A Web-Based Decision Support System for Aircraft Dispatch and Maintenance

Abstract

:1. Introduction

1.1. Aircraft Dispatch

1.2. Decision Support for Aircraft Maintenance

1.3. Research Contribution, Aim, and Scope

2. System Architecture and Key Functions

2.1. Prototype Requirements

- FR1 Provide technicians with a concise overview of the available dispatch options, following on from a fault message, including their expected outcome with respect to the flight schedule;

- FR2 Provide technicians with access to task-support information;

- FR3 Provide technicians with the most recent information to ensure safety compliance (i.e., work according to the latest manual revision) and accuracy (i.e., use the latest information for alternative ranking);

- FR4 Provide technicians with fast (i.e., <1 min) access to relevant maintenance information anywhere (assuming that a wireless network connection (mobile/WiFi) is available);

- FR5 Provide external applications with access to maintenance documentation.

- SR1 automate the information retrieval from maintenance documentation;

- SR2 split maintenance manuals on task level and transform the source data to a clear visual format;

- SR3 allow technicians to search maintenance manuals on task level;

- SR4 be able to integrate and process information from heterogeneous, distributed information sources, given that a wide variety of data formats and sources are used in airline and maintenance operations;

- SR5 combine information from different sources and generate a concise overview to support dispatch decision-making;

- SR6 update when new information becomes available (e.g., a new manual revision or defect);

- SR7 support ubiquitous computing to provide technicians with decision support information independent of their location;

- SR8 allow connections from external applications to access maintenance task documentation, in order to provide a seamless workflow between applications.

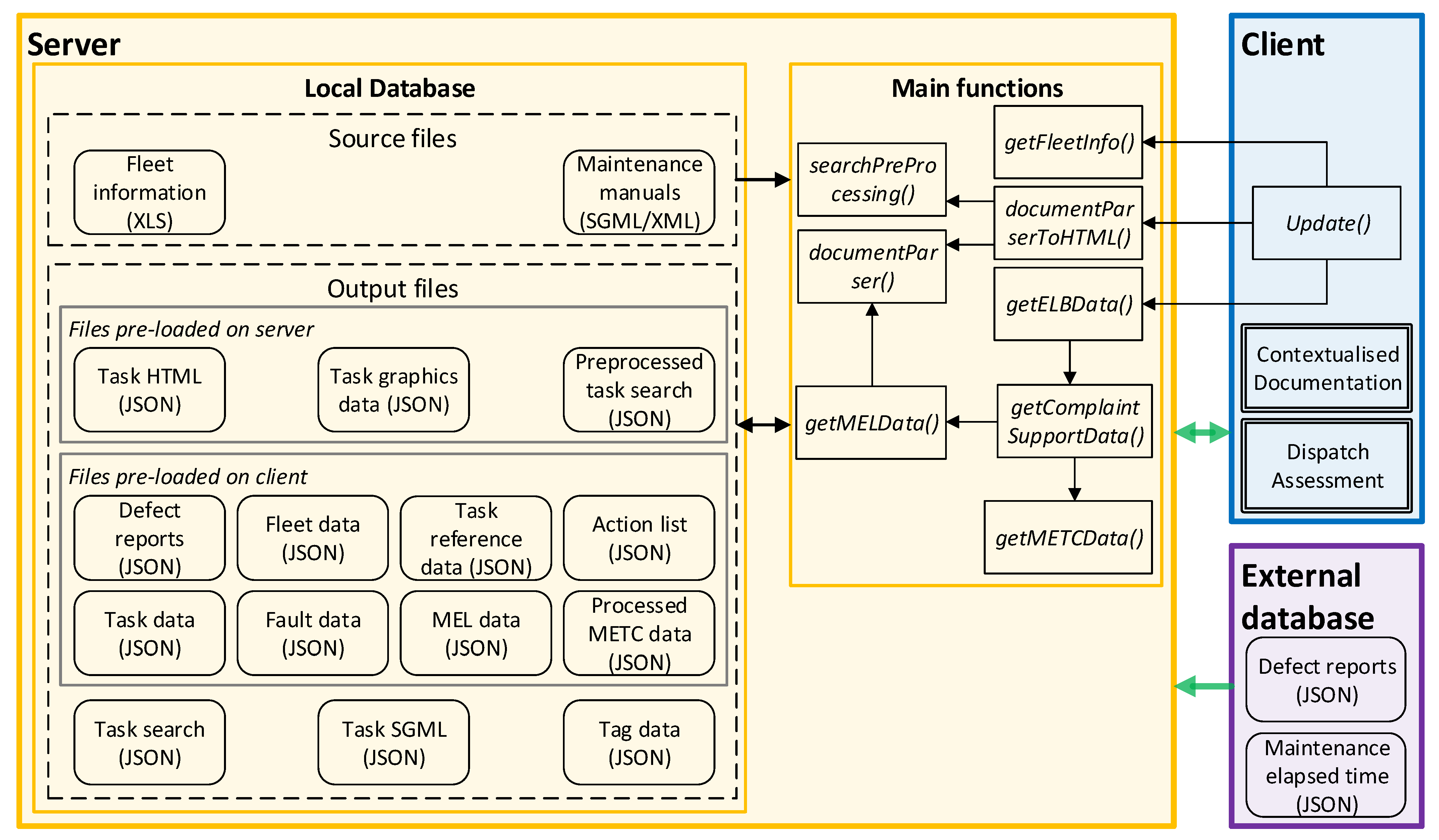

2.2. System Implementation and Architecture

2.2.1. Server

2.2.2. Client

2.2.3. External Database

2.3. Key System Functions

2.3.1. getFleetInfo()

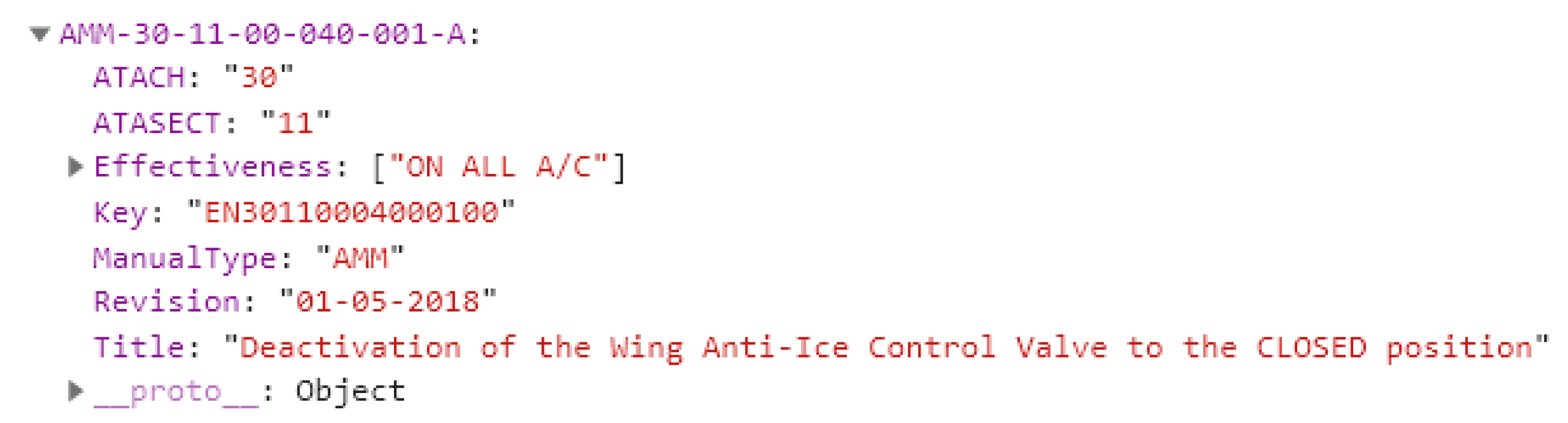

2.3.2. documentParserToHTML()

- the task data object (JSON) contains metadata for each individual task in the manual, such as the task title, the effectiveness array (i.e., to which CSNs this task applies), the task ATA chapter and section, and the revision date. An example is shown in Figure 3. The task identification (i.e., based on the ATA numbering system) is used as the main object key;

- the task graphics object (JSON) contains metadata about graphics used in the manual, such as the number of sheets (i.e., a graphics reference can include multiple sheets), the associated illustrations with their reference and title, and the effectiveness array. The illustration files are located on the server and are retrieved when requested by the client. Illustrations are referenced by the graphics reference in the manual, which is therefore used as the object key in this task graphics object;

- the task HTML object (JSON) contains the HTML conversion of the original SGML-based maintenance task and is used to display the task content on the client (i.e., contextualized documentation). To maintain the original look and feel of the manuals, a cascading style sheet (CSS) is developed to control the layout. Similar to the task data object, the task HTML object also uses the task identification as the main key.

2.3.3. documentParser()

- startWithTag: the index of the opening angle bracket (<) of the opening tag.

- startWithOutTag: the index of the closing angle bracket (>) of the opening tag. This value is increased by 1 to set the index after the closing angle bracket.

- endWithTag: the index of the opening angle bracket (<) of the closing tag. Initially, a value of −1 is assigned (i.e., non-existing), until it is updated when a corresponding closing tag is found.

- endWithOutTag: the index of the closing angle bracket (>) of the closing tag. This value is increased by 1 to set the index after the closing angle bracket. Initially, a value of −1 is assigned (i.e., non-existing), until it is updated when a corresponding closing tag is found.

- tag: this is the —in this case, “EIN”—indicating that this part of the string contains a Functional Item Number (FIN). For example, FIN 10DL refers to the right-hand wing anti-ice valve.

- tagProperties: an array of objects with all the tag properties. In this example, there is one property, indicating that the type of this “EIN” is exact.

- listlevel: a value to determine the indentation of content in the HTML representation.

| Algorithm 1: Depth-first parser algorithm for SGML-based documentation. |

|

2.3.4. searchPreProcessing()

2.3.5. getELBData()

2.3.6. getComplaintSupportData()

- (1)

- Identify related troubleshooting tasksThe TSM contains a section that lists fault messages and their related troubleshooting task(s). In order to automatically retrieve this information, this TSM section is sent to the documentParser() and, by combining the with the SGML of the TSM section, the relevant TSM tasks for each unique fault message are determined. Moreover, the process collects additional metadata for the given fault message from this TSM section, such as the ATA chapter and section numbers, the revision date of the TSM task, and its effectiveness (the effectiveness or applicability of a (part of a) maintenance task is determined by the Customer Serial Number (CSN), a unique identifier for an aircraft).

- (2)

- Identify maintenance alternatives per troubleshooting taskEvery troubleshooting task contains a table with a list of maintenance alternatives (i.e., tasks in other maintenance manuals) that potentially resolve the problem. Again, the documentParser() is called and now combined with the SGML per task (output of documentParserToHTML()) for each identified troubleshooting task, resulting in an object for each troubleshooting task with references to maintenance tasks, including their titles and effectiveness.

- (3)

- Identify deferral alternativesInstead of permanently resolving a problem, some faults allow for a so-called “dispatch by MEL”. The Minimum Equipment List (MEL) details which parts or systems of an aircraft may be inoperative, for how long, and if such deactivation leads to specific operational limitations. Deferring a problem is applied regularly in current daily operations and allows shifting of a rectifying maintenance action (such as a permanent repair) to a more convenient time and location (i.e., not during flight operations and at the maintenance facility), without compromising safety. The available deferral alternatives, if any, are identified by the getMELData() function detailed in Section 2.3.7. The returned information includes any references to other maintenance manuals, such as the Aircraft Maintenance Manual (AMM), because, typically, a deferral alternative also requires some type of maintenance execution—for example, the deactivation of a part.

- (4)

- Merge alternatives and retrieve decision criteria informationHere, all identified (unique) maintenance and deferral alternatives are combined into one dispatch options list and the decision criteria information associated with individual alternatives can be retrieved. Within the scope of this prototype, the decision criterion is time—in particular, the time available before the next departure and the time required to complete a maintenance task. The mobile METC application records the task execution time by having the technician confirm the start and end time of task execution on their mobile phone. While some maintenance manuals do provide this type of information, practitioners indicate that these indications are rarely accurate. The METC application provides realistic information about task execution times that can be used for optimized planning and progress monitoring. The METC data are stored on an external server and retrieved for every dispatch option by the getMETCData() function detailed in Section 2.3.8, having the maintenance task identifier as input. Once the METC information is returned, a final step in this process is to combine any removal and installation tasks. These are technically seen as separate alternatives but, in practice, are linked and executed in sequence. These combinations are identified and combined, including references to individual maintenance tasks and the METC information.

2.3.7. getMELData()

2.3.8. getMETCData()

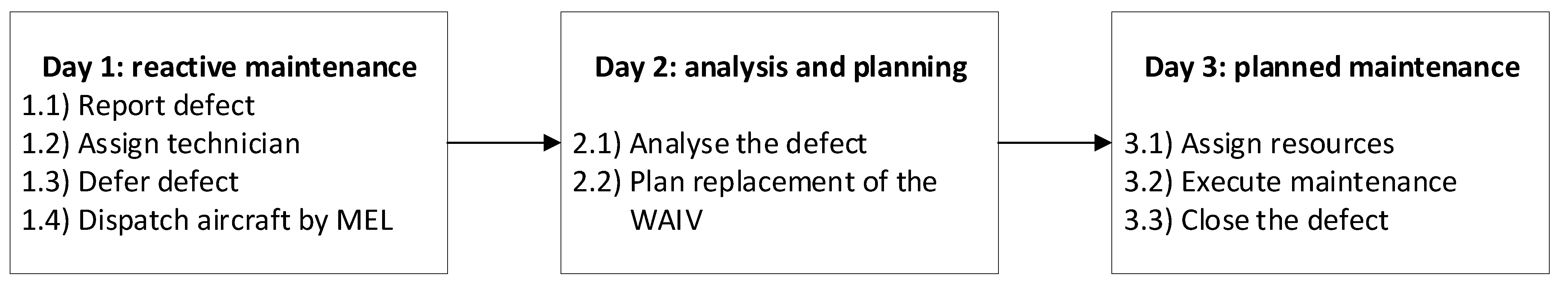

3. Case Study

3.1. Demonstration Setup and Scope

3.2. Demonstration Execution

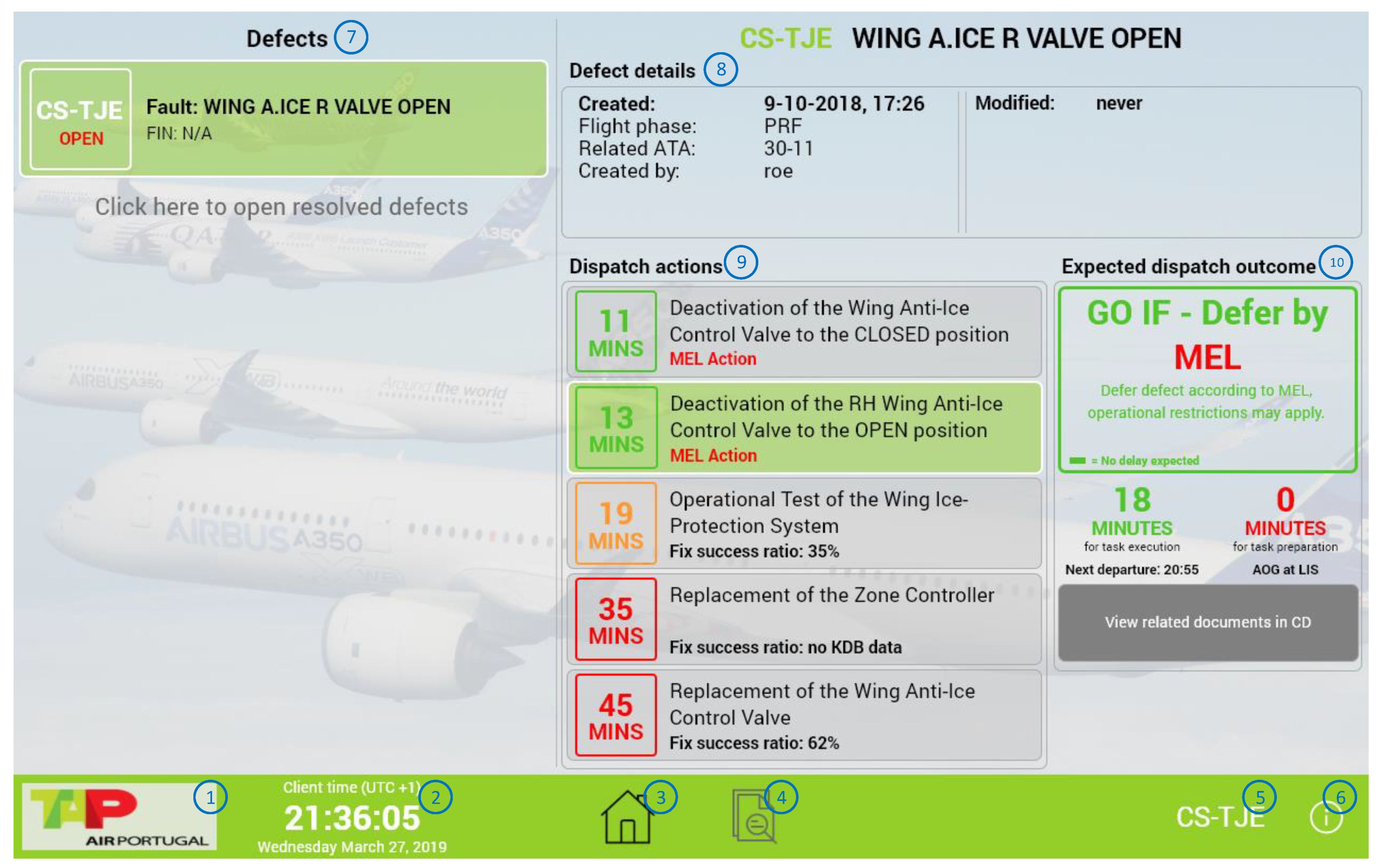

3.2.1. Prototype User Interface

- The currently logged-in user. The color scheme of the layout is adjusted to the user.

- The current local time and date, including an indication of the local time zone offset with respect to the Coordinated Universal Time (UTC).

- The home menu button that directly provides access to the dispatch assessment functionality (currently selected).

- The direct access button to contextualized documentation.

- The tail number associated with the currently selected defect (in item 7). Clicking this button provides access to aircraft details (e.g., model, CSN) and the flight schedule.

- An information button providing access to background information, such as contact information, the current prototype version, and the project website.

3.2.2. Comparing Dispatch Options

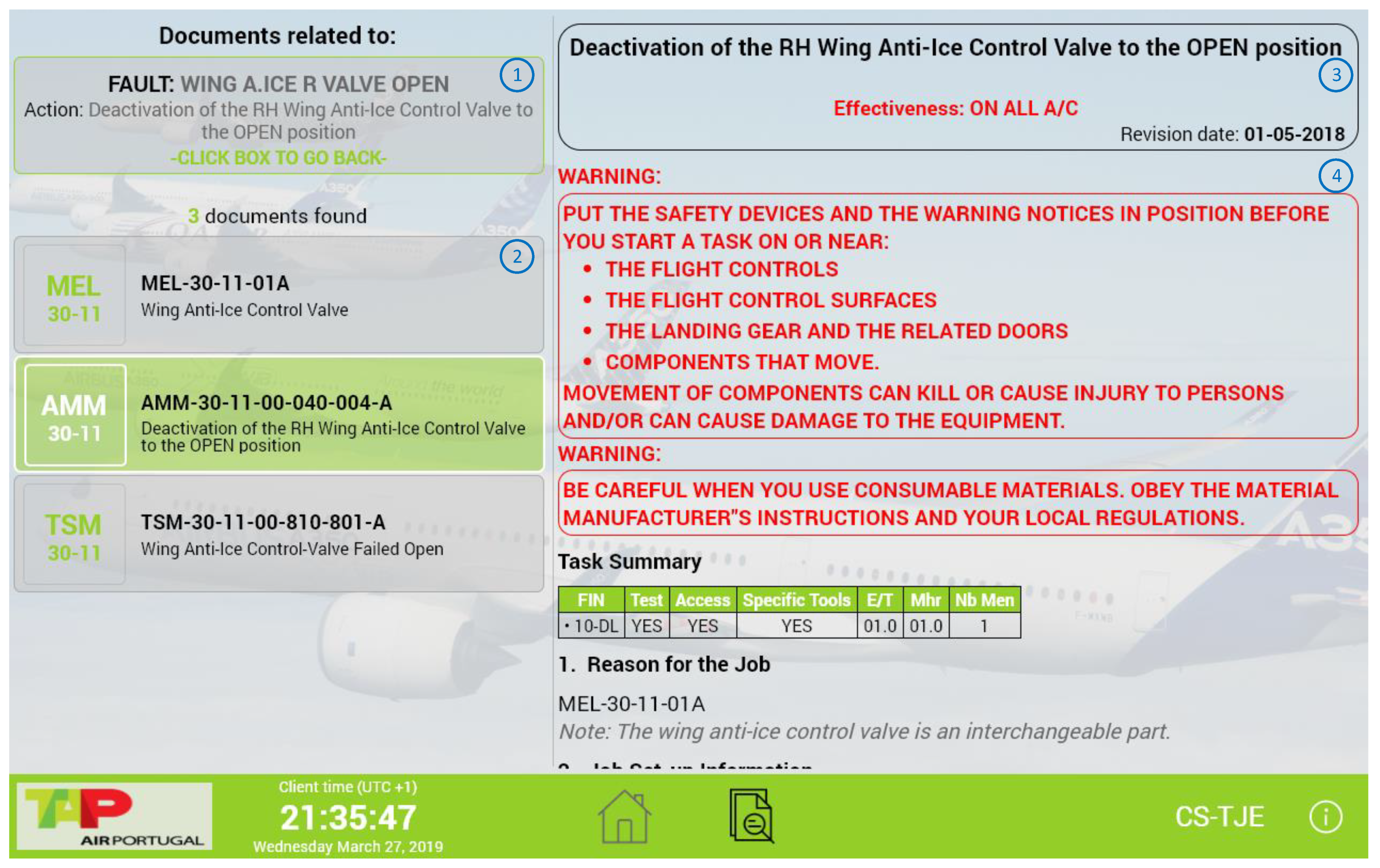

- the information container showing the current defect and selected alternative;

- the contextualized documents (3 in total, with the related AMM task selected);

- metadata of the selected document that will remain visible on top when scrolling;

- the actual content of the AMM maintenance task. When no alternative is selected, the link to contextualized documentation will show all maintenance tasks related to all alternatives.

3.2.3. Dispatch Decision-Making

4. Results and Discussion

Achievement of the Functional Requirements

5. Conclusions

- a lack of published research for operational decision-making in the (aircraft) maintenance domain, by introducing a novel system architecture and its subsequent implementation by means of a prototype to provide real-time decision support;

- the indicated lack of correlation between theory and practice in decision support systems research, by evaluation of the prototype through a case study in an operational environment and showing its practical relevance.

- The case study indicates that the decision time for aircraft dispatch can be reduced up to 98% by fully automating the information retrieval, alternative identification and evaluation, and subsequently providing the technician at the apron with relevant decision support information.

- The web-based implementation enables integration of multiple data sources and provides access to maintenance information for informed decision-making with almost no geographical limitations.

- Next to reducing technically induced delays, an additional benefit is the reduction of environmental impact by eliminating the use of paper and fuel consumption in current maintenance operations.

Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Steiner, A. A heuristic method for aircraft maintenance scheduling under various constraints. In Proceedings of the 6th Swiss Transport Research Conference, Ancona, Italy, 15–17 March 2006. [Google Scholar]

- Senturk, C.; Kavsaoglu, M.S.; Nikbay, M. Optimization of Aircraft Utilization by Reducing Scheduled Maintenance Downtime. In Proceedings of the 10th AIAA Aviation Technology, Integration, and Operations (ATIO) Conference, Fort Worth, TX, USA, 13–15 September 2010; p. 9143. [Google Scholar]

- Samaranayake, P.; Kiridena, S. Aircraft maintenance planning and scheduling: An integrated framework. J. Qual. Maint. Eng. 2012, 18, 432–453. [Google Scholar] [CrossRef] [Green Version]

- Deng, Q.; Santos, B.F.; Curran, R. A practical dynamic programming based methodology for aircraft maintenance check scheduling optimization. Eur. J. Oper. Res. 2020, 281, 256–273. [Google Scholar] [CrossRef]

- Gerdes, M.; Scholz, D.; Galar, D. Effects of condition-based maintenance on costs caused by unscheduled maintenance of aircraft. J. Qual. Maint. Eng. 2016, 22, 394–417. [Google Scholar] [CrossRef]

- Verhagen, W.J.; De Boer, L.W. Predictive maintenance for aircraft components using proportional hazard models. J. Ind. Inf. Integr. 2018, 12, 23–30. [Google Scholar] [CrossRef]

- Li, R.; Verhagen, W.J.; Curran, R. Toward a methodology of requirements definition for prognostics and health management system to support aircraft predictive maintenance. Aerosp. Sci. Technol. 2020, 102, 105877. [Google Scholar] [CrossRef]

- L-UP. AIRMES Project Website. 2019. Available online: http://www.airmes-project.eu/ (accessed on 11 September 2019).

- Ferguson, J.; Kara, A.Q.; Hoffman, K.; Sherry, L. Estimating domestic US airline cost of delay based on European model. Transp. Res. Part C Emerg. Technol. 2013, 33, 311–323. [Google Scholar] [CrossRef] [Green Version]

- Cook, A.J.; Tanner, G.; Jovanovic, R.; Lawes, A. The cost of delay to air transport in Europe: Quantification and management. In Proceedings of the 13th Air Transport Research Society (ATRS) World Conference, Abu Dhabi, United Arab Emirates, 27–30 June 2009. [Google Scholar]

- Cook, A.; Tanner, G.; Williams, V.; Meise, G. Dynamic cost indexing–Managing airline delay costs. J. Air Transp. Manag. 2009, 15, 26–35. [Google Scholar] [CrossRef]

- Cook, A.J.; Tanner, G.; Anderson, S. Evaluating the True Cost to Airlines of One Minute of Airborne or Ground Delay; Eurocontrol: Brussels, Belgium, 2004. [Google Scholar]

- Cook, A.J.; Tanner, G. European Airline Delay Cost Reference Values; Eurocontrol: Brussels, Belgium, 2011. [Google Scholar]

- Santos, B.F.; Wormer, M.M.; Achola, T.A.; Curran, R. Airline delay management problem with airport capacity constraints and priority decisions. J. Air Transp. Manag. 2017, 63, 34–44. [Google Scholar] [CrossRef] [Green Version]

- European Commission. TATEM—Results in Brief. 2012. Available online: https://cordis.europa.eu/project/id/502909 (accessed on 16 September 2019).

- International Civil Aviation Organization (ICAO). Runway and Ground Safety Working Group, Fifth Meeting (RGS WG/5). 2018. Available online: https://www.icao.int/MID/Pages/2018/RGS.ASPX.aspx (accessed on 12 February 2019).

- Airbus S.A.S. Aircraft Characteristics: Airport and Maintenance Planning Rev.25; Technical Report, Technical Data Support and Services; Airbus S.A.S.: Blagnac, France, 2019. [Google Scholar]

- Chang, Y.H.; Wang, Y.C. Significant human risk factors in aircraft maintenance technicians. Saf. Sci. 2010, 48, 54–62. [Google Scholar] [CrossRef]

- Shanmugam, A.; Robert, T.P. Human factors engineering in aircraft maintenance: A review. J. Qual. Maint. Eng. 2015, 21, 478–505. [Google Scholar] [CrossRef]

- Santos, L.F.; Melicio, R. Stress, Pressure and Fatigue on Aircraft Maintenance Personal. Int. Rev. Aerosp. Eng. 2019, 12, 35–45. [Google Scholar] [CrossRef]

- Papakostas, N.; Papachatzakis, P.; Xanthakis, V.; Mourtzis, D.; Chryssolouris, G. An approach to operational aircraft maintenance planning. Decis. Support Syst. 2010, 48, 604–612. [Google Scholar] [CrossRef]

- Dhanisetty, V.S.V.; Verhagen, W.J.C.; Curran, R. Multi-criteria weighted decision making for operational maintenance processes. J. Air Transp. Manag. 2018, 68, 152–164. [Google Scholar] [CrossRef]

- Chan, S.H.; Song, Q.; Sarker, S.; Plumlee, R.D. Decision support system (DSS) use and decision performance: DSS motivation and its antecedents. Inf. Manag. 2017, 54, 934–947. [Google Scholar] [CrossRef]

- Rastegari, A.; Mobin, M. Maintenance decision making, supported by computerized maintenance management system. In Proceedings of the 2016 IEEE Annual Reliability and Maintainability Symposium (RAMS), Tucson, AZ, USA, 25–28 January 2016; pp. 1–8. [Google Scholar]

- Arnott, D.; Pervan, G. A critical analysis of decision support systems research. J. Inf. Technol. 2005, 20, 67–87. [Google Scholar] [CrossRef] [Green Version]

- Arnott, D.; Pervan, G. Eight key issues for the decision support systems discipline. Decis. Support Syst. 2008, 44, 657–672. [Google Scholar] [CrossRef]

- Power, D.J.; Eom, S.B. Decision support systems discipline: Achievements and needs. J. Decis. Syst. 2006, 15, 9–21. [Google Scholar] [CrossRef]

- Power, D.J. Computerized Decision Support Case Study Research: Concepts and Suggestions. In Real-World Decision Support Systems: Case Studies; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; Chapter 1; pp. 1–13. [Google Scholar] [CrossRef]

- Power, D.J.; Heavin, C.; Keenan, P. Decision systems redux. J. Decis. Syst. 2019, 1–18. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Yang, X.; Haugen, S. Risk information for operational decision-making in the offshore oil and gas industry. Saf. Sci. 2016, 86, 98–109. [Google Scholar] [CrossRef]

- Ding, X.; Li, Z.; She, M. Effects of Information Acquisition Method on Diagnostic Task Performance Using Digitalized Interfaces. In Advances in Human Error, Reliability, Resilience, and Performance; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 300–309. [Google Scholar]

- Bhavnani, S.P.; Narula, J.; Sengupta, P.P. Mobile technology and the digitization of healthcare. Eur. Heart J. 2016, 37, 1428–1438. [Google Scholar] [CrossRef] [PubMed]

- National Transportation Safety Board. Aircraft Accident Report USAir Flight 405; Technical Report; NTSB: Washington, DC, USA, 1993. Available online: https://www.ntsb.gov/investigations/AccidentReports/Reports/AAR9302.pdf (accessed on 22 December 2019).

- National Transportation Safety Board. Aircraft Accident Report American Eagle Flight 4184; Technical Report; NTSB: Washington, DC, USA, 1996. Available online: https://www.ntsb.gov/investigations/AccidentReports/Reports/AAR9601.pdf (accessed on 22 December 2019).

- Hu, Y.; Song, Y.; Zhao, K.; Xu, B. Integrated recovery of aircraft and passengers after airline operation disruption based on a GRASP algorithm. Transp. Res. Part E Logist. Transp. Rev. 2016, 87, 97–112. [Google Scholar] [CrossRef]

- Pyrgiotis, N.; Malone, K.M.; Odoni, A. Modelling delay propagation within an airport network. Transp. Res. Part C Emerg. Technol. 2013, 27, 60–75. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koornneef, H.; Verhagen, W.J.C.; Curran, R. A Web-Based Decision Support System for Aircraft Dispatch and Maintenance. Aerospace 2021, 8, 154. https://doi.org/10.3390/aerospace8060154

Koornneef H, Verhagen WJC, Curran R. A Web-Based Decision Support System for Aircraft Dispatch and Maintenance. Aerospace. 2021; 8(6):154. https://doi.org/10.3390/aerospace8060154

Chicago/Turabian StyleKoornneef, Hemmo, Wim J. C. Verhagen, and Richard Curran. 2021. "A Web-Based Decision Support System for Aircraft Dispatch and Maintenance" Aerospace 8, no. 6: 154. https://doi.org/10.3390/aerospace8060154

APA StyleKoornneef, H., Verhagen, W. J. C., & Curran, R. (2021). A Web-Based Decision Support System for Aircraft Dispatch and Maintenance. Aerospace, 8(6), 154. https://doi.org/10.3390/aerospace8060154