1. Introduction

Space debris of any size poses a potential and actual threat to the operating spacecraft and the near-earth space ecology. In the low orbit area with the highest debris density, the relative velocity of the spacecraft and orbital debris could exceed 15 km/s. At such a velocity, impact with large as well as 1 cm or even smaller debris could cause serious or even catastrophic damage to the spacecraft [

1]. Therefore, it is necessary to study the hypervelocity impact between space debris and large-scale complex spacecraft. Research on problems in hypervelocity impacts is quite different from those of high- and low-velocity impact. When the impact velocity exceeds 3 km/s, it is very difficult to perform the test and the required test conditions are more demanding, and it is also difficult to acquire debris information and images, especially for such problems as space debris impacting spacecrafts or ballistic missile interception at hypervelocity. Therefore, this study is to find appropriate numerical simulation means to present the problem of hypervelocity impact more accurately on full-scale complex structures, and then accurately simulate and analyze their breakup, characteristic parameters of debris cloud and debris fragments as well as the dynamic response of materials and structures under hypervelocity impact, and finally perform test verification. The selected appropriate simulation method can also be extended to the calculation of larger-scale hypervelocity impact problems, thus better-guiding follow-up tests, reducing research costs, and improving research efficiency.

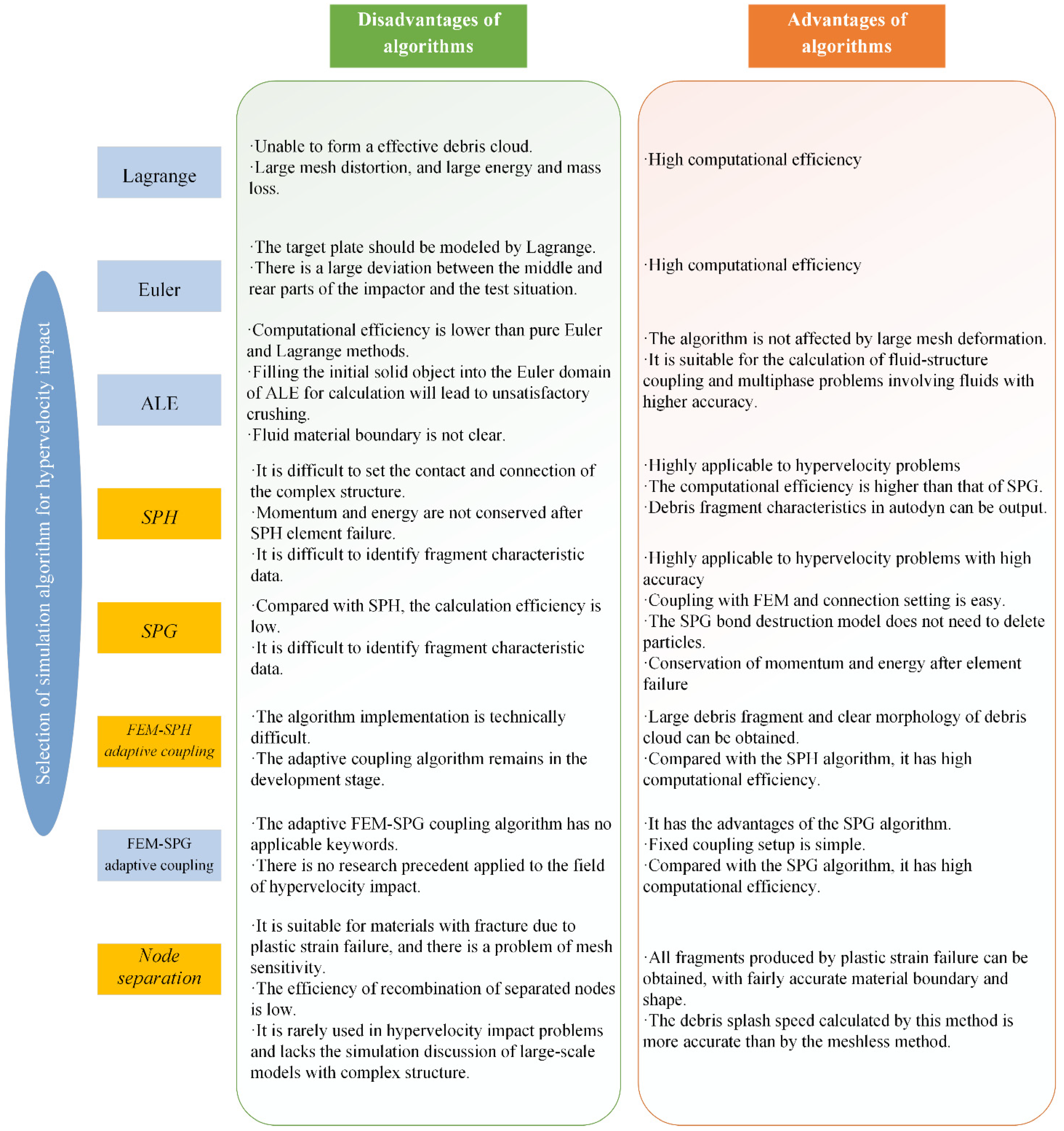

However, the numerical simulation of hypervelocity impacts is essentially a highly nonlinear dynamic matter. The commonly used methods to solve such problems are the Lagrange method, Eulerian method, Arbitrary Lagrangian–Eulerian (ALE), and meshless method. In recent years, the smooth particle hydrodynamics (SPH) method as a meshless method has been developed rapidly and played a key role in hypervelocity impact studies. However, these methods all have their limitations. In the Lagrange method, the impactor and target are eroded after impact, and cannot form an effective debris cloud. In the Eulerian method, the accurate debris cloud cannot be formed after impact, and situation of the middle and rear parts of the impactor is obviously inconsistent with the test results [

2]. The ALE method is suitable for the conditions that the initial impact objects are composed of solid and fluid, and that the material interface and the multiphase contact points are seriously deformed. This algorithm improves the calculation accuracy [

3] but reduces the calculation efficiency compared with the Lagrange method and the Euler method. In addition, there exists a problem that the boundary is not well-defined for substances treated as liquids. In the numerical simulation of hypervelocity impact using the SPH method, the debris cloud formed is composed of discrete particles, so the boundary of the debris cloud is fuzzy, and it is difficult to determine the debris shape; moreover, it is hard to identify a single fragment and the interface between the cracked and uncracked material, and there is no recognized criterion yet, so it cannot accurately describe the shape and quantity of debris fragments. Furthermore, for the full-scale complex object under hypervelocity impact, the research involves the contact, boundary, connection, and failure setting among components, which also poses a new challenge to the selection of simulation algorithms.

To address the problem of debris fragment recognition, researchers have proposed many methods, such as linked lists, hierarchical tree methods, linked list-based search algorithm, and breadth-first search (BFS) [

4,

5,

6,

7,

8], but they all determine the fragment based on the particle position at a specific time [

9]. Therefore, there are limitations in terms of computational cost, the feasibility of applying algorithms in the calculation of full-scale complex models, and the accuracy and uniformity of fragment shape recognition.

In view of the inherent defects of the SPH method, many studies have made improvement to address its computational instability, debris fragment identification, and boundary problems, which have been successfully applied to hypervelocity impact research. Libersky et al. [

10] improved the SPH method with tensile instability and without obvious boundary using the conservative smoothing method and FLIP code. Sakongaet et al. [

11] proposed the criterion of using the k-means algorithm to determine the same fragment from similar trajectories, which improved the accuracy of fragment recognition. Zhang Xiaotian et al. [

12,

13] proposed the finite element reconstruction (FER) method, which uses the SPH method for solution, and then uses vector coordinate interpolation and deletes failure elements, thus realizing finite element reconstruction. Compared with the 200 mm satellite model with a simple structure, their effects are in good agreement. Compared with the SPH method, the FER method can give the debris fragment shape and other information, but its computational efficiency remains low and the material boundary is not clear. Moreover, existing research lacks the analysis of the comparison and verification of the test results against calculation results by the simulation algorithms in hypervelocity impact on the large-scale simulated complex spacecraft structure.

To solve the problem that a single meshless method fails to produce good calculation results, researchers have tried to couple the finite element method (FEM) and the meshless method, namely, conducting fixed coupling of the FEM and the calculation region of particles at the beginning of calculation time. It is found that this method can better simulate the perforation characteristics in hypervelocity impact problems [

14,

15], but problems such as complex modeling, difficulty in obtaining fragment information, and tensile instability still exist. Therefore, researchers began to study the adaptive coupling algorithm that automatically converts elements into particles in the calculation process. In 1994, Johnson [

16] proposed the idea of transforming elements into particles using the element equivalent plastic failure criterion, and then improved and established the adaptive coupling algorithm, but tensile instability remains a problem. Subsequently, many domestic and foreign researchers used different methods and failure criteria to study the adaptive coupling algorithm [

17,

18,

19,

20]. Compared with other literature, He et al. [

21] improved the FEM-SPH adaptive coupling algorithm using the Johnson–Cook failure criterion and maximum tensile stress failure criterion, and the calculated results of characteristics and distribution of projectile spallation and debris cloud are in good agreement with the test results.

He et al.’s improved FEM-SPH adaptive coupling algorithm has advantages in dangerous debris fragment characteristic recognition and computational efficiency and also has good applicability in mesoscopic modeling. It may be an effective way of numerical simulation of hypervelocity impact on complex materials. However, for the dynamic response of different research object materials under high-velocity impact, the emerging smooth particle Galerkin (SPG) method [

22] and the previous node separation algorithm [

23,

24] perform better than the FEM-SPH coupling method in many aspects, such as contact setting, the effect of coupling with the FEM, and sensitivity of failure criterion. The advantages and disadvantages of each algorithm are shown in

Figure 1.

Many researchers have made valuable studies on the law of hypervelocity impact between space debris and spacecraft. Smirnov et al., used projectiles and shells of different materials (e.g., organic glass, aluminum, iron, and platinum) to carry out triple contact points hypervelocity impact numerical research on spherical thin-walled metal shell filled with ideal gas [

3]. Liu et al., established two parameterized 2D numerical models using the SPH and the FEM studied the characteristics of the polyimide flow field and proposed a dynamic fracture strain criterion [

25]. Rumyantsev et al., study the efficiency of screen protection of space vehicles against hypervelocity elongated projectiles that are an analog of the most dangerous space debris [

26]. Shakirzyanova et al., conducted numerical simulations using the ANSYS Autodyn software package to study the behavior of transparent spacecraft components composed of multilayer glass plates (including transparent ceramics and polymers) impacted by different objects at high velocities (up to 1 km/s) and hypervelocity (up to 10 km/s) [

27]. Toor et al., conducted two-dimensional, continuum shell, and three-dimensional modeling of a shielding system using the finite element method. The effect of thickness and velocity variation has been emphasized with a view to simulate the effect of space debris on the metallic shielding system [

28]. In addition to the research on the hypervelocity impact of individual components on spacecraft, Schimmerohn et al., established a numerical tool PHILOS-SOPHIA and used the FEM-SPH coupling method to simulate the impact between the ESA LOFT satellite model and small satellites under different impact geometries. It was found that the fluid coding results showed good agreement and obvious deviation from the Standard Satellite Breakup Model (SSBM) prediction, and the simple energy-to-mass ratio (EMR) criterion failed to reflect such complexity [

29]. Finally, concerning the comparison between the numerical simulation results and the experimental results, Meshkov et al., proposed a new algorithm to obtain the image edges by comparing the physical experiments and the calculation experiments based on fuzzy set theory and established an integrated system for modeling hypervelocity interaction of solids [

30].

The main novelties are the establishment of the keywords and parameters of several numerical simulation algorithms in the field of hypervelocity impact, the study of the sensitivity of different algorithms to the mesh size, and the comparison of the accuracy of the algorithms based on the exact solution, experimental data, and the accumulated error. Based on this, this study provides a set of suitable parameters for simulating the hypervelocity impact of large-scale complex spacecraft, and studies the applicability to non-symmetric targets (different impact positions).

Among the four algorithms that may be applicable to the full-scale numerical simulation of hypervelocity impact, namely, the SPH method, FEM-SPH adaptive coupling method, FEM-SPG fixed coupling method, and node separation algorithm, the applicability of the FEM-SPG fixed coupling method and node separation algorithm in hypervelocity problems were rarely discussed, and few researchers have compared the test data of debris fragment characteristic parameters obtained by the SPH method and FEM-SPH adaptive coupling method to verify the accuracy of simulation and calculation in the full-scale model with complex structure. In addition, existing research lacks the comparative analysis of the applicability of the four algorithms for the same hypervelocity impact scenario, and for the problem of large-scale spacecraft under hypervelocity impact in the future, testing of the necessary algorithms’ dependence on the mesh size is far from adequate.

Therefore, this paper will first compare the simulation results of SPH, FEM-SPG fixed coupling method, node separation method, and FEM-SPH adaptive coupling method under varying mesh/particle sizes with the test results of aluminum projectile impact on aluminum plate, so as to find the algorithm more suitable for the full-scale numerical simulation of hypervelocity impact that releases huge kinetic energy. Then, it is applied to the simulation and calculation of the hypervelocity impact of space debris on a simulated satellite. By comparing the debris’ statistical simulation results with the test results, the applicability of the algorithm for hypervelocity impact simulation analysis of the full-scale complex spacecraft structure is verified. The main research content of this paper is shown in

Figure 2.

5. Verification of Space Debris Impact Satellite Simulation

Through the study of four algorithms under the simulation conditions of different mesh/particle sizes based on the test of aluminum projectile impact on aluminum plate, it is found that the simulation results of the FEM-SPH adaptive coupling method are relatively less sensitive to the mesh size, and are closer to the real test values, making it more suitable for the simulation of hypervelocity impact on full-scale complex structures. However, there is still a lack of test verification of the distribution law of debris fragment characteristic parameters, which is a concern in the follow-up research. Therefore, the simulation condition TEST C in the characteristics study of debris fragments from satellite breakup due to hypervelocity impact by Liu Sen is selected as the simulation condition for verification [

28].

5.1. Establishment of Simulation Model of Satellite for Verification

The parameters set by Liu Sen in the test are shown in

Table 7, where the subscript

p represents space debris and the subscript

t represents the simulated satellite. Based on the setting of test conditions, the simulation structure model and parameters are determined. The thickness of the satellite’s bottom plate, side plates, inner diaphragm, and connecting parts is 2 mm [

29], and the material is 2024 aluminum alloy with a density of 2780 kg·m

−3. The thickness of the central cylinder of the satellite is 1.5 mm and its material is 2024 aluminum alloy. The sizes of the electronic box on the satellite diaphragm are 10 mm × 5 mm × 3.5 mm and 15 mm × 5 mm × 3.5 mm with a thickness of 1.5 mm. The material is 6063 aluminum alloy, which is commonly used for electronic boxes, with a density of 2700 kg·m

−3. The space debris is equivalent to the shape of a projectile. Its structure consists of a 13 mm hemisphere, a 10 mm cylindrical section, and a 35 mm hollow circular platform section. Its material is 6061 aluminum alloy with a density of 2700 kg·m

−3.

After the simulation model is established according to the above parameters, through calculation, the overall dimension of the satellite model is 400 mm × 400 mm × 400 mm, total mass

Mt = 7338.515 g, and simulated projectile mass

Mp = 98.706 g. The simulated complex satellite structure and the electronic box as well as their simulation models are shown in

Figure 24.

When we set the mesh size, according to the previous conclusions, although the characteristic parameters of debris clouds are minorly affected by the mesh size when using the FEM-SPH adaptive coupling method, accumulated error and the effective statistical number of debris fragments are greatly affected by it, and the fragment data near the minimum mesh size is distorted to a certain extent. Therefore, when meshing for the model of space debris impact on simulated satellite, the mesh scale is set to the maximum amount that the pre-processing software can handle, namely, 2 mm [

9]. The meshing for hypervelocity impact on the simulated satellite by the projectile using the FEM-SPH method is shown in

Figure 25.

When we set the FEM-SPH adaptive coupling method keyword for the calculation example of space debris equivalent projectile impact on the simulated satellite, the basic setting is similar to that of the test of aluminum projectile impact on aluminum plate, but the contact setting is changed from a simple structure to a complex structure. For the projectile and the satellite, the keyword *CONTACT_ERODING_SINGLE_SURFACE is set to automatically identify the erosion contact between the surfaces. The static friction coefficient is set to fs = 1.05 and the dynamic friction coefficient fd = 1.40 for the aluminum alloy materials. In addition, due to the high impact velocity of the hypervelocity problem, the meshes of the contact surfaces of the two impactors can easily penetrate each other, and as the impact position is where multiple satellite plate structures converge, the parameters SOFT = 2 and DEPTH = 5 are set in Optional Card A to prevent penetration between different parts and elements.

5.2. Suitability Analysis of the Finite Element Method-Smooth Particle Hydrodynamics Adaptive Coupling Numerical Simulation Algorithm for Asymmetric Spacecraft Target

Due to the existence of stiffeners, bolts, and structures alike, the metal targets on the spacecraft rarely affect each other in a cylindrical symmetrical way from all directions. Therefore, it is necessary to evaluate the suitability of the FEM-SPH method to non-symmetric targets. During the breakup of the satellite, the effect of space debris impact on non-symmetric targets is reflected in the change of the impact position, making it far away from the center of the impact surface. Therefore, the structural asymmetry is treated equivalently as the shift of the initial impact position of the spherical projectile while keeping the other conditions unchanged, and the suitability of the FEM-SPH method to the calculation of the breakup of the established satellite large-scale target is studied. The specific settings of the numerical simulation are shown in

Table 8. The ratio of the horizontal distance between the projectile center and the satellite geometric center to the half side-length of the satellite is defined as Δ.

Figure 26 shows schematics of the breakup of satellite 265 μs after the hypervelocity impact of space debris at four different positions on a large-scale simulated satellite. By analyzing the macroscopic damage and the stress diagram, it can be seen that when hitting a non-symmetric target, the change in the impact position not only results in the changes in space debris and components and structures in the satellite impact channel but also leads to different overall damage and breakup effects of the satellites. Through the same period of time after impact, the structural plates show different extents of disintegration. In the case of Δ = 0%, the disintegration of the satellite plates is the least serious. Furthermore, for fragment projectile hypervelocity impact, the peak value of the stress response of the satellites is basically the same, the stress concentration phenomenon can be observed around the perforation and the connecting parts. In addition, the mechanical responses of the target structure in the impact channel and its vicinities are more obvious. Therefore, the FEM-SPH adaptive coupling algorithm is suitable for the simulation of the hypervelocity impact of non-symmetric targets.

5.3. Comparison and Verification of Algorithm Accuracy Based on Test

Firstly, with regard to the study of hypervelocity impact on spacecrafts such as satellites, the focus is often on macroscopic phenomena such as spacecraft breakup and damage after impact. Therefore, the simulation process of simulated satellite breakup and damage by the FEM-SPH adaptive coupling method and the similarity of the damage effect graphs with the test results are compared firstly, so as to judge the calculation accuracy of the algorithm for such macroscopic events as breakup. The comparison of the simulation and test of the overall breakup and structural component damage is shown in

Figure 27.

As is seen from

Figure 27, the connection between the main structures of the satellite has been damaged, the main five aluminum plates of the main structure completely separated, the simulated electronic box near the impact area also damaged to varying degrees, and the inner diaphragm and central cylinder structure of the satellite also damaged. The simulation conditions for complete breakup are the same as in the conclusion of complete breakup obtained in the test. In addition, in the simulation, the corners of the five aluminum plates are deformed, and there are perforations by flying debris. Large holes are formed in the aluminum plates far away from the impact direction under the direct impact of the debris cloud, and the plates are almost completely destroyed.

Besides comparing the overall changes in the simulated satellite subjected to hypervelocity impact in the simulation and the test, it is also needed to further compare the differences between the debris fragment characteristic parameters in simulation results and test data. The fragment characteristic length distribution is shown in

Figure 28.

According to

Figure 28, although the number of fragments obtained by the SPH method is more than that by the adaptive coupling method, it is not consistent with the test result. The fragment characteristic length calculated by the FEM-SPH adaptive coupling method exceeds 100 mm, i.e., the distribution of larger fragments is consistent with the test data. Through Element search, it is found that the fragments with accurate characteristic length distribution are mainly large-scale debris formed after the damage of the main structural plate, central cylinder, and inner diaphragm. The consistency of these data also confirms that the adaptive coupling method produces more accurate results for the simulation of the breakup and macro damage of large-scale complex spacecraft structures subjected to hypervelocity impacts. However, from

Figure 27b, there is a certain gap between the characteristic length distribution of small-size (<100 mm) fragments calculated by the FEM-SPH method and the test results. From the fitting line in

Figure 27c, it can be seen that the characteristic size distribution of the simulation and the test can be fitted into a similar power function and converted based on the mathematical relationship. The characteristic length distribution functions fitted by the test and the simulation are shown in Equations (25) and (26), and the relationship between the cumulative number of fragments in the test and the simulation data is shown in Equation (27).

where

N is the cumulative number of fragments, whose size is greater than or equal to a certain characteristic size,

Lc is the number of fragments, the subscript

t represents the test data, and

s represents the simulation data.

Secondly, the fragment mass distribution is shown in

Figure 29. As illustrated, similar to the characteristic length distribution, the statistical distribution of fragment mass data calculated by the adaptive coupling algorithm is also in the range of large masses (10~1000 g), which is consistent with the test statistics. These fragments are mainly those generated after the breakup and destruction of the main structure of the satellite. In the range of small masses (<10 g), limited by the total amount of fragments output by the simulation method, the mass distribution obtained from the simulation data is quite different compared to the test.

Finally, the relationship between fragment characteristic length and mass is shown in

Figure 30. In the figure, the fragment data obtained from the characteristic length–mass simulation are highly consistent with the test data in the whole range, and Equation (28) for the functional relationship curve of the characteristic length and mass fitted according to the simulation data and Equation (29) for the curve fitted by the test [

36].

From the coefficient and index data in the expression, it can be seen that the function curves fitted by the simulation and the test are very close. In addition, it is noted that the power exponents of the characteristic sizes in the above formula are 2.29 and 2.2591, which are different from the general three-halves power of mass and size. The reason is that the fragment characteristic size used in the debris research does not characterize the actual volume occupied by the debris fragments, but the volume of hexahedron projected by them in the three-dimensional space [

36]. The actual fragment mass is less than the mass of the projected hexahedron, which shows in the functional relationship that the index of the characteristic size should be less than three. In this sense, the power exponent of the characteristic size in the above equation is also a reflection of the irregularity of fragment shape, and the coefficients 10

1.09 and 10

1.0684 are also parameters related to fragment material density and fragment shape. Therefore, it is deduced that the highly consistent characteristic length–mass relationship in the simulation and the test reflects that the fragment shape obtained by the FEM-SPH adaptive coupling method is generally close to the real situation.

5.4. Analysis of Simulation Results of Finite Element Method—Smooth Particle Hydrodynamics Adaptive Coupling Method

Firstly, to judge the overall breakup and damage of the satellite, through the comparison of the test photos and simulation results, it is found that using the FEM-SPH adaptive coupling method, the satellite breakup and damage are in line with the actual situation.

Secondly, the FEM-SPH adaptive coupling algorithm is suitable for the simulation of the hypervelocity impact of non-symmetric targets. In such conditions, the change of the impact position not only leads to the changes in the components and structures in the impact channel of space debris and satellites but also leads to different effects of overall damage and disintegration of the satellites. Through the same period of time after impact, the degrees of disintegration and separation between the structural plates are obviously affected, and the target structure in and near the impact channel show more obvious mechanical responses.

Thirdly, in calculating the debris fragment characteristic parameters, through the comparative analysis of the debris characteristic length distribution, mass distribution, and characteristic length–mass relationship obtained from the simulation and the test, it is found that there is a certain gap between the debris characteristic parameters obtained by the two methods and the test data. However, the characteristic length distribution and mass distribution of the fragments with sizes greater than 100 mm obtained by the FEM-SPH method are in good agreement with the test results. Therefore, the FEM-SPH method can better simulate the macro breakup and fragmentation of models of large-scale complex structures under hypervelocity impact, and can accurately output the characteristic parameters of large-scale fragments (50 times the mesh size). In addition, it is also found that although the output of fragment characteristic parameters in the scale of 0.0001~0.1 m does not conform to the test law due to the insufficient total amount of output fragments under certain mesh accuracy, there is a unified mathematical relationship between the lines fitted by the simulation and test data, which can be derived from each other.

Finally, as for the relationship between the fragment mass and characteristic length, it is found that the fragments at all scales simulated by the FEM-SPH method conform to the characteristic length–mass relationship obtained by the test. The power exponent and coefficient of the characteristic size is, to some extent, a reflection of fragment shape. Therefore, the fragment shape simulated by the FEM-SPH adaptive coupling method is generally consistent with the actual situation, and follow-up research can be done on the fragments’ aerodynamic, atmospheric reentry, or secondary damage analysis.

6. Discussion

This study aims to find appropriate numerical simulation means to address the problem of hypervelocity impact more accurately on large-scale complex spacecraft structures, so that the spacecraft’s breakup, debris cloud characteristic parameters, and debris fragment distribution can be accurately simulated and analyzed, and test verification performed. When the appropriate simulation method is determined, it can be extended to the problem of hypervelocity impact on larger-scale spacecraft, space stations, and incoming missile targets, which will better guide the follow-up tests, reduce research costs, and improve research efficiency.

6.1. Analysis on the Application of Constraint Algorithm in Hypervelocity Impact Field

In the study of hypervelocity impact on spacecraft, the first essential factor is the debris cloud. Since the debris cloud and secondary debris are also important damage sources for non-monolayer targets with complex structures, the simulation algorithm needs to accurately present the profile of debris clouds and related characteristic parameters, so that researchers can conduct better follow-up observation. The second is the acquisition of the characteristic parameters of large-scale debris fragments. The characteristic length, mass, and velocity of such debris fragments may become the input for the subsequent atmospheric reentry and impact point research. The third is the small-scale debris fragments generated after impact. They may later become space debris posing potential threats to other spacecraft.

Therefore, in the study of algorithms for hypervelocity impact on spacecraft, in order to display the debris cloud, the algorithm should not delete too many elements and maintain the conservation of mass and energy. The algorithm is critical for finite element meshes and particles, mesh and particle transformation conditions, and criteria for binding constraint establishment or interaction between elements. Moreover, in the simulation of the acquisition of large-scale spacecraft fragments, it has been found that the adaptive finite element and particle coupling method can accurately calculate the structural fragments. Finally, with regard to the potentially hazardous small-size fragments, through the adaptive coupling method with a certain initial mesh fineness, a certain number of space fragments with more real shapes can be obtained. If one wants to obtain small fragments whose number is similar to that of the real situation, in the simulation algorithm, the mesh-particle transformation conditions or the basic simulation method needs to be adjusted.

6.2. Discussion on the Influence of Mesh and Particle Size on Hypervelocity Problem

The hypervelocity impact problem is extended from the millimeter level to the centimeter or even meter level, and from the simple single-layer plate to complex spacecraft structures. If numerical simulations are used for the relevant research, the sensitivity of the algorithm to elements and particles becomes very important. For the algorithms involved in the research, regarding the calculation results of the debris cloud, it is found that the simulation method of establishing inter-node constraints to reduce element deletion represented by node separation, the formation of debris clouds is greatly affected by the mesh size. The FEM-SPG fixed coupling method, under the setting in the study, the mechanism of particle interaction is not suitable for the analysis of hypervelocity impact, and the debris cloud contour is different from the conventional situation. Both the FEM-SPH adaptive coupling and the SPH methods can obtain a better shape of debris clouds, and their characteristic parameters of the FEM-SPH adaptive coupling method are less affected by the mesh size.

As for the calculation results of debris fragment characteristics, if the full-scale study on hypervelocity impact is extended to the statistical analysis of breakup equations of different spacecraft and even missile interception, there are high requirements for the authenticity of the number of fragment output of the algorithm. It is found that both the FEM-SPH and SPH methods can output the information of fragment characteristic parameters, and the output by the adaptive coupling method is more accurate than test data. However, although the FEM-SPH method can produce fragments with clear and accurate shapes, the total amount of output fragments is greatly affected by the initial mesh size. Due to the use of the Johnson–Cook and maximum tensile stress failure models, the meshes at the crack position must be dense enough in the definition; otherwise, a large number of element failures will greatly impact the statistical results of the FEM fragments.

7. Conclusions

To address the problems in the calculation differences of the breakup, characteristic parameters of debris clouds, and fragments by various numerical simulation methods for hypervelocity impact on the full-scale model, we carried out this study. Firstly, the simulation results of the smooth particle hydrodynamics method, finite element method-smooth particle hydrodynamics adaptive coupling method, the finite element method- smoothed particle Galerkin fixed coupling method, and the node separation method under different mesh/particle sizes were compared against the test of aluminum projectile impact on the aluminum plate. It was found that the finite element method-smooth particle hydrodynamics adaptive coupling method has the advantage of low mesh sensitivity in the simulation of debris cloud characteristic parameters. Then, the accuracies of these four different numerical simulation algorithms are compared and analyzed from the perspectives of mesh sensitivity, the difference between the numerical simulation results and the exact solutions, the difference between the numerical simulation results and experimental data, and the accumulated error analysis. Therefore, the finite element method-smooth particle hydrodynamics adaptive coupling method is more suitable for the numerical simulation of large-scale hypervelocity kinetic energy impact.

Then this method was applied to the simulation and calculation of hypervelocity space debris impact on satellites. First, the suitability of this algorithm for hypervelocity impact numerical simulation of large-scale non-symmetric complex spacecraft is verified. Secondly, the fragment statistical program further developed in the study was employed and the result elements and node data were input to obtain the statistical law of fragment characteristic parameters. Comparing the statistical results of simulation data with the test results, we found that this algorithm had high accuracy in judging the overall macro breakup and damage and that the characteristic parameters and quantity distribution were more accurate in the output of large fragments. In addition, the characteristic length–mass relationship in the full-scale range of debris output from the simulation was in good agreement with the test results. In general, although the number of fragments output by the finite element method-smooth particle hydrodynamics adaptive coupling method was less than the real situation, the authenticity of the shape and other characteristics of the output fragments was high, which is suitable for the hypervelocity impact simulation analysis of complex structures under certain requirements.

The results of this study offer different numerical algorithms for selection and show the direction for improvements in the modeling of the breakup of full-scale complex spacecraft structures and other targets subjected to hypervelocity impacts. This is a follow-up study on spacecraft hypervelocity impact: the factors influencing spacecraft breakup (multi-material, impact position, relative impact velocity, impact dip, etc.), the formula of spacecraft damage critical velocity, the engineering algorithm of spacecraft perforation diameter (multi-layer target boards) and crater depth, and the summary of spacecraft breakup model, laying a good foundation for the methods selection and establishment of numerical simulation. However, further research is needed on the limitation of the node separation algorithm to the mesh scale and the optimization of the finite element method-smooth particle hydrodynamics coupling method. The following research needs to consider the computational efficiency and the limitation of the maximum allowable error and maintain a small mesh scale, meanwhile ensuring a certain number of simulation debris output. One method is to increase the mesh density of the target damage volume and reduce the mesh density of the region less affected by impacts, so as to achieve a balance between obtaining the finite element fragment number and computational efficiency. However, using this method, it is necessary to predict the damage volume accurately through an empirical formula for specific impact conditions, which needs further study. Or improvements can be made in the material failure model and algorithm, such as integrating the mechanism of node separation and “bond” failure of the smoothed particle Galerkin method into the finite element method-smooth particle hydrodynamics adaptive coupling method, and reducing the amount of mesh-transformed particles and the demand for mesh fineness.