Abstract

A novel fuel grain configuration comprising two star-segmented grains is proposed. The effect of the rotation, mid-chamber length, and segmented position on the fuel regression rate and the combustion efficiency in hybrid rocket motors with star-segmented grains is investigated in this paper. To this end, 90% hydrogen peroxide (H2O2) and hydroxyl-terminated polybutadiene (HTPB) are selected as the propellant combination in this research. Three-dimensional numerical simulations of the star-segmented grain configuration are conducted. A firing test of a lab-scale hybrid rocket motor was conducted to verify the accuracy of the numerical model, and the errors between simulation data and experimental results are no more than 4.5%. The case without segmented grain configuration is regarded as the base case. The simulation results demonstrate that the combustion flow field structure of the motor could be ameliorated by the segmented rotation grain configuration. Compared with the base case, the rotation of aft-section grain has little effect on the regression rate in the fore-section grain, while the average regression rate in aft-section grain increases, with a maximum increase of 25.04%. The combustion efficiency of the motor with the segmented rotation grain configuration is higher than the base case. Compared with the base case, the combustion efficiency of segmented rotation grain case with mid-chamber length 40 mm and segmented position of 1/2 is raised by 4.06%. The average fuel regression rate and the combustion efficiency of hybrid rocket motors with segmented rotation grains are higher than those in the base case during the entire period of operation, and the combustion efficiency is increased by 1.40–4.21% during the motor operation. The research findings of this paper can provide valuable guidance for the performance improvement of hybrid rocket motors with star grain.

1. Introduction

Hybrid rocket motors generally utilize solid fuel and a liquid oxidizer [1]. The solid fuel is in the combustion chamber and the liquid oxidizer is stored in a tank; therefore, they are not pre-mixed. This special structure provides hybrid rocket motors with multiple advantages, such as safety, low cost, high reliability, restart characteristics, and a wide range thrust regulation [2,3,4,5]. Because of these characteristics, hybrid rocket motors have become a promising thrust system in numerous fields, such as suborbital vehicle propulsion, sounding rockets, target drones, and interplanetary lander power systems [6,7,8,9,10]. However, the combustion of hybrid rocket motors is governed by the diffusion process, which leads to low fuel regression rates and low combustion efficiency [11]. Low regression rates can be compensated by utilizing star fuel grain configurations to provide enough burning surface area for sufficient thrust [11,12,13]. The burning surface of hybrid rocket motors with star grain possesses good designability. In addition, low combustion efficiency is primarily caused by the inadequate mixing of the propellants. Therefore, efforts should be made to enhance the propellant mixing of hybrid rocket motors.

Multiple investigations have been conducted recently to improve the fuel regression rate and combustion efficiency in hybrid rocket motors. One of the effective methods is to adopt special fuel grain configurations. Changjin Lee et al. conducted a number of tests to study the fuel regression rates in hybrid rocket motors with swirl and helical configurations [14]. PMMA and gaseous oxygen were used for the propellants. The test results showed that the grain with helical structure can cause an increase in the fuel regression rate up to 50% without a swirl injector and of up to 250% with a modified swirl injector. The regression rate behaviors of hybrid rocket motors with helical port grains were investigated by Whitmore et al. [15]. The regression rates of helical grains were higher than those of cylindrical grains, and the increases in fuel regression rates diminished with time. Regression rate characteristics and flow field structure in the hybrid rocket motors that use star swirl grain were numerically investigated by Zhang et al. [16]. The results exhibited that, under the same port area and grain length, the spatially averaged regression rate of the star swirl grain improved by about 60%, in contrast to that of the tube grain. In addition, the star swirl grain configuration can improve the combustion efficiency compared with tube grain. The fuel regression rate characteristics in hybrid rocket motors with helical fuel grain were analyzed by Tian et al. [17]. The simulation results demonstrated that the helical grain can enhance the fuel regression rate. Test results revealed that the fuel regression rate improved with the increase in the groove width and groove depth. The influence of rotation angles on the combustion efficiency and fuel regression rates in hybrid rocket motors with two-hole segmented grains were investigated in [18]. The numerical and test results showed that the regression rate in the aft-section grain increased, and the combustion efficiency was higher than that in the base case. When the rotation angle was 45°, the combustion efficiency reached a maximum. Combustion characteristics in hybrid rocket motors with multi-segmented grains were analyzed by numerical simulations in [19]. Both 90% H2O2 and PE were adopted in the simulations. The results indicated that, for the cases with two grain segments and three ports, the combustion efficiency was improved by 6–8.6%.

The research efforts mentioned above indicate that adopting helical grain configurations or segmented grains can enhance the fuel regression rate and combustion efficiency of hybrid rocket motors. However, to the best of the authors’ knowledge, the investigations are mainly focused on laboratory-scale motor (thrust is always no more than 1 kN) and little research based on the full-scale hybrid rocket motors with star-segmented grain has been conducted. In addition, the effect of rotation on the combustion performance in hybrid rocket motors with star-segmented grain has not been extensively studied to date. On the one hand, improving the average fuel regression rate can increase the total mass flow rate of propellants, which can enhance the motor thrust. On the other hand, the increase in combustion efficiency leads to the elevation of specific impulse, which is able to increase the theoretical velocity increment and the range of the rocket.

In order to further improve the regression rate and combustion efficiency, a novel fuel grain configuration comprising two segmented grains is proposed. Both the two segmented grains are star grains, and the aft-section grain is installed at a certain rotation angle with respect to the fore-section grain. A mid-chamber is located between the two segmented grains to promote the mixing of the fuel and the oxidizer. Three-dimensional steady numerical simulations are performed to investigate combustion performance of hybrid rocket motors with star segmented rotation grain in this article. A 90% H2O2 is used as the oxidizer and HTPB is adopted as the fuel. In order to verify the accuracy of the numerical model established in this paper, a firing test of a lab-scale hybrid rocket motor with tube grain was carried out, and the errors between the simulation data and experimental results are no more than 4.5%, indicating that it is feasible to predict the motor performance by using the numerical model. The temperature distribution, species mass fraction distribution, fuel regression rates, and combustion efficiency are obtained. The influence of the aft-section rotation, mid-chamber length, and segmented position on the regression rates and combustion efficiency in hybrid rocket motor is analyzed. In addition, steady numerical simulations at different working times are conducted to compare the full-time motor performances. The numerical results show that adopting star segmented rotation grain is an effective technique to improve the fuel regression rate and the combustion efficiency of hybrid rocket motors.

2. Model Description

2.1. Geometry Models

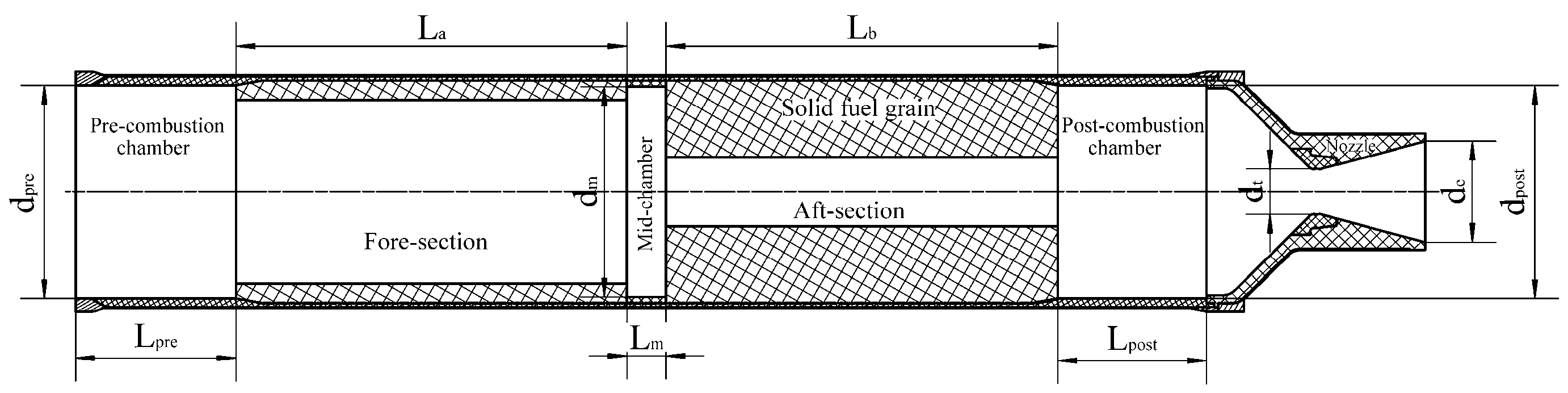

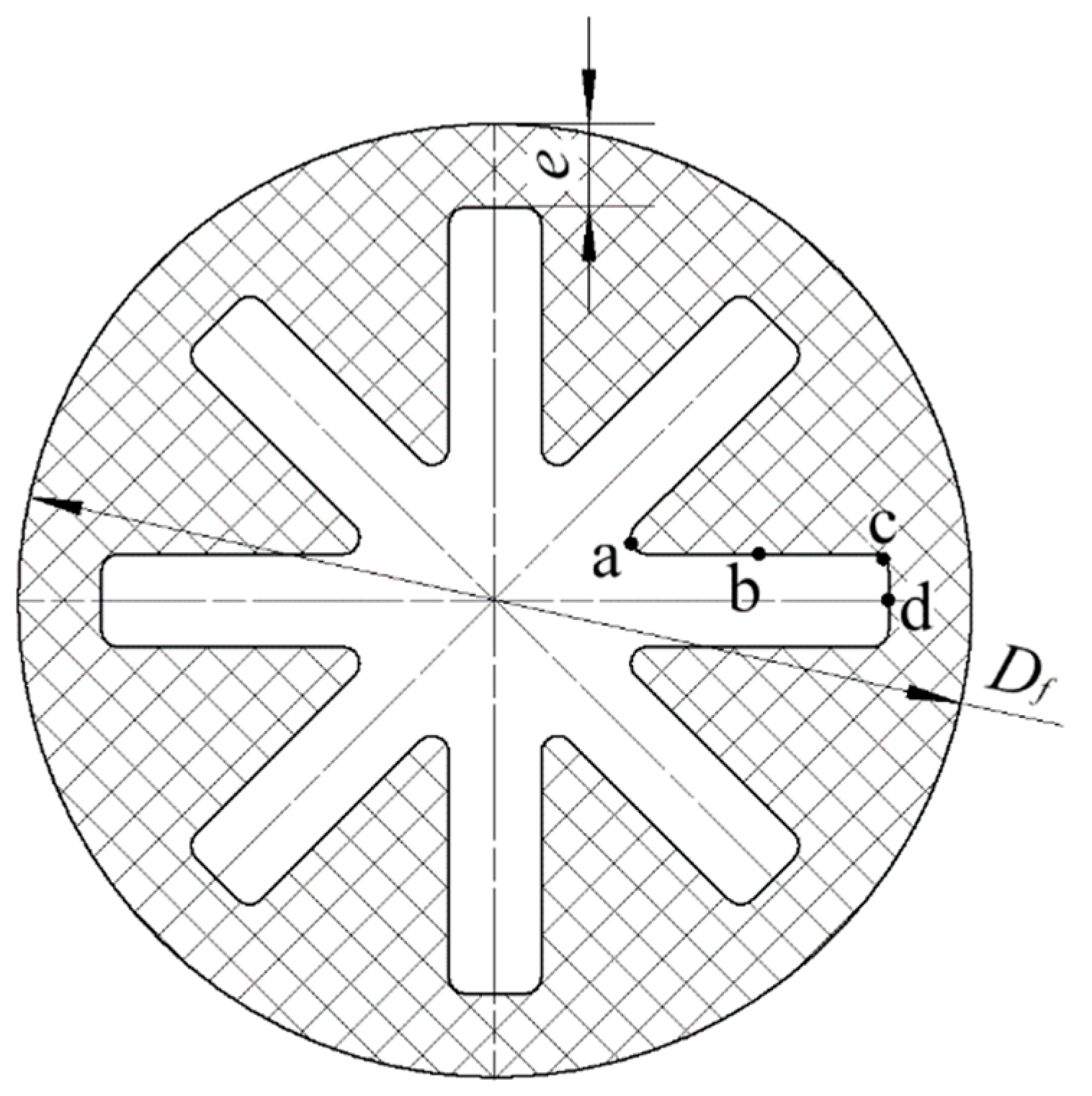

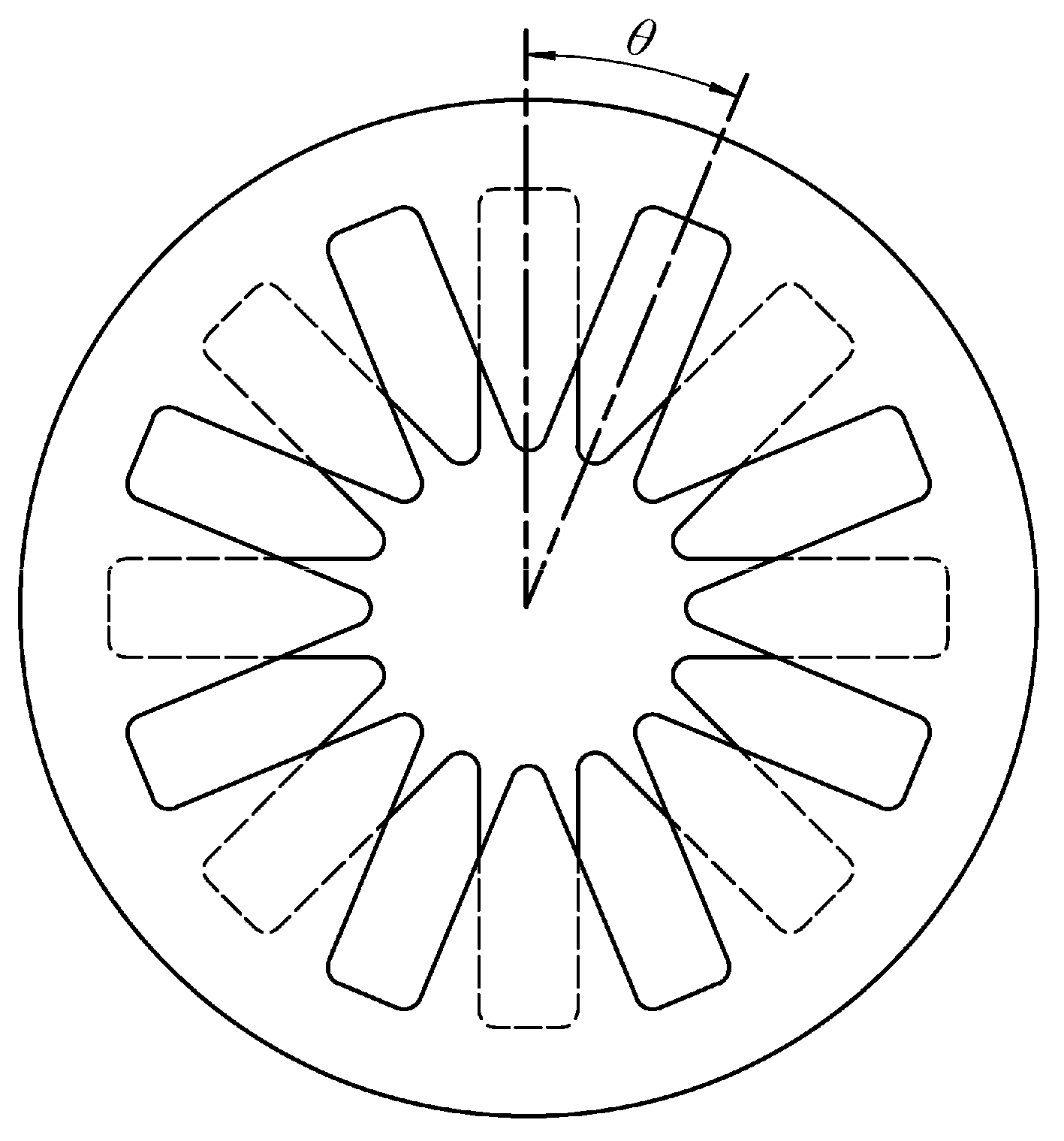

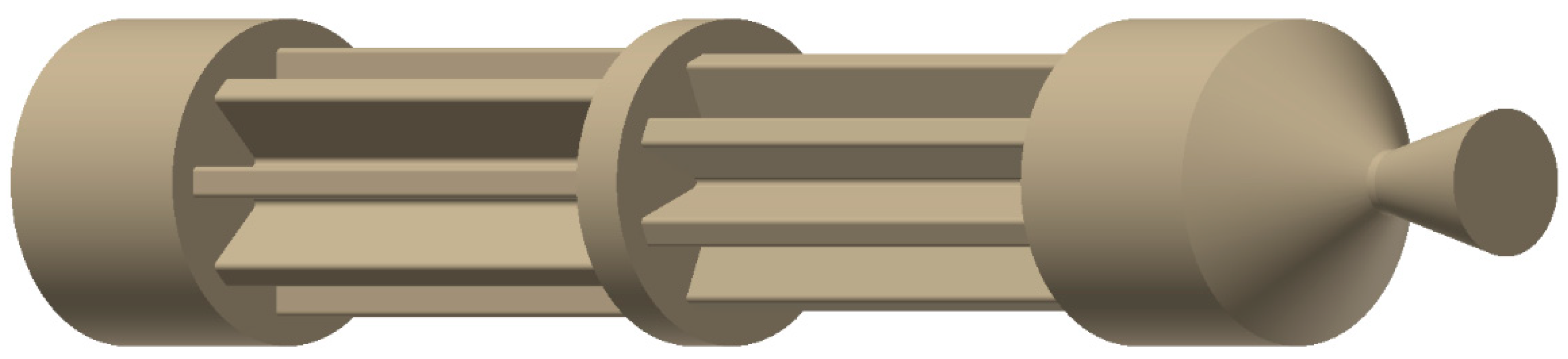

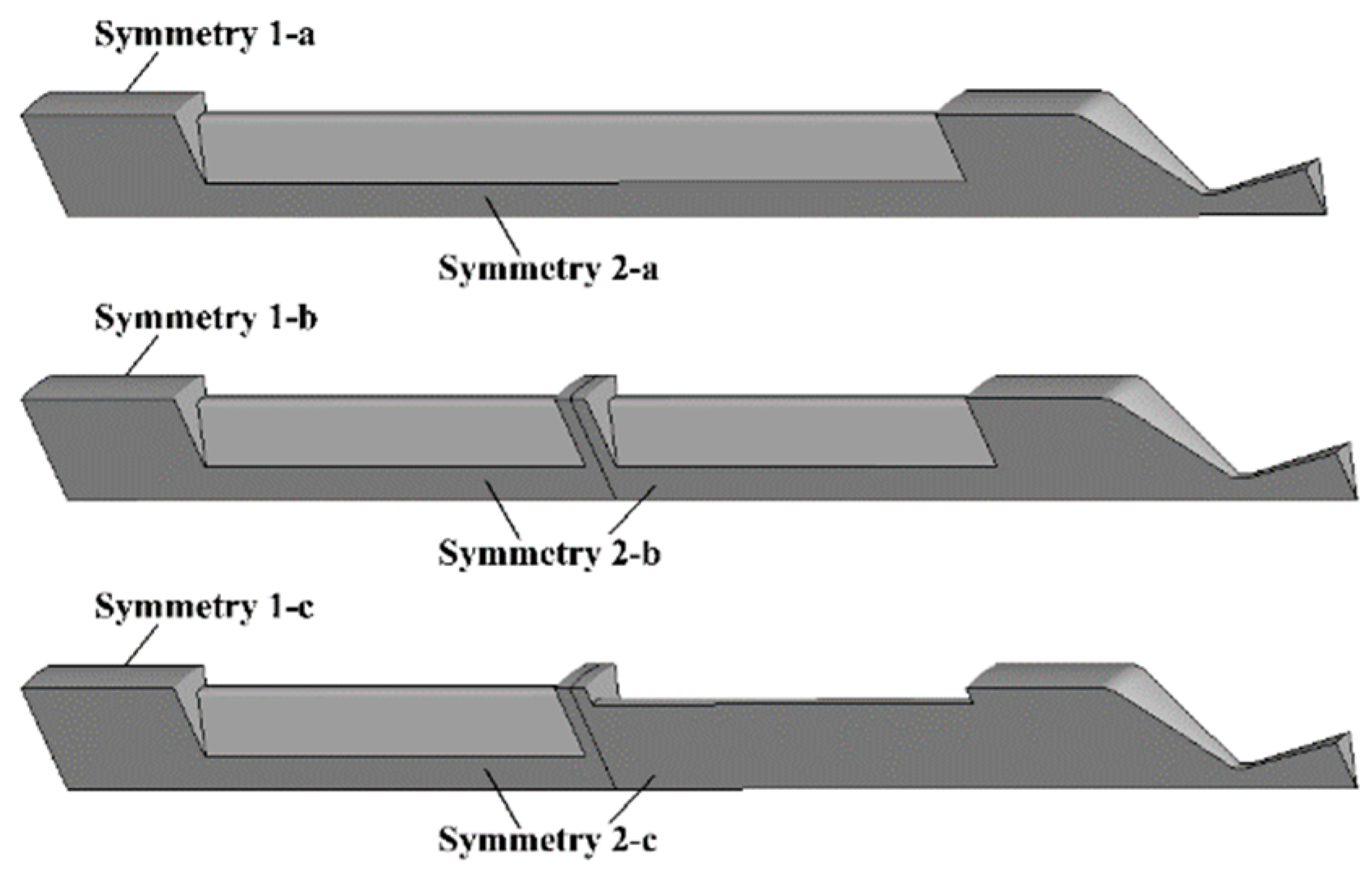

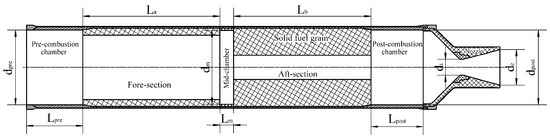

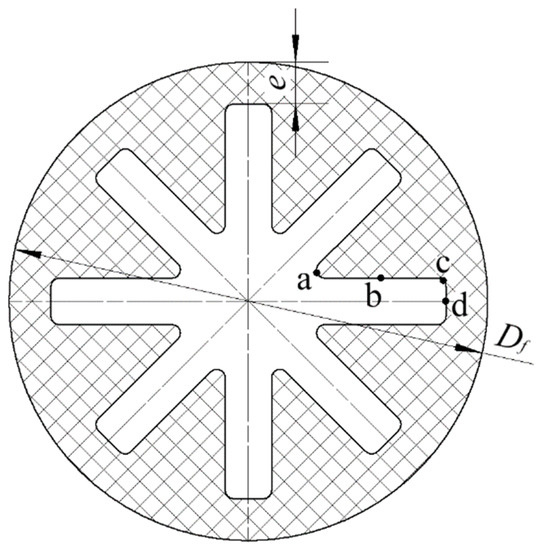

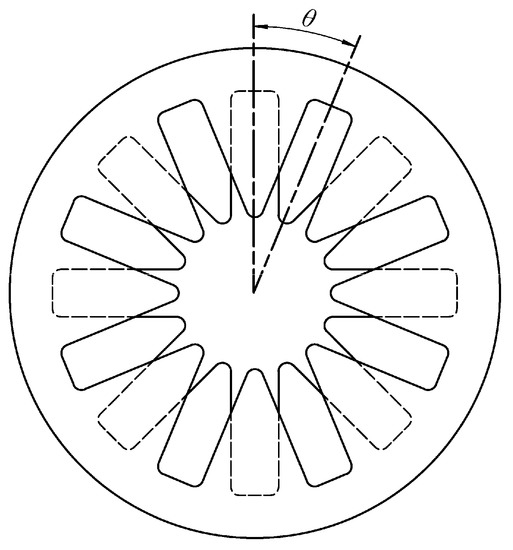

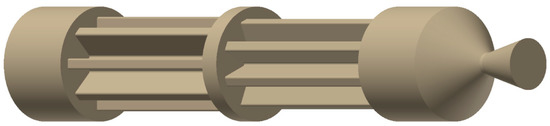

The structure of the full-scale hybrid rocket motor with star-segmented rotation grain is presented in Figure 1. The grain is separated into two sections and they are both star grains. The cross section of the star grain is shown in Figure 2, and the characteristic points are defined with letters a to d in Figure 2 for the convenience of discussions of solid fuel regression rates. The relative rotation angle of the two star-segmented grains is shown in Figure 3. Based on the fore-section grain, the rotation angle of the aft-section grain θ is 22.5°. The full-scale hybrid rocket motor is composed of pre-combustion chamber, fore-section, mid-chamber, aft-section, post-combustion chamber, and conical nozzle. The main structure parameters of the full-scale hybrid rocket motor are illustrated in Table 1.

Figure 1.

Full-scale motor with star-segmented rotation grain.

Figure 2.

The cross section in the middle of star grain.

Figure 3.

The rotation angle of the two star-segmented grains.

Table 1.

Main structure parameters of the full-scale hybrid rocket motor.

As can be seen in Figure 1, La is the fore-section grain length, Lb shows the aft-section grain length, and Lm indicates the mid-chamber length. With the value of Lm, θ, La, and Lb changing, 49 simulation cases were set up and the details of the simulation cases are listed in Table 2. The “no-seg” means that the grain is not segmented, and it is set as the base case for comparison. For case “seg-1/2-10”, the “seg” indicates that the grain is segmented and the rotation angle of the two sections is 0°. The “1/2” shows that the segmented position of the fuel grain is 1/2, which is equal to La/(La+Lb). It is worth mentioning that the sum of La and Lb is 1000 mm for all cases in this article, which shows that the total burning surface area remains equal. Additionally, the “10” demonstrates that the mid-chamber length is 10 mm. For case “rot-1/2-10”, the “rot” means that the grain is segmented and the rotation angle of the aft-section grain is 22.5°, relative to the fore-section grain. The meaning of the “1/2” and “10” is the same as that described above.

Table 2.

The schemes of the simulation cases.

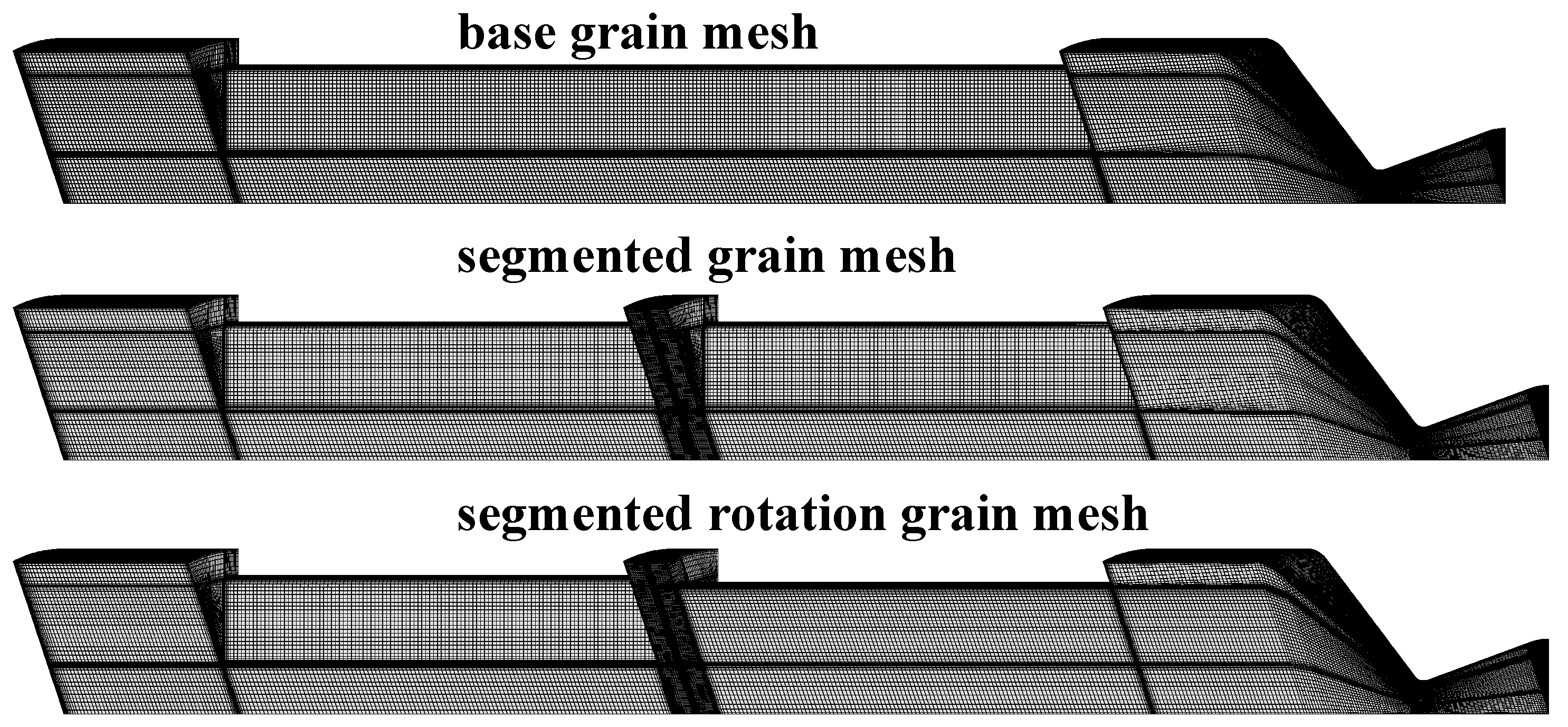

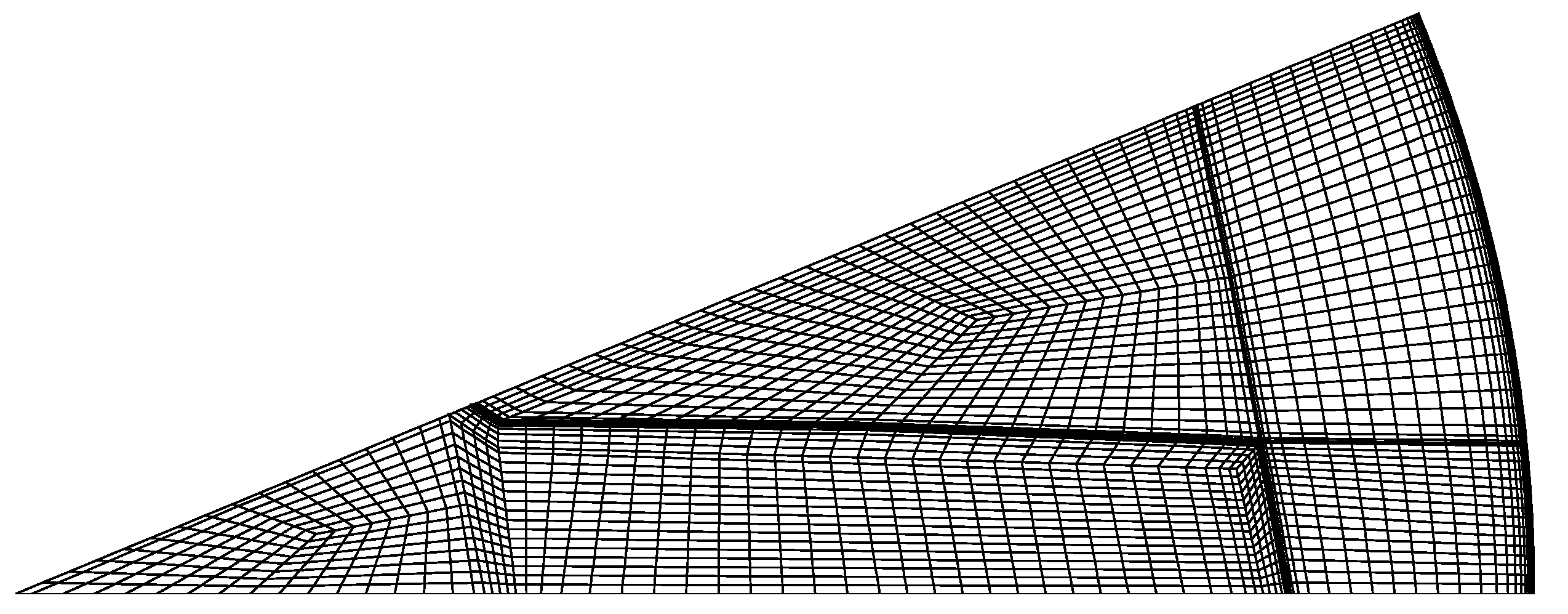

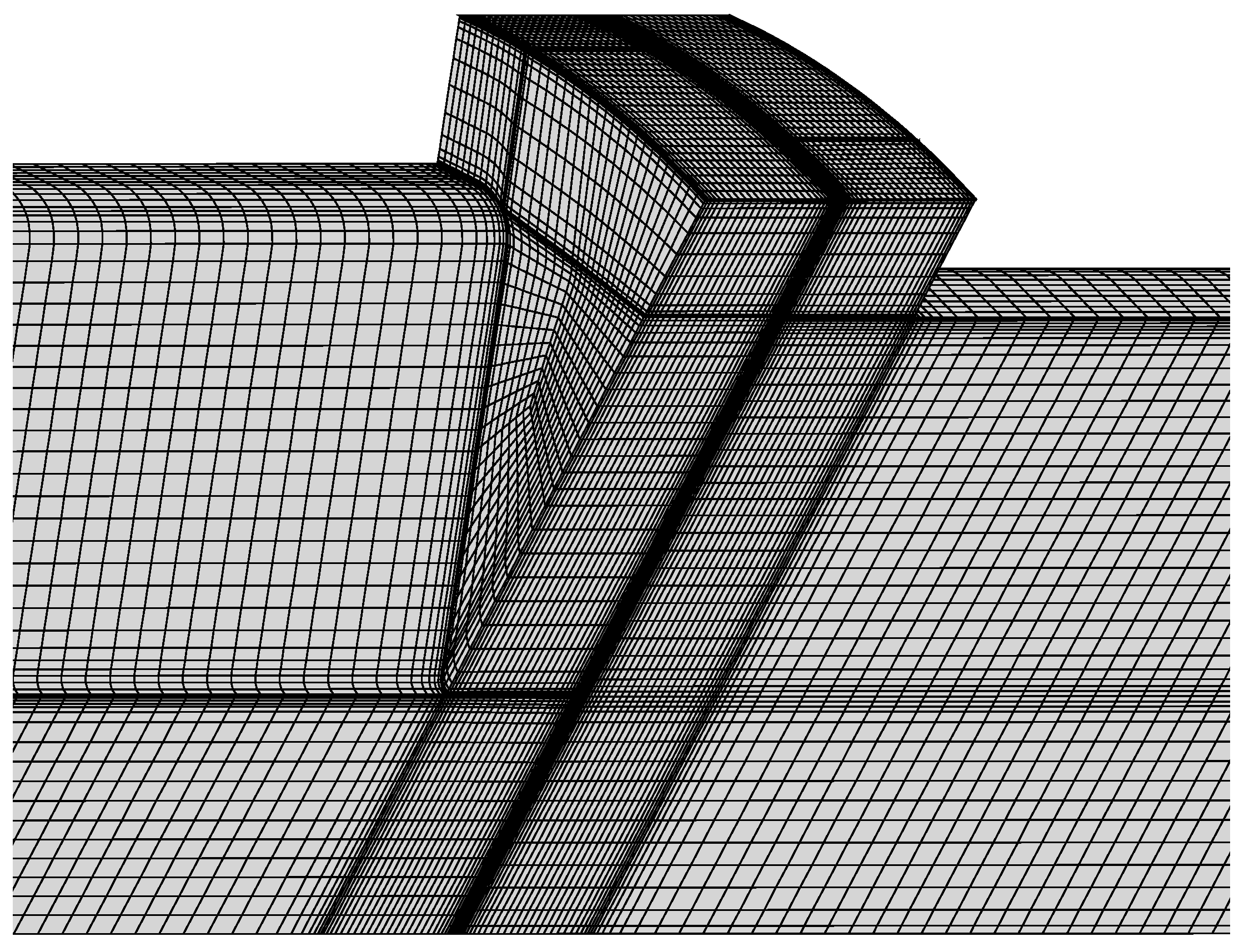

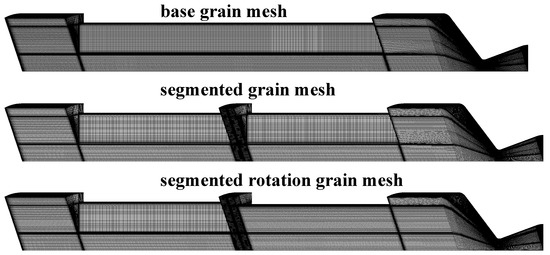

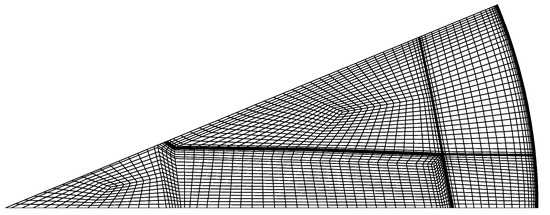

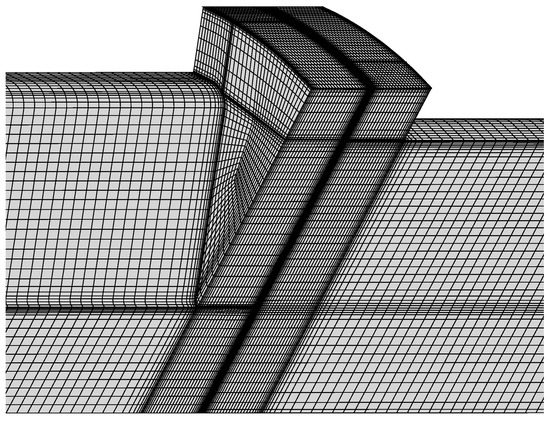

The geometry domain of the flow field of a hybrid rocket motor with star-segmented rotation grain is shown in Figure 4. Because the flow field possesses symmetry characteristics, a half of a star is chosen as the calculation domain in order to reduce the grid number. A structured mesh was applied as described by Li et al. [13]. Figure 5 shows the computational mesh of the base grain in case no-seg, segmented grain in case seg-1/2-50, and segmented rotation grain in case rot-1/2-50. For the purpose of meeting the requirement of the turbulence model, the meshes near the fuel surfaces and walls were refined. The thickness of the first layer grid near the fuel is 0.02 mm, which ensures that the dimensionless wall distance parameter y+ is approximately 1 [12]. The total number of computational meshes in Figure 5 are 624,463, 748,702, and 750,035, respectively. The meshes at the oxidizer inlet and mid-chamber are presented in Figure 6 and Figure 7, respectively.

Figure 4.

Domain of flow field of the motor with star-segmented rotation grain.

Figure 5.

Mesh of the calculation domain in different cases.

Figure 6.

Mesh at the oxidizer inlet.

Figure 7.

Mesh at the mid-chamber.

2.2. Numerical Models

The propellants utilized in this paper were 90% (mass fraction) H2O2 and HTPB. The combustion in hybrid rocket motors involves numerous physical changes and chemical reactions [20,21]. In order to reduce the difficulty of numerical simulations, the oxidizer atomization and vaporization process were neglected and only the gas phase was taken into account in the simulations. Additionally, the radiative heat flux was considered to be zero because there were no metal particles in the solid fuel grain. Because the fuel regression rate in hybrid rocket motors is quite low, the effect of the regression rate on the combustion flow field is negligible [22]. Thus, steady state numerical simulations can be performed. Three-dimensional numerical models were established with fluid dynamics, turbulence, gas phase reactions, and solid fuel pyrolysis. The main simulation process was carried out using ANSYS FLUENT solvers, while the fuel regression rate was calculated in user-defined functions (UDFs). The numerical model details are as follows.

2.2.1. Gas Governing Equations

The gas-phase governing equations consist of the coupled mass conservation equation, three-dimensional Navier–Stokes equations, energy conservation equation, and species transport equations.

2.2.2. Turbulence Model

The realizable turbulence model has been extensively applied in various flows, such as channel flows, boundary layer flows, and separated flows [23]. The realizable turbulence model is well suited to the numerical calculation of the vortex in the mid-chamber [18]. Therefore, the realizable turbulence model [23] was selected as the turbulence model in this paper. The transport equations for the turbulence kinetic energy and the dissipation rate can be expressed as:

where the constant parameters are , , , , , , and .

2.2.3. Chemical Reaction Model

The experimental results of Chiaverini et al. [24] demonstrate that the main pyrolysis product of HTPB is gaseous 1,3-butadiene (C4H6). A global two-step chemical reaction model was then chosen to describe the combustion of the gaseous propellants [25]. The first step indicates the oxidation of C4H6, while the second step means the oxidation of CO, which can be expressed as:

The combustion in a hybrid rocket motor with star-segmented rotation grain is controlled by diffusion, which means that the reaction time is much shorter than the mixing time of the propellants. Hence, the chemical kinetic rates can be ignored. In this paper, the eddy-dissipation model [26] was used to solve the chemical reaction rate, which exhibits superior performance for chemical reactions in which the mixing time determines the reaction rate. In the eddy-dissipation model, the generation rate of component due to the chemical reaction is calculated by:

2.2.4. Fluid–Solid Coupling and Fuel Regression Rate Model

The pyrolysis behavior of solid fuel grain in hybrid rocket motors follows the law of energy conservation and mass conservation. The law of energy conservation at the fuel grain surface is expressed by:

where indicates the convective and radiative heat flux that is transferred from the flame zone to the fuel grain inner surface, is the total enthalpy transmitted to the pyrolyzing surface that is caused by the regression of grain surface, is the heat loss resulted from the conduction into the solid fuel, and is the total enthalpy taken away from the pyrolyzing surface by the fuel pyrolysis products through bulk motion and diffusion.

Because the solid fuel grain adopted in this paper does not contain any metal components, the radiation heat transfer was omitted, that is . Then

where is the outward normal direction of the flow field at the fuel surface, and the orientation pointing out of the flow field is defined as the positive direction.

The can be described as:

With the radiative heat flux neglected, the temperature distribution inside the solid fuel can be calculated by:

The boundary conditions of Equation (7) are:

where represents the temperature at the grain inner surface, and is the reference temperature (298.16 K), which is the initial temperature (aka room temperature) of the fuel grain deep below the pyrolyzing surface. Thus, can be expressed as:

is regarded as the total enthalpy of the HTPB at the temperature and it can be represented as:

It is assumed that the diffusion velocity can be ignored compared to the bulk velocity. is considered to be the total enthalpy of C4H6, which can be calculated as:

Substituting Equations (5) and (8)–(10) into Equation (4), the energy conservation at the fuel grain surface can be written as:

which can be simplified as:

The law of mass conservation requires that

The fuel regression rate of hybrid rocket motor was mostly determined by the temperature at the solid grain inner surface. According to the work of Cohen et al. [27], the fuel regression rate can be described as:

where A expresses the pre-exponential factor and E represents the activation energy. Following the experimental investigations in [24], the pyrolysis performances of HTPB are listed in Table 3.

Table 3.

Pyrolysis performance of HTPB.

With Equations (12) and (14) combined, both the inner surface temperature of fuel grain and the fuel regression rate can be calculated by the UDFs in the form of boundary conditions. After the calculation of , the corresponding source terms of mass, momentum, energy, and species can be obtained and added into the meshes near the grain inner surface in the process of simulation iteration.

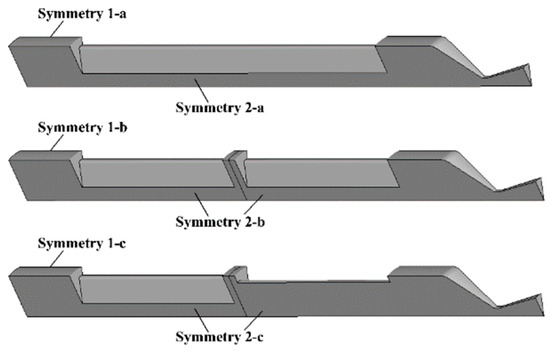

2.2.5. Boundary Conditions

The boundary conditions in the numerical simulations were mainly composed of oxidizer inlet, solid fuel wall, other walls, symmetry plane, and nozzle outlet. The oxidizer inlet was set as a mass flow rate inlet, and the total oxidizer mass flow rate of the hybrid rocket motor was 2.0 kg/s. Due to the symmetry characteristic, only 1/16 of the flow field was selected as the computational domain. It was assumed that the 90% H2O2 is completely decomposed before being injected into the pre-combustion chamber. Thus, the oxidizer inlet was considered to be a mixture that contains 57.65% water vapor and 42.35% gaseous oxygen at a temperature of 1024 K [28]. The initial pressure at the oxidizer inlet was set as 1.4 MPa, according to the predicted value of combustion chamber pressure. At the fuel grain surface, the fuel regression rate and fuel wall temperature were solved by fluid–solid coupling and fuel regression rate model during the iterations. Other solid walls were set as no-slip and adiabatic wall boundaries. At the symmetry planes, which are shown in Figure 8, the normal gradients and normal velocity component of flow variables were zero [29]. The nozzle outlet was set as the pressure outlet.

Figure 8.

Schematic of symmetry planes in the computation domain.

2.3. Model Validation

2.3.1. Grid Independence Verification

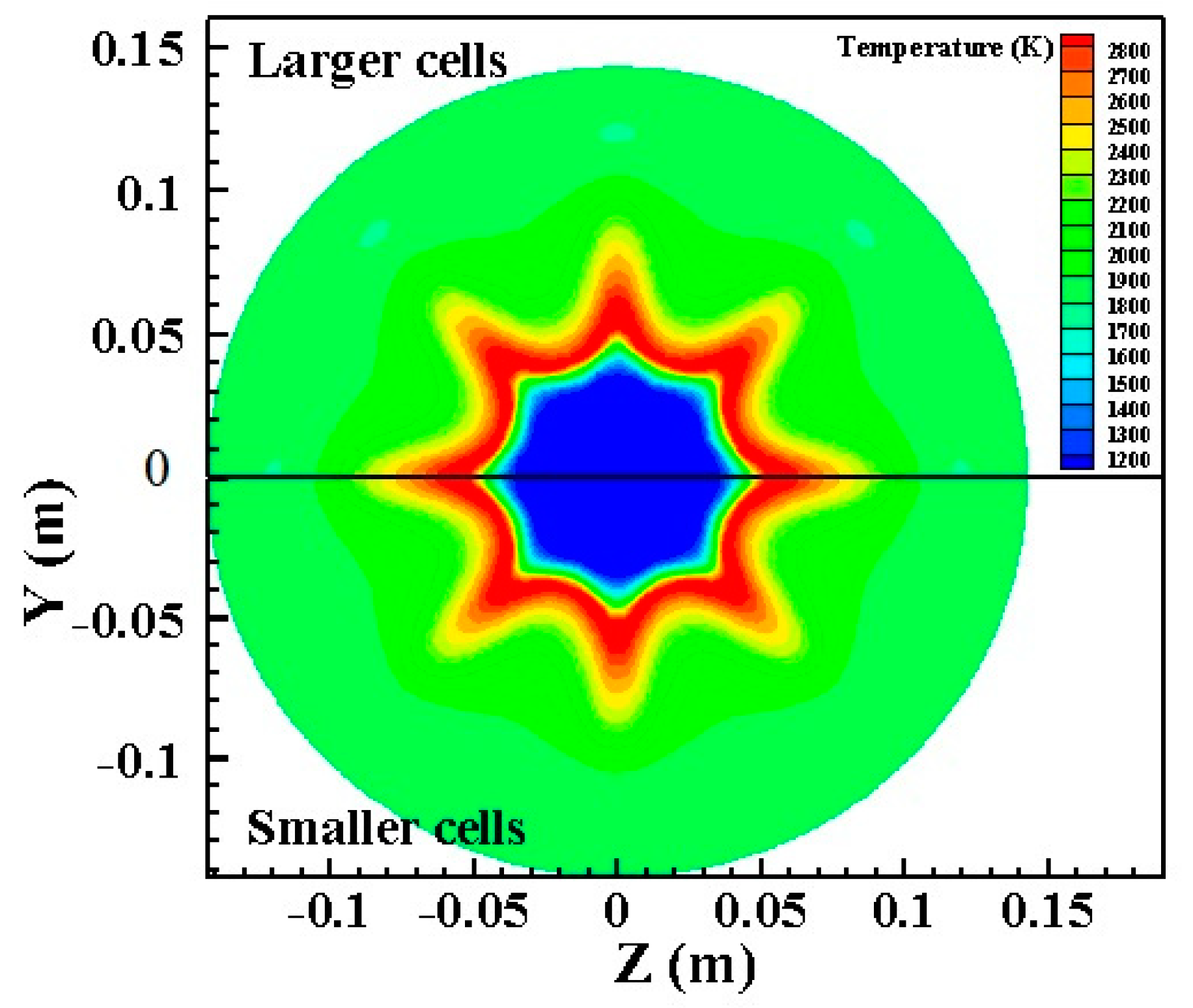

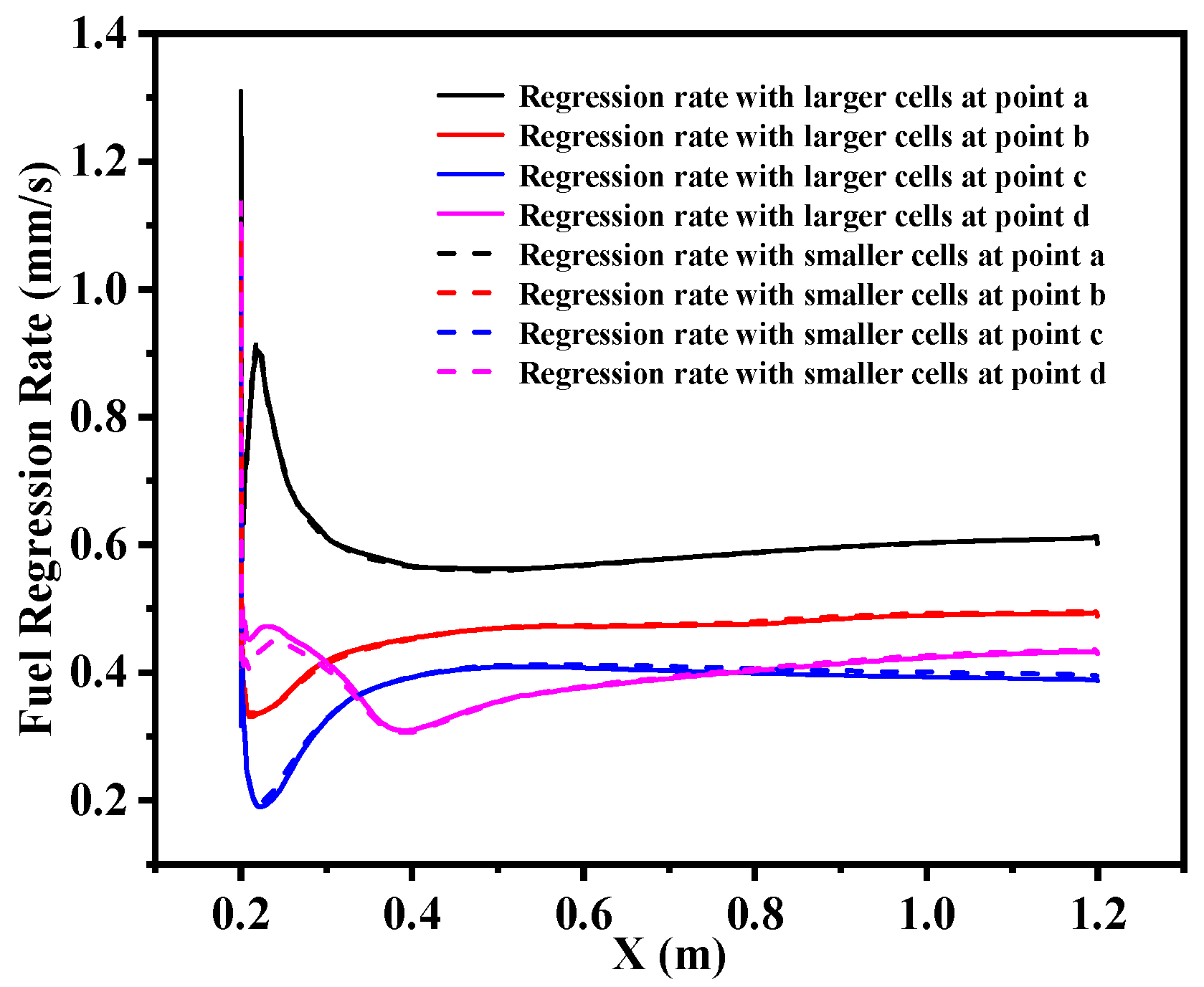

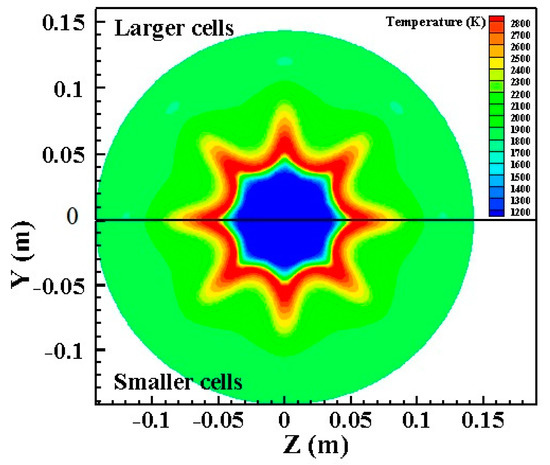

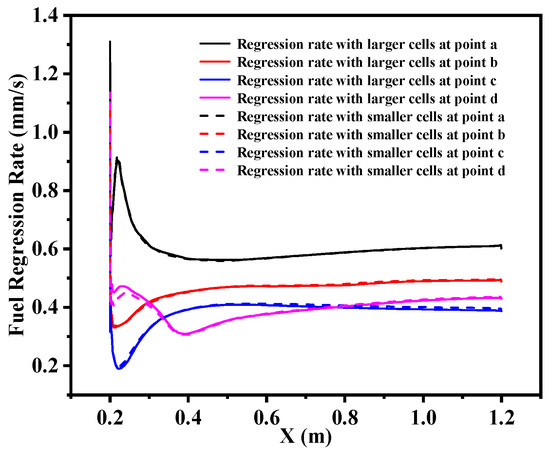

The simulation case was solved through two kinds of meshes to verify the grid independency in the numerical simulations. Figure 5 presents the standard mesh in case no-seg and the total cell number was 624463. Much smaller cells were adopted in the comparison mesh in case no-seg, in which the total cell number was 1,186,230. The comparison is shown in Figure 9 and Figure 10. As can be seen from Figure 9 and Figure 10, the simulated temperature distributions and axial distribution of fuel regression rates are nearly identical with both meshes. Thus, it can be concluded that the influence of grid size applied here on the simulation results can be neglected.

Figure 9.

Temperature distribution with different meshes at the nozzle entrance.

Figure 10.

Fuel regression rate distributions with two kinds of CFD meshes.

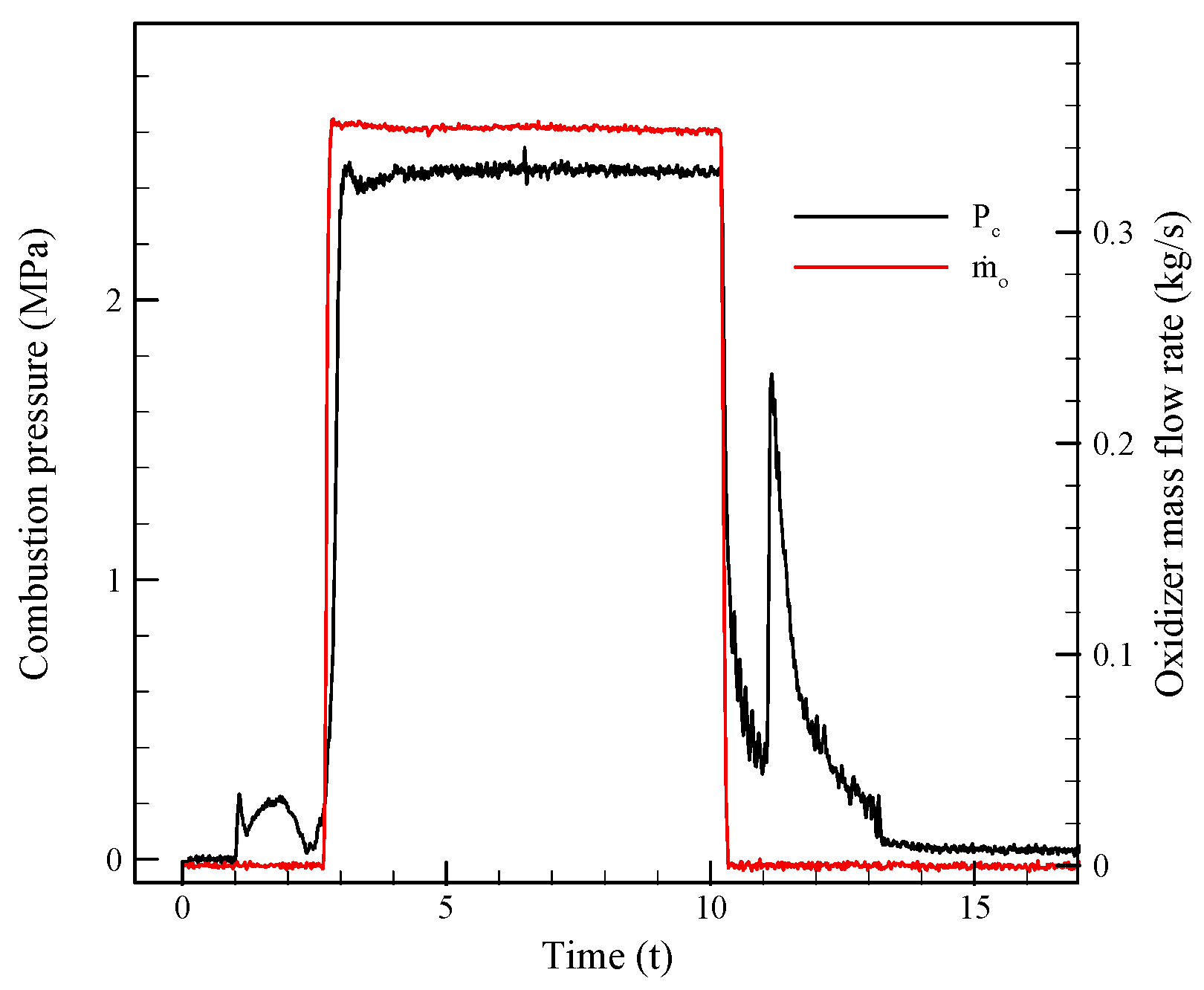

2.3.2. Numerical Model Verification

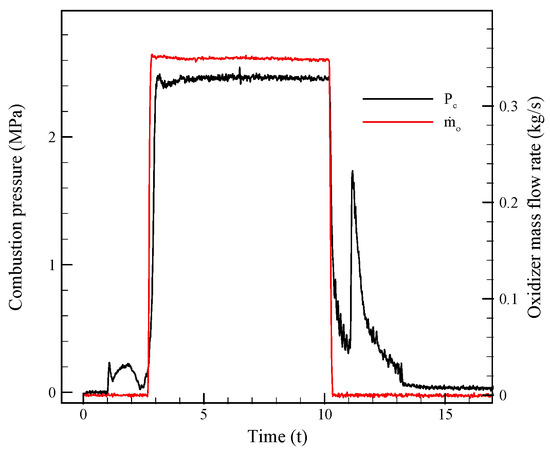

In order to verify the accuracy of the numerical model established in this paper, a ground firing experimental test of a hybrid rocket motor with tube grain was conducted. The motor utilized 90% H2O2 and HTPB propellant combination. The fuel grain length was 500 mm, the fuel grain port diameter was 50 mm, the nozzle throat diameter was 18 mm, and the nozzle expansion area ratio was 3. The experimental curves obtained using this lab-scale motor are shown in Figure 11. The burn time of the motor was approximately 7.3 s. A steady state numerical simulation of the motor that adopted the same propellant combination and structure as that used in the lab-scale firing test was performed. The differences between the simulation results and test data are illustrated in Table 4. The comparison shows that the simulation results are in good agreement with the test results. The main parameters differ by no more than 4.5%. Therefore, it is reasonable to investigate the combustion characteristics of hybrid rocket motors using the numerical model established in this paper. In addition, the accuracy of the simulation model adopted in this paper was successfully verified through the comparison of the simulated regression rates and experimental regression rates conducted by Cai et al. [30].

Figure 11.

Experimental curves of the ground firing test.

Table 4.

Comparison between simulation results and test data.

3. Results and Discussion

The simulation cases shown in Table 2 were calculated in this paper. For the convenience of comparison and analysis, case no-seg, case seg-1/2-40, and case rot-1/2-40 were taken as the representative of the simulation cases. The effects of the rotation, mid-chamber length, and segmented position on the combustion flow field characteristics, the fuel regression rate, and the combustion efficiency are discussed in this section.

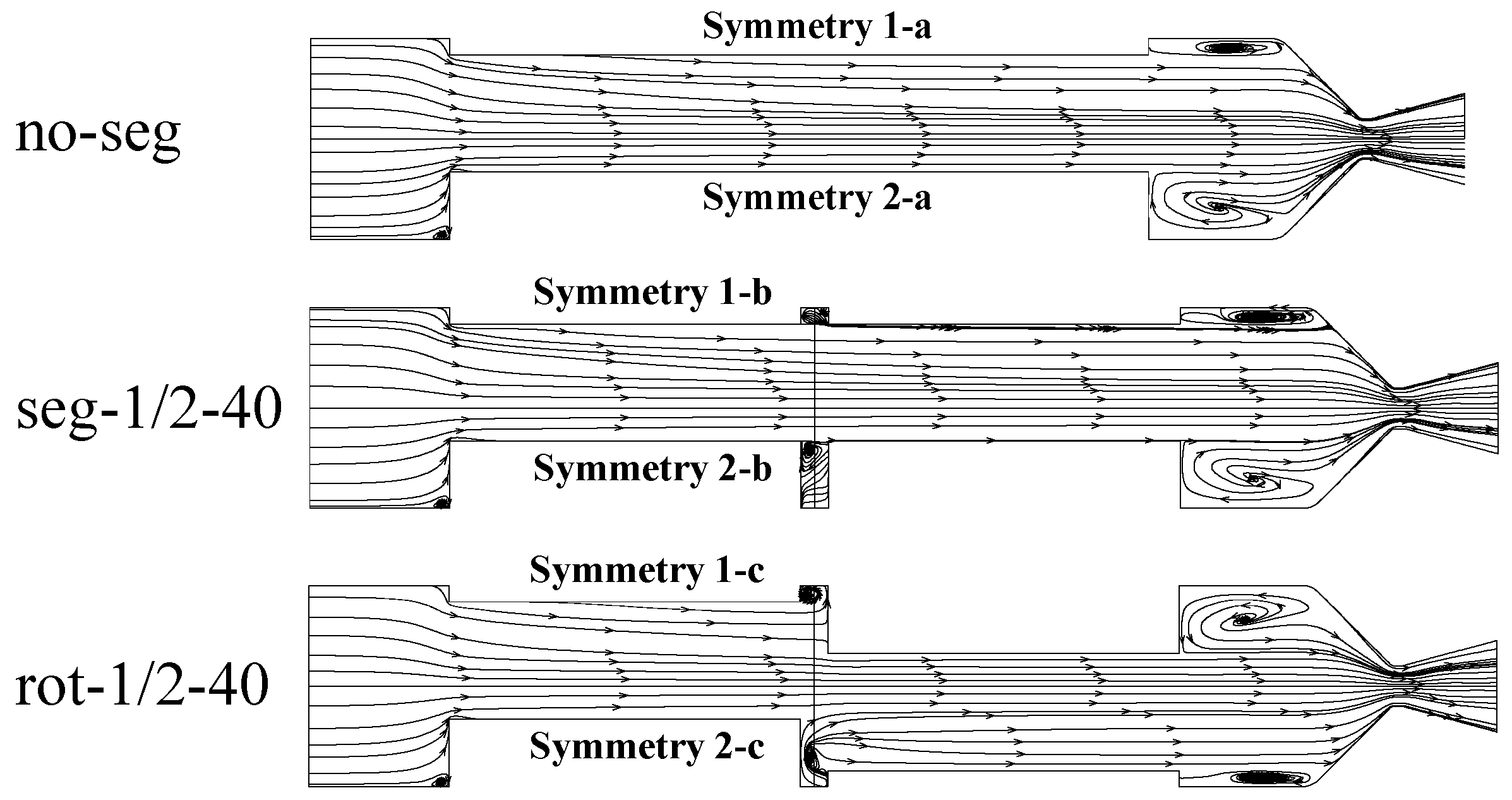

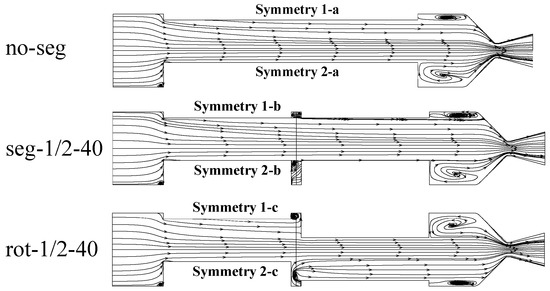

3.1. Combustion Flow Field Characteristics

Streamlines of case no-seg, case seg-1/2-40, and case rot-1/2-40 are illustrated in Figure 12. It is evident that vortices exist in the post-combustion chamber in all three cases. In case no-seg, the streamlines in the combustion chamber are relatively straight and no vortex is found in the fuel grain port. In case seg-1/2-40, there are vortex zones in the mid-chamber due to the sudden expansion caused by the mid-chamber. These vortex zones can promote the mixing of the propellants and increase the combustion efficiency. However, the vortex zones in case seg-1/2-40 are limited within the mid-chamber, which have little influence on the inner flow field of the aft-section grain. In case rot-1/2-40, owing to the sudden expansion produced by the mid-chamber and the obstacle caused by the front-end face of the aft-section grain, the vortexes are captured in the mid-chamber. In addition, these vortices affect the flow in the aft-section grain port and therefore further promote the mixing of the combustion gas, which makes the combustion process more complete.

Figure 12.

Streamlines of symmetry planes in different cases.

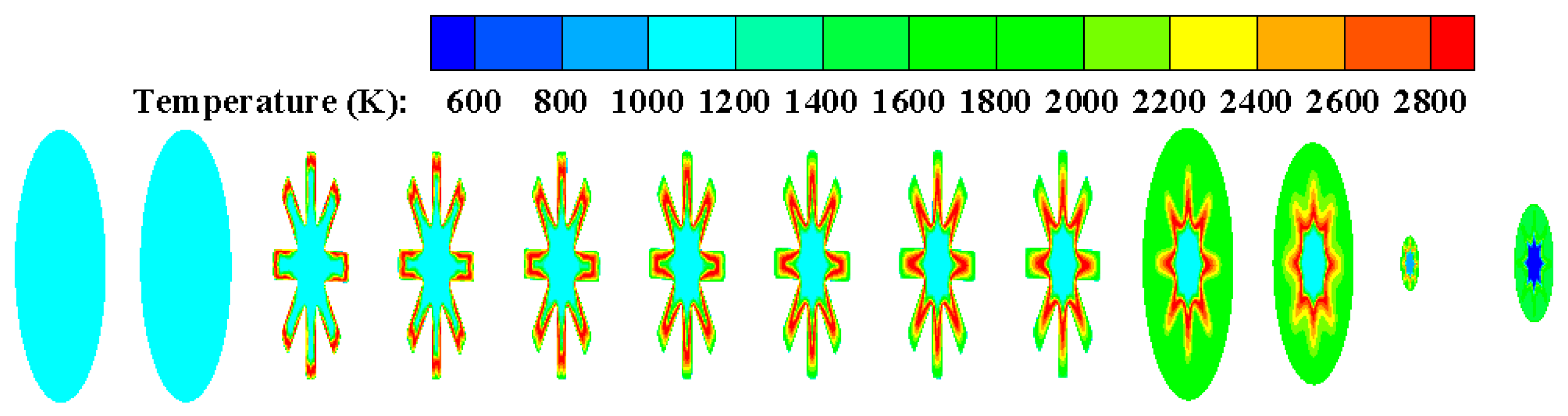

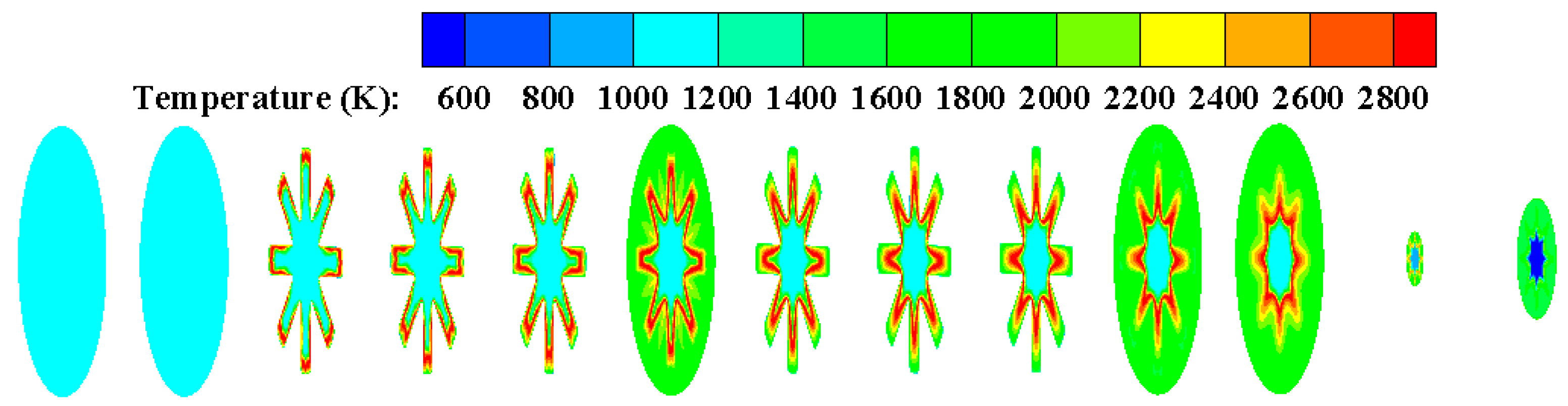

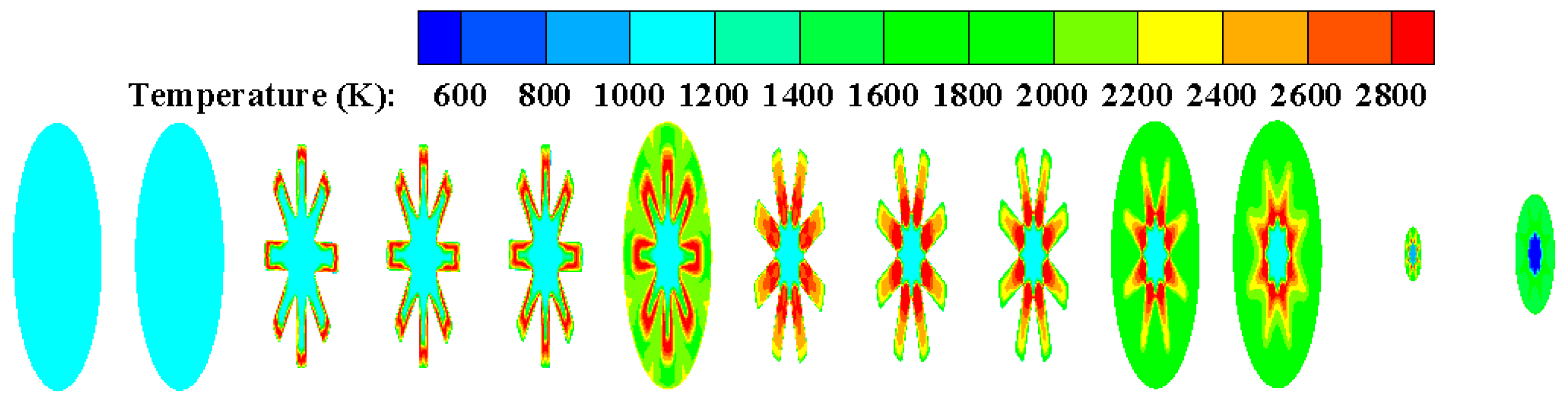

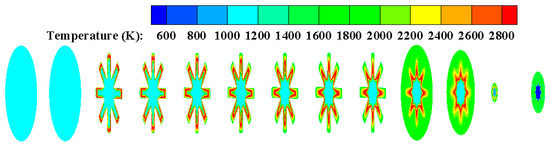

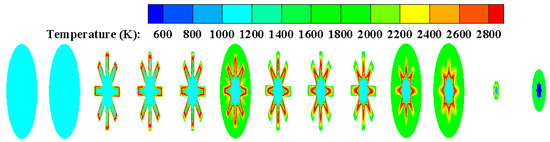

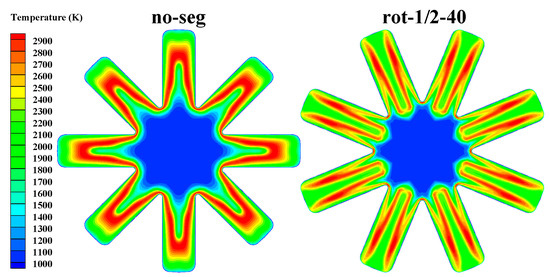

Figure 13, Figure 14 and Figure 15 show the cross-sectional temperature distributions in the hybrid rocket motor in case no-seg, case seg-1/2-40, and case rot-1/2-40, respectively. As can be seen in Figure 13, the flame zone profile is close to the grain port profile, and the distance between the flame and the fuel inner surface increases with the increase in the axial distance due to the depletion of the oxidizer. In addition, the flame is near the fuel wall at the star root (point a in Figure 2), and the thickness is the smallest. Both the distance to the fuel grain inner surface and the thickness of the flame layer increase in the slot of the star (points c and d in Figure 2) by looking ahead to Figure 18. The temperature distribution in Figure 13 is quite similar to the temperature distributions of hybrid rocket motors with star grain in references [11,12,31]. The temperature peak point is approximately 3030 K in case no-seg. In Figure 14 and Figure 15, it is obvious that the temperature distributions in both the pre-combustion chamber and fore-section are almost identical to those in case no-seg, which indicates that the segmented rotation grain configuration has little influence on the combustion flow field in the fore-section. The temperature distribution in aft-section in case seg-1/2-40 is not significantly changed when the mid-chamber is set up in the hybrid rocket motor. The highest temperature in case seg-1/2-40 reaches about 3030 K. However, when the two sections of grains are offset with a rotation angle of 22.5° in case rot-1/2-40, the flow field in aft-section is disturbed by the front-end face of the aft-section grain. The flame shifts towards the central core flow, which suggests that more oxidizer participates in the chemical reaction. In addition, the highest temperature in case rot-1/2-40 is about 3113 K, demonstrating the positive effect of the segmented rotation grain configuration on combustion completeness. Therefore, the combustion efficiency can be improved due to segmented rotation grains.

Figure 13.

Temperature distribution in the motor for case no-seg.

Figure 14.

Temperature distribution in the motor for case seg-1/2-40.

Figure 15.

Temperature distribution in the motor for case rot-1/2-40.

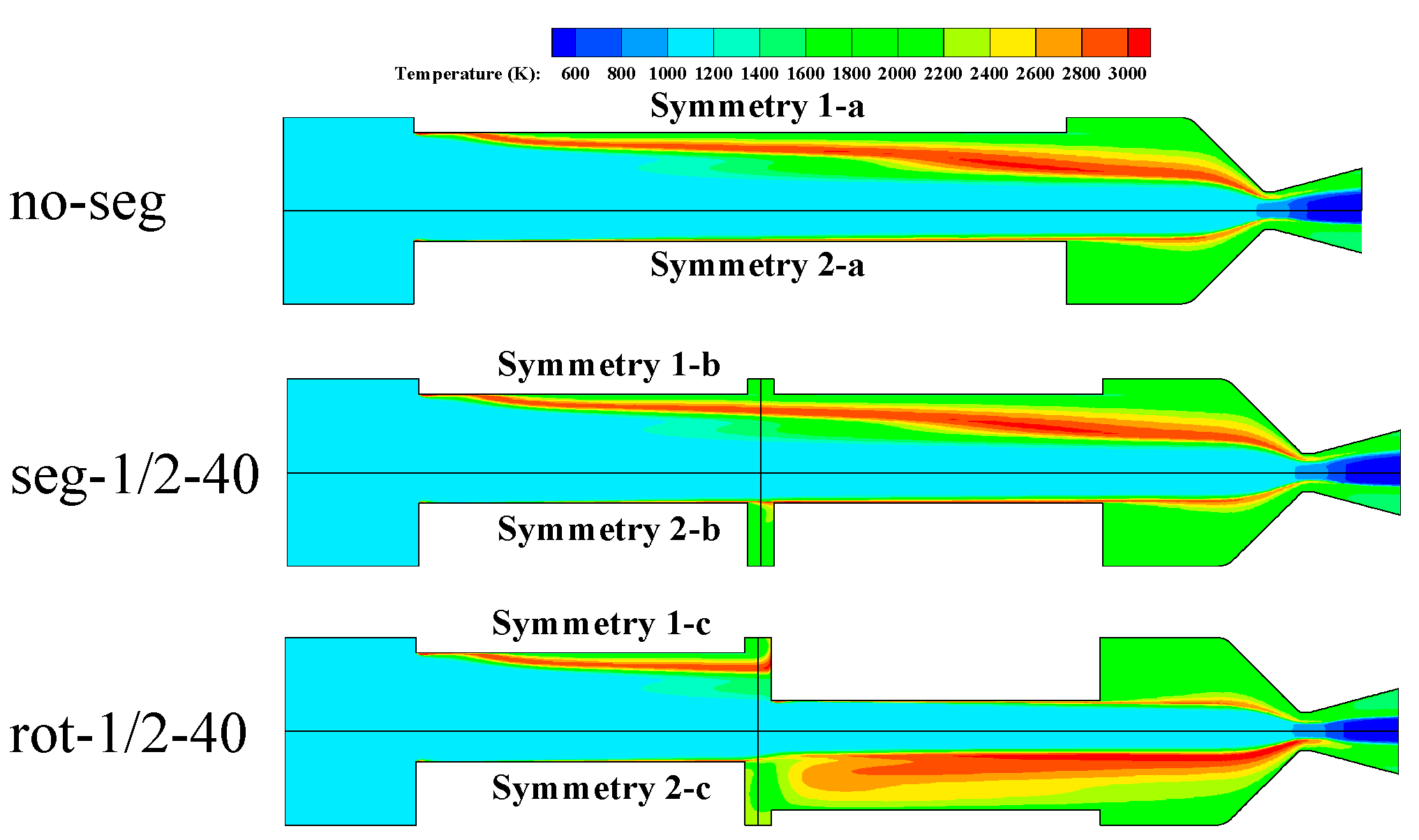

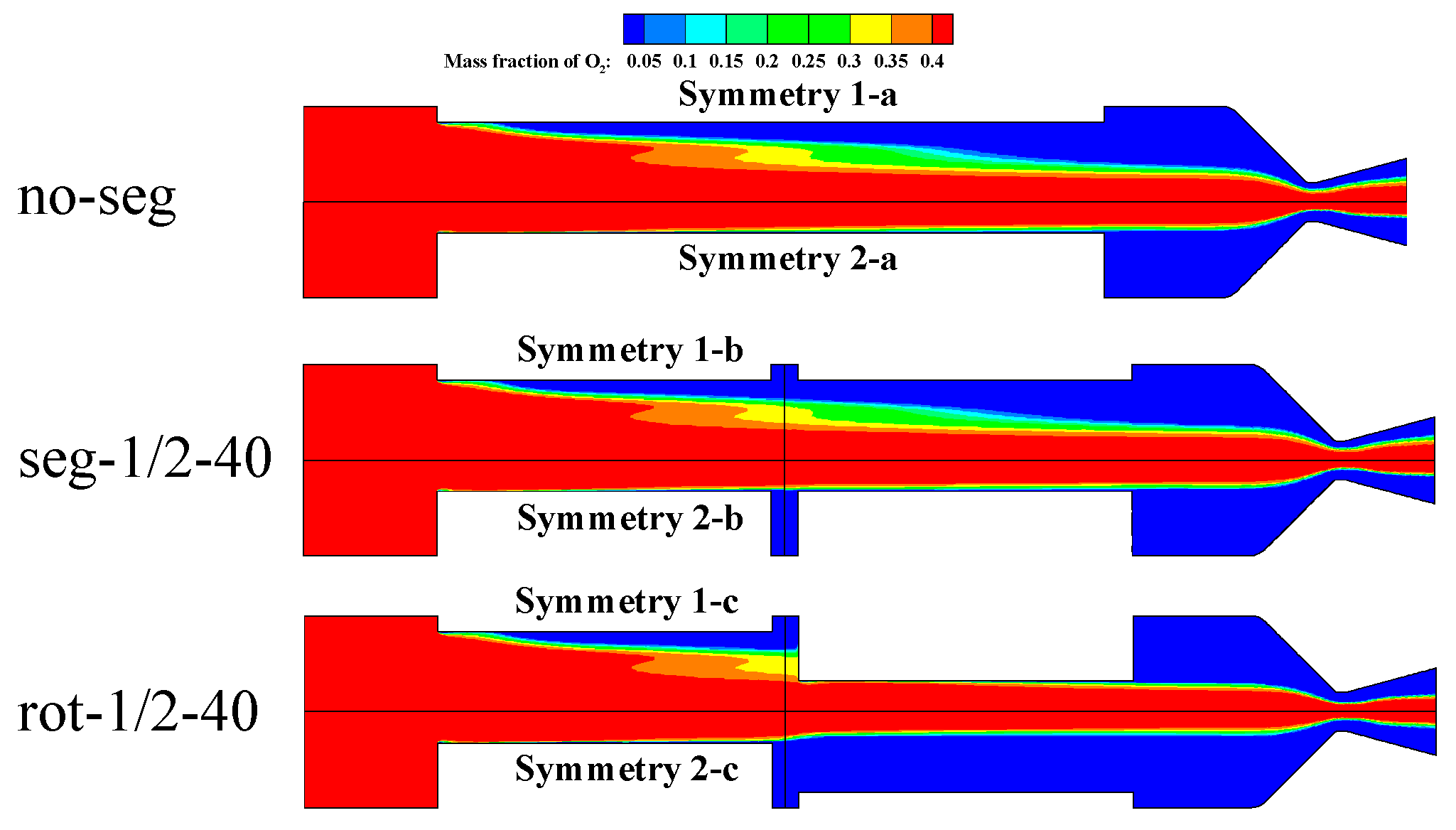

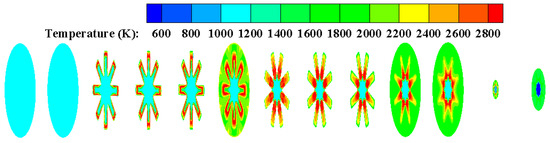

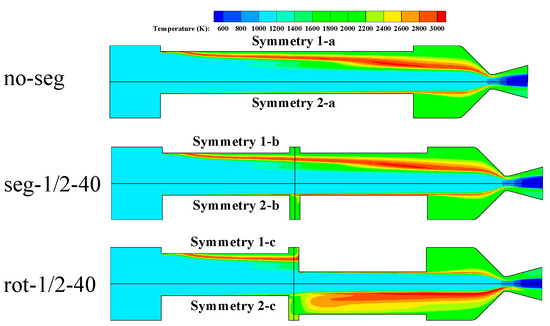

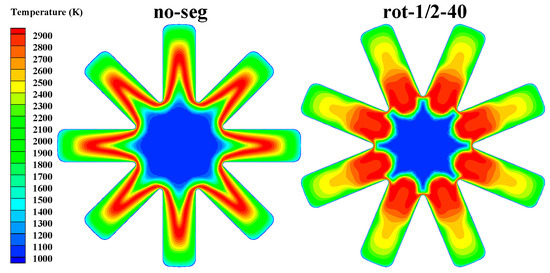

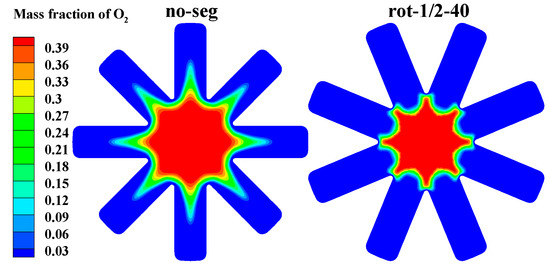

The temperature distributions of symmetry planes (shown in Figure 8) in case no-seg, case seg-1/2-40, and case rot-1/2-40 are shown in Figure 16. There is a diffusion flame zone close to the grain inner surface in case no-seg and it extends to the centerline of the fuel grain port. In case seg-1/2-40, the temperature contour of the motor with segmented grain is close to that in case no-seg. However, under the influence of the segmented rotation grain configuration, the combustion gas is barricaded by the front-end face of the aft-section grain and the resident time of the combustion gas in the combustion chamber is extended. In addition, the flame layer is closer to the motor axis line, which is consistent with Figure 15. These are beneficial for the combustion efficiency in the hybrid rocket motor. Figure 17 presents the mass fraction of O2 distributions of symmetry planes in several cases. In contrast with case no-seg and case seg-1/2-40, more oxidizer in the central core region in case rot-1/2-40 is consumed, which indicates that the utilization of the oxidizer increases.

Figure 16.

Temperature distributions in symmetry planes for different cases.

Figure 17.

Mass fraction of O2 distributions in symmetry planes for different cases.

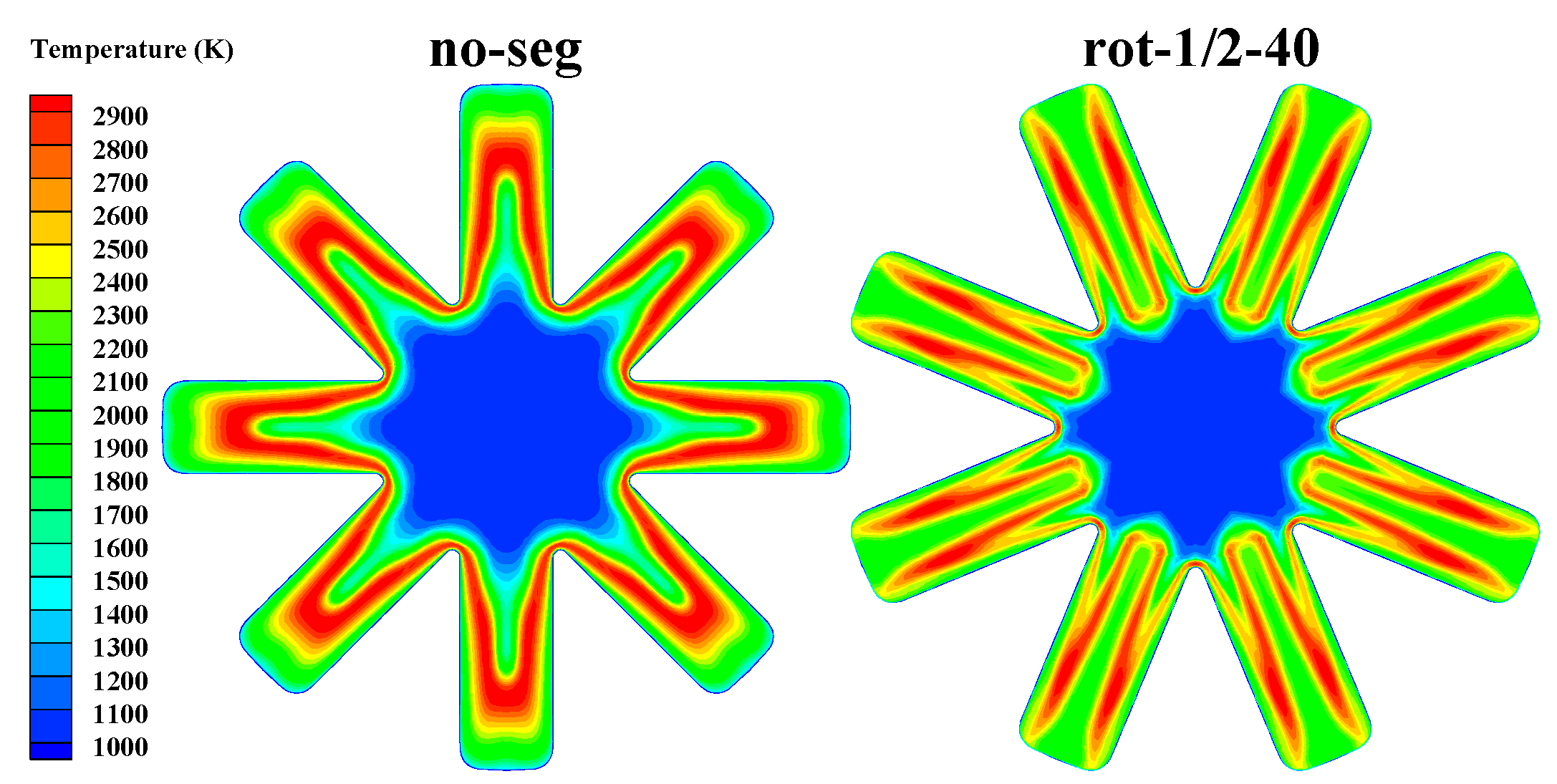

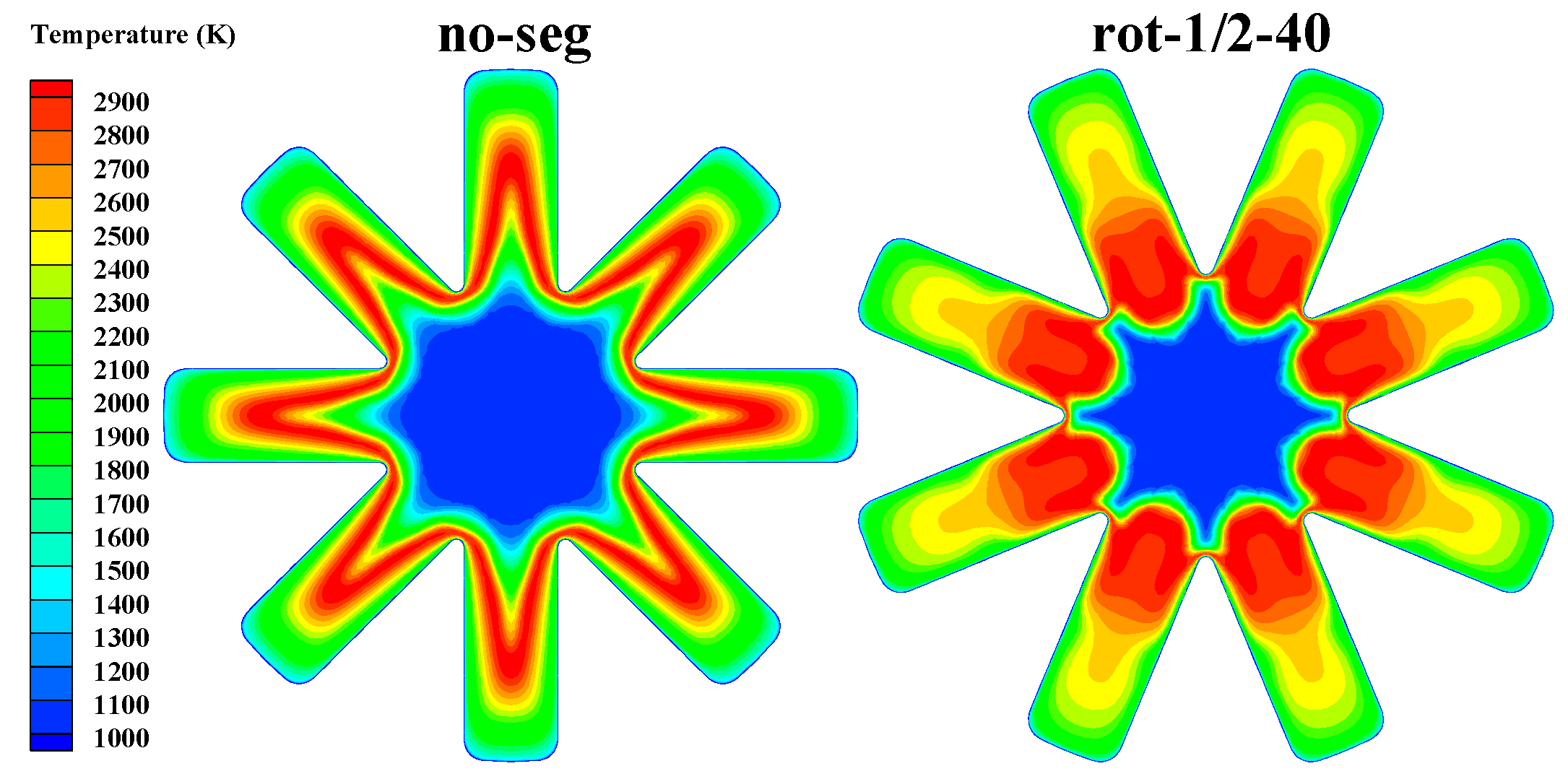

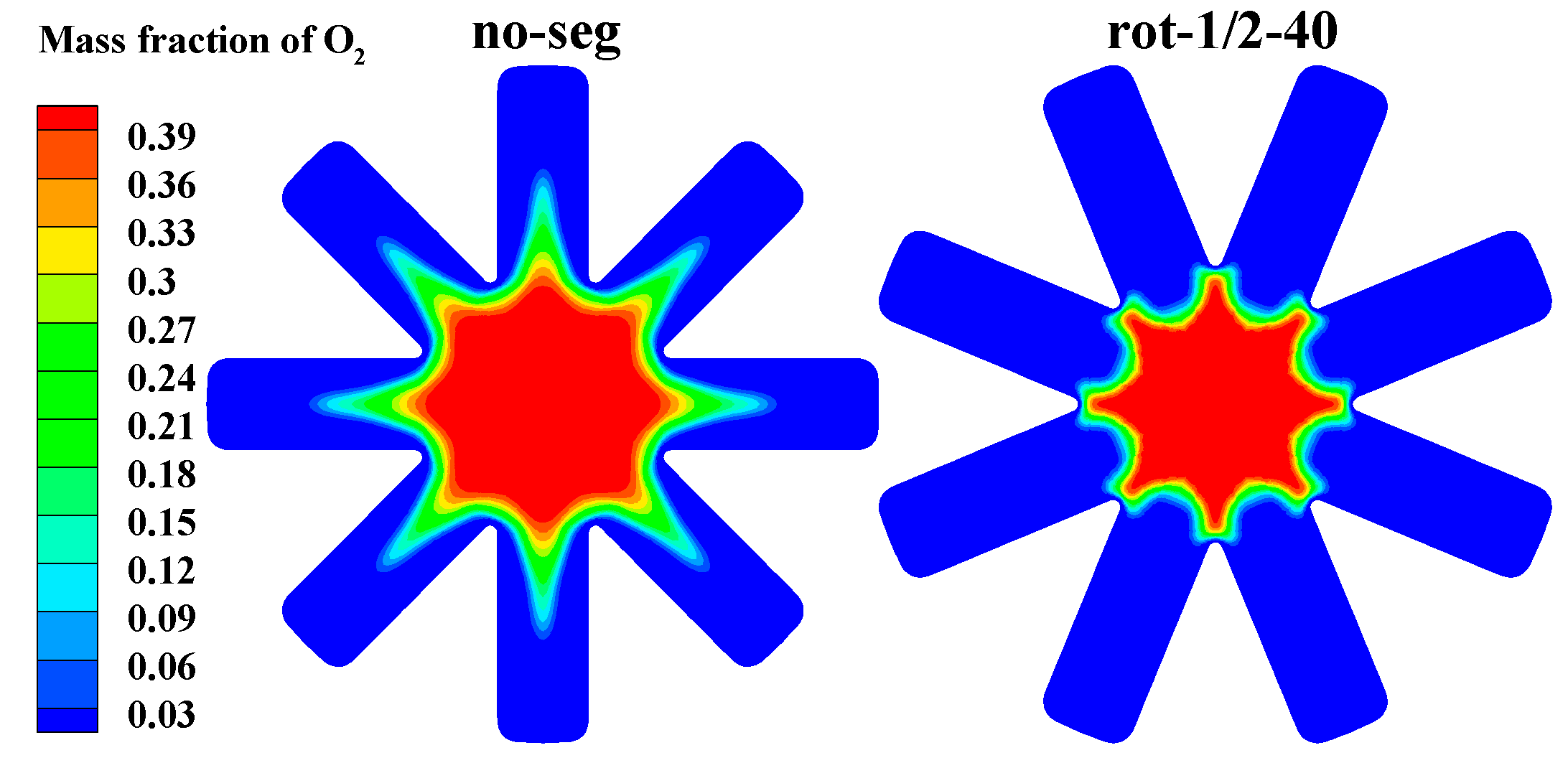

The temperature contours in cross sections at the front end of aft-section grain port are illustrated in Figure 18. It is worth noting that there is only a single fuel grain in case no-seg and therefore the cross section shown in Figure 18 is taken at the same axial position as that in case rot-1/2-40. In case no-seg, the flame in the same slot of the star is separated into two sections by the front-end face of the aft-section grain. Then, the two parts of flame enter two adjacent slots of the star, respectively, and they distribute along the sides of the star slots, which is evident in case rot-1/2-40 in Figure 18. As the combustion gas moves downstream, the temperature distribution of central cross section of the aft-section grain port is formed, which is shown in case rot-1/2-40 in Figure 19. It can be seen that the flame is closer to the fuel wall at the star root (point a in Figure 2), and it is thinner in case rot-1/2-40 compared to that in case no-seg. In contrast with point b in case no-seg, point b in case rot-1/2-40 in Figure 19 is farther from the flame layer. In addition, the temperature of flow field near point c and point d in case rot-1/2-40 is higher than that in the same position in case no-seg. As is clearly illustrated in Figure 20, the O2 in the slot of the star in case rot-1/2-40 is greatly depleted and this agrees with Figure 17.

Figure 18.

Temperature comparison of the cross sections at the front end of aft-section grain port.

Figure 19.

Temperature comparison of the central cross sections of aft-section grain port.

Figure 20.

Mass fraction of O2 comparison of the central cross sections of aft-section grain port.

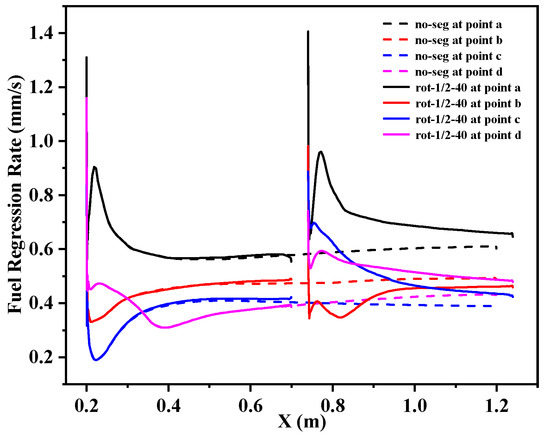

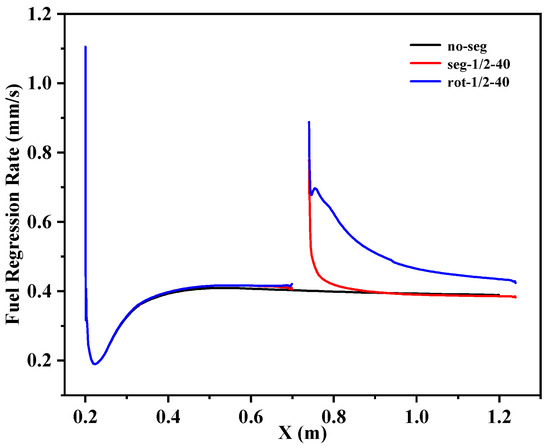

3.2. Regression Rates

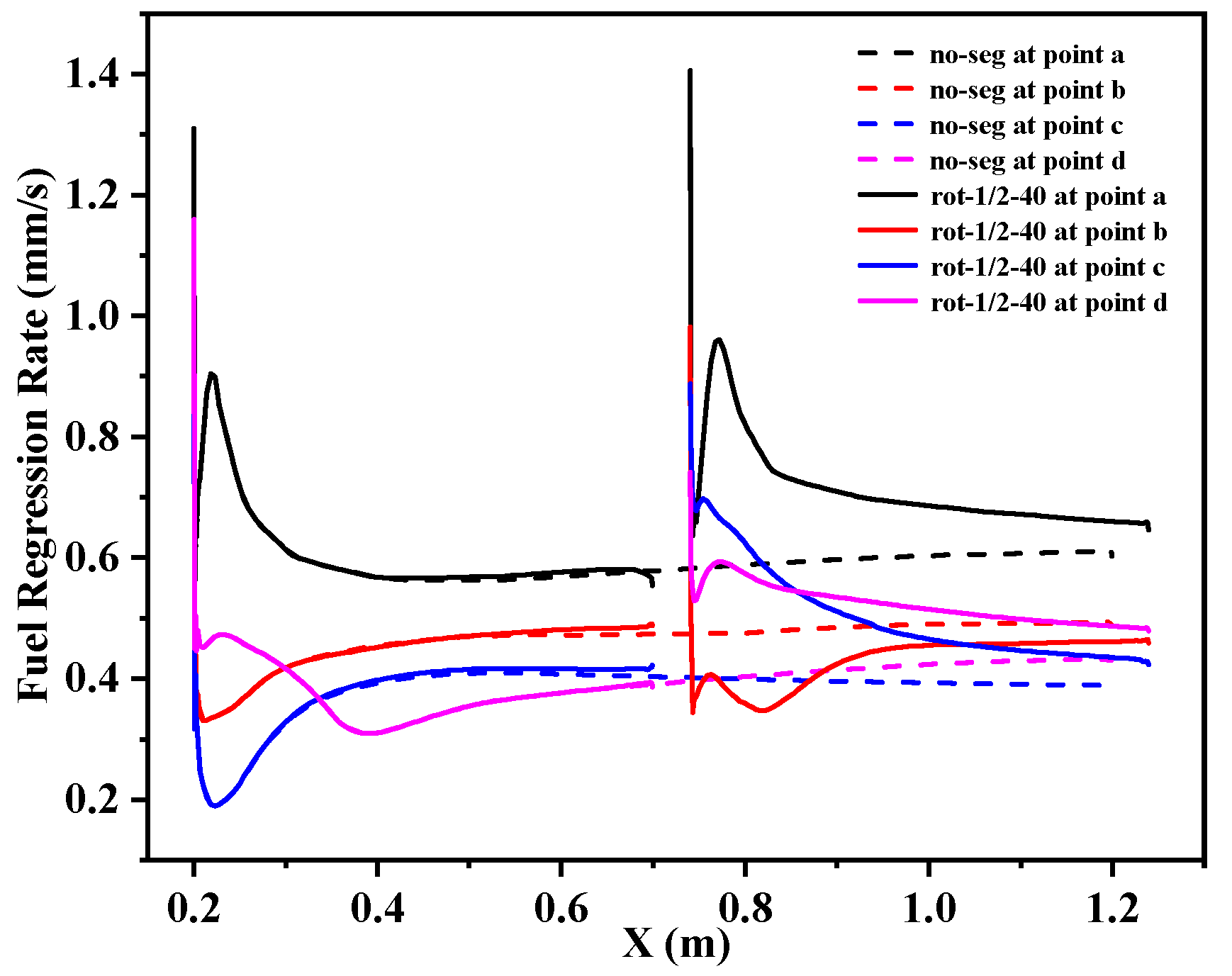

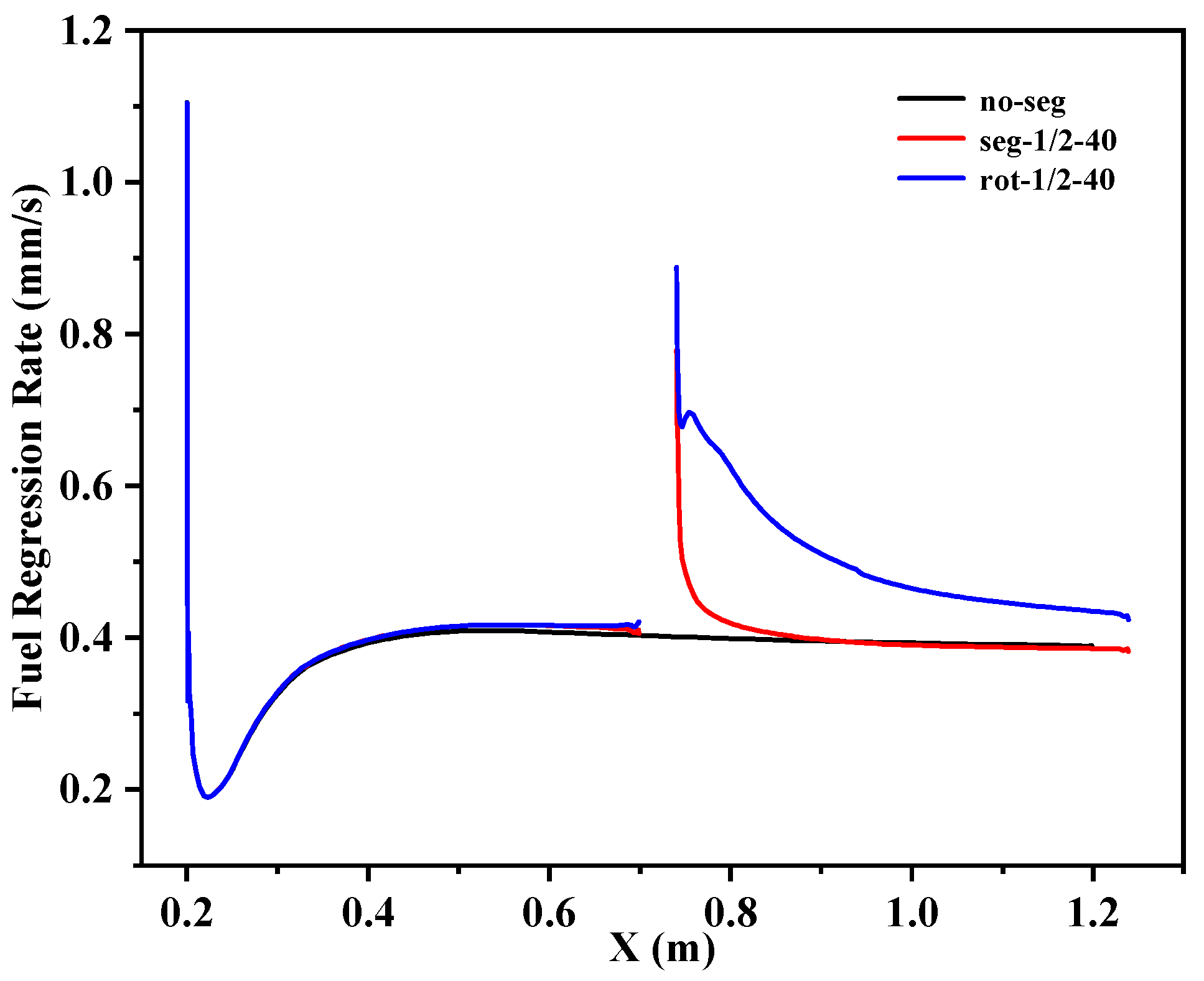

The fuel regression rate is an important parameter that plays a considerable part in the internal ballistic performance and the design of hybrid rocket motors. Therefore, the fuel regression rate distribution characteristics should be analyzed. Figure 21 shows the fuel regression rates at various characteristic points along the motor axis in case no-seg and case rot-1/2-40. It can be clearly seen that the regression rate distributions in fore-section grain in case rot-1/2-40 are almost identical to those in case no-seg. This indicates that the segmented rotation grain configuration has very little effect on the regression rates in fore-section grain, which can be explained by the temperature distributions in Figure 13, Figure 15 and Figure 16. As mentioned in Section 3.1, the temperature distributions in fore-section grain in case no-seg and case rot-1/2-40 are almost the same, and thus the temperature gradient and heat flux to the fuel wall are quite similar. This contributes to the similar fuel regression rates, while the fuel regression rate distributions in the aft-section grain in case rot-1/2-40 are different from that in case no-seg, this can be analyzed according to Figure 19. At point a, the fuel regression rate in case rot-1/2-40 is higher than that in case no-seg. This is because the flame layer is closer to the grain surface and the temperature gradient is higher in case rot-1/2-40, which leads to a larger heat flux to the fuel wall, and the regression rate is enhanced. From the curves in Figure 21, it is apparent that the fuel regression rates of point c and point d in case rot-1/2-40 are also greater than those at the same characteristic points in case no-seg. The reason is that the temperature gradients at point c and point d in case rot-1/2-40 in Figure 19 are higher than those at the same points in case no-seg. Due to the longer distance between the flame layer and the grain inner surface at point b, the fuel regression rate in case rot-1/2-40 is lower than that at point b in case no-seg. It can be seen from Figure 22 that both the segmented grain configuration (case seg-1/2-40) and the segmented rotation grain configuration (case rot-1/2-40) can improve the regression rates in the aft-section grain. Furthermore, the rotation configuration improves the aft-section grain regression rate significantly.

Figure 21.

Regression rates at various positions along the motor axis.

Figure 22.

Fuel regression rates of point c (defined in Figure 2) along the motor axis in various cases.

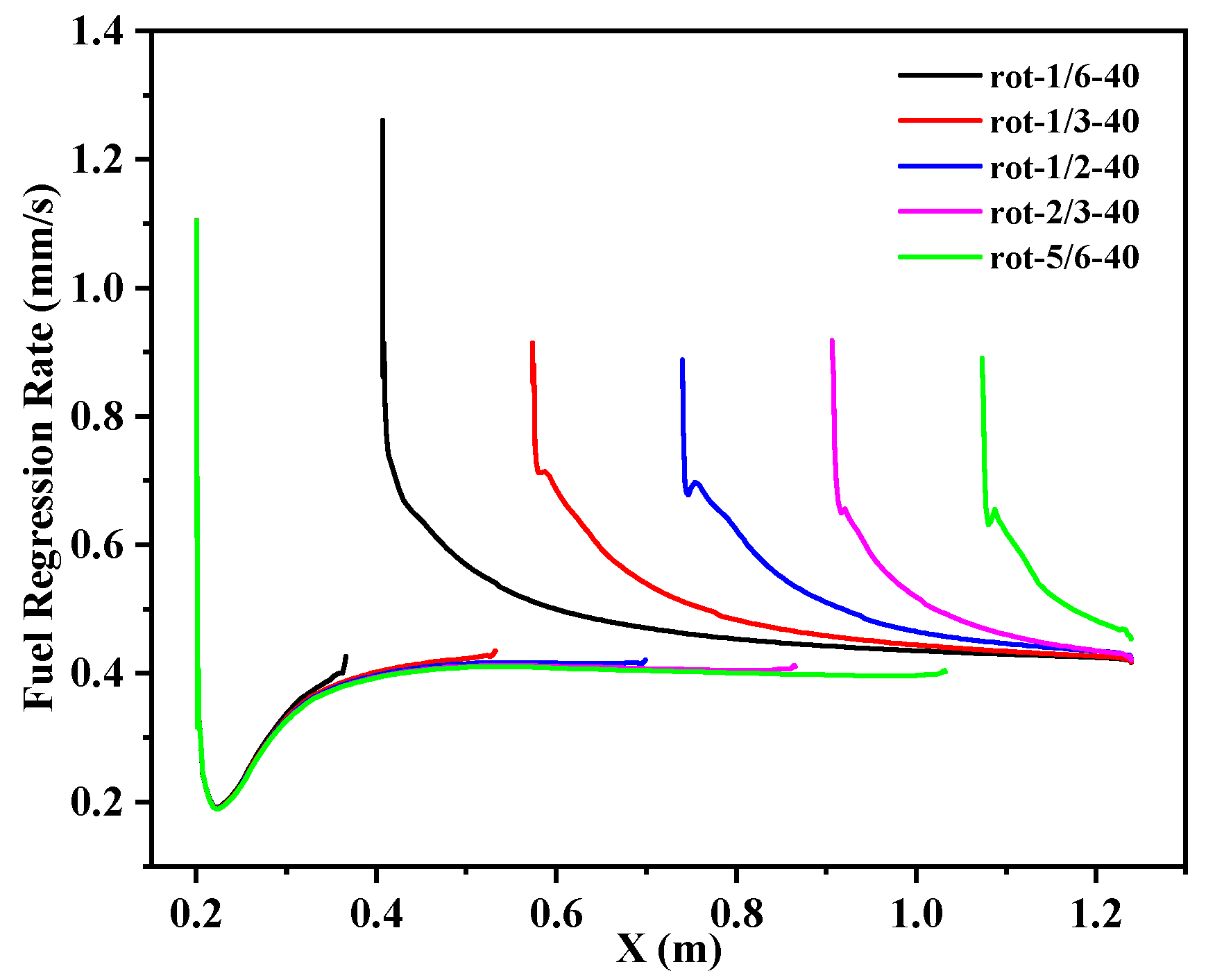

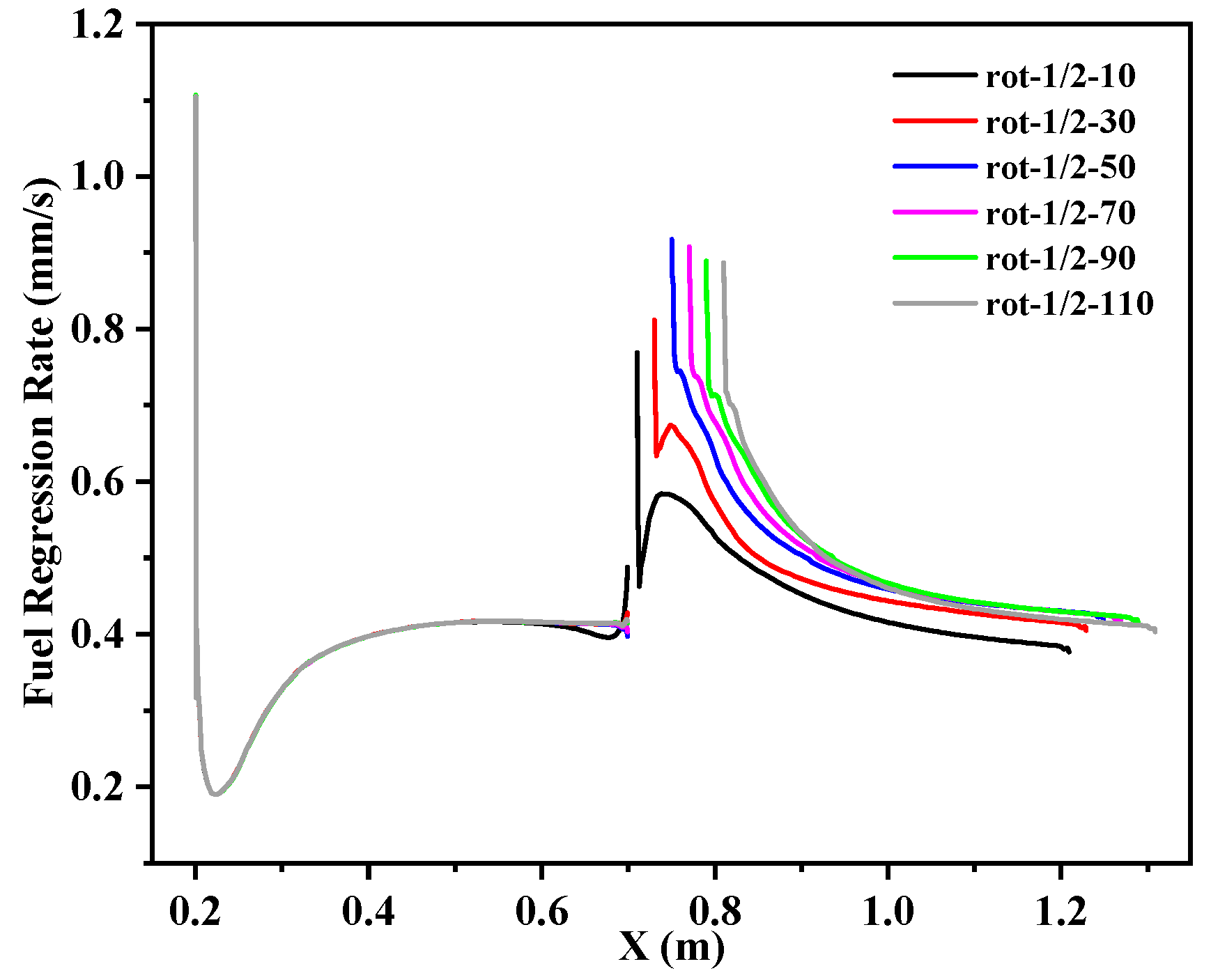

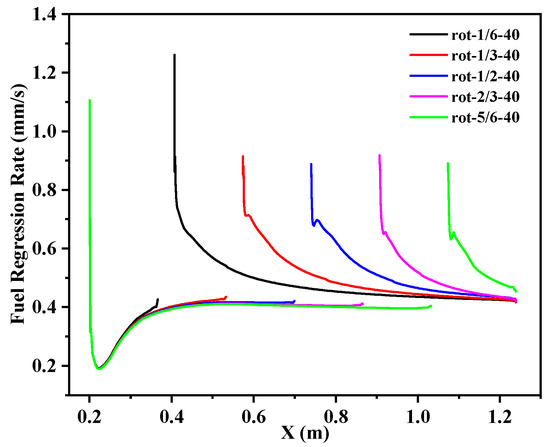

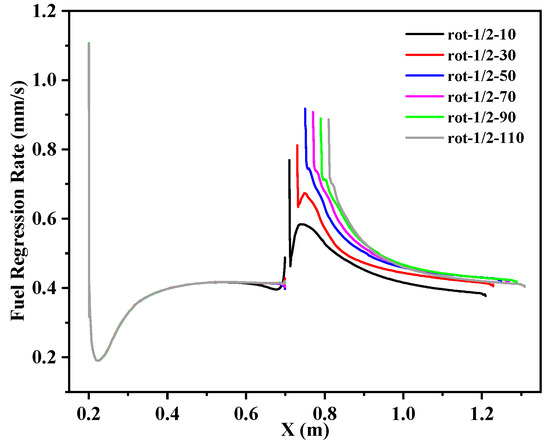

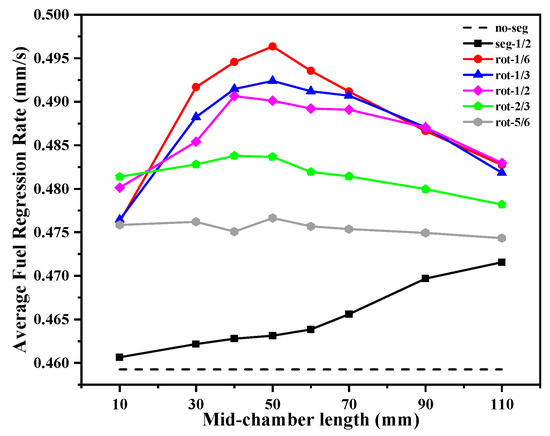

Figure 23 shows the fuel regression rate distributions at point c along the motor axis in cases with various segmented positions. The regression rates in the fore-section grain are similar, which indicates that the segmented position rarely affects the fore-section fuel regression rates. In the aft-section grain, the general change tendency of the fuel regression rates is that it decreases rapidly and then reduces slowly. The vortices in the mid-chamber can strengthen the heat transfer; hence, the regression rate is very high at the front edge of the aft-section grain. As the axial location increases along the aft-section grain, the influence of vortices in the mid-chamber weakens rapidly, which leads to a sharp drop in the regression rate. With the flow developing downstream, the distance between the flame layer and the fuel wall increases gradually, resulting in a reduction in the temperature gradient. Therefore, the regression rate decreases slowly. In addition, the regression rate at the leading edge of the aft-section grain in case rot-1/6-40 in Figure 23 is higher than that at the front edge of the aft-section grain in the other cases. This is because the fore-section grain length is the shortest in case rot-1/6-40, which means that the flame at the front edge of the aft-section grain in case rot-1/6-40 is the closest to the grain inner surface. The increased temperature gradient causes the increase in the local regression rate. In the same axial location of the aft-section grain, the fuel regression rate increases with the increase in segmented position. Figure 24 shows the regression rates of point c along axial locations in cases with various mid-chamber lengths. It can be seen that the mid-chamber length has little influence on the regression rate of the fore-section grain. In the aft-section grain, the regression rate in case rot-1/2-10 is the lowest. The main reason is that the mid-chamber length in case rot-1/2-10 is the shortest and the effect of the mid-chamber on enhancing propellants mixing is comparatively small. Therefore, the heat transfer to the grain surface is relatively low. In the front part of the aft-section grain, the fuel regression rate increases with increasing mid-chamber length. However, distributions of regression rates are similar in the aft end of the aft-section grain.

Figure 23.

Fuel regression rates of point c along the motor axis in cases with various segmented positions.

Figure 24.

Fuel regression rates of point c along the motor axis in cases with various mid-chamber lengths.

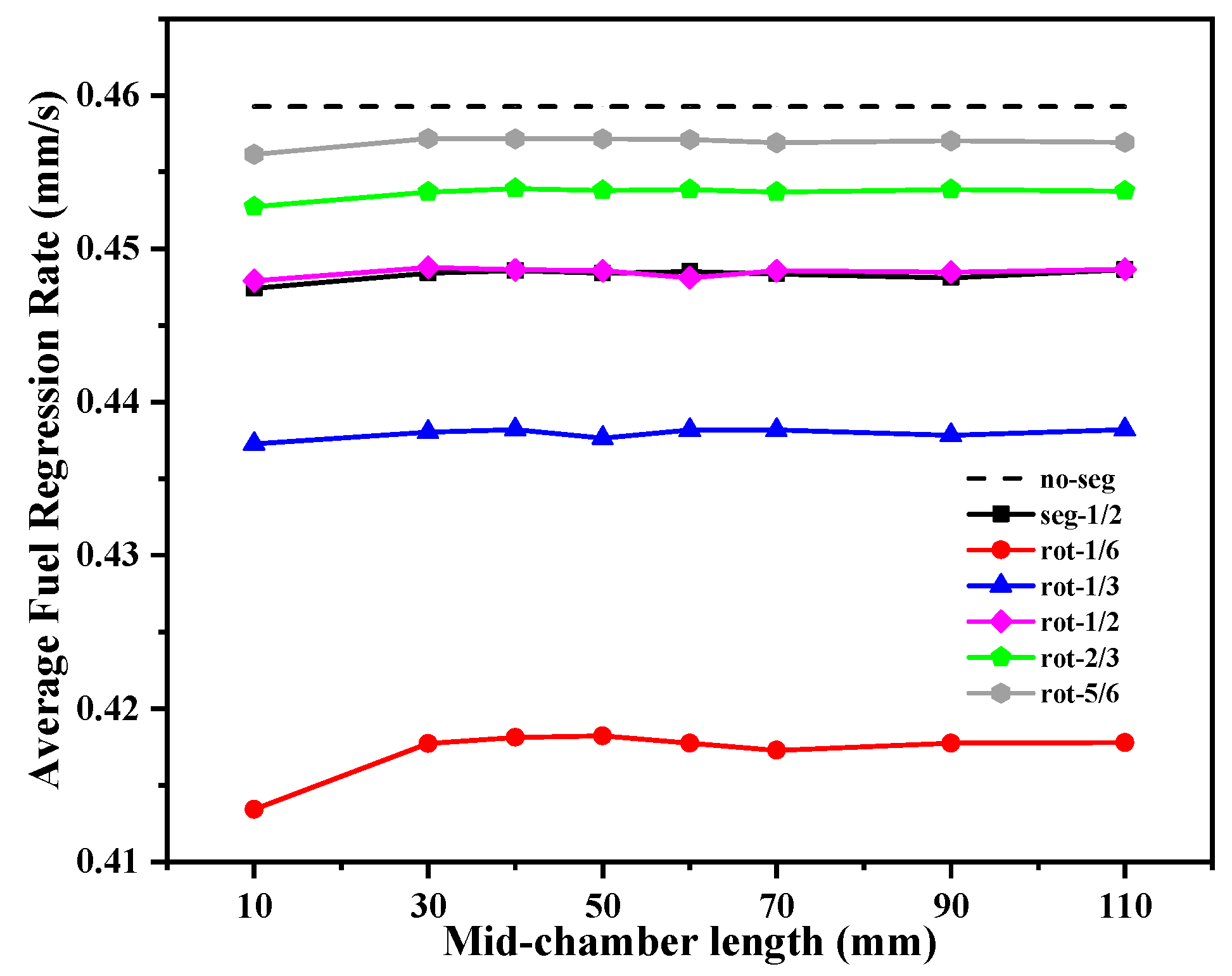

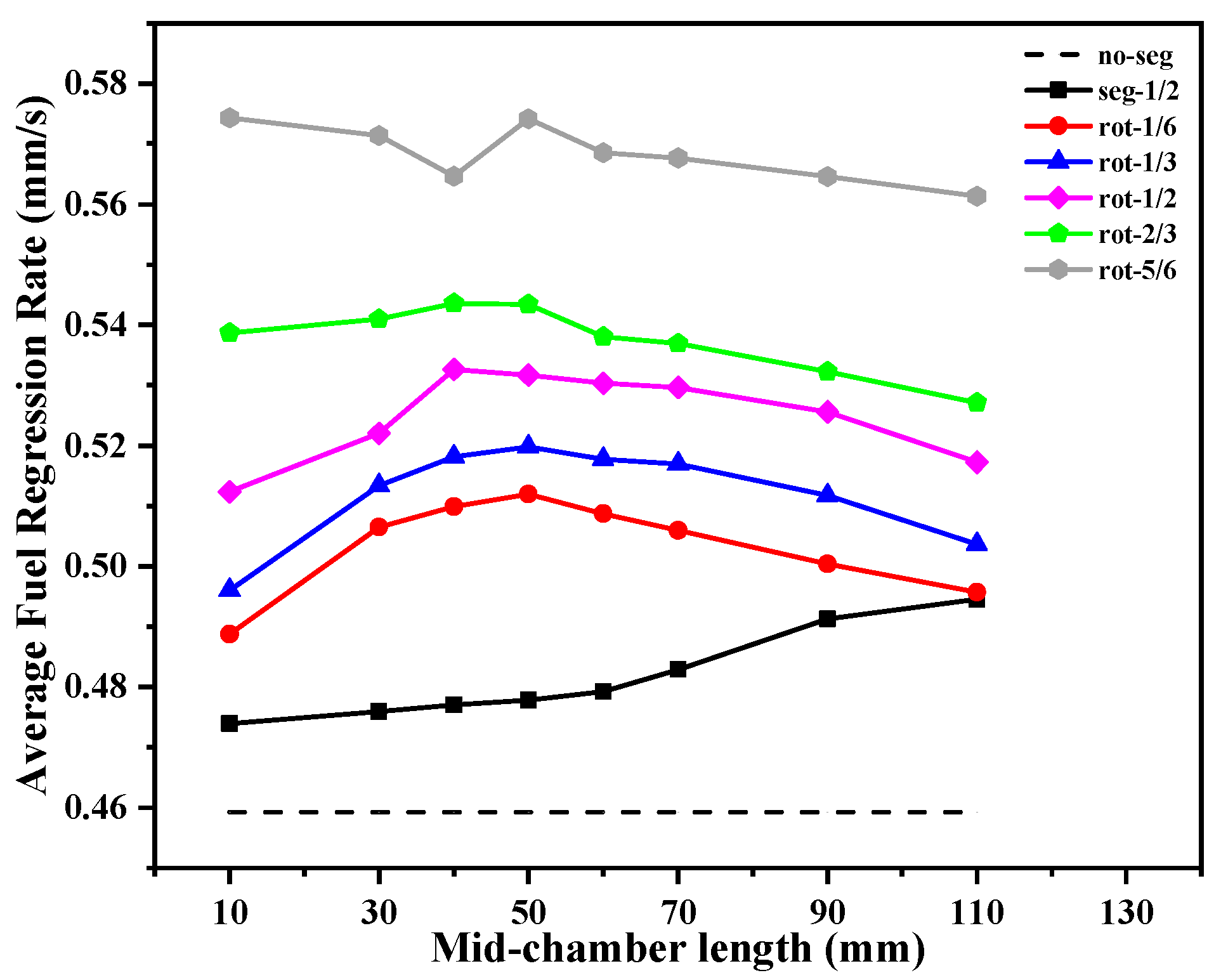

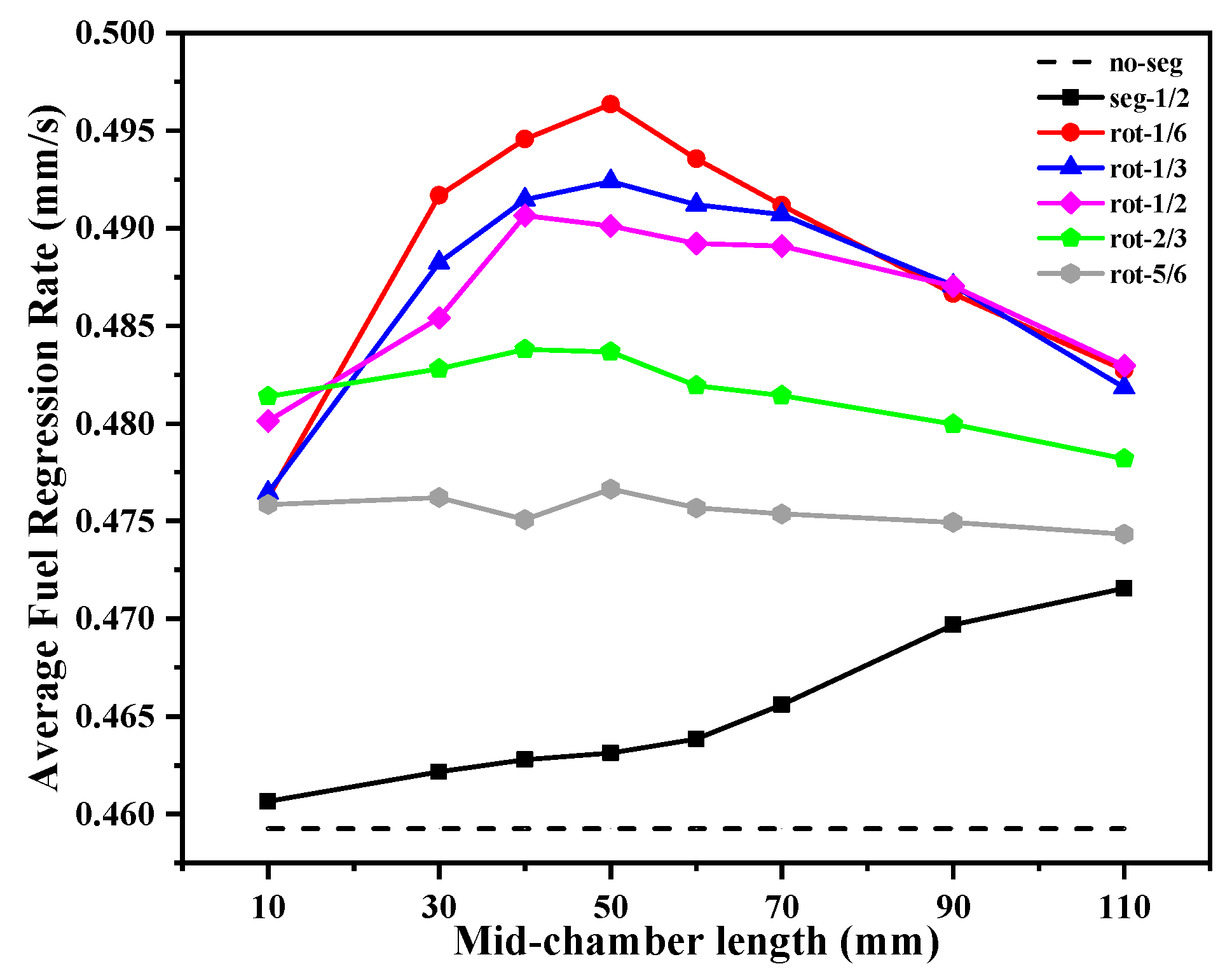

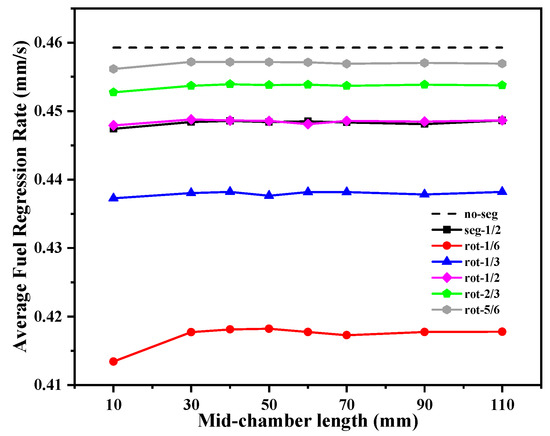

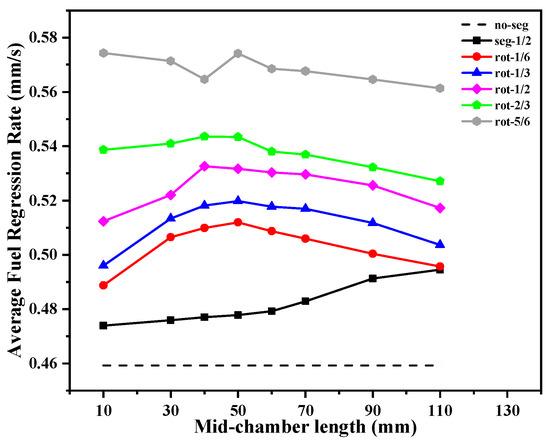

The simulation cases and computed average fuel regression rates are listed in Table 5, where is the average fuel regression rate in fore-section grain, is the average fuel regression rate in aft-section grain, and is the average fuel regression rate of the whole fuel grain. The average fuel regression rates in fore-section grain are presented in Figure 25. Notice that the average fuel regression rate in the fore-section grain in case no-seg is higher than those in other cases. When the segmented position increases (from 1/6 to 5/6), the average regression rate in the fore-section grain increases gradually and the growth rate becomes slower. The case no-seg can be regarded as a special circumstance whose segmented position is 1. Figure 25 shows that the average regression rates in the fore-section grain in cases seg-1/2 are extremely close to those in cases rot-1/2. This shows that the rotation angle of the two sections hardly influences the average regression rates in fore-section grain. Additionally, the average regression rates in the fore-section grain vary slightly with the increase in the mid-chamber length. The average fuel regression rates in the aft-section grain are shown in Figure 26. It is apparent that the average regression rates in the aft-section grain in cases with segmented grains are higher than those in case no-seg. When the relative rotation angle of the two grains is 0°, the average regression rate in the aft-section grain increases as the mid-chamber length increases. However, when the rotation angle of the two grains is 22.5°, the average regression rates in the aft-section grain are greater than those in cases with the rotation angle of 0°. This demonstrates that the disturbance caused by the front-end face of the aft-section grain plays a more important role in enhancing fuel regression rates. For cases with a rotation angle of 22.5°, the average regression rate in the aft-section grain increases with increasing segmented position. When the segmented position is lower than 5/6, the average regression rate in the aft-section grain increases first and then decreases with the increase in mid-chamber length when the rotation angle is 22.5°. This is probably because, when the mid-chamber length increases, the mixing of propellants is more sufficient, and more heat is released. On the other hand, a longer mid-chamber makes the flame farther from the fuel wall in the aft-section. These two reasons result in the trend noted above. In addition, the average regression rate in the aft-section grain in case rot-5/6-10 is the highest, which is increased by 25.04%, compared to that in case no-seg. The average fuel regression rates of the whole grain are illustrated in Figure 27. The change tendency of the average regression rates of the whole grain in cases seg-1/2 is similar to that in the aft-section grain in cases seg-1/2. For cases with the rotation angle of 22.5°, the average regression rates are the lowest, and this may be due to the smallest burning surface area that is influenced by the segmented grain configuration. When the variation of the segmented position is 1/6-2/3, the average regression rate increases first and then decreases as the mid-chamber length increases. The average fuel regression rate in case rot-1/6-50 is the highest at 0.4963 mm/s.

Table 5.

Average area regression rates of the simulation cases.

Figure 25.

Average fuel regression rates in the fore-section grain for various cases.

Figure 26.

Average fuel regression rates in the aft-section grain for various cases.

Figure 27.

Average fuel regression rates of the whole grain for various cases.

3.3. Combustion Efficiency

The combustion efficiency can be calculated from:

where indicates the theoretical characteristic velocity, which is determined according to the combustion chamber pressure and the oxidizer to fuel ratio by thermodynamic calculation, and is the simulated characteristic velocity.

The simulated characteristic velocity can be calculated from:

where represents the combustion chamber pressure, is the nozzle throat area, and is the propellant mass flow rate. Values for the three parameters can be obtained from the simulation cases.

The average oxidizer to fuel ratio O/F can be expressed by:

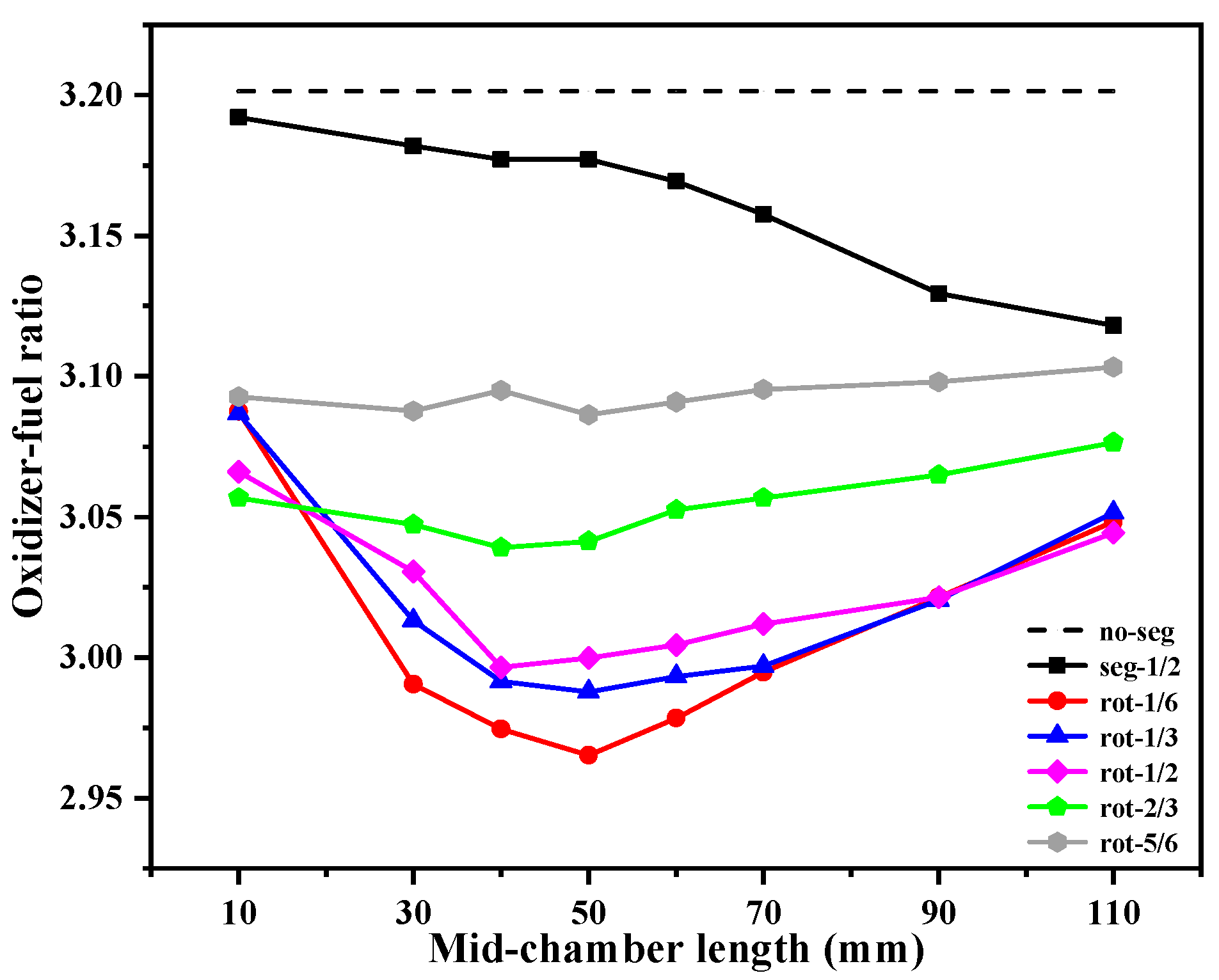

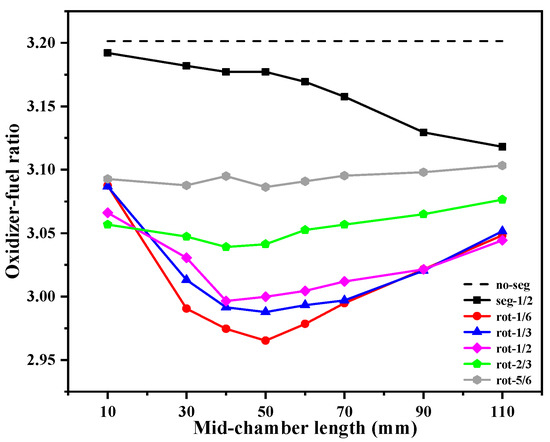

The performance parameters obtained from numerical simulations are shown in Table 6. Figure 28 presents the oxidizer to fuel ratio in the simulation cases. By comparing Figure 27 and Figure 28, the change trend in the oxidizer to fuel ratio is associated with that of the average fuel regression rate. This is because the oxidizer mass flow rate and the total burning surface area are invariant in all cases, and therefore the value of the oxidizer to fuel ratio is determined by the average regression rate.

Table 6.

Performance parameters obtained from the numerical simulations.

Figure 28.

Oxidizer to fuel ratio in various cases.

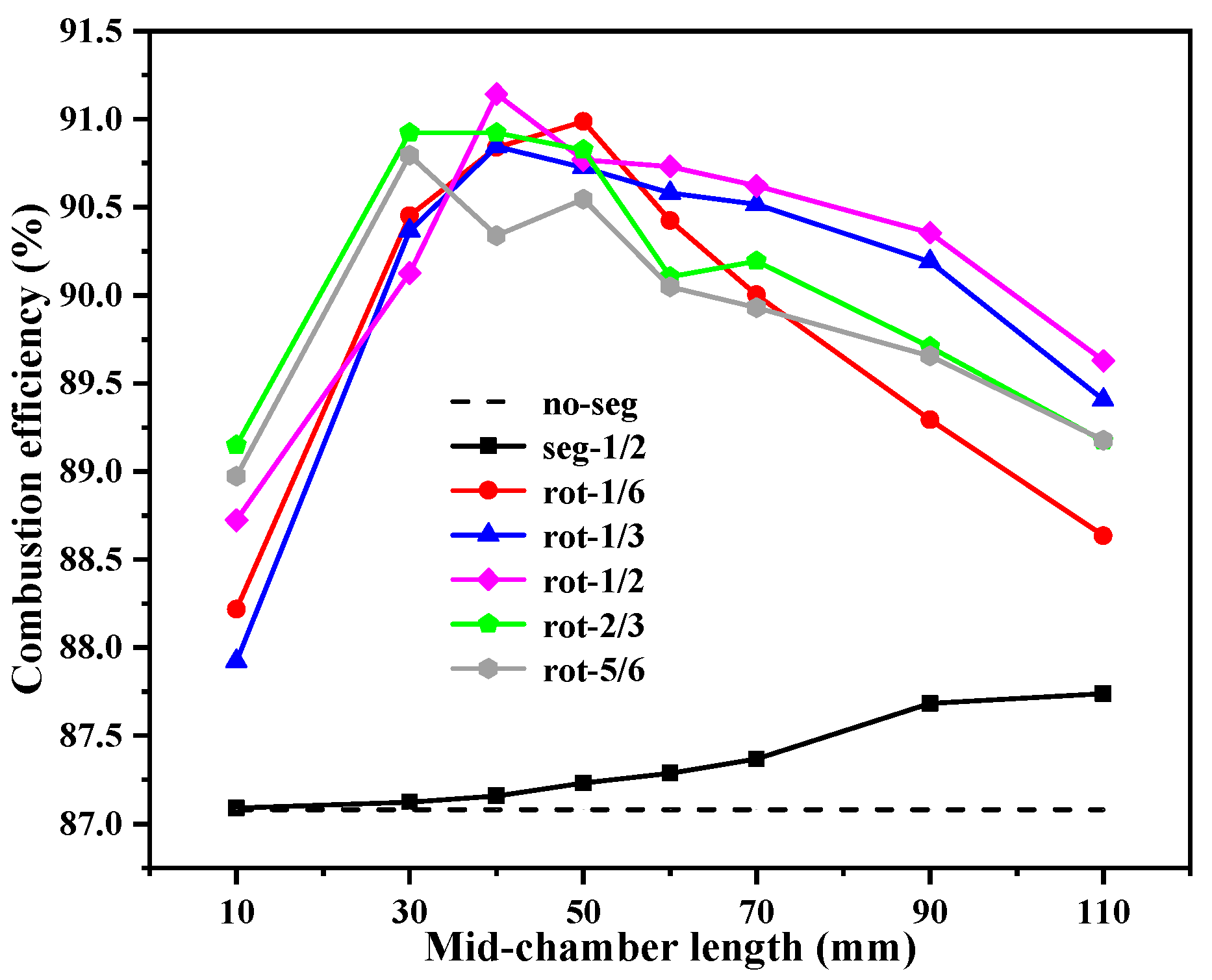

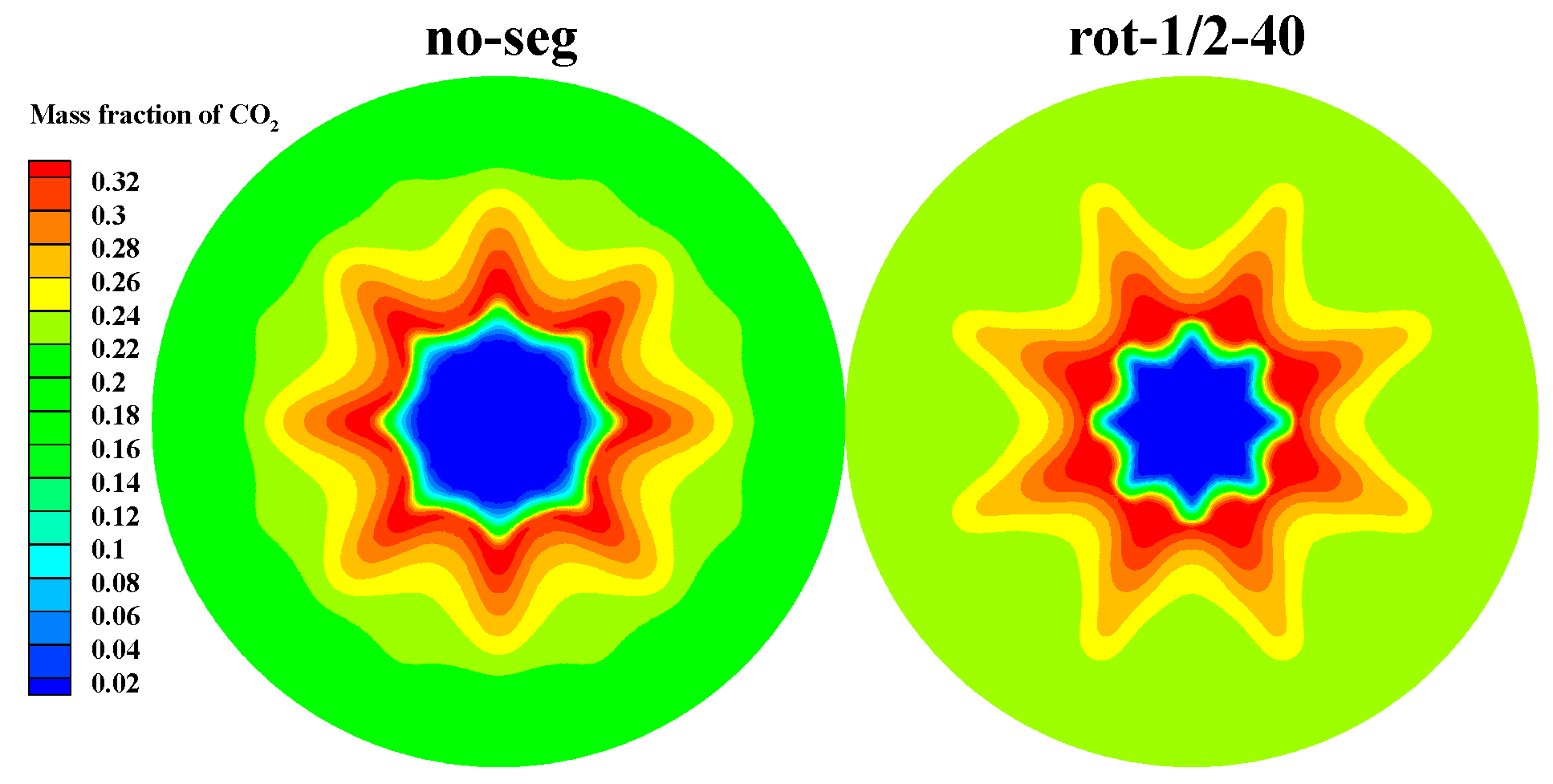

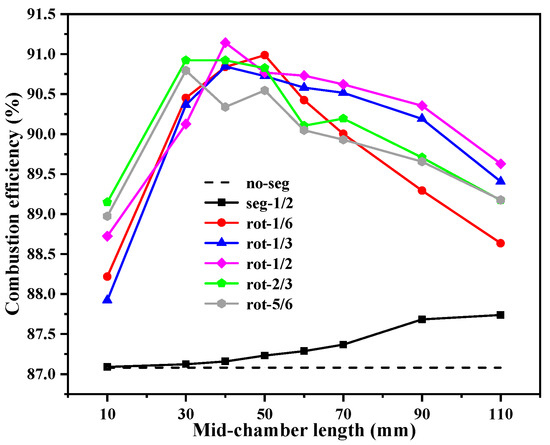

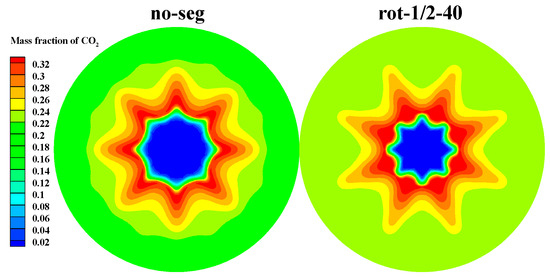

The combustion efficiency of the hybrid rocket motor is illustrated in Figure 29. It can be seen that the combustion efficiency in cases seg-1/2 is higher than that in case no-seg. This indicates that the segmented grain configuration with the rotation angle of 0° has a positive effect on the combustion efficiency, but the effect is relative subtle. As the mid-chamber length increases, the combustion efficiency in cases seg-1/2 keeps increasing. When the rotation angle is 0°, the combustion chamber pressure (listed in Table 6) maintains the trend of increasing with the increase in mid-chamber length, which leads to an increase in the combustion efficiency. When the rotation angle is 22.5°, the combustion efficiency is significantly improved, and this demonstrates that the disturbance caused by the front-end face of the aft-section grain can promote the increase in combustion efficiency. For cases with the rotation angle of 22.5°, the general change tendency of combustion efficiency is that it first rises and then declines with the increase in the mid-chamber length. The main reason is that when the mid-chamber length is relatively small, the disturbance created by the front-end face of the aft-section grain is gradually strengthened as the mid-chamber length increases, which can promote the mixing of the species. With the further increase in the mid-chamber length, the disturbance does not significantly increase but the combustion chamber volume enlarges, which causes a decrease in the combustion chamber pressure and of the combustion efficiency. The effect of the segmented position on the combustion efficiency is related to the mid-chamber length. When the mid-chamber length is not larger than 30 mm, the cases with the segmented position of 2/3 achieve higher combustion efficiency. When the mid-chamber length is greater than 60 mm, the cases with the segmented position of 1/2 reach higher combustion efficiency. Among all simulation cases in this paper, the combustion efficiency in case rot-1/2-40 is the highest, at 91.14%, and it is 4.06% greater than that in case no-seg. Because CO2 is the final product of the combustion process, the mass fraction of CO2 can reflect the degree of combustion completeness. The mass fraction of CO2 in the nozzle entrance is shown in Figure 30. The area with low mass fraction of CO2 in case rot-1/2-40 is smaller than that in case no-seg, and the area with relatively high mass fraction of CO2 in case rot-1/2-40 is larger than that in case no-seg. Therefore, the mass fraction of CO2 in the nozzle entrance in case rot-1/2-40 is higher than that in case no-seg, which indicates that the segmented rotation grain configuration can make the combustion process more efficient.

Figure 29.

Combustion efficiency in various cases.

Figure 30.

Mass fraction of CO2 at the nozzle entrance.

3.4. Full-Time Motor Performances

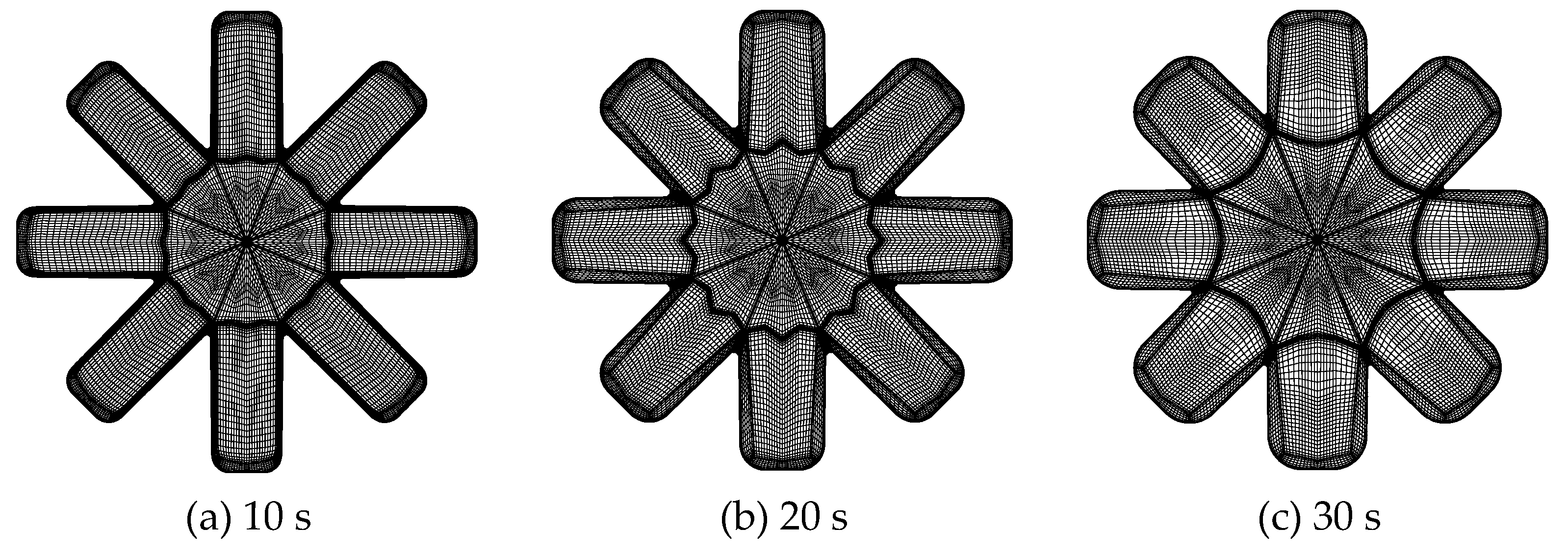

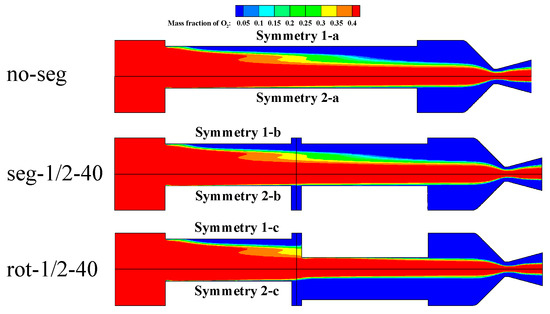

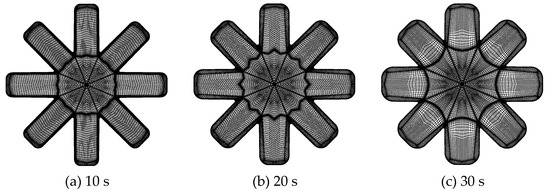

In order to acquire the performance parameters of the hybrid rocket motor at different working time and compare the performances during the whole period of operation, steady numerical simulations on different working time were conducted. The combustion condition in next time step was simulated by using the calculated fuel regression rate in the current time step. The cross sections of the fuel grain at t = 10 s, 20 s, and 30 s are shown in Figure 31. The history of combustion chamber pressure, thrust, average fuel regression rate, and combustion efficiency was obtained, and full-time motor performances are discussed.

Figure 31.

Cross sections of fuel grain at 10 s, 20 s, and 30 s.

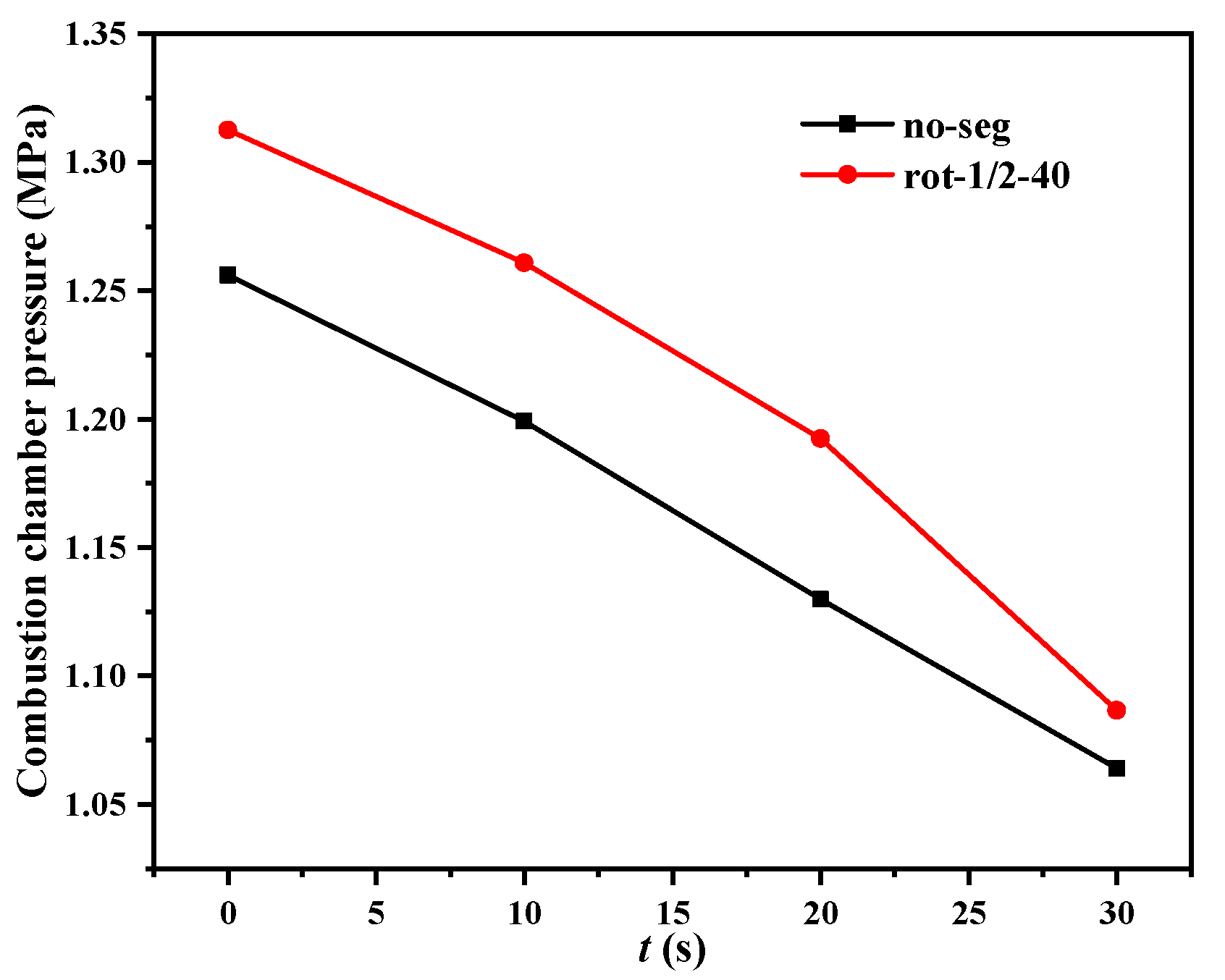

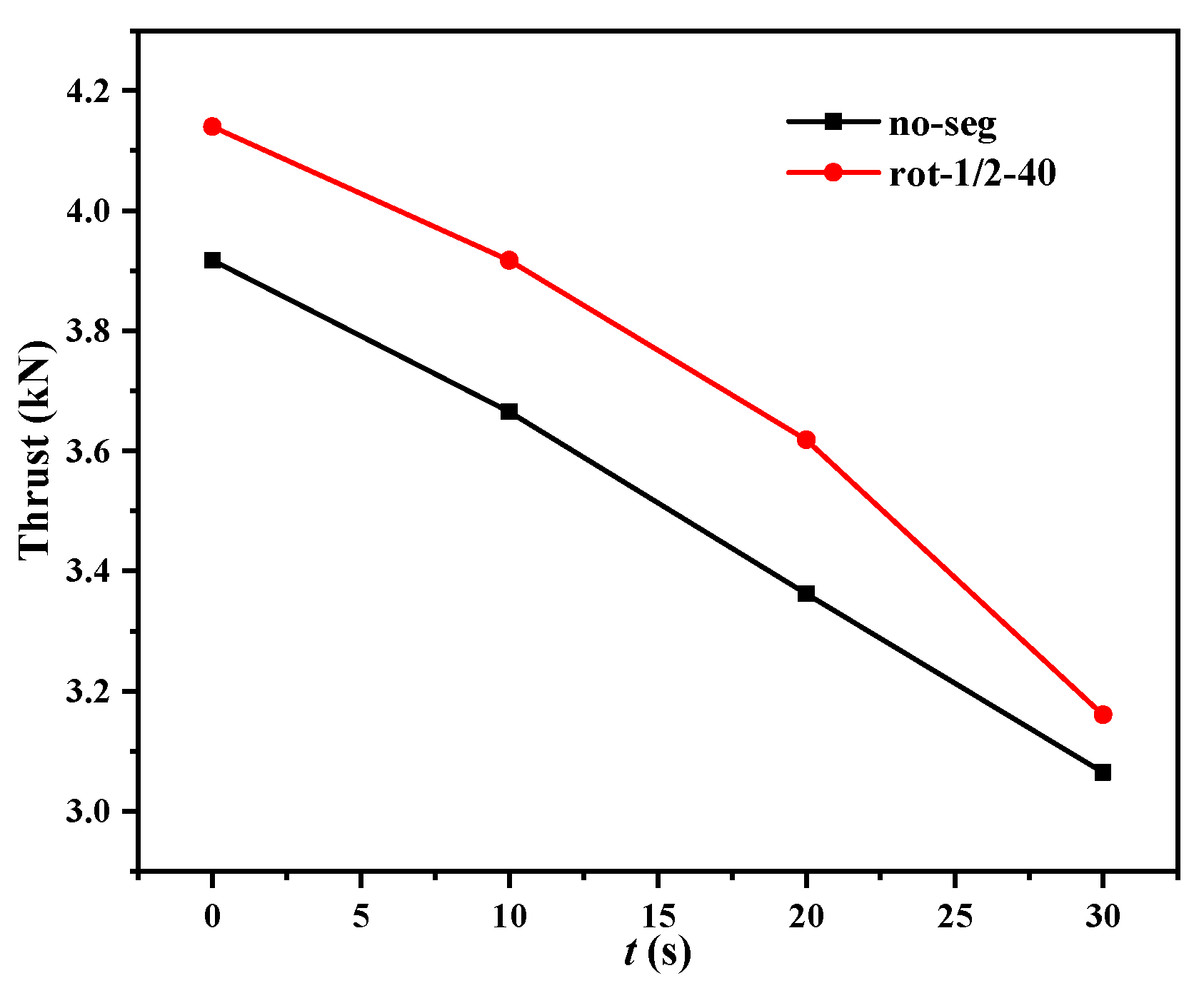

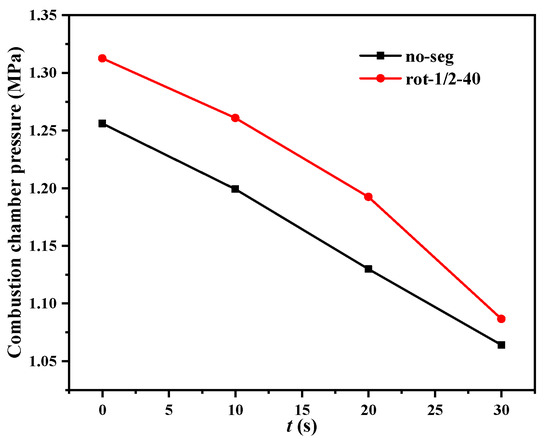

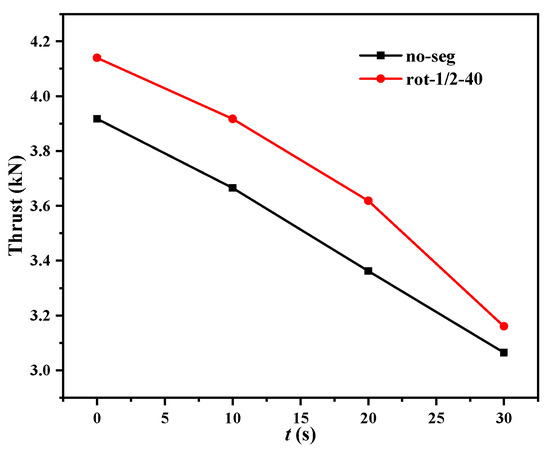

Table 7 shows the simulation results at different times. The pressure history and thrust history are shown in Figure 32 and Figure 33, respectively. As can be seen in Figure 32, the combustion chamber pressure decreases with the increase in the working time. This is because, during the motor operation, the fuel mass flow rate gradually decreases, which can be seen in Table 7, and the oxidizer mass flow rate is constant. Therefore, the mass flow rate of propellants reduces, which causes the drop of the chamber pressure. In addition, the combustion chamber pressure in case rot-1/2-40 is higher than that in case no-seg, and the pressure increases by 0.023 MPa–0.056 MPa. Figure 33 shows that the thrust also decreases with the working time increasing, and this is due to the reduction in the total mass flow rate and specific impulse (affected by oxidizer-fuel ratio). The thrust in case rot-1/2-40 is higher than that in case no-seg, and it increases by 96 N–256.7 N.

Table 7.

Simulation results at different times.

Figure 32.

Combustion chamber pressure history in cases no-seg and rot-1/2-40.

Figure 33.

Thrust history in cases no-seg and rot-1/2-40.

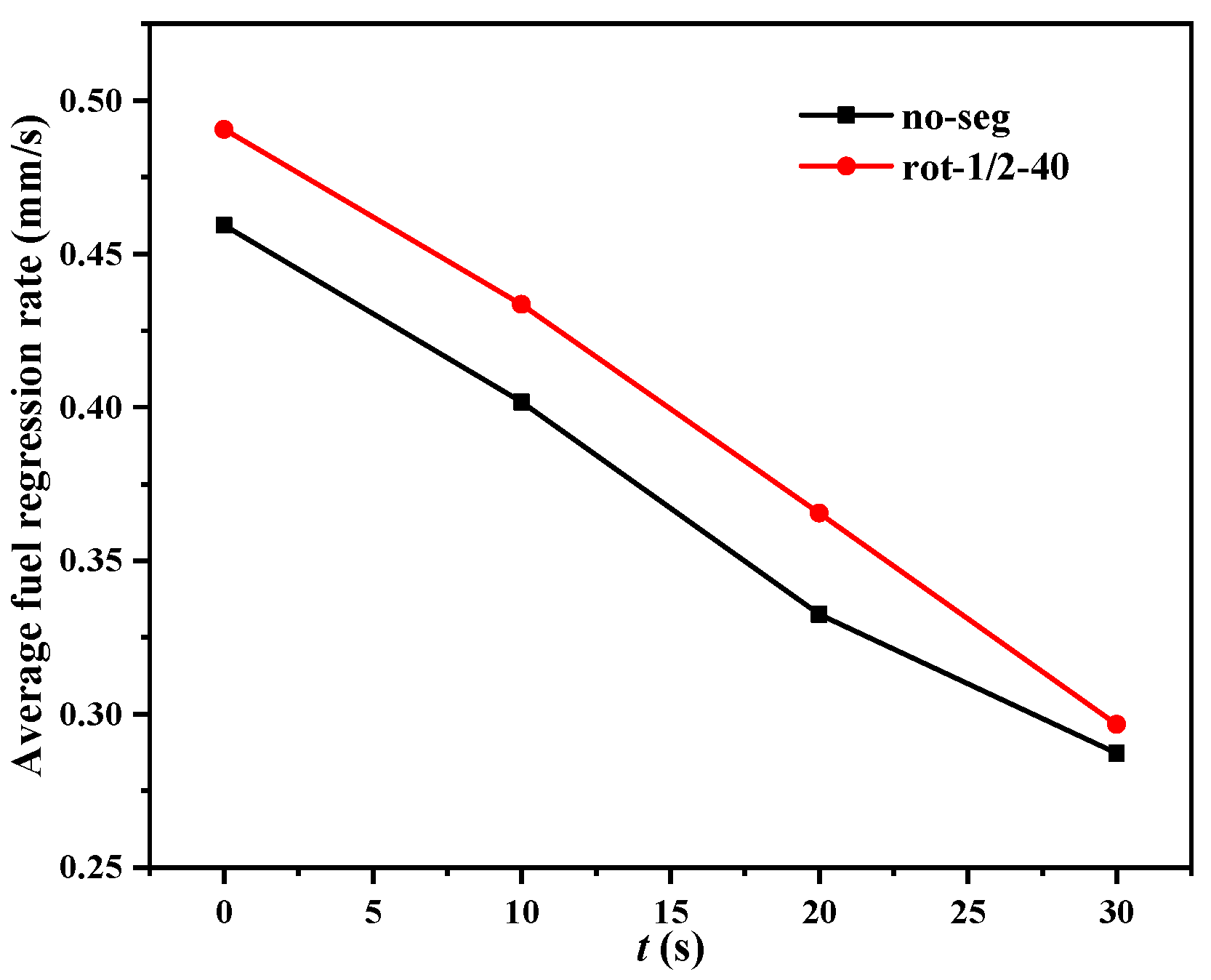

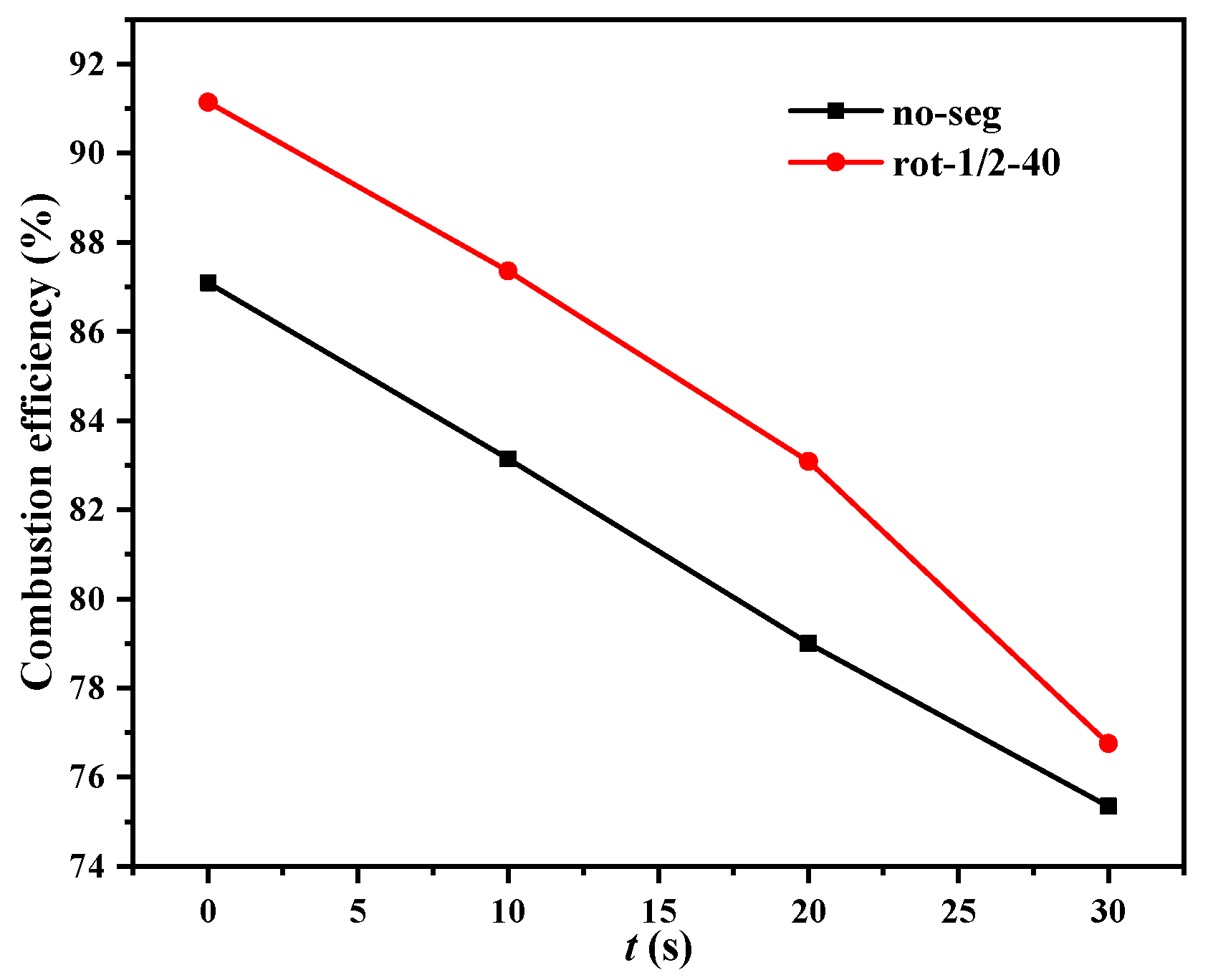

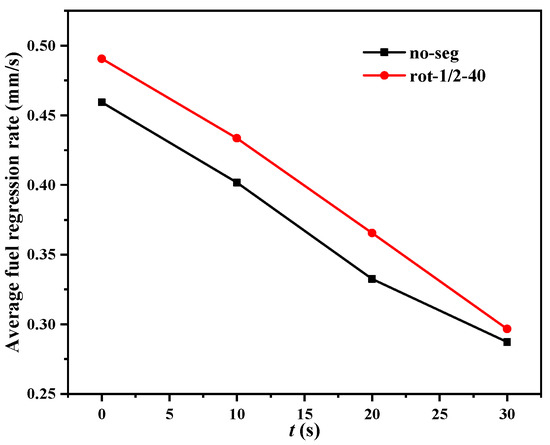

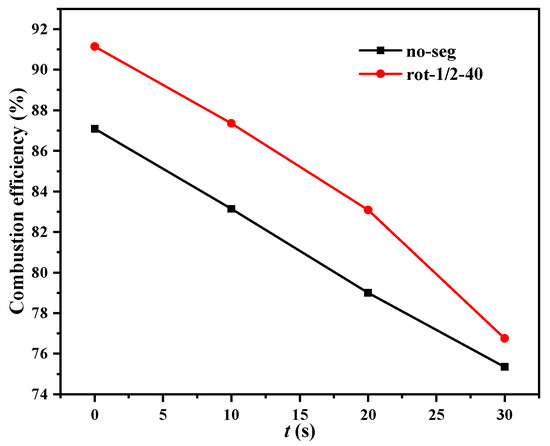

Figure 34 and Figure 35 show the average fuel regression rate and combustion efficiency at different times in cases no-seg and rot-1/2-40. It is obvious that the average regression rate gradually decreases with the increase in the working time, which is due to the increase in grain port diameter. In addition, the average fuel regression rate in case rot-1/2-40 is higher than that in case no-seg, and this indicates that the fuel regression rate can be improved by adopting segmented rotation grain configuration during the entire period of operation. For case no-seg, when the working time increases, the grain inner surface regresses and it is gradually farther from the oxidizer. Thus, the mixing of the fuel and oxidizer is worse, which decreases the combustion efficiency. For case rot-1/2-40, when the working time increases, the disturbing effect of the front-end face of the after-section grain weakens, and thus the mixing of the propellants is gradually insufficient. This reduces the combustion efficiency. The combustion efficiency in case rot-1/2-40 is higher than that in case no-seg, and it improves by 1.40–4.21%. Therefore, a conclusion can be drawn that the combustion efficiency of hybrid rocket motors with segmented rotation grain can be increased in the whole motor operation.

Figure 34.

Average fuel regression rates at different times.

Figure 35.

Combustion efficiency at different times.

4. Conclusions

Three-dimensional steady state numerical simulations of hybrid rocket motors with star-segmented rotation grain were carried out. The effects of the relative grain rotation, mid-chamber length, and segmented position on the combustion characteristics were discussed in detail. The main conclusions obtained in this paper are as follows:

- The segmented rotation grain configuration has little influence on the combustion flow field in fore-section, while the flow field in the aft-section is disturbed by the front-end face of the aft-section grain. The flame in the aft-section shifts towards the central core flow and the oxidizer in the slot of the star in the aft-section is depleted more. The highest temperature in case rot-1/2-40 increases by about 83 K in comparison with that in case no-seg.

- The fuel regression rate distributions along the motor axis in the fore-section grain are only slightly affected by the segmented rotation grain configuration, while the segmented rotation grain configuration can enhance the average fuel regression rates in the aft-section grain. When the segmented position increases (from 1/6 to 5/6), the average regression rate in the fore-section grain increases gradually. The average regression rates in fore-section grain vary little with the increase in the mid-chamber length. As for cases with the rotation angle of 22.5°, the average regression rate in the aft-section grain rises with the increase in segmented position. The average regression rate in aft-section grain in case rot-5/6-10 is the highest, which increases by 25.04% compared with that in case no-seg. The average fuel regression rate of the entire grain in case rot-1/6-50 is the highest, with a maximum regression rate of 0.4963 mm/s.

- The segmented rotation grain configuration has a positive influence on the combustion efficiency. For cases with the rotation angle of 22.5°, the general change tendency of combustion efficiency is that it increases at first and then declines with the increase in mid-chamber length. When the mid-chamber length is not larger than 30 mm, the cases with the segmented position of 2/3 achieve higher combustion efficiency. While the mid-chamber length is greater than 60 mm, the cases with the segmented position of 1/2 reach higher combustion efficiency. In comparison with the base case, the combustion efficiency in case rot-1/2-40 increases 4.06%.

- The combustion chamber pressure, thrust, average fuel regression rate, and combustion efficiency decrease with the increase in the working time, and they are improved by adopting segmented rotation grain configuration during the entire period of operation. The combustion efficiency increases by 1.40–4.21% during the motor operation.

Author Contributions

Conceptualization, X.J. and H.Z.; methodology, H.T. and G.C.; software, H.T. and X.J.; validation, X.J. and Y.L. (Yudong Lu); formal analysis, H.T., X.J., and Y.L. (Yu Liang); investigation, H.T. and G.C.; resources, H.T. and H.Z.; data curation, X.J. and Y.L. (Yudong Lu); writing—original draft preparation, H.T. and X.J.; writing—review and editing, X.J., Y.L. (Yudong Lu) and Y.L. (Yu Liang); visualization, H.T. and Y.L. (Yudong Lu); supervision, H.Z.; project administration, H.T. and G.C.; funding acquisition, G.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Please turn to the CRediT taxonomy for the term explanation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Di Martino, G.D.; Carmicino, C.; Mungiguerra, S.; Savino, R. The Application of Computational Thermo-Fluid-Dynamics to the Simulation of Hybrid Rocket Internal Ballistics with Classical or Liquefying Fuels: A Review. Aerospace 2019, 6, 56. [Google Scholar] [CrossRef]

- Oztan, C.; Coverstone, V. Utilization of additive manufacturing in hybrid rocket technology: A review. Acta Astronaut. 2020, 180, 130–140. [Google Scholar] [CrossRef]

- Rashkovskiy, S.A.; Yakush, S.E. Numerical simulation of low-melting temperature solid fuel regression in hybrid rocket engines. Acta Astronaut. 2020, 176, 710–716. [Google Scholar] [CrossRef]

- Vignesh, B.; Kumar, R. Effect of multi-location swirl injection on the performance of hybrid rocket motor. Acta Astronaut. 2020, 176, 111–123. [Google Scholar] [CrossRef]

- Dinesh, M.; Rajput, S.S.; Kumar, R. Protrusion effect on the performance of hybrid rocket with liquefying and non-liquefying fuels. Acta Astronaut. 2021, 178, 536–547. [Google Scholar] [CrossRef]

- Okninski, A. On use of hybrid rocket propulsion for suborbital vehicles. Acta Astronaut. 2018, 145, 1–10. [Google Scholar] [CrossRef]

- Yun, Y.; Seo, J.; Park, K.; Huh, J.; Lim, J.; Kwon, S. Integration validation of key components for small sounding rockets. Aerosp. Sci. Technol. 2020, 100, 105823. [Google Scholar] [CrossRef]

- Ahn, B.; Huh, J.; Bhosale, V.K.; Kwon, S. Three-Dimensionally Printed Polylactic Acid as Solid Fuel for Hydrogen Peroxide Hybrid Rockets. J. Propuls. Power 2021, 37, 171–175. [Google Scholar] [CrossRef]

- Davydenko, N.A.; Gollender, R.G.; Gubertov, A.M.; Mironov, V.V.; Volkov, N.N. Hybrid rocket engines: The benefits and prospects. Aerosp. Sci. Technol. 2007, 11, 55–60. [Google Scholar] [CrossRef]

- Zhu, H.; Tian, H.; Cai, G. Hybrid uncertainty-based design optimization and its application to hybrid rocket motors for manned lunar landing. Chin. J. Aeronaut. 2017, 30, 719–725. [Google Scholar] [CrossRef]

- Tian, H.; Li, X.; Yu, N.; Cai, G. Numerical and experimental investigation on the effects of aft mixing chamber diaphragm in hybrid rocket motor. Sci. China Technol. Sci. 2013, 56, 2721–2731. [Google Scholar] [CrossRef]

- Li, X.; Tian, H.; Cai, G. Numerical analysis of fuel regression rate distribution characteristics in hybrid rocket motors with different fuel types. Sci. China Technol. Sci. 2013, 56, 1807–1817. [Google Scholar] [CrossRef]

- Li, X.; Tian, H.; Yu, N.; Cai, G. Three-Dimensional Numerical Simulation of Two-Phase Flow in Hybrid Rocket Motor. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, San Jose, CA, USA, 14–17 July 2013. [Google Scholar]

- Lee, C.; Na, Y.; Lee, G. The Enhancement of Regression Rate of Hybrid Rocket Fuel by Helical Grain Configuration and Swirl Flow. In Proceedings of the 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Tucson, AZ, USA, 10–13 July 2005. [Google Scholar]

- Whitmore, S.A.; Walker, S.D.; Merkley, D.P.; Sobbi, M. High regression rate hybrid rocket fuel grains with helical port struc-tures. J. Propuls. Power. 2015, 31, 1727–1738. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, F.; Zhang, W. Numerical investigation on the regression rate of hybrid rocket motor with star swirl fuel grain. Acta Astronaut. 2016, 127, 384–393. [Google Scholar] [CrossRef]

- Tian, H.; Li, Y.; Li, C.; Sun, X. Regression rate characteristics of hybrid rocket motor with helical grain. Aerosp. Sci. Technol. 2017, 68, 90–103. [Google Scholar] [CrossRef]

- Tian, H.; He, L.; Zhu, H.; Wang, P.; Xu, X. Numerical and experimental investigation on hybrid rocket motor with two-hole segmented rotation grain. Aerosp. Sci. Technol. 2019, 92, 820–830. [Google Scholar] [CrossRef]

- Tian, H.; Duan, Y.; Zhu, H. Three-dimensional numerical analysis on combustion performance and flow of hybrid rocket motor with multi-segmented grain. Chin. J. Aeronaut. 2020, 33, 1181–1191. [Google Scholar] [CrossRef]

- Betelin, V.B.; Kushnirenko, A.G.; Smirnov, N.N.; Nikitin, V.F.; Tyurenkova, V.V.; Stamov, L.I. Numerical investigations of hybrid rocket engines. Acta Astronaut. 2018, 144, 363–370. [Google Scholar] [CrossRef]

- Mangeot, A.; William-Louis, M.; Gillard, P. Static and moving solid/gas interface modeling in a hybrid rocket engine. Acta Astronaut. 2018, 148, 89–98. [Google Scholar] [CrossRef]

- Zhu, H.; Li, M.; Tian, H.; Wang, P.; Yu, N.; Cai, G. Numerical and experimental investigations on injection effects of orifice injector plate in hybrid rocket motors. Acta Astronaut. 2019, 162, 275–283. [Google Scholar] [CrossRef]

- Shih, T.-H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A new k-ϵ eddy viscosity model for high reynolds number turbulent flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Chiaverini, M.J.; Harting, G.C.; Lu, Y.-C.; Kuo, K.K.; Peretz, A.; Jones, H.S.; Wygle, B.S.; Arves, J.P. Pyrolysis Behavior of Hybrid-Rocket Solid Fuels Under Rapid Heating Conditions. J. Propuls. Power 1999, 15, 888–895. [Google Scholar] [CrossRef]

- Venkateswaran, S.; Merkle, C. Size Scale-up in Hybrid Rocket Motors. In Proceedings of the 34th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 15–18 January 1996. [Google Scholar]

- Magnussen, B.F.; Hjertager, B.H. On mathematical modeling of turbulent combustion with special emphasis on soot formation and combustion. Symp. (Int.) Combust. 1977, 16, 719–729. [Google Scholar] [CrossRef]

- Cohen, N.S.; Fleming, R.W.; Derr, R.L. Role of Binders in Solid Propellant Combustion. AIAA J. 1974, 12, 212–218. [Google Scholar] [CrossRef]

- Sun, X.; Tian, H.; Cai, G. Diameter and position effect determination of diaphragm on hybrid rocket motor. Acta Astronaut. 2016, 126, 325–333. [Google Scholar] [CrossRef]

- Tian, H.; Jiang, X.; Yu, R.; Zhu, H.; Zhang, Y.; Cai, G. Numerical analysis of the hybrid rocket motor with axial injection based on oxidizer flow distribution. Acta Astronaut. 2022, 192, 245–257. [Google Scholar] [CrossRef]

- Cai, G.; Cao, B.; Zhu, H.; Tian, H.; Ma, X. Parametric investigation of secondary injection in post-chamber on combustion performance for hybrid rocket motor. Acta Astronaut. 2017, 140, 427–438. [Google Scholar] [CrossRef]

- Tian, H.; Yu, R.; Li, C.; Zhao, S.; Zhu, H. Numerical and experimental study of the thermochemical erosion of a graphite nozzle in a hybrid rocket motor with a star grain. Acta Astronaut. 2018, 155, 10–22. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).