Largest Lyapunov Exponent Parameter of Stiffened Carbon Fiber Reinforced Epoxy Composite Laminated Plate Due to Critical Buckling Load Using Average Logarithmic Divergence Approach

Abstract

:1. Introduction

2. Analytic Solution of the Bending Deflection

3. Equations of Motion

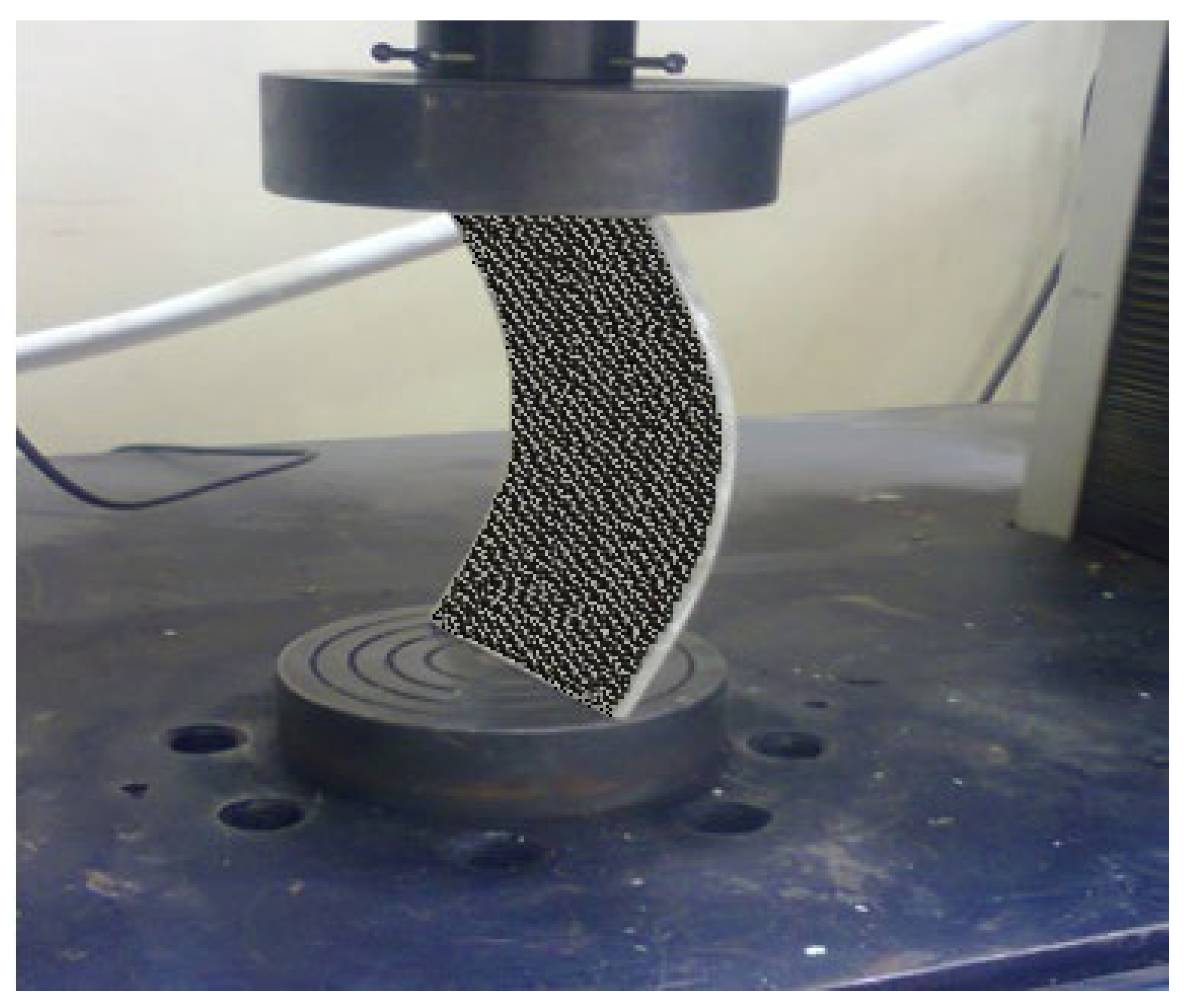

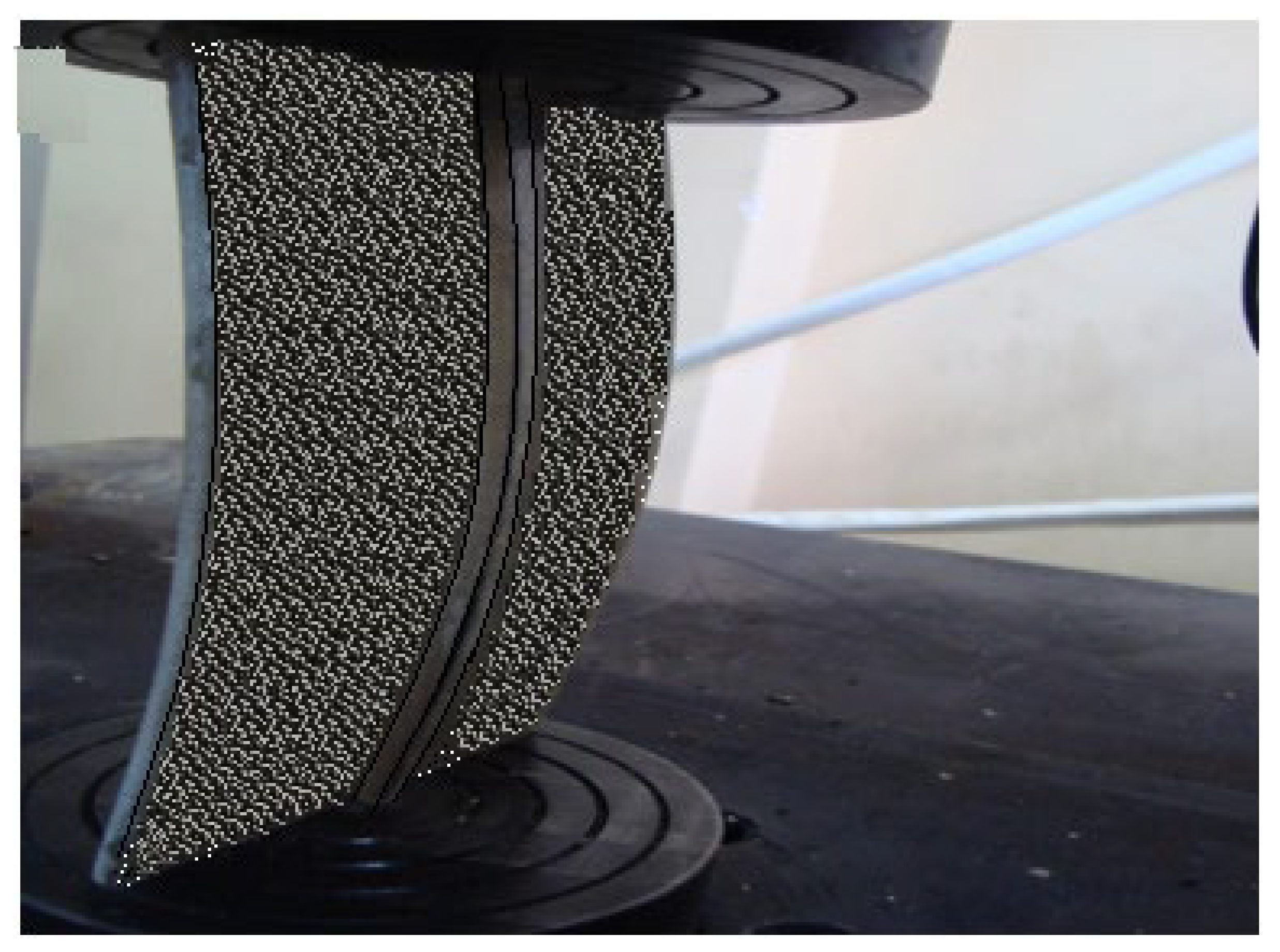

4. Solution of Analytic Equation of Motion

4.1. Solution of Equation of Motion of Unstiffened Plate

4.2. Solution of Equation of Motion of Stiffener

5. Experiment Setup

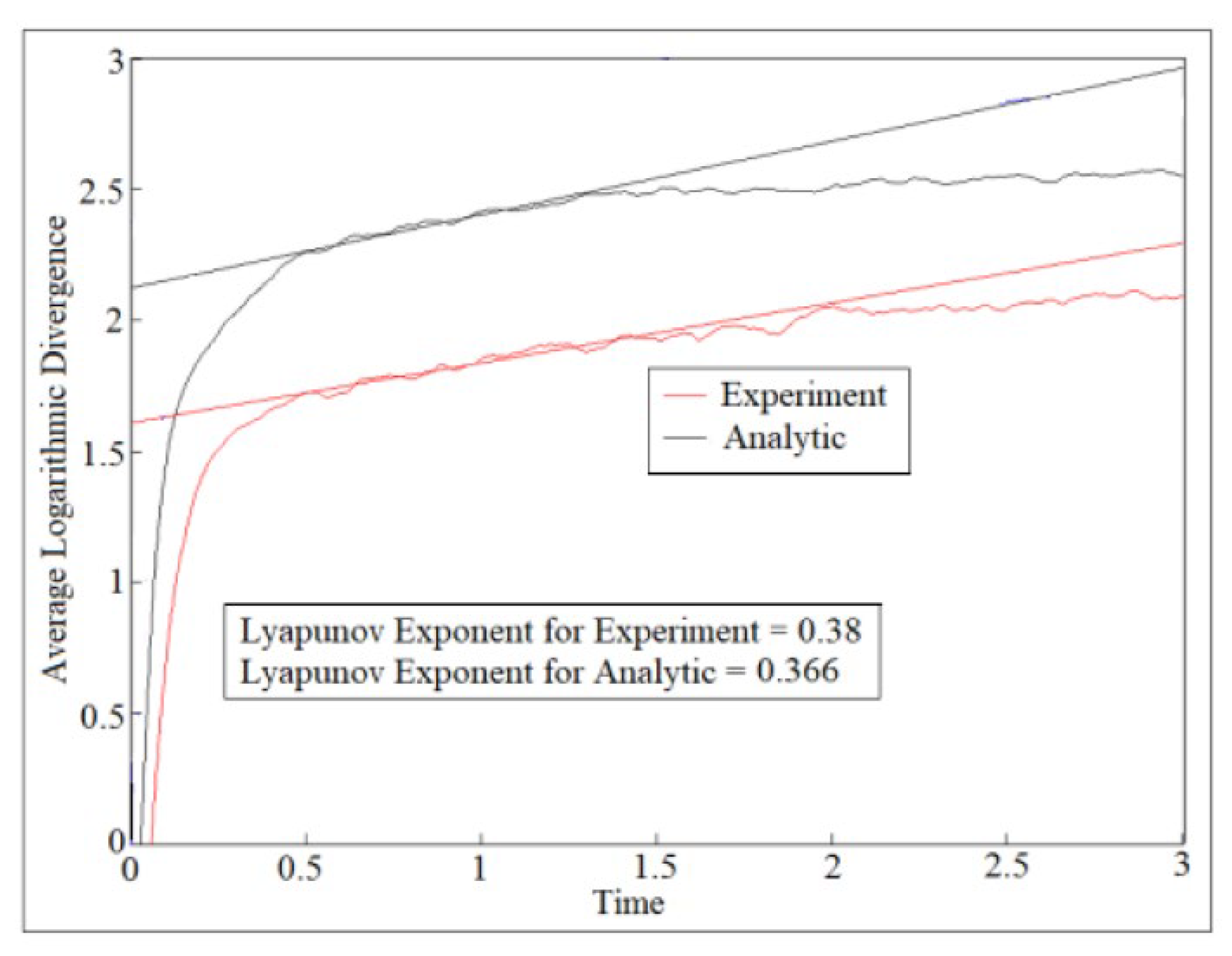

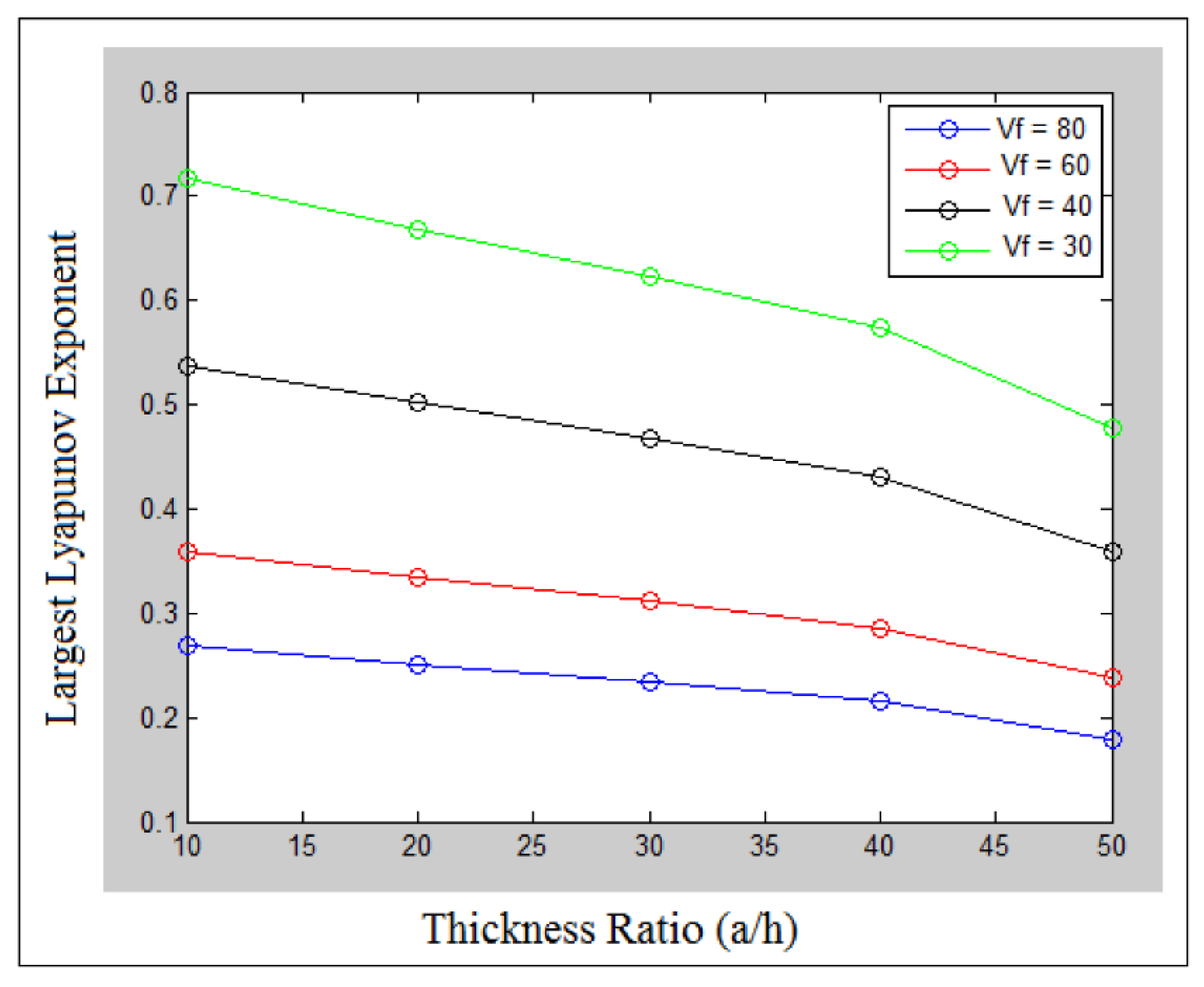

6. Largest Lyapunov Exponent Parameter

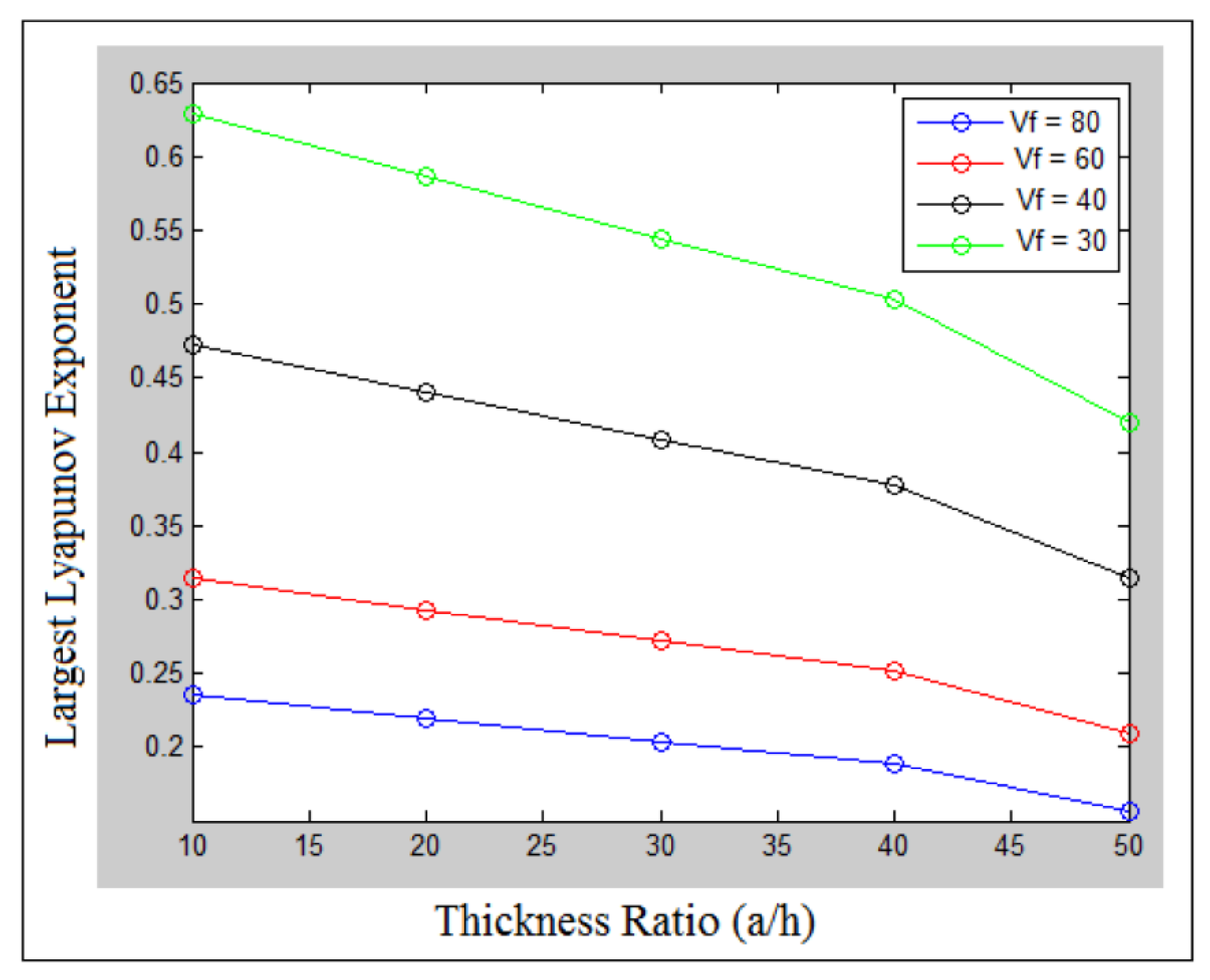

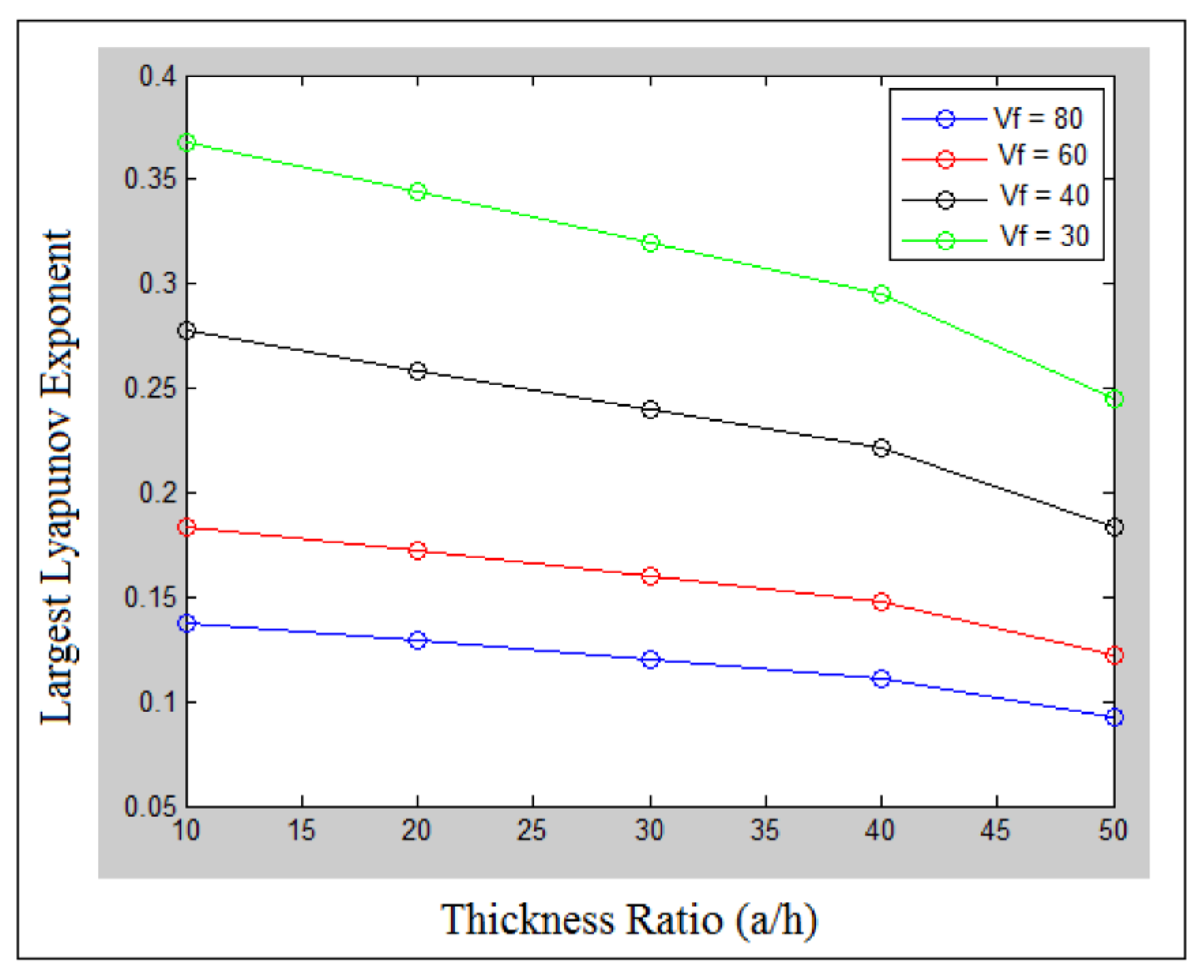

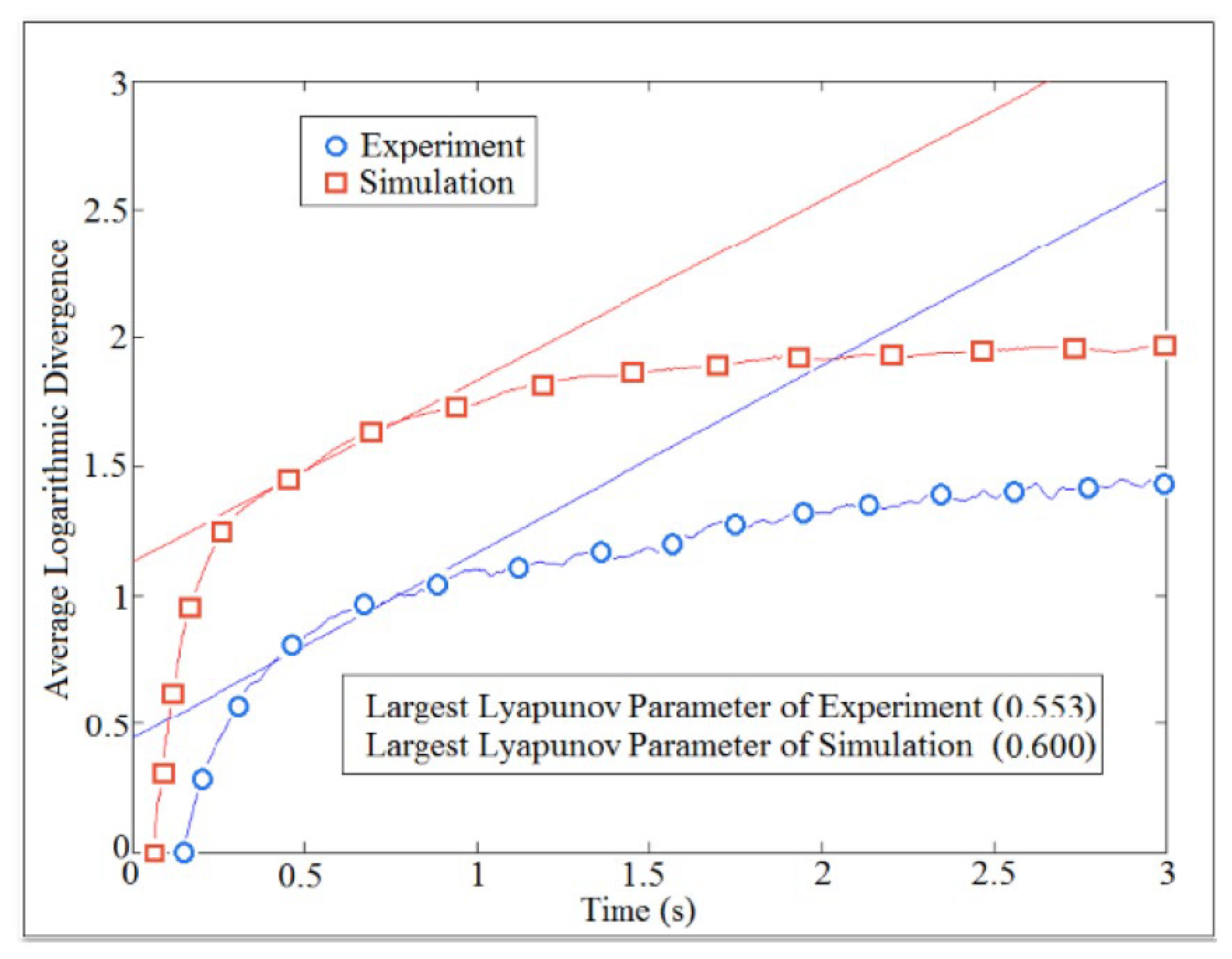

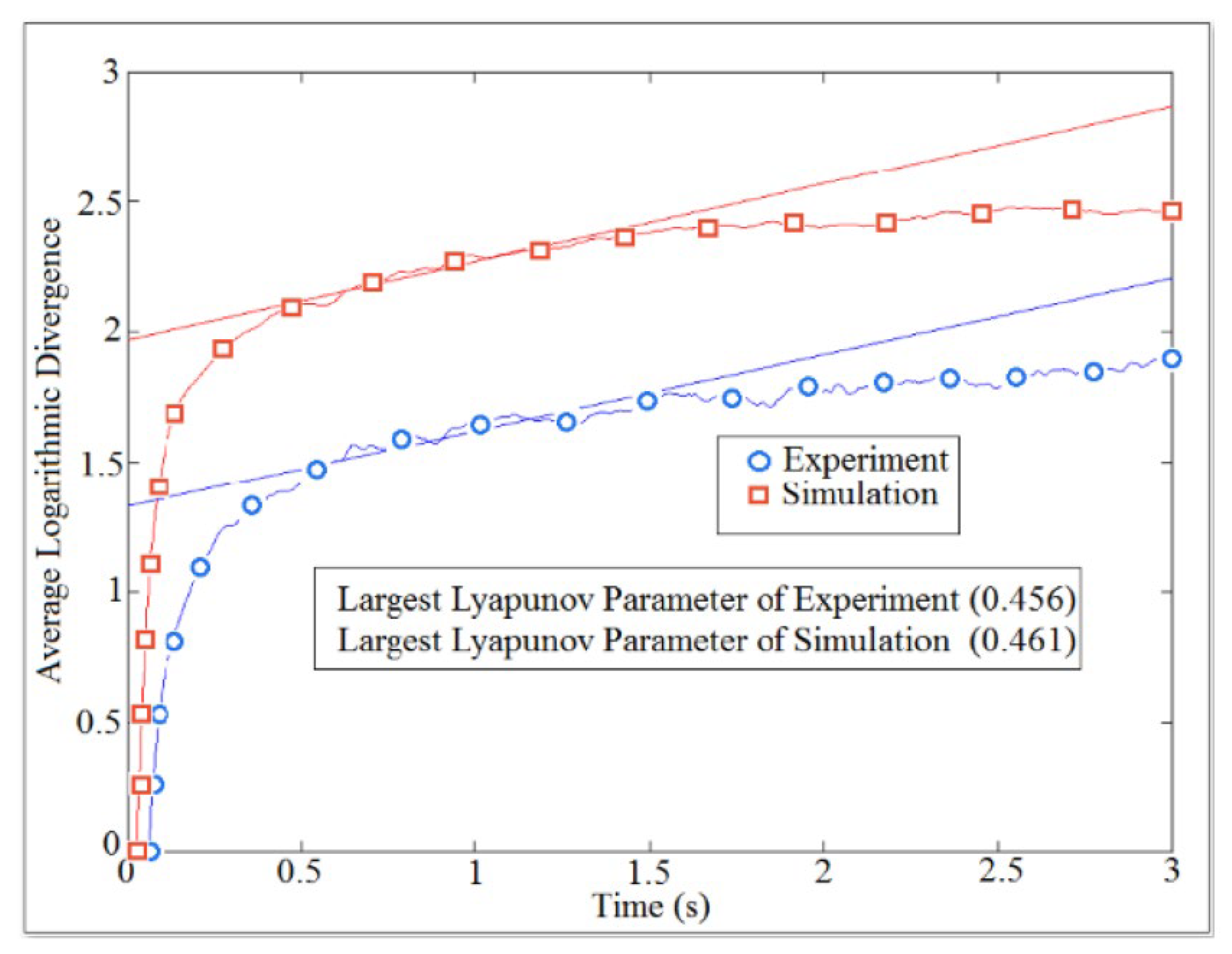

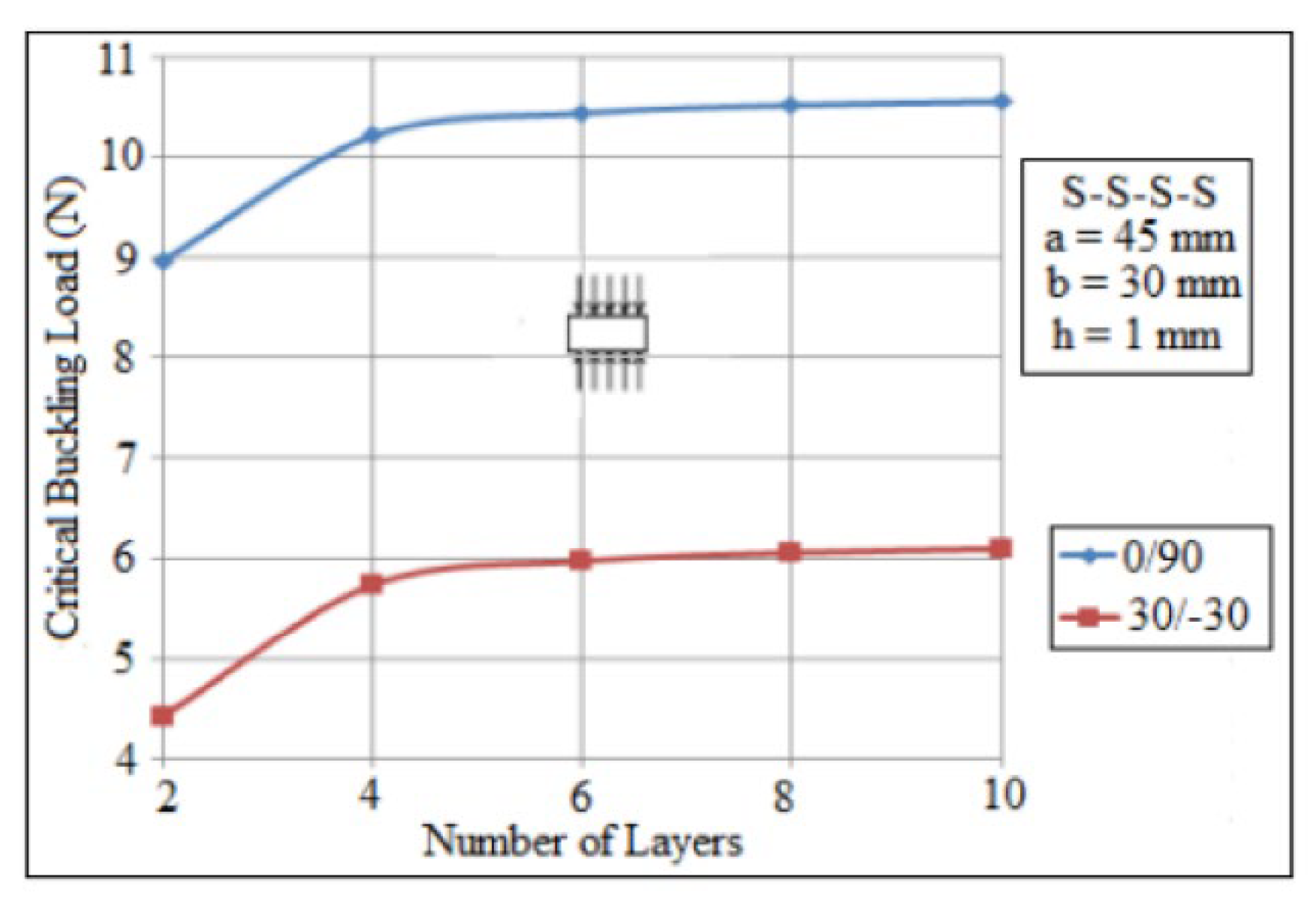

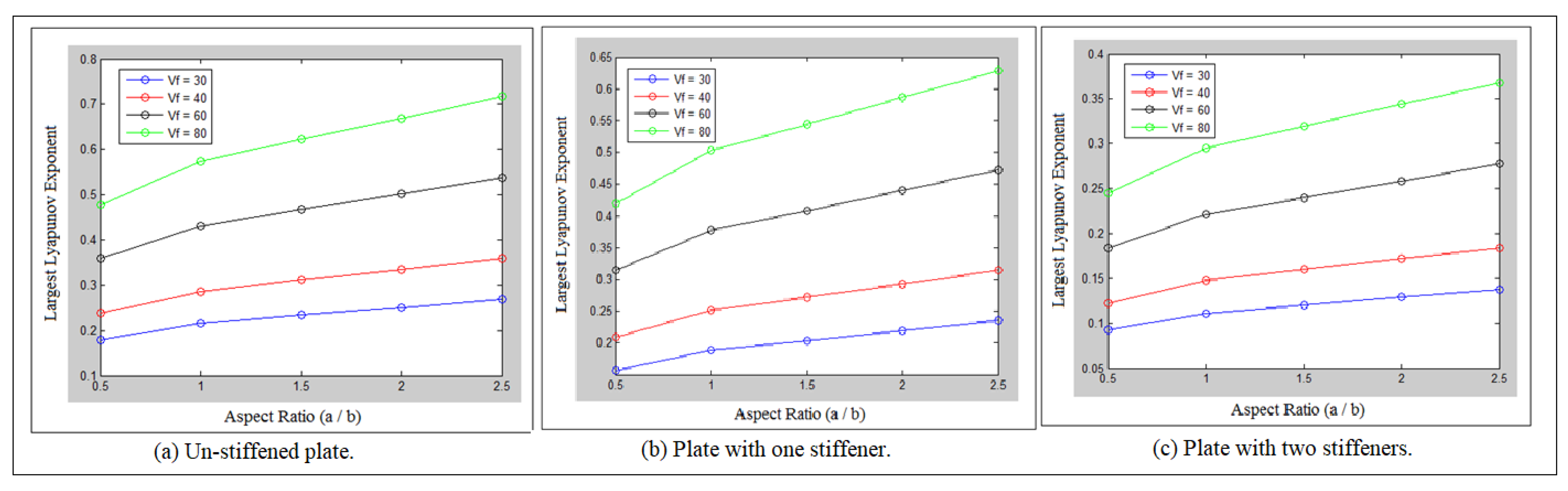

7. Results and Discussions

8. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures

| a | Length of the large span of the rectangular plate, m |

| b | Length of the small span of the rectangular plate, m |

| h | Thickness of the un-stiffened composite laminated plate, m |

| uo, vo, wo | Displacement components in the 3-D coordinate system |

| Qij | Reduced stiffness elements, N/m2 |

| wo | Mid plane deflection along the z-direction, m |

| tx, hx, bx | Thickness, depth, distance between stiffeners when the stiffener is placed along the x-axis, mm |

| ty, hy, by | Thickness, depth, distance between stiffeners when the stiffener is placed along the y-axis, mm |

| εzz | the experiment strain through the composite plate thickness |

| δzz | the experiment bending deflection through the composite plate thickness |

| λ | The largest Lyapunov exponent parameter |

References

- Lal, A.; Parghi, A.; Markad, K. Post-buckling nonlinear analysis of sandwich laminated composite plate. J. Mater. Today Proc. 2021, 44, 4934–4939. [Google Scholar] [CrossRef]

- Yousuf, L.S. Nonlinear dynamics investigation of flexural stiffness of composite laminated plate under the effect of temperature and combined loading using Lyapunov exponent parameter. Compos. Part B Eng. 2021, 219, 108926. [Google Scholar] [CrossRef]

- Mondal, S.; Ramachandra, L.S. Nonlinear dynamic pulse buckling of imperfect laminated plate with delamination. Int. J. Solids Struct. 2020, 198, 170–182. [Google Scholar] [CrossRef]

- Keshav, V.; Patel, S.N. Non-linear dynamic pulse buckling of laminated composite curved panels. Int. J. Struct. Eng. Mech. 2020, 73, 181–190. [Google Scholar]

- Keshav, V.; Patel, S.; Kumar, R. Nonlinear dynamic buckling and failure study of laminated composite plates subjected to axial impulse loads. In Advances in Fluid Mechanics and Solid Mechanics; Springer: Berlin/Heidelberg, Germany, 2020; pp. 281–295. [Google Scholar]

- Balkan, D.; Demir, Ö.; Arıkoğlu, A. Dynamic analysis of a stiffened composite plate under blast load: A new model and experimental validation. Int. J. Impact 2020, 143, 103591. [Google Scholar] [CrossRef]

- Yousyf, L.S. Nonlinear Dynamics Suppression of Bending Deflection in a Composite Laminated Plate Using a Beam Stiffener Due to Critical Buckling Load and Shear Force. J. Appl. Sci. 2022, 12, 1204. [Google Scholar] [CrossRef]

- Reddy, J.N. Mechanics of Laminated Composite Plates and Shells: Theory and Analysis; CRC press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Troitsky, M.; Hoppmann, W. Stiffened plates: Bending, stability and vibrations. J. Appl. Mech. 1977, 44, 516. [Google Scholar] [CrossRef]

- Gopalan, V.; Suthenthiraveerappa, V.; David, J.S.; Subramanian, J.; Annamalai, A.R.; Jen, C.-P. Experimental and numerical analyses on the buckling characteristics of woven flax/epoxy laminated composite plate under axial compression. Polymers 2021, 13, 995. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.-T.; Adnan, A. Mechanics of Aircraft Structures; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Terrier, P.; Reynard, F. Maximum lyapunov exponent revisited: Long-term attractor divergence of gait dynamics is highly sensitive to the noise structure of stride intervals. Gait Posture 2018, 66, 236–241. [Google Scholar] [CrossRef] [PubMed]

- Hussain, V.S.; Spano, M.L.; Lockhart, T.E. Effect of data length on time delay and embedding dimension for calculating the lyapunov exponent in walking. J. R. Soc. Interface 2020, 17, 20200311. [Google Scholar] [CrossRef] [PubMed]

- Matilla-García, M.; Morales, I.; Rodríguez, J.M.; Marín, M.R. Selection of embedding dimension and delay time in phase space reconstruction via symbolic dynamics. Entropy 2021, 23, 221. [Google Scholar] [CrossRef]

| Boundary Conditions | Analytic (N) | Numerical (N) | Error (%) |

|---|---|---|---|

| S-F-S-F | 16.426 | 17.533 | 6.317 |

| S-F-S-S | 17.023 | 18.115 | 6.032 |

| S-F-S-C | 19.389 | 20.468 | 5.272 |

| S-S-S-S | 35.232 | 36.351 | 3.078 |

| S-S-S-C | 59.288 | 60.409 | 1.855 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yousuf, L.S. Largest Lyapunov Exponent Parameter of Stiffened Carbon Fiber Reinforced Epoxy Composite Laminated Plate Due to Critical Buckling Load Using Average Logarithmic Divergence Approach. Mathematics 2022, 10, 2020. https://doi.org/10.3390/math10122020

Yousuf LS. Largest Lyapunov Exponent Parameter of Stiffened Carbon Fiber Reinforced Epoxy Composite Laminated Plate Due to Critical Buckling Load Using Average Logarithmic Divergence Approach. Mathematics. 2022; 10(12):2020. https://doi.org/10.3390/math10122020

Chicago/Turabian StyleYousuf, Louay S. 2022. "Largest Lyapunov Exponent Parameter of Stiffened Carbon Fiber Reinforced Epoxy Composite Laminated Plate Due to Critical Buckling Load Using Average Logarithmic Divergence Approach" Mathematics 10, no. 12: 2020. https://doi.org/10.3390/math10122020

APA StyleYousuf, L. S. (2022). Largest Lyapunov Exponent Parameter of Stiffened Carbon Fiber Reinforced Epoxy Composite Laminated Plate Due to Critical Buckling Load Using Average Logarithmic Divergence Approach. Mathematics, 10(12), 2020. https://doi.org/10.3390/math10122020