Abstract

Green sustainable energy, especially renewable energy, is gaining huge popularity and is considered a vital energy in addressing energy conservation and global climate change. One of the most significant renewable energy sources in the UAE is solar energy, due to the country’s high solar radiation levels. This paper focuses on advanced technology that integrates parabolic trough mirrors, molten salt storage, and thermoelectric generators (TEGs) to provide a reliable and effective solar system in the UAE. Furthermore, the new system can be manufactured in different sizes suitable for consumption whether in ordinary houses or commercial establishments and businesses. The proposed design theoretically achieves the target electrical energy of 2.067 kWh/day with 90% thermal efficiency, 90.2% optical efficiency, and 8% TEG efficiency that can be elevated to higher values reaching 149% using the liquid-saturated porous medium, ensuring the operation of the system throughout the day. This makes it a suitable solar system in off-grid areas. Moreover, this system is a cost-effective, carbon-free, and day-and-night energy source that can be dispatched on the electric grid like any fossil fuel plant under the proposed method, with less maintenance, thus contributing to the UAE’s renewable energy strategy.

1. Introduction

Green sustainable energy is now considered a vital energy source in addressing energy conservation and global climate change since the sources of renewable energy, Confirmed such as wind, solar, and other sources, limit gas emissions and mitigate the effects of climate change. Green energy technologies are essential for achieving global climate objectives while enhancing energy access and promoting economic growth. Although numerous research studies have explored the potential of sustainable energy sources, innovative solutions are still needed to address these issues effectively.

The United Arab Emirates (UAE), like other gulf countries, has depended on oil exports in past decades. But the government has acknowledged the importance of using different energy sources to include significant investments in renewable energy. Its strategic geographical location and abundant solar resources have helped the UAE to utilize solar energy as part of its vision for a sustainable future. The UAE Energy Strategy 2050 targets a 50% contribution of clean energy to the entire energy mix by 2050, emphasizing the UAE’s commitment to becoming a global leader in sustainable renewable energy [1].

One of the most significant renewable energy sources in the UAE is solar energy, due to the country’s high solar radiation levels. The use of solar energy is not only limited to reducing greenhouse gas emissions and opposing climate change but also contributes to energy conservation and economic development. However, the irregular nature of solar energy imposes efficient storage solutions to provide a reliable power supply. This paper focuses on integrating trough solar mirrors with Molten Salt Energy Storage (MSES) and thermoelectric generators (TEGs) to provide a dispatchable renewable energy source in the UAE. This can be accomplished by optimizing the charging and discharging processes of thermal energy storage systems, and also by maximizing power generation from solar systems.

This research is distinctive in that it proposed a new design of trough mirrors that combines the use of the two extendable parabolic mirrors as collectors with the use of a salt tank that is attached and held between the two mirrors. The molten salt acts as a heat transfer fluid and storage system at the same time, without the need for receivers, molten fluids, pipes, storage tanks, and batteries that exist in traditional trough systems. Also, TEGs are used to convert heat directly into electricity using the Seebeck effect. To achieve this, the following objectives have been identified:

- Assess the utilization of the current state of solar energy in the UAE by evaluating the existing solar power projects, especially photovoltaic (PV) systems and concentrated solar power (CSP) systems. Also, analyze the efficiency and cost-effectiveness of these technologies used in the UAE.

- Integrate Molten Salt Energy Storage (MSES) with solar power systems and study the recent technological achievements in molten salt as a heat storage system in trough solar systems and then explore the feasibility of this integration and its benefits in the UAE’s renewable energy systems.

- Optimize thermal energy storage systems for increasing power generation by optimizing the thermal energy’s charging and discharging processes.

- Evaluate the environmental and economic impacts and benefits such as greenhouse gas emissions and improve energy sustainability and efficiency.

By considering these objectives, this research aims to contribute to the UAE’s renewable energy strategy, thus ensuring sustainable, reliable, and cost-effective power supply systems while advancing economic growth and environmental conservation. This study represents a pre-feasibility analysis, with the proposed design’s performance requiring validation through the construction, characterization, and experimental qualification of a prototype.

The research methodology comprises the following: Conduct a comprehensive review of the existing literature on CSP systems, focusing on advancements in high-efficiency panels and bifacial designs, MSES technology, including its operating principles, integration with CSP (concentrated solar power), and case studies of existing SP and CSP plants with MSES integration. Then, gather relevant high-resolution solar irradiation data for targeted locations and typical electricity demand patterns in the UAE. After that, design the solar system based on the collected data and evaluate its effectiveness and sustainability.

2. Literature Review

Green sustainable energy plays an essential role in addressing global climate change and energy preservation. It includes renewable energy sources such as solar, wind, hydro, and biomass energy [2], which curb greenhouse gas emissions and mitigate climate change effects [3]. The use of green energy technologies is essential for achieving global climate objectives while enhancing energy access and fostering economic growth [4]. Innovative solutions are needed to address intermittent issues and storage challenges when integrating renewable energy into the power grid [5].

Over the years, numerous research studies have been conducted to explore the potential of sustainable energy sources and renewable energy technologies [6]. These research studies have focused on various aspects, including technical feasibility, economic viability, environmental impacts, and policy frameworks related to sustainable energy sources [7]. One of the key research studies related to sustainable energy sources is a study that focuses on the theoretical problems surrounding the adoption of renewable energy policies. The researchers aim to highlight the potential for sustainable growth using renewable energy and identify viable policy mechanisms for enhancing grid-tied solar energy adoption [8]. This study utilizes qualitative and quantitative data collection methods, as well as the HOMER Grid software, to identify a unified renewable energy policy mechanism that can significantly enhance the adoption of grid-tied solar energy generation [2]. Another important aspect of sustainable energy research is the economic impact of renewable energy technologies. Researchers have explored the economic viability of renewable energy technologies and their potential to create job opportunities and stimulate economic development [4]. For example, economic support policies that encourage investments in new technologies promoting the adoption of renewable energy have been implemented in many countries [9]. These policies aim to ensure the security of energy supply, minimize the usage of fossil fuels, reduce greenhouse gas emissions, improve industrial capabilities, and increase local benefits through job creation and economic development [10]. In addition to the economic impacts, research studies have also examined the environmental benefits of sustainable energy sources. These studies have looked at the reduction in greenhouse gas emissions, air pollution, and water usage associated with the use of renewable energy technologies [11]. For instance, one study investigated a wind-photovoltaic power plant that produces green hydrogen for a hydrogen refueling station and operates an electrocoagulation system for wastewater treatment. This study concluded that this integrated system not only generates renewable energy but also reduces greenhouse gas emissions and minimizes water usage compared to conventional energy systems [2]. Additionally, research has also focused on the reliability and scalability of renewable energy sources. For example, researchers have explored the stability and consistency of renewable energy sources, such as solar and wind power, and how they can be integrated into existing electricity grids without compromising reliability [12]. Furthermore, the geographical location and availability of renewable energy resources have been considered in research studies. For instance, some regions may have more favorable conditions for solar or wind power generation, while others may have limited access to these resources. In terms of policy frameworks, well-structured policies and strategies are crucial for promoting the deployment of renewable energy [13]. These policies can include feed-in tariffs, net metering, renewable energy auctions, and other mechanisms that incentivize the adoption of and investment in renewable energy technologies. In addition to the economic and environmental benefits, it is important to consider the social impacts of sustainable energy sources. Research studies have examined the social benefits of renewable energy, including job creation, community engagement, and improved health outcomes [14]. These studies have shown that the transition to sustainable energy sources can create jobs in the renewable energy sector, stimulate local economies, and improve community resilience [15]. Moreover, research has also explored the economic impacts of renewable energy sources. For example, studies have analyzed the cost-effectiveness of renewable energy technologies compared to conventional energy sources. These studies have found that while the initial investment may be higher for renewable energy technologies, the long-term operational and maintenance costs are often lower, resulting in cost savings over time [14]. Furthermore, research has also investigated the environmental impacts of sustainable energy sources. These studies have assessed the lifecycle greenhouse gas emissions of renewable energy technologies, comparing them to those of fossil-fuel-based energy systems. They have found that renewable energy sources significantly reduce greenhouse gas emissions and contribute to mitigating climate change [5,16]. The use of renewable energy sources, such as solar and wind power, has been extensively researched in the context of sustainable energy systems. These sources have been identified as key components of future energy systems due to their low costs, global potential, and ability to avoid some of the severe environmental impacts associated with other renewable energy sources like hydropower and bioenergy [17].

The United Arab Emirates has historically relied heavily on oil exports; however, it has now acknowledged the importance of expanding its energy sources to encompass significant investments in renewable energy [18]. The UAE, with its strategic geographical location and its ample solar resources, has embraced this technology as part of its vision for a sustainable future [19]. Additionally, the UAE Energy Strategy 2050 targets a 50% contribution of clean energy to the entire energy mix by 2050. These strategic initiatives underscore the UAE’s commitment to becoming a global leader in renewable energy and sustainability [20].

One of the key renewable energy sources that has gained significant attention in the United Arab Emirates is solar energy [18]. Solar energy holds immense significance in the UAE due to its abundance of solar radiation throughout the year. The UAE has one of the highest solar radiation levels in the world, making it an ideal location for harnessing solar energy. The utilization of solar radiation levels in the UAE not only helps reduce greenhouse gas emissions and combat climate change but also contributes to energy security and diversification of the economy. The UAE government has recognized the potential of solar energy and has taken proactive measures to promote its adoption. These measures include the establishment of the Dubai Clean Energy Strategy 2050, which aims to provide 75% of Dubai’s total power output from clean energy sources by 2050, with solar energy playing a key role. In line with this strategy, the UAE has launched several major solar energy projects, including the Mohammed bin Rashid Al Maktoum Solar Park and the Noor Abu Dhabi Solar Project. These projects not only contribute to the country’s renewable energy targets but also attract significant investments, create job opportunities, and stimulate economic growth. Moreover, the UAE’s focus on solar energy aligns with global efforts to transition towards a low-carbon and sustainable future.

The two primary types of solar technologies used in the world are photovoltaic (PV) systems and concentrated solar power (CSP) systems. PV systems convert solar radiation directly into electricity using semiconductor materials, while CSP systems use mirrors or lenses to concentrate solar radiation onto a small area to generate heat, which is then used to produce electricity. Both technologies have seen significant advancements in recent years, improving their efficiency and cost-effectiveness. The efficiency of solar thermal systems is influenced by factors such as solar irradiance, collector design, and heat transfer fluids. Parabolic trough systems, for example, achieve thermal efficiencies of up to 75%, while flat-plate collectors typically range between 40% and 60% [21], while the efficiency of solar panels has increased significantly over the past decade, driven by technological advancements and research. Modern PV panels now achieve efficiencies of over 20%, compared to less than 15% a decade ago [22]. Recent innovations in solar technology have greatly enhanced the performance and viability of solar power systems. Recent advancements in flat-plate collectors include the integration of nanofluids and phase-change materials (PCMs) to enhance heat transfer with 20% efficiency and storage capabilities [23]. Advancements in CSP technology, such as the use of molten salt as a heat transfer fluid, have improved the efficiency and storage capabilities of CSP plants [24]. For example, Grogan indicates that using molten salt plants is better than the traditional oil HTF by 22% to 28% [25]. Andasol station, one the largest solar stations in the world located in Spain, uses molten salt to effectively generate electrical power even after sunset since it can store the thermal energy up to 7.5 h [26]. In the UAE, molten salt was used in the Mohammed bin Rashid Al Maktoum Solar Park to ensure the generation of power during the night and cloudy weather [27]; molten salt was also used in the Noor Abu Dhabi Solar Project, with 90% thermal efficiency and 24 h of electrical power generation [1]. Similarly, the cost of solar technology has decreased dramatically. The cost of solar PV modules has dropped by more than 80% since 2010, making solar power more competitive with traditional energy sources. To enhance the generation of electrical energy, several researchers have focused on using thermoelectric generators (TEGs) to enhance the overall performance of the system. The efficiency of these TEGs is relatively small; studies have used TEGs to generate energy from excess heat dissipated from the system or waste heat. For example, the efficiency of the trough solar system in [26] increased by 12% when using the TEG as a complementary electrical generator. The United Arab Emirates (UAE) has significant potential to utilize solar power given its abundant solar insolation levels [28]. The country has made substantial efforts to diversify its energy mix and reduce its reliance on fossil fuels, with a particular emphasis on harnessing solar energy. Dubai has taken the lead in this regard by implementing a net metering solar rooftop scheme, which has made significant strides in promoting the adoption of rooftop solar photovoltaics. Despite the successful implementation of several record-breaking renewable energy projects, the UAE faces challenges in transitioning to a sustainable energy-driven economy, including the rentier mentality, the intermittent nature of renewables, and geopolitical constraints [28,29]. To offer the required energy in the desert and off-grid areas, the UAE uses a hybrid solar–thermoelectric system that utilizes the use of molten salt as a storage system to generate electricity throughout the day and TEGs to ensure sufficient power generation since they generate electricity from lost heat [30]. After reviewing the literature, and to align with the UAE’s sustainability goals, this study focuses on integrating the use of two mirrors of a trough system with Molten Salt Energy Storage (MSES) and TEGs to create a dispatchable renewable energy source in the UAE. The mirrors used have high reflectivity specifications to collect solar radiation and reflect it on another mirror that is used to concentrate the radiation on the molten salt tank directly instead of the receiver that is used in traditional trough system. The molten salt tank acts as a heat transfer medium and thermal storage system. TEGs use thermal energy stored in the tank to generate the required electrical energy. The high temperature of molten salt allows for efficient thermal energy storage, which can be utilized to generate power during periods of low solar irradiance. This innovative system offers a cost-effective and adaptable solution for storing renewable energy, making it suitable across different applications, including residential homes, small businesses, and medium-sized enterprises.

3. Design Methodology

The main goal of this system is to provide an efficient and effective solar energy system for the generation and storing of electricity. This system is suitable in terms of price, design, size, and efficiency. Furthermore, the new system can be manufactured in different sizes suitable for consumption whether in ordinary houses or commercial establishments and businesses. It is also effective in remote areas and deserts (off-grid). Similarly, salt is characterized by a high heat capacity and requires smaller tanks in the case of any leakage; it is not harmful to the environment and works as a fertilizer in some cases as well. Moreover, solar power can be made an inexpensive, carbon-free, day-and-night energy source that can be dispatched on the electric grid like any fossil fuel plant under the proposed method, also with less maintenance, less initial costs, and improved efficiency than traditional solar systems.

The proposed system is based on the use of molten salts as an energy storage system and contributes to the continuity of electricity generation even in the absence of solar radiation using TEGs; the proposed system is unique as it uses parabolic mirrors and thermal generators rather than steam generators and turbines.

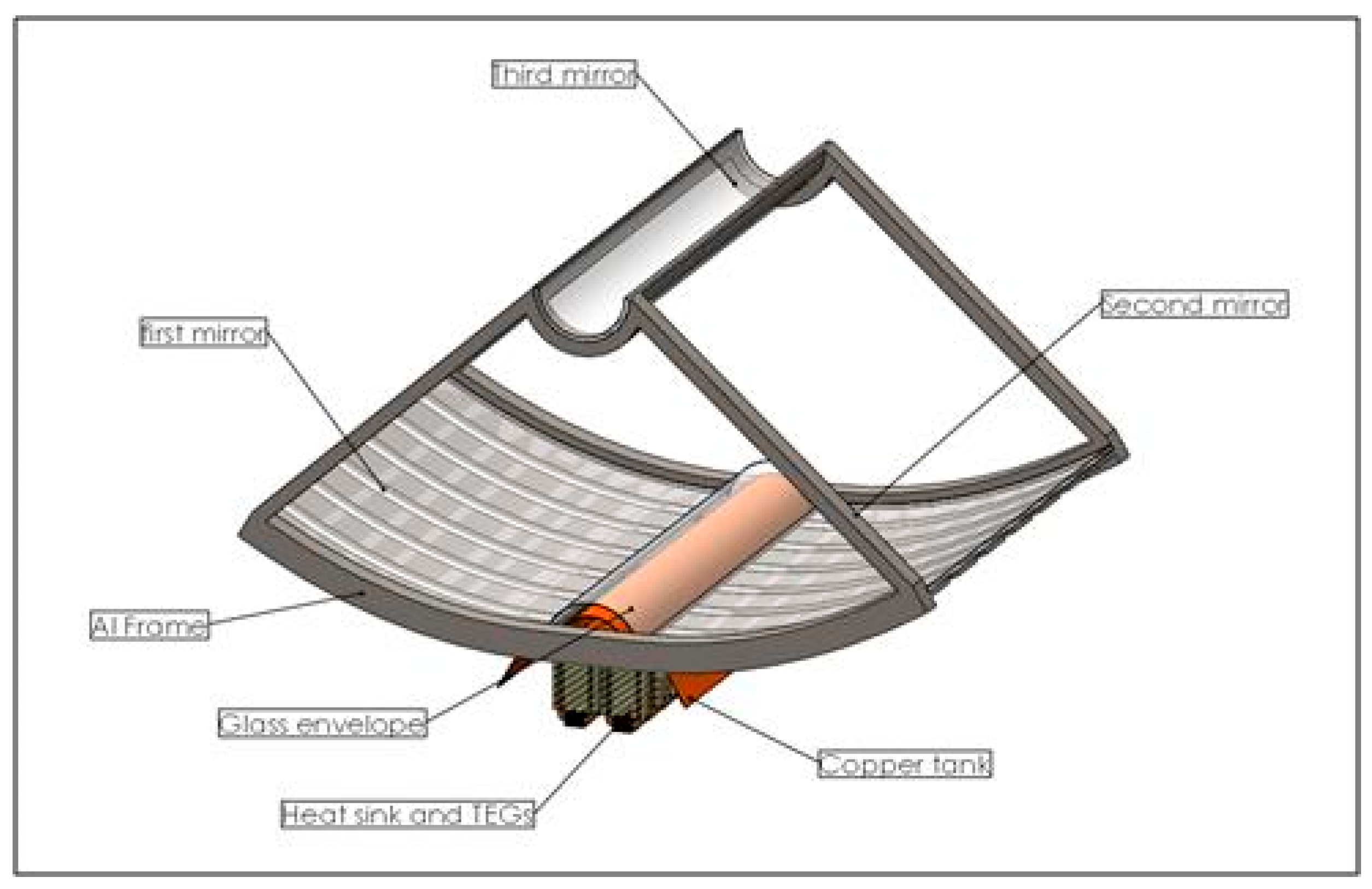

The concept of this design is that when the solar radiation hits the mirrors on the frame, these radiations are reflected to the third mirror and then reflected again to the molten salt tank that is placed in a hollow between the mirrors on the frame. When the tank is heated, it transfers this heat to the molten salt inside, and then the TEGs start generating electrical energy by converting the thermal energy generated by the molten salt using the phenomenon of Seeback. TEGs have two sides: hot and cold sides. The hot side is connected with the heat source and the cold side is connected with the heat sinks. When heat passes through the TEG from the hot side to the cold side, the TEG material became exposed to a temperature difference, which allows the electrons to move from the hot side to the cold side; this movement generates an electric current. As the temperature difference increases, the current generation increases, which means that more electrical energy is generated. In this study, the hot side of the TEGs is connected with the molten salt, and the cold side is connected with a heat sink and fan to ensure the required temperature difference.

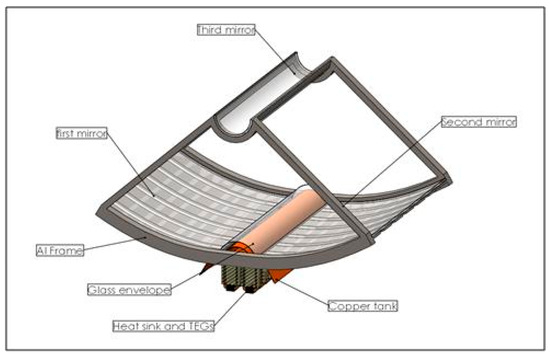

The components of the design can be broken as follows:

- Aluminum frame: The design of solar systems is an essential aspect for boosting the efficiency and affordability of solar applications [24]. One key component of these systems is the structure that holds the mirrors, tank, and the whole design. Numerous academic investigations have highlighted the benefits of using durable and lightweight materials in solar systems. These studies have revealed that the careful selection of the frame material can enhance thermal performance, reduce installation complexity, which can lead to reductions in installation costs, and enhance overall system reliability [31]. For our design, we selected aluminum to be the frame material. AL is considered an ideal choice for this design because of its superior characteristics, such as its high strength-to-weight ratio and resistance to corrosion; these characteristics ensure its durability in all environments [32].

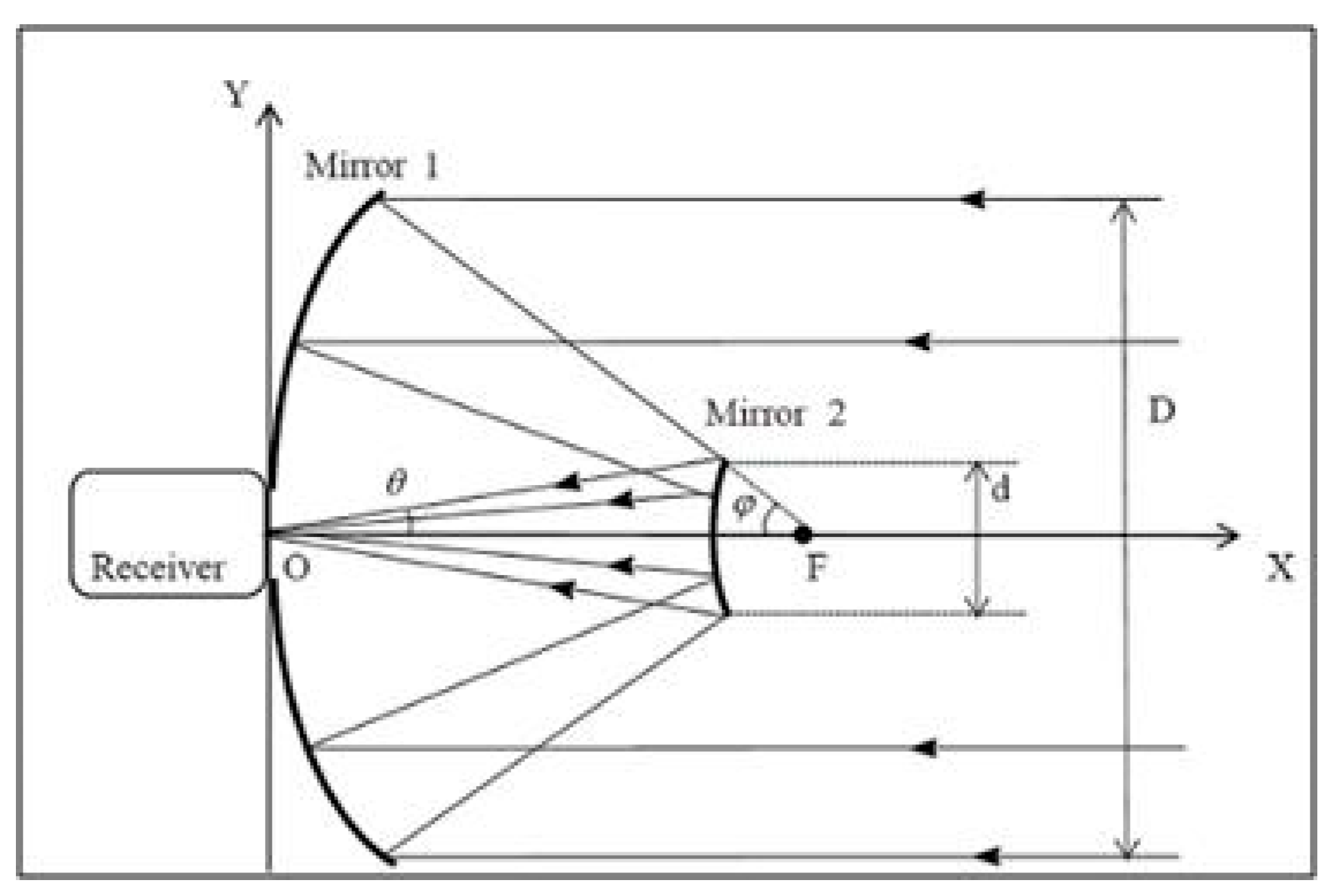

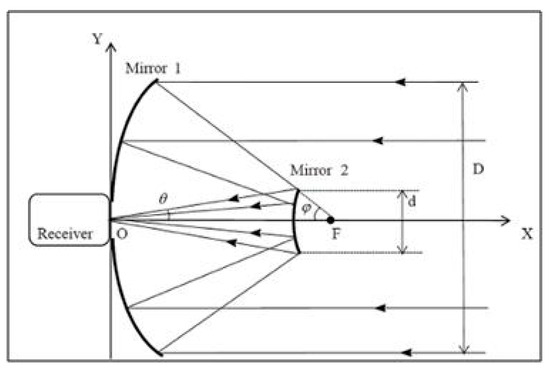

- Parabolic trough system: The design of this system is built based on the idea of the novel design developed by [21] as illustrated in Figure 1. The idea of this design was to have two mirrors: the solar radiation reflected from mirror 1 toward its focal point. This point (F) is in front of mirror 2 that is responsible for reflecting the lights back to the front focal point of mirror 2, where the receiver is placed.

Figure 1. Optical principle of the 2-stage concentrator (reference concentrator system).

Figure 1. Optical principle of the 2-stage concentrator (reference concentrator system).

The proposed parabolic trough system in Figure 2 consists of two parabolic mirrors (instead of mirror 1) separated by a hollow to place the salt tank in that hollow instead of the receiver. These mirrors act as solar radiation collectors that reflect the solar radiation to the third mirror that reflects the lights back to the salt tank. This setup maximizes the concentration of solar energy onto the salt storage tank. The dimensions of the mirrors will depend on the desired energy output and the efficiency we aim to achieve.

Figure 2.

The components of the proposed design.

- 3.

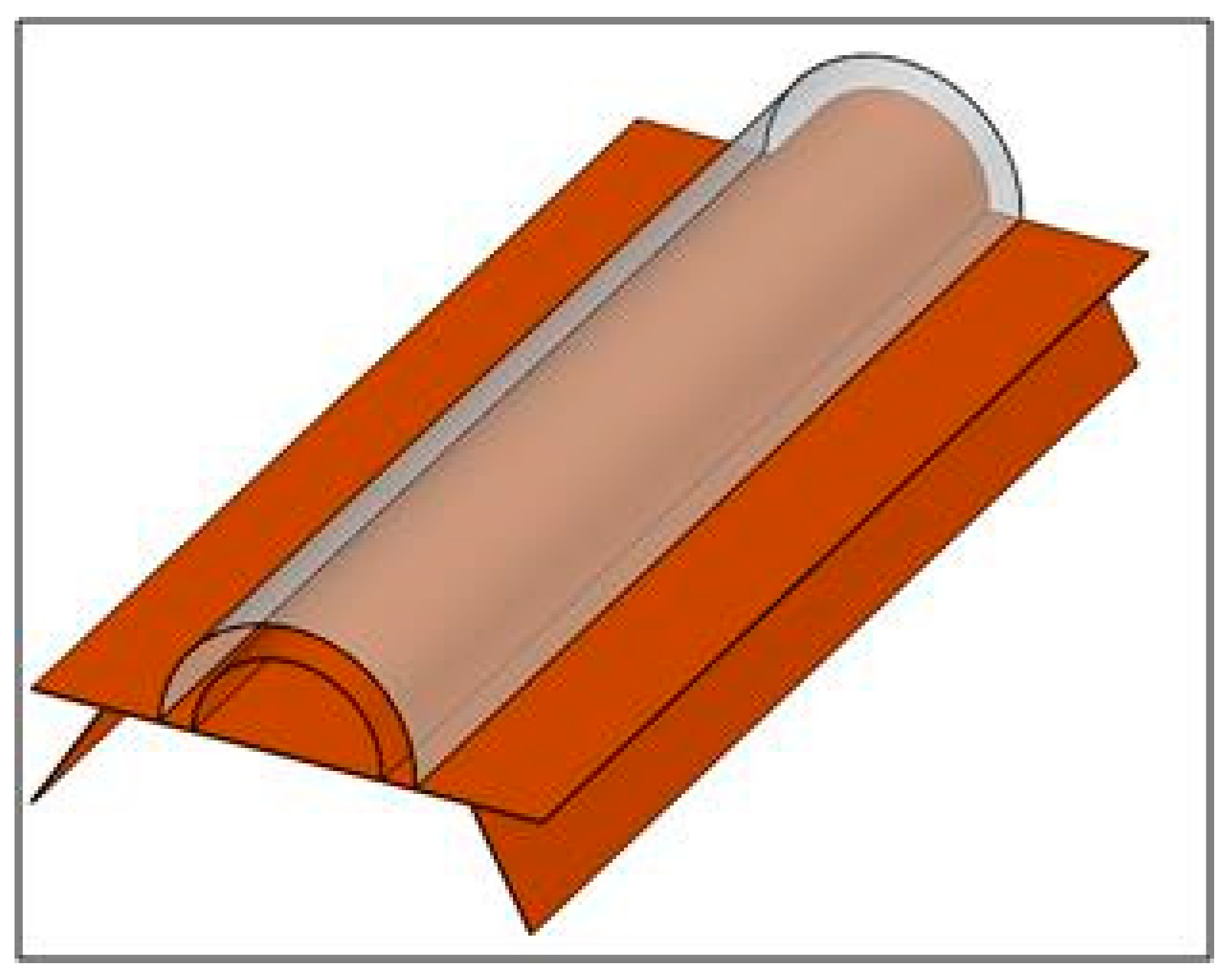

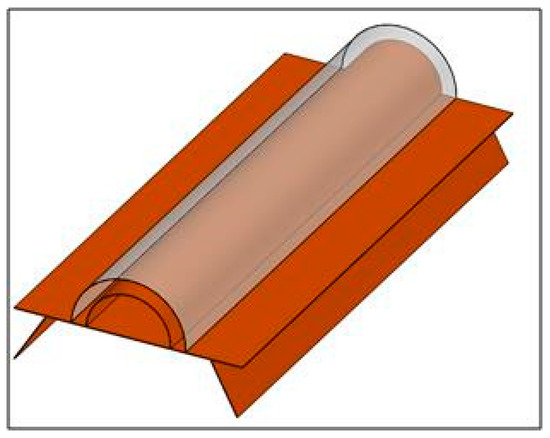

- Copper tank: Another core subsystem in our design is the tank of molten salts. This tank, shown in Figure 3, is composed of a copper interior and a glass-covered upper portion. When the solar radiation is reflected by the third mirror directly to this tank, it transfers the heat to the molten salt inside. The copper material provides excellent heat conductivity, and the thermal conductivity is constant with a value of 385, while the glass cover allows for solar radiation to penetrate while helping to retain heat. The vacuum between the copper and the glass is created to minimize heat loss, improving the tank’s ability to store heat efficiently. In the literature, there are several materials used in heat storage tanks in addition to copper such as nickel-based alloys, silicon carbide and alumina, stainless steel 316L, and carbon steel. These options are evaluated based on its availability, cost, thermal conductivity, resistance to corrosion, and thermal stability. Copper material is found to be the best for our design.

Figure 3. Molten salt tank.

Figure 3. Molten salt tank. - 4.

- Molten salts: The molten salt acts as a heat transfer fluid, storing and transferring the thermal energy collected by the parabolic trough system. The selection of the molten salt will depend on several factors to ensure optimal performance and safety, such as the following [23]:

- Thermal stability, where the molten salt with higher decomposition temperature is more efficient in transferring and storing heat.

- Thermal conductivity, where molten salts with higher thermal conductivity are preferable to ensure that the heat is transferred and stored quickly and efficiently.

- Specific heat capacity, to enhance the storing efficiency; high specific heat means that more thermal energy can be stored per unit mass.

- Corrosion resistance: selecting salts that exhibit low corrosivity is crucial to prevent damage to storage tanks and thermal stability.

- Viscosity: Molten salts with low viscosity are preferable.

- Cost and Availability: Molten salt should be available and affordable.

- Non-Toxicity and Safety: The selected molten salt should be non-toxic and environmentally friendly in the case of leaks or spills; this ensures safety for operators and the environment.

To select the best molten salt for our design, several studies in the literature have been reviewed and analyzed. The selected molten salt is a ternary mixture of calcium nitrate, sodium nitrate, and potassium nitrate (Ca (NO3)2:NaNO3:KNO3 = 32:24:44 wt%. This salt had the best performance for latent heat storage with the following specifications: enthalpy of 67 J/g; melting point of about 80 °C. The specific heat capacity is 1.7 J/(g °C) for the solid phase and 1.2 J/(g °C) for the liquid phase, the viscosity is next to zero at 200 °C, and the mixture density is 482 kg/m3. This molten salt is also chemically stable and does not react with most metals. In terms of absorptance, molten salt has a value of around 0.95. This means that it absorbs about 95% of the solar radiation that hits it. This is a high absorptance, which is important for maximizing the efficiency of the solar system. The emittance of the molten salt is around 0.05. This means that it emits about 5% of the heat that it absorbs. This is a low emittance, which is important for minimizing heat loss from the receiver. Also, it has excellent properties for latent heat storage. The high enthalpy of fusion (67 J/g) means that a lot of heat can be stored in a small amount of material. The melting point of 80 °C is also relatively low, which makes it suitable for a wide range of applications. The specific heat capacity of the salt is also good, both in the solid and liquid phases. This means that salt can absorb and release heat slowly, which is important for maintaining a stable temperature in a thermal storage system. The viscosity of the salt is low, which means that it flows easily. This is important for heat transfer, as it allows the heat to be distributed evenly throughout the salt. The density of the salt is also good at 482 kg/m3. This means that a lot of salt can be stored in a small volume, which is important for space-constrained applications.

- 5.

- Thermoelectric generator (TEG) and heat sinks: In our design, we combine the use of molten salts with other systems, such as TEGs, to enhance the efficiency and effectiveness of thermal energy storage solutions and generate electricity rapidly. The number and size of TEG modules will depend on the desired power output and the temperature gradient available. The used TEG is TEG1-12611-8.0, which has the following specifications: the hot side temperature is 300 °C, the cold side temperature is 30 °C, the open circuit voltage is 9.5 V, where the matched load resistance is 1.8 ohms, the matched load output voltage is 4.8 V, and the matched load output current is 2.7 A, the matched load output power is 13.0 W, the heat flow across the module is 325 W, the heat flow density is 10.4 W, the AC resistance (ohms) measured under 27 °C at 1000 HZ is 0.7~1.0, its dimensions are 56 mm × 56 mm, and the TEM leg height of TEG1-12611-8.0 is 1.7 mm. Based on these specifications, it appears that the TEG1-12611-8.0 module has a high temperature difference between the hot and cold sides, resulting in a significant heat flow across the module. This, in turn, generates electrical power through the Seebeck effect. The heat flow across the module is approximately 325 W, and the heat flow density is approximately 10.4 W. This indicates that the module can handle a substantial amount of heat and convert it into electrical power. Additionally, the AC resistance of the module is measured under specific conditions. The measured AC resistance at 27 °C and 1000 Hz falls within the range of 0.7 to 1.0 ohms. This resistance value is important for determining the electrical performance and efficiency of the module. These modules work best in the temperature range of 220 to 300 °C. The capability to operate at higher-temperature ranges and deliver superior performance in these conditions makes the TEG1-12611-8.0 module a reliable choice for thermoelectric power generation. These specifications make this type of TEG the best choice to use in our design. With respect to the heat sinks, the heat sink is used to maintain the temperature difference necessary for TEGs to generate electricity efficiently.

- 6.

- Fan: We can use a fan to aid the heat sink with generating the high-temperature difference; therefore, TEGs will operate with more efficiency.

- 7.

- Tracking system: A single-axis tracker can be used to track the solar radiation during the day. This type of tracking system ensures the balance between solar radiation capture, cost, and complexity [33]. The UAE’s location (latitude ~24° N) makes the application of the proposed design in the research of [33] very useful since the sun’s path is relatively consistent throughout the year. Also, their proposed design aligns with this study’s objectives of scalability and the ability to apply this technology in off-grid areas. The specifications of the recommended tracker system that match this study are summarized in Table 1.

Table 1. Single-axis tracker specifications.

Table 1. Single-axis tracker specifications.

4. Data Analysis and Results

Solar Photovoltaics (SPs) System Performance: Based on the literature, the PV panel in the UAE has a power output rating of 400 W and receives an average of 5.84 peak sun hours per day [30], so we aim to generate the same power as this panel. The energy output of the panel per day can be calculated as follows:

Energy output per day = Solar panel output × Peak sun hours per day

The value of the power rating indicates that the maximum electrical energy that can be produced under ideal conditions is 852.64 kWh/year, but the wattage can vary from hour to hour, and other real-world conditions may affect this value. To account for the real-world losses and inefficiencies in temperature, shading, panel age, dust, and other factors, the performance rating of the panel should be encountered. [34] found that the performance ratio (PR) measured for different systems in the UAE with different conditions ranges between 70% and 80%. Then, the realistic energy output will be as follows:

Realistic energy output per year: 852.64 kWh/year × 0.75 = 639.48 kWh/year.

Also, this value can be estimated by using the value of the Global Horizontal Irradiation (GHI) value that equals 2285 kWh/m2, as approximated by [35]. Also, system efficiency should be encountered. [36] indicate that the PV system efficiency lies between 14% and 20% for the PV panels used in the UAE. We assume that the size of the 400 W panel is 2.2 m2. With a system efficiency of 20%, then the realistic energy output is as follows:

This value is close to the value generated by the Global Solar Atlas, so we will use it in our analysis.

The proposed system, as mentioned earlier, generates electrical energy by integrating parabolic trough mirrors, molten salt as thermal storage and heat transfer medium, and thermoelectric generators (TEGs). The design aims to achieve daily energy output equivalent to a 400 W photovoltaic (PV) panel operating under UAE conditions. All parameters and specifications are shown in Table 2.

Table 2.

Design parameters summary.

- Solar Energy Collection and Mirror Area:

The daily energy requirement needed from the proposed design is equal to the realistic energy output per day generated by the SP

where

= daily electrical energy requirement (kWh/day);

= 754.05 kWh/year (realistic annual energy output);

= 365 days/year.

Thus, the system must generate 2.067 kWh/day.

This value will be generated by thermoelectric generators (TEGs); TEGs convert thermal energy into electricity using the Seebeck effect. So, the thermal energy required at the thermoelectric generators (TEGs) should be determined.

- Thermal Energy Required at the Collector:

The thermal energy required at TEGs is calculated by considering the efficiency of the TEG:

where

- The total energy required at the collector (Q collector):

The total energy required at the collector (Q collector), taking into consideration the optical and thermal losses, is as follows:

where:

= 0.9025 (mirror reflectivity 0.95 times absorber (molten salt tank)) and absorptance = 0.95.

= 0.90 (thermal efficiency of molten salt tank, estimated considering conduction, convection, and radiation losses).

Thus, 31.82 kWh/day of solar energy needs to be collected.

- Trough Calculations:

The required mirror area (Acollector) is determined using the average daily direct normal irradiance (DNI):

where

DNI = 6.2 kWh/m2/day [26].

Thus, the system requires 5.13 m2 of mirrors to collect the necessary solar energy.

- Parabolic Trough Opening ():

Width: Set to 2 m for effective solar radiation capture.

- Parabolic Trough Length (L):

To achieve the required area of 5.13 m2 with a width of 2 m,

Then, the length of the system will be 2.565 m.

- To calculate the focal length () and the collector opening at focal length ():

- Thermal Energy Storage in Molten Salt

The molten salt tank is used for thermal energy storage. The required mass (m) of molten salt is determined by the following equation:

where

;

(specific heat of molten salt in liquid phase);

(the temperature difference across the molten salt).

Thus, the system requires kg of molten salt for storage.

- Molten salt tank:

The tank must accommodate 352.27 kg of molten salt with a density of 482 kg/m3; the required volume is 0.731 m3 (352.27 ÷ 482). A cylindrical tank is designed with a length of 2.565 m (matching the trough) and an internal diameter of 0.60 m, providing sufficient volume (π × (0.30 m) 2 × 2.565 m = 0.731 m3).

Copper’s thermal conductivity (385 W/m·K) allows for a thin wall; a thickness of 2 mm (0.002 m) is assumed for small-scale applications, consistent with industrial standards [23]. External diameter = 0.60 + 2 × 0.002 = 0.604 m. Copper volume = π × [(0.302 m) 2 − (0.300 m) 2] × 2.565 m = 0.00967 m3. Using a density of 8940 kg/m3 [32], mass = 0.00967 × 8940 = 86.45 kg.

Glass Tube: External diameter = 0.630 m, internal diameter = 0.624 m (1 cm clearance), thickness = 3 mm (0.003 m). Volume = π × [(0.315 m) 2 − (0.312 m) 2] × 2.565 m = 0.00985 m3. Glass density = 2500 kg/m3, so mass = 0.00985 × 2500 = 24.63 kg.

The difference of across the molten salt is selected to ensure the stability of molten salt, as mentioned in the study of [37], also to consider maximizing the efficiency of the TEG, and to ensure the high performance of the heat sink and fan that affected by the ambient temperature of the UAE (up to avg. max. temperature of 34.4 °C for the years 2013–2023 according to [38].

- Thermoelectric Generator (TEG) Performance

The TEG1-12611-8.0 module has a matched load output power of 13 W and a heat flow () of 325 W, yielding an efficiency of 4%. However, to achieve the target daily energy requirement of 2.067 kWh/day, our design assumes a theoretical efficiency of 8% (26 W per TEG), resulting in the following electric power output () per TEG:

The number of TEGs required is calculated as follows:

where:

= 2067 Wh/day;

= 26 W;

Peak sun hours = 5.84 h/day.

Thus, 14 TEGs are required.

Under standard conditions, the manufacturer reports an efficiency of 4% for the TEG1-12611-8.0, reflecting a typical performance for bismuth telluride (Bi2Te3)-based modules. However, theoretical maximum efficiencies () at a slightly higher temperature difference of ΔT = 230 °C are reported to range from 7.9% (with an average figure of merit, ) to 9.3% (), with values expected to be marginally lower at 220 °C [39]. Also, 8% efficiency of the advanced BiTe module can be gained at ΔT = 225 °C, with zT = 1.08 for the p-type and 0.84 for the n-type [40]. These studies and other advancements suggest that 8% is a feasible design target, with such optimizations applied to the proposed copper tank design. The used TEG in our design has 126 legs (63 p-type, 63 n-type) that contribute to this potential, with n-type ()~8% under ideal conditions [41], supporting our assumption as a pre-feasibility goal pending validation.

These TEGs can be connected in series, parallel, or series–parallel combination based on the system requirements. If the 14 TEGs are connected in series, the system will have a high voltage output and resistance. But if one TEG fails, the system will fail. If the 14 TEGs are connected in parallel, the system will have a high current output, and this is suitable for charging applications. Also, because of low voltage, the system will require an additional converter to enhance the voltage. The series–parallel hybrid connection will balance between the current and voltage outputs that can be easily managed and endure a flexible system and moderate costs.

- Overall system efficiency

The overall system efficiency is determined by considering all the inefficiencies and losses in the system:

The values of these efficiencies are estimated based on reasonable assumptions and manufacturer specifications.

- represents the radiative, conductive, and convective losses. Using the glass envelope and the vacuum-insulated copper tank can reduce these losses. This is an estimated value and needs to be validated by an experiment. This value can be improved by using low E-glass and anti-reflective coatings on the envelope.

- combining the mirror reflectivity (95%) and tank absorptance (95%): These values are assumed to be based on the manufacturing tolerances, and they are common in most of the solar systems but need to be verified. The copper material and the vacuum with a semicylindrical shape of a tank ensure the high value of absorbance. The reflectivity of mirrors can be increased by using the proposed tracking system and by using the anti-reflective coatings on the mirror.

- : This value is considered as mentioned in the technical characteristics of the used TEG. In the current design, the use of a heat sink and fan can reduce the temperature of the cold side of the TEG; this will maximize the and efficiency. To increase the temperature of the hot side, ref. [42] studied the effect of using liquid-saturated porous medium in enhancing the heat transfer from TEGs and improving the TEG’s performance. The used TEG is the same TEG we use in this study. The results of their experiments showed a significant improvement in efficiency, especially when they used the copper particles; the performance improved by 149%. Following this approach in our design may enhance the efficiency of TEGs since it is the same TEG used in this study, and the molten salt tank is made of copper. We can attach a layer of copper foam to the outer surface of the copper tank and mount the TEG directly using a thermal interface material onto the porous medium that is saturated with the molten salt that acts as a heat transfer medium for the TEG in our design. Although this study promises a significant increase in performance, an experimental study should be utilized to validate the design.

Keeping the 8% efficiency, the total electrical energy that can be generated from the system is equal to the following:

This confirmed that the system can generate the target electrical energy per day. In the theoretical analysis, the DNI is measured during the year considering day and night and sunny and rainy days. This means that the system is theoretically under assumed numbers and conditions that are capable of operating throughout the day. However, practical challenges such as the actual thermal losses under operating conditions, temperature variability, and system degradation must be addressed to ensure reliable continuous operation.

The following values are used as the specifications of our design.

5. Economic Assessment and Comparative Analysis

The proposed hybrid system integrates parabolic trough mirrors, molten salt storage, and thermoelectric generators (TEGs) to produce 2.067 kWh/day, equivalent to 754.05 kWh/year. This section presents an economic evaluation of the required investments, estimating the initial expenditures, lifetime costs, levelized cost of electricity, and levelized cost of storage based on the design specifications detailed in this study. The monetary values provided are estimates based on the available literature and market data, reflecting the economic conditions in the United Arab Emirates as of February 2025.

5.1. Initial Investment Costs

- Parabolic Trough Mirrors:

The system employs mirrors totaling 5.13 m2, as determined by the trough length (2.565 m) and width (2 m). Estimated costs range from USD 50 to 100 per m2, based on industry benchmarks for parabolic trough systems in the Middle East [26]. This yields a cost range of USD 256.50 to 513 (5.13 × USD 50 to 5.13 × USD 100). These values align with global trends, where the International Renewable Energy Agency [43] notes CSP mirror costs dropping to USD 50–120/m2 with technological advancements, applicable to 2025 UAE projections.

- Copper Tank: With a mass of 86.45 kg, the estimated cost = USD 12/kg (UAE 2025 market estimate), totaling USD 1037.40 (86.45 × USD 12).

- Glass Tube: Glass mass = 24.63 kg. The estimated cost = USD 1–2/kg [44], totaling USD 24.63–49.26 (24.63 × USD 1 to 24.63 × USD 2).

- Vacuum and Assembly: A vacuum layer enhances insulation, estimated at USD 50–100 for small-scale fabrication, consistent with CSP component cost breakdowns [45].

- Molten Salt: 352.27 kg at an estimated USD 0.626/kg, totaling USD 220.50 (352.27 × USD 0.626).

- Total Tank Cost: Ranges between USD 1332.53 and 1407.16 (USD 1037.40 + 24.63 + 50 + 220.50 to USD 1037.40 + 49.26 + 100 + 220.50).

- Thermoelectric Generators (TEGs): 14 TEG1-12611-8.0 units at an estimated USD 20–40/unit, with USD 20 cited from [46] and USD 40 from [42], totaling USD 280–560 (14 × USD 20 to 14 × USD 40).

- Heat sinks and fan add an estimated USD 50–100, summing to USD 330–660.

- Aluminum Frame: 15 kg at an estimated USD 2.24/kg (UAE 2025 market estimate), totaling USD 33.60 (15 × USD 2.24/kg; [32]).

- Single-Axis Tracker: Estimated USD 150–300 [33].

- Miscellaneous (Wiring, Assembly): Estimated USD 50–100.

- Total Initial Cost: Falls in the ranges of USD 2102.63–2913.76 and USD 256.50 + 1332.53 + 280 + 33.60 + 150 + 50 to USD 513 + 1407.16 + 560 + 33.60 + 300 + 100.

5.2. Lifetime Costs

- TEG Replacement: Assumed negligible over 25 years due to solid-state reliability, as evidenced by Voyager 1’s TEG operating over 41 years [47]. TEGs (300 °C hot side, 30 °C cold side) operate within specifications, and their solid-state design eliminates mechanical failure. The UAE climate may slightly reduce system lifespan, but 25 years is feasible with proper heat sink appropriate maintenance and upkeep.

- Operation and Maintenance (O&M): Estimated USD 10–20/year for 25 years, using a discount value at 8.14% [26], Table 2), then the present value annuity factor is calculated as PV = C × [(1 − (1 + 0.0814)^(−25))/0.0814], where C = USD 10–20). The resulting O&M cost is estimated to be in the range of USD 108.62–217.

- Total Lifetime Cost: Estimated to range between USD 2211.25 and 3130.24 (USD 2102.63 + 108.62 to USD 2913.76 + 217.24).

5.3. Levelized Cost of Electricity (LCOE)

- Lifetime energy output: 18,851.25 kWh (754.05 kWh/year × 25 years).

- LCOE = Total Lifetime Cost/lifetime energy:

- Minimum with USD 2211.25 lifetime cost: USD 2211.25/18,851.25 = USD 0.117/kWh.

- Maximum with USD 3130.24 lifetime cost: USD 3130.24/18,851.25 = USD 0.166/kWh.

- Range: USD 0.117–0.166/kWh.

5.4. Levelized Cost of Storage (LCOS)

- Storage cost: USD 1332.53–1407.16 (tank only).

- Lifetime stored energy: 18,851.25 kWh (all energy passes through storage).

- LCOS = Storage cost/lifetime stored energy:

- Minimum: USD 1332.53/18,851.25 = USD 0.071/kWh.

- Maximum: USD 1407.16/18,851.25 = USD 0.075/kWh.

- Range: USD 0.071–0.075/kWh.

5.5. Comparative Analysis with Alternative Systems

- PV with Battery System

- -

- Initial Cost:

- 400 W PV panel: Based on wholesale and retail pricing in the UAE, USD 158–330. This aligns with the UAE’s competitive solar market, driven by initiatives like Shams Dubai and low labor costs.

- 12 V 200 Ah LiFePO4 battery: Based on wholesale and retail pricing in the UAE, USD 500–800. This aligns with the UAE’s competitive solar market, driven by initiatives like Shams Dubai and low labor costs.

- Controller and wiring: USD 120–250 (estimated).

- Total: USD 778–1380 (USD 158 + 500 + 120 to USD 330 + 800 + 250).

- -

- Lifetime Cost:

- Battery degradation: 2.5% annually, requiring replacements at years 10 and 20.

- Replacement costs: Year 10 (USD 500–800 × 0.458 = USD 229–366.40), Year 20 (USD 500–800 × 0.210 = USD 105–168; discounted at 8.14%, [26], Table 2).

- O&M: Estimated USD 10–20/year for 25 years, discounted at 8.14% to USD 108.62–217.24 ([26], Table 2).

- Total: USD 1220.62–2131.64 (USD 778 + 229 + 105 + 108.62 to USD 1380 + 366.40 + 168 + 217.24; estimated).

- -

- LCOE:

- Adjusted lifetime energy (with degradation): 16,348 kWh.

- Minimum: USD 1220.62/16,348 = 0.075/kWh.

- Maximum: USD 2131.64/16,348 = 0.130/kWh.

- Range: USD 0.075–0.130/kWh (estimated).

- -

- LCOS: USD 0.027–0.042/kWh (USD 500–800/18,851.25; estimated).

- Standard Parabolic Trough System

- -

- Initial Cost:

- Mirrors (5.13 m2): USD 256.50–513 ([26]; estimated).

- Two-tank molten salt system (450 kg, estimated for 33 kWh/day thermal):

- Copper (139.46 kg): Volume = 2 × π × [(0.242 m)2 − (0.24 m)2] × 2.565 m = 0.0156 m3, mass = 0.0156 × 8940 = 139.46 kg [32], cost = USD 1673.52 (139.46 × USD 12; estimated).

- Glass (40 kg): Volume = 2 × π × [(0.252 m)2 − (0.249 m)2] × 2.565 m = 0.016 m3, mass = 0.016 × 2500 = 40 kg, cost = USD 40–80 (40 × USD 1–2; [44]; estimated).

- Vacuum and assembly: USD 100–200 (two tanks; [45]; estimated).

- Molten salt (450 kg): USD 281.70 (450 × USD 0.626; estimated).

- Total: USD 2095.22–2235.22 (USD 1673.52 + 40 + 100 + 281.70 to USD 1673.52 + 80 + 200 + 281.70; estimated).

- Receiver and turbine: USD 500–1000 ([45]; estimated).

- Tracker and misc: USD 200–400 ([33]; estimated).

- Total: USD 3051.72–4148.22 (USD 256.50 + 2095.22 + 500 + 200 to USD 513 + 2235.22 + 1000 + 400; estimated).

- -

- Lifetime Cost:

- O&M: USD 10–20/year for 25 years, discounted at 8.14% to USD 108.62–217.24 ([26], Table 2; estimated).

- Total: USD 3160.34–4365.46 (USD 3051.72 + 108.62 to USD 4148.22 + 217.24; estimated).

- -

- LCOE:

- Lifetime energy: 18,851.25 kWh.

- Minimum: USD 3160.34/18,851.25 = USD 0.168/kWh.

- Maximum: USD 4365.46/18,851.25 = USD 0.232/kWh.

- Range: USD 0.168–0.232/kWh (estimated).

- -

- LCOS: USD 0.111–0.119/kWh (USD 2095.22–2235.22/18,851.25; estimated).

This analysis constitutes a pre-feasibility study, with the presented results requiring validation through the construction of a prototype, followed by its characterization and experimental qualification. As summarized in Table 3, the proposed hybrid system’s LCOE (USD 0.117–0.166/kWh) falls within the universal cost range for concentrating solar power (CSP) systems (USD 0.10–0.28/kWh; [45]), affirming its economic viability. Compared to the PV with a battery system (USD 0.075–0.130/kWh) and standard trough system (USD 0.168–0.232/kWh), the hybrid system offers superior specifications, including 24/7 power availability due to efficient molten salt storage and exceptional TEG reliability, eliminating replacement costs over 25 years [47]. The PV system’s lower LCOE is offset by battery degradation, necessitating multiple replacements, while the standard trough’s higher cost reflects turbine inefficiency and increased molten salt usage (450 kg vs. 352.27 kg) for a small-scale operation.

Table 3.

Comparative study summary.

6. Design Evaluation and Alignment with the UAE’s Policy

The United Arab Emirates has established ambitious renewable energy objectives as part of its Vision 2021 and UAE Energy Strategy 2050, which aim to elevate the share of clean energy in the total energy portfolio to 50% by 2050. The proposed solar energy system aligns with these policy directives in multiple respects. The first aspect is that this design supports the renewable energy goals; the proposed system is designed to be more economically viable than conventional solar photovoltaic technologies, with lower initial goals and diminished maintenance needs. This is well aligned with the UAE’s objective of fostering accessible renewable energy solutions.

The second aspect is scalability and versatility. The system’s scalability, with the capability to be manufactured in diverse sizes, renders it adaptable for both residential and commercial applications. This versatility aligns with the UAE’s need to address the varied energy demands across different sectors, encompassing both urban and rural areas. The third aspect is the off-grid capability; the system’s capability to operate effectively in remote, desert regions address the critical challenge of ensuring energy accessibility in areas disconnected from the main power grid. This feature is particularly relevant for the United Arab Emirates, where certain localities may lack direct access to conventional power sources. The fourth aspect is sustainability and environmental benefit. The utilization of molten salts, which possess a high heat storage capacity and are environmentally friendly, contributes to the system’s sustainability. Moreover, the potential for these salts to act as fertilizers augments their ecological value, aligning with the UAE’s commitment to environmental protection and sustainable practices.

The fifth aspect is the continuity of energy generation; by employing thermoelectric generators, the system maintains the ability to generate electricity even in the absence of direct solar radiation, thereby ensuring a consistent energy supply. This capability is crucial for fulfilling the UAE’s escalating energy requirements and facilitates the transition towards a more resilient energy infrastructure. The last aspect is innovative technology. The incorporation of parabolic mirrors and thermoelectric generators, in lieu of conventional steam generators and turbines, constitutes a notable technological innovation. This advancement aligns with the UAE’s emphasis on adopting cutting-edge technologies to enhance energy efficiency and sustainability.

7. Conclusions

The pre-feasibility proposed design in this study represents a significant step toward achieving a reliable and sustainable energy source in the UAE by integrating the use of trough solar mirrors with molten salts and TEGs. The configuration integrates an advanced trough design along with TEG technology to meet a specified daily energy output of 2.067 kWh/day from a collector area of 5.13 m2. Economic assessments indicate that the system is competitive with photovoltaic battery systems and conventional trough technologies, rendering it appropriate for off-grid and arid applications within the UAE. Nevertheless, an empirical validation of the performance assumptions is imperative prior to any potential commercial production.

Author Contributions

Conceptualization, S.M.A.D. and G.M.M.; methodology, S.M.A.D. and G.M.M.; software, S.M.A.D.; validation, M.Z.M., G.M.M. and S.M.A.D.; formal analysis, M.Z.M., G.M.M. and S.M.A.D.; investigation, G.M.M. and S.M.A.D.; resources, M.Z.M.; data curation, G.M.M. and S.M.A.D.; writing—original draft preparation, S.M.A.D.; writing—review and editing, M.Z.M. and G.M.M.; visualization, G.M.M.; supervision, G.M.M.; project administration, M.Z.M. and G.M.M.; funding acquisition, M.Z.M. All authors have read and agreed to the published version of the manuscript.

Funding

This paper is based upon work supported by the Research Unit at Liwa College under the Internal Research Grant number (IRG-ENG-002-2023).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analyzed are included in this published article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Alnaqbi, S.A.; Alami, A.H. Sustainability and renewable energy in the UAE: A case study of Sharjah. Energies 2023, 16, 7034. [Google Scholar] [CrossRef]

- Rizk-Allah, R.M.; Hassan, I.A.; Snášel, V.; Hassanien, A.E. An optimal standalone wind-photovoltaic power plant system for green hydrogen generation: Case study for hydrogen refueling station. Results Eng. 2024, 22, 102234. [Google Scholar] [CrossRef]

- Erdemir, D.; Dinçer, İ. Renewable energy integration and storage challenges: A comprehensive review. Renew. Sustain. Energy Rev. 2024, 50, 100801. [Google Scholar]

- Nasser, M.; Awad, M.M.; Hassan, A.A. 4E assessment of all-day clean electricity generation systems based on green hydrogen integrated system using PV and PVT solar collectors and wind turbines. Int. J. Hydrogen Energy 2024, 104, 393–406. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, Z. Digitalization, trust, and sustainability transitions: Insights from two blockchain-based green experiments in China’s electricity sector. Environ. Innov. Soc. Transit. 2024, 50, 100801. [Google Scholar] [CrossRef]

- Kodirov, D.; Muratov, K.; Tursunov, O.; Ugwu, E.I.; Durmanov, A. The use of renewable energy sources in integrated energy supply systems for agriculture. IOP Conf. Ser. Earth Environ. Sci. 2020, 614, 012007. [Google Scholar] [CrossRef]

- Alsalman, M.; Ahmed, V.; Bahroun, Z.; Saboor, S. An economic analysis of solar energy generation policies in the UAE. Multidiscip. Digit. Publ. Inst. 2023, 16, 3165. [Google Scholar] [CrossRef]

- Østergaard, P.A.; Duić, N.; Noorollahi, Y.; Kalogirou, S.A. Advances in renewable energy for sustainable development. Renew. Energy 2023, 219, 119377. [Google Scholar] [CrossRef]

- Mezher, T.; Dawelbait, G.; Abbas, Z. Renewable energy policy options for Abu Dhabi: Drivers and barriers. Energy Policy 2012, 42, 315–328. [Google Scholar] [CrossRef]

- Kabel, T.S.; Bassim, M. Literature review of renewable energy policies and impacts. Eur. J. Mark. Econ. 2019, 2, 28–41. [Google Scholar] [CrossRef]

- Nazir, M.S.; Bilal, M.; Sohail, H.M.; Liu, B.; Chen, W.; Iqbal, H.M. Impacts of renewable energy atlas: Reaping the benefits of renewables and biodiversity threats. Int. J. Hydrogen Energy 2020, 45, 22113–22124. [Google Scholar] [CrossRef]

- Hassan, Q.; Algburi, S.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. A review of hybrid renewable energy systems: Solar and wind-powered solutions: Challenges, opportunities, and policy implications. Results Eng. 2023, 20, 101621. [Google Scholar] [CrossRef]

- Falcone, P.M. Sustainable energy policies in developing countries: A review of challenges and opportunities. Multidiscip. Digit. Publ. Inst. 2023, 16, 6682. [Google Scholar] [CrossRef]

- Rosak-Szyrocka, J.; Allahham, A.; Żywiołek, J.; Turi, J.A.; Das, A. Expectations for renewable energy, and its impacts on quality of life in European Union countries. Manag. Syst. Prod. Eng. 2023, 31, 128–137. [Google Scholar] [CrossRef]

- Walker, B.J.; Wiersma, B.; Bailey, E. Community benefits, framing and the social acceptance of offshore wind farms: An experimental study in England. Energy Res. Soc. Sci. 2014, 3, 46–54. [Google Scholar] [CrossRef]

- Talwar, P.; Verma, N.; Khatri, H.L.; Ahire, P.D.; Chaudhary, G.; Lindenberger, C.; Vivekanand, V. A systematic review of photovoltaic-green roof systems in different climatic conditions focusing on sustainable cities and societies. Sustain. Cities Soc. 2023, 98, 104813. [Google Scholar] [CrossRef]

- Darwish, A.S.; AL-Dabbagh, R. Wind energy state of the art: Present and future technology advancements. Renew. Energy Environ. Sustain. 2020, 5, 7. [Google Scholar] [CrossRef]

- Juaidi, A.; Montoya, F.G.; Gázquez, J.A.; Manzano-Agugliaro, F. An overview of energy balance compared to sustainable energy in United Arab Emirates. Renew. Sustain. Energy Rev. 2016, 55, 1195–1209. [Google Scholar] [CrossRef]

- Masdar Institute. UAE Renewable Energy Strategy 2050; Masdar Institute: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- Hydrogen Central. Updated Energy Plan and Hydrogen Strategy Affirm UAE’s Commitment to Generating a Sustainable Economy. 2023. Available online: https://hydrogen-central.com/updated-energy-plan-hydrogen-strategy-affirm-uae-commitment-sustainable-economy/ (accessed on 21 February 2025).

- Wang, J.; Yang, S.; Jiang, C.; Yan, Q.; Lund, P.D. A novel 2-stage dish concentrator with improved optical performance for concentrating solar power plants. Renew. Energy 2017, 108, 92–97. [Google Scholar] [CrossRef]

- Marathe, S.A.; Patil, B.P. Mechanisms for improving the productivity of the existing photovoltaic panels: A review. In Proceedings of the 2020 International Conference on Computational Performance Evaluation (ComPE), Shillong, India, 2–4 July 2020. [Google Scholar]

- Prieto, C.; Blindu, A.; Cabeza, L.F.; Valverde, J.; García, G. Molten salts tanks thermal energy storage: Aspects to consider during design. Energies 2023, 17, 22. [Google Scholar] [CrossRef]

- Ahmad, A.; Prakash, O.; Kausher, R.; Kumar, G.V.N.; Pandey, S.; Hasnain, S. Parabolic trough solar collectors: A sustainable and efficient energy source. Mater. Sci. Energy Technol. 2024, 7, 99–106. [Google Scholar] [CrossRef]

- Grogan, D.C. Development of Molten-Salt Heat Transfer Fluid Technology for Parabolic Trough Solar Power Plants-Public Final Technical Report; No. DOE/08GO18038; Abengoa Solar, LLC: Sanlúcar la Mayor, Spain, 2013. [Google Scholar]

- Soomro, M.I.; Mengal, A.; Shafiq, Q.N.; Ur Rehman, S.A.; Soomro, S.A.; Harijan, K. Performance improvement and energy cost reduction under different scenarios for a parabolic trough solar power plant in the Middle-East region. Processes 2019, 7, 429. [Google Scholar] [CrossRef]

- Dersch, J.; Paucar, J.; Polkas, T.; Schweitzer, A.; Stryk, A. Blueprint for molten salt CSP power plant. Final Report of the Project “CSP-Reference Power Plant” 2021. No. 0324253. [Google Scholar]

- Griffiths, M.; Shonin, E.; Van Gordon, W. Mindfulness as a Treatment for Gambling Disorder. J. Gambl. Commer. Gaming Res. 2016, 1, 1–6. [Google Scholar]

- Mezher, T.; Fath, H.; Abbas, Z.; Khaled, A. Techno-Economic Assessment and Environmental Impacts of Desalination Technologies. Desalination 2011, 266, 263–273. [Google Scholar] [CrossRef]

- Almenhali, A.; Alshamsi, H.; Aljunaibi, Y.; Almussabi, D.; Alshehhi, A.; Hilal, H.B. Mini solar and sea current power generation system. IOP Conf. Ser. Earth Environ. Sci. 2017, 73, 012012. [Google Scholar] [CrossRef]

- Shan, F.; Tang, F.; Cao, L.; Fang, G. Performance evaluations and applications of photovoltaic–thermal collectors and systems. Renew. Sustain. Energy Rev. 2014, 33, 467. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and aluminum alloys. In Alloying: Understanding the Basics; ASM International: Materials Park, OH, USA, 2001; pp. 351–416. [Google Scholar]

- Poulek, V.; Khudysh, A.; Libra, M. Self-powered solar tracker for low concentration PV (LCPV) systems. Sol. Energy 2016, 127, 109–112. [Google Scholar] [CrossRef]

- Emziane, M.; Al Ali, M. Performance assessment of rooftop PV systems in Abu Dhabi. Energy Build. 2015, 108, 101–105. [Google Scholar] [CrossRef]

- Hejase, H.A.; Assi, A.H. Global and diffuse solar radiation in the United Arab Emirates. Int. J. Environ. Sci. Dev. 2013, 4, 470. [Google Scholar] [CrossRef]

- Said, Z.; Mehmood, A. Standalone photovoltaic system assessment for major cities of United Arab Emirates based on simulated results. J. Clean. Prod. 2017, 142, 2722–2729. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Zhao, C.Y. Thermophysical properties of Ca(NO3)2-NaNO3-KNO3 mixtures for heat transfer and thermal storage. Sol. Energy 2017, 146, 172–179. [Google Scholar] [CrossRef]

- Statista Maximum Temperature Dubai 2023, by Month. Available online: https://www.statista.com/statistics/1372821/uae-maximum-temperature-dubai-by-month/ (accessed on 21 February 2025).

- Faizan, M.; Hawkey, J.; Mughal, M.A.; Farhat, L.B.; Mughal, M.Z. Performance analysis of a higher power thermoelectric generator with enhanced radiating fins. Micromachines 2020, 11, 676. [Google Scholar]

- Faizan, M.; Mughal, M.A.; Farhat, L.B.; Mughal, M.Z.; Hawkey, J. Performance enhancement of thermoelectric generators using novel geometry radiating fins. Int. J. Energy Res. 2023, 2023, 3693308. [Google Scholar]

- Sikora, A.; Wojciechowski, K.T. Efficiency calculation of a thermoelectric generator with segmented legs. J. Renew. Sustain. Energy 2017, 9, 014701. [Google Scholar]

- Mansour, M.A.; Beithou, N.; Othman, A.; Qandil, A.; Khalid, M.B.; Borowski, G.; Alsaqoor, S.; Alahmer, A.; Jouhara, H. Effect of liquid saturated porous medium on heat transfer from thermoelectric generator. Int. J. Thermofluids 2023, 17, 100264. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2020; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Alibaba. Industrial Glass Pricing Trends. Alibaba Supplier Data. 2025. Available online: https://www.alibaba.com (accessed on 21 February 2025).

- Aseri, T.K.; Sharma, C.; Kandpal, T.C. Cost reduction potential in parabolic trough collector based CSP plants: A case study for India. Renew. Sustain. Energy Rev. 2021, 138, 110658. [Google Scholar] [CrossRef]

- Ávila, G.M.; Fuente, J.A.G.; Ponce, L.G.; Martín, C.J.R. Domestic thermoelectric cogeneration system optimization analysis, energy consumption and CO2 emissions reduction. Appl. Therm. Eng. 2018, 130, 1286–1295. [Google Scholar]

- Thermoelectric Solutions. How Thermoelectric Generators Work. Available online: https://thermoelectricsolutions.com/how-thermoelectric-generators-work/ (accessed on 21 February 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).