Investigations on an All-Oxide Ceramic Composites Based on Al2O3 Fibres and Alumina–Zirconia Matrix for Application in Liquid Rocket Engines

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Properties

2.1.1. Strength Tests

2.1.2. Leakage Tests

2.1.3. Hot Gas Tests

2.2. Prototype Development

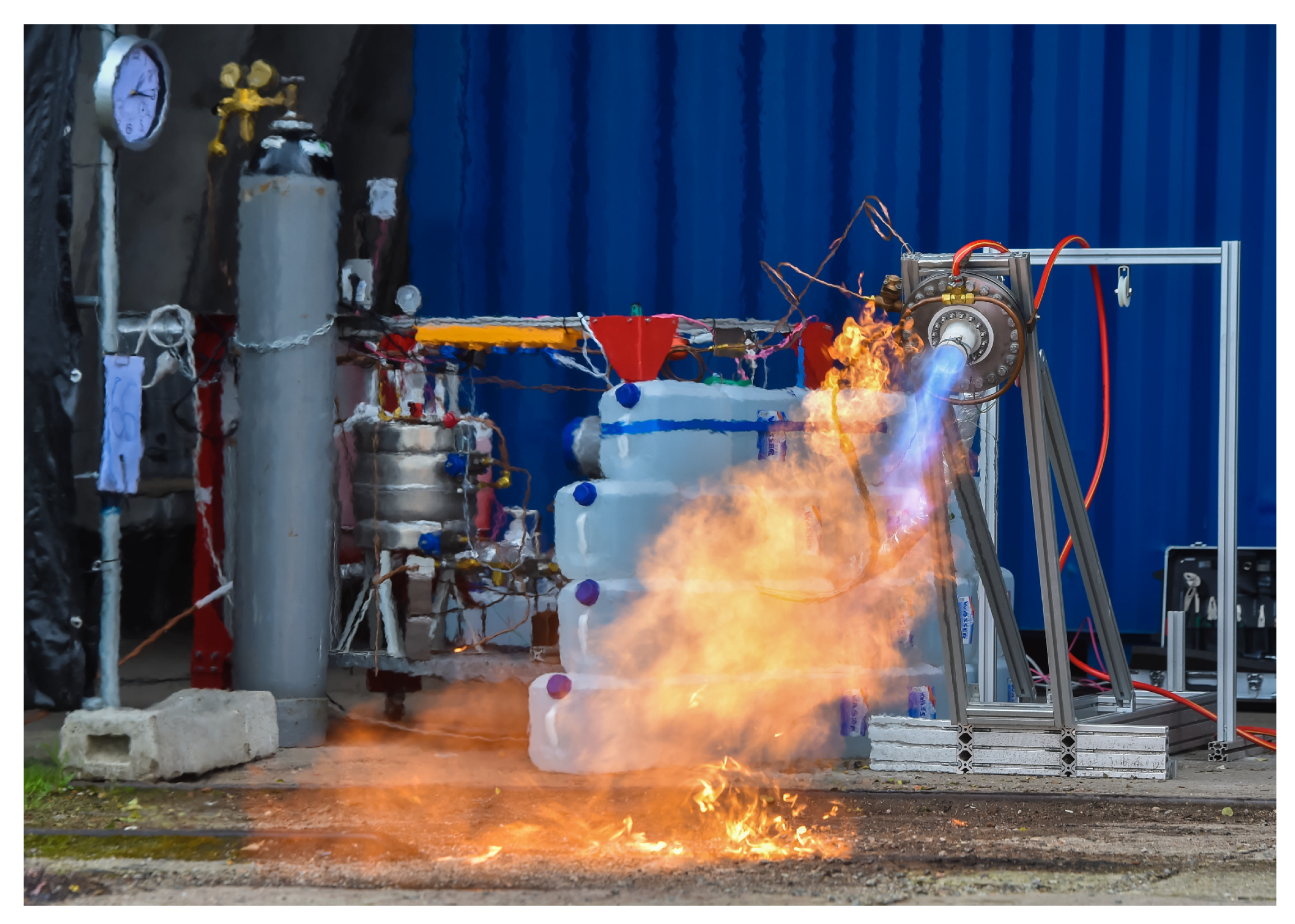

2.2.1. Rocket Engine Test Bench

2.2.2. Flame Tube

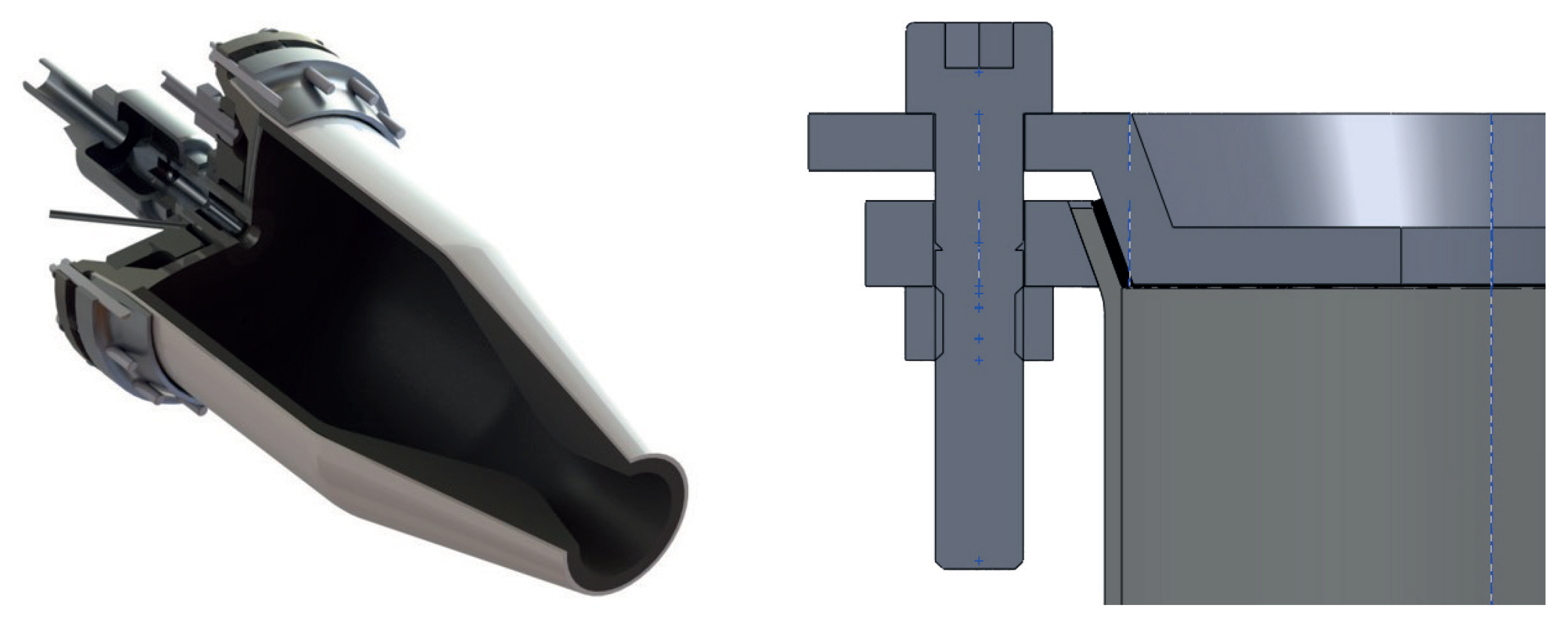

2.2.3. Ceramic Chamber and Nozzle

2.2.4. Ceramic Chamber with Graphite Inlay

3. Results

3.1. Strength Test Results

3.2. Leakage Test Results

3.3. Hot Gas Test Results

3.4. Flame Tube Test Results

3.5. Ceramic Chamber and Nozzle Results

3.6. Ceramic Chamber with Graphite Inlay Test Results

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BMWi | Federal Ministry for Economic Affairs and Energy |

| CFRP | Carbon-Fibre Reinforced Plastic |

| CMC | Ceramic Matrix Composite |

| DLR | German Space Agency |

| EBC | Environmental Barrier Coating |

| LOX | Liquid Oxygen |

| LPRE | Liquid-Propellant Rocket Engine |

| MDPI | Multidisciplinary Digital Publishing Institute |

| OCMC | Oxide-oxide Ceramic Matrix Composite |

| TBC | Thermal Barrier Coating |

| YSZ | Yttrium-stabilised Zirconia |

References

- Krenkel, W. Ceramic Matrix Composites; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2008. [Google Scholar] [CrossRef]

- Boeing. FAA Continuous Lower Energy, Emissions and Noise (CLEEN) Technologies—Boeing Program Overview. In Proceedings of the CLEEN Consortium Public Session, Federal Aviation Administration, Atlanta, GA, USA, 19 November 2014. [Google Scholar]

- Pritzkow, W.E.C.; Wehner, F.; Koch, D. Oxide Fiber Reinforced Oxide Ceramic Matrix Composite—An Alternative to Metallic Alloys at High Temperature; Elsevier: Amsterdam, The Netherlands, 2022; Volume 1, pp. 425–441. [Google Scholar]

- Schmidt, S.; Beyer, S.; Knabe, H.; Immich, H.; Meistring, R.; Gessler, A. Advanced ceramic matrix composite materials for current and future propulsion technology applications. Acta Astronaut. 2004, 55, 409–420. [Google Scholar] [CrossRef]

- Boeing. FAA Coninuous Lower Energy, Emissions and Noise (CLEEN) Technologies—Boeing Program Overview (Presentation). In Proceedings of the CLEEN Consortium Public Session Federal Aviation Administration, Atlanta, GA, USA, 19 November 2014. [Google Scholar]

- Göring, J.; Hackemann, S.; Kanka, B. WHIPOX: Ein faserverstärkter keramischer Werkstoff für Hochtemperatur-Langzeitanwendungen. Mater. Werkst. 2007, 38, 766–772. [Google Scholar] [CrossRef]

- Ortelt, M.; Hald, H.; Müller, I. Status and future Perspectives of the CMC Rocket Thrust Chamber Development at DLR. In Proceedings of the 65th International Astronautical Congress, Toronto, ON, Canada, 29 September–3 October 2014. [Google Scholar]

- Ortelt, M.; Elsässer, H.; Herbertz, A.; Müller, I.; Hald, H. Structural Investigations on Cryogenically Operated and Transpiration Cooled Fiber Reinforced Rocket Thrust Chambers. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 30 July–1 August 2012. [Google Scholar]

- Rüdinger, A.; Pritzkow, W. Die Entwicklung oxidkeramischer Faserverbundwerkstoffe am Fraunhofer ISC/Zentrum HTL in Zusammenarbeit mit W.E.C. Pritzkow Spezialkeramik. Keram. Z. 2013, 3, 166–169. [Google Scholar]

- Levi, C.G.; Zok, F.W.; Yang, J.Y.; Mattoni, M.; Löfwander, J.P.A. Microstructural Design of Stable Porous Matrices for All-Oxide Ceramic Composites. Ztg. Met. 1999, 90, 1037–1047. [Google Scholar]

- Deutsches Institut für Normung e. V. DIN EN 658-3; Hochleistungskeramik—Mechanische Eigenschaften von keramischen Verbundwerkstoffen bei Raumtemperatur—Teil 3: Bestimmung der Biegefestigkeit. Beuth Publishing: Berlin, Germany, 2002.

- Deutsches Institut für Normung e. V. DIN EN 1779; Zerstörungsfreie Prüfung—Dichtheitsprüfung - Kriterien zur Auswahl von Prüfmethoden und -verfahren. Beuth Publishing: Berlin, Germany, 1999.

- Deutsches Institut für Normung e. V. DIN EN 1893; Hochleistungskeramik—Mechanische Eigenschaften von keramischen Verbundwerkstoffen bei hoher Temperatur in Luft bei Atmosphärendruck—Bestimmung der Eigenschaften unter Zug. Beuth Publishing: Berlin, Germany, 2005.

- Deutsches Institut für Normung e. V. DIN EN 12789; Hochleistungskeramik—Mechanische Eigenschaften von keramischen Verbundwerkstoffen bei hoher Temperatur in Luft bei Atmosphärendruck—Bestimmung der Biegefestigkeit. Beuth Publishing: Berlin, Germany, 2003.

- Matthes, K.J.; Schneider, W. Schweißtechnik—Schweißen von Metallischen Konstruktionswerkstoffen; Carl Hanser Verlag: München, Germany, 2016. [Google Scholar]

- Sika Deutschland GmbH. Produktdatenblatt zu SikaBlock M940; Sika Deutschland GmbH: Stuttgart, Germany, 2014. [Google Scholar]

- Thoenes Dichtungstechnik. Datenblatt zum Graphit SF TRD 401; Thoenes Dichtungstechnik: Klipphausen, Germany, 2011. [Google Scholar]

- Thoenes Dichtungstechnik. Datenblatt zum Glimmer Hi-Temp 710; Thoenes Dichtungstechnik: Klipphausen, Germany, 2010. [Google Scholar]

- FUJIFILM Europe GmbH. Datenblatt zur Indikatorfolie für mittlere Drücke (10–50 MPa); FUJIFILM Europe GmbH: Düsseldorf, Germany, 2014. [Google Scholar]

- Mattoni, M.A.; Yang, J.Y.; Levi, C.G.; Zok, F.W. Effects of Matrix Porosity on the Mechanical Properties of a Porous-Matrix, All Oxide Ceramic Composite. J. Am. Ceram. Soc. 2001, 84, 2594–2602. [Google Scholar] [CrossRef]

- Kaya, C.; Kaya, F.; Butler, E.G.; Boccaccini, A.R.; Chawla, K.K. Development and Characterization of High-Density Oxide Fibre-Reinforced Oxide Ceramic Matrix Composites with Improved Mechanical Properties. J. Eur. Ceram. Soc. 2009, 29, 1631–1639. [Google Scholar] [CrossRef]

- Fliegener, S. Mechanische Charakterisierung von Oxidischen Faserkeramiken (OCMC). Master’s Thesis, Universität Karlsruhe, Karlsruhe, Germany, 2010. [Google Scholar]

- Tushtev, K.; Horvath, J. Mechanische Werkstoffprüfung am OCMC FW12 (Auftragsmessung); Technical Report; Universität Bremen-Fachgebiet Keramische Werkstoffe und Bauteile: Bremen, Germany, 2012. [Google Scholar]

- Sieder, J.; Kleebusch, K.; Bach, C.; Tajmar, M. Development History and Verification of the Flight Model of a 500 N Ethanol/LOX Rocket Engine. In Proceedings of the 7th European Conference for Aeronautics and Space Sciences, Milan, Italy, 3–6 July 2017. [Google Scholar]

| Characteristic | Value |

|---|---|

| Matrix | 75% AlO + 25% ZrO (3YSZ) |

| Fibres | Nextel™ 610 DF-11 |

| Fibre composition | >99% AlO |

| Crystalline phase | -AlO |

| Filament diameter | 10–µm |

| Fibre density | g/cm |

| Fibre-Tensile strength | MPa |

| Yarn count | tex |

| Texture | Satin weave |

| Thickness of woven fabric | mm |

| Material Property | Value |

|---|---|

| Bending strength | 400 MPa |

| Tensile strength | 133 MPa |

| Interlaminar shear strength | 17 MPa |

| Porosity | 25–30% |

| Density | 2.5–2.9 g/cm |

| Continuous operating temperature | 1500 K |

| Melting temperature | 2300 K |

| Thermal expansion | 8 × 10/K |

| Thermal conductivity | 3.8 W/mK at 300 °C |

| 2.8 W/mK at 600 °C | |

| 2.3 W/mK at 900 °C | |

| 2.2 W/mK at 1100 °C |

| Measured Variable | Test A | Test B | Test C | Test D | Test E |

|---|---|---|---|---|---|

| [g/s] | 36 | 33 | 62 | 40 | 70–90 |

| [g/s] | 44 | 45 | 83 | 80 | 77 |

| / | 0.82 | 0.73 | 0.75 | 0.5 | 0.91–1.17 |

| [s] | 7 | 14 | 26 | 63 | 30 |

| Test Results | Steel | OCMC | Design |

|---|---|---|---|

| Measurements | |||

| Thrust [N] | 394 | 367 | 500 |

| [kg/s] | 0.104 | 0.108 | 0.125 |

| [kg/s] | 0.117 | 0.121 | 0.125 |

| Calculations | |||

| / | 0.889 | 0.893 | 1 |

| Exhaust velocity [m/s] | 1783 | 1.603 | 2.000 |

| Specific Impulse [s] | 182 | 163 | 205 |

| Estimated with “Rocket Propulsion Analysis” | |||

| Combustion pressure [MPa] | 1.3 | 1.35 | 1.5 |

| Combustion temperature [K] | 2350 | 2060 | 2060 |

| Test Run | Design | #130 | #135 | #136 |

|---|---|---|---|---|

| Measurements | ||||

| Thrust [N] | 520 | 235 | 320 | 424 |

| Duration of constant thrust [s] | 20 | 6 | 9 | 17 |

| [kg/s] | 0.133 | 0.086 | 0.107 | 0.125 |

| [kg/s] | 0.111 | 0.081 | 0.086 | 0.102 |

| Calculations | ||||

| / | 1.20 | 1.06 | 1.26 | 1.23 |

| Specific Impulse [s] | 217 | 144 | 169 | 190 |

| Estimated with “Rocket Propulsion Analysis” | ||||

| Combustion pressure [MPa] | 1.6 | 1.05 | 1.28 | 1.5 |

| Combustion temperature [K] | 2810 | 2497 | 2681 | 2645 |

| Characteristic velocity [m/s] | 1615 | 1608 | 1684 | 1679 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bach, C.; Wehner, F.; Sieder-Katzmann, J. Investigations on an All-Oxide Ceramic Composites Based on Al2O3 Fibres and Alumina–Zirconia Matrix for Application in Liquid Rocket Engines. Aerospace 2022, 9, 684. https://doi.org/10.3390/aerospace9110684

Bach C, Wehner F, Sieder-Katzmann J. Investigations on an All-Oxide Ceramic Composites Based on Al2O3 Fibres and Alumina–Zirconia Matrix for Application in Liquid Rocket Engines. Aerospace. 2022; 9(11):684. https://doi.org/10.3390/aerospace9110684

Chicago/Turabian StyleBach, Christian, Frank Wehner, and Jan Sieder-Katzmann. 2022. "Investigations on an All-Oxide Ceramic Composites Based on Al2O3 Fibres and Alumina–Zirconia Matrix for Application in Liquid Rocket Engines" Aerospace 9, no. 11: 684. https://doi.org/10.3390/aerospace9110684

APA StyleBach, C., Wehner, F., & Sieder-Katzmann, J. (2022). Investigations on an All-Oxide Ceramic Composites Based on Al2O3 Fibres and Alumina–Zirconia Matrix for Application in Liquid Rocket Engines. Aerospace, 9(11), 684. https://doi.org/10.3390/aerospace9110684