Model-Based Fault Detection and Identification for Prognostics of Electromechanical Actuators Using Genetic Algorithms

Abstract

:1. Introduction

2. Aim of This Work

3. Reference Model of the Electromechanical Actuator

- The Actuator Control Electronics (ACE) evaluates the corrective action for the motor bridge comparing the actual and commanded positions;

- The Power Drive Electronics (PDE) is the motor bridge itself, converting the DC power supply into the three-phase current necessary to drive the motor, modulated accordingly to rotor angular position and signal from the ACE module;

- An electric motor, usually BLDC type (BrushLess Direct Current), converts electrical power into mechanical power;

- A mechanical transmission, composed by a gear reducer and/or a rotary/linear conversion mechanism (e.g., a ball or roller screw) transfers the motion from the motor to the user, i.e., the aircraft control surface;

- A set of position, velocity and current transducers send their measured dimension to the ACE module, allowing the closure of the feedback loop.

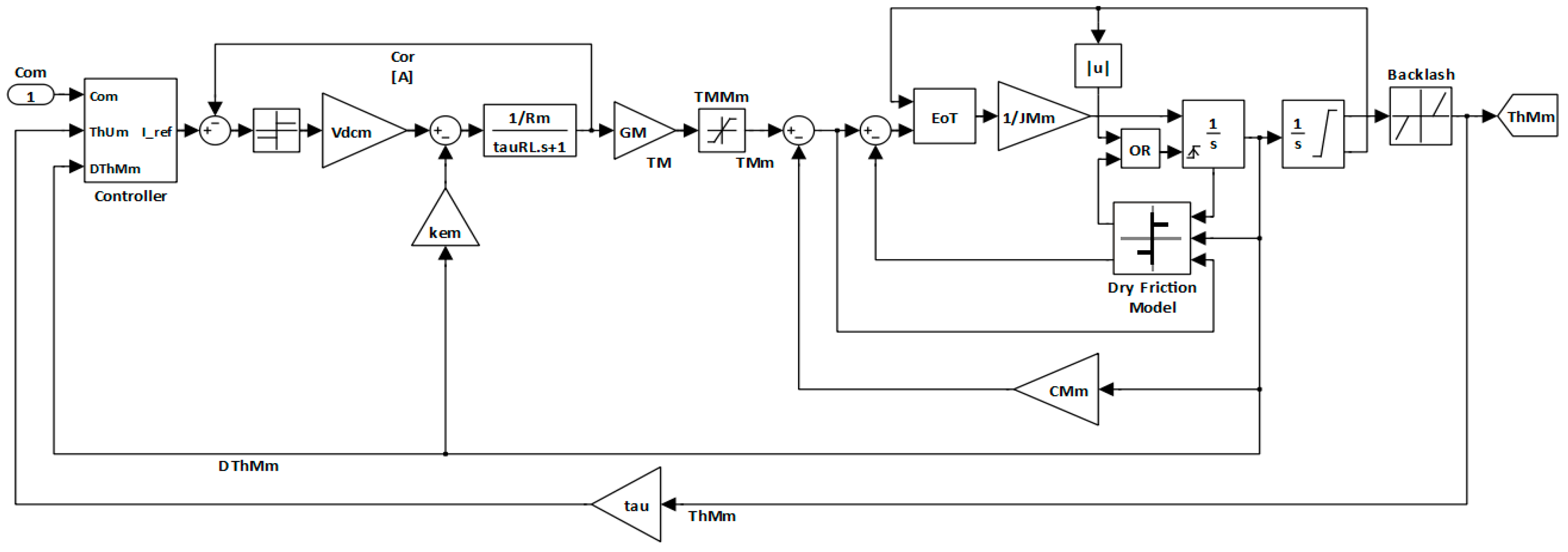

- The ACE block simulates the behavior of the control electronics module by generating the output reference current Iref, as shown in [19];

- The BLDC EM Model subsystem represents the power drive electronic module and includes the electromagnetic model of the trapezoidal BLDC motor; it evaluates the torque delivered by the motor as a function of the voltages generated by the three-phase electrical power regulator (BLDC EM Model); this model, as employed in [17], has been developed according to the mathematical models and the assumptions propositioned by [20,21,22];

- The EMA Dynamical Model block simulates the mechanical effects within the motor and the transmission, by means of a single degree of freedom MCK model. Additionally, this model accounts for several non-linear effects that characterize the dynamic response of the mechanical system, such as dry friction [23,24], backlash [25], and mechanical end-stops [26].

- The Com input block simulates the pilot’s command and allows to generate different functions as steps, ramps, sine waves etc.;

- Another input block (TR), similar to the previous one, is used to consider the aerodynamic load on the control surface.

4. EMA Degradations and Fault Modes

- Mechanical or structural failures;

- BLDC motor failures;

- electronics failures;

- sensor failures.

5. Monitor Model of the Electromechanical Actuator

6. Proposed Fault Detection and Identification Algorithm and Problem Setup

7. Genetic Algorithm Tuning

7.1. Definition of Bounds and Constraints

7.2. Definition of Population Size

7.3. Initialization of the First Generation

7.4. Definition of the Initial Range

7.5. Scaling of the Fitness Function

7.6. Definition of the Selection Fuction

7.7. Setting of the Crossover Fraction and Crossover Function

8. Results

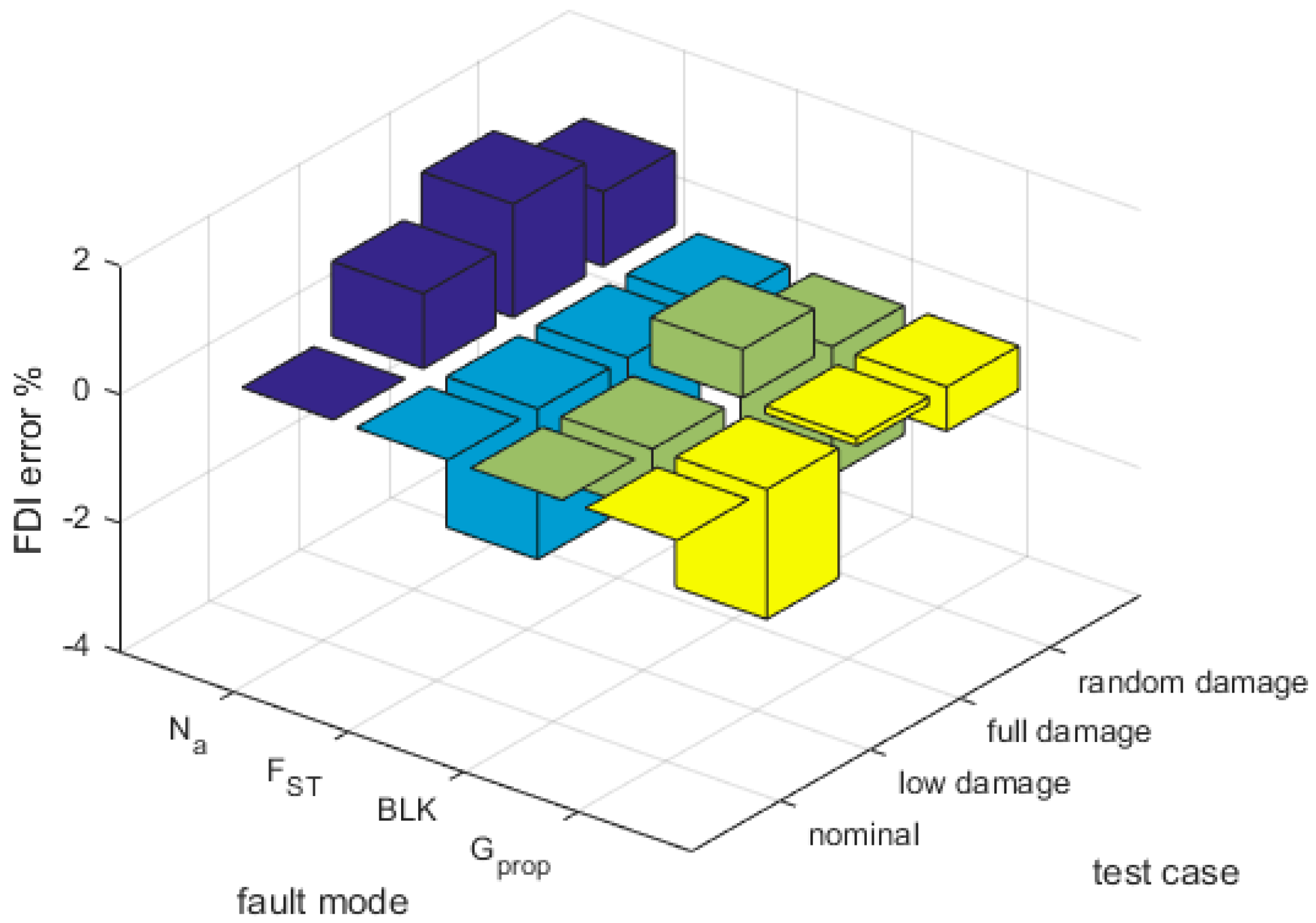

Results for Multiple Faults Identification

- Nominal conditions: This test case corresponds to a non-damaged system. The FDI algorithm is able to quickly recognize this condition since the initial population setting contains an individual in nominal condition; then, the GA converges in a single iteration, and the execution is terminated as the stopping criteria are satisfied. Results of these tests are reported in Table 2.

- Incipient damage: This condition is of particular interest for the prognostic field since it represents the early stages of progressive faults; the extent of damages is small, so that they are detectable but do not compromise the system performance. Correctly identifying those damages is the goal of prognostic FDI and supplies the data necessary for estimation of the system Remaining Useful Life. Results of incipient damage tests are reported in Table 3.

- Full damage: A larger fault level results in a full damage, i.e., the system cannot meet its functional or performance requirements any more. This condition falls into the field of diagnostics since the system has already failed, and no estimation of Remaining Useful Life can be performed to plan a maintenance intervention. However, an FDI algorithm shall be robust enough to identify such conditions with acceptable accuracy, in order to trigger a corrective maintenance intervention. Results of these tests are reported in Table 4.

- Random damage combination: A last group of test cases includes fault combinations of heterogeneous extent, randomly sampled in the problem domain. This condition is expected to be the closest to the real operating condition of the proposed FDI strategy, since in a field operation multiple fault modes are likely to occur at the same time, but with widely different damage levels. Results of tests for random multiple faults are reported in Table 5.

9. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Byington, C.S.; Watson, W.; Edwards, D.; Stoelting, P. A Model-Based Approach to Prognostics and Health Management for Flight Control Actuators. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 6–13 March 2004. [Google Scholar]

- Borello, L.; Dalla Vedova, M.D.L.; Jacazio, G.; Sorli, M. A Prognostic Model for Electrohydraulic Servovalves. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 27 September–1 October 2009. [Google Scholar]

- Dalla Vedova, M.D.L.; Maggiore, P.; Pace, L. Proposal of Prognostic Parametric Method Applied to an Electrohydraulic Servomechanism Affected by Multiple Failures. WSEAS Trans. Environ. Dev. 2014, 10, 478–490. [Google Scholar]

- Bindu, S.; Thomas, V.V. A Modified Direct-Quadrature Axis Model for Characterization of Air-Gap Mixed Eccentricity Faults in Three-Phase Induction Motor. Int. Rev. Model. Simul. 2018, 11, 6. [Google Scholar] [CrossRef]

- Battipede, M.; Dalla Vedova, M.D.L.; Maggiore, P.; Romeo, S. Model based analysis of precursors of electromechanical servomechanisms failures using an artificial neural network. In Proceedings of the AIAA SciTech Modeling and Simulation Technologies Conference, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Elasha, F.; Shanbr, S.; Li, X.; Mba, D. Prognosis of a Wind Turbine Gearbox Bearing Using Supervised Machine Learning. Sensors 2019, 19, 3092. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Hu, W.; Cao, D.; Zhang, B.; Huang, Q.; Chen, Z.; Blaabjerg, F. An Imbalance Fault Detection Algorithm for Variable-Speed Wind Turbines: A Deep Learning Approach. Energies 2019, 12, 2764. [Google Scholar] [CrossRef]

- Maggiore, P.; Dalla Vedova, M.D.L.; Pace, L.; Desando, A. Evaluation of the correlation coefficient as a prognostic indicator for electromechanical servomechanism failures. Int. J. Progn. Health Manag. 2015, 6, 1–13. [Google Scholar]

- Liu, H.; Qin, C.; Liu, M. A Rail Fault Diagnosis Method Based on Quartic C2 Hermite Improved Empirical Mode Decomposition Algorithm. Sensors 2019, 19, 3300. [Google Scholar] [CrossRef]

- Quigley, R.E.J. More electric aircraft. In Proceedings of the Eighth Annual IEEE Applied Power Electronics Conference—APEC 93, San Diego, CA, USA, 7–11 March 1993. [Google Scholar]

- Howse, M. All-electric aircraft. Power Eng. 2003, 17, 35–37. [Google Scholar] [CrossRef]

- Balaban, E.; Bansal, P.; Stoelting, P.; Saxena, A.; Goebel, K.F.; Curran, S. A diagnostic approach for electro-mechanical actuators in aerospace systems. In Proceedings of the 2009 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2009. [Google Scholar]

- Balaban, E.; Saxena, A.; Goebel, K.; Byington, C.S.; Bharadwaj, S.P.; Smith, M. Experimental Data Collection and Modeling for Nominal and Fault Conditions on Electro-Mechanical Actuators. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 27 September–1 October 2009. [Google Scholar]

- Balaban, E.; Saxena, A.; Narasimhan, S.; Roychoudhury, I.; Goebel, K.; Koopmans, M. Airborne Electro-Mechanical Actuator Test Stand for Development of Prognostic Health Management Systems. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Portland, OR, USA, 10–16 October 2010. [Google Scholar]

- Fico, V.M.; Rodríguez Vázquez, A.L.; Martín Prats, M.Á.; Bernelli-Zazzera, F. Failure Detection by Signal Similarity Measurement of Brushless DC Motors. Energies 2019, 12, 1364. [Google Scholar] [CrossRef]

- De Martin, A.; Jacazio, G.; Vachtsevanos, G. Windings fault detection and prognosis in electro-mechanical flight control actuators operating in active-active configuration. Int. J. Progn. Health Manag. 2017, 8, 2. [Google Scholar]

- Dalla Vedova, M.D.L.; Berri, P.C.; Re, S. Novel metaheuristic bio-inspired algorithms for prognostics of onboard electromechanical actuators. Int. J. Mech. Control 2018, 19, 95–101. [Google Scholar]

- Dalla Vedova, M.D.L.; Germanà, A.; Maggiore, P. Proposal of a new simulated annealing model-based fault identification technique applied to flight control EM actuators. In Risk, Reliability and Safety: Innovating Theory and Practice, Proceedings of the 26th European Safety and Reliability Conference (ESREL 2016), Glasgow, Scotland, 25–29 September 2016; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Todić, I.; Miloš, M.; Pavišić, M. Position and speed control of electromechanical actuator for aerospace applications. Teh. Vjesn. 2013, 20, 853–860. [Google Scholar]

- Çunkas, M.; Aydoğdu, O. Realization of Fuzzy Logic Controlled Brushless DC Motor Drives using Matlab/Simulink. Math. Comput. Appl. 2010, 15, 218–229. [Google Scholar] [CrossRef]

- Halvaei Niasar, A.; Moghbelli, H.; Vahedi, A. Modelling, Simulation and Implementation of Four-Switch Brushless DC Motor Drive Based on Switching Functions. In Proceedings of the IEEE EUROCON 2009, St. Petersburg, Russia, 18–23 May 2009. [Google Scholar]

- Hua, J.; Zhiyong, H. Simulation of Sensorless Permanent Magnetic Brushless DC Motor Control System. In Proceedings of the IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2008. [Google Scholar]

- Dalla Vedova, M.D.L.; Maggiore, P.; Pace, L. A new prognostic method based on simulated annealing algorithm to deal with the effects of dry friction on electromechanical actuators. Int. J. Mech. 2015, 9, 236–245. [Google Scholar]

- Borello, L.; Villero, G.; Dalla Vedova, M.D.L. New asymmetry monitoring techniques: Effects on attitude control. Aerospace Science and Technology 2009, 13, 475–487. [Google Scholar] [CrossRef]

- Borello, L.; Villero, G.; Dalla Vedova, M.D.L. Flap failure and aircraft controllability: Developments in asymmetry monitoring techniques. J. Mech. Sci. Technol. 2014, 28, 4593–4603. [Google Scholar] [CrossRef]

- Dalla Vedova, M.D.L.; De Fano, D.; Maggiore, P. Neural network design for incipient failure detection on aircraft EM actuator. Int. J. Mech. Control 2016, 17, 77–83. [Google Scholar]

- Lee, B.K.; Ehsani, M. Advanced Simulation Model for Brushless DC Motor Drives. Electr. Power Compon. Syst. 2003, 31, 841–868. [Google Scholar] [CrossRef]

- Kaliappan, E.; Chellamuthu, C. Simplified Modeling, Analysis and Simulation of Permanent Magnet Brushless Direct Current Motors for Sensorless Operation. Am. J. Appl. Sci. 2012, 9, 1046–1054. [Google Scholar] [Green Version]

- Gökdere, L.U.; Chiu, S.L.; Keller, K.J.; Vian, J. Lifetime control of electromechanical actuators. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 5–12 March 2005. [Google Scholar]

- Kenjo, T.; Nagamori, S. Brushless Motors: Advanced Theory and Modern Applications; Sogo Electronics Press: Tokyo, Japan, 2003. [Google Scholar]

- Chesley, J.C. Handbook of Reliability Prediction Procedures for Mechanical Equipment; NSWC Carderock Division: Bethesda, MD, USA, 2011. [Google Scholar]

- Weiss, J. Control Actuation Reliability and Redundancy for Long Duration, Underwater Vehicle Missions with High Value Payloads. In Proceedings of the 2014 Underwater Intervention Conference, New Orleans, LA, USA, 11–13 February 2014. [Google Scholar]

- Borello, L.; Dalla Vedova, M.D.L. A Dry Friction Model and Robust Computational Algorithm for Reversible or Irreversible Motion Transmission. Int. J. Mech. Control 2012, 13, 37–48. [Google Scholar]

- Shashidhara, S.M.; Raju, P.S. Stator Winding Fault Diagnosis of Three-Phase Induction Motor by Parks Vector Approach. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2013, 2, 2901–2906. [Google Scholar]

- Ginart, A.; Brown, D.; Kalgren, P.; Roemer, M. On-line Ringing Characterization as a PHM Technique for Power Drives and Electrical Machinery. In Proceedings of the IEEE Autotestcon 2007, Baltimore, MD, USA, 17–20 September 2007. [Google Scholar]

- Ginart, A.; Brown, D.; Kalgren, P.; Roemer, M. Inverter Power Drive Transistor Diagnostic and Extended Operation under One-Transistor Trigger Suppression. In Proceedings of the Applied Power Electronics Conference and Exposition 2008 (APEC 2008), Austin, TX, USA, 24–28 February 2008. [Google Scholar]

- Berri, P.C.; Dalla Vedova, M.D.L.; Mainini, L. Diagnostics of Actuation System Faults from Dynamic Data. In Proceedings of the 6th European Conference on Computational Mechanics (ECCM 6), European Community on Computational Methods in Applied Sciences (ECCOMAS), Glasgow, UK, 11–15 June 2018. [Google Scholar]

- Raie, A.; Rashtchi, V. Using a genetic algorithm for detection and magnitude determination of turn faults in an induction motor. Electr. Eng. 2002, 84, 275–279. [Google Scholar] [CrossRef]

- Alamyal, M.; Gadoue, S.M.; Zahawi, B. Detection of induction machine winding faults using genetic algorithm. In Proceedings of the 9th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Valencia, Spain, 27–30 August 2013; pp. 157–161. [Google Scholar]

- Mitchell, M. An Introduction to Genetic Algorithms; MIT Press: Cambridge, UK, 1996. [Google Scholar]

- Mishra, R.G.; Mishra, R.; Kuchhal, P.; Kumari, P. Optimization and Analysis of High Gain Wideband Microstrip Patch Antenna using Genetic Algorithm. Int. J. Eng. Technol. 2018, 7, 176–179. [Google Scholar] [CrossRef]

- Kahraman, M.; Erbatur, F. A GA Approach for Simultaneous Structural Optimization. In Proceedings of the International Conference on Structural Engineering, Mechanics and Computation, Cape Town, South Africa, 2–4 April 2001. [Google Scholar]

- Vijay, M.; Jena, D. GA Based Adaptive Controller for 2DOF Robot Manipulator. IFAC Proc. Vol. 2016, 47, 670–675. [Google Scholar] [CrossRef]

- Shimoyama, K.; Yoshimizu, S.; Jeong, S.; Obayashi, S.; Yokono, Y. Multi-Objective Design Optimization for a Steam Turbine Stator Blade Using LES and GA. J. Comput. Sci. Technol. 2011, 5, 134–147. [Google Scholar] [CrossRef] [Green Version]

- Germanà, A. Genetic Algorithms for the prognostic of electro-mechanic servomechanisms for aeronautical applications. Master’s Thesis, Politecnico di Torino, Turin, Italy, 2015. [Google Scholar]

| Bounds | Na | FST (N) | BLK (rad) | Gprop (s−1) |

|---|---|---|---|---|

| Lower Bound | 0.8 | 0.1689 1 | 0 1 | 5 × 104 |

| Upper Bound | 1 1 | 0.8445 | 0.04 | 1.5 × 105 |

| Fault Mode | Actual Value | Estimated Value | Accuracy 1 |

|---|---|---|---|

| Na | 1 | 1 | 100% |

| FST | 0.1689 | 0.1689 | 100% |

| BLK | 0 | 0 | 100% |

| Gprop | 1.0000 × 105 | 1.0000 × 105 | 100% |

| Fault Mode | Actual Value | Estimated Value | Accuracy |

|---|---|---|---|

| Na | 0.9500 | 0.9611 | 98.83% |

| FST | 0.3378 | 0.3299 | 97.65% |

| BLK | 0.0100 | 0.0099 | 98.60% |

| Gprop | 1.0000 × 105 | 9.798 × 104 | 97.98% |

| Fault Mode | Actual Value | Estimated Value | Accuracy |

|---|---|---|---|

| Na | 0.8000 | 0.8141 | 98.23% |

| FST | 0.8445 | 0.8274 | 97.97% |

| BLK | 0.0400 | 0.0403 | 99.25% |

| Gprop | 1.5000 × 105 | 1.4982 × 105 | 99.87% |

| Fault Mode | Actual Value | Estimated Value | Accuracy |

|---|---|---|---|

| Na | 0.9500 | 0.9610 | 98.41% |

| FST | 0.6756 | 0.6729 | 99.60% |

| BLK | 0.0100 | 0.0098 | 98.00% |

| Gprop | 1.2500 × 105 | 1.2414 × 105 | 99.31% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dalla Vedova, M.D.L.; Germanà, A.; Berri, P.C.; Maggiore, P. Model-Based Fault Detection and Identification for Prognostics of Electromechanical Actuators Using Genetic Algorithms. Aerospace 2019, 6, 94. https://doi.org/10.3390/aerospace6090094

Dalla Vedova MDL, Germanà A, Berri PC, Maggiore P. Model-Based Fault Detection and Identification for Prognostics of Electromechanical Actuators Using Genetic Algorithms. Aerospace. 2019; 6(9):94. https://doi.org/10.3390/aerospace6090094

Chicago/Turabian StyleDalla Vedova, Matteo D. L., Alfio Germanà, Pier Carlo Berri, and Paolo Maggiore. 2019. "Model-Based Fault Detection and Identification for Prognostics of Electromechanical Actuators Using Genetic Algorithms" Aerospace 6, no. 9: 94. https://doi.org/10.3390/aerospace6090094

APA StyleDalla Vedova, M. D. L., Germanà, A., Berri, P. C., & Maggiore, P. (2019). Model-Based Fault Detection and Identification for Prognostics of Electromechanical Actuators Using Genetic Algorithms. Aerospace, 6(9), 94. https://doi.org/10.3390/aerospace6090094