Identification of Time Variations of Moving Loads Applied to Plates Resting on Viscoelastic Foundation Using a Meshfree Method

Abstract

:1. Introduction

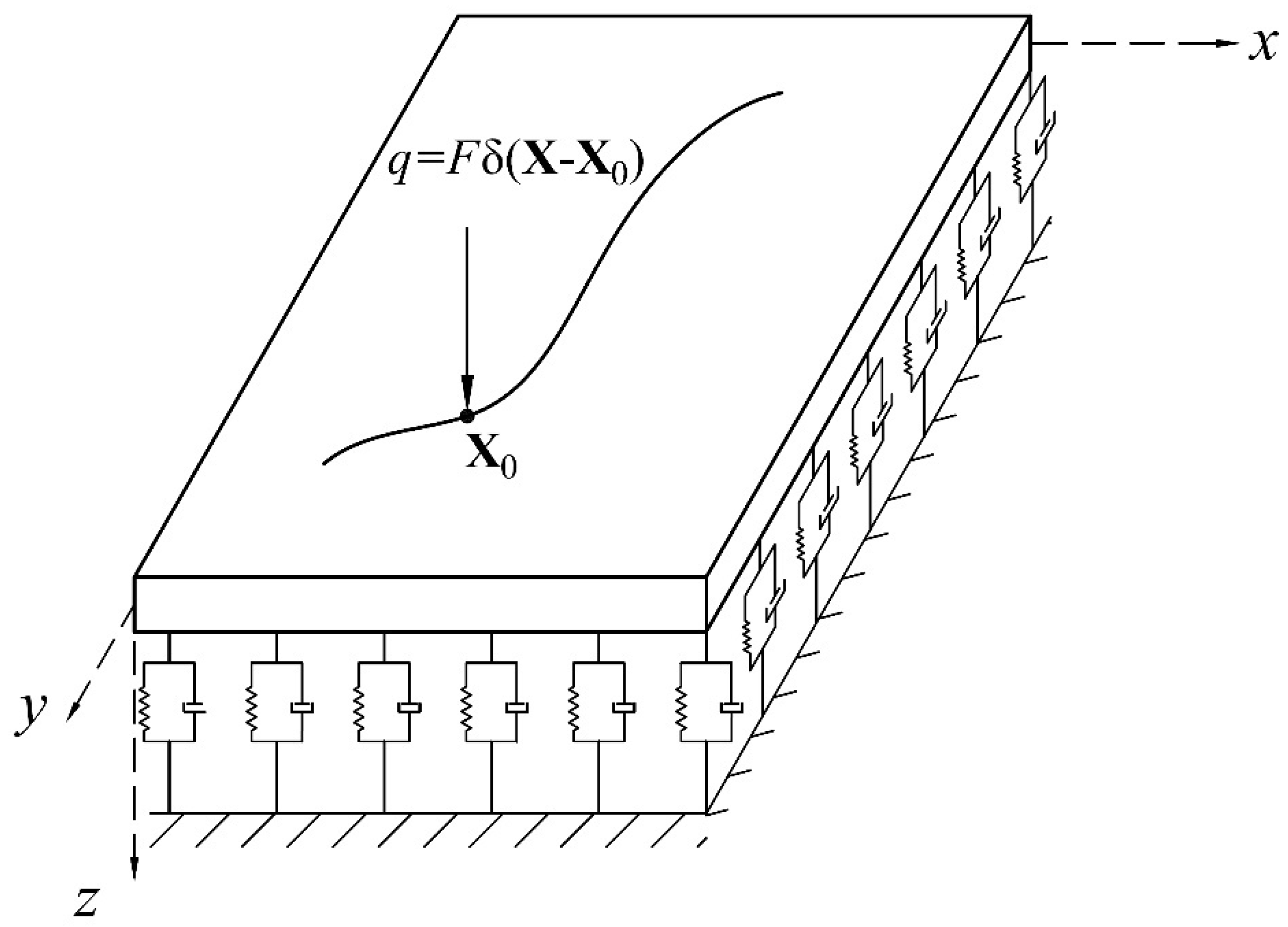

2. Meshfree Formulation of a Plate Resting on Viscoelastic Foundation under a Moving Load

3. Inverse Analysis

4. Results and Discussion

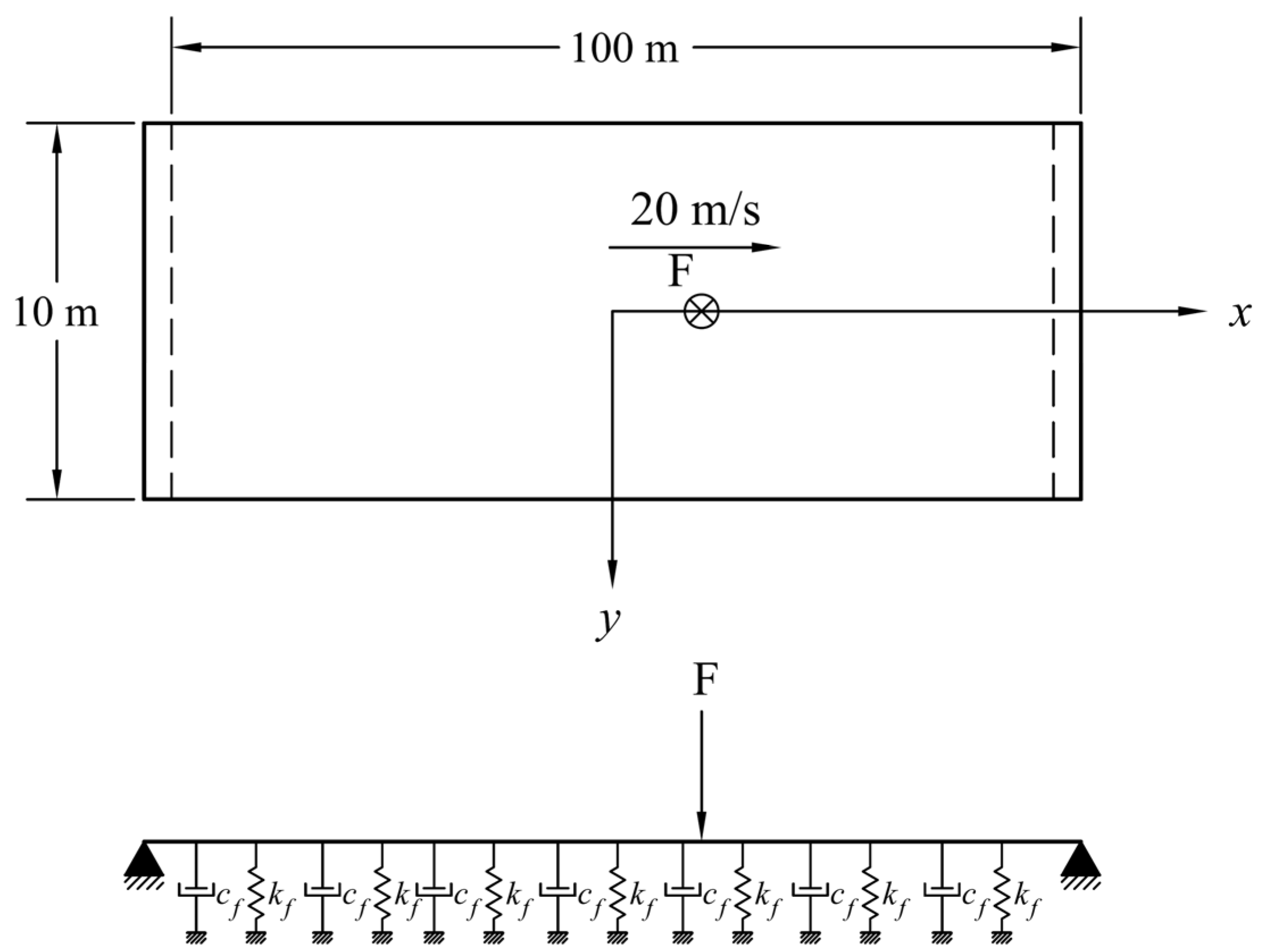

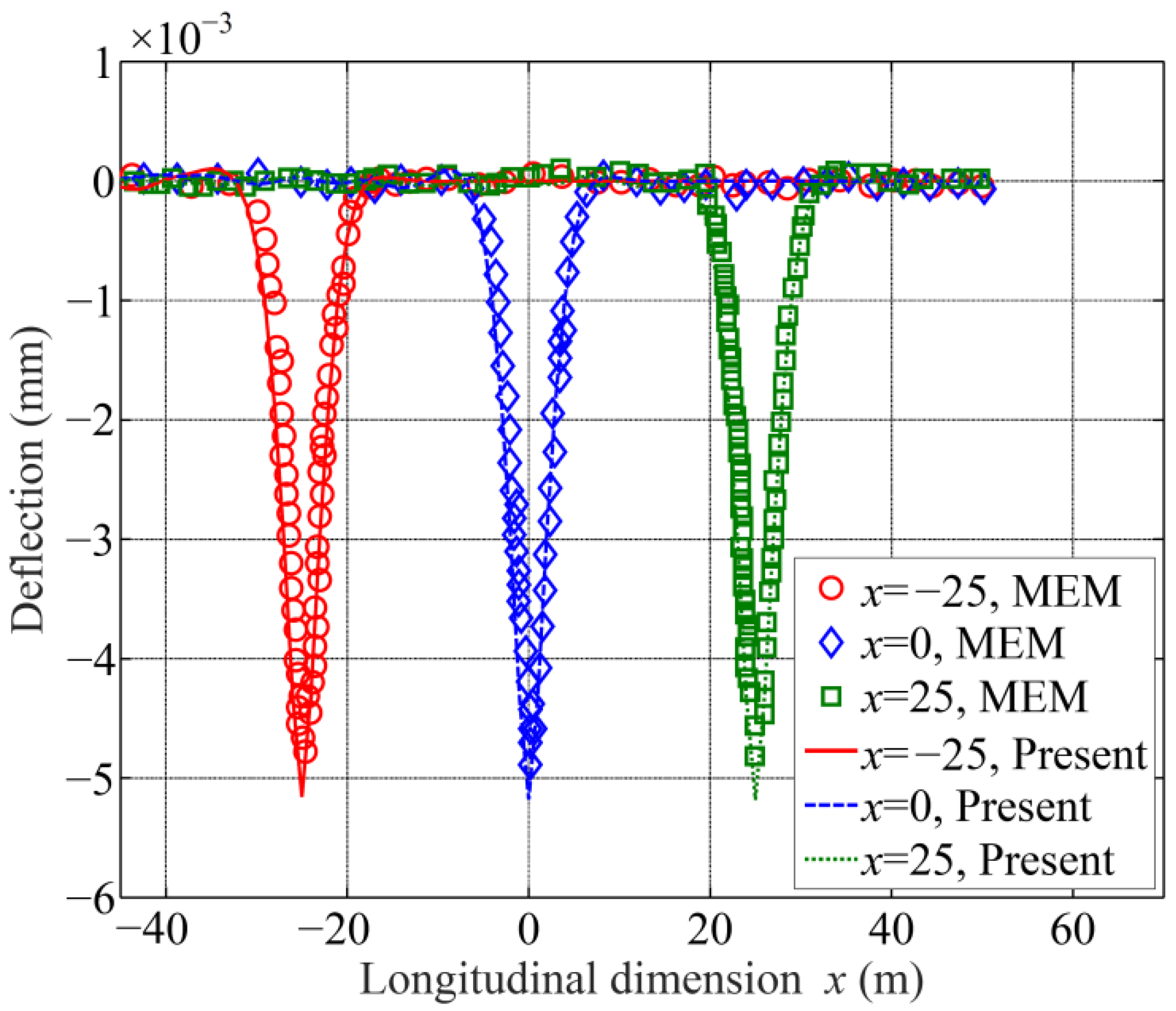

4.1. Verification of the Meshfree Method for Analysis of Moving Force Problems

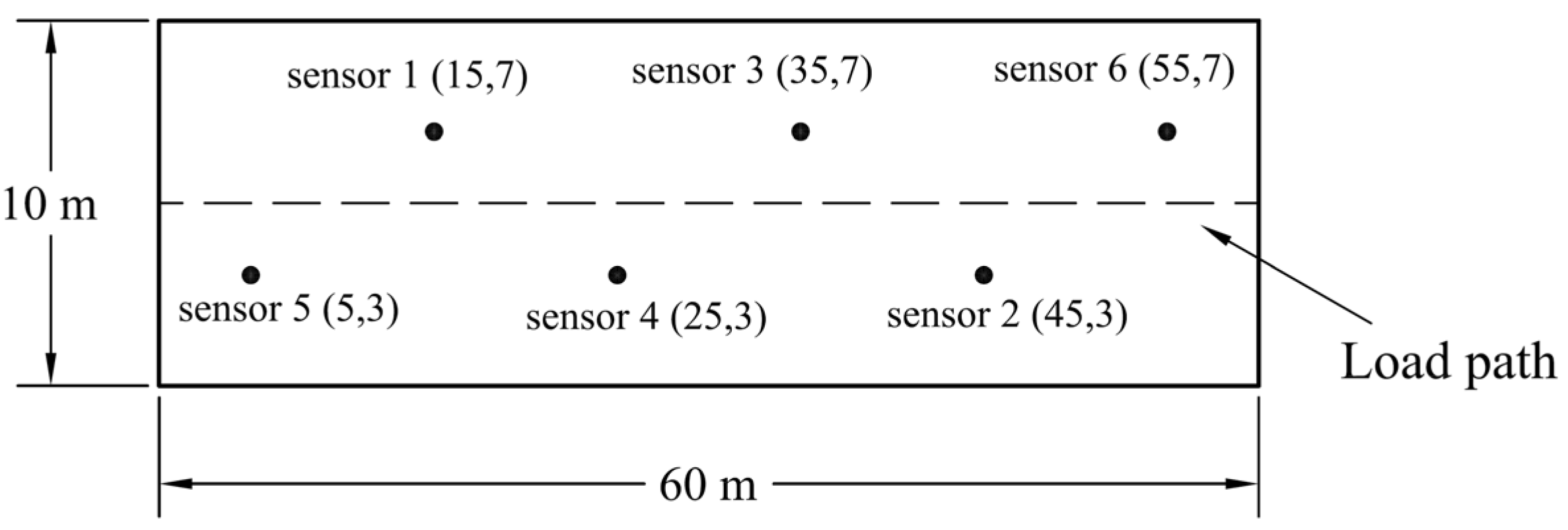

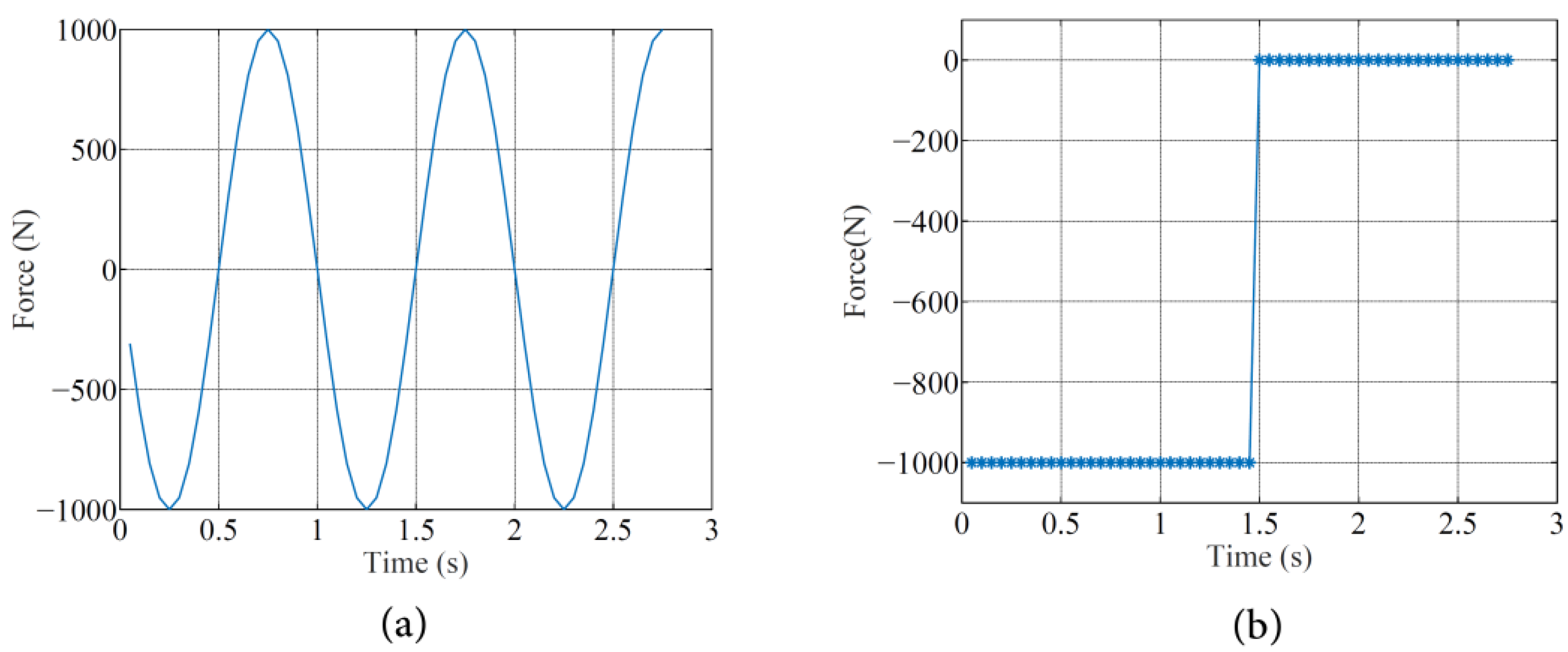

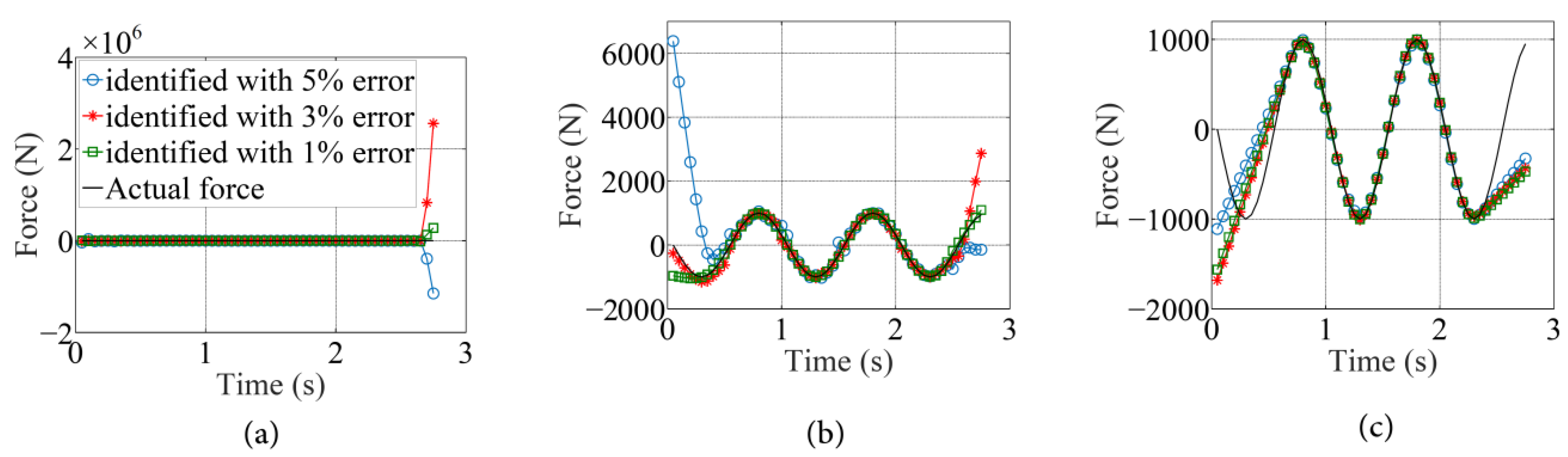

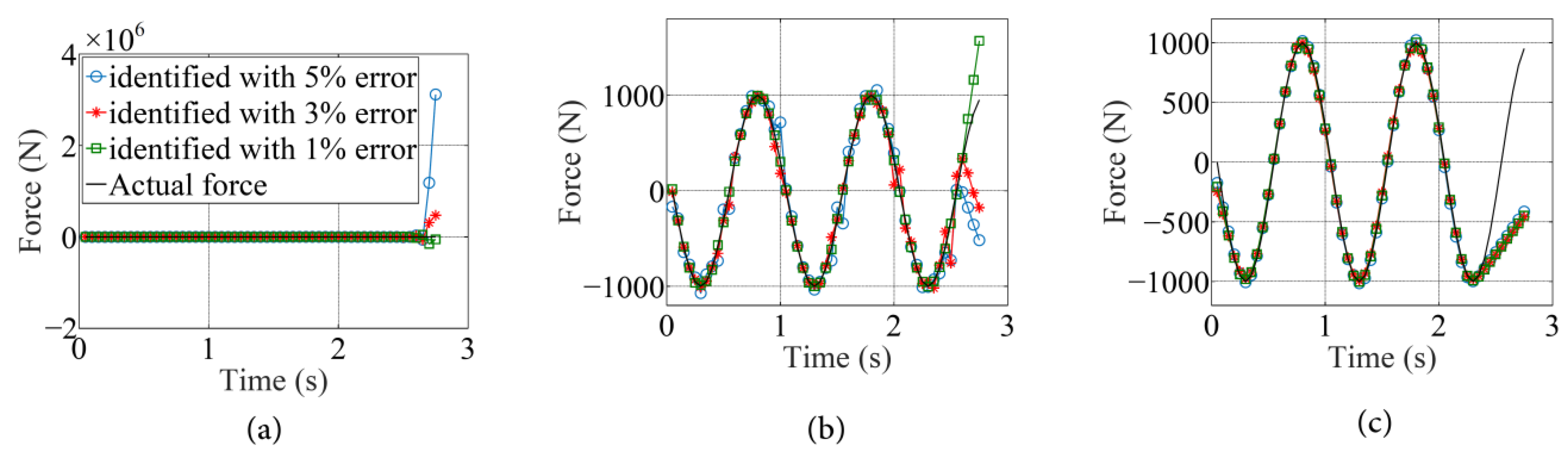

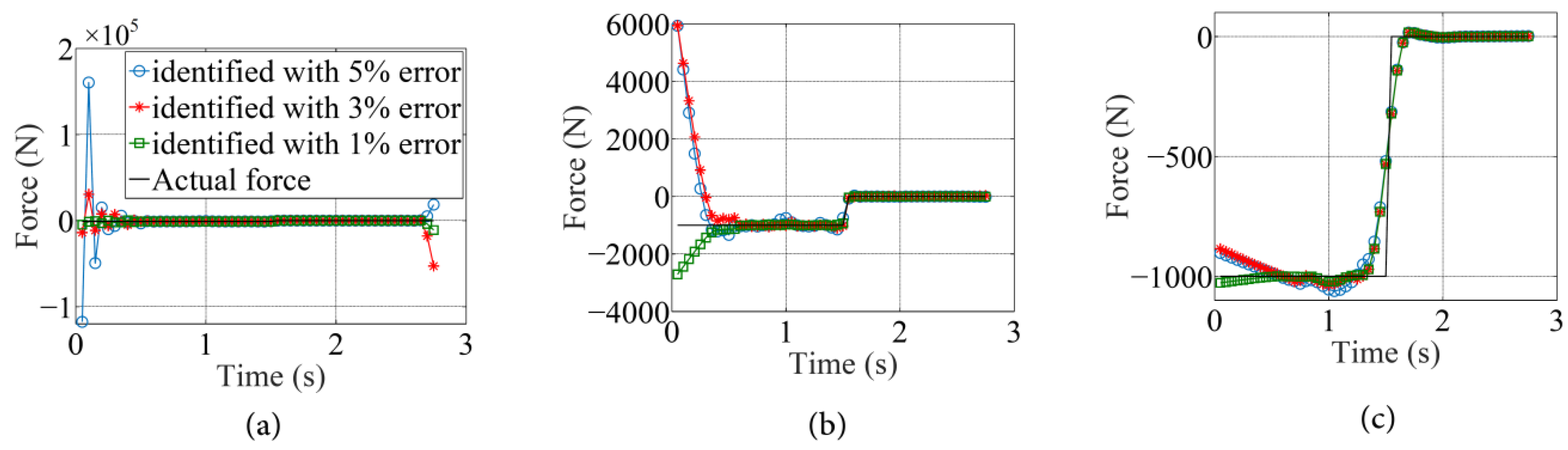

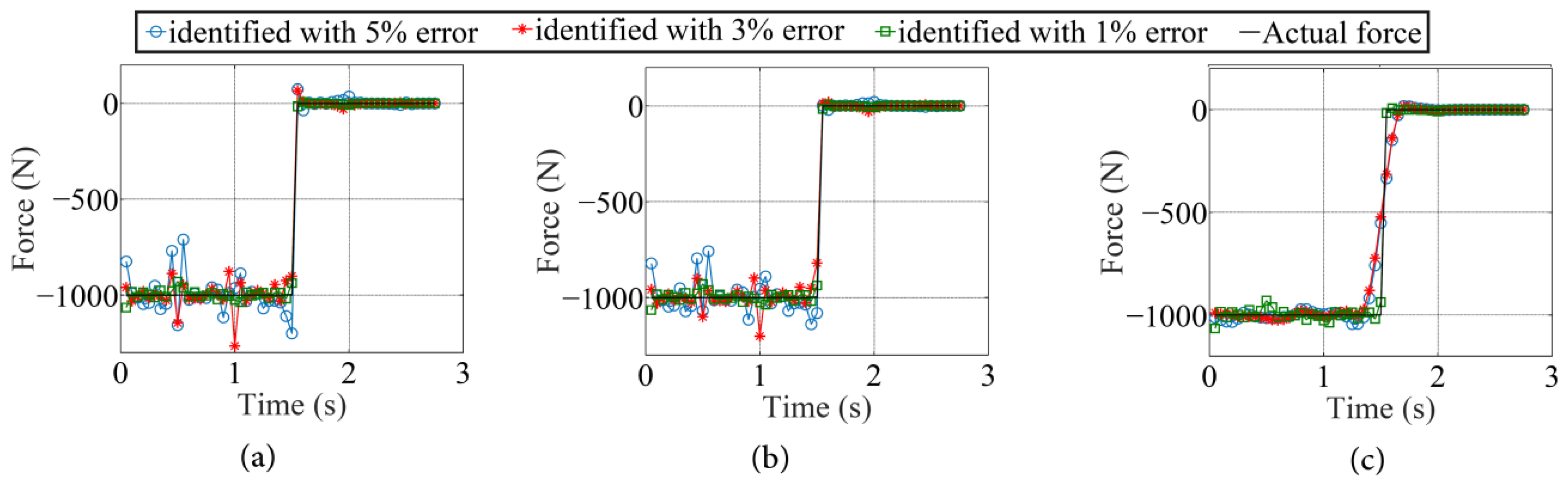

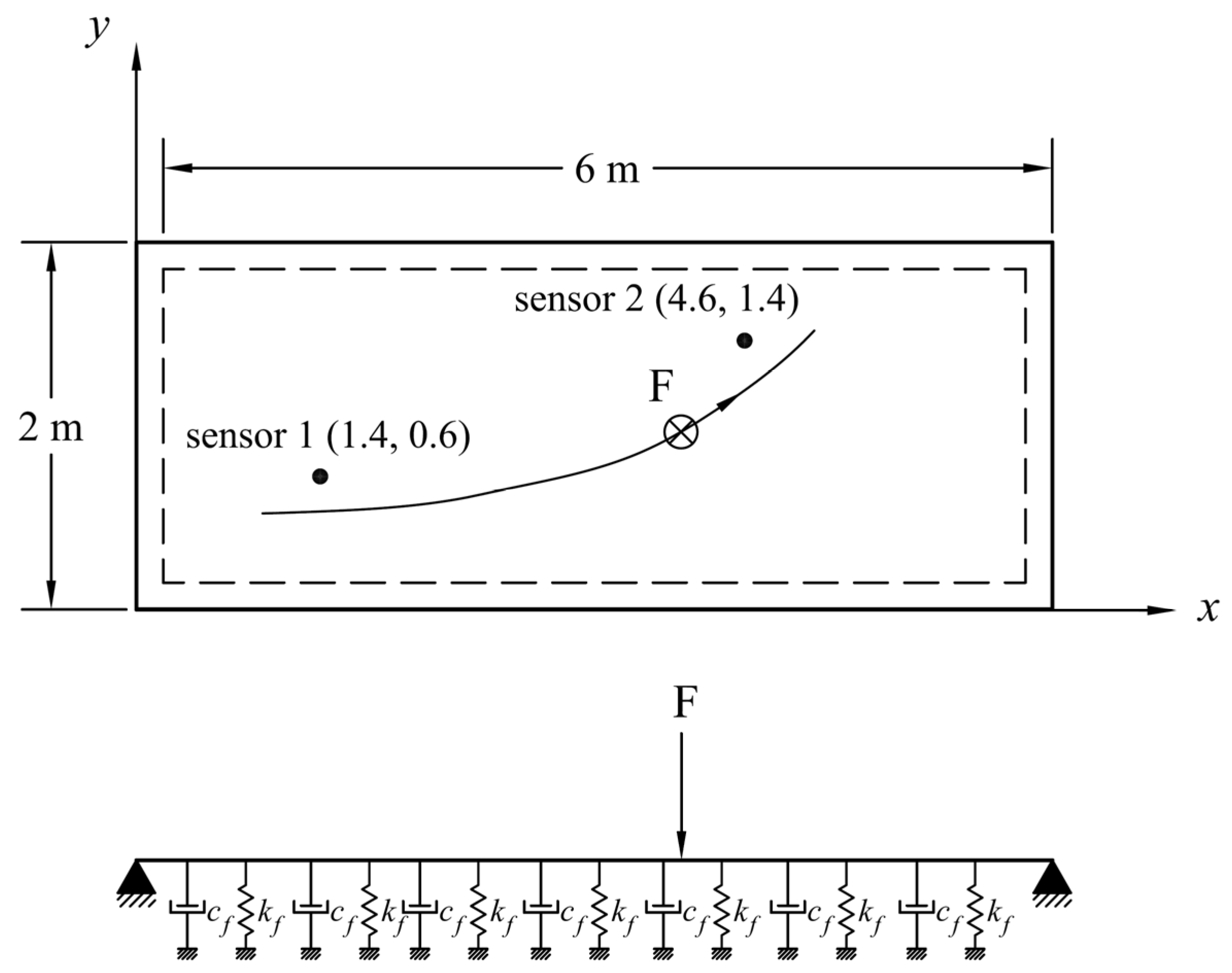

4.2. Example 1: Identification of Time Variation in a Moving Force Travelling on a Straight Path

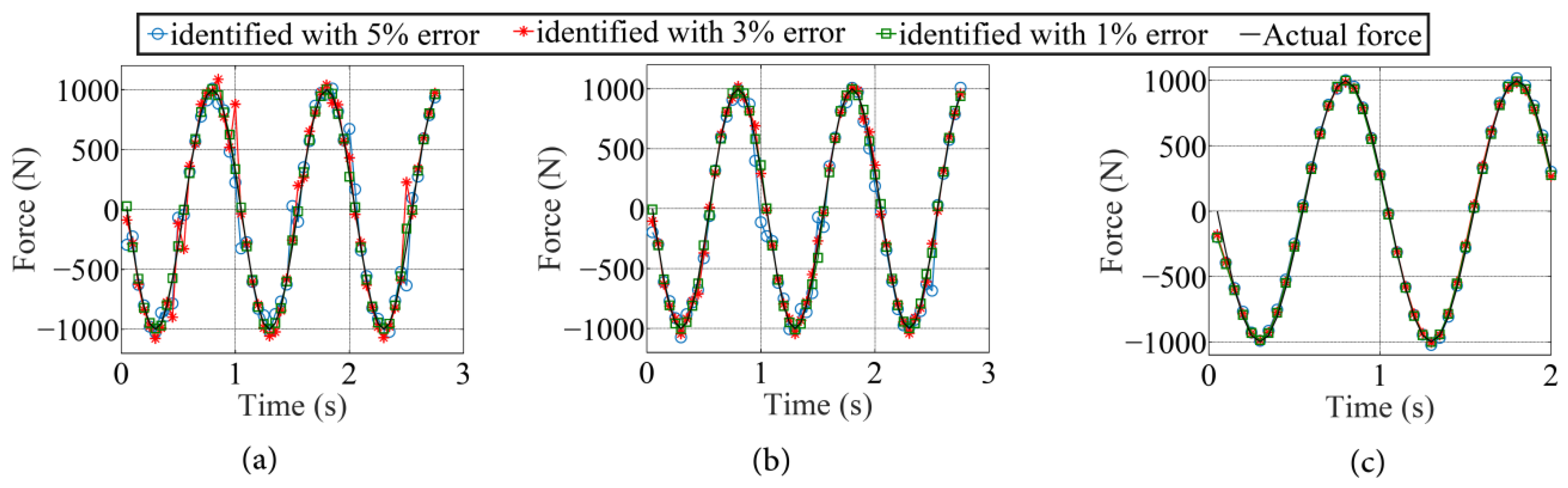

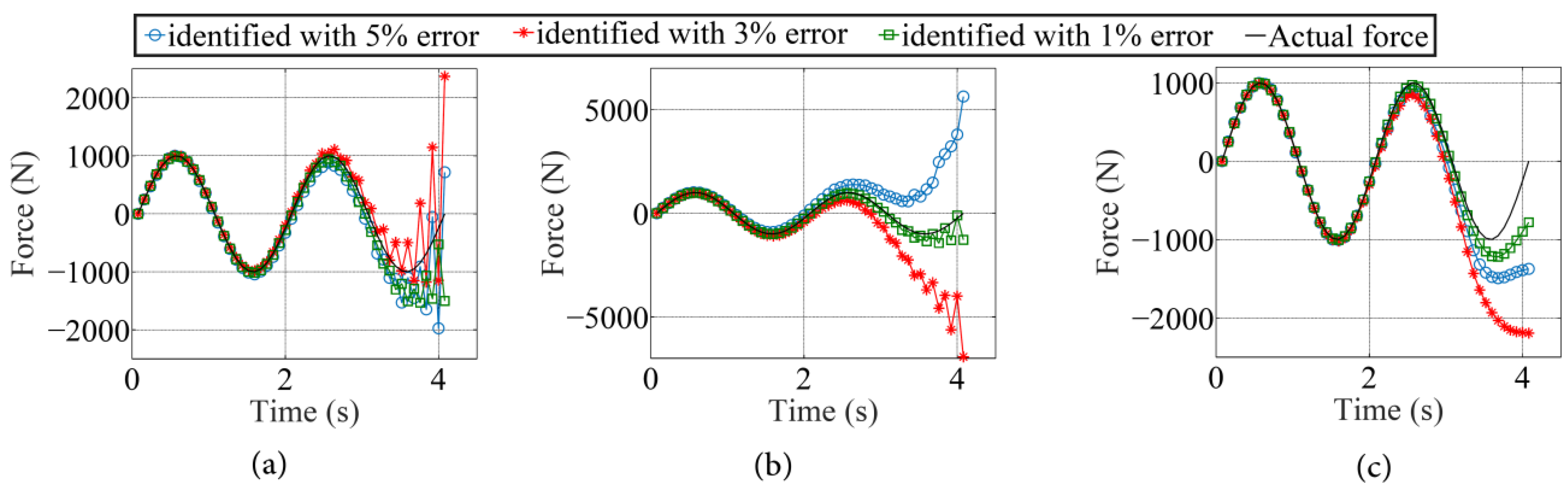

4.3. Example 2: Identification of Time Variation in a Moving Force Travelling on a Curved Path

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zenkour, A.M.; El-Shahrany, H.D. Hygrpothermal forced vibration of a viscoelastic laminated plate with magnetostrictive actuators resting on viscoelastic foundations. Int. J. Mech. Mater. Des. 2021, 17, 301–320. [Google Scholar] [CrossRef]

- Vu, T.V.; Khosravifard, A.; Hematiyan, M.R.; Bui, T.Q. Enhanced meshfree method with new correlation functions for functionally graded plates using a refined inverse sin shear deformation plate theory. Eur. J. Mech.-A/Solids 2019, 74, 160–175. [Google Scholar] [CrossRef]

- Zarei, A.; Khosravifard, A. Meshfree investigation of the vibrational behavior of pre-stressed laminated composite plates based on a variationally consistent plate model. Eng. Anal. Bound. Elem. 2020, 111, 118–133. [Google Scholar] [CrossRef]

- NasrollahBarati, A.H.; EtemadiHaghighi, A.A.; Haghighi, S.; Maghsoudpour, A. Free and Forced Vibration Analysis of Shape Memory Alloy Annular Circular Plate in Contact with Bounded Fluid. Iran. J. Sci. Technol. Trans. Mech. Eng. 2022. [Google Scholar] [CrossRef]

- Kazemi, M.; Hematiyan, M.R. An efficient inverse method for identification of the location and time history of an elastic impact load. J. Test. Eval. 2009, 37, 545–555. [Google Scholar]

- Ghajari, M.; Sharif-Khodaei, Z.; Aliabadi, M.H.; Apicella, A. Identification of impact force for smart composite stiffened panels. Smart Mater. Struct. 2013, 22, 085014. [Google Scholar] [CrossRef] [Green Version]

- Esposito, M.; Mattone, M.; Gherlone, M. Experimental Shape Sensing and Load Identification on a Stiffened Panel: A Comparative Study. Sensors 2022, 22, 1064. [Google Scholar] [CrossRef]

- Wu, J.S.; Lee, M.L.; Lai, T.S. The dynamic analysis of a flat plate under a moving load by finite element method. Int. J. Numer. Methods Eng. 1987, 24, 743–762. [Google Scholar] [CrossRef]

- Zaman, M.; Taheri, M.R.; Alvappillai, A. Dynamic response of a thick plate on viscoelastic foundation to moving loads. Int. J. Numer. Anal. Methods Geomech. 1991, 15, 627–647. [Google Scholar] [CrossRef]

- Gbadeyan, J.A.; Oni, S.T. Dynamic response to moving concentrated masses of elastic plates on a non-Winkler elastic foundation. J. Sound Vibration. 1992, 154, 343–358. [Google Scholar] [CrossRef]

- Kim, S.M.; Roesset, J.M. Moving loads on a plate on elastic foundation. J. Eng. Mech. 1998, 124, 1010–1017. [Google Scholar] [CrossRef]

- Malekzadeh, P.; Fiouz, A.R.; Razi, H. Three-dimensional dynamic analysis of laminated composite plates subjected to moving load. Compos. Struct. 2009, 90, 105–114. [Google Scholar] [CrossRef]

- Cao, T.N.T.; Luong, V.H.; Vo, H.N.; Nguyen, X.V.; Bui, V.N.; Tran, M.T.; Ang, K.K. A moving element method for the dynamic analysis of composite plate resting on a Pasternak foundation subjected to a moving load. Int. J. Comput. Methods 2019, 16, 1850124. [Google Scholar] [CrossRef]

- Praharaj, R.K.; Datta, N. Dynamic response of plates resting on a fractional viscoelastic foundation and subjected to a moving load. Mech. Based Des. Struct. Mach. 2020, 50, 2317–2332. [Google Scholar] [CrossRef]

- Zhu, X.Q.; Law, S.S. Moving load identification on multi-span continuous bridges with elastic bearings. Mech. Syst. Signal Processing 2006, 20, 1759–1782. [Google Scholar] [CrossRef]

- Vosoughi, A.R.; Anjabin, N. Dynamic moving load identification of laminated composite beams using a hybrid FE-TMDQ-GAs method. Inverse Probl. Sci. Eng. 2017, 25, 1639–1652. [Google Scholar] [CrossRef]

- Qiao, G.; Rahmatalla, S. Moving load identification on Euler-Bernoulli beams with viscoelastic boundary conditions by Tikhonov regularization. Inverse Probl. Sci. Eng. 2021, 29, 1070–1107. [Google Scholar] [CrossRef]

- Hansen, P.C. Analysis of discrete ill-posed problems by means of the L-curve. SIAM Rev. 1992, 34, 561–580. [Google Scholar] [CrossRef]

- Hematiyan, M.R.; Khosravifard, A.; Shiah, Y.C. A new stable inverse method for identification of the elastic constants of a three-dimensional generally anisotropic solid. Int. J. Solids Struct. 2017, 106, 240–250. [Google Scholar] [CrossRef]

- Dadar, N.; Hematiyan, M.R.; Khosravifard, A.; Shiah, Y.C. An inverse meshfree thermoelastic analysis for identification of temperature-dependent thermal and mechanical material properties. J. Therm. Stress. 2020, 43, 1165–1188. [Google Scholar] [CrossRef]

- Zhu, X.Q.; Law, S.S. Identification of moving loads on an orthotropic plate. J. Vib. Acoust. 2001, 123, 238–244. [Google Scholar] [CrossRef]

- Law, S.S.; Bu, J.Q.; Zhu, X.Q.; Chan, S.L. Moving load identification on a simply supported orthotropic plate. Int. J. Mech. Sci. 2007, 49, 1262–1275. [Google Scholar] [CrossRef]

- Zhang, W.; Yu, L. Bidirectional Moving Force Identification on an Orthotropic Rectangular Plate. In Advanced Materials Research; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2012; Volume 378, pp. 171–175. [Google Scholar]

- Liu, G.R.; Gu, Y.T. An Introduction to Meshfree Methods and Their Programming; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Vu, T.V.; Khosravifard, A.; Hematiyan, M.R.; Bui, T.Q. A new refined simple TSDT-based effective meshfree method for analysis of through-thickness FG plates. Appl. Math. Model. 2018, 57, 514–534. [Google Scholar] [CrossRef]

- Zarei, A.; Khosravifard, A. A meshfree method for static and buckling analysis of shear deformable composite laminates considering continuity of interlaminar transverse shearing stresses. Compos. Struct. 2019, 209, 206–218. [Google Scholar] [CrossRef]

- Wang, C.M.; Reddy, J.N.; Lee, K.H. Shear Deformation Beams and Plates; Elsevier: London, UK, 2000. [Google Scholar]

- Liu, G.R. Meshfree Methods, Moving beyond the Finite Element Method; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Reddy, J.N. Energy principles and variational methods in applied mechanics; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- He, J.H. Hamilton’s principle for dynamical elasticity. Appl. Math. Lett. 2017, 72, 65–69. [Google Scholar] [CrossRef]

- Arsenin, V.Y.; Tikhonov, A.N. Solutions of Ill-Posed Problems; John Wiley & Sons: Hoboken, NJ, USA, 1977. [Google Scholar]

- Jamshidi, B.; Hematiyan, M.R.; Mahzoon, M.; Shiah, Y.C. Load identification for a viscoelastic solid by an accurate meshfree sensitivity analysis. Eng. Struct. 2020, 203, 109895. [Google Scholar] [CrossRef]

- Ozisik, M.N.; Orlande, H.R.B. Inverse Heat Transfer: Fundamentals and Applications; Taylor and Francis: New York, NY, USA, 2000. [Google Scholar]

- Luong, V.H.; Cao, T.N.T.; Reddy, J.N.; Ang, K.K.; Tran, M.T.; Dai, J. Static and Dynamic Analysis of Mindlin Plates Resting on Viscoelastic foundation by using Moving Element Method. Int. J. Struct. Stab. Dyn. 2018, 18, 1850131. [Google Scholar] [CrossRef]

- Silling, S.A.; Askari, E. A meshfree method based on the peridynamic model of solid mechanics. Comput. Struct. 2005, 83, 1526–1535. [Google Scholar] [CrossRef]

- Shojaei, A.; Hermann, A.; Cyron, C.J.; Seleson, P.; Silling, S.A. A hybrid meshfree discretization to improve the numerical performance of peridynamic models. Comput. Methods Appl. Mech. Eng. 2022, 391, 114544. [Google Scholar] [CrossRef]

- Mossaiby, F.; Sheikhbahaei, P.; Shojaei, A. Multi-adaptive coupling of finite element meshes with peridynamic grids: Robust implementation and potential applications. Eng. Comput. 2022. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behradnia, S.; Khosravifard, A.; Hematiyan, M.-R.; Shiah, Y.-C. Identification of Time Variations of Moving Loads Applied to Plates Resting on Viscoelastic Foundation Using a Meshfree Method. Aerospace 2022, 9, 357. https://doi.org/10.3390/aerospace9070357

Behradnia S, Khosravifard A, Hematiyan M-R, Shiah Y-C. Identification of Time Variations of Moving Loads Applied to Plates Resting on Viscoelastic Foundation Using a Meshfree Method. Aerospace. 2022; 9(7):357. https://doi.org/10.3390/aerospace9070357

Chicago/Turabian StyleBehradnia, Sogol, Amir Khosravifard, Mohammad-Rahim Hematiyan, and Yui-Chuin Shiah. 2022. "Identification of Time Variations of Moving Loads Applied to Plates Resting on Viscoelastic Foundation Using a Meshfree Method" Aerospace 9, no. 7: 357. https://doi.org/10.3390/aerospace9070357

APA StyleBehradnia, S., Khosravifard, A., Hematiyan, M.-R., & Shiah, Y.-C. (2022). Identification of Time Variations of Moving Loads Applied to Plates Resting on Viscoelastic Foundation Using a Meshfree Method. Aerospace, 9(7), 357. https://doi.org/10.3390/aerospace9070357