A Preliminary Investigation of Maintenance Contributions to Commercial Air Transport Accidents

Abstract

:1. Introduction

- How many accidents in the ICAO official accident dataset are contributed to by maintenance factors, and by extension, what proportion of ICAO official accidents have a maintenance contribution? (RQ1)

- How does the distribution of accidents that show a contribution from maintenance activities differ to all scheduled commercial air transport accidents, reported by ICAO? (RQ2)

- Has the number of ‘official’ accidents with maintenance contributions reduced over time? (RQ3)

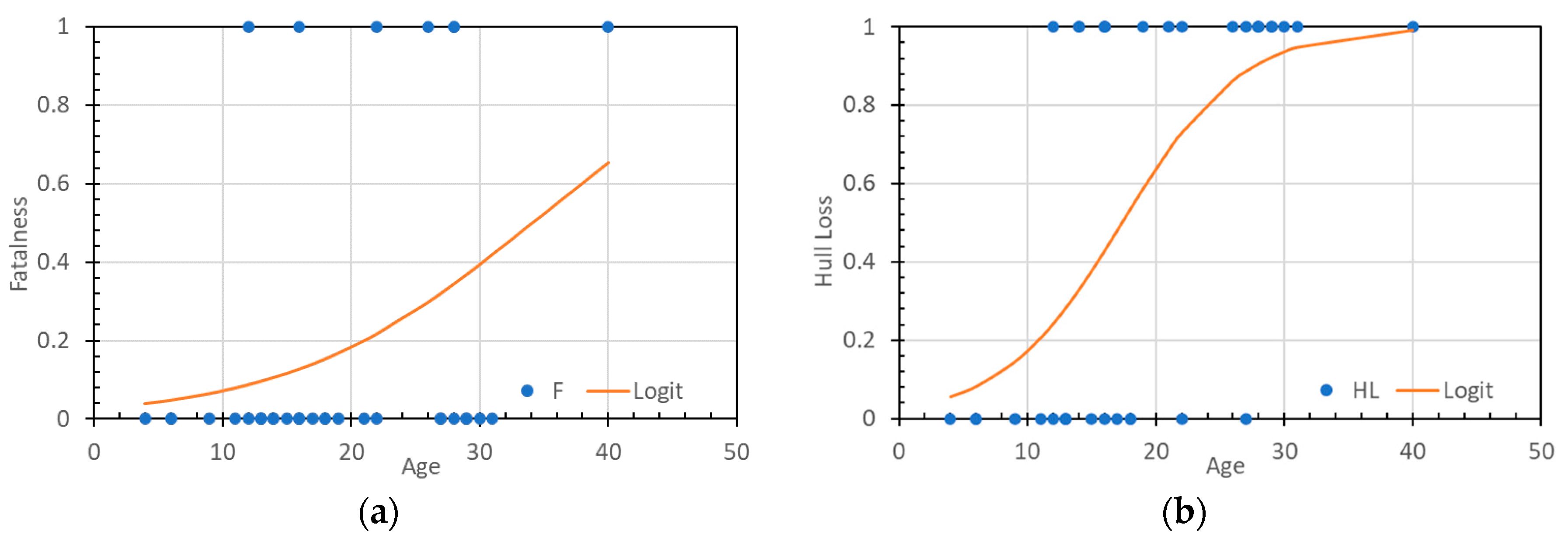

- How does the age of an aircraft in an ‘official’ accident with maintenance contributions influence the outcome (fatalness and aircraft damage) of the occurrence? (RQ4)

- There is currently no reported number for the proportion of accidents that have maintenance as a contributing factor. Estimates for air traffic management accidents are on the order of 8%, hence a similar single digit percentage would be reasonable to expect.

- Accidents with maintenance contributions will show unique features in comparison to all aviation accidents; occurrences will typically be categorized as system component failures, and they will be more common in earlier phases of flight.

- Given the short timeframe of the ICAO official accident dataset (since 2008), it is anticipated that the number of events will have remained constant over time, potentially with a slight reduction.

- Older aircraft will be more likely to result in fatalities and hull losses.

2. Literature Review

2.1. Aircraft Maintenance Related Safety Occurrences in General Aviation

2.2. Aircraft Maintenance Related Safety Occurrences in Commercial Air Transport

2.3. Aircraft Maintenance Related Safety Occurrences in Military Aviation

2.4. Research Gap

3. Materials and Methods

3.1. Research Design

3.2. Data Collection, Coding, and Cleaning

- Maintenance issue,

- Type of operation,

- Operator’s business model,

- Phase of flight (in which the maintenance issue first appeared)

- Age (difference between year of the aircraft’s first flight and the year of the accident),

- Accident category (A1 a hull loss, or A2 repairable), and

- ICAO occurrence categories.

- Repair of previous damage,

- Engine issue,

- Failure to follow airworthiness directives or service bulletins,

- Wrong or incorrect installation of parts, and

- General issues (substandard practices etc).

3.3. Data Analysis

3.3.1. Non-Parametric Analysis

HA: PO,n ≠ PE,n

3.3.2. Longitudinal Analysis

4. Non-Parametric Results and Analysis

4.1. Summary of Results

4.2. Comparative Data

4.2.1. Fatalness

4.2.2. World Region

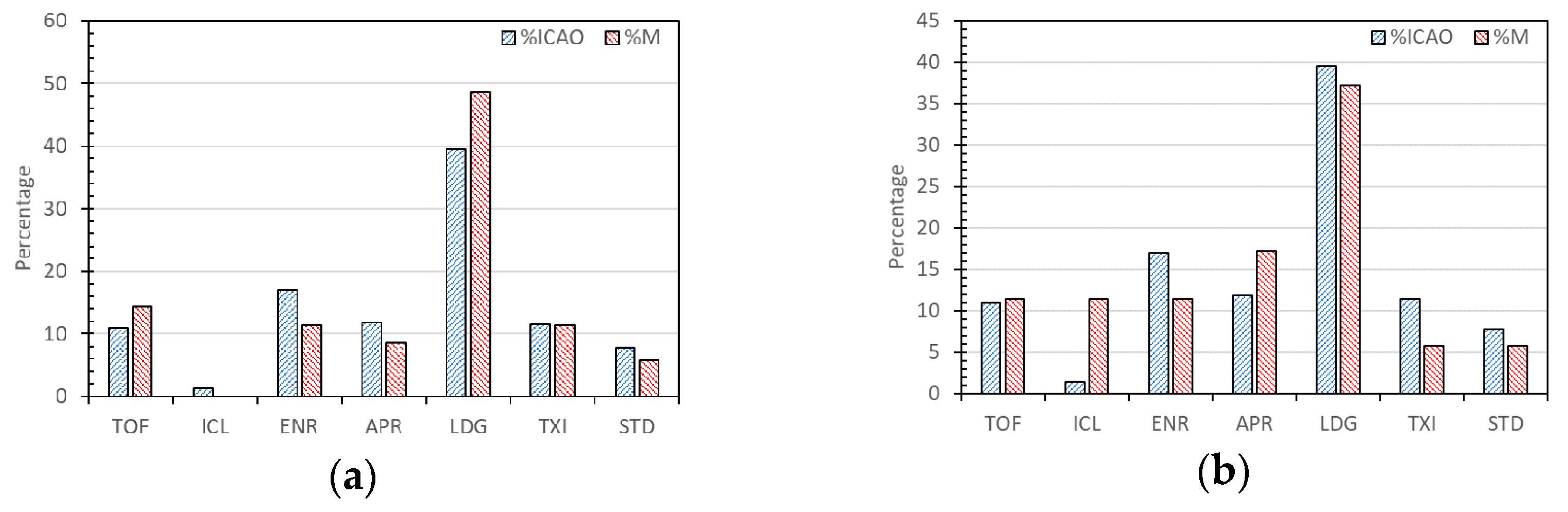

4.2.3. Phase of Flight

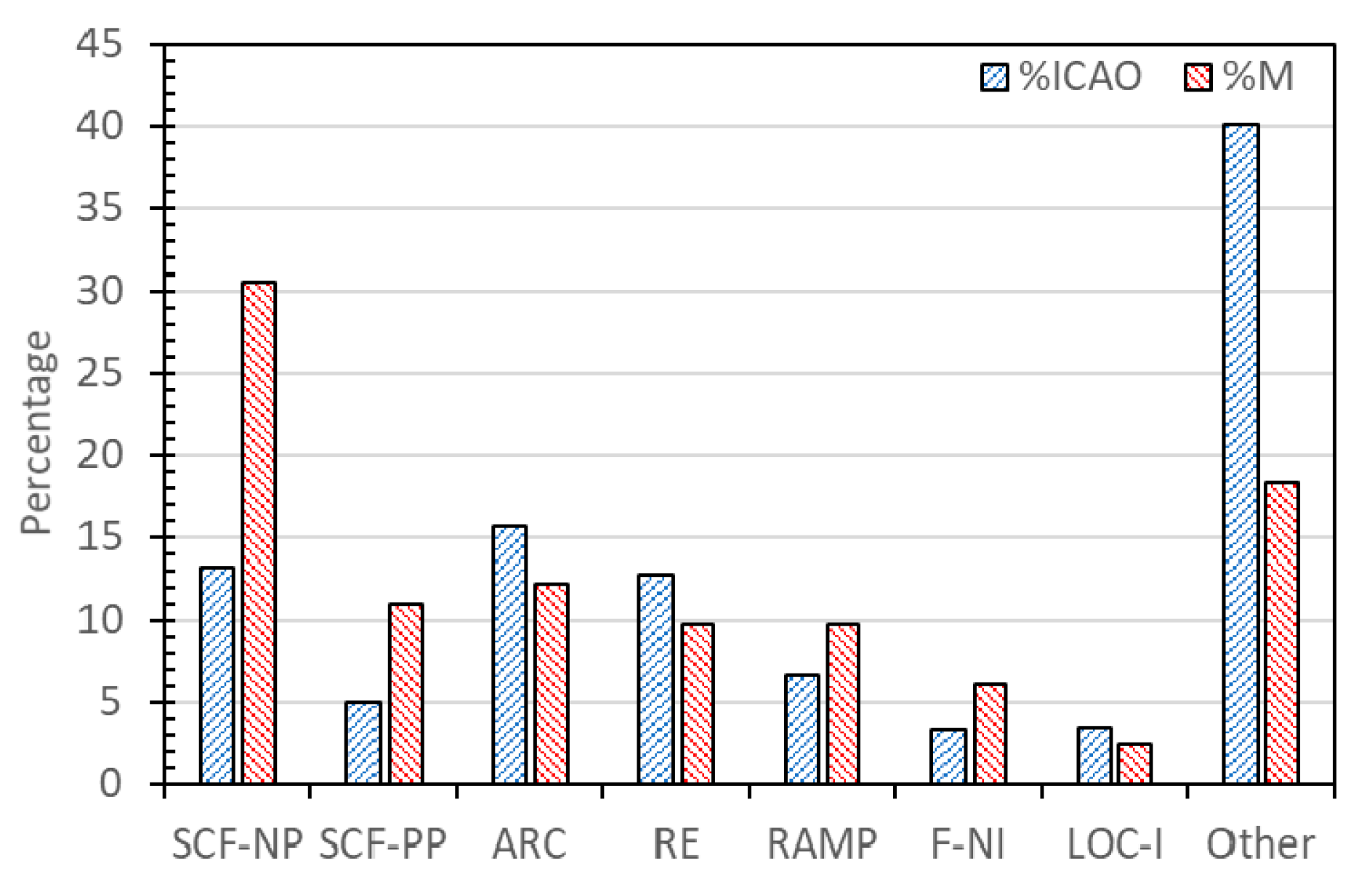

4.2.4. Occurrence Category

4.2.5. Manufacturer

4.2.6. Mass Category

4.2.7. Engines

4.2.8. Maintenance Issue

4.2.9. Operator and Operation

4.2.10. Age

5. Parametric Results and Analysis

5.1. Longitudinal Study

- ICAO, the total number of ICAO official accidents,

- M, the number of ICAO official accidents with maintenance contributions,

- M%, the percentage of accidents with maintenance contributions relative to all ICAO official accidents,

- pICAO, the proportion of ICAO official accidents (relative to 2008),

- pM, the proportion of accidents with maintenance contributions (relative to 2008), and

- The model given by (3) above.

5.2. Logistic Regression Results

5.3. Aircraft Maintenance Fraction

6. Case Study

6.1. Rational

6.2. The Flight

6.3. Maintenance of the Accident Aircraft

6.4. Drift into Failure

“not following procedures does not necessarily lead to trouble, and safe outcomes may be preceded by just as (relatively) many procedural deviations as those that precede accidents”.

6.5. Aircraft Swap

6.6. Active Failures and Latent Conditions

7. Discussion

7.1. Findings

7.2. Assumptions and Limitations

7.3. Future Work

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- EASA. Official Journal of the European Union: Commission Regulation (EU) No 1321/2014; European Aviation Safety Agency: Cologne, Germany, 2014.

- FAA. Maintenance Programs for U.S.-Registered Aircraft Operated Under 14 CFR Part 129 FAA; Federak Aviation Authority: Washington, DC, USA, 2009.

- PCAA. Approved Maintenance Organisations-Air Navigation Order, 3rd ed.; Pakistan Civil Aviation Authority: Karachi, Pakistan, 2019.

- Wang, L.; Sun, R.; Yang, Z. Analysis and evaluation of human factors in aviation maintenance based on fuzzy and AHP method. In Proceedings of the 2009 IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009; pp. 876–880. [Google Scholar]

- Rajee Olaganathan, D.; Miller, M.; Mrusek, B.M. Managing Safety Risks in Airline Maintenance Outsourcing. Int. J. Aviat. Aeronaut. Aerosp. 2020, 7, 7. [Google Scholar] [CrossRef]

- Bağan, H.; Gerede, E. Use of a nominal group technique in the exploration of safety hazards arising from the outsourcing of aircraft maintenance. Saf. Sci. 2019, 118, 795–804. [Google Scholar] [CrossRef]

- Insley, J.; Turkoglu, C. A Contemporary Analysis of Aircraft Maintenance-Related Accidents and Serious Incidents. Aerospace 2020, 7, 81. [Google Scholar] [CrossRef]

- Illankoon, P.; Tretten, P.; Kumar, U. A prospective study of maintenance deviations using HFACS-ME. Int. J. Ind. Ergon. 2019, 74, 102852. [Google Scholar] [CrossRef]

- Lestiani, M.E.; Yudoko, G.; Purboyo, H. Developing a conceptual model of organizational safety risk: Case studies of aircraft maintenance organizations in Indonesia. Transp. Res. Procedia 2017, 25, 136–148. [Google Scholar] [CrossRef]

- Dalkilic, S. Improving aircraft safety and reliability by aircraft maintenance technician training. Eng. Fail. Anal. 2017, 82, 687–694. [Google Scholar] [CrossRef]

- Hobbs, A.; Williamson, A. Skills, rules and knowledge in aircraft maintenance: Errors in context. Ergonomics 2002, 45, 290–308. [Google Scholar] [CrossRef] [PubMed]

- Floyd, H.L. Maintenance Errors as Cause for Electrical Injuries-What We Can Learn from Aviation Safety. In Proceedings of the 2019 IEEE IAS Electrical Safety Workshop (ESW), Jacksonville, FL, USA, 4–8 March 2019; pp. 1–6. [Google Scholar]

- PeriyarSelvam, U.; Tamilselvan, T.; Thilakan, S.; Shanmugaraja, M. Analysis on costs for aircraft maintenance. Adv. Aerosp. Sci. Appl. 2013, 3, 177–182. [Google Scholar]

- IATA MCTG. Airline Maintenance Cost Executive Commentary; International Air Transport Association: Montreal, QC, Canada, 2019. [Google Scholar]

- Nelson, N.L.; Goldman, S.M. Maintenance-Related Accidents: A Comparison of Amateur-Built Aircraft to all Other General Aviation. Hum. Factors Ergon. Soc. Annu. Meet. 2003, 47, 191–193. [Google Scholar] [CrossRef]

- Rashid, H.; Place, C.; Braithwaite, G. Helicopter maintenance error analysis: Beyond the third order of the HFACS-ME. Int. J. Ind. Ergon. 2010, 40, 636–647. [Google Scholar] [CrossRef]

- Saleh, J.H.; Tikayat Ray, A.; Zhang, K.S.; Churchwell, J.S. Maintenance and inspection as risk factors in helicopter accidents: Analysis and recommendations. PLoS ONE 2019, 14, e0211424. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, T.; Von Thaden, T.L.; Geibel, W.D. Coordination and safety behaviors in commercial aircraft maintenance. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, New York, NY, USA, 22–26 September 2008; pp. 89–93. [Google Scholar]

- Geibel, W.D.; Von Thaden, T.L.; Suzuki, T. Issues that precipitate errors in airline maintenance. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, New York, NY, USA, 22–26 September 2008; pp. 94–98. [Google Scholar]

- Reynolds, R.; Blickensderfer, E.; Martin, A.; Rossignon, K.; Maleski, V. Human Factors Training in Aviation Maintenance: Impact on Incident Rates. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, San Francisco, CA, USA, 27 September 2010; pp. 1518–1520. [Google Scholar]

- Ng, M.-W.; Li, S.Y. An analysis of aircraft maintenance incidents using psychological and cognitive engineering knowledge. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, Washington, DC, USA, 19–23 September 2016; pp. 1676–1680. [Google Scholar]

- Schmidt, J.; Schmorrow, D.; Figlock, R. Human factors analysis of naval aviation maintenance related mishaps. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, San Diego, CA, USA, 30 July 2000; pp. 775–778. [Google Scholar]

- Wild, G.; Murray, J.; Baxter, G. Exploring Civil Drone Accidents and Incidents to Help Prevent Potential Air Disasters. Aerospace 2016, 3, 22. [Google Scholar] [CrossRef] [Green Version]

- ICAO. ICAO iSTARS API Data Service. Available online: https://www.icao.int/safety/istars/pages/api-data-service.aspx (accessed on 18 July 2020).

- Aviation Safety Network. ASN Aviation Safety Database. Available online: https://aviation-safety.net/database/ (accessed on 18 July 2020).

- Raymond, M.; Rousset, F. An Exact Test for Population Differentiation. Evolution 1995, 49, 1280–1283. [Google Scholar] [CrossRef] [PubMed]

- Ayiei, A.; Murray, J.; Wild, G. Visual Flight into Instrument Meteorological Condition: A Post Accident Analysis. Safety 2020, 6, 19. [Google Scholar] [CrossRef] [Green Version]

- Kharoufah, H.; Murray, J.; Baxter, G.; Wild, G. A review of human factors causations in commercial air transport accidents and incidents: From to 2000–2016. Prog. Aerosp. Sci. 2018, 99, 1–13. [Google Scholar] [CrossRef]

- ICAO. ICAO Long-Term Traffic Forecasts; International Civil Aviation Organization: Montreal QC, Canada, 2016. [Google Scholar]

- Airfleet.net. Airline Fleet Age. Available online: https://www.airfleets.net/ageflotte/fleet-age.htm (accessed on 7 July 2020).

- ATSB. An Overview of Human Factors in Aviation Maintenance; Australian Transport Safety Bureau: Canberra, Australia, 2018.

- Daniels, G.S. The Average Man? Air Force Aerospace Medical Research Lab Wright-Patterson Air Force Base: Dayton, OH, USA, 1952.

- Hertzberg, H.; Daniels, G.S.; Churchill, E. Anthropometry of Flying Personnel-1950; Antioch College: Yellow Springs, OH, USA, 1954. [Google Scholar]

- Parker, M. Humble Pi: A Comedy of Maths Errors; Penguin Books Limited: London, UK, 2019. [Google Scholar]

- AAIB. Report on the Accident to Airbus A319-13, G-EUOE London Heathrow Airport 24 May 2013; AAIB: Farnborough, UK, 2015.

- Dekker, S. Why we need new accident models. Hum. Factors Aerosp. Saf. 2004, 2. Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2%3A244497&dswid=-3453 (accessed on 2 August 2020).

- Dekker, S. Drift into Failure: From Hunting Broken Components to Understanding Complex Systems; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Dekker, S. Failure to adapt or adaptations that fail: Contrasting models on procedures and safety. Appl. Ergon. 2003, 34, 233–238. [Google Scholar] [CrossRef]

- Reason, J. Managing the Risks of Organizational Accidents; Routledge: New York, NY, USA, 2016. [Google Scholar]

- Kourousis, K.I.; Chatzi, A.V.; Giannopoulos, I.K. The airbus A320 family fan cowl door safety modification: A human factors scenario analysis. Aircr. Eng. Aerosp. Technol. 2018, 90, 967–972. [Google Scholar] [CrossRef]

| Fat | ROp | ROc | PoF | OC | Manu | Mass | ET | nE | |

|---|---|---|---|---|---|---|---|---|---|

| p | 0.28 | 0.58 | 0.04 | 0.03 | ~0 | 0.02 | 0.93 | 0.84 | 0.59 |

| Conc | N | N | Y | Y | Y | Y | N | N | N |

| MI | SC | Gear | BM | Op | Age | |

|---|---|---|---|---|---|---|

| p | 0.01 | 0.01 | 0.17 | 0.31 | 0.02 | 0.03 |

| Conc | Y | Y | N | N | Y | Y |

| ICAO | M | M% | pICAO | pM | Model | |

|---|---|---|---|---|---|---|

| β | −2.77 | −0.29 | −0.14 | −0.02 | −0.05 | −0.21 |

| r2 | 0.24 | 0.42 | 0.10 | 0.24 | 0.42 | 0.22 |

| n | 12 | 12 | 12 | 12 | 12 | 12 |

| v | 10 | 10 | 10 | 10 | 10 | 9 |

| t | 5.58 | 8.45 | 3.29 | 5.58 | 8.45 | 4.73 |

| p | <0.01 | <0.01 | 0.01 | <0.01 | <0.01 | <0.01 |

| Sig | Y | Y | Y | Y | Y | Y |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, F.N.; Ayiei, A.; Murray, J.; Baxter, G.; Wild, G. A Preliminary Investigation of Maintenance Contributions to Commercial Air Transport Accidents. Aerospace 2020, 7, 129. https://doi.org/10.3390/aerospace7090129

Khan FN, Ayiei A, Murray J, Baxter G, Wild G. A Preliminary Investigation of Maintenance Contributions to Commercial Air Transport Accidents. Aerospace. 2020; 7(9):129. https://doi.org/10.3390/aerospace7090129

Chicago/Turabian StyleKhan, Fatima Najeeb, Ayiei Ayiei, John Murray, Glenn Baxter, and Graham Wild. 2020. "A Preliminary Investigation of Maintenance Contributions to Commercial Air Transport Accidents" Aerospace 7, no. 9: 129. https://doi.org/10.3390/aerospace7090129