Numerical Investigation on Cooling Performance of Rectangular Channels Filled with X-Shaped Truss Array Structures

Abstract

:1. Introduction

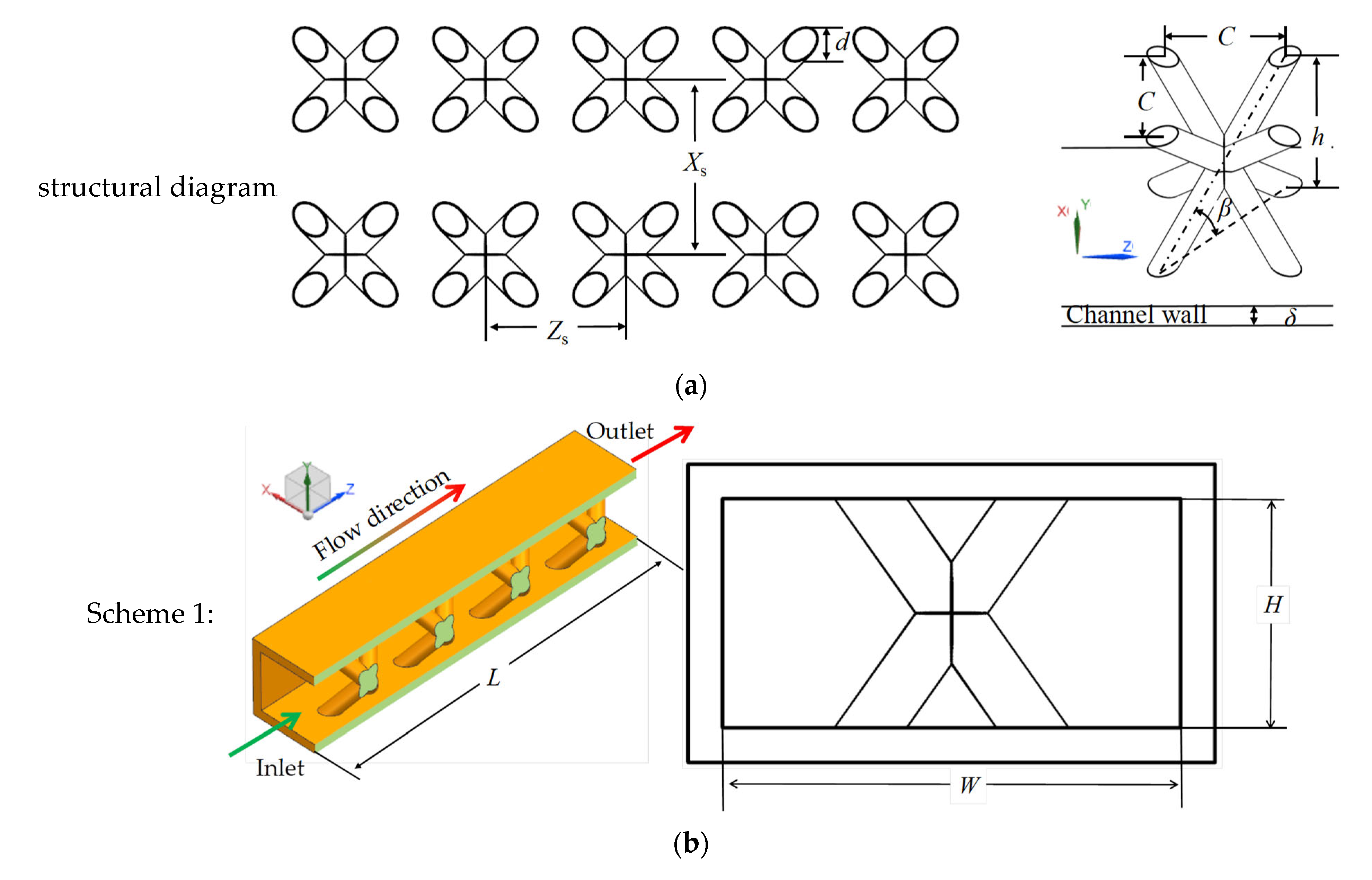

2. Research Object

2.1. Physical Model

2.2. Data Reduction

3. Numerical Methods

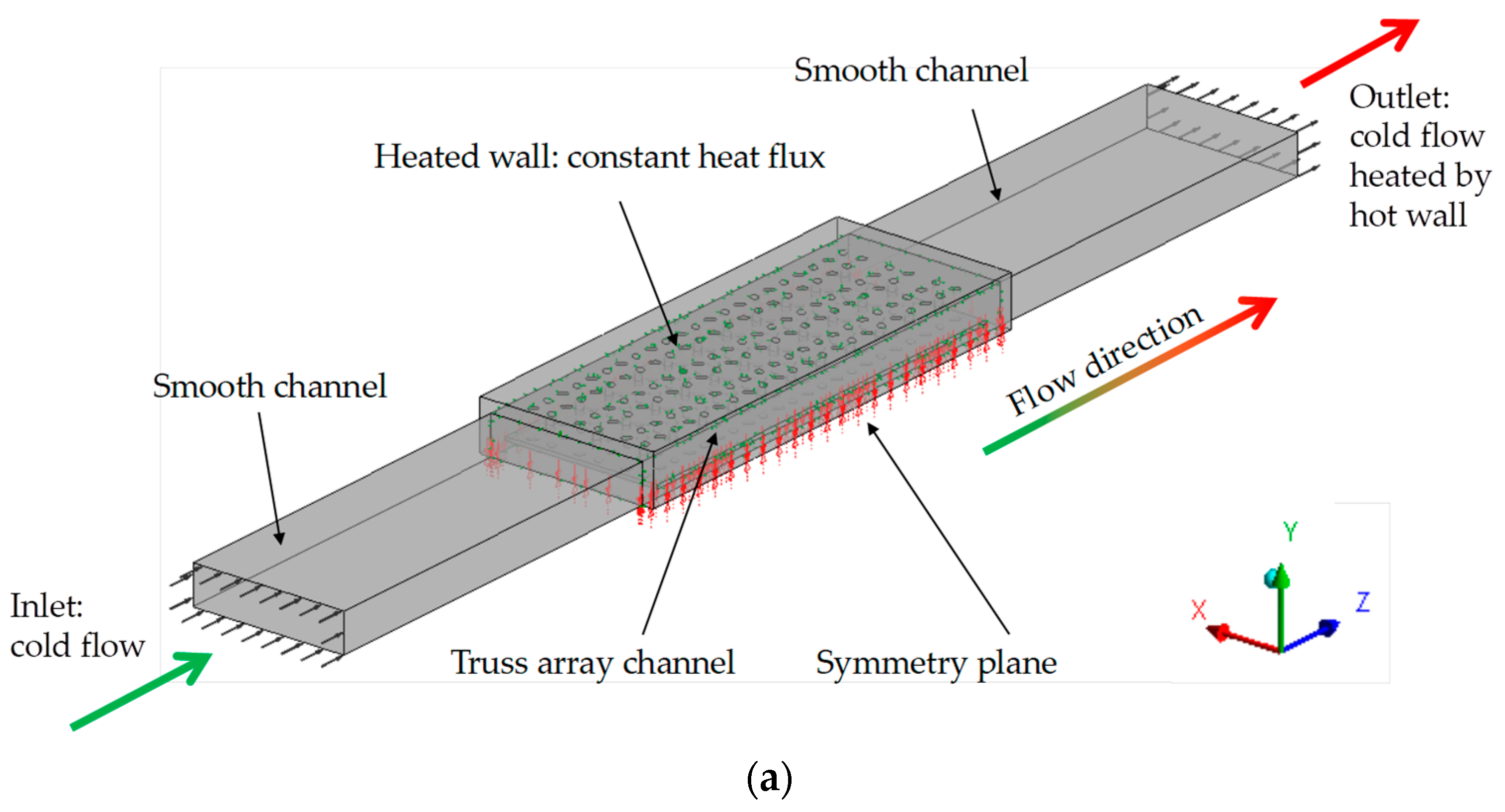

3.1. Numerical Model

3.2. Numerical Calculation Method

3.3. Boundary Conditions

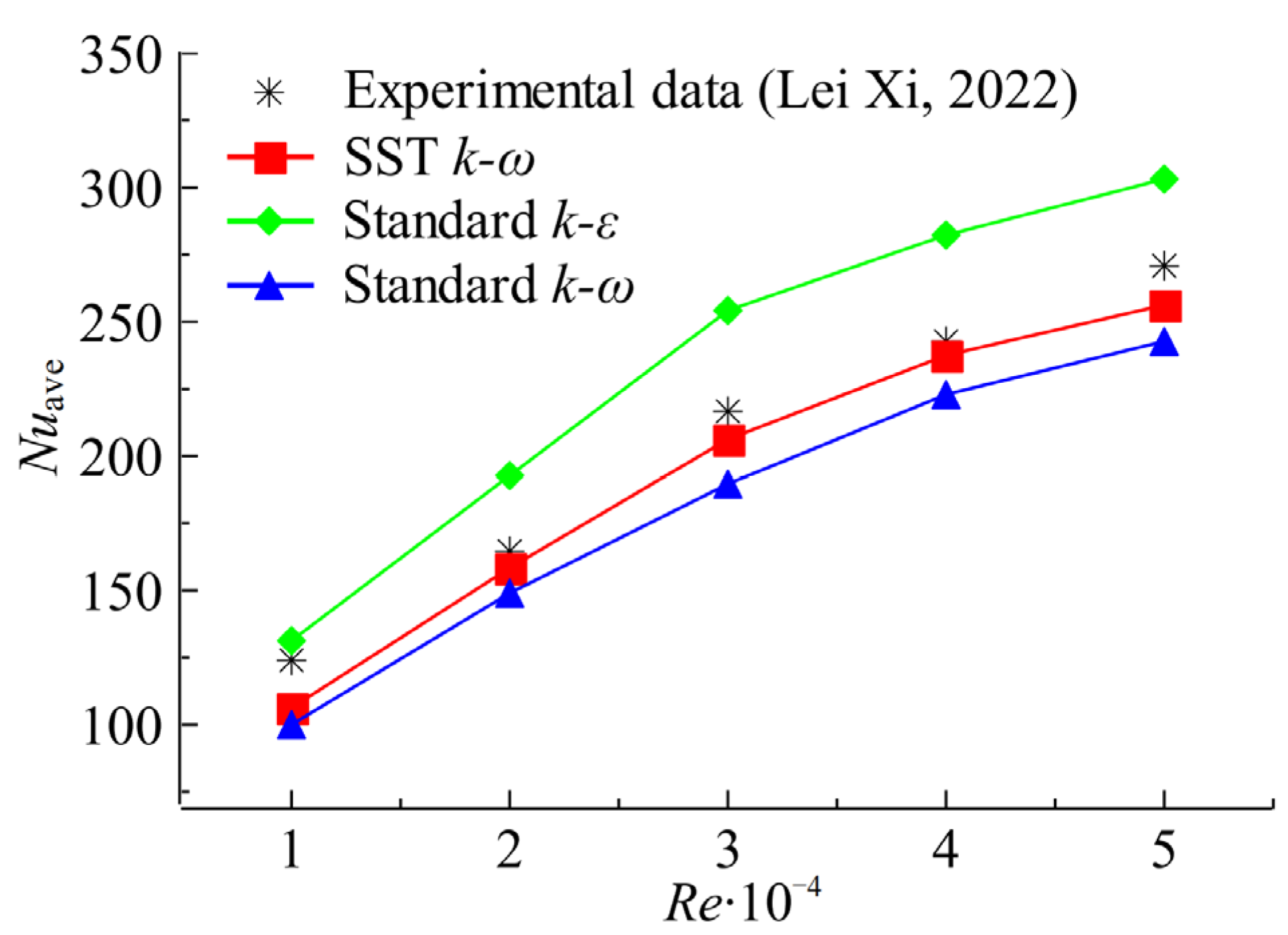

3.4. Verification of Numerical Method

4. Results and Discussion

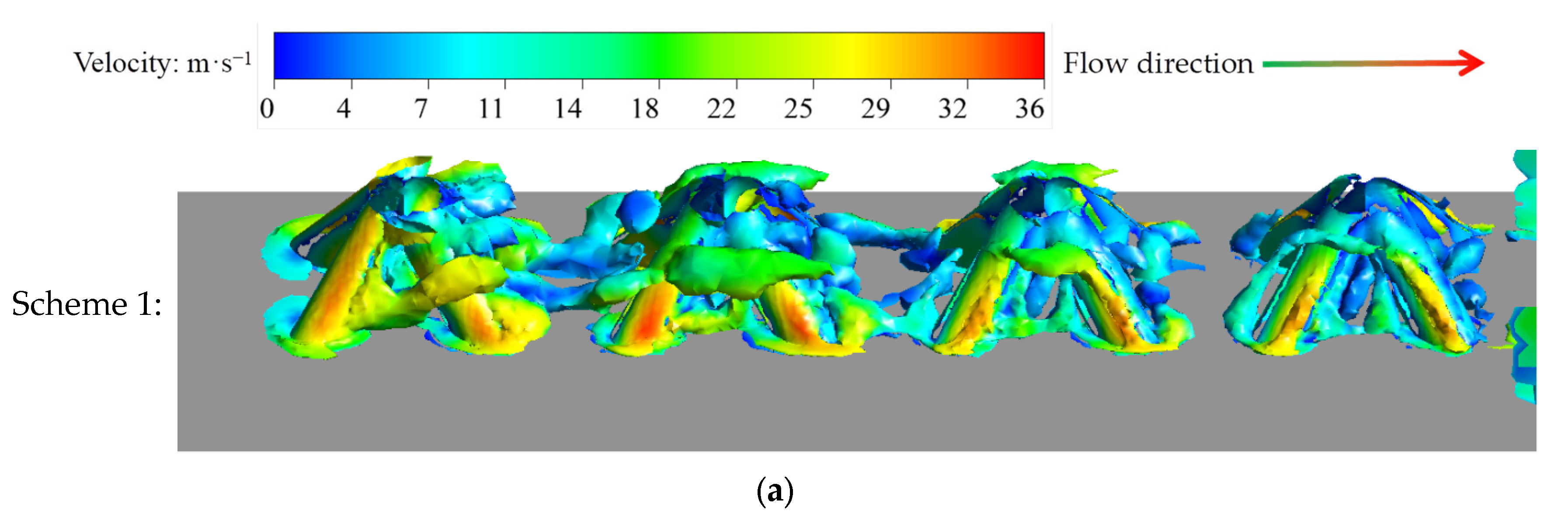

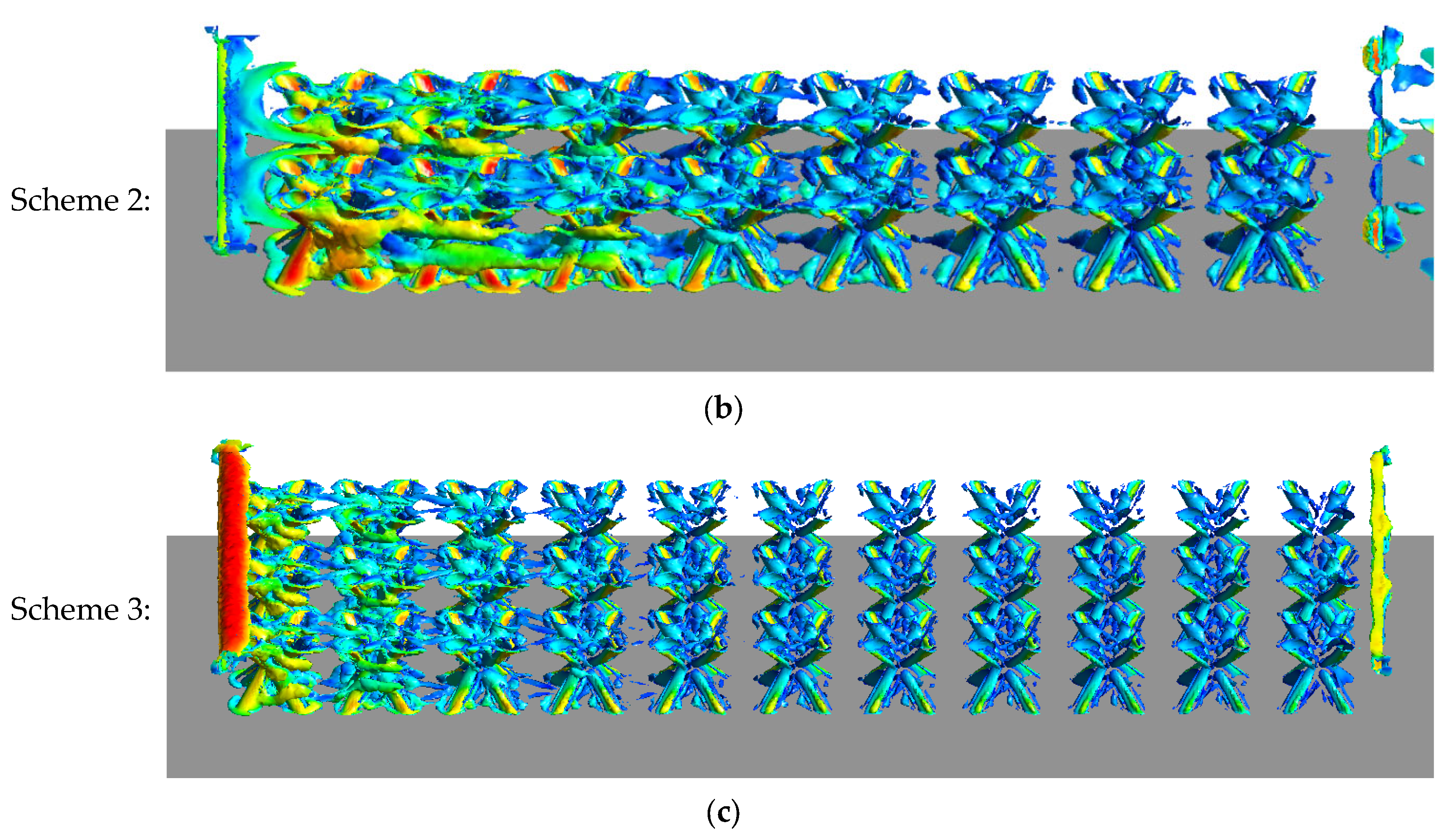

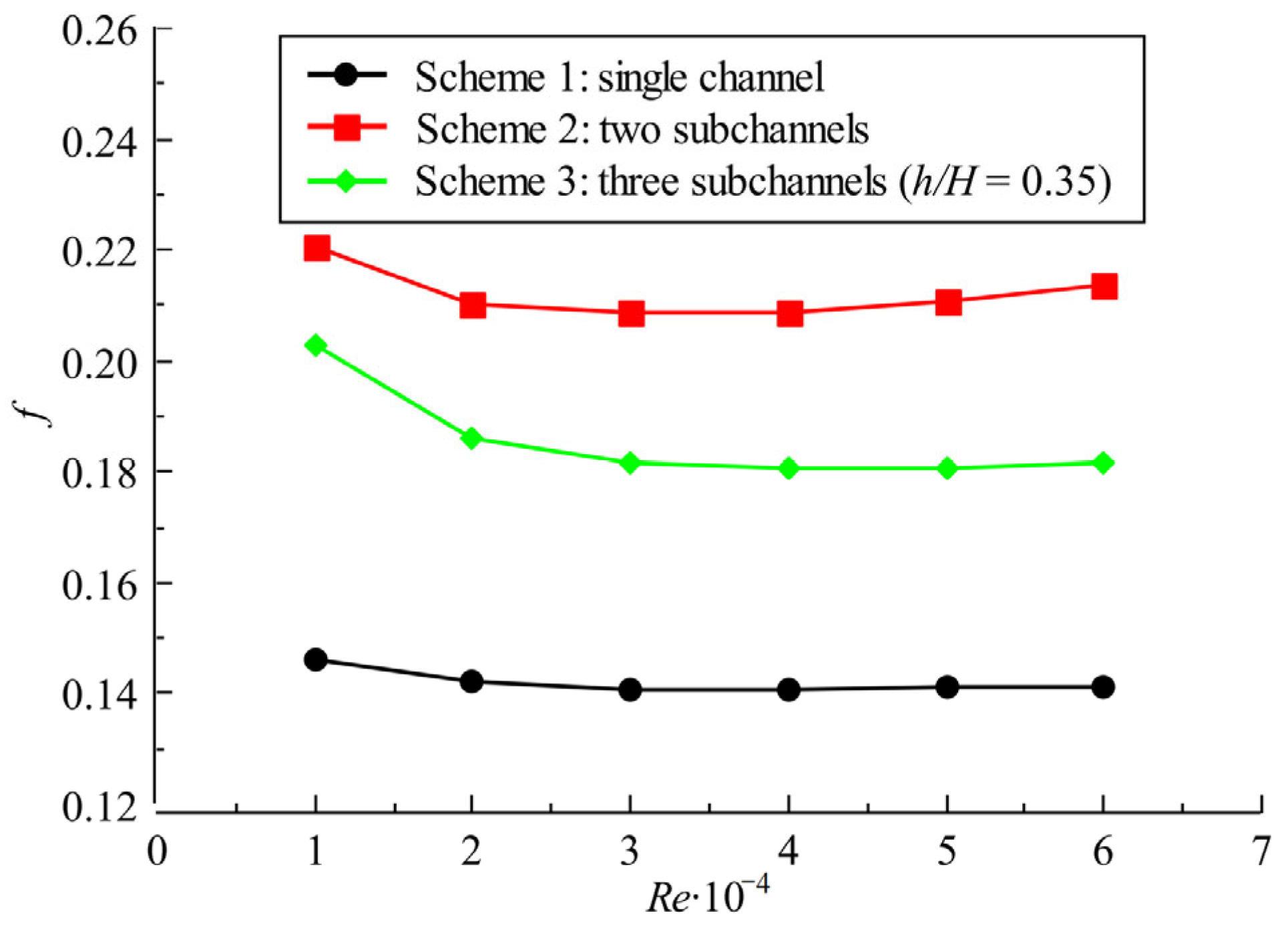

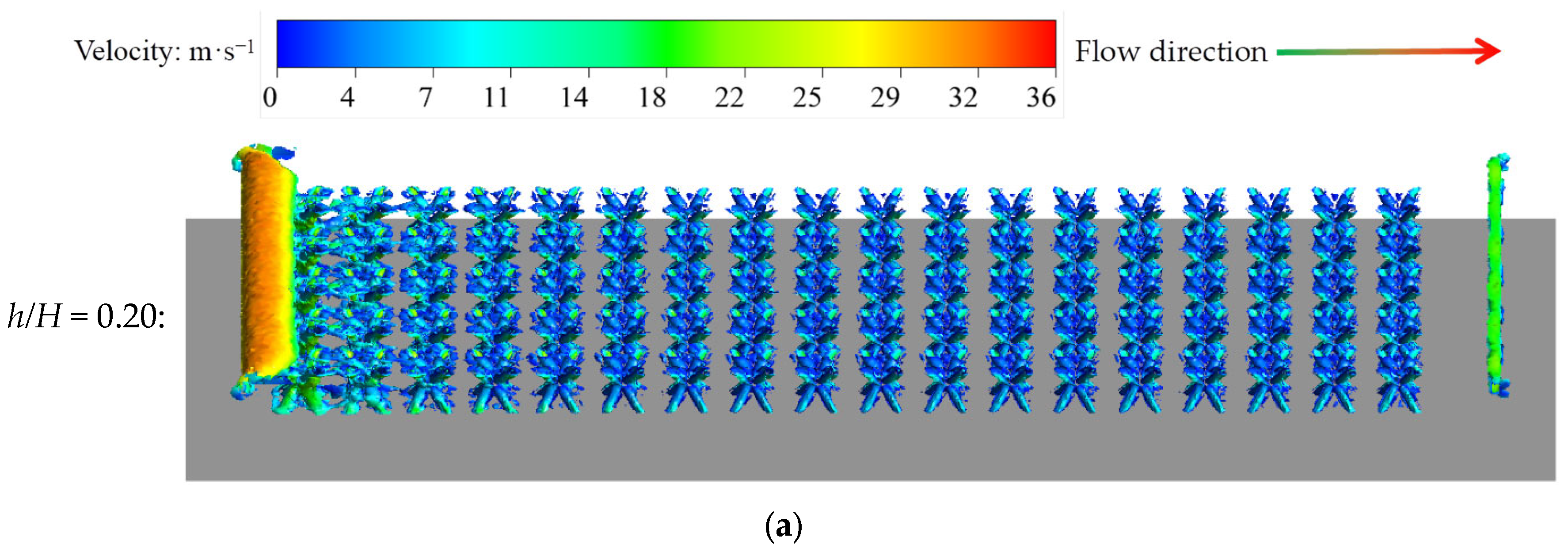

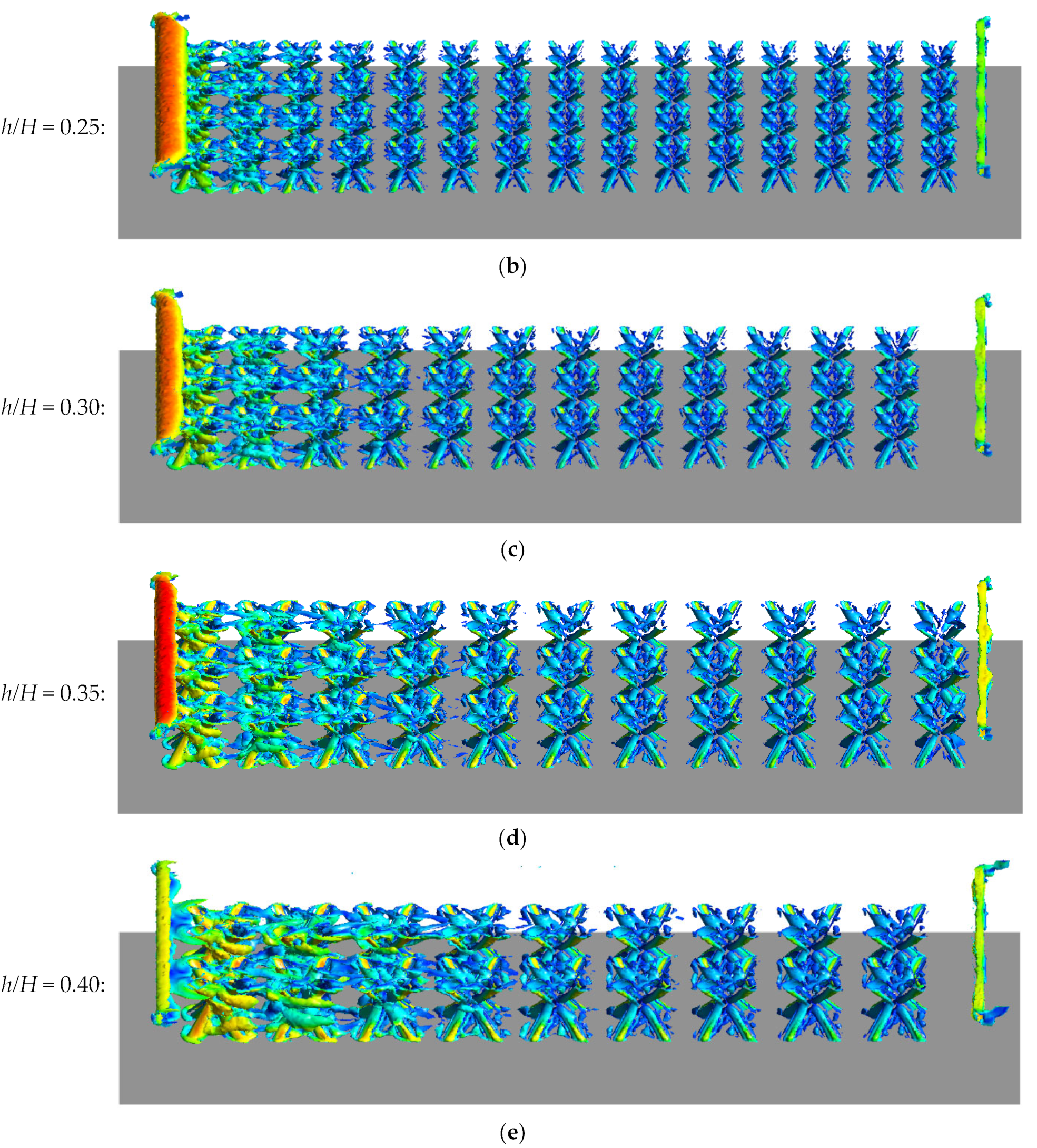

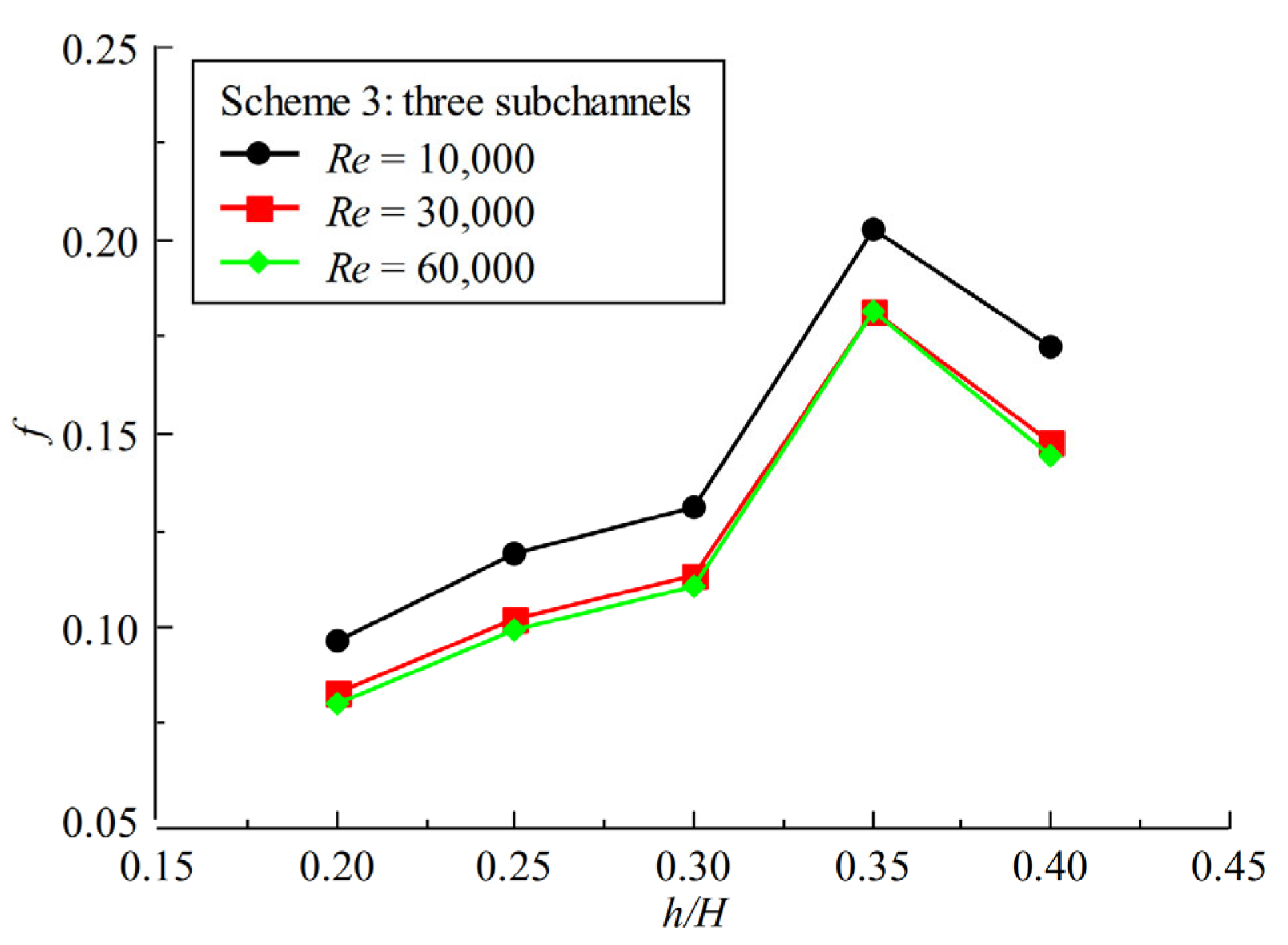

4.1. Flow Performance

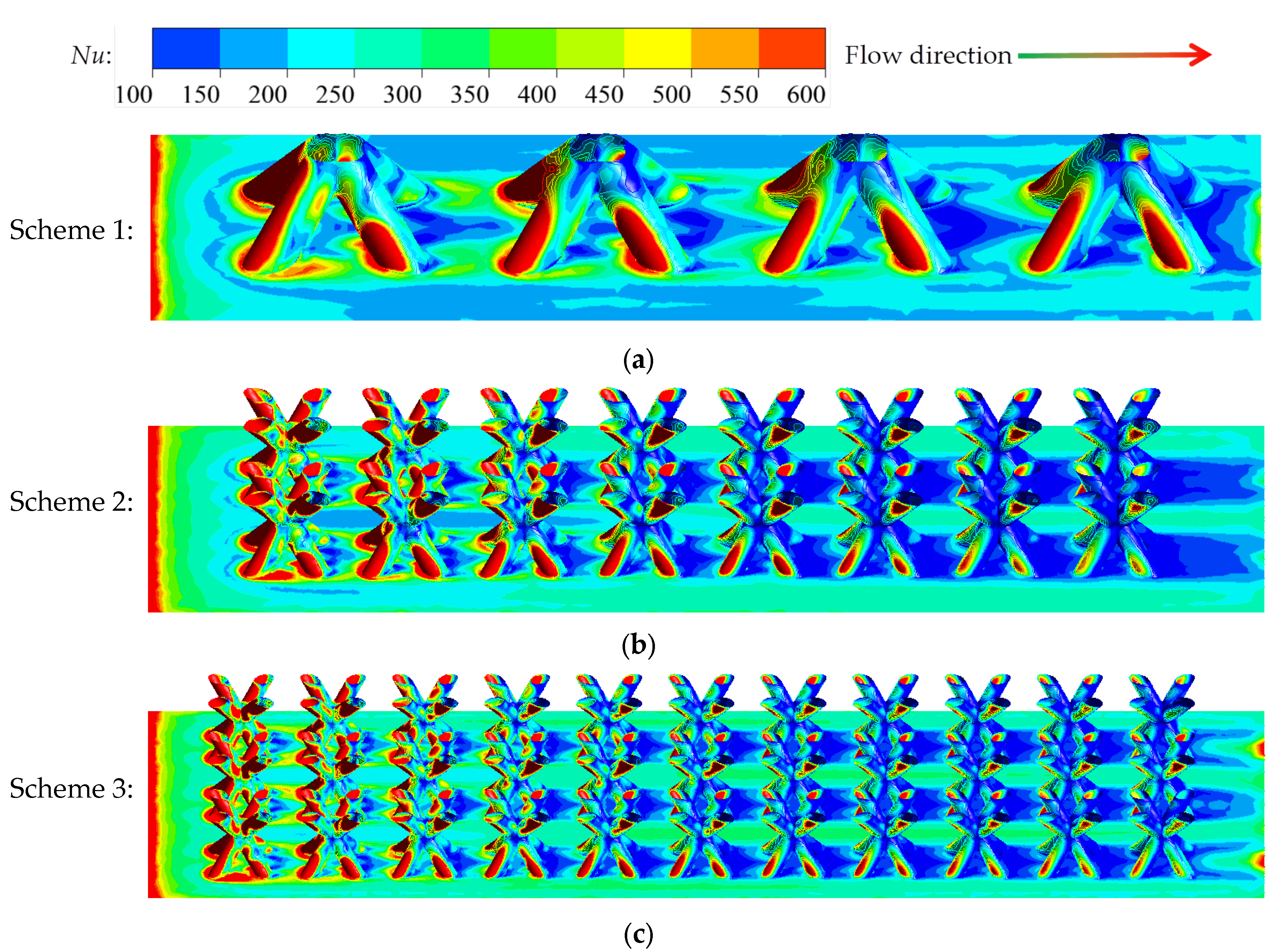

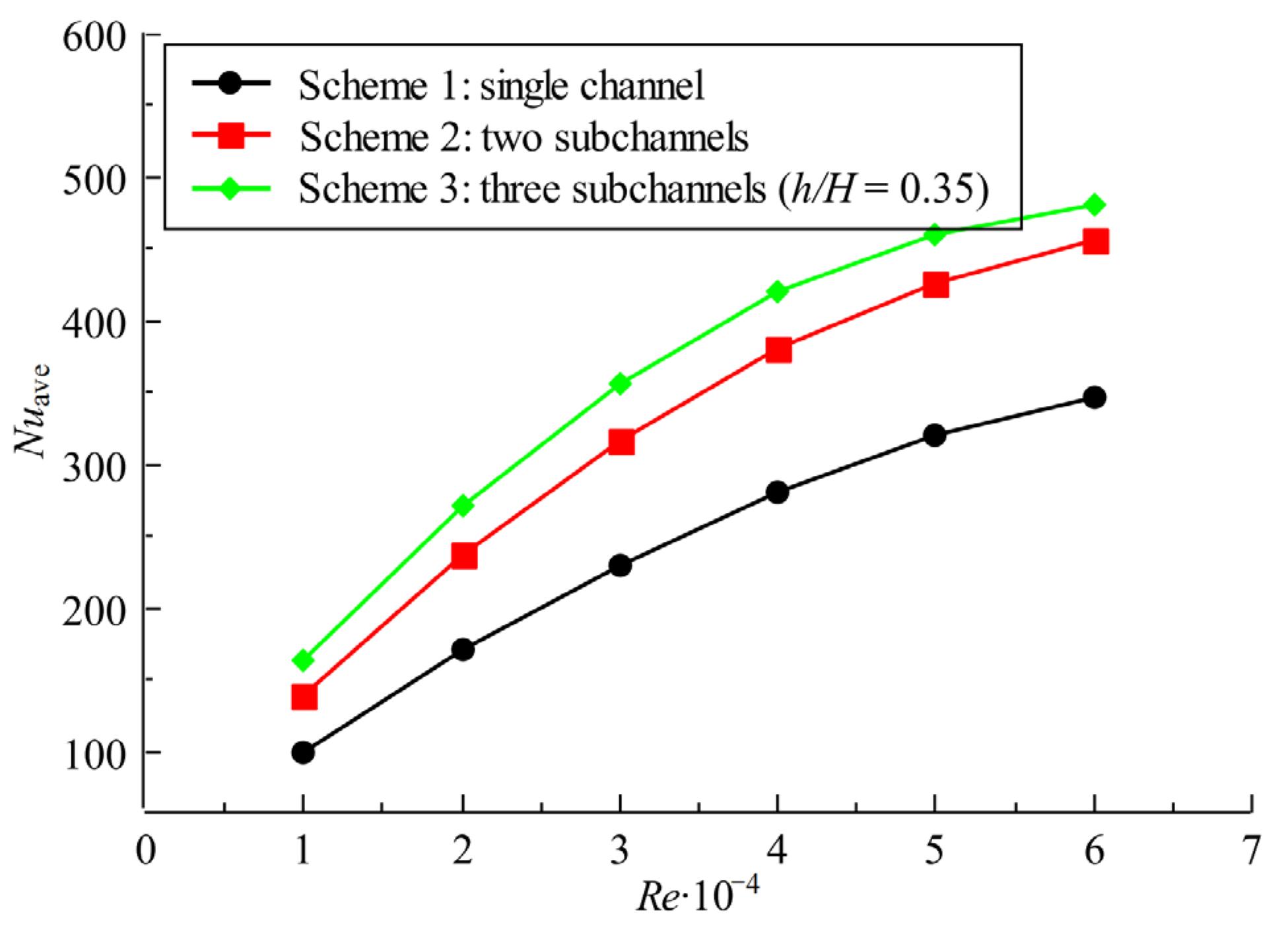

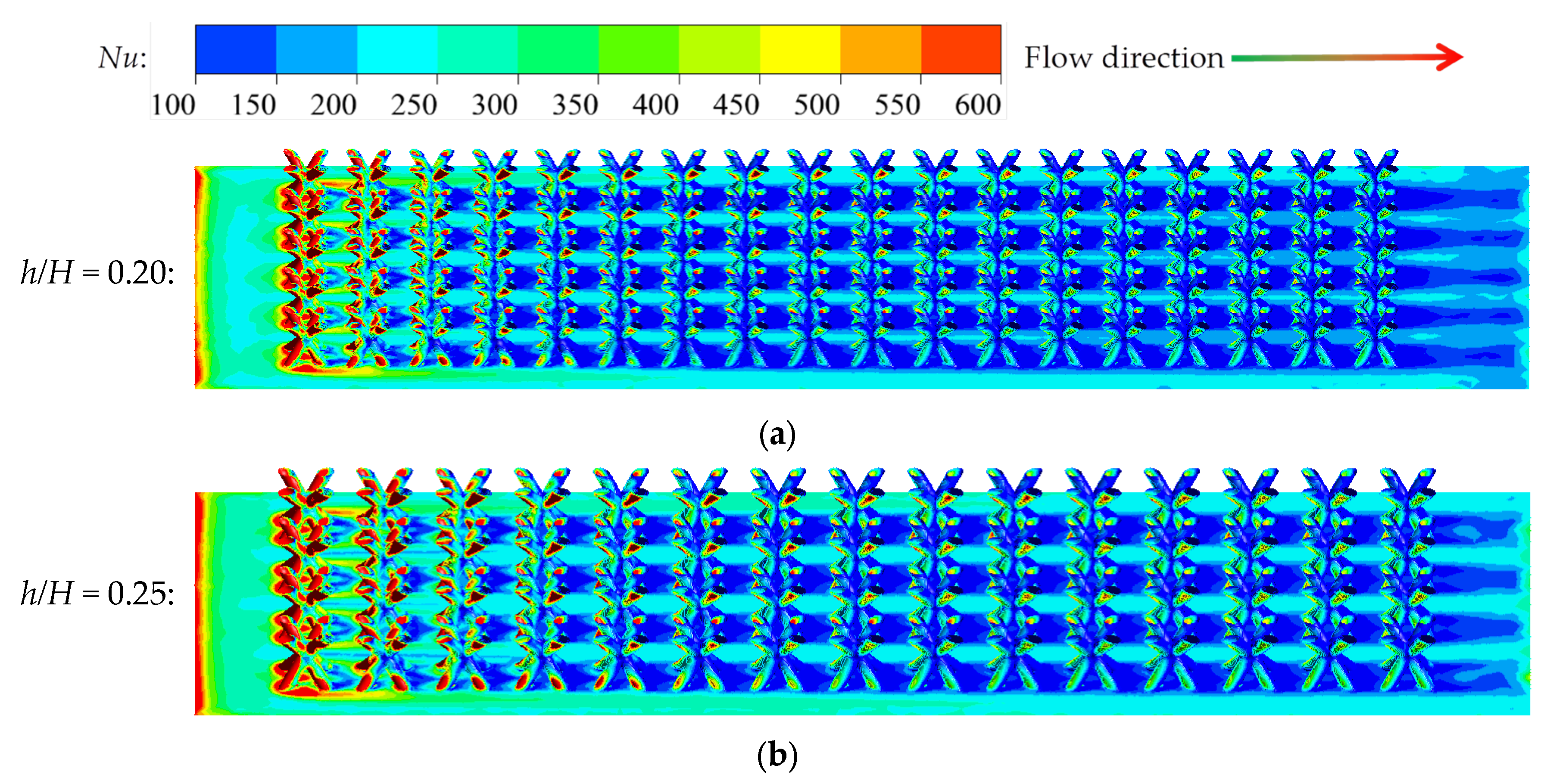

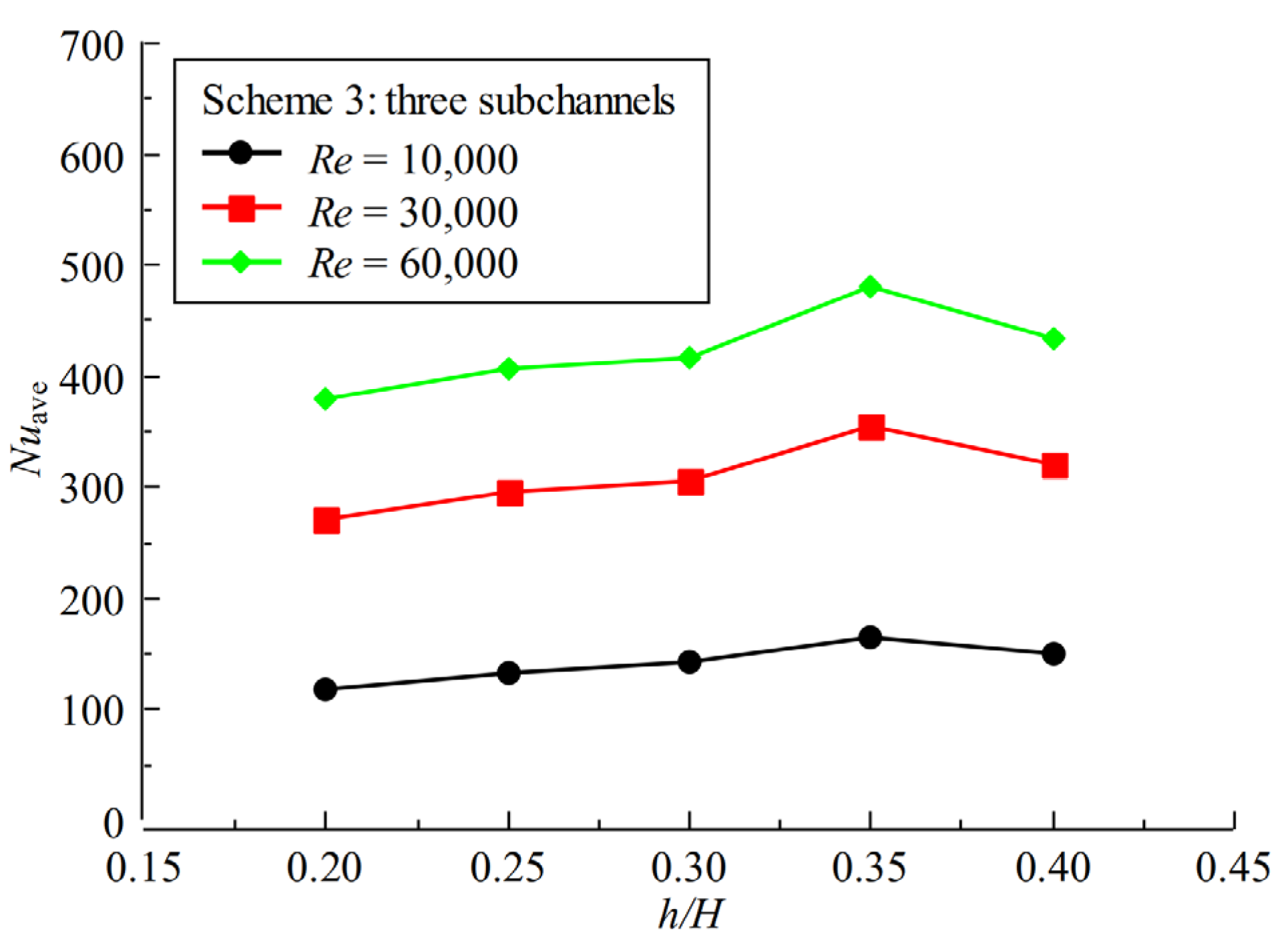

4.2. Heat Transfer Performance

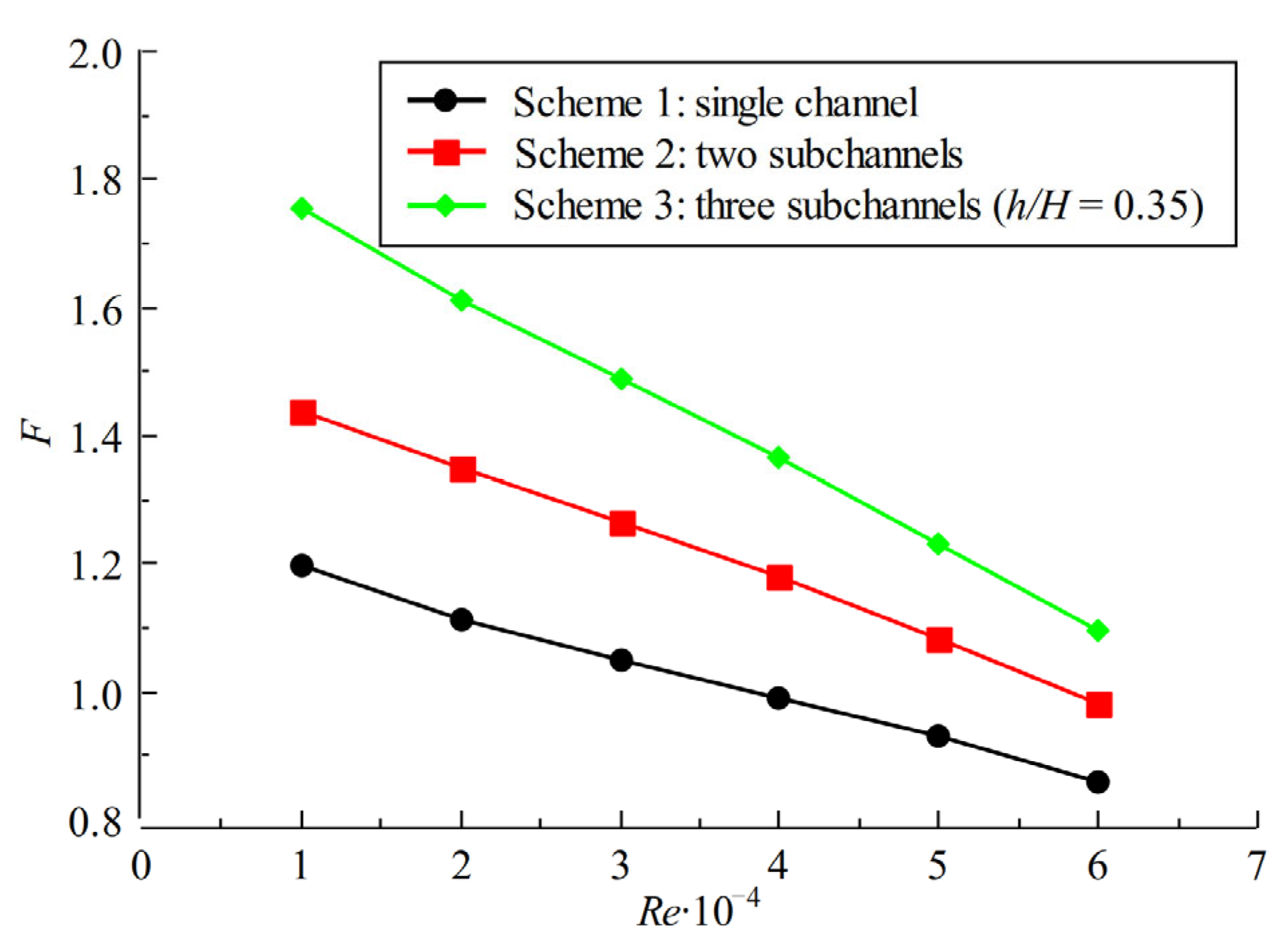

4.3. Comprehensive Thermal Performance

4.4. Empirical Correlations

5. Conclusions

- (1)

- Among the three layout schemes of X-shaped truss array channels, the channel of Scheme 1 has the best flow performance, while the channel of Scheme 3 has the best heat transfer performance and comprehensive thermal performance.

- (2)

- At different Reynolds numbers, the average Nusselt numbers and comprehensive thermal coefficients of the X-shaped truss array channel of Scheme 3 range from 38.94% to 63.49% and 27.74% to 46.49% higher than those of Scheme 1, and from 5.68% to 18.65% and 11.61% to 21.96% higher than those of Scheme 2.

- (3)

- With the increase in subchannel height ratio, the friction coefficient and average Nusselt number of the X-shaped truss array channel of Scheme 3 both show a trend of first increasing and then decreasing, while the comprehensive thermal coefficient shows a slow decreasing trend at higher Reynolds numbers.

- (4)

- As a result of comprehensive consideration, the X-shaped truss array channel of Scheme 3 at h/H = 0.25 has a better overall cooling performance and is more suitable for cooling the mid-chord region of gas turbine blades.

- (5)

- The layout scheme has significant effects on the flow performance, heat transfer performance and comprehensive thermal performance of X-shaped truss array channels. The subchannel height ratio has a great influence on the flow performance, but has a relatively small influence on the heat transfer performance and comprehensive thermal performance of the channel.

- (6)

- The heat transfer and friction correlations of X-shaped truss array cooling channels were obtained under different layout schemes, which may provide a reference for the application of truss array structures in the internal cooling of advanced high-temperature turbine blades in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| C | truss unit characteristic length, mm |

| d | truss rod diameter, mm |

| f | friction coefficient |

| f0 | friction coefficient of the smooth channel |

| F | comprehensive thermal coefficient |

| h | subchannel height, mm |

| H | channel height, mm |

| L | channel length, mm |

| Nu | local Nusselt number |

| Nuave | average Nusselt number |

| Nu0 | average Nusselt number of the smooth channel |

| pin | channel inlet pressure, Pa |

| pout | channel outlet pressure, Pa |

| q | heat flux, W·m−2 |

| Re | inlet Reynolds number |

| Tf | reference temperature, K |

| Tw | wall temperature, K |

| u | inlet velocity, m·s−1 |

| W | channel width, mm |

| Xs | transverse spacing, mm |

| Zs | streamwise spacing, mm |

| Greek symbols | |

| β | inclination angle of truss rod, ° |

| δ | thickness of channel wall, mm |

| Δp | pressure difference between channel inlet and outlet, Pa |

| λ | air thermal conductivity, W·m−1·K−1 |

| ρ | air density, kg·m−3 |

| υ | air kinematic viscosity, m2·s−1 |

References

- Wu, W.; Yao, R.; Wang, J.; Su, H.; Wu, X. Leading edge impingement cooling analysis with separators of a real gas turbine blade. Appl. Therm. Eng. 2022, 208, 118275. [Google Scholar] [CrossRef]

- Han, J.C. Advanced cooling in gas turbines 2016 Max Jakob memorial award paper. J. Heat Trans. T ASME 2018, 140, 113001. [Google Scholar] [CrossRef]

- Nourin, F.N.; Amano, R.S. Review of gas turbine internal cooling improvement technology. J. Energ. Resour.-ASME 2021, 143, 080801. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, S.; Wang, C.; Tan, X. Recent advances in film cooling enhancement: A review. Chin. J. Aeronaut. 2020, 33, 1119–1136. [Google Scholar] [CrossRef]

- Ye, L.; Liu, C.L.; Jiang, P.X.; Zhu, Y.H. Heat transfer characteristics in a trailing-edge slot cooling surface with outward protrusions. Exp. Heat Transf. 2022, 35, 1–20. [Google Scholar] [CrossRef]

- Li, Y.; Liu, T.; Tao, J.; Yang, W.; Dong, L. Heat transfer characteristics in a narrow confined channel with discrete impingement cooling. Chin. J. Aeronaut. 2022, 35, 220–229. [Google Scholar] [CrossRef]

- Zhang, G.; Zhu, R.; Xie, G.; Li, S.; Sunde, B. Optimization of cooling structures in gas turbines: A review. Chin. J. Aeronaut. 2022, 35, 18–46. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, H.; Li, G. Experimental study of heat transfer on the internal surfaces of a double-wall structure with pin fin array. Energies 2020, 13, 6573. [Google Scholar] [CrossRef]

- Xi, L.; Gao, J.; Xu, L.; Zhao, Z.; Ruan, Q.; Li, Y. Numerical investigation and parameter sensitivity analysis on flow and heat transfer performance of jet array impingement cooling in a quasi-leading-edge channel. Aerospace 2022, 9, 87. [Google Scholar] [CrossRef]

- Gasparetto, V.E.; ElSayed, M.S. Multiscale optimization of specific elastic properties and microscopic frequency band-gaps of architectured microtruss lattice materials. Int. J. Mech. Sci. 2021, 197, 106320. [Google Scholar] [CrossRef]

- Di Caprio, F.; Acanfora, V.; Franchitti, S.; Sellitto, A.; Riccio, A. Hybrid Metal/Composite Lattice Structures: Design for Additive Manufacturing. Aerospace 2019, 6, 71. [Google Scholar] [CrossRef] [Green Version]

- Di Caprio, F.; Franchitti, S.; Borrelli, R.; Bellini, C.; Di Cocco, V.; Sorrentino, L. Ti-6Al-4V Octet-Truss Lattice Structures under Bending Load Conditions: Numerical and Experimental Results. Metals 2022, 12, 410. [Google Scholar] [CrossRef]

- Li, J.; Huang, Z.; Liu, G.; An, Q.; Chen, M. Topology optimization design and research of lightweight biomimetic three-dimensional lattice structures based on laser powder bed fusion. J. Manuf. Process. 2022, 74, 220–232. [Google Scholar] [CrossRef]

- Daynes, S.; Feih, S. Bio-inspired lattice structure optimisation with strain trajectory aligned trusses. Mater. Design 2022, 213, 110320. [Google Scholar] [CrossRef]

- Guo, J.; Li, Y.; Xiao, Y.; Fan, Y.; Yu, D.; Wen, J. Multiscale modeling and design of lattice truss core sandwich metastructures for broadband low-frequency vibration reduction. Compos. Struct. 2022, 289, 115463. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Y.; Deng, Z.; Wu, X. Two elastically equivalent compound truss lattice materials with controllable anisotropic mechanical properties. Int. J. Mech. Sci. 2022, 213, 106879. [Google Scholar] [CrossRef]

- Shangguan, H.; Kang, J.; Yi, J.; Zhang, X.; Wang, X.; Wang, H.; Huang, T. The Design of 3D-Printed Lattice-Reinforced Thickness-Varying Shell Molds for Castings. Materials 2018, 11, 535. [Google Scholar] [CrossRef] [Green Version]

- Shahrzadi, M.; Emami, M.D.; Akbarzadeh, A.H. Heat transfer in BCC lattice materials: Conduction, convection, and radiation. Compos. Struct. 2022, 284, 115159. [Google Scholar] [CrossRef]

- Le, V.T.; Ha, N.S.; Goo, N.S. Advanced sandwich structures for thermal protection systems in hypersonic vehicles: A review. Compos. Part B Eng. 2021, 226, 109301. [Google Scholar] [CrossRef]

- Luo, S.; Xu, D.; Song, J.; Liu, J. A review of regenerative cooling technologies for scramjets. Appl. Therm. Eng. 2021, 190, 116754. [Google Scholar] [CrossRef]

- Kim, T.; Hodson, H.P.; Lu, T.J. Contribution of vortex structures and flow separation to local and overall pressure and heat transfer characteristics in an ultralightweight lattice material. Int. J. Heat Mass Transf. 2005, 48, 4242–4264. [Google Scholar] [CrossRef]

- Wei, K.; He, R.; Cheng, X.; Pei, Y.; Zhang, R.; Fang, D. Fabrication and heat transfer characteristics of C/SiC pyramidal core lattice sandwich panel. Appl. Therm. Eng. 2015, 81, 10–17. [Google Scholar] [CrossRef]

- Gao, L.; Sun, Y.G. Thermal control of composite sandwich structure with lattice truss cores. J. Thermophys. Heat Tr. 2015, 29, 47–54. [Google Scholar] [CrossRef]

- Gao, L.; Sun, Y.; Cong, L. Active cooling performance of all-composite lattice truss core sandwich structure. Heat Transf. Res. 2016, 47, 1093–1108. [Google Scholar] [CrossRef]

- Dixit, T.; Nithiarasu, P.; Kumar, S. Numerical evaluation of additively manufactured lattice architectures for heat sink applications. Int. J. Therm. Sci. 2020, 159, 106607. [Google Scholar] [CrossRef]

- Qian, B.; Fan, H.; Liu, G.; Zhang, J.; Li, P. Microchannel Liquid-Cooled Heat Exchanger Based on a Nonuniform Lattice: Study on Structure Calculation, Formation Process, and Boiling Heat Transfer Performance. Materials 2021, 14, 7248. [Google Scholar] [CrossRef]

- Son, Y.W.; Kim, T.; Lu, T.J.; Chang, S.M. On thermally managing lithium-ion battery cells by air-convection aspirated in tetrahedral lattice porous cold plates. Appl. Therm. Eng. 2021, 189, 116711. [Google Scholar] [CrossRef]

- You, J.H.; Park, K. Design and additive manufacturing of thermal metamaterial with high thermal resistance and cooling capability. Addit. Manuf. 2021, 41, 101947. [Google Scholar] [CrossRef]

- Yun, S.; Lee, D.; Jang, D.S.; Lee, M.; Kim, Y. Numerical analysis on thermo-fluid–structural performance of graded lattice channels produced by metal additive manufacturing. Appl. Therm. Eng. 2021, 193, 117024. [Google Scholar] [CrossRef]

- Kaur, I.; Singh, P. Critical evaluation of additively manufactured metal lattices for viability in advanced heat exchangers. Int. J. Heat Mass Transf. 2021, 168, 120858. [Google Scholar] [CrossRef]

- Kaur, I.; Singh, P. Endwall heat transfer characteristics of octahedron family lattice-frame materials. Int. Commun. Heat Mass 2021, 127, 105522. [Google Scholar] [CrossRef]

- Zhou, M.; Geng, D. Multi-scale and multi-material topology optimization of channel-cooling cellular structures for thermomechanical behaviors. Comput. Methods Appl. Mech. Eng. 2021, 383, 113896. [Google Scholar] [CrossRef]

- Lai, X.; Wang, C.; Peng, D.; Yang, H.; Wei, Z. Analysis of heat transfer characteristics of a heat exchanger based on a lattice filling. Coatings 2021, 11, 1089. [Google Scholar] [CrossRef]

- Xu, L.; Chen, H.; Xi, L.; Xiong, Y.; Gao, J.; Li, Y. Flow and heat transfer characteristics of a staggered array of Kagome lattice structures in rectangular channels. Heat Mass Transf. 2022, 58, 41–64. [Google Scholar] [CrossRef]

- Hussain, S.; Ghopa, W.A.W.; Singh, S.S.K.; Azman, A.H.; Abdullah, S. Experimental and Numerical Vibration Analysis of Octet-Truss-Lattice-Based Gas Turbine Blades. Metals 2022, 12, 340. [Google Scholar] [CrossRef]

- Xu, L.; Ruan, Q.; Shen, Q.; Xi, L.; Gao, J.; Li, Y. Optimization design of lattice structures in internal cooling channel with variable aspect ratio of gas turbine blade. Energies 2021, 14, 3954. [Google Scholar] [CrossRef]

- Xu, L.; Shen, Q.; Ruan, Q.; Xi, L.; Gao, J.; Li, Y. Optimization design of lattice structures in internal cooling channel of turbine blade. Appl. Sci. 2021, 11, 5838. [Google Scholar] [CrossRef]

- Kaur, I.; Aider, Y.; Nithyanandam, K.; Singh, P. Thermal-hydraulic performance of additively manufactured lattices for gas turbine blade trailing edge cooling. Appl. Therm. Eng. 2022, 211, 118461. [Google Scholar] [CrossRef]

- Liang, D.; He, G.; Chen, W.; Chen, Y.; Chyu, M.K. Fluid flow and heat transfer performance for micro-lattice structures fabricated by Selective Laser Melting. Int. J. Therm. Sci. 2022, 172, 107312. [Google Scholar] [CrossRef]

- Xi, L.; Xu, L.; Gao, J.; Zhao, Z.; Li, Y. Study on flow and heat transfer performance of X-type truss array cooling channel. Case Stud. Therm. Eng. 2021, 26, 101034. [Google Scholar] [CrossRef]

- Xi, L.; Xu, L.; Gao, J.; Zhao, Z.; Li, Y. Cooling performance analysis and structural parameter optimization of X-shaped truss array channel based on neural networks and genetic algorithm. Int. J. Heat Mass Transf. 2022, 186, 122452. [Google Scholar] [CrossRef]

- Xu, L.; Wang, W.; Gao, T.; Gao, J. An experimental research on the cooling performance of the turbine vane with an advanced duplex-medium combined cooling. Int. J. Heat Mass Transf. 2014, 79, 72–81. [Google Scholar] [CrossRef]

- Gao, T.; Zeng, J.; Li, J.; Gong, J. Numerical prediction on mist/steam cooling in a square ribbed channel at real gas turbine operational conditions. Int. J. Heat Mass Transf. 2017, 108, 1089–1102. [Google Scholar] [CrossRef]

| Channel Types | h/H | Row Number | Column Number |

|---|---|---|---|

| Scheme 1: single channel | 1 | 1 | 4 |

| Scheme 2: two subchannels | 0.475 | 2 | 8 |

| Scheme 3: three subchannels | 0.20 | 5 | 18 |

| Scheme 3: three subchannels | 0.25 | 4 | 15 |

| Scheme 3: three subchannels | 0.30 | 3 | 12 |

| Scheme 3: three subchannels | 0.35 | 3 | 11 |

| Scheme 3: three subchannels | 0.40 | 2 | 9 |

| Maximum Mesh Size/mm | Total Mesh Number/Million | Nuave | Difference/% |

|---|---|---|---|

| 2.4 | 4.01 | 163.78 | - |

| 2.0 | 4.63 | 181.64 | 10.90 |

| 1.6 | 5.39 | 196.14 | 7.98 |

| 1.2 | 6.86 | 207.22 | 5.65 |

| 0.8 | 8.32 | 210.13 | 1.40 |

| Channels | Nuave | f | Re | ||||

|---|---|---|---|---|---|---|---|

| C | m | R2 | C | m | R2 | ||

| Scheme 1 | 0.163 | 0.700 | 0.995 | 0.172 | −0.019 | 0.884 | 10,000 to 60,000 |

| Scheme 2 | 0.286 | 0.675 | 0.991 | 0.258 | −0.019 | 0.866 | 10,000 to 60,000 |

| Scheme 3 | 0.605 | 0.614 | 0.985 | 0.351 | −0.062 | 0.877 | 10,000 to 60,000 |

| Channels | Nuave | f | Re | ||||

|---|---|---|---|---|---|---|---|

| C | m | R2 | C | m | R2 | ||

| h/H = 0.20 | 0.229 | 0.659 | 0.987 | 0.240 | −0.101 | 0.932 | 10,000 to 60,000 |

| h/H = 0.25 | 0.396 | 0.637 | 0.986 | 0.294 | −0.101 | 0.925 | 10,000 to 60,000 |

| h/H = 0.30 | 0.532 | 0.612 | 0.987 | 0.305 | −0.094 | 0.912 | 10,000 to 60,000 |

| h/H = 0.35 | 0.605 | 0.614 | 0.985 | 0.351 | −0.062 | 0.877 | 10,000 to 60,000 |

| h/H = 0.40 | 0.589 | 0.606 | 0.987 | 0.418 | −0.099 | 0.909 | 10,000 to 60,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, L.; Gao, J.; Xu, L.; Zhao, Z.; Yang, Z.; Li, Y. Numerical Investigation on Cooling Performance of Rectangular Channels Filled with X-Shaped Truss Array Structures. Aerospace 2022, 9, 405. https://doi.org/10.3390/aerospace9080405

Xi L, Gao J, Xu L, Zhao Z, Yang Z, Li Y. Numerical Investigation on Cooling Performance of Rectangular Channels Filled with X-Shaped Truss Array Structures. Aerospace. 2022; 9(8):405. https://doi.org/10.3390/aerospace9080405

Chicago/Turabian StyleXi, Lei, Jianmin Gao, Liang Xu, Zhen Zhao, Zhengheng Yang, and Yunlong Li. 2022. "Numerical Investigation on Cooling Performance of Rectangular Channels Filled with X-Shaped Truss Array Structures" Aerospace 9, no. 8: 405. https://doi.org/10.3390/aerospace9080405

APA StyleXi, L., Gao, J., Xu, L., Zhao, Z., Yang, Z., & Li, Y. (2022). Numerical Investigation on Cooling Performance of Rectangular Channels Filled with X-Shaped Truss Array Structures. Aerospace, 9(8), 405. https://doi.org/10.3390/aerospace9080405