Back Analysis of Surrounding Rock Parameters in Pingdingshan Mine Based on BP Neural Network Integrated Mind Evolutionary Algorithm

Abstract

:1. Introduction

2. Methodology

2.1. Prediction Method

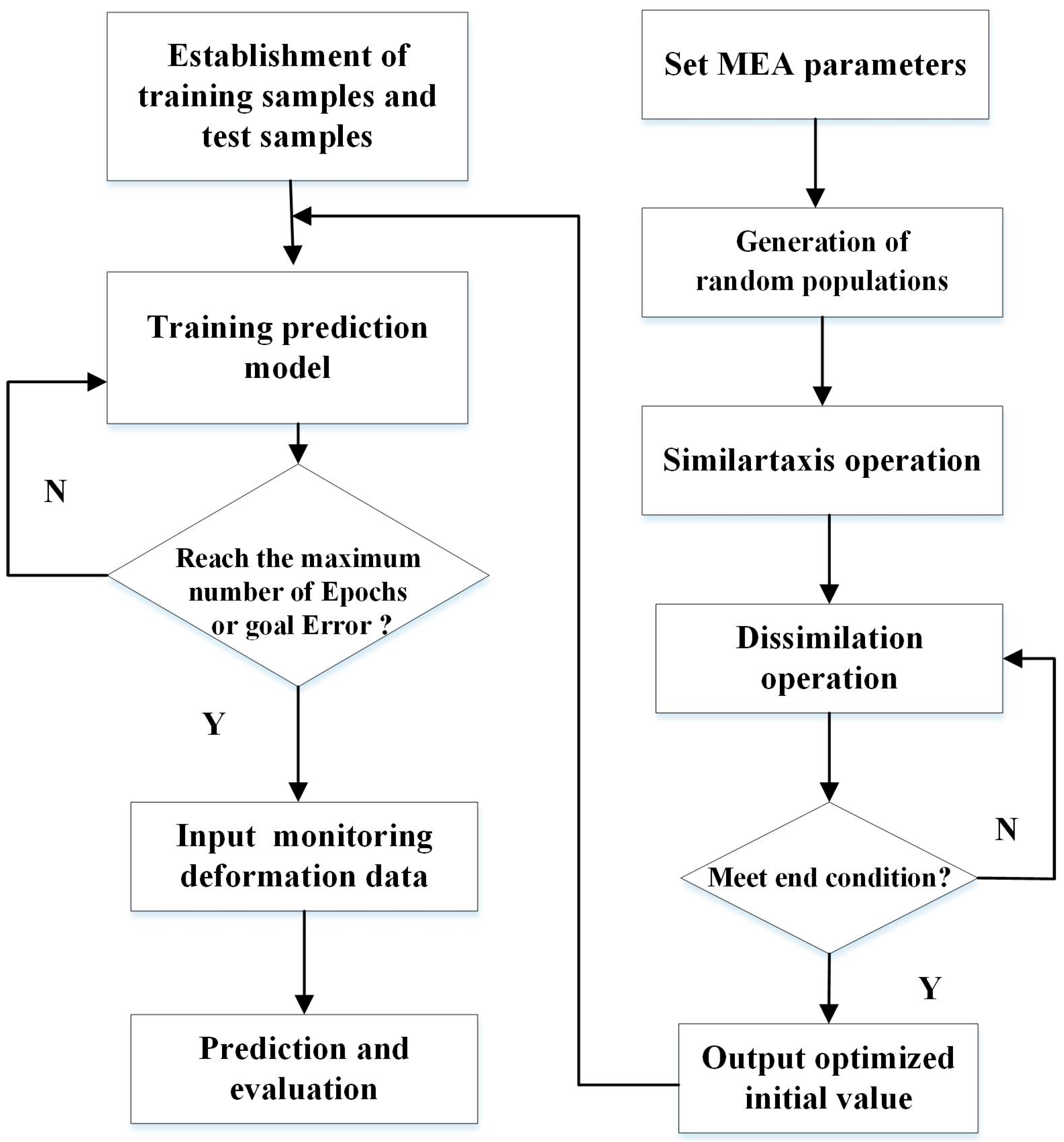

2.2. The Optimized BP Model

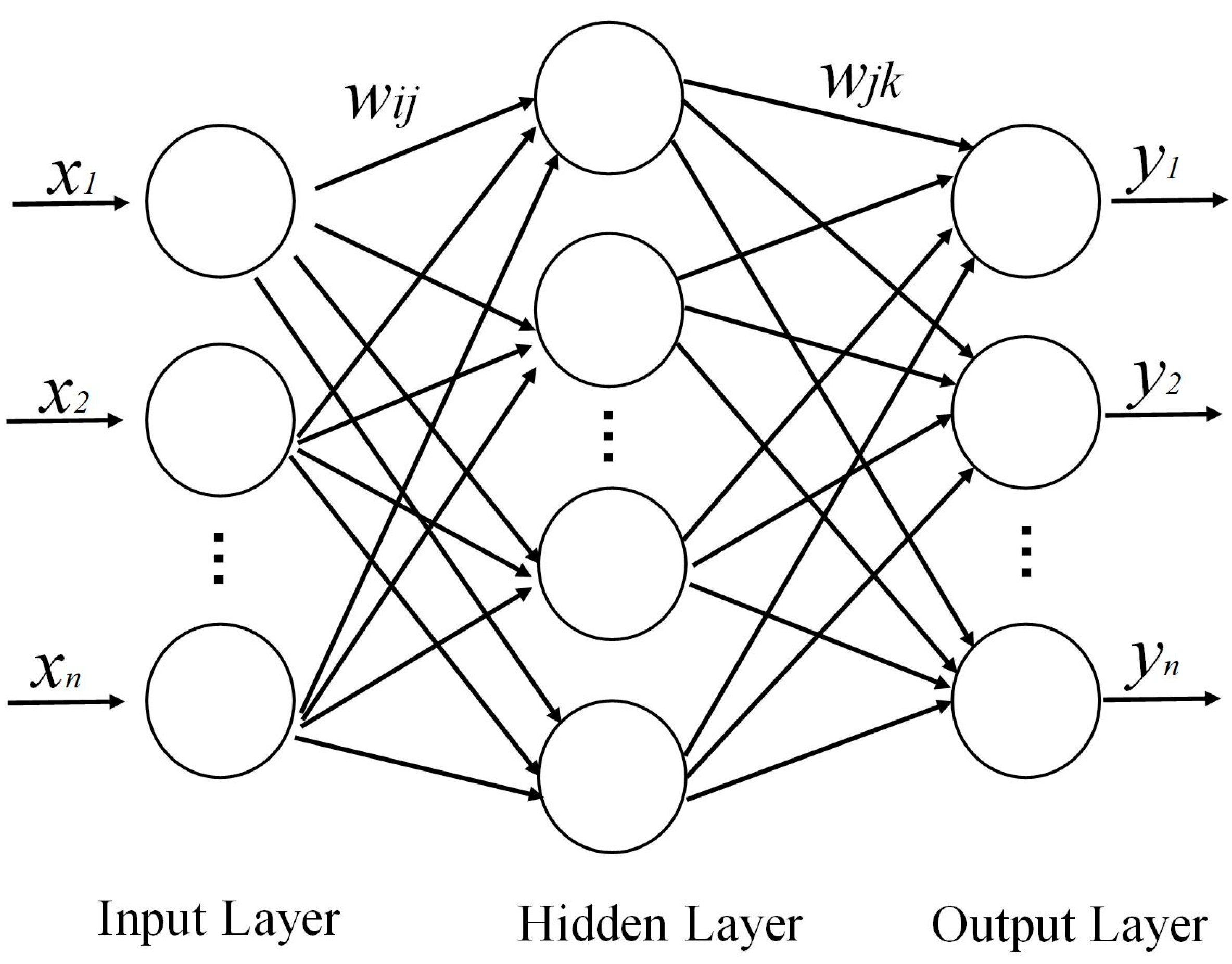

2.2.1. BP Neural Network Model

2.2.2. Mind Evolutionary Algorithm

- (a)

- The population of MEA consists of several groups surviving around the environment. Those groups are divided into superior groups and temporary groups randomly. Each group includes several individuals according to their uniform distribution.

- (b)

- MEA searches for the individual with the highest score as a superior individual. At the same time, other individuals which have the highest score as temporary individuals. Each superior individual and temporary individual as the center to generate the superior subgroups and temporary subgroups.

- (c)

- The “similar-taxis” process is completed within the subgroups. The population maturity discriminant function is used to confirm whether the subgroup is mature. If it is, the mature subgroup stops this process. Then, the score of the optimal individual is regarded as the group score. The immature subgroup will produce subgroups with new centers. The above process will be repeated until they mature.

- (d)

- The disassimilation process is completed globally. If the score of the temporary subgroup is higher than that of the optimal subgroup, this process is carried out. Then, individuals in the temporary subgroup with a high score will replace those with a low score. At the same time, the individuals in the optimal subgroup are released. A new temporary subgroup is reconstructed in the global space.

- (e)

- Repeating the above process until the score of the optimal group is so high that it is impossible to increase. Then, the algorithm is convergent, and the winner of the superior group is just the global optimization.

2.3. Combined Prediction Method

3. Application of Prediction Model

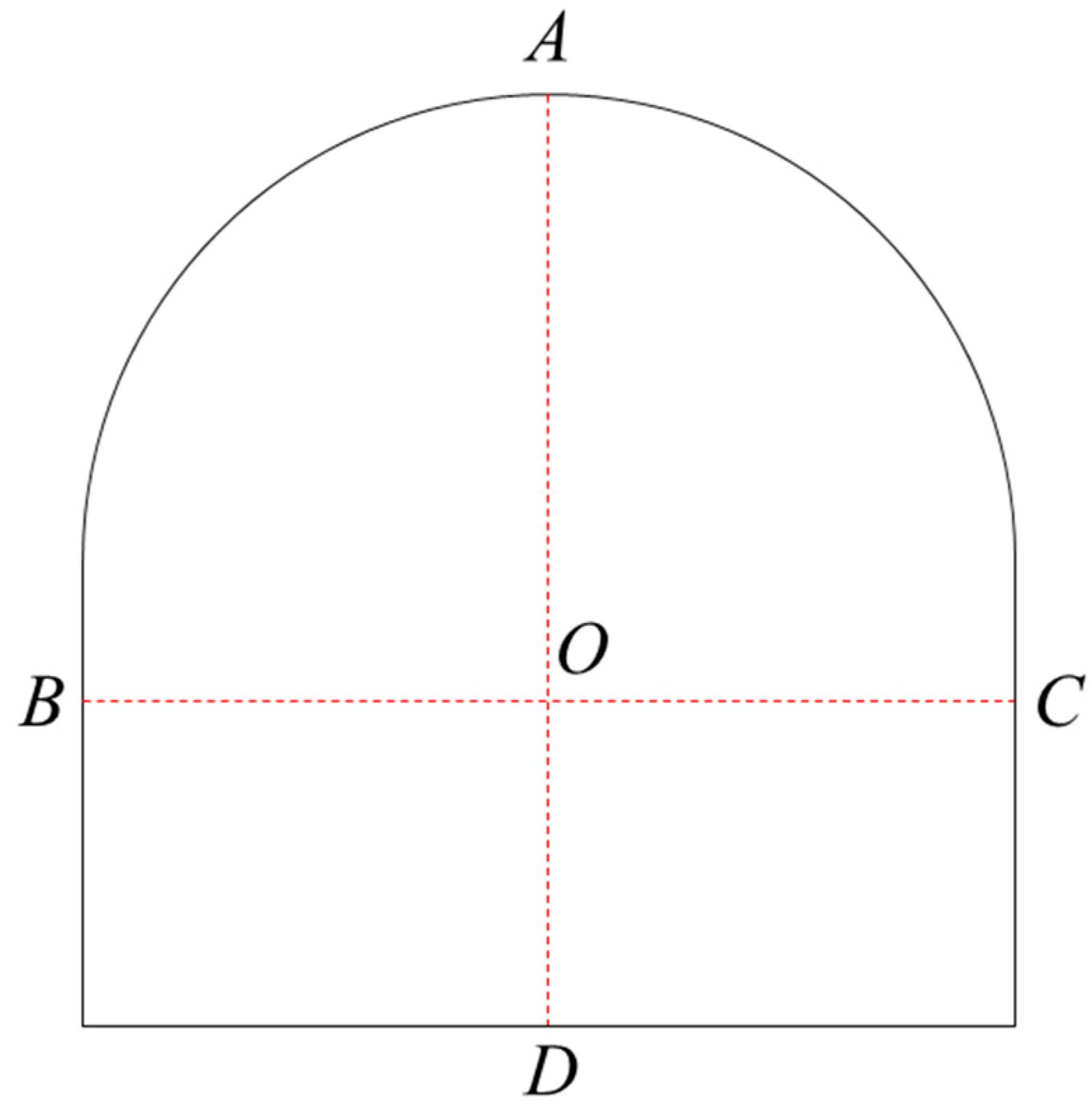

3.1. Geological and Numerical Model

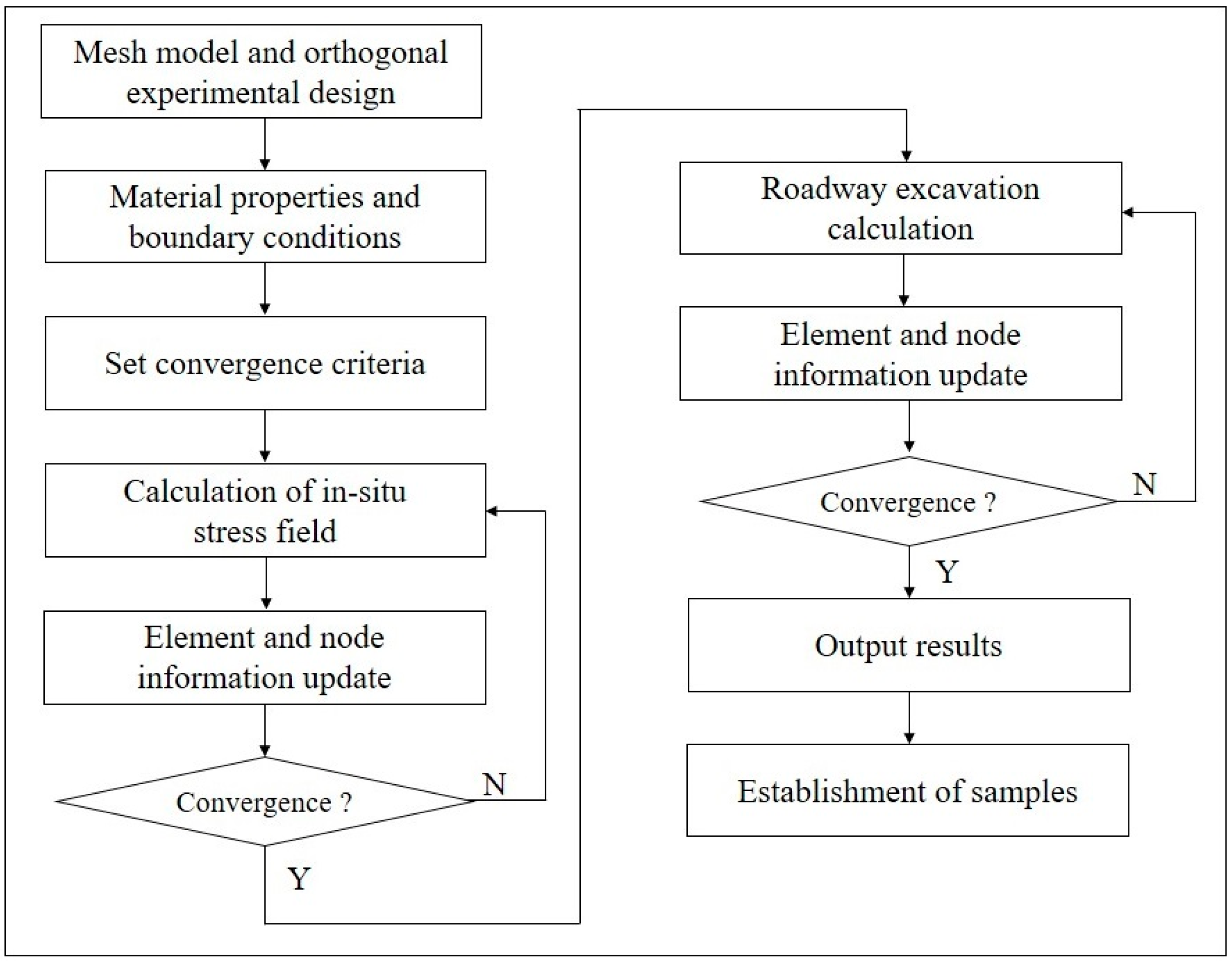

3.2. Establishment of Training Sample

3.3. Importance Analysis of Input Variables

- (1)

- Based on the BQ rating system, eight group mechanical parameters of test samples are generated by the random method. Then, the deformation of surrounding rock is obtained by the finite element numerical method. The data of test sample is shown in Table 3. The surrounding rock deformation results and mechanical parameters are regarded as the input value and observed value for the test samples.

- (2)

- Train the MEA-BP model based on the original training samples (L64). Then, the prediction of the test sample (Table 3) is obtained, and the RMSE is calculated by Equation (4).where, observedt represents the observed value; predictedt represents the predicted value; t represents the predicted variable, N represents the number of input variables.

- (3)

- Shuffle the ith input variable of the training samples in reverse order, and the others remain unchanged.

- (4)

- Train the MEA-BP model on the shuffled training samples. The prediction of the test sample and RMSE is calculated by Equation (4).

- (5)

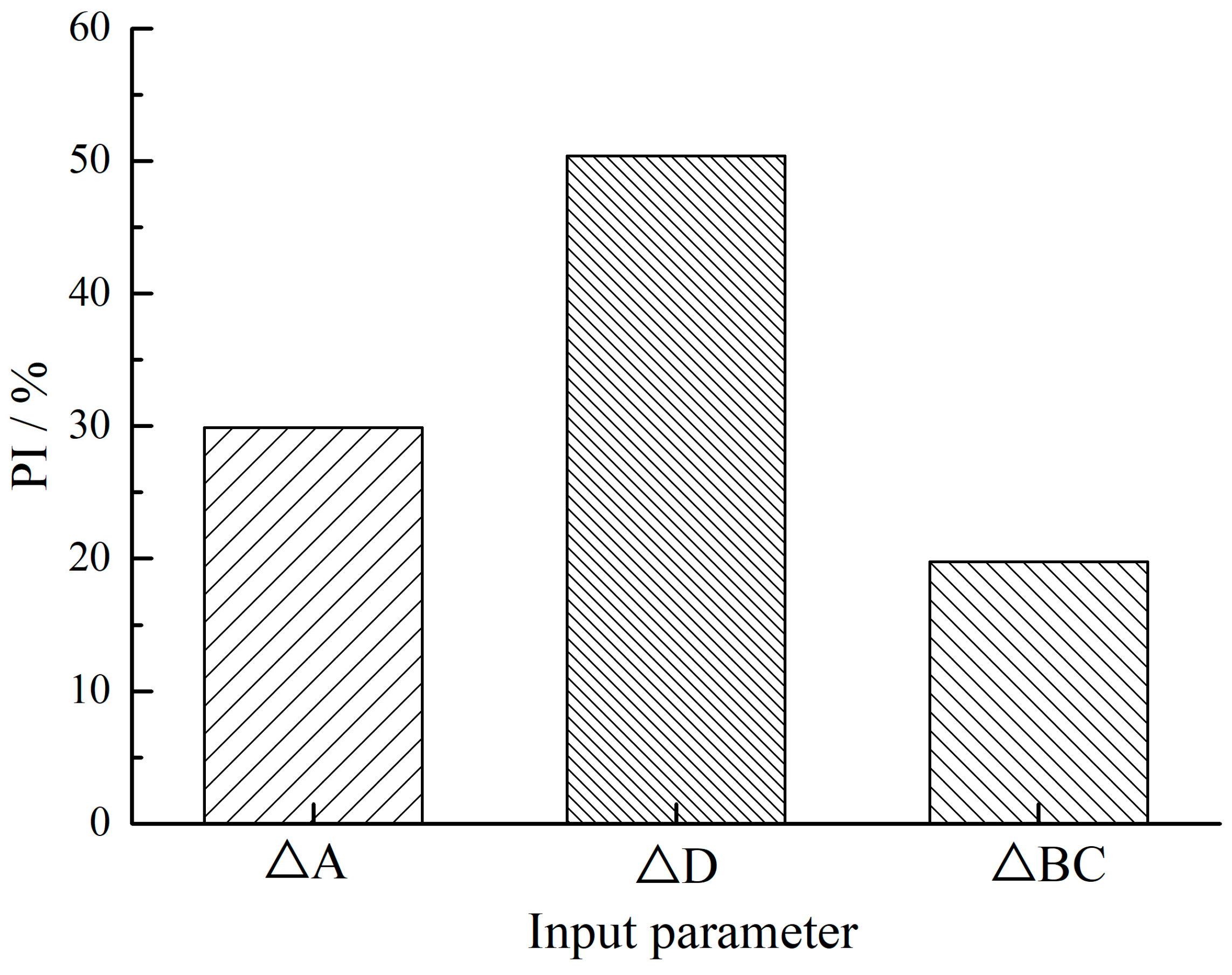

- Calculate PI of the ith input variable using Equation (5);where, RMSEi and RMSE* are separately calculated on the shuffled training samples and original training samples; i (i = 1, 2, 3) represents the input variable (∆A, ∆D, ∆BC).

- (6)

- Repeat (3)~(4) until PI of all input variables (∆A, ∆D, ∆BC) is obtained. To be more intuitive, PI is standardized by Equation (6).

3.4. Model Analysis

3.5. Application of MEA-BP Model

4. Conclusions

- (1)

- To avoid the local extreme value and improve the convergence speed of the BP neural network model, the initial weights and thresholds are optimized by the mind evolutionary algorithm. So, the combination of the mind evolutionary algorithm and BP neural network is proposed in this paper, which is aimed at a good prediction of rock mechanical parameters.

- (2)

- Based on the orthogonal test method and finite element numerical method, training samples and test samples are established. The rock mechanical parameters are the observed value, while the deformation of surrounding rock (∆A, ∆D, ∆BC) is the input value. The nonlinear relationship between rock mechanical parameters and roadway deformation is established by the BP model and MEA-BP model, respectively.

- (3)

- The important analysis of different input variables for the MEA-BP model shows that the RMSE of ∆D is the largest. While the RMSE and PI for ∆BC are the smallest. It indicates that the ∆D is the most important input variable, while the influence of ∆BC is the least.

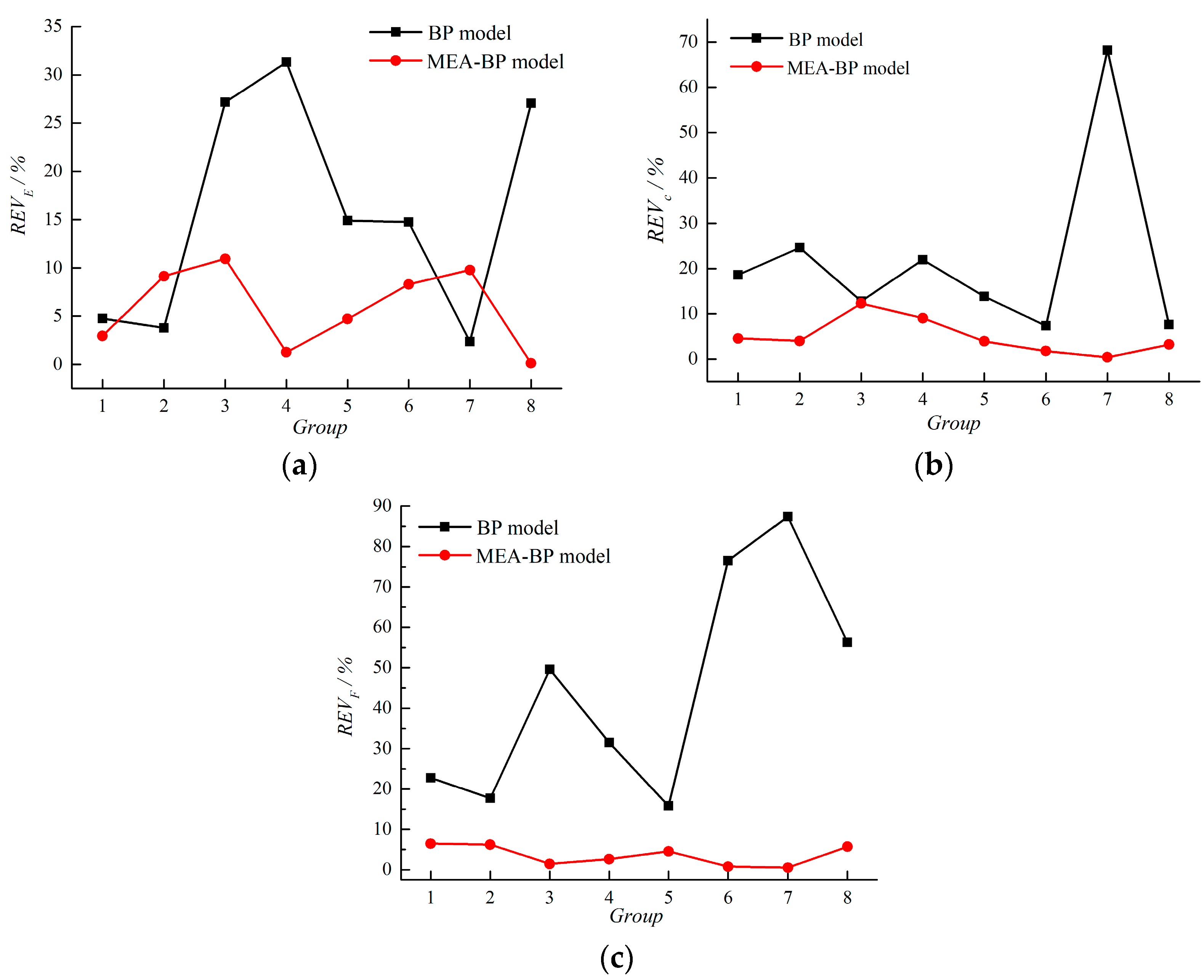

- (4)

- The comparison between the MEA-BP model and BP model shows that the RMSE value for the MEA-BP model is reduced by about 48.89~79.91%. What is more, the REV of the MEA-BP model is also smaller than that of the BP model. The MEA-BP model cannot decrease the sensitivity of input variables, but the accuracy of the prediction is improved. So, the prediction performance of the MEA-BP model is better than the BP model, which also demonstrates the advantages of the optimized initial weights and thresholds.

- (5)

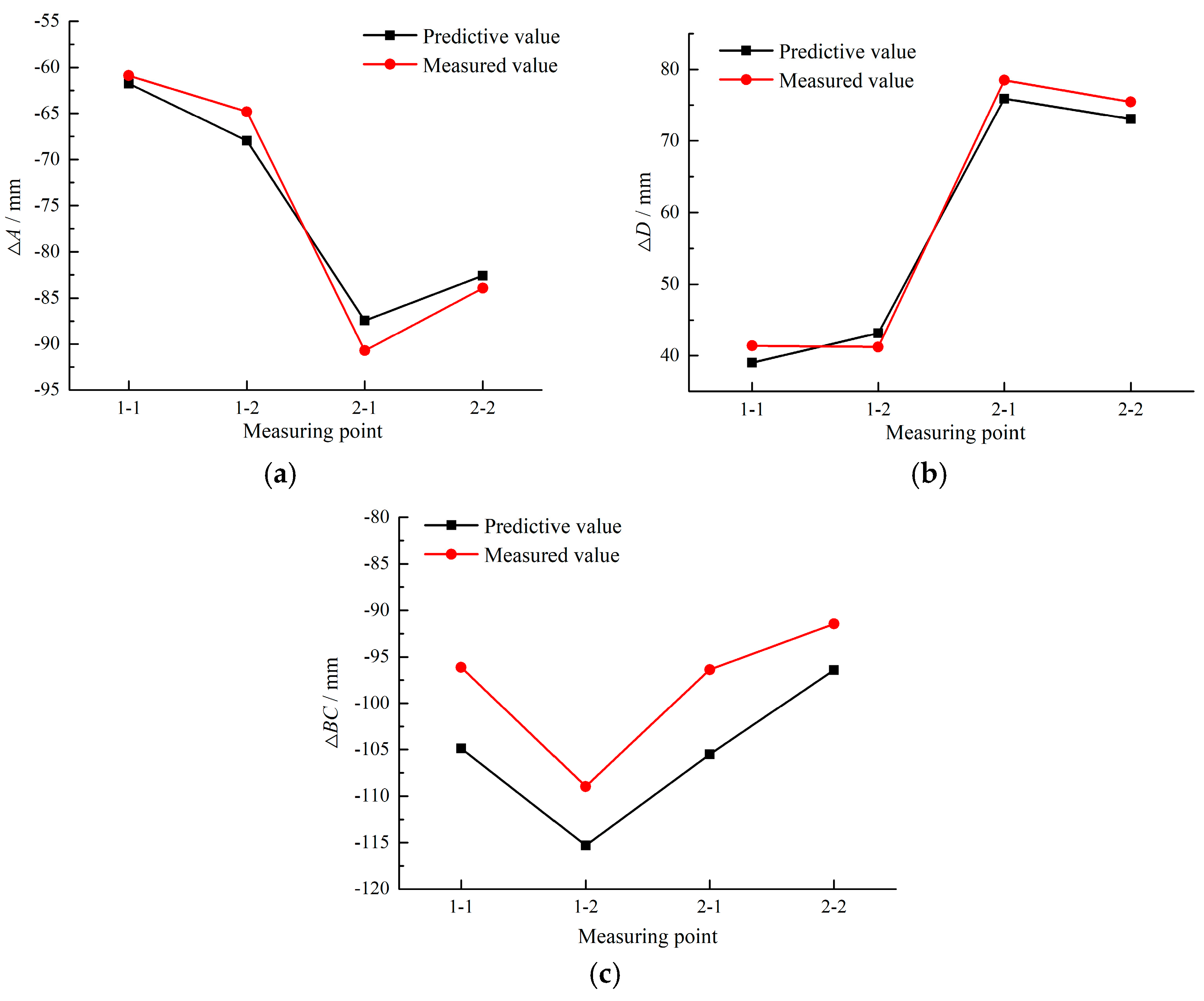

- The MEA-BP model is used to predict mechanical parameters for roadways in the Pingdingshan mine area. The predicted deformation results are consistent with the observed value, which demonstrated the accuracy and reliability of the optimized model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, H.; Chen, B.; Li, S.; Li, Z.; Zhu, C. Updating the models and uncertainty of mechanical parameters for rock tunnels using Bayesian inference. Geosci. Front. 2021, 12, 101198. [Google Scholar] [CrossRef]

- Feng, X.-T.; Zhou, Y.-Y.; Jiang, Q. Rock mechanics contributions to recent hydroelectric developments in China. J. Rock Mech. Geotech. Eng. 2019, 11, 511–526. [Google Scholar] [CrossRef]

- Meng, F.; Wong, L.N.Y.; Zhou, H. Rock brittleness indices and their applications to different fields of rock engineering: A review. J. Rock Mech. Geotech. Eng. 2021, 13, 221–247. [Google Scholar] [CrossRef]

- Han, X.; Li, W.; Li, X.; Zhu, Z. Virtual reality assisted techniques in field tests and engineering application of the mechanical parameters of a horizontally layered rock mass. Alex. Eng. J. 2022, 61, 4027–4039. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Q.; Ma, H.; Fish, J. A novel GPGPU-parallelized contact detection algorithm for combined finite-discrete element method. Int. J. Rock Mech. Min. Sci. 2021, 144, 104782. [Google Scholar] [CrossRef]

- Salmi, E.F.; Sellers, E.J. A review of the methods to incorporate the geological and geotechnical characteristics of rock masses in blastability assessments for selective blast design. Eng. Geol. 2021, 281, 105970. [Google Scholar] [CrossRef]

- Rostamsowlat, I.; Evans, B.; Kwon, H.J. A review of the frictional contact in rock cutting with a PDC bit. J. Pet. Sci. Eng. 2022, 208, 109665. [Google Scholar] [CrossRef]

- Schaefer, L.N.; Kereszturi, G.; Villeneuve, M.; Kennedy, B. Determining physical and mechanical volcanic rock properties via reflectance spectroscopy. J. Volcanol. Geotherm. Res. 2021, 420, 107393. [Google Scholar] [CrossRef]

- Lawal, A.I.; Kwon, S. Application of artificial intelligence to rock mechanics: An overview. J. Rock Mech. Geotech. Eng. 2021, 13, 248–266. [Google Scholar] [CrossRef]

- Liu, K.; Liu, B.; Fang, Y. An intelligent model based on statistical learning theory for engineering rock mass classification. Bull. Eng. Geol. Environ. 2018, 78, 4533–4548. [Google Scholar] [CrossRef]

- Barnoud, A.; Cayol, V.; Lelièvre, P.G.; Portal, A.; Labazuy, P.; Boivin, P.; Gailler, L. Robust Bayesian Joint Inversion of Gravimetric and Muographic Data for the Density Imaging of the Puy de Dôme Volcano (France). Front. Earth Sci. 2021, 8, 575872. [Google Scholar] [CrossRef]

- Hajihassani, M.; Jahed Armaghani, D.; Kalatehjari, R. Applications of Particle Swarm Optimization in Geotechnical Engineering: A Comprehensive Review. Geotech. Geol. Eng. 2017, 36, 705–722. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Q.; Huang, X.; Pan, Y. Perception model of surrounding rock geological conditions based on TBM operational big data and combined unsupervised-supervised learning. Tunn. Undergr. Space Technol. 2022, 120, 104285. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Q.; Huang, X.; Pan, Y. Real-time prediction of rockburst intensity using an integrated CNN-Adam-BO algorithm based on microseismic data and its engineering application. Tunn. Undergr. Space Technol. 2021, 117, 104133. [Google Scholar] [CrossRef]

- Liu, B.; Wang, R.; Zhao, G.; Guo, X.; Wang, Y.; Li, J.; Wang, S. Prediction of rock mass parameters in the TBM tunnel based on BP neural network integrated simulated annealing algorithm. Tunn. Undergr. Space Technol. 2020, 95, 103103. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Q.; Pan, Y.; Huang, X. A novel tree-based algorithm for real-time prediction of rockburst risk using field microseismic monitoring. Environ. Earth Sci. 2021, 80, 504. [Google Scholar] [CrossRef]

- Suman, S.; Khan, S.Z.; Das, S.K.; Chand, S.K. Slope stability analysis using artificial intelligence techniques. Nat. Hazards 2016, 84, 727–748. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, Y.; Tang, H.; Fang, K.; Jiang, Y.; Liu, C.; Wang, X. Peak shear strength prediction for discontinuities between two different rock types using a neural network approach. Bull. Eng. Geol. Environ. 2018, 78, 2315–2329. [Google Scholar] [CrossRef]

- Salsani, A.; Daneshian, J.; Shariati, S.; Yazdani-Chamzini, A.; Taheri, M. Predicting roadheader performance by using artificial neural network. Neural Comput. Appl. 2013, 24, 1823–1831. [Google Scholar] [CrossRef]

- Sarkar, K.; Tiwary, A.; Singh, T.N. Estimation of strength parameters of rock using artificial neural networks. Bull. Eng. Geol. Environ. 2010, 69, 599–606. [Google Scholar] [CrossRef]

- Dai, B.; Gu, H.; Zhu, Y.; Chen, S.; Rodriguez, E.F.; Geem, Z.W. On the Use of an Improved Artificial Fish Swarm Algorithm-Backpropagation Neural Network for Predicting Dam Deformation Behavior. Complexity 2020, 2020, 5463893. [Google Scholar] [CrossRef]

- Feng, G.; Xia, G.; Chen, B.; Xiao, Y.; Zhou, R. A Method for Rockburst Prediction in the Deep Tunnels of Hydropower Stations Based on the Monitored Microseismicity and an Optimized Probabilistic Neural Network Model. Sustainability 2019, 11, 3212. [Google Scholar] [CrossRef] [Green Version]

- Kordnaeij, A.; Kalantary, F.; Kordtabar, B.; Mola-Abasi, H. Prediction of recompression index using GMDH-type neural network based on geotechnical soil properties. Soils Found. 2015, 55, 1335–1345. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Tang, R.; Li, C.; Liu, P.; Luo, L. A BP neural network model optimized by Mind Evolutionary Algorithm for predicting the ocean wave heights. Ocean. Eng. 2018, 162, 98–107. [Google Scholar] [CrossRef]

- Gobeyn, S.; Mouton, A.M.; Cord, A.F.; Kaim, A.; Volk, M.; Goethals, P.L.M. Evolutionary algorithms for species distribution modelling: A review in the context of machine learning. Ecol. Model. 2019, 392, 179–195. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, Q.; Xu, W.; Wang, R.; Zhang, H. Study on Unloading Relaxation Characteristics of Columnar Jointed Rock Masses Based on Displacement Back Analysis. Front. Earth Sci. 2021, 9, 665275. [Google Scholar] [CrossRef]

- Ocak, I.; Seker, S.E. Calculation of surface settlements caused by EPBM tunneling using artificial neural network, SVM, and Gaussian processes. Environ. Earth Sci. 2013, 70, 1263–1276. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.-z.; He, Y. Application of optimized grey discrete Verhulst—BP neural network model in settlement prediction of foundation pit. Environ. Earth Sci. 2019, 78, 441. [Google Scholar] [CrossRef]

- Jie, J.; Zeng, J.; Han, C. An extended mind evolutionary computation model for optimizations. Appl. Math. Comput. 2007, 185, 1038–1049. [Google Scholar] [CrossRef]

- Yin, X.; Gao, F.; Wu, J.; Huang, X.; Pan, Y.; Liu, Q. Compressive strength prediction of sprayed concrete lining in tunnel engineering using hybrid machine learning techniques. Undergr. Space 2021, 6, 1–16. [Google Scholar] [CrossRef]

- Rohola, H.; Jamal, R.; Jürgen, S.; Yilmaz, O.; Babak, S. Prediction of TBM jamming risk in squeezing grounds using Bayesian and artificial neural networks. J. Rock Mech. Geotech. Eng. 2021, 12, 21–31. [Google Scholar]

- Cui, Z.; Sheng, Q.; Zhang, G.-m.; Liu, H. A modified rock mass classification considering seismic effects in the basic quality (BQ) system. Bull. Eng. Geol. Environ. 2021, 80, 2249–2260. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Q.; Pan, Y.; Huang, X.; Wu, J.; Wang, X. Strength of Stacking Technique of Ensemble Learning in Rockburst Prediction with Imbalanced Data: Comparison of Eight Single and Ensemble Models. Nat. Resour. Res. 2021, 30, 1795–1815. [Google Scholar] [CrossRef]

| Mechanical Parameters | Density ρ/Kg·m−3 | Elasticity Modulus E/GPa | Poisson’s Ratio/μ | Cohesion c/MPa | Friction Angle φ/(°) | Dilation Angle ψ/(°) |

|---|---|---|---|---|---|---|

| Value | 2450 | 3~13.5 | 0.21 | 0.5~4 | 15~32.5 | 10 |

| Level | Parameter | ||

|---|---|---|---|

| E/MPa | c/MPa | φ/° | |

| 1 | 3 | 0.5 | 15 |

| 2 | 4.5 | 1.0 | 17.5 |

| 3 | 6.0 | 1.5 | 20 |

| 4 | 7.5 | 2.0 | 22.5 |

| 5 | 9.0 | 2.5 | 25 |

| 6 | 10.5 | 3.0 | 27.5 |

| 7 | 12.0 | 3.5 | 30 |

| 8 | 13.5 | 4.0 | 32.5 |

| Group | Mechanical Parameters | Displacement/mm | ||||

|---|---|---|---|---|---|---|

| E/MPa | c/MPa | φ/° | ∆A | ∆D | ∆BC | |

| 1 | 12.69 | 2.49 | 24.08 | −19.3 | 16.9 | −20.6 |

| 2 | 9.91 | 2.25 | 29.92 | −18.3 | 21.0 | 15.0 |

| 3 | 3.01 | 1.86 | 25.28 | −93.4 | 79.1 | −126.0 |

| 4 | 3.84 | 0.78 | 32.10 | −82.2 | 82.7 | −115.8 |

| 5 | 7.25 | 2.24 | 16.40 | −65.7 | 41.8 | −110.7 |

| 6 | 4.01 | 0.63 | 31.15 | −102.7 | 97.8 | −143.0 |

| 7 | 6.76 | 1.82 | 36.40 | −24.2 | 29.9 | −14.7 |

| 8 | 6.34 | 2.54 | 17.38 | −55.1 | 36.3 | −87.5 |

| No. | RMSE1 | RMSE2 | RMSE3 | RMSE* |

|---|---|---|---|---|

| 1 | 6.04 | 7.60 | 3.67 | 0.93 |

| 2 | 4.66 | 1.49 | 5.13 | 1.20 |

| 3 | 1.71 | 8.25 | 1.63 | 0.31 |

| 4 | 6.41 | 10.62 | 1.35 | 0.49 |

| 5 | 0.35 | 1.65 | 0.58 | 0.48 |

| 6 | 5.16 | 10.07 | 4.60 | 0.24 |

| 7 | 2.67 | 2.09 | 2.88 | 0.40 |

| 8 | 2.01 | 3.45 | 0.86 | 0.57 |

| Average | 3.63 | 5.65 | 2.59 | 0.58 |

| Prediction Model | The Initial Values |

|---|---|

| BP model | η = 0.05; g = 0.001 |

| MEA-BP model | η = 0.05; S = 200; m = 10; Nt = 5; Ns = 5; g = 0.001 |

| Measuring Point | Roadway Deformation Value | Predicted Mechanical Parameter | ||||

|---|---|---|---|---|---|---|

| ∆A/mm | ∆D/mm | ∆BC/mm | E/MPa | c/MPa | φ/° | |

| 1-1 | −60.9 | 41.4 | −96.1 | 8.52 | 2.23 | 15.79 |

| 1-2 | −64.8 | 41.2 | −108.9 | 8.03 | 2.18 | 15.84 |

| 2-1 | −90.7 | 78.5 | −96.4 | 3.16 | 1.76 | 26.27 |

| 2-2 | −83.9 | 75.5 | −91.5 | 3.30 | 1.72 | 26.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Li, P.; Yin, X.; Wang, S.; Zhu, Y. Back Analysis of Surrounding Rock Parameters in Pingdingshan Mine Based on BP Neural Network Integrated Mind Evolutionary Algorithm. Mathematics 2022, 10, 1746. https://doi.org/10.3390/math10101746

Zhang J, Li P, Yin X, Wang S, Zhu Y. Back Analysis of Surrounding Rock Parameters in Pingdingshan Mine Based on BP Neural Network Integrated Mind Evolutionary Algorithm. Mathematics. 2022; 10(10):1746. https://doi.org/10.3390/math10101746

Chicago/Turabian StyleZhang, Jianguo, Peitao Li, Xin Yin, Sheng Wang, and Yuanguang Zhu. 2022. "Back Analysis of Surrounding Rock Parameters in Pingdingshan Mine Based on BP Neural Network Integrated Mind Evolutionary Algorithm" Mathematics 10, no. 10: 1746. https://doi.org/10.3390/math10101746

APA StyleZhang, J., Li, P., Yin, X., Wang, S., & Zhu, Y. (2022). Back Analysis of Surrounding Rock Parameters in Pingdingshan Mine Based on BP Neural Network Integrated Mind Evolutionary Algorithm. Mathematics, 10(10), 1746. https://doi.org/10.3390/math10101746