Observer-Based Backstepping Adaptive Force Control of Electro-Mechanical Actuator with Improved LuGre Friction Model

Abstract

:1. Introduction

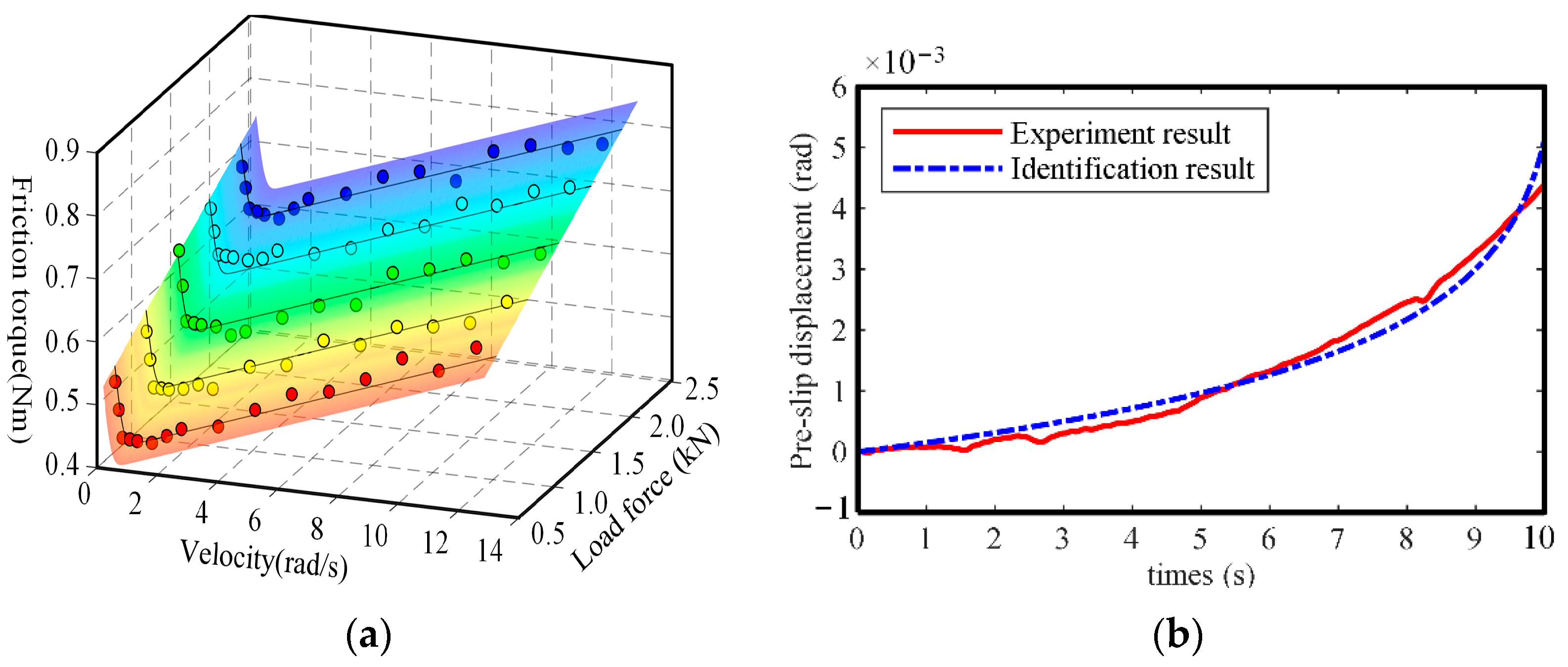

2. System Description and Mathematical Model

3. Friction Model Improvement and Parameter Identification

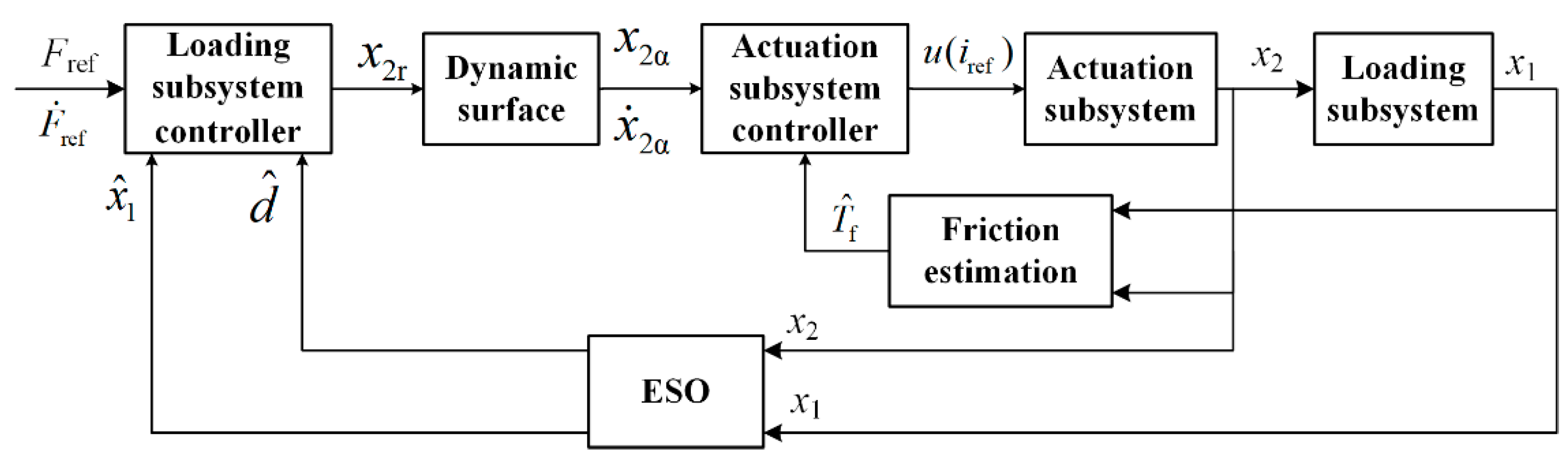

4. Observer-Based Adaptive Backstepping Control

4.1. ‘Loading’ Subsystem

4.1.1. Disturbance Estimation

4.1.2. Control Law Design

4.2. ‘Actuation’ Subsystem

4.2.1. Modified Observer for LuGre Model

4.2.2. Control Law Design

4.2.3. Dynamic Surface Control

4.3. Stability Analysis

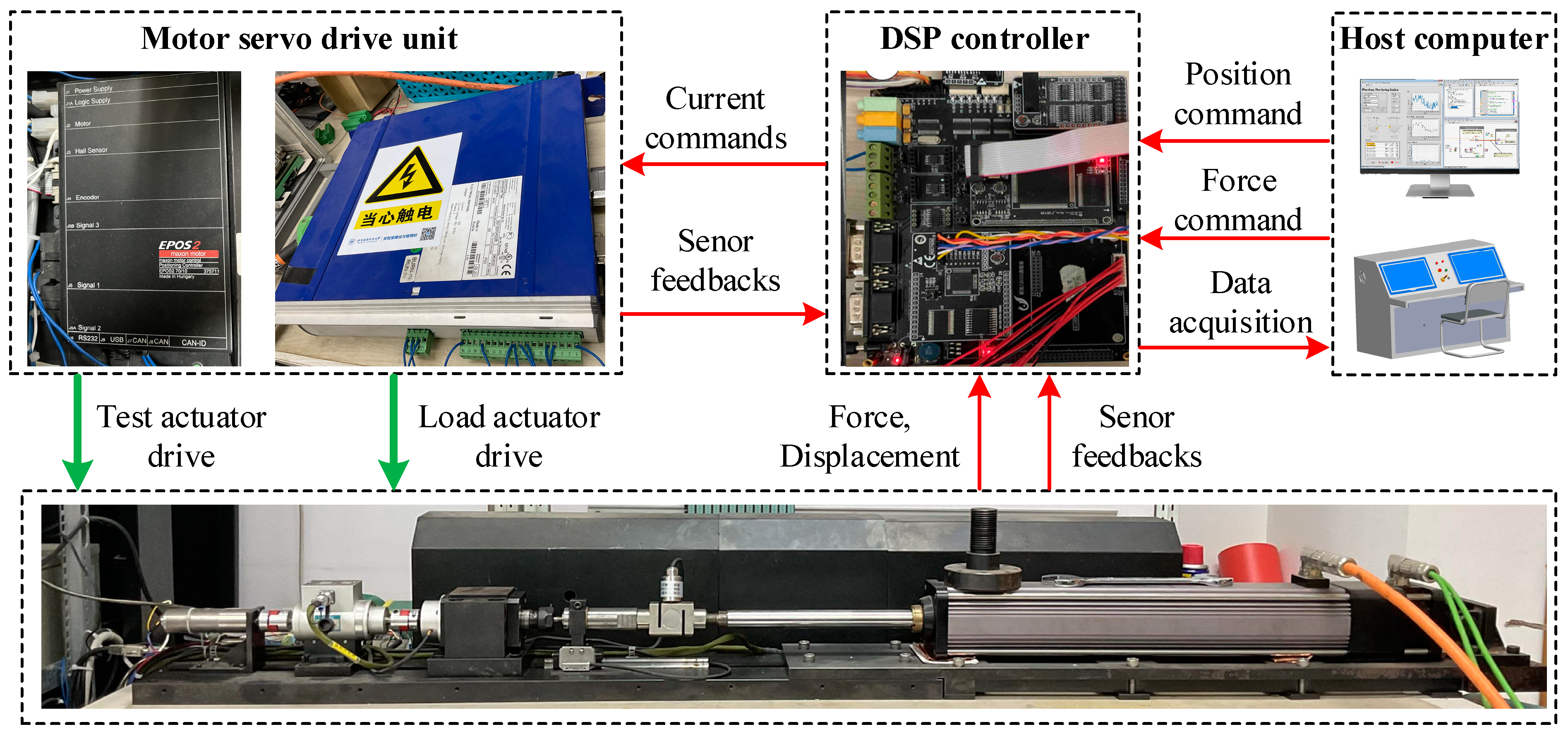

5. Experiment Validation

5.1. Experimental Setup

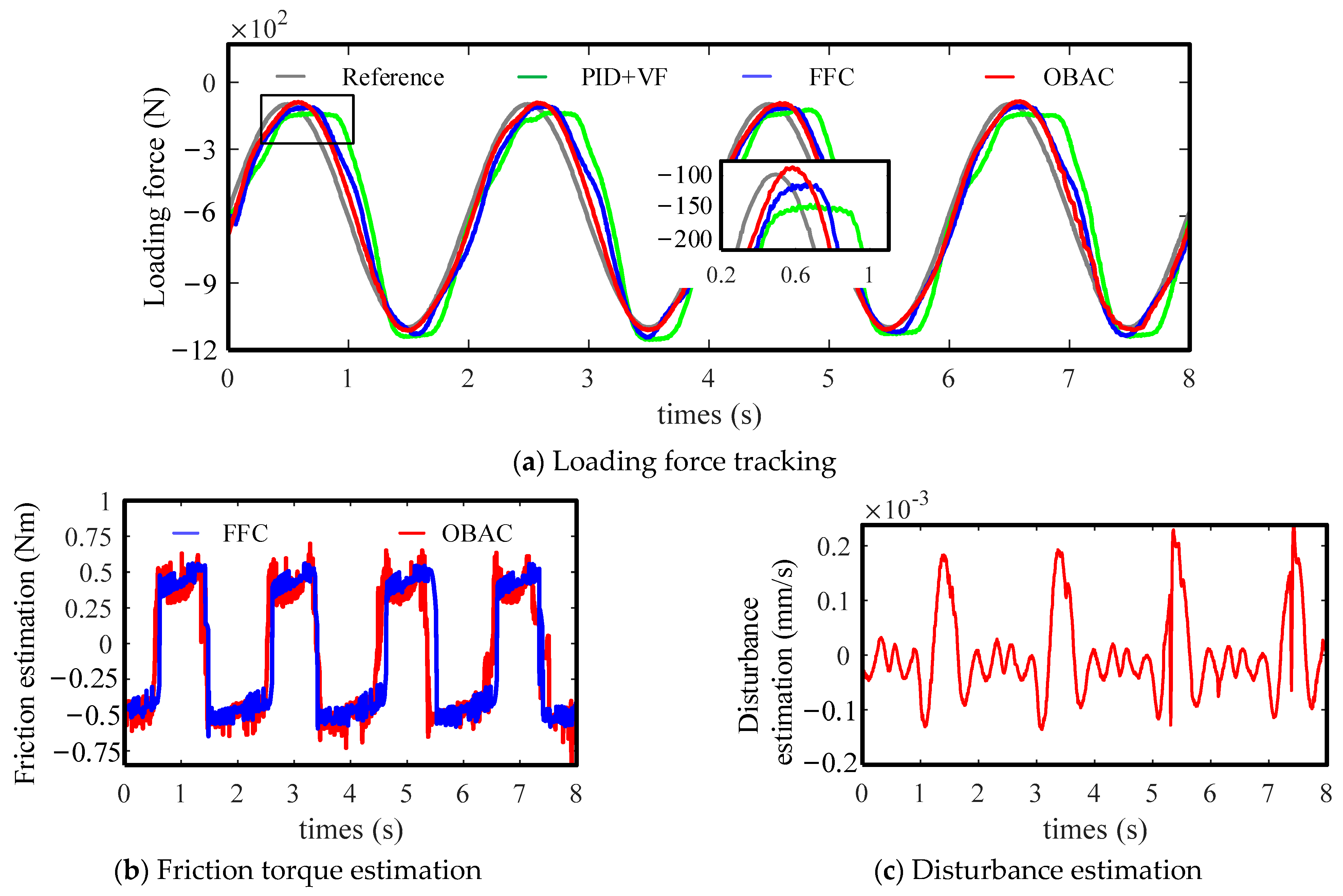

5.2. Experimental Results Analysis

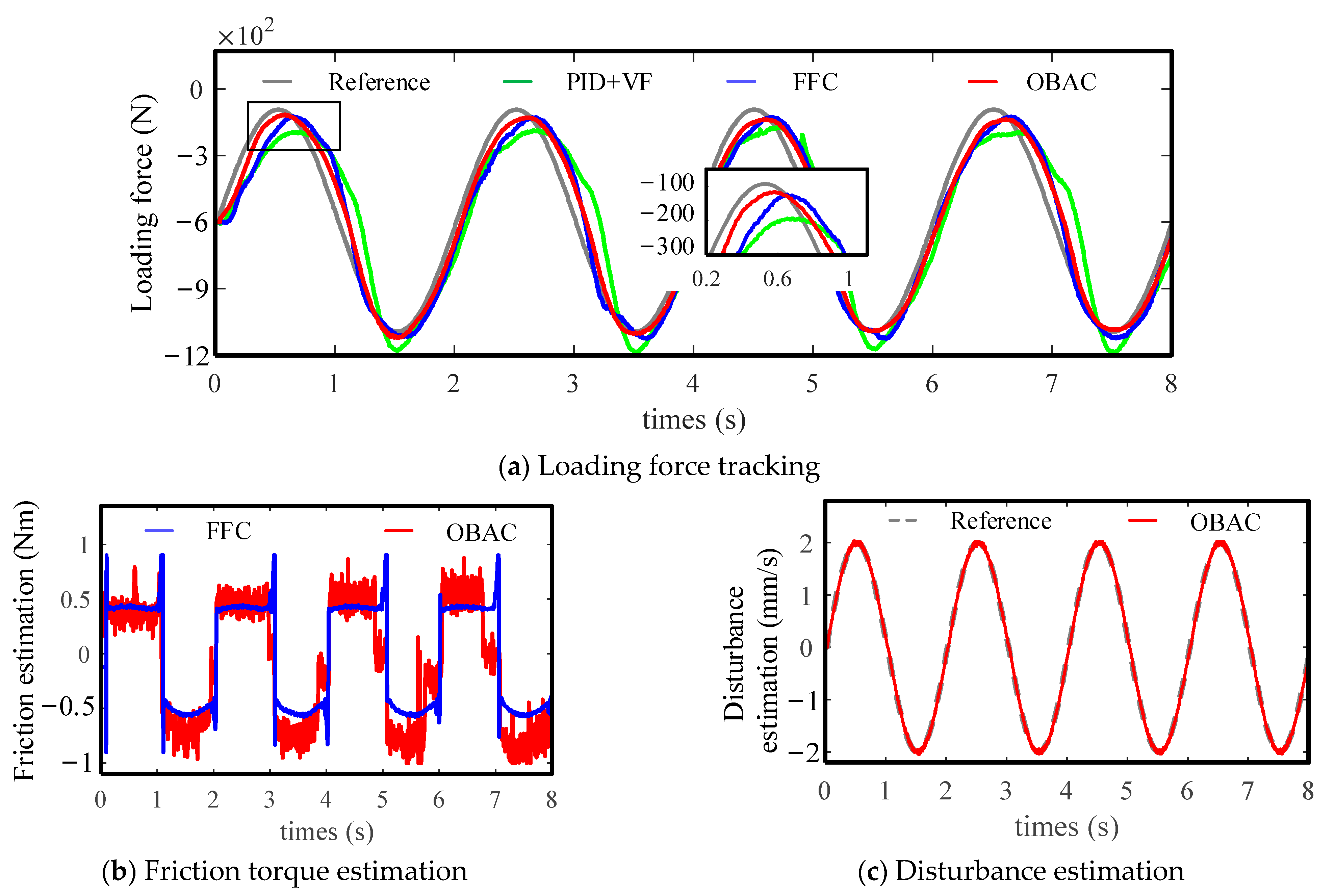

5.2.1. Static Loading Experiment

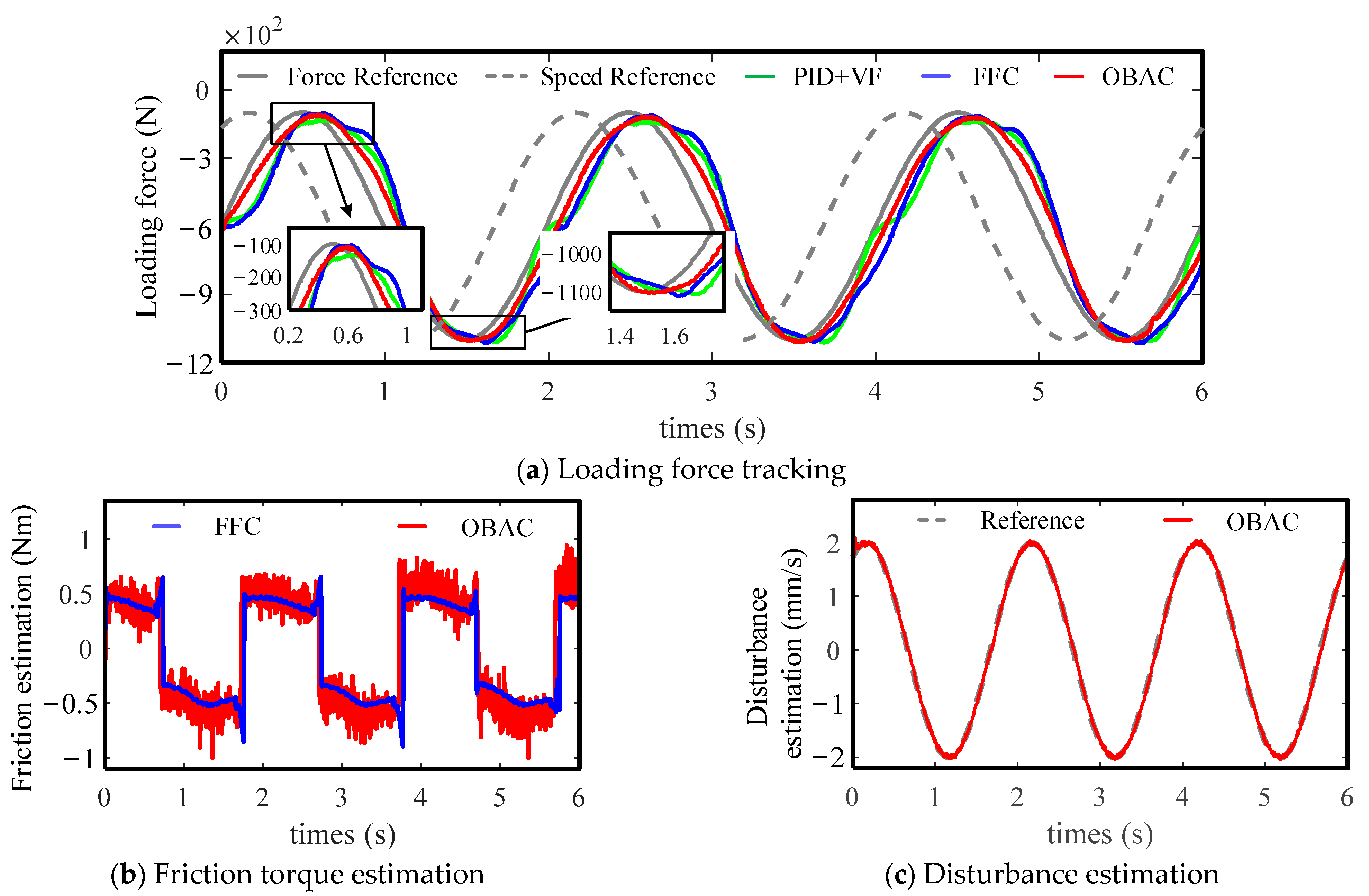

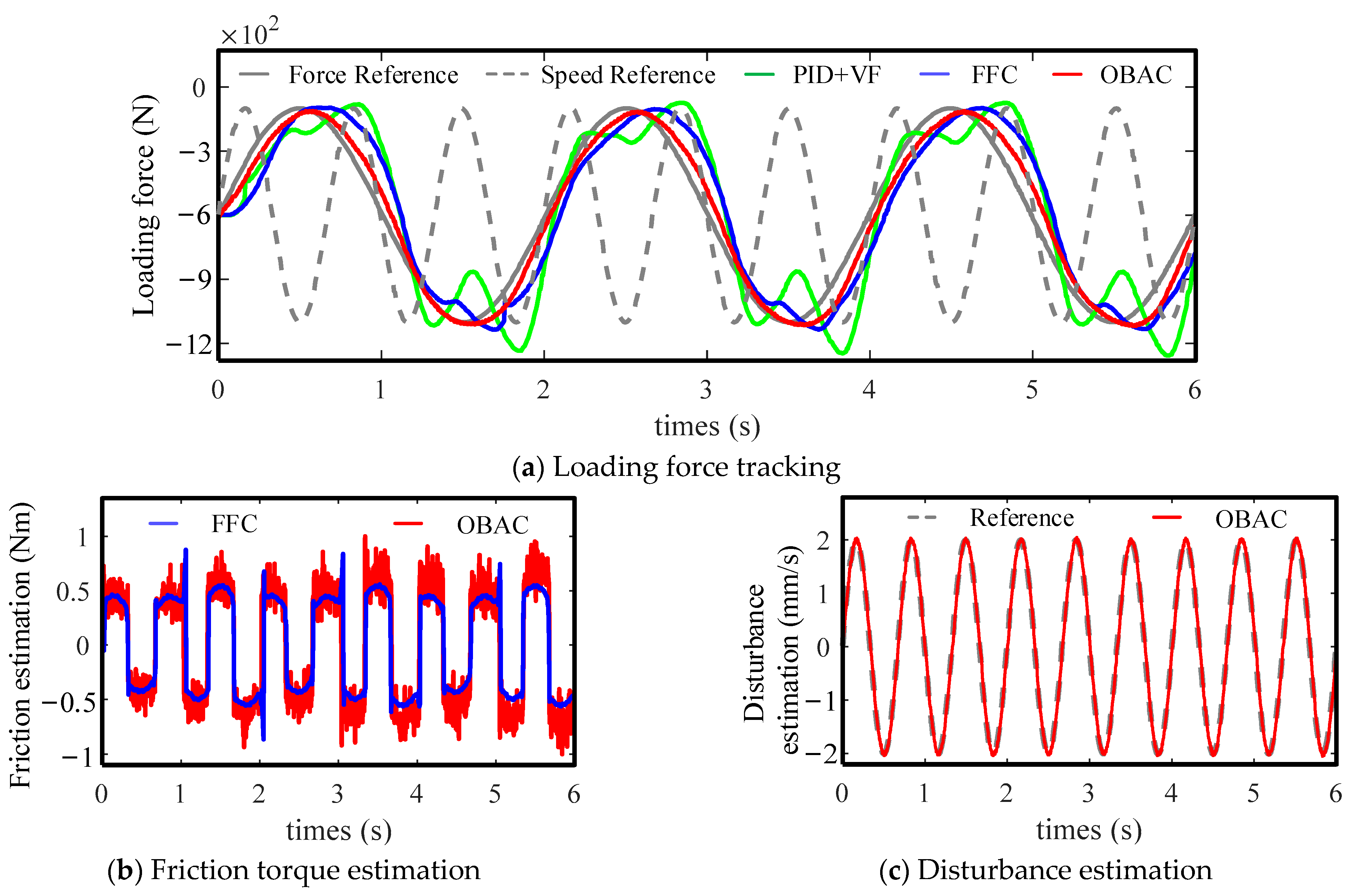

5.2.2. Dynamic Loading Experiment

6. Conclusions

- (1)

- Under the influence of friction nonlinearity, position disturbance and parameter uncertainties, an observer-based backstepping adaptive control (OBAC) strategy was proposed to achieve high-load force tracking performance for an electro-mechanical actuator. The whole system was divided into ‘actuation’ and ‘loading’ subsystems with the backstepping design concept. The dynamic control surface was introduced to solve the so-called differential explosion problem.

- (2)

- The estimation of the position disturbance was obtained by an extended stated observer and used for feedforward compensation for the ‘loading’ subsystem. For the ‘actuation’ subsystem, a friction scale factor with a reasonable adaptive updating law was introduced to reject the disturbance of the friction parameter uncertainties for both simplified and effective purposes. Combining the observer for internal state of friction model and an improved LuGre based friction model, which considers the load influence on friction, adaptive friction compensation was conducted.

- (3)

- The static and three different types of dynamic loading experiments sufficiently verified that the proposed OBAC control strategy achieved high-precision load force tracking and strong robustness. The designed ESO accurately obtained the lumped position disturbance caused by forced motion of the tested actuator. By using the friction torque estimation for compensation, the ‘flat-top’ or distortion phenomenon can be eliminated or weakened. Compared to the FFC approach, the proposed OBAC method utilizes the parameter adaptive law to suppress friction parameter uncertainties, which leads to superior performance of the loading force control.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mare, J.C.; Fu, J. Review on signal-by-wire and power-by-wire actuation for more electric aircraft. Chin. J. Aeronaut. 2017, 30, 857–870. [Google Scholar] [CrossRef]

- Qiao, G.; Liu, G.; Shi, Z.; Wang, Y.; Ma, S.; Lim, T.C. A Review of Electromechanical Actuators for More/All Electric Aircraft Systems. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2017, 232, 4128–4151. [Google Scholar] [CrossRef] [Green Version]

- Bajcinca, N.; Schurmann, N.; Bals, J. Two degree of freedom motion control of an energy optimized aircraft ram air inlet actuator. In Proceedings of the International Conference on Control and Automation (ICCA), Budapest, Hungary, 26–29 June 2005; pp. 818–821. [Google Scholar]

- SAE Aerospace. Trimmable Horizontal Stabilizer Actuator Descriptions: SAE AIR6052; SAE International: Warrendale, PA, USA, 2011; pp. 1–38. [Google Scholar]

- Jensen, S.C.; Jenney, G.D.; Dawson, D. Flight Test Experience with an Electromechanical Actuator on the F-18 Systems Research Aircraft. In Proceedings of the 19th Digital Avionics Systems Conference (DASC), Philadelphia, PA, USA, 7–13 October 2000; pp. 1–10. [Google Scholar]

- Todeschi, M. Airbus-EMAs for Flight Controls Actuation System-An Important Step Achieved in 2011; SAE Technical Paper 2011-01-2732; SAE International: Warrendale, PA, USA, 2011; Volume 1. [Google Scholar]

- Jiménez, A.; Lasa, J.; Novillo, E.; Eguizabal, I.; Aguado, F.; Lopez, I. Electromechanical Actuator with Anti-Jamming System for Safety critical aircraft applications. In Proceedings of the 7th International Conference on Recent Advances in Aerospace Actuation Systems and Components, Toulouse, France, 16–18 March 2016; pp. 27–32. [Google Scholar]

- Whitley, C.; Ropert, J. Development, manufacture & flight test of spoiler EMA system. In Proceedings of the 3rd International Conference on Recent Advances in Aerospace Actuation Systems and Components, Toulouse, France, 13–15 June 2007; pp. 215–220. [Google Scholar]

- Bohr, G.; Hamilton, S. Force control is the issue in aerospace structural test lab. Hydraul. Pneum. 2000, 53, 43–47. [Google Scholar]

- Nam, Y.; Sung, K. Force control system design for aerodynamic load simulator. Control Eng. Pract. 2002, 10, 549–558. [Google Scholar] [CrossRef]

- Arena, M.; Amoroso, F.; Pecora, R.; Ameduri, S. Electro-Actuation System Strategy for a Morphing Flap. Aerospace 2019, 6, 1. [Google Scholar] [CrossRef] [Green Version]

- Mare, J.C. Dynamic loading systems for ground testing of high speed aerospace actuators. Aircr. Eng. Aerosp. Tec. 2006, 78, 275–282. [Google Scholar] [CrossRef]

- Kang, S.; Yan, H.; Dong, L.; Li, C. Finite-time adaptive sliding mode force control for electro-hydraulic load simulator based on improved GMS friction model. Mech. Syst. Signal Process. 2018, 102, 117–138. [Google Scholar] [CrossRef]

- Matsui, T.; Mochizuki, Y. Effect of positive angular velocity feedback on torque control of hydraulic actuator. Trans. Jpn. Soc. Mech. Eng. 2008, 57, 1604–1609. [Google Scholar]

- Zheng, S.; Fu, Y.; Wang, D.; Zhang, W.; Pan, J. Investigations on system integration method and dynamic performance of electromechanical actuator. Sci. Prog. 2020, 103, 03685042094092. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.; Jiao, Z.; Han, S. Friction compensation for low velocity control of hydraulic flight motion simulator: A simple adaptive robust approach. Chin. J. Aeronaut. 2013, 26, 814–822. [Google Scholar] [CrossRef] [Green Version]

- Yao, J.; Jiao, Z.; Yao, B. Robust Control for Static Loading of Electro-hydraulic Load Simulator with Friction Compensation. Chin. J. Aeronaut. 2012, 25, 954–962. [Google Scholar] [CrossRef] [Green Version]

- Alleyne, A.; Liu, R. A simplified approach to force control for electro-hydraulic systems. Control Eng. Pract. 2000, 8, 1347–1356. [Google Scholar] [CrossRef]

- Wang, C.; Jiao, Z.; Quan, L.; Meng, H. Application of adaptive robust control for electro-hydraulic motion loading system. Trans. Inst. Meas. Control 2018, 40, 873–884. [Google Scholar]

- Wang, L.; Wang, M.; Guo, B.; Wang, Z.; Wang, D.; Li, Y. A Loading Control Strategy for Electric Load Simulators Based on Proportional Resonant Control. IEEE Trans. Ind. Electron. 2018, 65, 4608–4618. [Google Scholar] [CrossRef]

- Zhao, J.; Shen, G.; Zhu, W.; Yang, C.; Yao, J. Robust force control with a feed-forward inverse model controller for electro-hydraulic control loading systems of flight simulators. Mechatronics 2016, 38, 42–53. [Google Scholar] [CrossRef]

- Jing, C.; Xu, H.; Jiang, J. Dynamic surface disturbance rejection control for electro-hydraulic load simulator. Mech. Syst. Signal Process. 2019, 134, 1026293. [Google Scholar] [CrossRef]

- Niksefat, N.; Sepehri, N. Design and experimental evaluation of a robust force controller for an electro-hydraulic actuator via quantitative feedback theory. Control Eng. Pract. 2000, 8, 1335–1345. [Google Scholar] [CrossRef]

- Truong, D.Q.; Ahn, K.K. Force control for hydraulic load simulator using self-tuning grey predictor fuzzy PID. Mechatronics 2009, 19, 233–246. [Google Scholar] [CrossRef]

- Li, C.; Pan, X.; Wang, G. Torque tracking control of electric load simulator with active motion disturbance and nonlinearity based on T-S fuzzy model. Asian J. Control 2018, 22, 1280–1294. [Google Scholar] [CrossRef]

- Li, C.; Li, Y.; Wang, G. H-infinity output tracking control of Electric-motor-driven aerodynamic Load Simulator with external active motion disturbance and nonlinearity. Aerosp. Sci. Technol. 2018, 82–83, 334–349. [Google Scholar] [CrossRef]

- de Wit, C.C.; Olsson, H.; Astrom, K.; Lischinsky, P. A new model for control of systems with friction. IEEE Trans. Autom. Control 1995, 40, 419–425. [Google Scholar] [CrossRef] [Green Version]

- Fu, J.; Maré, J.C.; Fu, Y. Modelling and Simulation of Flight Control Electromechanical Actuators with Special Focus on Model Architecting, Multidisciplinary Effects and Power Flows. Chin. J. Aeronaut. 2017, 30, 47–65. [Google Scholar] [CrossRef] [Green Version]

- Ping, Z.; Zhang, W.; Fu, Y. Improved LuGre-based friction modeling of the electric linear load simulator. In Proceedings of the 8th International Conference on Manufacturing Technology and Applied Materials (ICAMMT), Hangzhou, China, 15–17 April 2022. [Google Scholar]

- Wang, X.; Wang, S. High Performance Adaptive Control of Mechanical Servo System with LuGre Friction Model: Identification and Compensation. J. Dyn. Syst. Meas. Control 2012, 134, 011021. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.; Chen, H.; Zhu, D.; Li, L. Design and Analysis of an Active Disturbance Rejection Robust Adaptive Control System for Electromechanical Actuator. Actuators 2021, 10, 307. [Google Scholar] [CrossRef]

- Xu, D.; Huang, J.; Su, X.; Shi, P. Adaptive command-filtered fuzzy backstepping control for linear induction motor with unknown end effect. Inf. Sci. 2019, 477, 118–131. [Google Scholar] [CrossRef]

- Swaroop, D.; Hedrick, J.K.; Yip, P.P.; Gerdes, J. Dynamic surface control for a class of nonlinear systems. IEEE Trans. Autom. Control 2002, 45, 1893–1899. [Google Scholar] [CrossRef] [Green Version]

| Static Parameters | Dynamic Parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| ac (N·m/N) | bc (N·m) | as (N·m/N) | bs (N·m) | σ2 (N·m·s/rad) | ωst (rad/s) | σ0 (N·m/rad) | σ1 (N·m·s/rad) | |

| P.D. | 1.01 × 10−4 | 0.3317 | 1.13 × 10−4 | 0.5189 | 0.0173 | 0.3468 | 351.03 | 0.9014 |

| N.D. | 1.07 × 10−4 | 0.2755 | 1.46 × 10−4 | 0.5006 | 0.0234 | 0.3431 | ||

| AA | PL (°) | MTE (N) | MSE (N) | |

|---|---|---|---|---|

| NFC | 7.8% | 41.0 | 345.5 | 157.4 |

| FFC | 2.2% | 29.8 | 277 | 118.8 |

| OBAC | −2.2% | 17.8 | 155 | 74.5 |

| AA | PL (°) | MTE (N) | MSE (N) | |

|---|---|---|---|---|

| NFC | 14.4% | 41.6 | 337.5 | 143.5 |

| FFC | 4.8% | 27.6 | 228.5 | 93.2 |

| OBAC | 3.2% | 18.7 | 138.2 | 53.6 |

| AA | PL (°) | MTE (N) | MSE (N) | |

|---|---|---|---|---|

| NFC | 7.1% | 28.8. | 293.0 | 120.3 |

| FFC | 0.9% | 21.6 | 271.5 | 134.8 |

| OBAC | 1.8% | 13.7 | 136.2 | 70.6 |

| AA | PL (°) | MTE (N) | MSE (N) | |

|---|---|---|---|---|

| NFC | −4.9% | 61.2 | 442.5 | 196.1 |

| FFC | −0.7% | 24.3 | 256.0 | 136.5 |

| OBAC | 2.5% | 12.6 | 117.7 | 63.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Ping, Z.; Fu, Y.; Zheng, S.; Zhang, P. Observer-Based Backstepping Adaptive Force Control of Electro-Mechanical Actuator with Improved LuGre Friction Model. Aerospace 2022, 9, 415. https://doi.org/10.3390/aerospace9080415

Zhang W, Ping Z, Fu Y, Zheng S, Zhang P. Observer-Based Backstepping Adaptive Force Control of Electro-Mechanical Actuator with Improved LuGre Friction Model. Aerospace. 2022; 9(8):415. https://doi.org/10.3390/aerospace9080415

Chicago/Turabian StyleZhang, Wensen, Zilong Ping, Yongling Fu, Shicheng Zheng, and Peng Zhang. 2022. "Observer-Based Backstepping Adaptive Force Control of Electro-Mechanical Actuator with Improved LuGre Friction Model" Aerospace 9, no. 8: 415. https://doi.org/10.3390/aerospace9080415

APA StyleZhang, W., Ping, Z., Fu, Y., Zheng, S., & Zhang, P. (2022). Observer-Based Backstepping Adaptive Force Control of Electro-Mechanical Actuator with Improved LuGre Friction Model. Aerospace, 9(8), 415. https://doi.org/10.3390/aerospace9080415