End For |

| 11. Solve Problem with the updated objective Formula (10) and obtain the optimal objective |

| 12. Set , and set . |

| 13. End while |

| 14. Return |

| END |

4. Application Analysis and Results

4.1. Application Background Description

4.2. Application Results

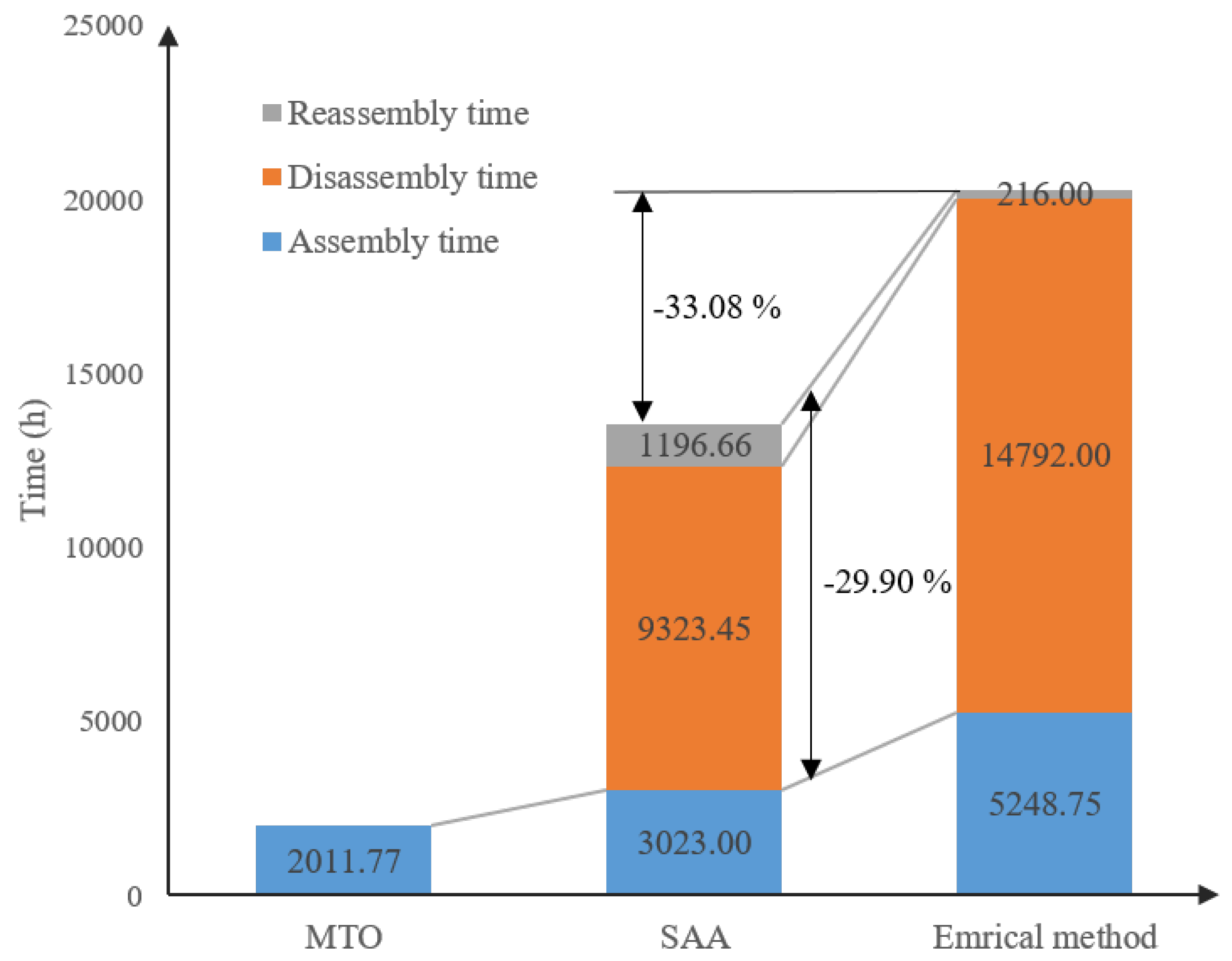

4.2.1. Effectiveness Analysis

- (1)

- The ideal situation of applying the MTO strategy.

- (2)

- An empirical method in real production.

- (3)

- The GCA strategy obtained by the SAA approach.

- (1)

- The MTO strategy had a production time of 2011.77 h with no reworking time, which was the least of the three modes. Aircraft OEMs usually hope for a proper and fixed pace of aircraft production. However, due to changes in the airline’s product business strategy, operational status, etc., the aircraft delivery time to the airline is highly uncertain. The MTO strategy is inapplicable under uncertainty conditions because the MTO production is usually idealized for each order.

- (2)

- When the aircraft order is highly uncertain and the MTO strategy is no longer applicable, OEMs adopt a GCA approach for aircraft production. OEMs apply the SAA approach solution with the total production time reduced by 33.08% compared to the empirical method solution for the same orders, as demonstrated in Figure 5. The reason is that the empirical method generates the configuration by individually optimizing each option group; thus, it cannot optimize the configuration from a global perspective or considering the uncertainty of orders.

- (3)

- Additional work has to be conducted after planning; a rework workstation is set to take pro-active actions to convert the GCA into an order-specific configuration. However, the workload in the rework station in real production often exceeds the limit. As shown in Figure 5, the total time (including disassembly and re-assembly periods) of the SAA approach was 29.90% lower than the empirical method, confirming that the SAA solution gives a more reasonable aircraft configuration.

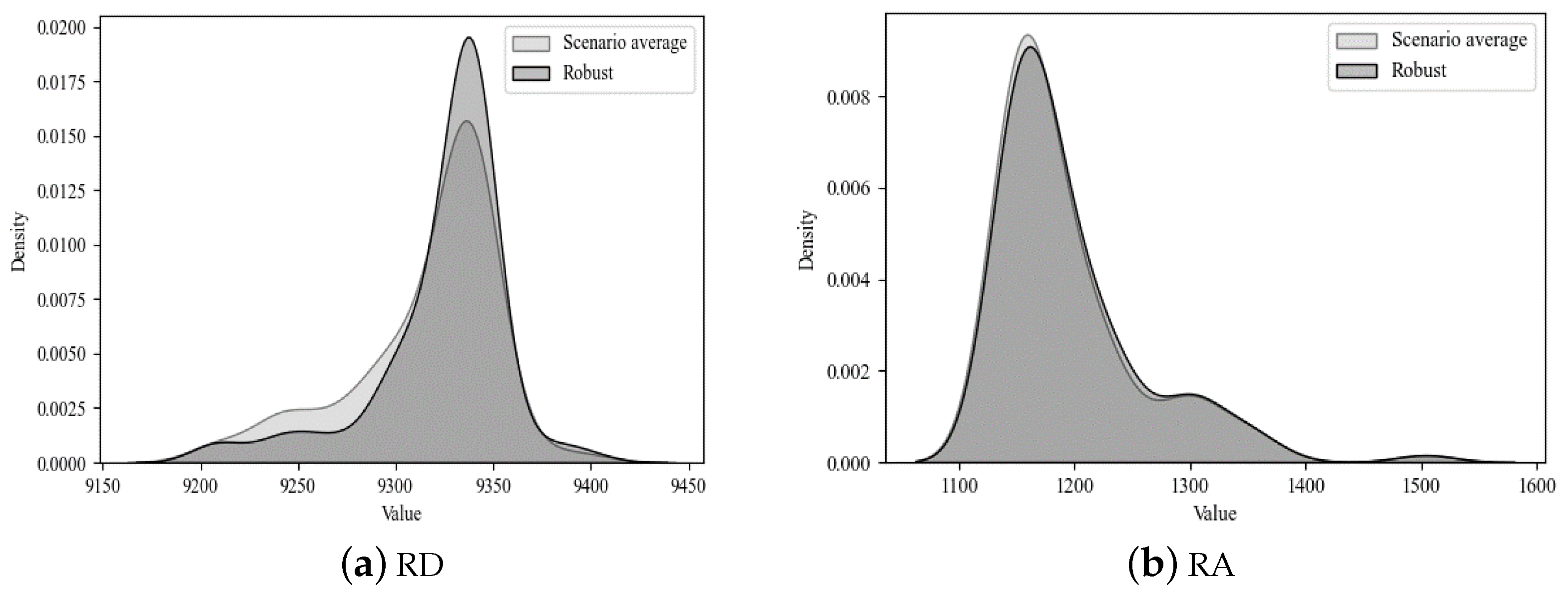

4.2.2. Robustness and Sensitivity Analysis

- (1)

- The gap between the robust solution and the single scenario optimal solutions was 0.05%, implying that these costs are expected to be saved if orders are predicted accurately or are known. This result confirms that the objective of the robust solution is very close to the optimal solutions of each scenario; thus, the robust solution is acceptable.

- (2)

- The variances of the disassembly time and re-assembly time for the robust solution were 18.28 and 0.81% less than that of the scenario optimal solutions, which was an expected trend. The robust solution obtained by the SAA approach could achieve higher production stability.

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GCA | General-Configuration Aircraft |

| SAA | Sample Average Approximate |

| OEM | Original Equipment Manufacturer |

| MSN | Manufacturing Serial Number |

| BOM | Bill of Materials |

| MTO | Make-To-Order |

| AMAL | Aircraft Moving Assembly Line |

References

- McIntyre, J.R.; Hoadley, J.R. Chinese Commercial Aircraft Manufacturing Policy: The View from the Commanding Heights. In The New Chinese Dream: Industrial Transition in the Post-Pandemic Era; Spigarelli, F., McIntyre, J.R., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 105–119. [Google Scholar] [CrossRef]

- Zheng, X.; Hu, X.; Arista, R.; Lu, J.; Sorvari, J.; Lentes, J.; Ubis, F.; Kiritsis, D. A semantic-driven tradespace framework to accelerate aircraft manufacturing system design. J. Intell. Manuf. 2024, 35, 175–198. [Google Scholar] [CrossRef]

- Kyrdoda, Y.; Balzano, M.; Marzi, G. Learn to survive crises: The role of firm resilience, innovation capabilities and environmental dynamism. Technol. Soc. 2023, 74, 102285. [Google Scholar] [CrossRef]

- Mundt, C.; Lödding, H. Coping with the uncertainties of make-to-order production: A new approach for determining reliable delivery times with the throughput diagram. In Production Planning & Control; Taylor & Francis: Abingdon, UK, 2024; pp. 1–27. [Google Scholar] [CrossRef]

- Cai, Y.; He, Y.; Shi, R.; Feng, T.; Li, J. Resilience-oriented approach of dynamic production and maintenance scheduling optimisation considering operational uncertainty. Int. J. Prod. Res. 2024, 62, 7812–7835. [Google Scholar] [CrossRef]

- Peng, J.; Yang, H.; Wan, H. Production-and-order strategy with demand information updating and uncertain spot price. INFOR Inf. Syst. Oper. Res. 2024, 62, 480–528. [Google Scholar] [CrossRef]

- Elyasi, M.; Altan, B.; Ekici, A.; Özener, O. Ö; Yanıkoğlu, İ; Dolgui, A. Production planning with flexible manufacturing systems under demand uncertainty. Int. J. Prod. Res. 2024, 62, 157–170. [Google Scholar] [CrossRef]

- Hu, H.; Guo, S.; Qin, Y.; Lin, W. Two-stage stochastic programming model and algorithm for mitigating supply disruption risk on aircraft manufacturing supply chain network design. Comput. Ind. Eng. 2023, 175, 108880. [Google Scholar] [CrossRef]

- Polotski, V.; Kenné, J.P.; Gharbi, A. Estimation-based production control of manufacturing–remanufacturing systems with uncertain seasonal return and imprecise demand and inventory. Int. J. Prod. Res. 2024, 62, 4595–4622. [Google Scholar] [CrossRef]

- Wu, Y. A stochastic model for production loading in a global apparel manufacturing company under uncertainty. Prod. Plan. Control 2011, 22, 269–281. [Google Scholar] [CrossRef]

- Zhang, F.; Li, J.; Hui, J.; Zhu, B.; Ding, K. Uncertain demand modeling of warehouse product service system based on interval number optimization. Int. J. Comput. Integr. Manuf. 2020, 33, 133–141. [Google Scholar] [CrossRef]

- Lin, H.J. An economic production quantity model with backlogging and imperfect rework process for uncertain demand. Int. J. Prod. Res. 2021, 59, 467–482. [Google Scholar] [CrossRef]

- Zhang, L.L. Product configuration: A review of the state-of-the-art and future research. Int. J. Prod. Res. 2014, 52, 6381–6398. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, S.; Qiu, L.; Wang, Z.; Hu, K. A factorisation-based recommendation model for customised products configuration design. Int. J. Prod. Res. 2023, 61, 6381–6402. [Google Scholar] [CrossRef]

- Feng, Y.; Song, Z.; Lu, C. The Optimization of Civil Aircraft Product Option Selection Considering the Economy Response with an Improved Non-Dominated Sorting Genetic Algorithm. Appl. Sci. 2022, 12, 5294. [Google Scholar] [CrossRef]

- Yang, T.; Wang, Q.; Fu, Q.; Li, Y. Evaluation and Decision Methods for Product Configuration Design Process based on Network Planning Technology with the Demand Preferences of Customers. In Proceedings of the 2021 3rd International Conference on Artificial Intelligence and Advanced Manufacture (AIAM), Manchester, UK, 23–25 October 2021; pp. 446–452. [Google Scholar] [CrossRef]

- Colledani, M.; Silipo, L.; Yemane, A.; Lanza, G.; Bürgin, J.; Hochdörffer, J.; Georgoulias, K.; Mourtzis, D.; Bitte, F.; Bernard, A.; et al. Technology-based Product-services for Supporting Frugal Innovation. Procedia CIRP 2016, 47, 126–131. [Google Scholar] [CrossRef]

- Hochdörffer, J.; Buergin, J.; Vlachou, E.; Zogopoulos, V.; Lanza, G.; Mourtzis, D. Holistic approach for integrating customers in the design, planning, and control of global production networks. CIRP J. Manuf. Sci. Technol. 2018, 23, 98–107. [Google Scholar] [CrossRef]

- Hong, G.; Hu, L.; Xue, D.; Tu, Y.L.; Xiong, Y.L. Identification of the optimal product configuration and parameters based on individual customer requirements on performance and costs in one-of-a-kind production. Int. J. Prod. Res. 2008, 46, 3297–3326. [Google Scholar] [CrossRef]

- Tang, D.; Wang, Q.; Ullah, I. Optimisation of product configuration in consideration of customer satisfaction and low carbon. Int. J. Prod. Res. 2017, 55, 3349–3373. [Google Scholar] [CrossRef]

- Buergin, J.; Blaettchen, P.; Kronenbitter, J.; Molzahn, K.; Schweizer, Y.; Strunz, C.; Almagro, M.; Bitte, F.; Ruehr, S.; Urgo, M.; et al. Robust assignment of customer orders with uncertain configurations in a production network for aircraft manufacturing. Int. J. Prod. Res. 2018, 57, 749–763. [Google Scholar] [CrossRef]

- Yang, D.; Li, X.; Jiao, R.J.; Wang, B. Decision support to product configuration considering component replenishment uncertainty: A stochastic programming approach. Decis. Support Syst. 2018, 105, 108–118. [Google Scholar] [CrossRef]

- Song, Q.; Ni, Y.; Ralescu, D.A. The impact of lead-time uncertainty in product configuration. Int. J. Prod. Res. 2021, 59, 959–981. [Google Scholar] [CrossRef]

- Song, Q.; Ni, Y.; Ralescu, D.A. Product configuration using redundancy and standardisation in an uncertain environment. Int. J. Prod. Res. 2021, 59, 6451–6470. [Google Scholar] [CrossRef]

- Rzevski, G.; Knezevic, J.; Skobelev, P.; Borgest, N.; Lakhin, O. Managing aircraft lifecycle complexity. Int. J. Des. Nat. Ecodyn. 2016, 11, 77–87. [Google Scholar] [CrossRef]

- Heiets, I.; Oleshko, T.; Leshchinsky, O. Airline-within-Airline business model and strategy: Case study of Qantas Group. Transp. Res. Procedia 2021, 56, 96–109. [Google Scholar] [CrossRef]

- Kuyucak Sengur, F.; Aldemir, H.; Akınet, M. Competitive Strategies in the Airline Industry; IGI Global: Hershey, PA, USA, 2022; pp. 148–163. [Google Scholar] [CrossRef]

| Number | Identification | Description | Mandatory? |

|---|---|---|---|

| 1 | OPT_XX-YY-ZZ-001 | normal range | No |

| 2 | OPT_XX-YY-ZZ-002 | long range | No |

| 3 | OPT_XX-YY-WW-001 | 90 seats cabin furnishing | Yes |

| … | … | … | … |

| Indices | Representation |

|---|---|

| i | Index of product option groups. |

| I | Number of configurations in the product. |

| Index of options in the option group i. | |

| Number of options associated with the option group i. | |

| The least number of options should be chosen for the option group i. | |

| Disassemble time of options for the option group i. | |

| Re-assemble time of options for the option group i. | |

| j | Index of customers. |

| J | Number of customers. |

| Binary random variable, equal to 1 if option is chosen for the option | |

| group i by the customer j. | |

| Random matrix with three dimensions (customers, option groups, and | |

| options), a combination of orders. | |

| k | Index of stations. |

| K | Number of stations in the production line. |

| Duration time of the configuration i performed as the option | |

| at the station k. | |

| Maximal duration times reserved for options of option groups | |

| at the station k. | |

| Binary variable equals 1 if the option is chosen for | |

| the option group i. |

| Workstation | Reserved Time (h) |

|---|---|

| 1 | 560 |

| 2 | 800 |

| 3 | 320 |

| 4 | 400 |

| 5 | 80 |

| 6 | 720 |

| 7 | 80 |

| Robust Solution | Scenario Optimal Solutions | Gap | |

|---|---|---|---|

| AS (h) | 3023.00 | 3026.22 | −0.11% |

| RD (h) | 9323.45 | 9315.89 | 0.08% |

| RA (h) | 1196.66 | 1194.14 | 0.21% |

| Total (h) | 13,543.11 | 13,536.25 | 0.05% |

| 1136.76 | 1391.05 | −18.28% | |

| 4168.04 | 4202.06 | −0.81% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Qiu, K.; Niu, B.; Chen, L.; Xi, J. A Sample Average Approximation Approach for Aircraft Product Configuration Optimization with Customer Order Uncertainty. Aerospace 2025, 12, 199. https://doi.org/10.3390/aerospace12030199

Zhang X, Qiu K, Niu B, Chen L, Xi J. A Sample Average Approximation Approach for Aircraft Product Configuration Optimization with Customer Order Uncertainty. Aerospace. 2025; 12(3):199. https://doi.org/10.3390/aerospace12030199

Chicago/Turabian StyleZhang, Xinyuan, Kejun Qiu, Bo Niu, Lu Chen, and Juntong Xi. 2025. "A Sample Average Approximation Approach for Aircraft Product Configuration Optimization with Customer Order Uncertainty" Aerospace 12, no. 3: 199. https://doi.org/10.3390/aerospace12030199

APA StyleZhang, X., Qiu, K., Niu, B., Chen, L., & Xi, J. (2025). A Sample Average Approximation Approach for Aircraft Product Configuration Optimization with Customer Order Uncertainty. Aerospace, 12(3), 199. https://doi.org/10.3390/aerospace12030199