Load-Identification Method for Flexible Multiple Corrugated Skin Using Spectra Features of FBGs

Abstract

:1. Introduction

2. Background

2.1. Uniform Strain Sensing of the FBG

2.2. Nonuniform Strain Sensing of the FBG

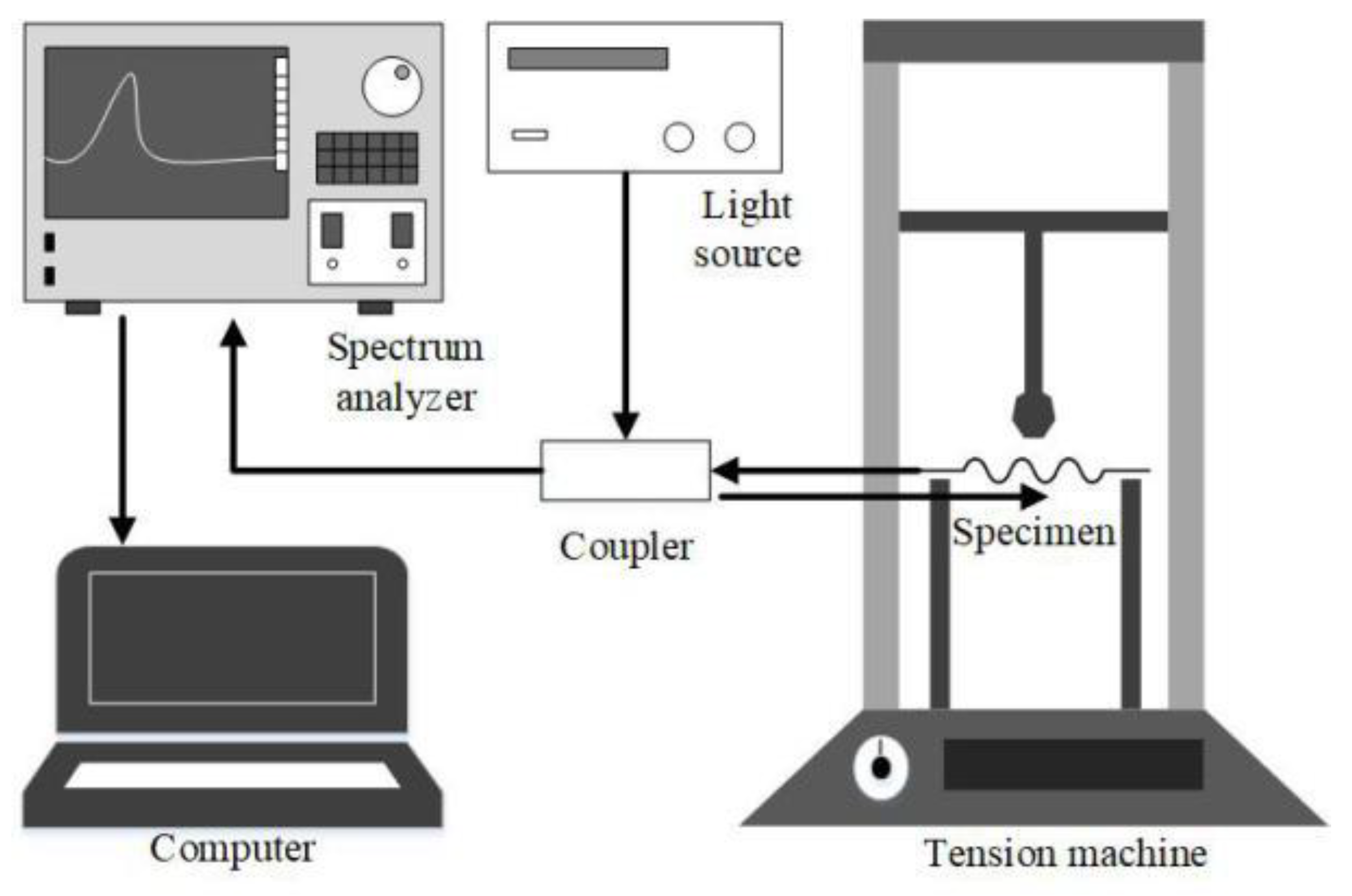

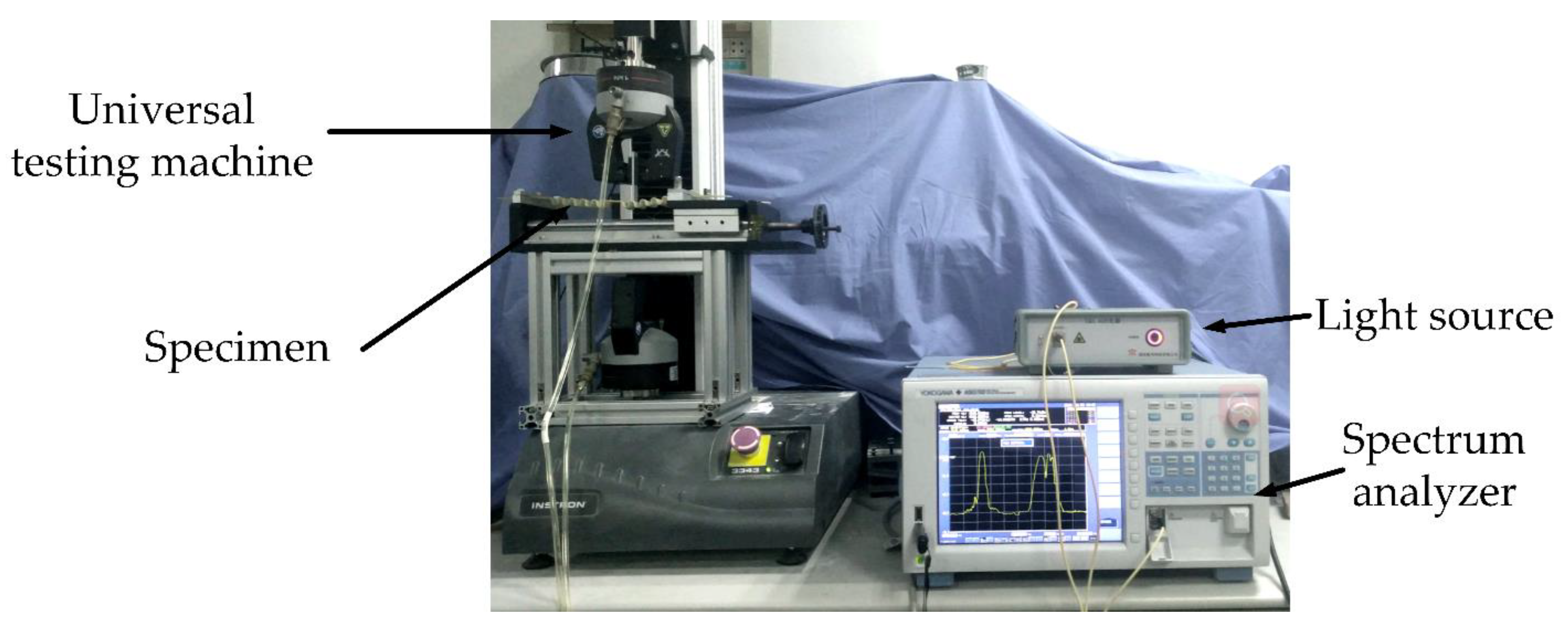

3. Experimental Setup

3.1. Specimen Analysis

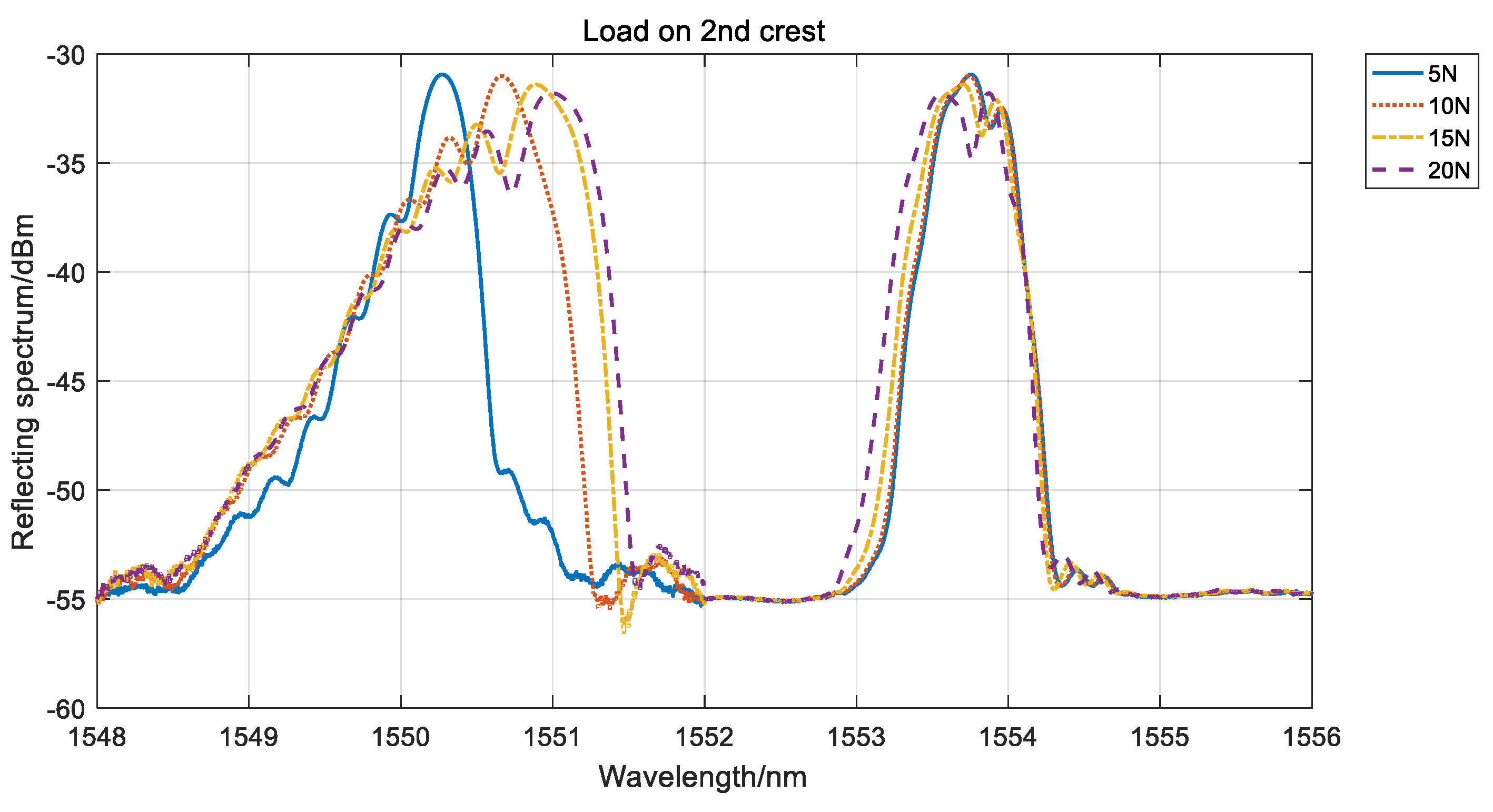

3.2. Feature Extraction

- The central wavelength of the main peak shifted.

- Side-lobes were generated in the reflection spectrum.

- The bandwidth of the main peak broadened.

- The symmetry of the reflection spectrum changed.

- The magnitude of the main peak;

- The value of the main peak shift, , where is the absolute value of the main peak shift;

- The secondary peak magnitude;

- The wavelength difference between the secondary peak and the main peak. The form is the same as for parameter 2;

- The tertiary peak magnitude;

- The wavelength differences between the tertiary peak and the main peak. The form is the same as for parameter 2;

- The full width at half-maximum (FWHM), , where and are the left and right half-maximum widths, respectively;

- The index of local asymmetry (ILA), . This reflects the symmetry of the main peak of the reflection spectrum.

4. Algorithm Design

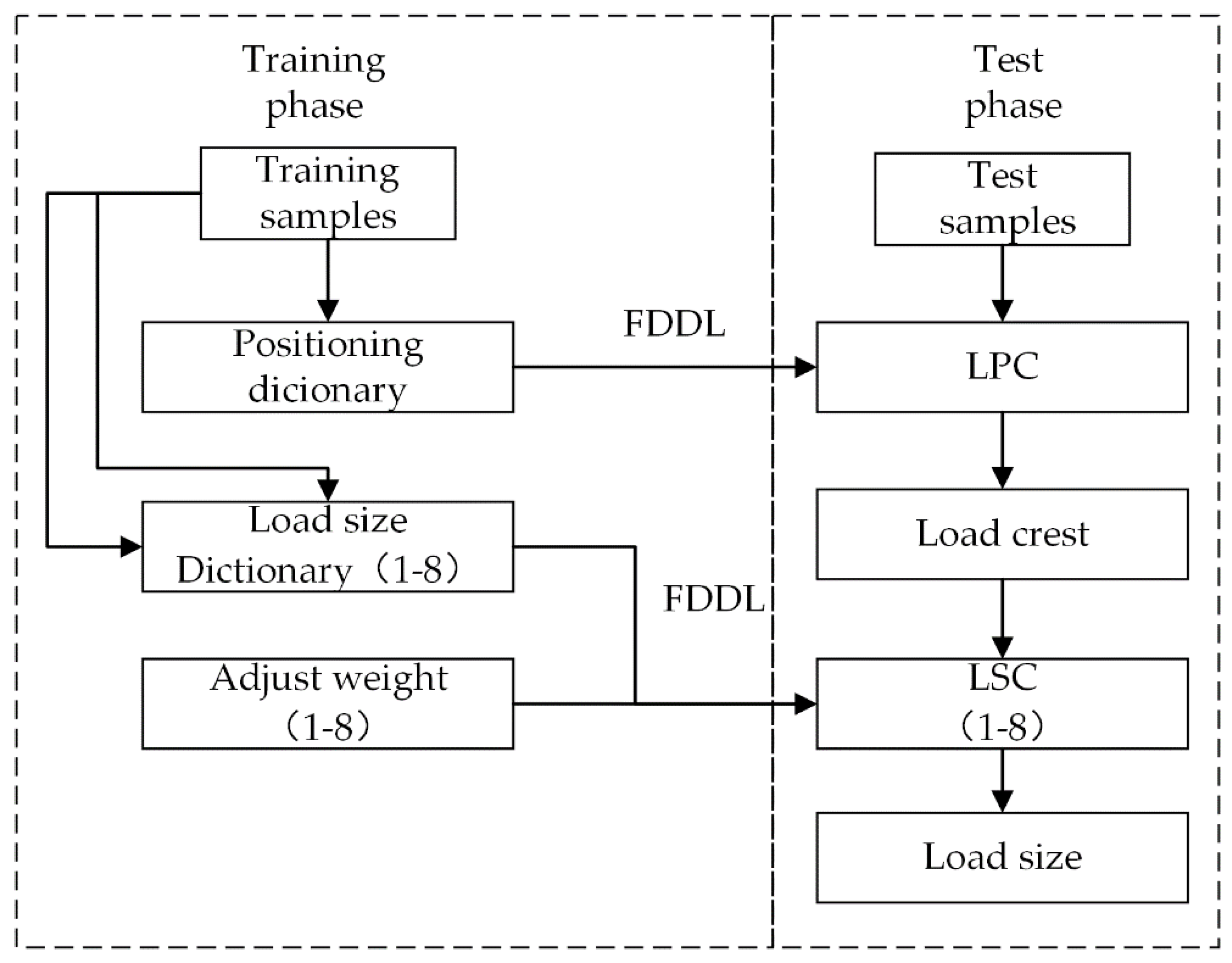

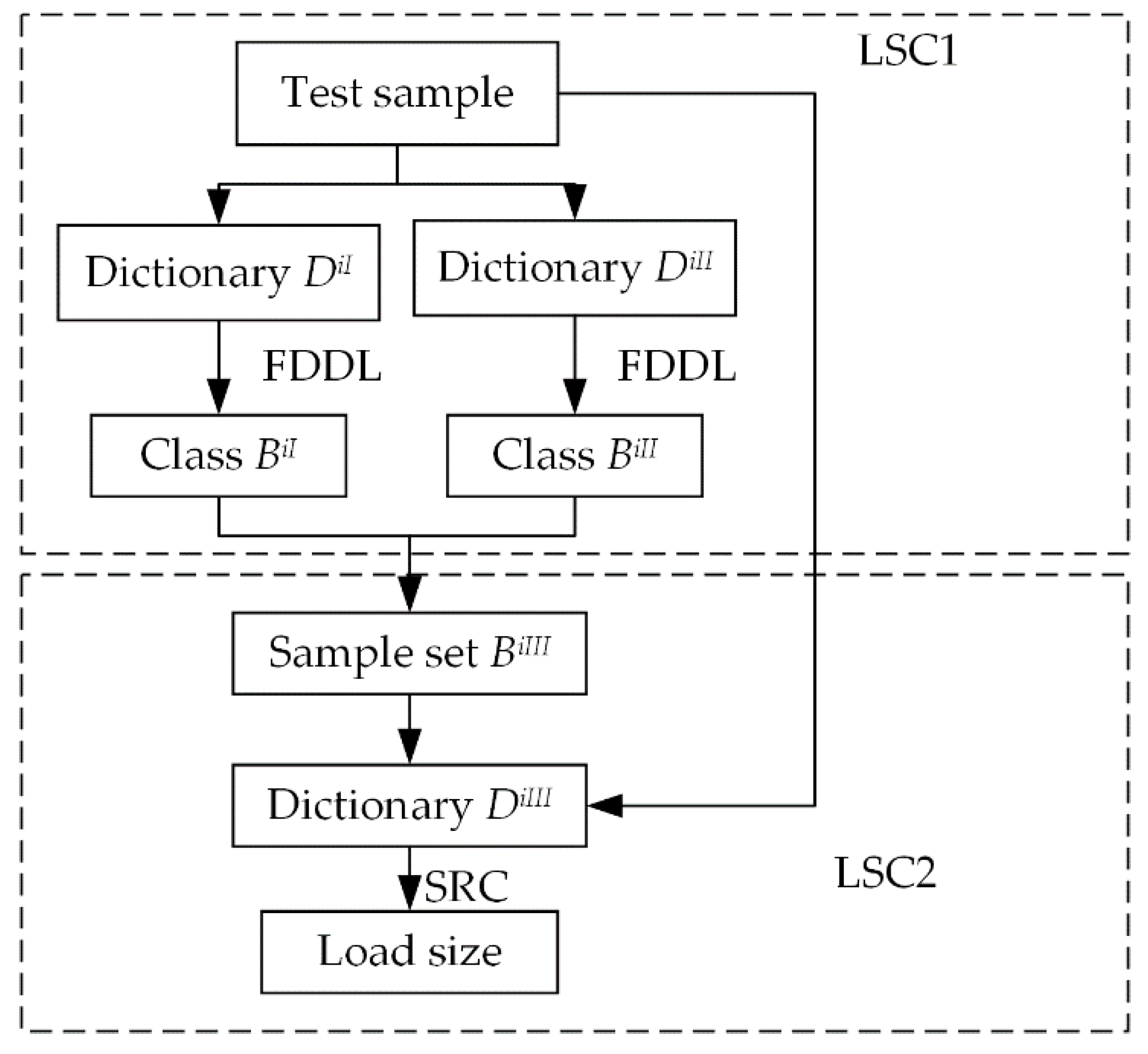

4.1. Algorithm Flow

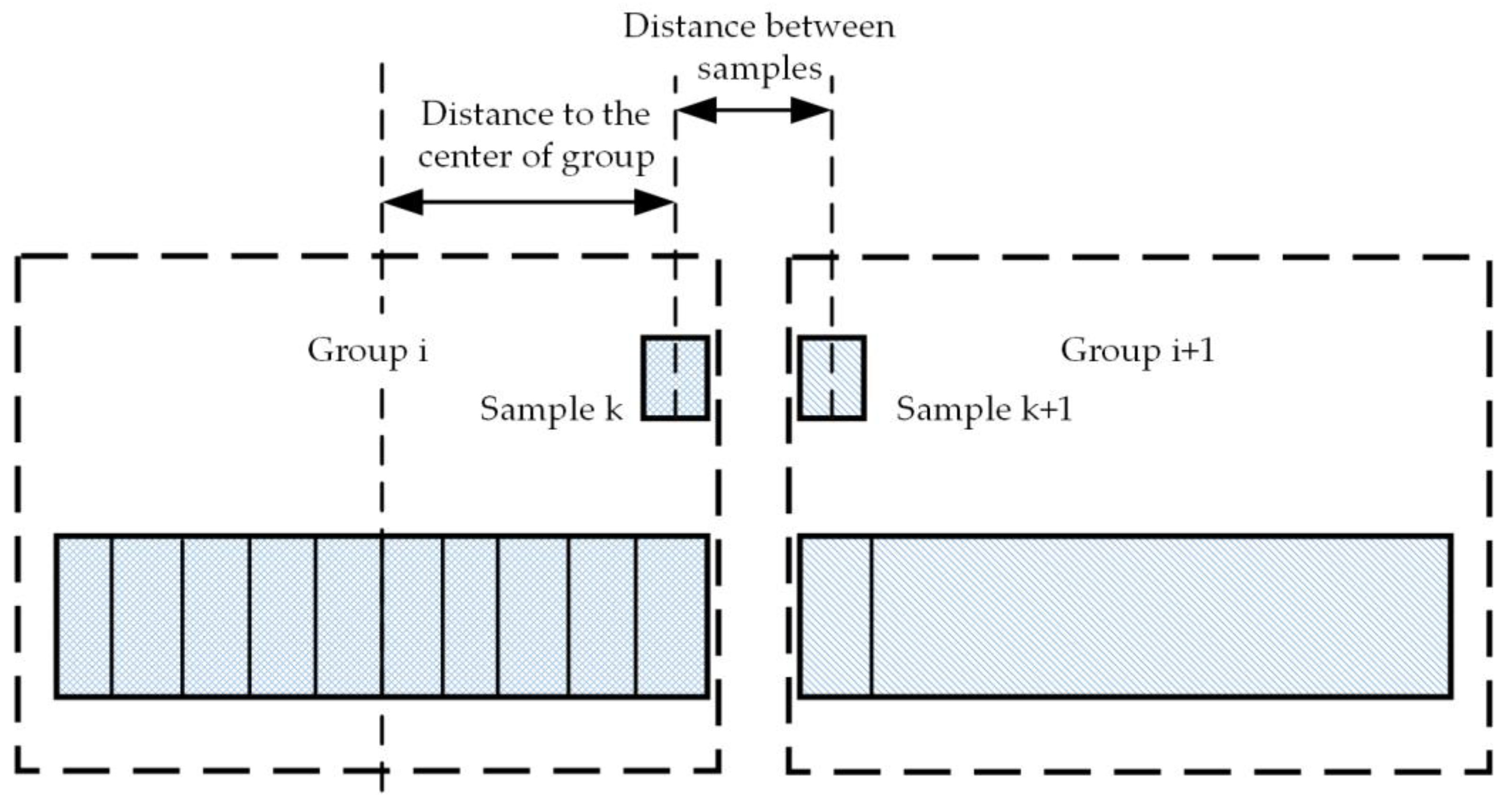

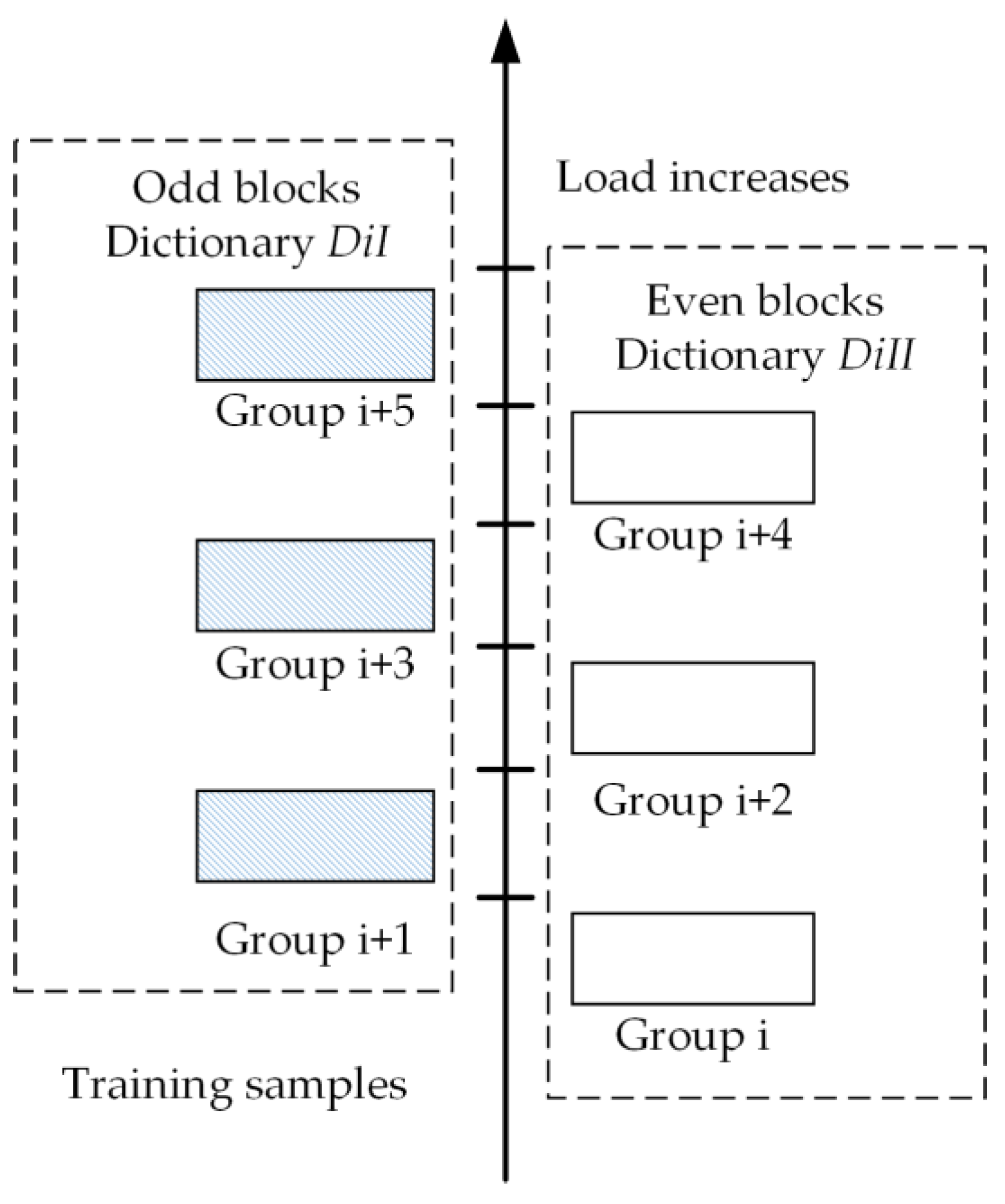

4.2. Composition of Load-Size Dictionaries

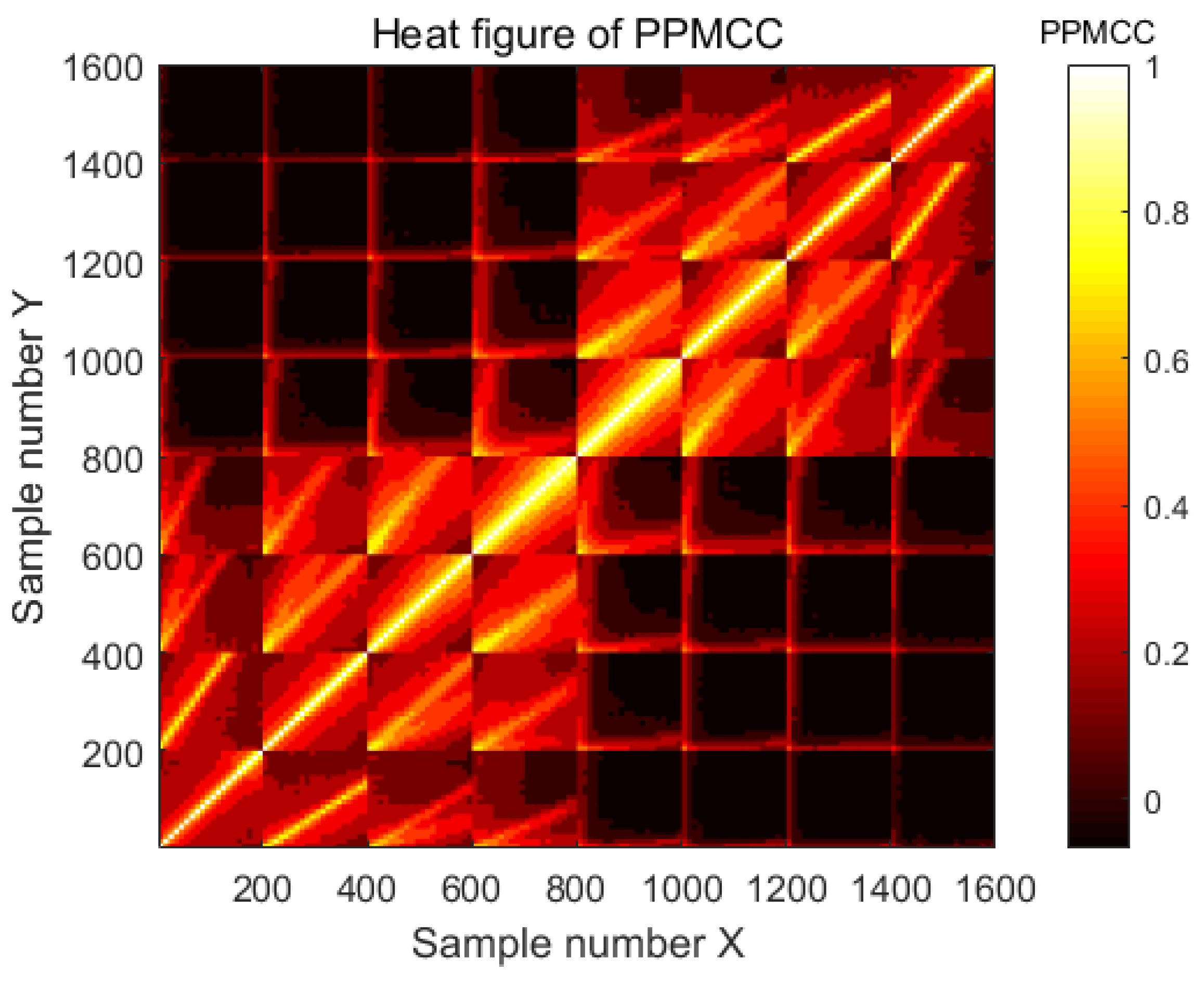

4.3. Two-Resolution LSCs

4.4. SRC Algorithm

4.5. Optimized FDDL Algorithm

4.5.1. FDDL Classifiers

4.5.2. GC Optimization

5. Experiments and Results

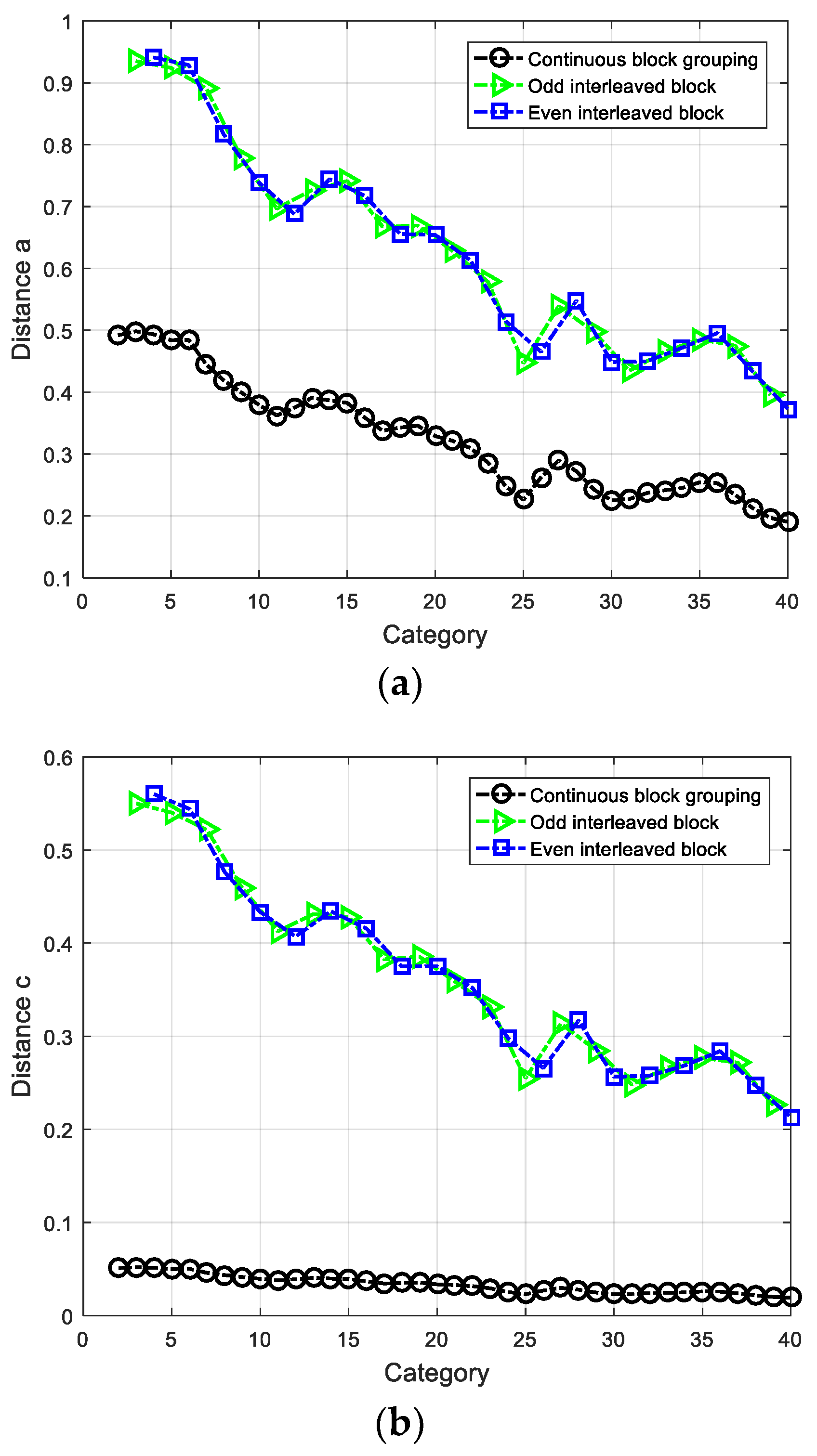

5.1. Parameter Selection

5.2. Control-Group (CG) Settings

5.2.1. CG Settings of the LPCs

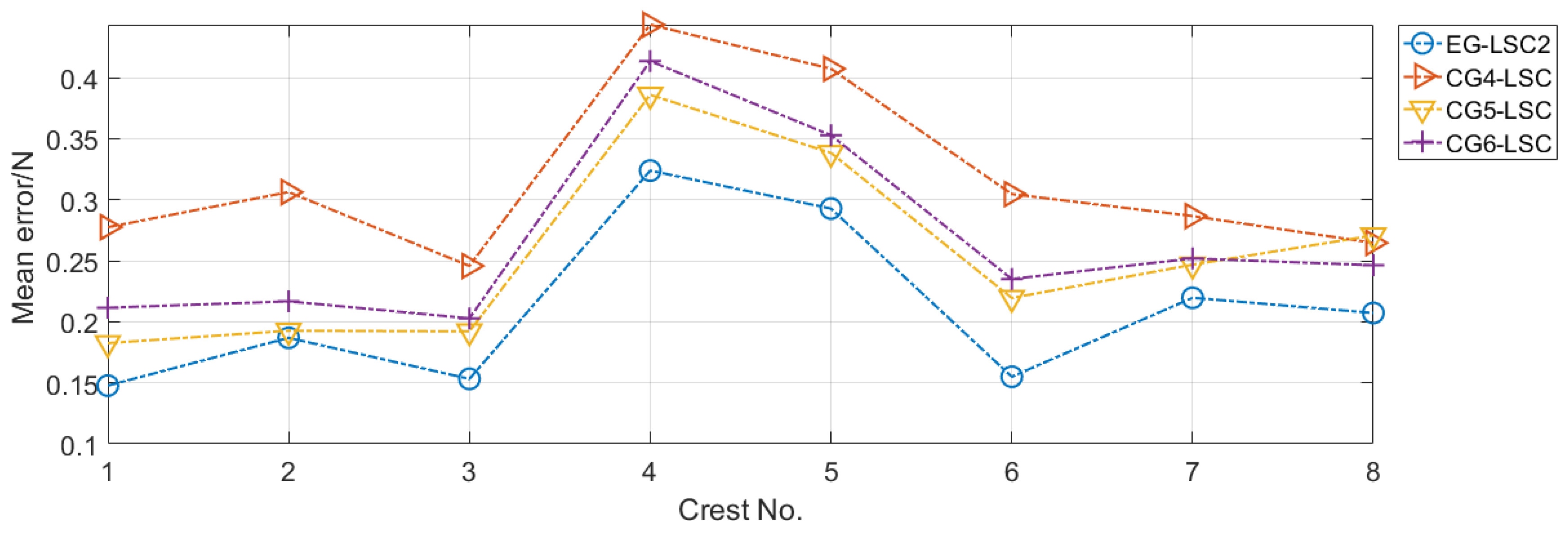

5.2.2. CG Settings of the LSCs

- CG1-LSC, with D-KSVD selected as the DL algorithm and the LSC1 classifier; LSC2 is not executed, and the other parts are the same as in EG-LSC1.

- CG2-LSC, with LC-KSVD selected as the DL algorithm and the LSC1 classifier; LSC2 is not executed, and the other parts are the same as in EG-LSC1.

- CG3-LSC, with the FDDL with adjustable weights selected as the DL algorithm. LSC2 is not executed, and the other parts are the same as in EG-LSC.

- CG4-LSC, with SVM selected as LSC1 and LSC2; the other parts are the same as in EG-LSC.

- CG5-LSC, with training samples grouped into continuous blocks in LSC1; other parts are the same as in EG-LSC. FDDL and SRC with adjustable weights are used in LSC1 and LSC2.

- CG6-LSC, with no adjustable weights used in LSC1 and LSC2; other parts are the same as in EG-LSC.

5.3. Results and Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Golzar, M.; Ghabezi, P. Corrugated composite skins. Mech. Compos. Mater. 2014, 50, 137–148. [Google Scholar] [CrossRef]

- Thill, C.; Downsborough, J.D.; Lai, S.J.; Bond, I.P.; Jones, D.P. Aerodynamic study of corrugated skins for morphing wing applications. Aeronaut. J. 2010, 114, 237–244. [Google Scholar] [CrossRef]

- Thill, C.; Ethche, J.A.; Bond, I.P.; Potter, K.D.; Weaver, P.M. Composite corrugated structures for morphing wing skin applications. Smart Mater. Struct. 2010, 19, 124009. [Google Scholar] [CrossRef]

- Mayes, J.S.; Andrew, C.H. Composite laminate failure analysis using multicontinuum theory. Compos. Sci. Technol. 2004, 64, 379–394. [Google Scholar] [CrossRef]

- Maimi, P.; Mayugo, J.A.; Camanho, P.P. A three-dimensional damage model for transversely isotropic composite laminates. J. Compos. Mater. 2008, 42, 2717–2745. [Google Scholar] [CrossRef]

- Qiao, P.; Lestari, W.; Shah, M.; Wang, J. Dynamics-based damage detection of composite laminated beams using contact and noncontact measurement systems. J. Compos. Mater. 2007, 41, 1217–1252. [Google Scholar] [CrossRef]

- Brown, S. Mechanically relevant consequences of the composite laminate-like design of the abdominal wall muscles and connective tissues. Med. Eng. Phys. 2012, 34, 521–523. [Google Scholar] [CrossRef]

- Xin, C.; Gu, Y.; Li, M.; Li, Y.; Zhang, Z. Online monitoring and analysis of resin pressure inside composite laminate during zero-bleeding autoclave process. Polym. Compos. 2011, 32, 314–323. [Google Scholar] [CrossRef]

- Navaratne, R.; Dayyani, I.; Woods, B.; Friswell, M. Development and testing of a corrugated skin for a camber morphing aerofoil. In Proceedings of the 23rd AIAA/AHS Adaptive Structures Conference, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar] [CrossRef]

- Grenestedt, J.; Jack, R. Wrinkling of corrugated skin sandwich panels. Compos. Part A Appl. Sci. Manuf. 2007, 38, 576–589. [Google Scholar] [CrossRef]

- Ghabezi, P.; Golzar, M. Mechanical analysis of trapezoidal corrugated composite skins. Appl. Compos. Mater. 2013, 20, 341–353. [Google Scholar] [CrossRef]

- Yokozeki, T.; Aya, S.; Yoshiyasu, H. Development of variable camber morphing airfoil using corrugated structure. J. Aircr. 2014, 51, 1023–1029. [Google Scholar] [CrossRef] [Green Version]

- Previtali, F.; Molinari, G.; Arrieta, A.; Guillaume, M.; Ermanni, P. Design and experimental characterisation of a morphing wing with enhanced corrugated skin. J. Intell. Mater. Syst. Struct. 2016, 27, 278–292. [Google Scholar] [CrossRef]

- Brachman, R.; Elshimi, T.; Mak, A.; Moore, I. Testing and analysis of a deep-corrugated large-span box culvert prior to burial. J. Bridge Eng. 2012, 17, 81–88. [Google Scholar] [CrossRef]

- Manko, Z.; Beben, D. Dynamic testing of a corrugated steel arch bridge. Can. J. Civ. Eng. 2008, 35, 246–257. [Google Scholar] [CrossRef]

- Beben, D. Field Performance of Corrugated Steel Plate Road Culvert under Normal Live-Load Conditions. J. Perform. Constr. Facil. 2013, 27, 807–817. [Google Scholar] [CrossRef]

- Kinet, D.; Mégret, P.; Goossen, K.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg grating sensors toward structural health monitoring in composite materials: Challenges and solutions. Sensors 2014, 14, 7394. [Google Scholar] [CrossRef]

- Wei, P.; Liu, J.; Dai, Z.; Li, M. Monitoring the shape of satellite wing frame using FBG sensors in high electronic noise, vacuum, and-196 C environment. IEEE Trans. Ind. Electron. 2016, 64, 691–700. [Google Scholar] [CrossRef]

- Ramzyzan, R.; Kuntjoro, W.; Rahman, M. Using embedded fiber Bragg grating (FBG) sensors in smart aircraft structure materials. Procedia Eng. 2012, 41, 600–606. [Google Scholar] [CrossRef] [Green Version]

- Rajabzadeh, A.; Heusdens, R.; Hendriks, R.; Groves, R. Calculation of the mean strain of smooth non-uniform strain fields using conventional FBG sensors. J. Lightwave Technol. 2018, 36, 3716–3725. [Google Scholar] [CrossRef]

- Ling, H.; Lau, K.; Cheng, L.; Chow, K. Embedded fibre Bragg grating sensors for non-uniform strain sensing in composite structures. Meas. Sci. Technol. 2005, 16, 2415. [Google Scholar] [CrossRef] [Green Version]

- Song, C.; Shang, E.; Huang, X.; Zhang, J. Monitoring the cohesive damage of the adhesive layer in CFRP double-lapped bonding joint based on non-uniform strain profile reconstruction using dynamic particle swarm optimization algorithm. Measurement 2018, 123, 235–245. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, B.; Lu, J. Progressive damage monitoring of corrugated composite skins by the FBG spectral characteristics. Spectrosc. Spectr. Anal. 2014, 34, 757–761. [Google Scholar] [CrossRef]

- Julien, M.; Elad, M.; Sapiro, G. Sparse representation for color image restoration. IEEE Trans. Image Process. 2007, 17, 53–69. [Google Scholar] [CrossRef] [Green Version]

- Donoho, D. Compressed sensing. IEEE Trans. Inf. Theory 2006, 52, 1289–1306. [Google Scholar] [CrossRef]

- Wright, J.; Ma, Y.; Mairal, J.; Sapiro, G.; Huang, T.; Yan, S. Sparse representation for computer vision and pattern recognition. Proc. IEEE 2010, 98, 1031–1044. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Zhou, W.; Chang, P.; Liu, J.; Yan, Z.; Wang, T.; Li, F. Kernel sparse representation-based classifier. IEEE Trans. Signal Process. 2011, 60, 1684–1695. [Google Scholar] [CrossRef]

- Ron, R.; Bruckstein, A.; Elad, M. Dictionaries for sparse representation modeling. Proc. IEEE 2010, 98, 1045–1057. [Google Scholar] [CrossRef]

- Kreutz-Delgado, K.; Murray, J.; Rao, B.; Engan, K.; Lee, T.; Sejnowski, T. Dictionary learning algorithms for sparse representation. Neural Comput. 2003, 15, 349–396. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, Z.; Xu, Y.; Yang, J.; Li, X.L.; Zhang, D. A survey of sparse representation: Algorithms and applications. IEEE Access 2015, 3, 490–530. [Google Scholar] [CrossRef]

- Tan, X.; Triggs, B. Enhanced local texture feature sets for face recognition under difficult lighting conditions. IEEE Trans. Image Process. 2010, 19, 1635–1650. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.; Zhang, L.; Feng, X.; Zhang, D. Fisher discrimination dictionary learning for sparse representation. In Proceedings of the 2011 International Conference on Computer Vision, Barcelona, Spain, 6–13 November 2011. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.; Zhang, L.; Feng, X.; Zhang, D. Sparse representation based fisher discrimination dictionary learning for image classification. Int. J. Comput. Vis. 2014, 109, 209–232. [Google Scholar] [CrossRef]

- Hill, K.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Lightwave Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef] [Green Version]

- Yamada, M.; Kyohei, S. Analysis of almost-periodic distributed feedback slab waveguides via a fundamental matrix approach. Appl. Opt. 1987, 26, 3474–3478. [Google Scholar] [CrossRef] [PubMed]

- Wright, J.; Yang, A.; Ganesh, A.; Sastry, S.; Ma, Y. Robust face recognition via sparse representation. IEEE Trans. Pattern Anal. Mach. Intell. 2008, 31, 210–227. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Q.; Li, B. Discriminative K-SVD for dictionary learning in face recognition. In Proceedings of the 2010 IEEE Computer society Conference on Computer Vision and Pattern Recognition, San Francisco, CA, USA, 5 August 2010. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhe, L.; Davis, L. Label consistent K-SVD: Learning a discriminative dictionary for recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 2651–2664. [Google Scholar] [CrossRef] [PubMed]

- Noble, W. What is a support vector machine? Nat. Biotechnol. 2006, 24, 1565–1567. [Google Scholar] [CrossRef]

| (mm) | (mm) | (mm) | (mm) | |

|---|---|---|---|---|

| 350 | 25 | 7.5 | 1.2 | 6 |

| (GPa) | (GPa) | (g/mm3) | (%) | (%) | |

|---|---|---|---|---|---|

| 37.08 | 5.56 | 1.78 × 10−6 | 48 | 52 | 0.26 |

| Crest No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Adjustable weight (Fisher discrimination dictionary learning, FDDL) | 0.40 | 0.20 | 0.45 | 0.70 | 0.85 | 0.30 | 0.15 | 0.35 |

| Adjustable weight (sparse representation classifier, SRC) | 1.00 | 0.75 | 0.80 | 0.85 | 0.90 | 0.80 | 0.85 | 0.75 |

| Group | EG-LSC | CG1-LSC | CG2-LSC | CG3-LSC | CG6-LSC |

|---|---|---|---|---|---|

| Mean error (N) | 0.1844 | 0.3625 | 0.3313 | 0.2844 | 0.2063 |

| Group | EG-LSC | CG4-LSC | CG5-LSC | CG6-LSC |

|---|---|---|---|---|

| Mean error (N) | 0.2106 | 0.3169 | 0.2531 | 0.2663 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.; Lu, J.; Liang, D. Load-Identification Method for Flexible Multiple Corrugated Skin Using Spectra Features of FBGs. Aerospace 2021, 8, 134. https://doi.org/10.3390/aerospace8050134

Zheng Z, Lu J, Liang D. Load-Identification Method for Flexible Multiple Corrugated Skin Using Spectra Features of FBGs. Aerospace. 2021; 8(5):134. https://doi.org/10.3390/aerospace8050134

Chicago/Turabian StyleZheng, Zhaoyu, Jiyun Lu, and Dakai Liang. 2021. "Load-Identification Method for Flexible Multiple Corrugated Skin Using Spectra Features of FBGs" Aerospace 8, no. 5: 134. https://doi.org/10.3390/aerospace8050134

APA StyleZheng, Z., Lu, J., & Liang, D. (2021). Load-Identification Method for Flexible Multiple Corrugated Skin Using Spectra Features of FBGs. Aerospace, 8(5), 134. https://doi.org/10.3390/aerospace8050134