Influence of Plasma on the Combustion Mode in a Scramjet

Abstract

:1. Introduction

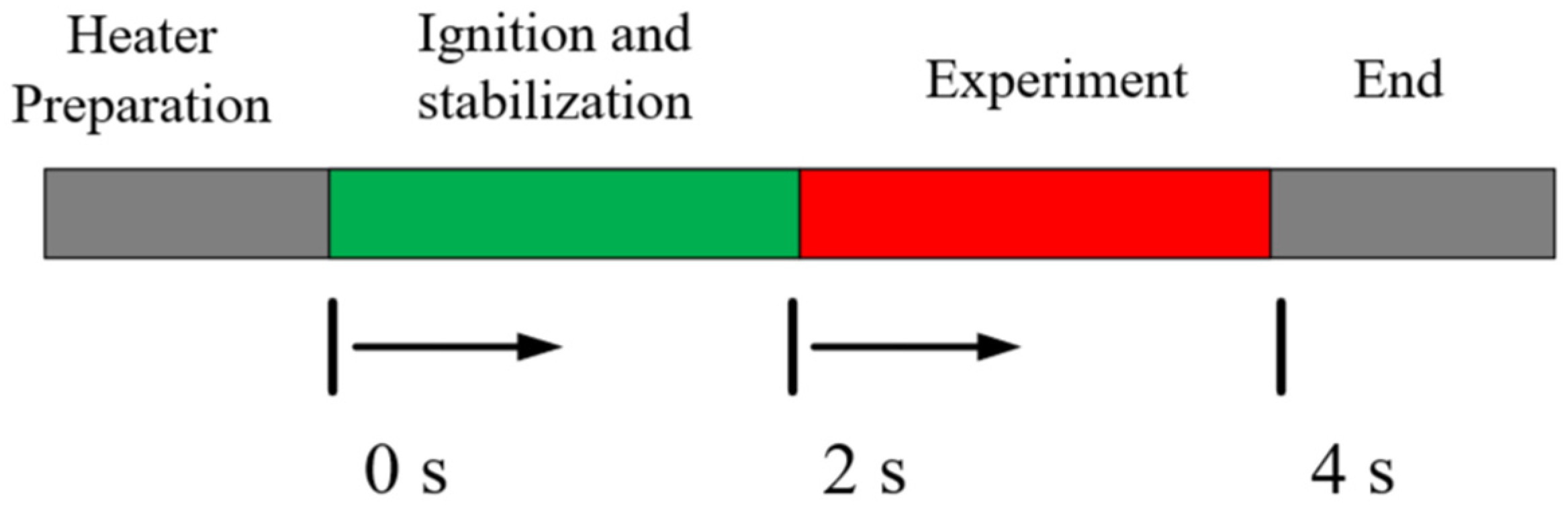

2. Materials and Methods

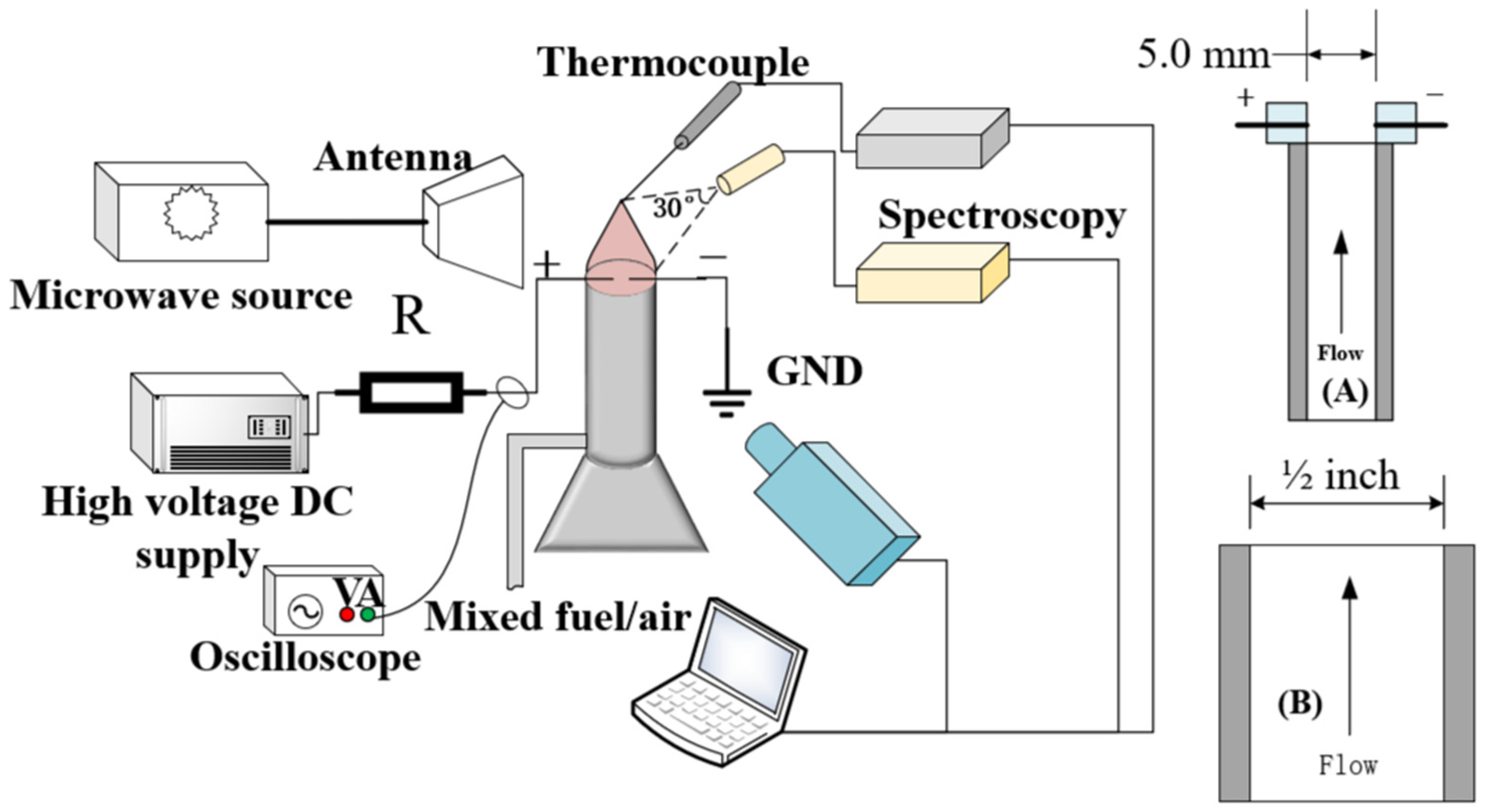

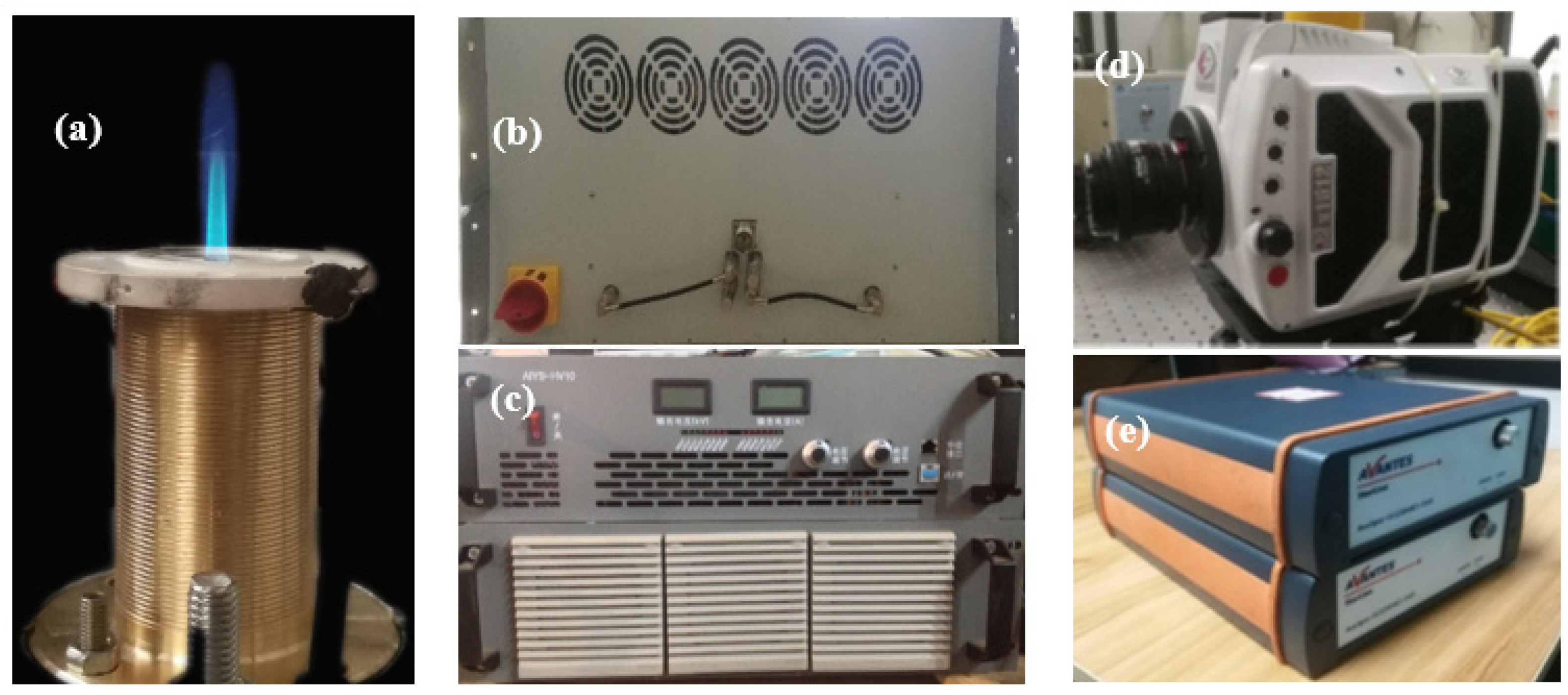

2.1. Experimental Setup on a Bunsen Burner

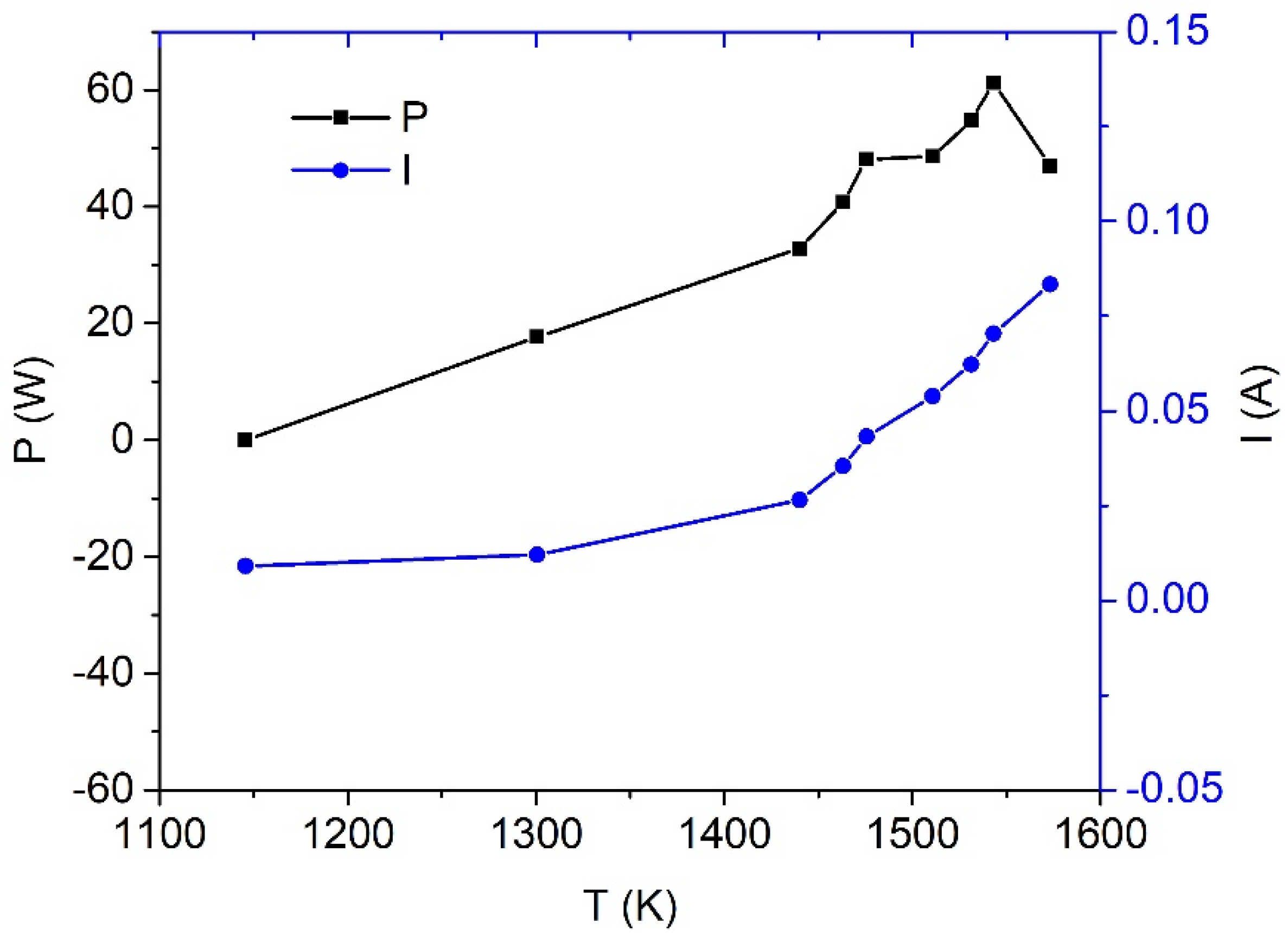

2.2. Discharge Characteristics of the DC Arc in the Bunsen Burner

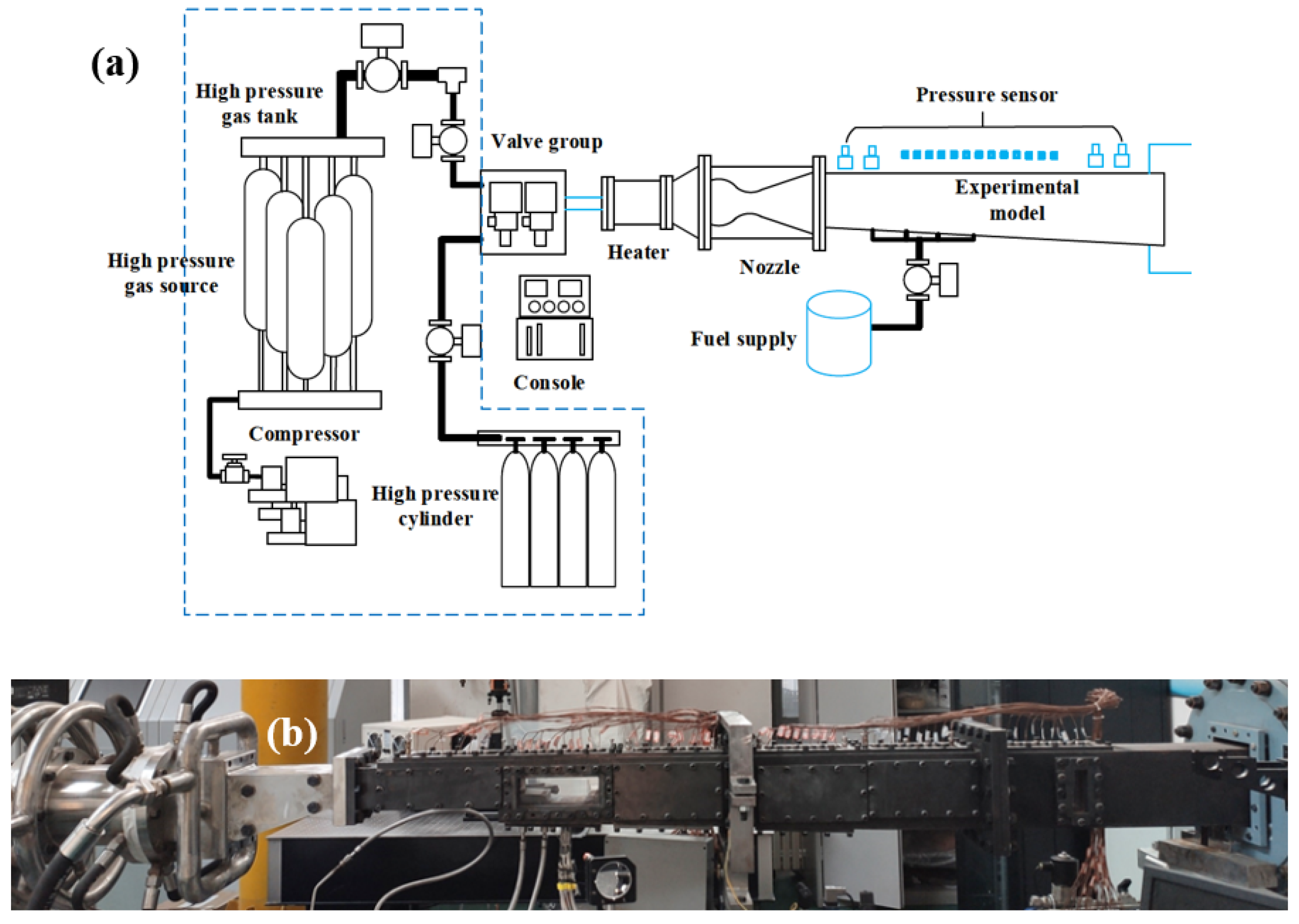

2.3. Experimental Setup of the Scramjet Experiment

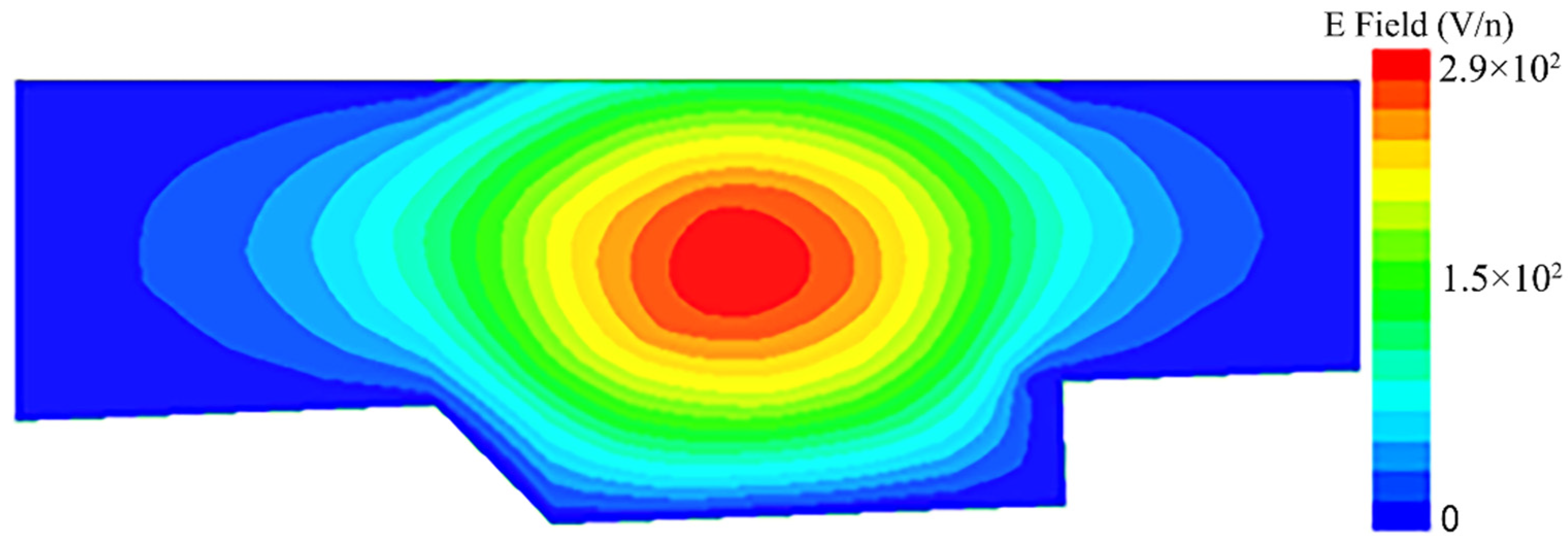

2.4. Microwave Feed Design and Intensity Calculation

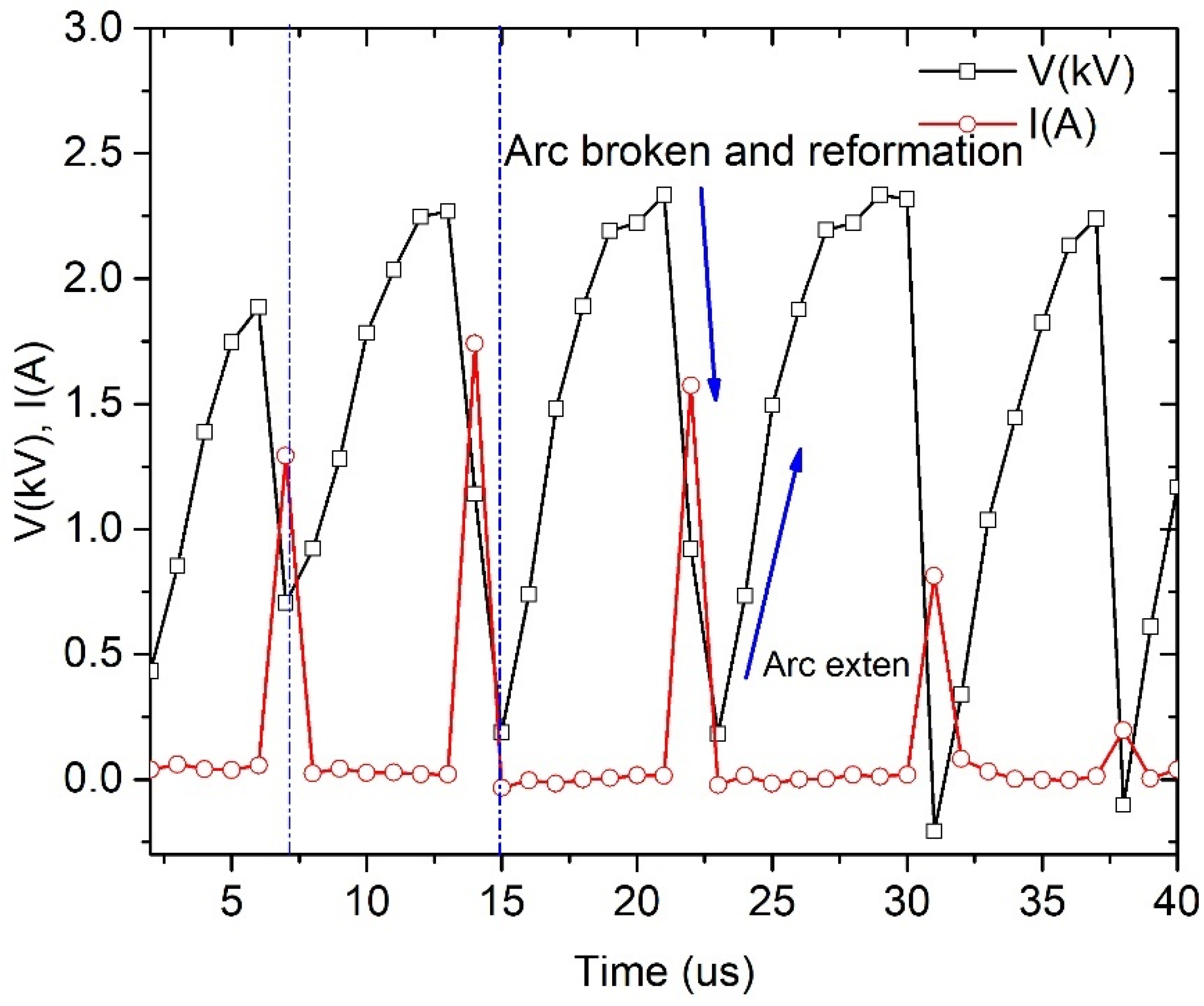

2.5. Discharge Characteristics of the Gliding Arc in Supersonic Flow

2.6. Method of OH Rotation and Vibration Temperature Analysis

3. Results

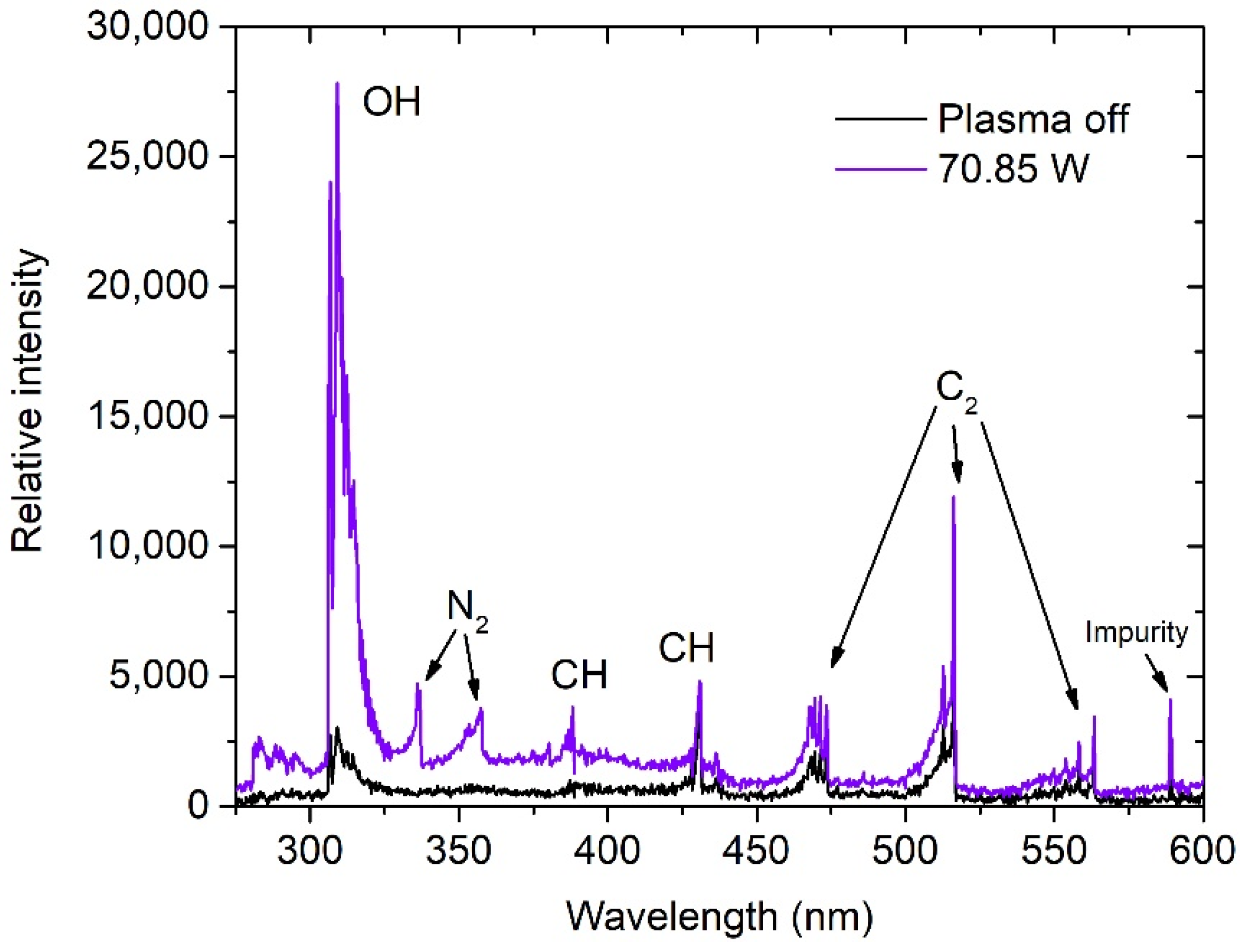

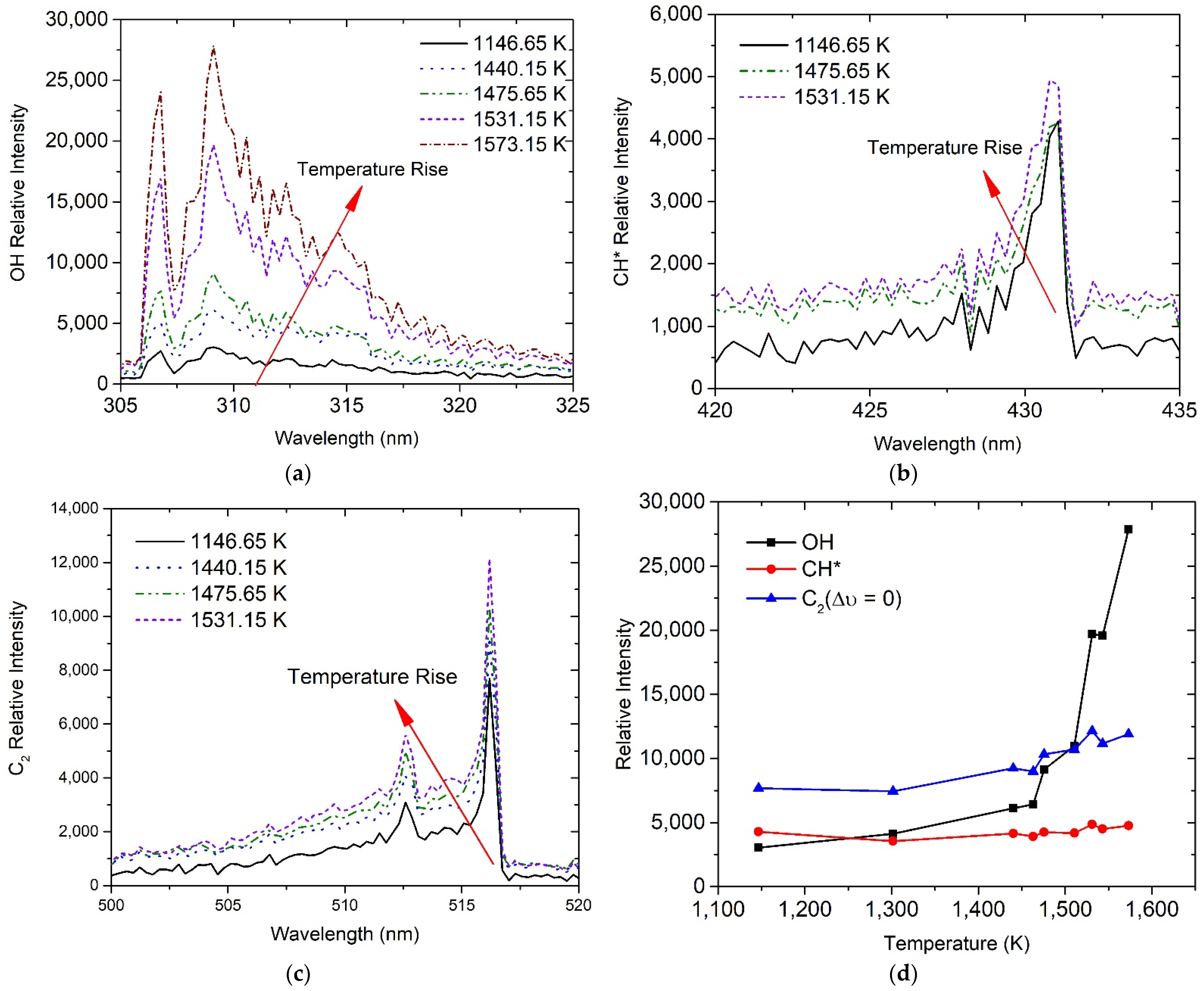

3.1. Analysis of Flame Emission Spectra Influenced by Arc Plasma

3.2. Analysis of OH Rotation and Vibration Temperature Influenced by Arc Plasma

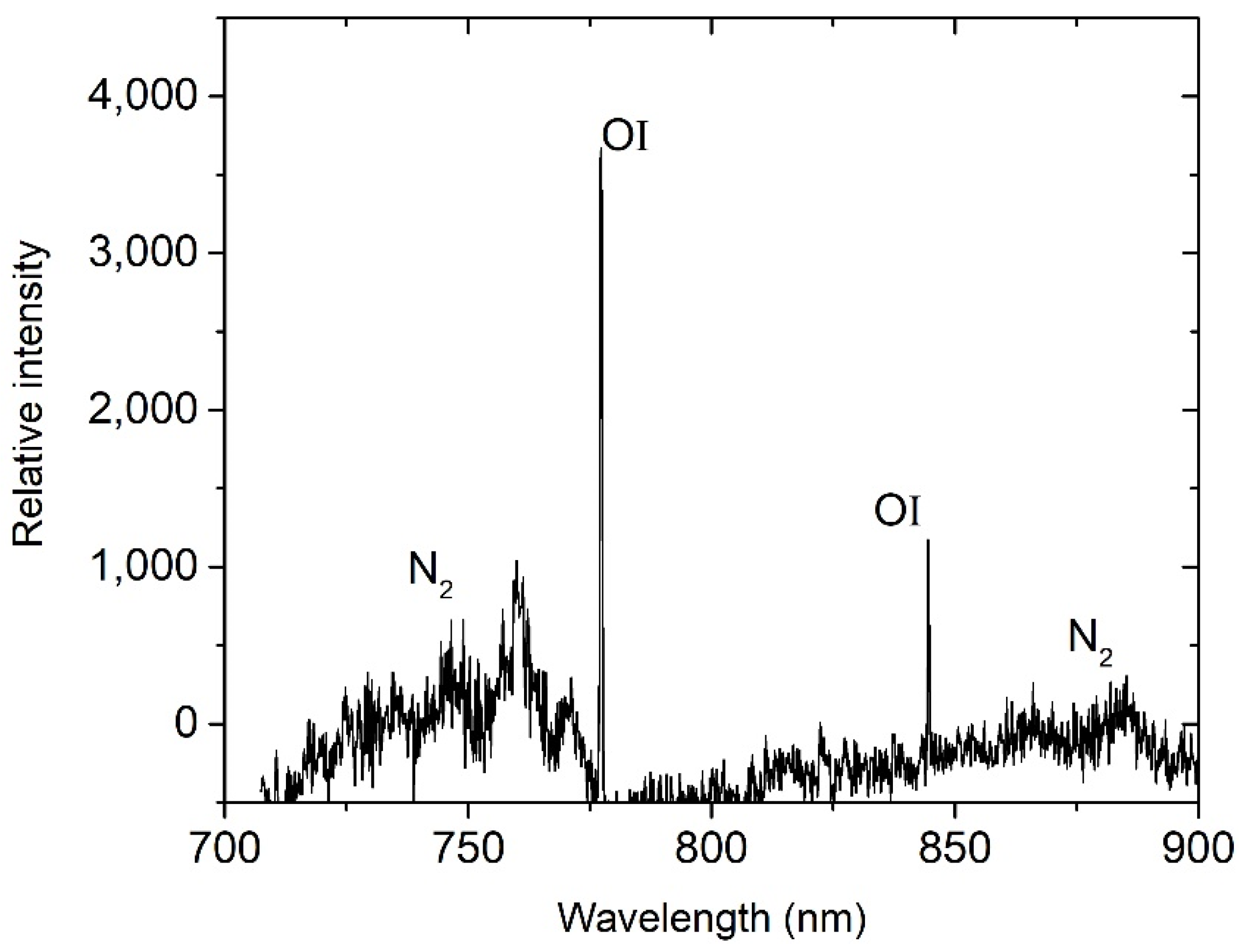

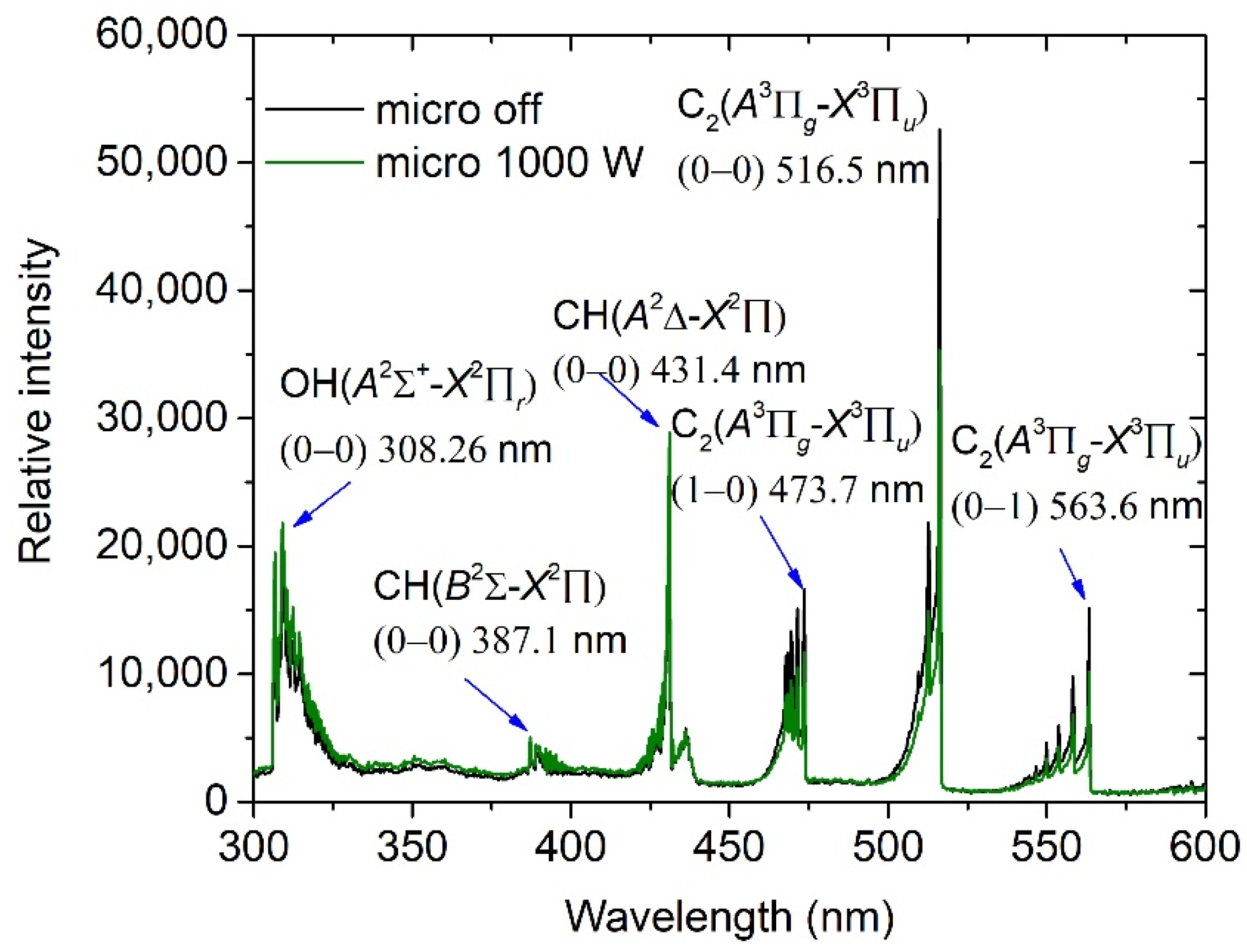

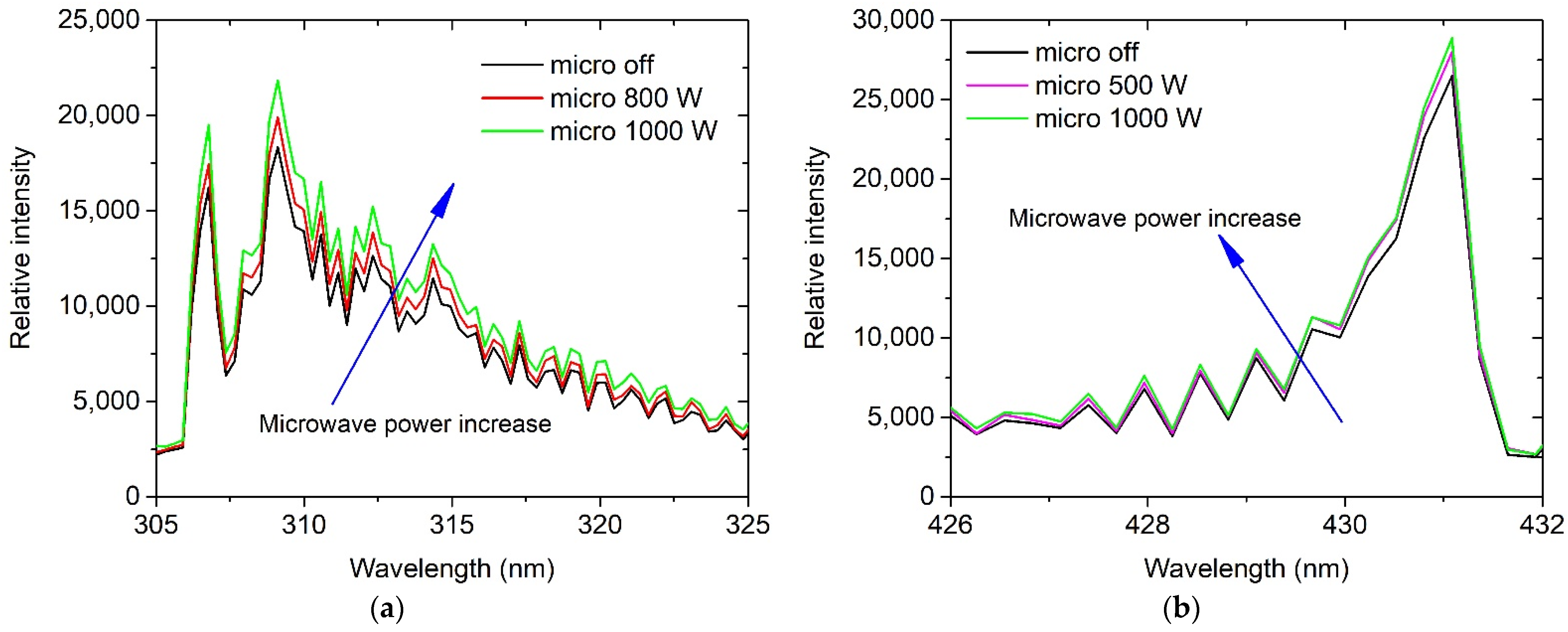

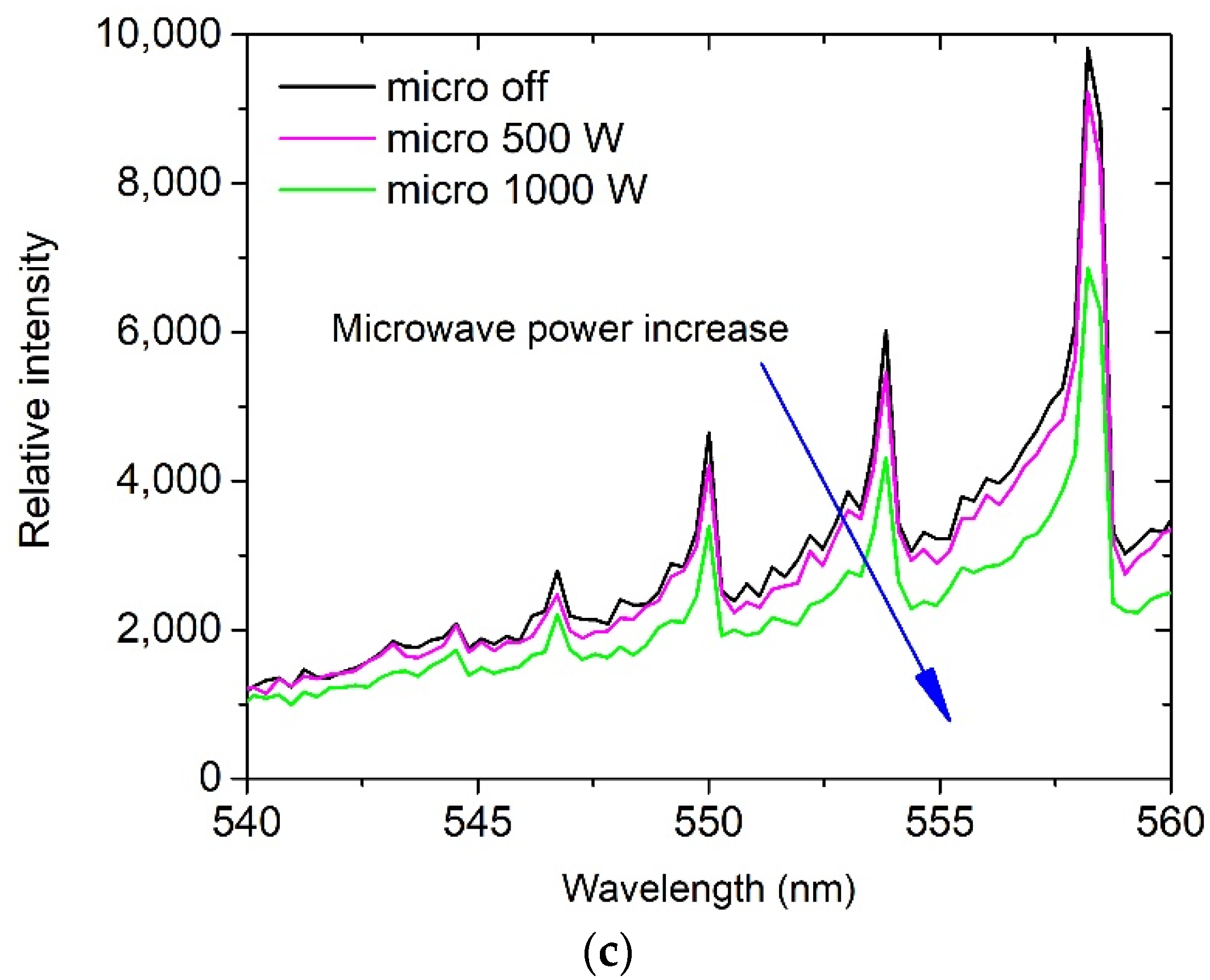

3.3. Spectral Analysis of Flames Affected by Microwaves

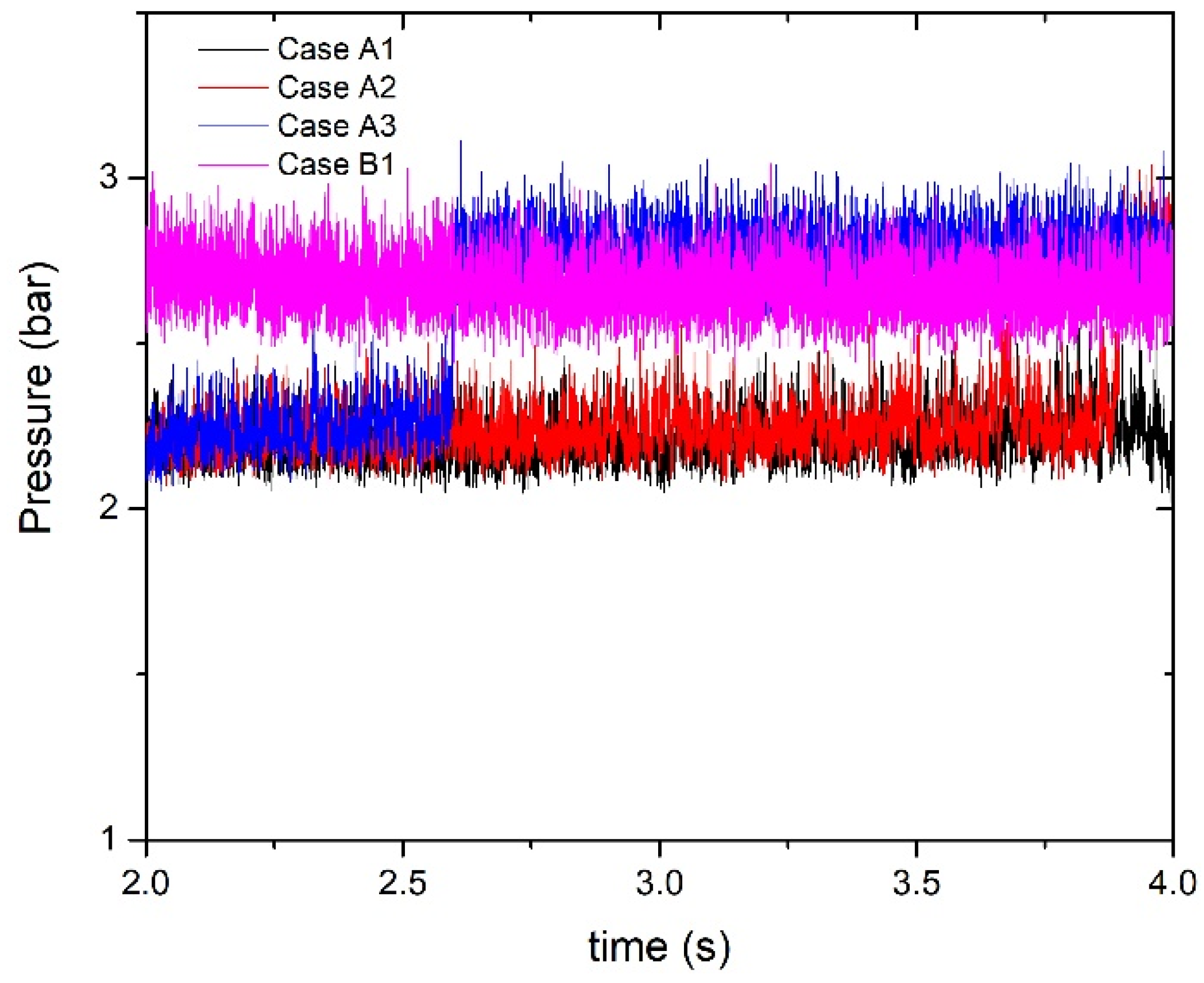

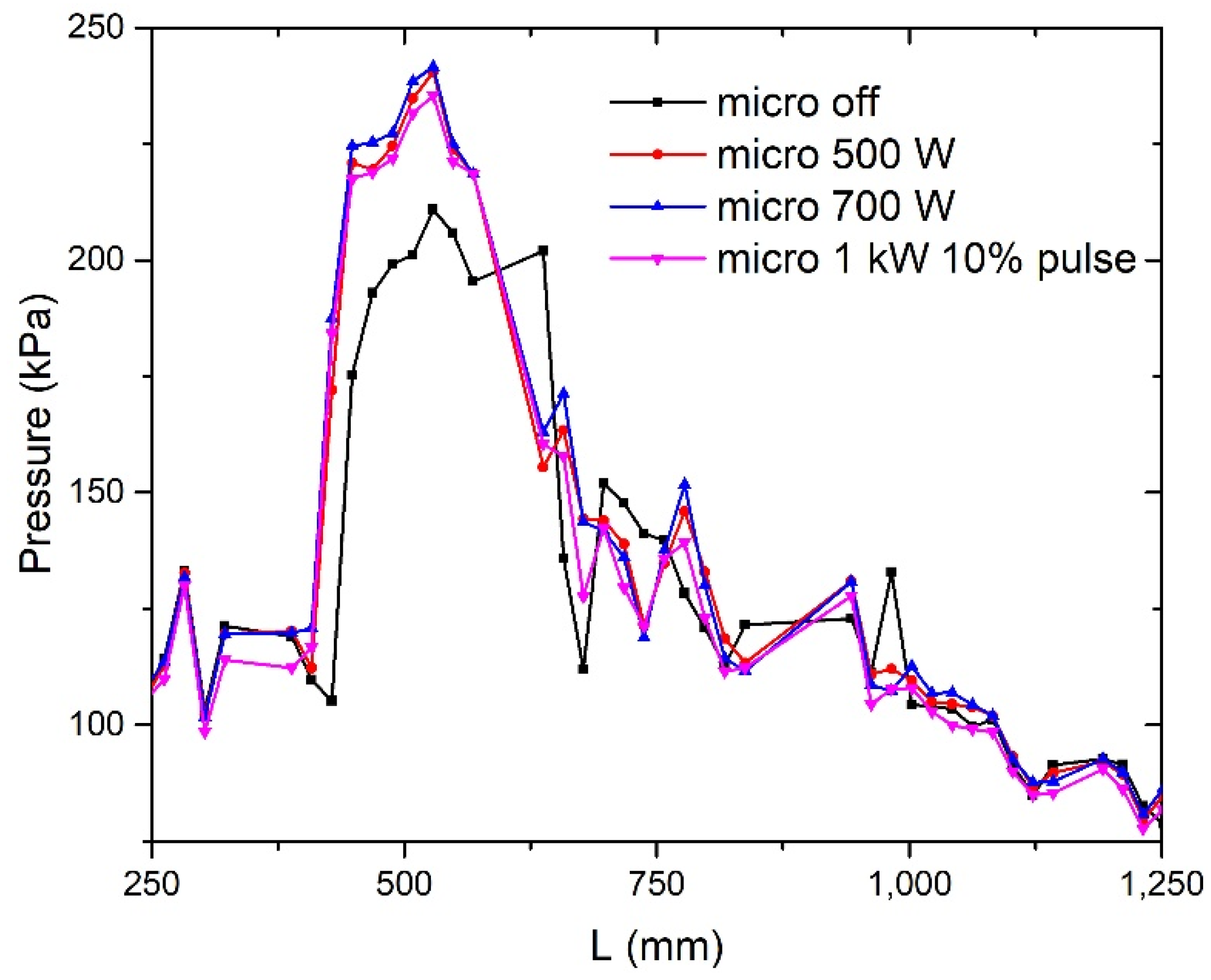

3.4. Pressure Characteristics of Scramjet Influenced by Plasma

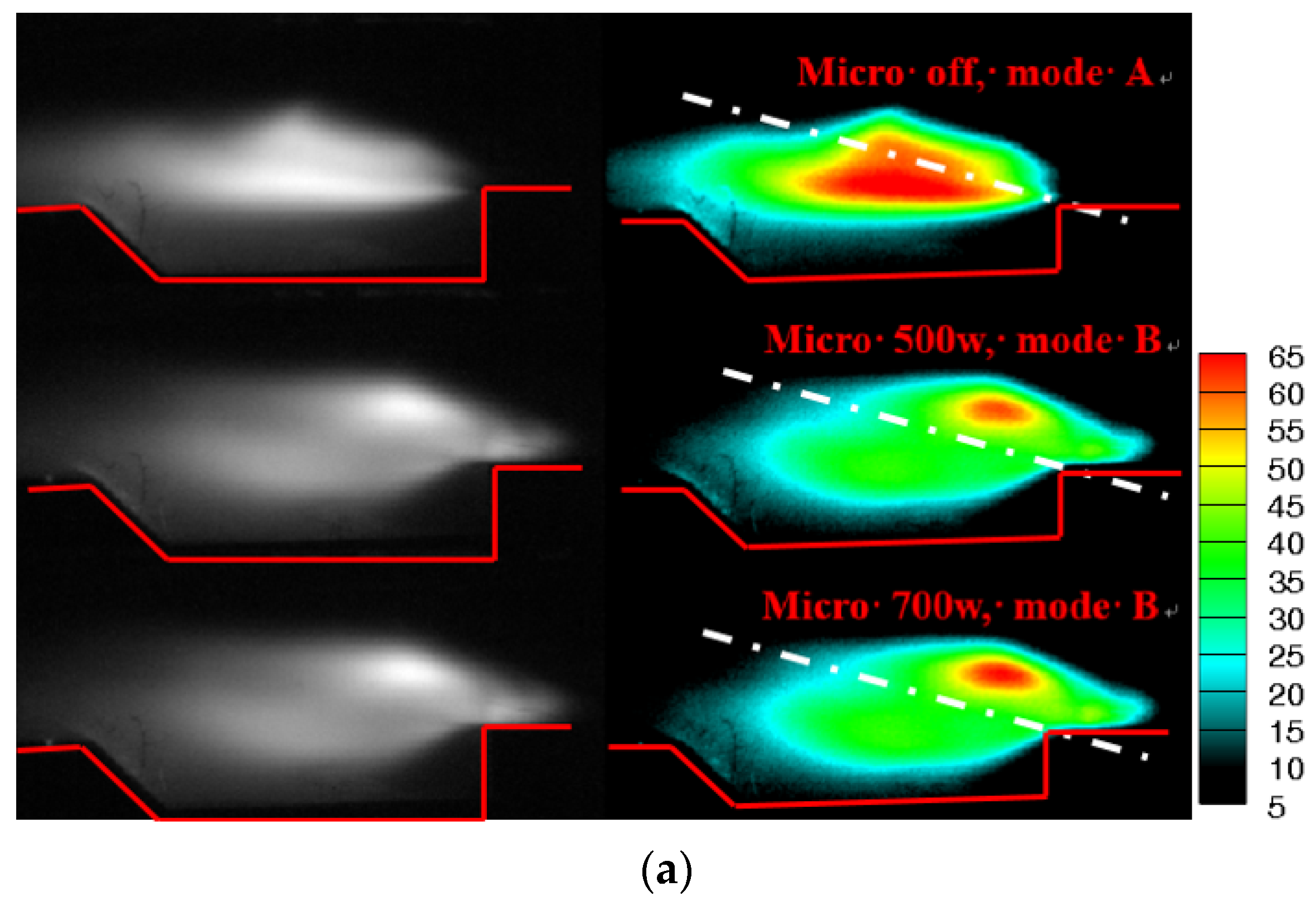

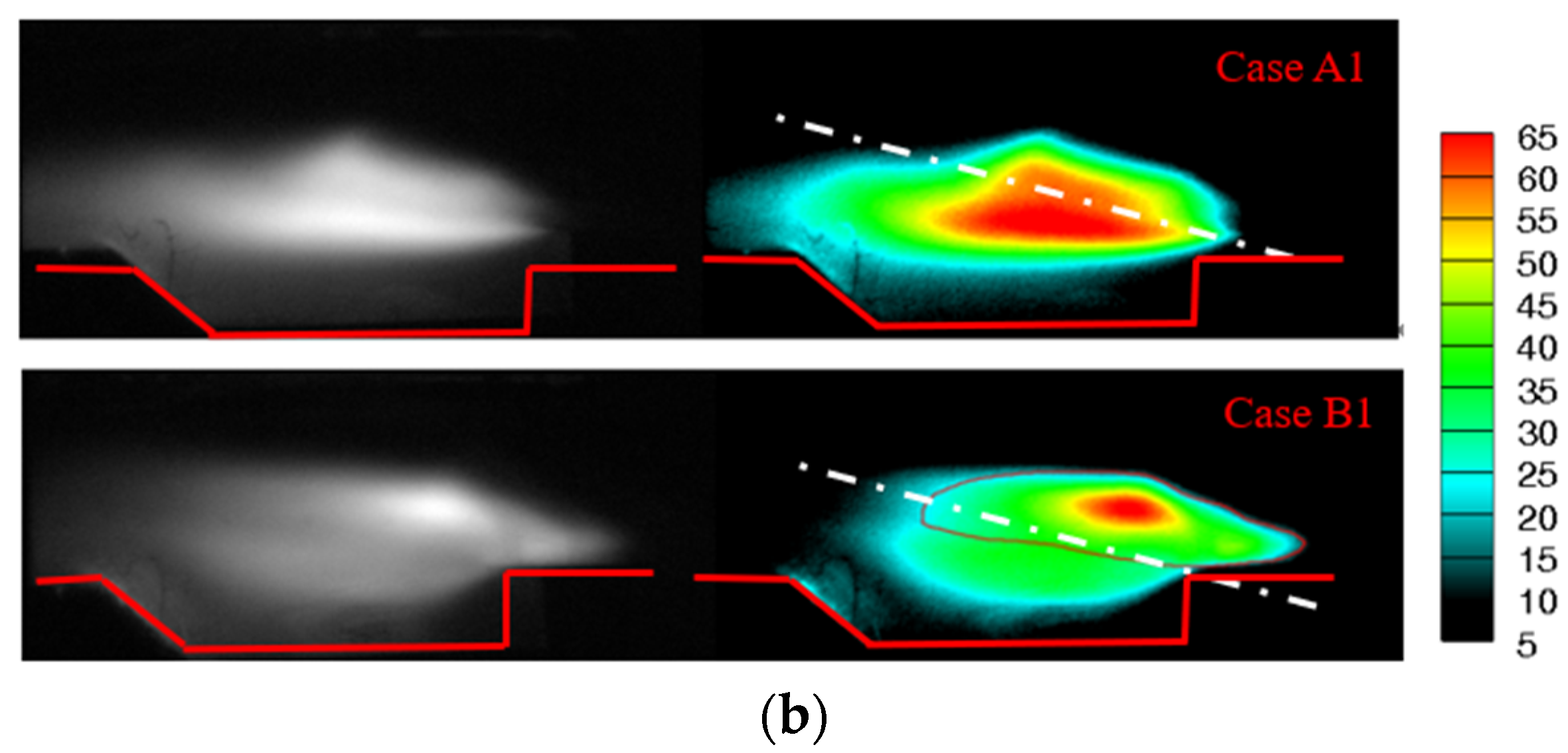

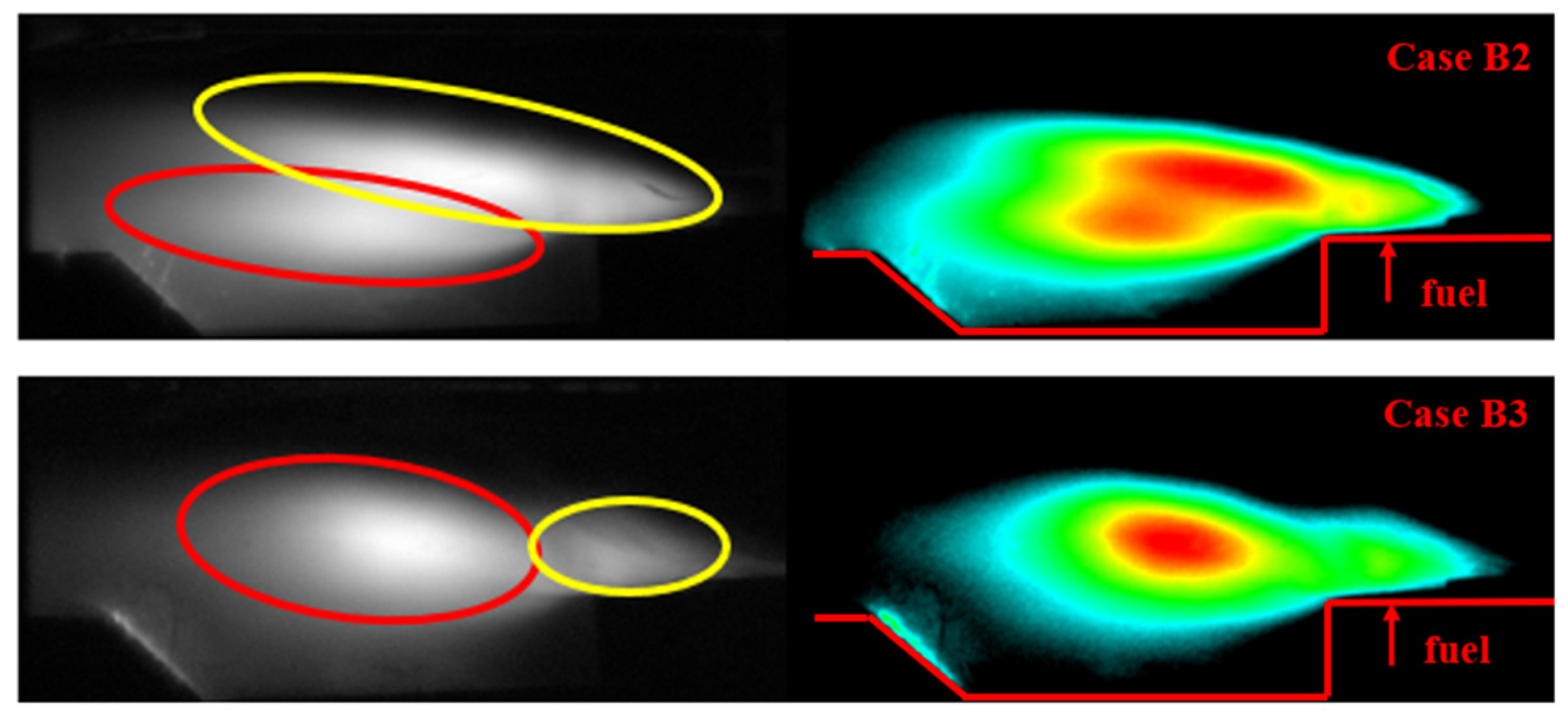

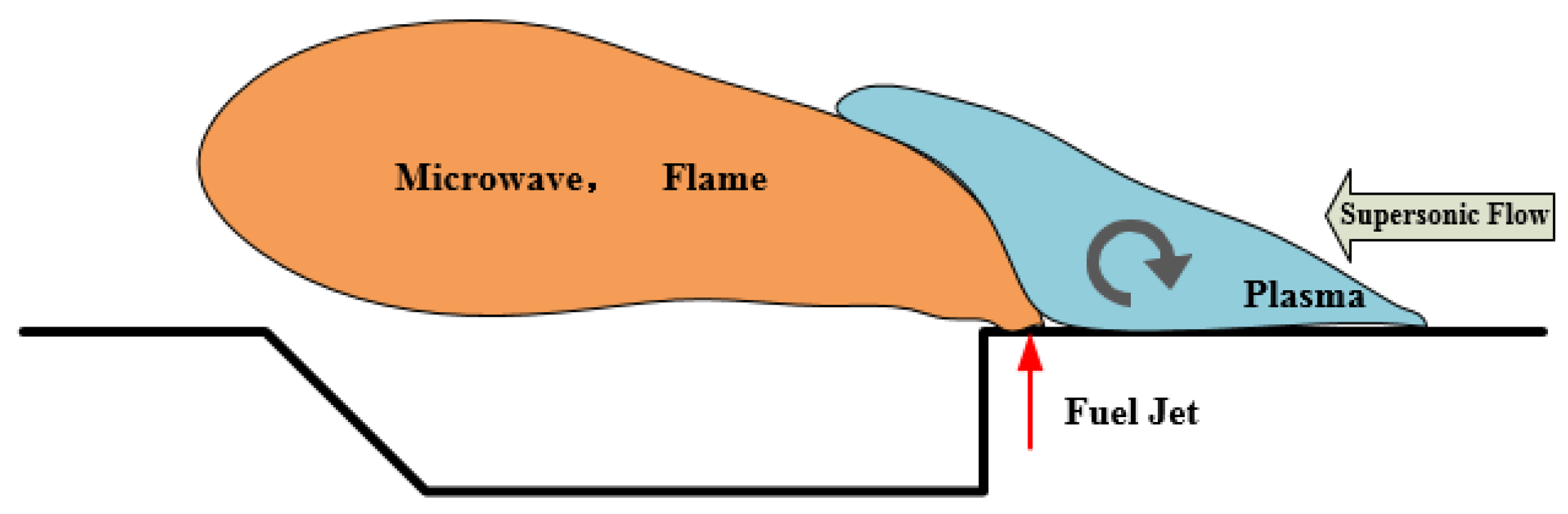

3.5. Characteristics of Average Flame Structure Affected by Plasma

4. Discussion

- The arc plasma could increase the flame temperature in the power range of 0–70.85 W, and the temperature was not proportional to the arc power but, rather, to the current;

- With the increase in the flame temperature, the concentration of OH radicals in the intermediate combustion increased ninefold at an arc power of 70.85 W, while the concentrations of CH* and C2 did not change significantly;

- The rotation temperature and vibration temperature of the OH radicals did not change with the increase in the emission intensity, which was assisted by arc plasma;

- The intensity of OH and CH* radical emission increased while the intensity of C2 emission decreased with the action of the microwaves. However, in the limited energy range of the microwaves (<800 W), there was no typical change in the intensity of the radicals. Nevertheless, when the microwave power reached a certain point (800–1000 W), the effect became obvious. Therefore, the effect of the microwaves on the flame was an integral effect, and only when a certain value was reached could the microwaves play a significant role;

- The microwave-enhanced gliding arc plasma changed the structure of the scramjet flame sharply with low power. The integral effect explained the relationship between the flame structure’s abrupt increasing position and microwave power.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Billig, F.S. Research on Supersonic Combustion. J. Propuls. Power 1993, 9, 499–514. [Google Scholar] [CrossRef]

- Ju, Y.G.; Sun, W.T. Plasma assisted combustion: Dynamics and chemistry. Prog. Energy Combust. Sci. 2015, 48, 21–83. [Google Scholar] [CrossRef]

- Reddy, P.N.; Venkatasubbaiah, K. Numerical Investigations on Development of Scramjet Combustor. J. Aerosp. Eng. 2015, 28, 04014120. [Google Scholar] [CrossRef]

- Dooley, S.; Won, S.H.; Heyne, J.; Farouk, T.I.; Ju, Y.G.; Dryer, F.L.; Kumar, K.; Hui, X.; Sung, C.J.; Wang, H.W.; et al. The experimental evaluation of a methodology for surrogate fuel formulation to emulate gas phase combustion kinetic phenomena. Combust. Flame 2012, 159, 1444–1466. [Google Scholar] [CrossRef]

- Zhu, S.-H.; Xu, X. Experimental Study on Flame Transition in a Two-Stage Struts Dual-Mode Scramjet. J. Aerosp. Eng. 2017, 30, 06017002. [Google Scholar] [CrossRef]

- Aradag, S.; Gelisli, K.A.; Yaldir, E.C. Effects of Active and Passive Control Techniques on Mach 1.5 Cavity Flow Dynamics. Int. J. Aerosp. Eng. 2017, 2017, 1–24. [Google Scholar] [CrossRef]

- Zhu, S.; Xu, X.; Ji, P. Flame Stabilization and Propagation in Dual-Mode Scramjet with Staged-Strut Injectors. AIAA J. 2017, 55, 171–179. [Google Scholar] [CrossRef]

- Yan, Z.; Shaohua, Z.; Bing, C.; Xu, X. Hysteresis of mode transition in a dual-struts based scramjet. Acta Astronaut. 2016, 128, 147–159. [Google Scholar] [CrossRef]

- Zhu, S.; Xu, X.; Yang, Q.; Jin, Y. Intermittent back-flash phenomenon of supersonic combustion in the staged-strut scramjet engine. Aerosp. Sci. Technol. 2018, 79, 70–74. [Google Scholar] [CrossRef]

- Zhang, J.; Chang, J.; Ma, J.; Zhang, C.; Bao, W. Investigation of flame establishment and stabilization mechanism in a kerosene fueled supersonic combustor equipped with a thin strut. Aerosp. Sci. Technol. 2017, 70, 152–160. [Google Scholar] [CrossRef]

- Masumoto, R.; Tomioka, S.; Kudo, K.; Murakami, A.; Kato, K.; Yamasaki, H. Experimental Study on Combustion Modes in a Supersonic Combustor. J. Propuls. Power 2011, 27, 346–355. [Google Scholar] [CrossRef]

- Meng, Y.; Gu, H.; Zhuang, J.; Sun, W.; Gao, Z.; Lian, H.; Yue, L.; Chang, X. Experimental study of mode transition characteristics of a cavity-based scramjet combustor during acceleration. Aerosp. Sci. Technol. 2019, 93, 105316. [Google Scholar] [CrossRef] [Green Version]

- Meng, Y.; Gu, H.; Zhang, X. Experimental Study of Kerosene Ignition and Flame Stabilization in a Supersonic Combustor. Int. J. Turbo Jet-Engines 2019. [Google Scholar] [CrossRef]

- Talati, H.; Aliakbari, K.; Ebrahimi-Moghadam, A.; Khoshbakht Farokhad, H.; Eskandary Nasrabad, A. Optimal design and analysis of a novel variable-length intake manifold on a four-cylinder gasoline engine. Appl. Therm. Eng. 2022, 200, 117631. [Google Scholar] [CrossRef]

- Ebrahimi-Moghadam, A.; Ildarabadi, P.; Aliakbari, K.; Fadaee, F. Sensitivity analysis and multi-objective optimization of energy consumption and thermal comfort by using interior light shelves in residential buildings. Renew. Energy 2020, 159, 736–755. [Google Scholar] [CrossRef]

- Ebrahimi-Moghadam, A.; Moghadam, A.J.; Farzaneh-Gord, M.; Aliakbari, K. Proposal and assessment of a novel combined heat and power system: Energy, exergy, environmental and economic analysis. Energy Convers. Manag. 2020, 204, 112307. [Google Scholar] [CrossRef]

- Ju, Y.; Lefkowitz, J.K.; Reuter, C.B.; Won, S.H.; Yang, X.; Yang, S.; Sun, W.; Jiang, Z.; Chen, Q. Plasma assisted low temperature combustion. Plasma Chem. Plasma Process. 2016, 36, 85–105. [Google Scholar] [CrossRef]

- Ju, Y.G.; Sun, W.T. Plasma assisted combustion: Progress, challenges, and opportunities. Combust. Flame 2015, 162, 529–532. [Google Scholar] [CrossRef]

- Starikovskiy, A.; Aleksandrov, N. Plasma-assisted ignition and combustion. Prog. Energy Combust. Sci. 2013, 39, 61–110. [Google Scholar] [CrossRef] [Green Version]

- Shahrbabaki, A.N.; Bazazzadeh, M.; Khoshkhoo, R.; Páscoa, J.C. Investigation on Supersonic Flow Control Using Nanosecond Dielectric Barrier Discharge Plasma Actuators. Int. J. Aerosp. Eng. 2021, 2021, 1–14. [Google Scholar] [CrossRef]

- Li, X.; Yang, L.; Peng, J.; Yu, X.; Liang, J.; Sun, R. Cavity ignition of liquid kerosene in supersonic flow with a laser-induced plasma. Opt. Express 2016, 24, 25362. [Google Scholar] [CrossRef] [PubMed]

- An, B.; Wang, Z.; Yang, L.; Li, X.; Zhu, J. Experimental investigation on the impacts of ignition energy and position on ignition processes in supersonic flows by laser induced plasma. Acta Astronaut. 2017, 137, 444–449. [Google Scholar] [CrossRef]

- Zhong, H.; Mao, X.; Rousso, A.C.; Patrick, C.L.; Yan, C.; Xu, W.; Chen, Q.; Wysocki, G.; Ju, Y. Kinetic study of plasma-assisted n-dodecane/O2/N2 pyrolysis and oxidation in a nanosecond-pulsed discharge. Proc. Combust. Inst. 2020, 38, 6521–6531. [Google Scholar] [CrossRef]

- Zhao, B.-b.; Chen, G.-C.; He, L.-M.; Jin, T.; Jing, B. Experimental Investigation of Plasma Jet Ignition Characteristics in Kerosene-Air Mixtures. J. Aerosp. Eng. 2020, 33, 04019113. [Google Scholar] [CrossRef]

- Li, F.; Yu, X.-L.; Tong, Y.-G.; Shen, Y.; Chen, J.; Chen, L.-H.; Chang, X.-Y. Plasma-assisted ignition for a kerosene fueled scramjet at Mach 1.8. Aerosp. Sci. Technol. 2013, 28, 72–78. [Google Scholar] [CrossRef] [Green Version]

- Cai, Z.; Zhu, J.; Sun, M.; Wang, Z. Spark-enhanced ignition and flame stabilization in an ethylene-fueled scramjet combustor with a rear-wall-expansion geometry. Exp. Therm. Fluid Sci. 2018, 92, 306–313. [Google Scholar] [CrossRef]

- Feng, R.; Li, J.; Wu, Y.; Zhu, J.; Song, X.; Li, X. Experimental investigation on gliding arc discharge plasma ignition and flame stabilization in scramjet combustor. Aerosp. Sci. Technol. 2018, 79, 145–153. [Google Scholar] [CrossRef]

- Jaggers, H.C.; Vonengel, A. Effect of electric fields on burning velocity of various flames. Combust. Flame 1971, 16, 275–285. [Google Scholar] [CrossRef]

- Shinohara, K.; Takada, N.; Sasaki, K. Enhancement of burning velocity in premixed burner flame by irradiating microwave power. J. Phys. D Appl. Phys. 2009, 42, 182008. [Google Scholar] [CrossRef]

- Stockman, E.S.; Zaidi, S.H.; Miles, R.B.; Carter, C.D.; Ryan, M.D. Measurements of combustion properties in a microwave enhanced flame. Combust. Flame 2009, 156, 1453–1461. [Google Scholar] [CrossRef]

- Michael, J.B.; Chng, T.L.; Miles, R.B. Sustained propagation of ultra-lean methane/air flames with pulsed microwave energy deposition. Combust. Flame 2013, 160, 796–807. [Google Scholar] [CrossRef]

- Ombrello, T.; Won, S.H.; Ju, Y.G.; Williams, S. Flame propagation enhancement by plasma excitation of oxygen. Part II: Effects of O2(a1Δg). Combust. Flame 2010, 157, 1916–1928. [Google Scholar] [CrossRef]

- Khodataev, K.V. Microwave discharges and possible applications in aerospace technologies. J. Propuls. Power 2008, 24, 962–972. [Google Scholar] [CrossRef]

- Baurov, A.Y.; Shibkova, L.V.; Shibkov, V.M.; Kopyl, P.V.; Surkont, O.S. External combustion of high-speed multicomponent hydrocarbon-air flow under conditions of low-temperature plasma. Mosc. Univ. Phys. Bull. 2013, 68, 293–298. [Google Scholar] [CrossRef]

- Shibkov, V.M.; Shibkova, L.V.; Karachev, A.A.; Kopyl, P.V.; Surkont, O.S. The spatial-temporal evolution of combustion under conditions of low temperature discharge plasma of liquid alcohol injected into an air stream. Mosc. Univ. Phys. Bull. 2012, 67, 138–142. [Google Scholar] [CrossRef]

- Shibkov, V.M.; Shibkova, L.V.; Gromov, V.G.; Karachev, A.A.; Konstantinovskii, R.S. Influence of surface microwave discharge on ignition of high-speed propane-air flows. High Temp. 2011, 49, 155–167. [Google Scholar] [CrossRef]

- Shibkov, V.M.; Shibkova, L.V. Parameters of the flame due to surface-microwave discharge-initiated inflammation of thin alcohol films. Tech. Phys. 2010, 55, 58–65. [Google Scholar] [CrossRef]

- Babushok, V.I.; DeLucia, F.C.; Gottfried, J.L.; Munson, C.A.; Miziolek, A.W. Double pulse laser ablation and plasma: Laser induced breakdown spectroscopy signal enhancement. Spectrochim. Acta Part B At. Spectrosc. 2006, 61, 999–1014. [Google Scholar] [CrossRef]

- Michael, J.B.; Dogariu, A.; Shneider, M.N.; Miles, R.B. Subcritical microwave coupling to femtosecond and picosecond laser ionization for localized, multipoint ignition of methane/air mixtures. J. Appl. Phys. 2010, 108, 093308. [Google Scholar] [CrossRef]

- Wolk, B.; DeFilippo, A.; Chen, J.-Y.; Dibble, R.; Nishiyama, A.; Ikeda, Y. Enhancement of flame development by microwave-assisted spark ignition in constant volume combustion chamber. Combust. Flame 2013, 160, 1225–1234. [Google Scholar] [CrossRef]

- Ikeda, Y.; Nishiyama, A.; Kaneko, M. Microwave Enhanced Ignition Process for Fuel Mixture at Elevated Pressure of 1MPa. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Prlando, FL, USA, 5–8 January 2009. [Google Scholar] [CrossRef]

- ElSabbagh, M.; Kado, S.; Ikeda, Y.; Sasaki, K. Measurements of Rotational Temperature and Density of Molecular Nitrogen in Spark-Plug Assisted Atmospheric-Pressure Microwave Discharges by Rotational Raman Scattering. Jpn. J. Appl. Phys. 2011, 50, 076101. [Google Scholar] [CrossRef]

- Fridman, A.; Nester, S.; Kennedy, L.A.; Saveliev, A.; Mutaf-Yardimci, O. Gliding arc gas discharge. Prog. Energy Combust. Sci. 1999, 25, 211–231. [Google Scholar] [CrossRef]

- Sun, Z.W.; Zhu, J.J.; Li, Z.S.; Alden, M.; Leipold, F.; Salewski, M.; Kusano, Y. Optical diagnostics of a gliding arc. Opt. Express 2013, 21, 6028–6044. [Google Scholar] [CrossRef] [PubMed]

- Peng, Z.M.; Ding, Y.J.; Zhai, X.D.; Yang, Q.S.; Jiang, Z.L. Spectral Characteristics of CN Radical (B→X) and Its Application in Determination of Rotational and Vibrational Temperatures of Plasma. Chin. Phys. Lett. 2011, 28, 044703. [Google Scholar] [CrossRef] [Green Version]

- Fridman, A.A. Plasma Chemistry; Cambridge University Press: Cambridge, NY, USA, 2008; p. 978. [Google Scholar]

- Rao, X.; Hemawan, K.; Wichman, I.; Carter, C.; Grotjohn, T.; Asmussen, J.; Lee, T. Combustion dynamics for energetically enhanced flames using direct microwave energy coupling. Proc. Combust. Inst. 2011, 33, 3233–3240. [Google Scholar] [CrossRef]

| Case | C2H4 Flow (L/min) | Air Flow (L/min) | Equivalence Ratio | Arc Power (W) |

|---|---|---|---|---|

| HV | 0.05 | 7.2 | 1 | off |

| 32.85 | ||||

| 37.93 | ||||

| 42.89 | ||||

| 49.52 | ||||

| 56.27 | ||||

| 70.85 |

| Case | Flow Velocity (m/s) | Flow (L/min) | Equivalence Ratio | Microwave Power (W) |

|---|---|---|---|---|

| MW | 0.5 | 3.80 | 0.6 | off |

| 100 | ||||

| 300 | ||||

| 500 | ||||

| 800 | ||||

| 1000 |

| Case | Equivalence Ratio | Microwave Power | Gliding Arc | ||

|---|---|---|---|---|---|

| Peak | Repeated Frequency | Duty Cycle | |||

| A1 | 0.15 | Off | Off | ||

| A2 | 0.15 | 500 W | Off | 100% | Off |

| A3 | 0.15 | 700 W | Off | 100% | Off |

| B1 | 0.15 | 1 kW | 10 kHz | 10% | 8 kV |

| B2 | 0.18 | Off | Off | ||

| B3 | 0.18 | 1 kW | 10 kHz | 10% | 8 kV |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Y.; Gu, H.; Chen, F. Influence of Plasma on the Combustion Mode in a Scramjet. Aerospace 2022, 9, 73. https://doi.org/10.3390/aerospace9020073

Meng Y, Gu H, Chen F. Influence of Plasma on the Combustion Mode in a Scramjet. Aerospace. 2022; 9(2):73. https://doi.org/10.3390/aerospace9020073

Chicago/Turabian StyleMeng, Yu, Hongbin Gu, and Fang Chen. 2022. "Influence of Plasma on the Combustion Mode in a Scramjet" Aerospace 9, no. 2: 73. https://doi.org/10.3390/aerospace9020073

APA StyleMeng, Y., Gu, H., & Chen, F. (2022). Influence of Plasma on the Combustion Mode in a Scramjet. Aerospace, 9(2), 73. https://doi.org/10.3390/aerospace9020073