Using Principal Component Analysis for Temperature Readings from YF3:Pr3+ Luminescence

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

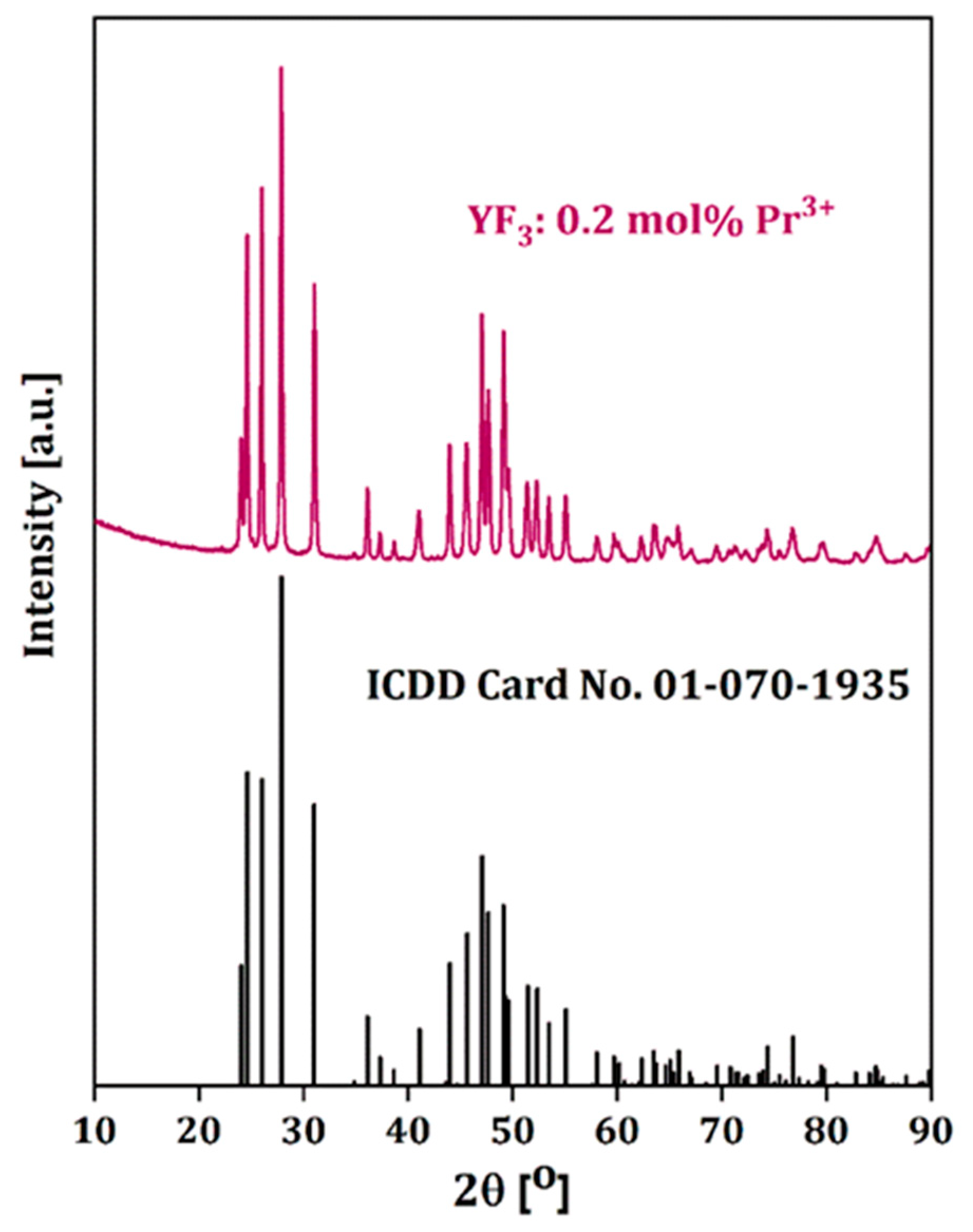

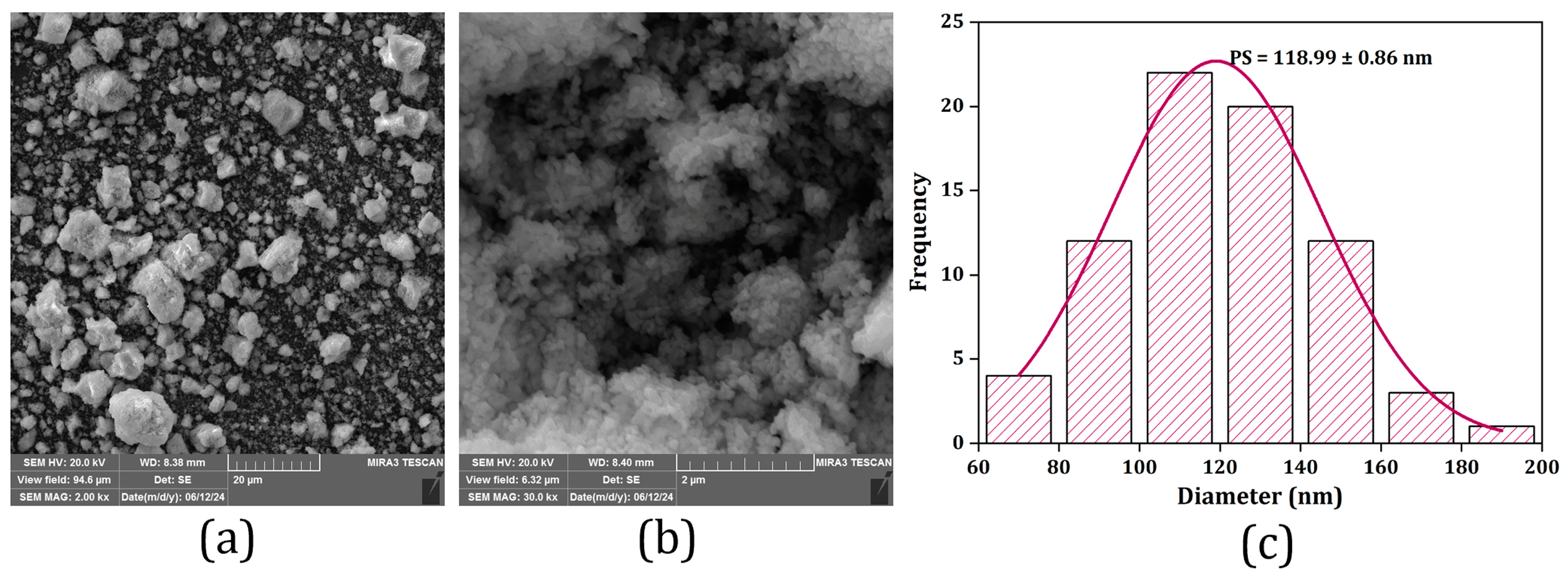

3.1. Structural and Morphological Analysis

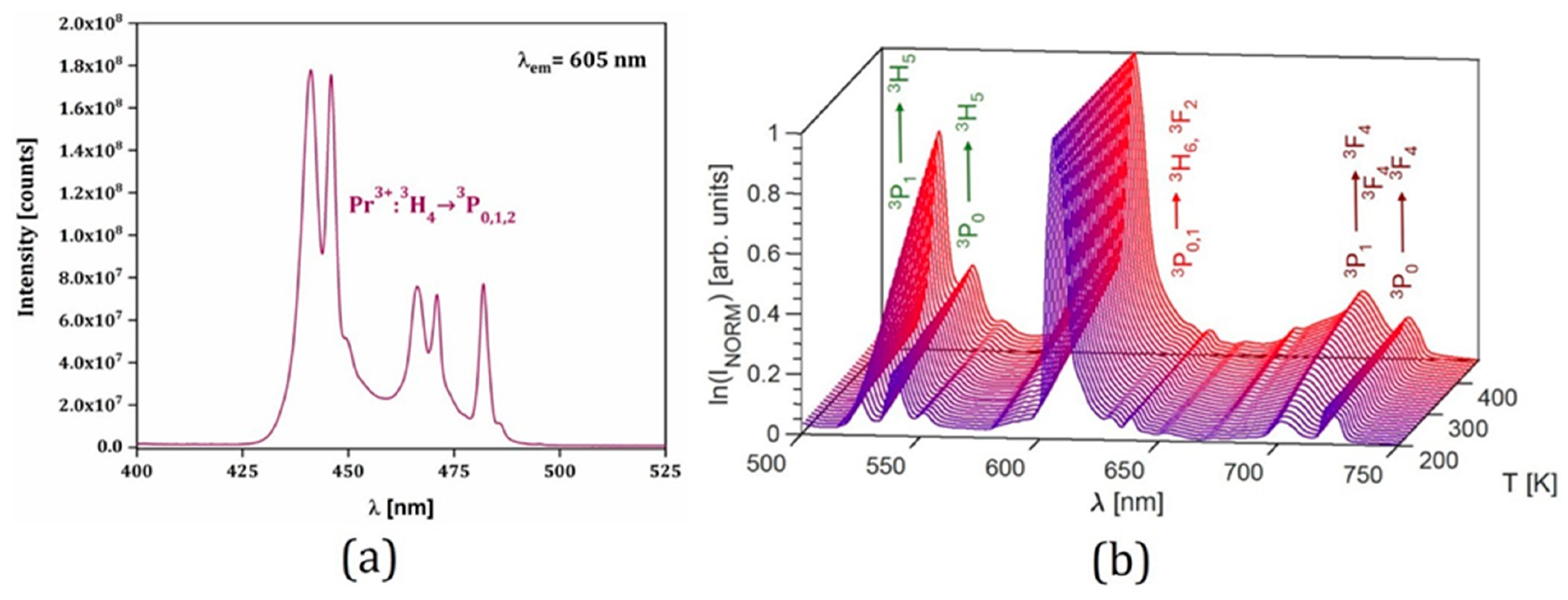

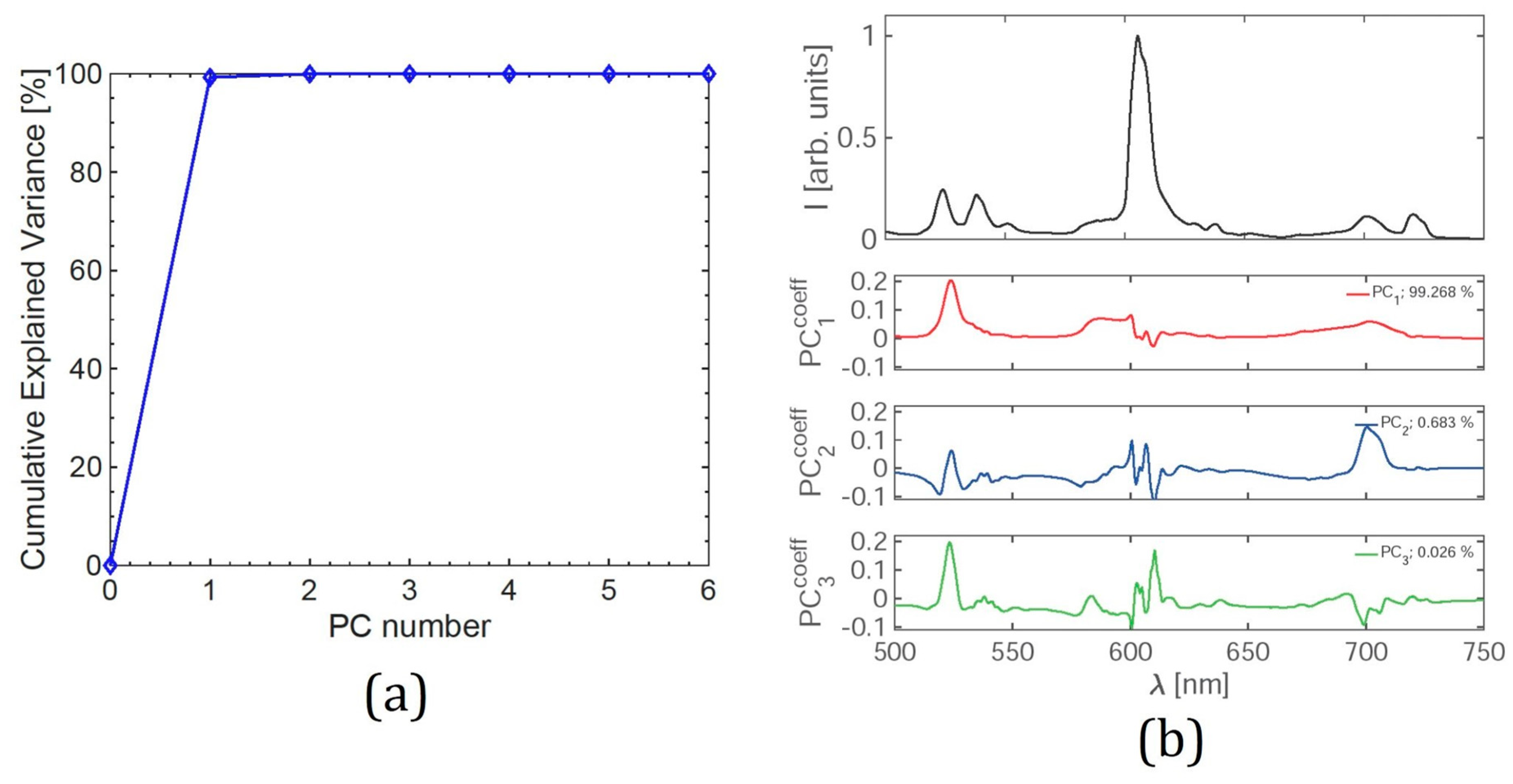

3.2. Temperature-Dependent Photoluminescent Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dramićanin, M. Luminescence Thermometry: Methods, Materials, and Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Carvajal Martí, J.J.; Pujol Baiges, M.C. (Eds.) Luminescent Thermometry Applications and Uses; Springer: Cham, Switzerland, 2023. [Google Scholar]

- Đačanin Far, L.; Dramićanin, M.D. Luminescence thermometry with nanoparticles: A review. Nanomaterials 2023, 13, 2904. [Google Scholar] [CrossRef]

- Brites, C.D.S.; Balabhadra, S.; Carlos, L.D. Lanthanide-based thermometers: At the cutting-edge of luminescence thermometry. Adv. Opt. Mater. 2018, 7, 1801239. [Google Scholar] [CrossRef]

- Brites, C.D.S.; Marin, R.; Suta, M.; Carneiro Neto, A.N.; Ximendes, E.; Jaque, D.; Carlos, L.D. Spotlight on luminescence thermometry: Basics, challenges, and cutting-edge applications. Adv. Mater. 2023, 35, 2302749. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Guo, X.; Zhang, Z.; Fu, Z.; Zheng, H. Luminescence thermometry with rare earth doped nanoparticles: Status and challenges. J. Lumin. 2022, 250, 119110. [Google Scholar] [CrossRef]

- Bednarkiewicz, A.; Drabik, J.; Trejgis, K.; Jaque, D.; Ximendes, E.; Marciniak, L. Luminescence based temperature bio-imaging: Status, challenges, and perspectives. Appl. Phys. Rev. 2021, 8, 011317. [Google Scholar] [CrossRef]

- Dramićanin, M.D. Trends in luminescence thermometry. J. Appl. Phys. 2020, 128, 040902. [Google Scholar] [CrossRef]

- Lewis, C.; Erikson, J.W.; Sanchez, D.A.; McClure, C.E.; Nordin, G.P.; Munro, T.R.; Colton, J.S. Use of machine learning with temporal photoluminescence signals from CdTe quantum dots for temperature measurement in microfluidic devices. ACS Appl. Nano Mater. 2020, 3, 4045–4053. [Google Scholar] [CrossRef] [PubMed]

- Cai, T.; Deng, Z.; Park, Y.; Mohammadshahi, S.; Liu, Y.; Kim, K.C. Acquisition of kHz-frequency two-dimensional surface temperature field using phosphor thermometry and proper orthogonal decomposition assisted long short-term memory neural networks. Int. J. Heat Mass Transf. 2021, 165, 120662. [Google Scholar] [CrossRef]

- Ximendes, E.; Marin, R.; Carlos, L.D.; Jaque, D. Less is more: Dimensionality reduction as a general strategy for more precise luminescence thermometry. Light Sci. Appl. 2022, 11, 237. [Google Scholar] [CrossRef]

- Šević, D.; Vlašić, A.; Rabasović, M.S.; Savić-Sević, S.; Rabasović, M.; Nikolić, M.G.; Murić, B.; Marinković, B.; Križan, J. Temperature effects on luminescent properties of Sr2CeO4:Eu3+ nanophosphor: A machine learning approach. Tehnika 2020, 75, 279–283. [Google Scholar] [CrossRef]

- Aoun, N.B. A Review of automatic pain assessment from facial information using machine learning. Technologies 2024, 12, 92. [Google Scholar] [CrossRef]

- Manakitsa, N.; Maraslidis, G.S.; Moysis, L.; Fragulis, G.F. A Review of machine learning and deep learning for object detection, semantic segmentation, and human action recognition in machine and robotic vision. Technologies 2024, 12, 15. [Google Scholar] [CrossRef]

- González-Rodríguez, J.-R.; Córdova-Esparza, D.-M.; Terven, J.; Romero-González, J.-A. Towards a bidirectional Mexican sign language–Spanish translation system: A deep learning approach. Technologies 2024, 12, 7. [Google Scholar] [CrossRef]

- Bakthavatchalam, K.; Karthik, B.; Thiruvengadam, V.; Muthal, S.; Deepa, J.; Kotecha, K.; Varadarajan, V. IoT framework for measurement and precision agriculture: Predicting the crop using machine learning algorithms. Technologies 2022, 10, 13. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. Sect. A. 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Zalkin, A.; Templeton, D.H. The crystal structures of YF3 and related compounds. J. Am. Chem. Soc. 1953, 75, 2453–2458. [Google Scholar] [CrossRef]

- Wang, X.; Mao, Y. Recent advances in Pr3+-activated persistent phosphors. J. Mater. Chem. C 2022, 10, 3626–3646. [Google Scholar] [CrossRef]

- Antić, Ž.; Racu, A.V.; Medić, M.; Alodhayb, A.N.; Kuzman, S.; Brik, M.G.; Dramićanin, M.D. Concentration and temperature dependence of Pr3+ f-f emissions in La(PO3)3. Opt. Mater. 2024, 150, 115226. [Google Scholar] [CrossRef]

- Pellé, F.; Dhaouadi, M.; Michely, L.; Aschehoug, P.; Toncelli, A.; Veronesi, S.; Tonelli, M. Spectroscopic Properties and upconversion in Pr3+: YF3 nanoparticles. Phys. Chem. Chem. Phys. 2011, 13, 17453–17460. [Google Scholar] [CrossRef]

- Srivastava, A.M. Aspects of Pr3+ luminescence in solids. J. Lumin. 2016, 169, 445–449. [Google Scholar] [CrossRef]

- Srivastava, A.M.; Duclos, S.J. On the luminescence of YF3-Pr3+ under vacuum ultraviolet and X-ray excitation. Chem. Phys. Lett. 1997, 275, 453–456. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajčić, A.; Ristić, Z.; Periša, J.; Milićević, B.; Aldawood, S.; Alodhayb, A.N.; Antić, Ž.; Dramićanin, M.D. Using Principal Component Analysis for Temperature Readings from YF3:Pr3+ Luminescence. Technologies 2024, 12, 131. https://doi.org/10.3390/technologies12080131

Rajčić A, Ristić Z, Periša J, Milićević B, Aldawood S, Alodhayb AN, Antić Ž, Dramićanin MD. Using Principal Component Analysis for Temperature Readings from YF3:Pr3+ Luminescence. Technologies. 2024; 12(8):131. https://doi.org/10.3390/technologies12080131

Chicago/Turabian StyleRajčić, Anđela, Zoran Ristić, Jovana Periša, Bojana Milićević, Saad Aldawood, Abdullah N. Alodhayb, Željka Antić, and Miroslav D. Dramićanin. 2024. "Using Principal Component Analysis for Temperature Readings from YF3:Pr3+ Luminescence" Technologies 12, no. 8: 131. https://doi.org/10.3390/technologies12080131

APA StyleRajčić, A., Ristić, Z., Periša, J., Milićević, B., Aldawood, S., Alodhayb, A. N., Antić, Ž., & Dramićanin, M. D. (2024). Using Principal Component Analysis for Temperature Readings from YF3:Pr3+ Luminescence. Technologies, 12(8), 131. https://doi.org/10.3390/technologies12080131