Study on Failure Characteristics and Control Technology of Roadway Surrounding Rock under Repeated Mining in Close-Distance Coal Seam

Abstract

:1. Introduction

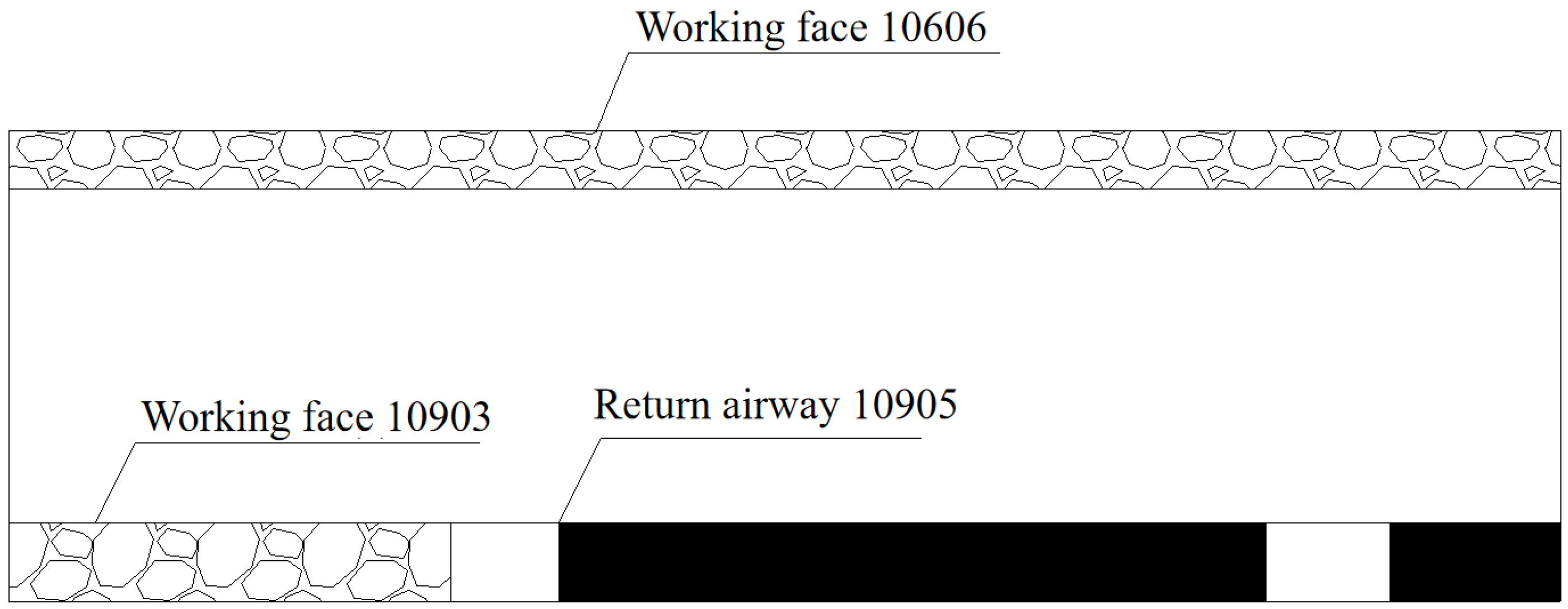

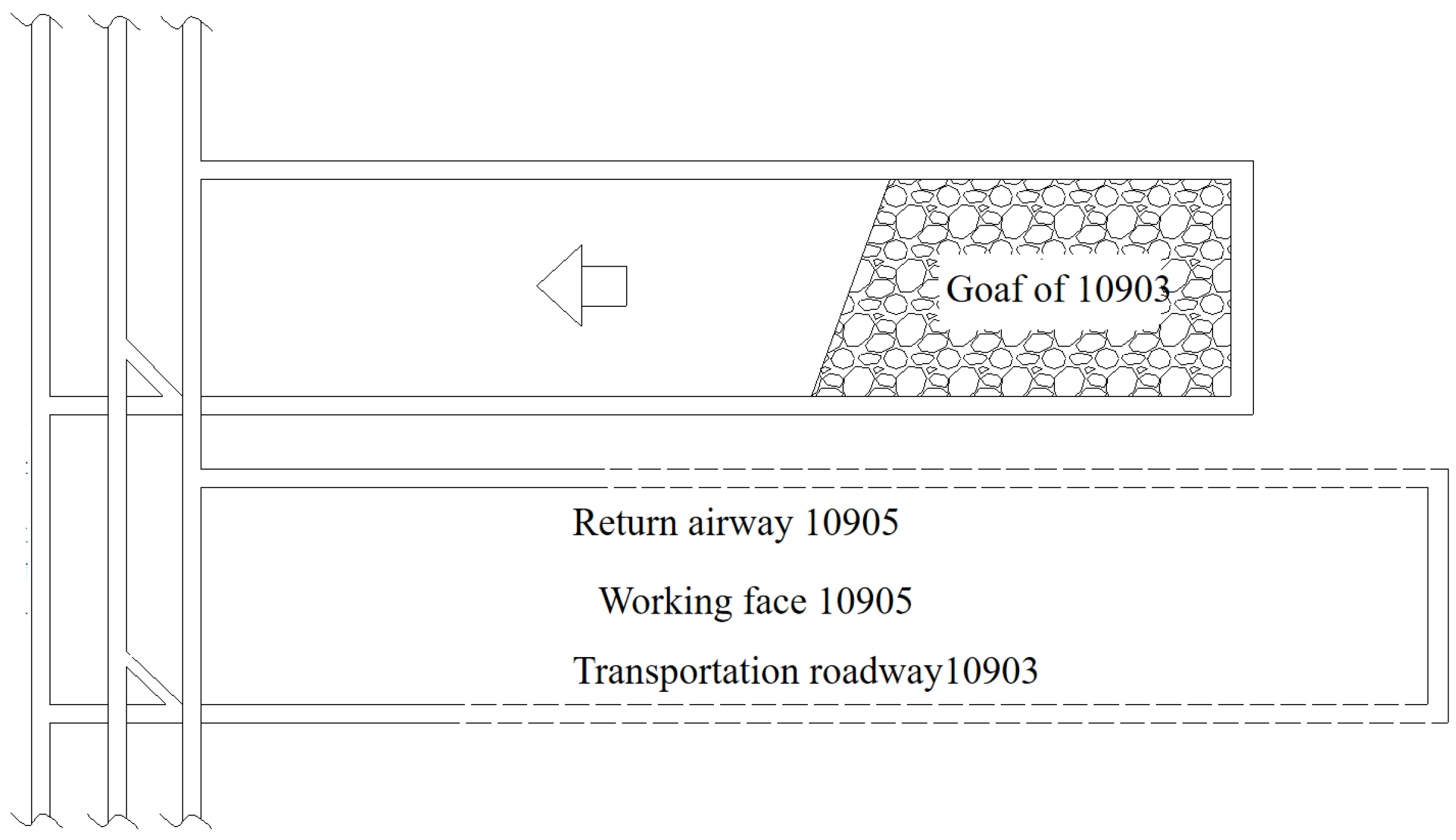

2. Engineering Background

2.1. Geological Conditions

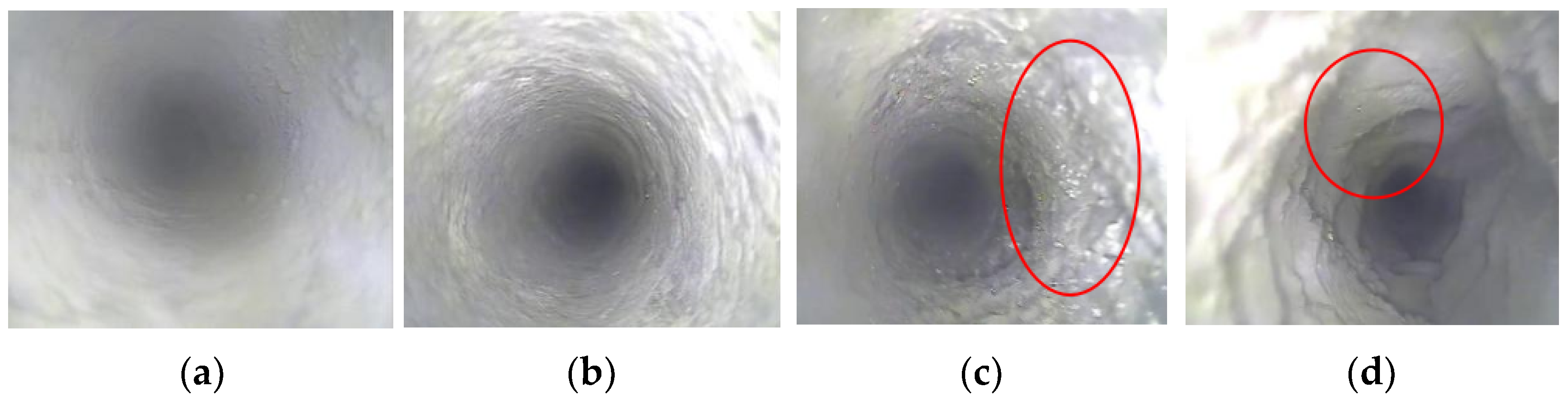

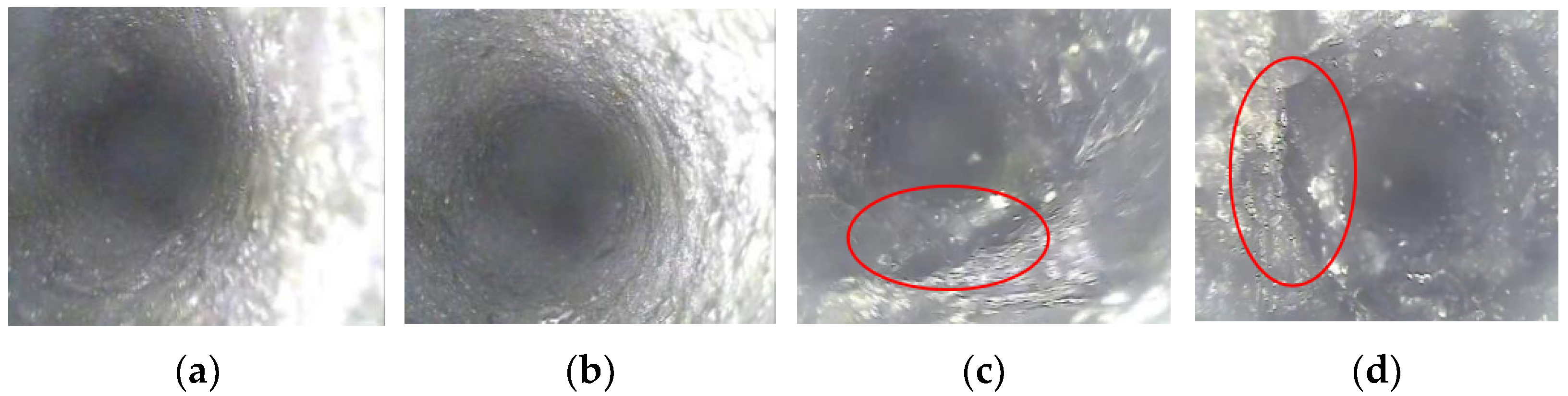

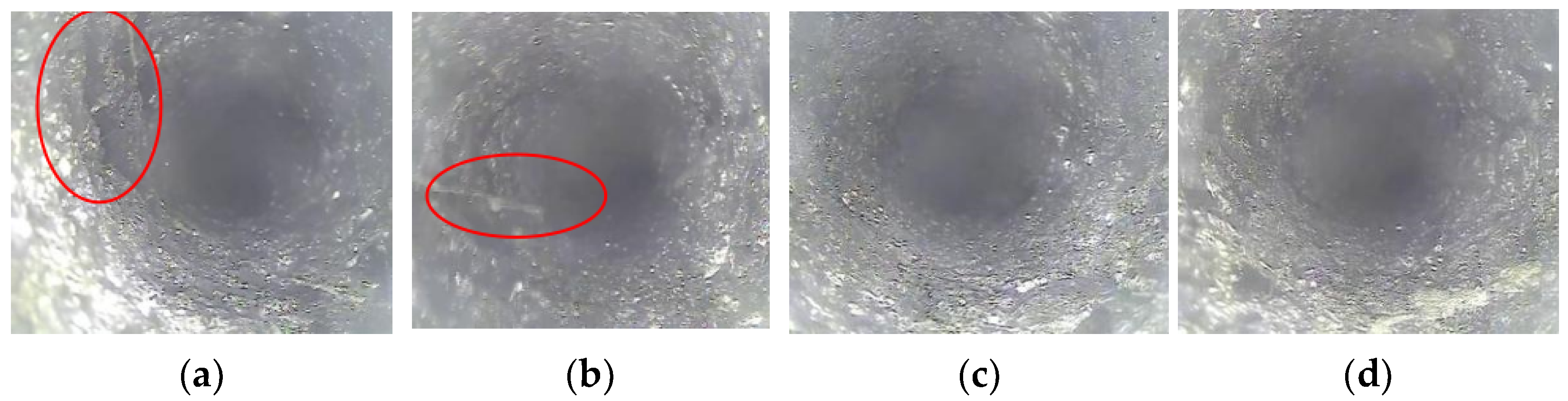

2.2. Roof Failure Characteristics of Return Airway in Working Face 10905

2.3. Instability Factors of Roadway

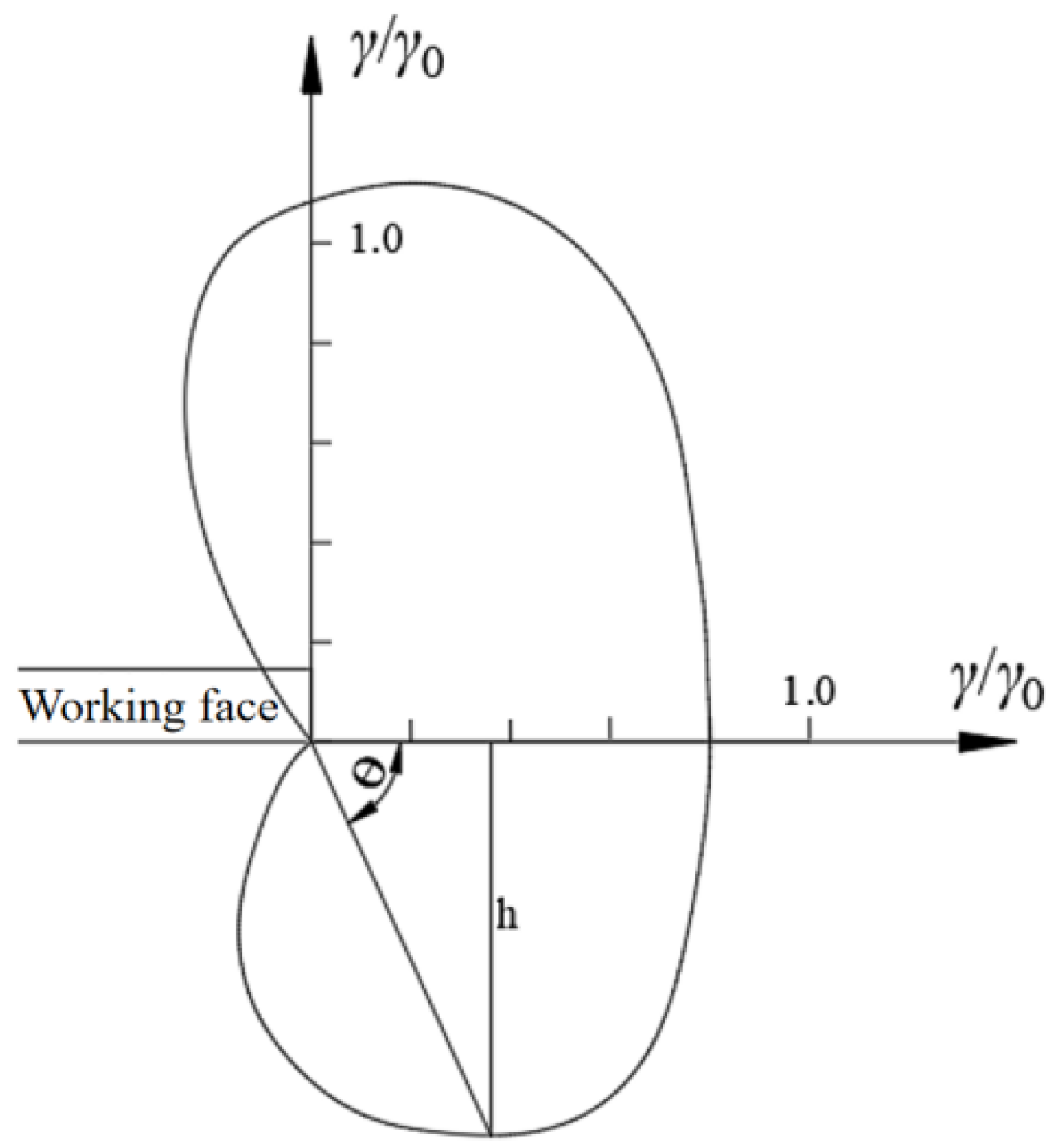

3. Calculation of Floor Damage Depth after Coal Seam #6 Mining

4. Numerical Simulation of Roadway Instability under Repeated Mining

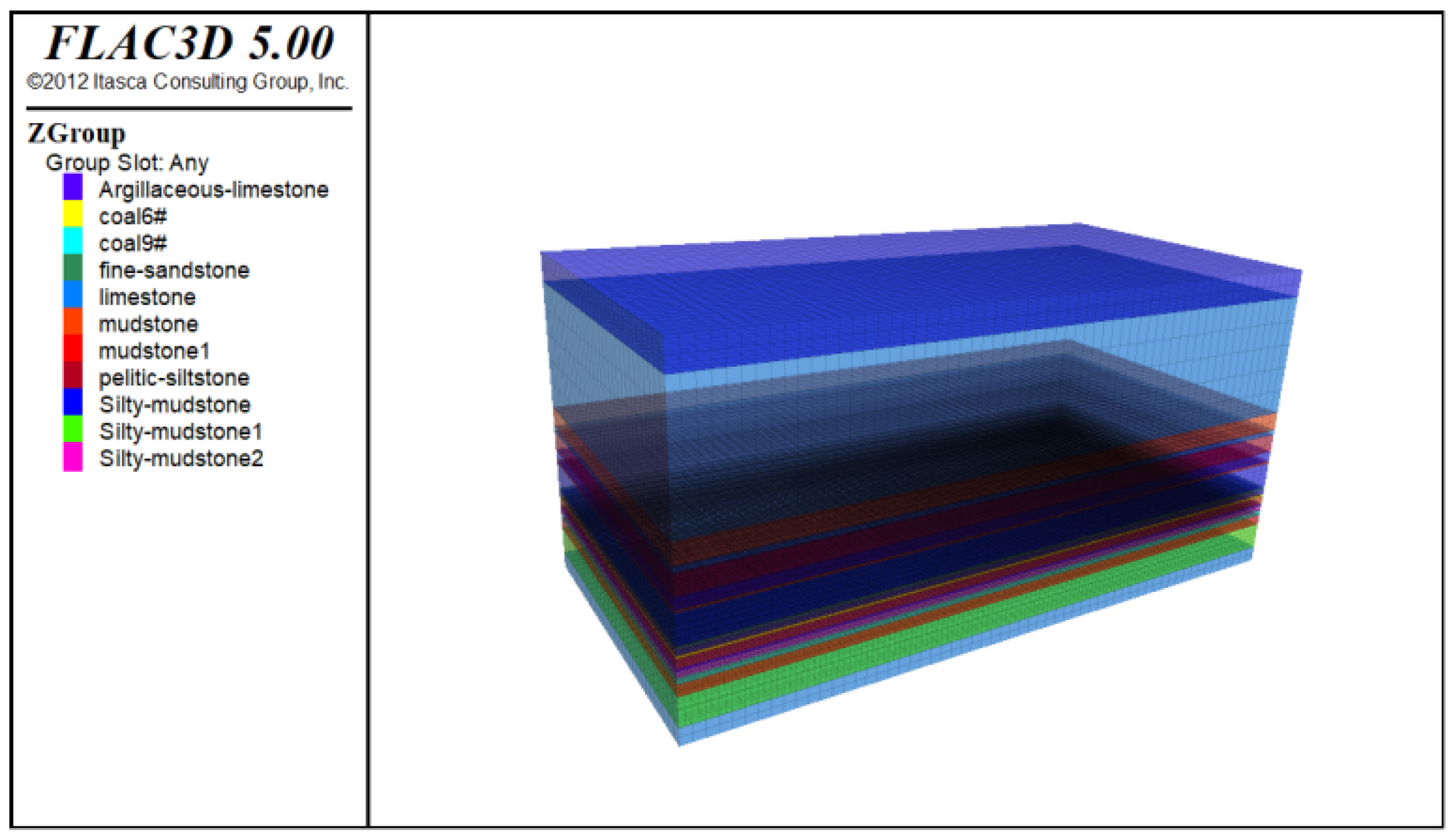

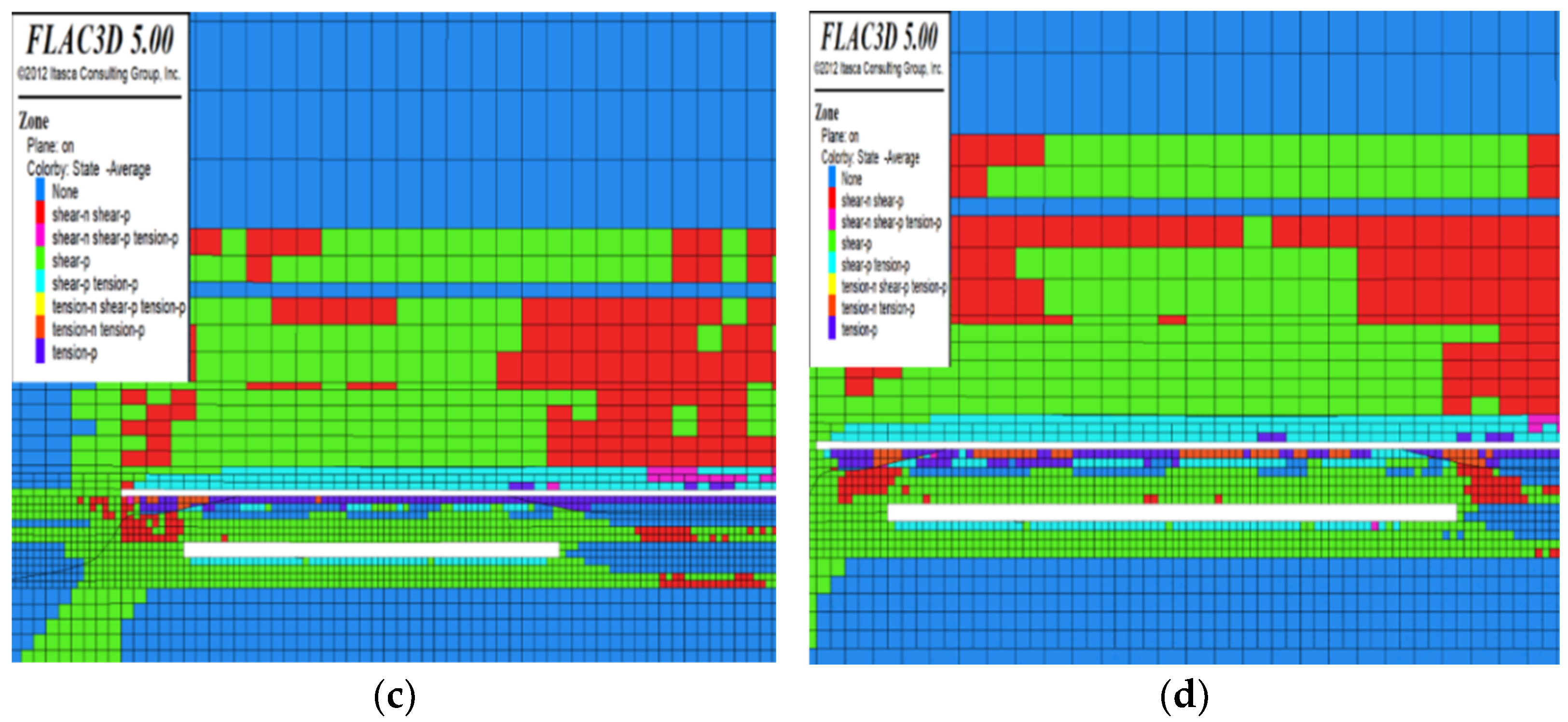

4.1. Numerical Model Establishment and Parameter Determination

4.2. Stress and Displacement Characteristics of Surrounding Rock in Lower Coal Seam

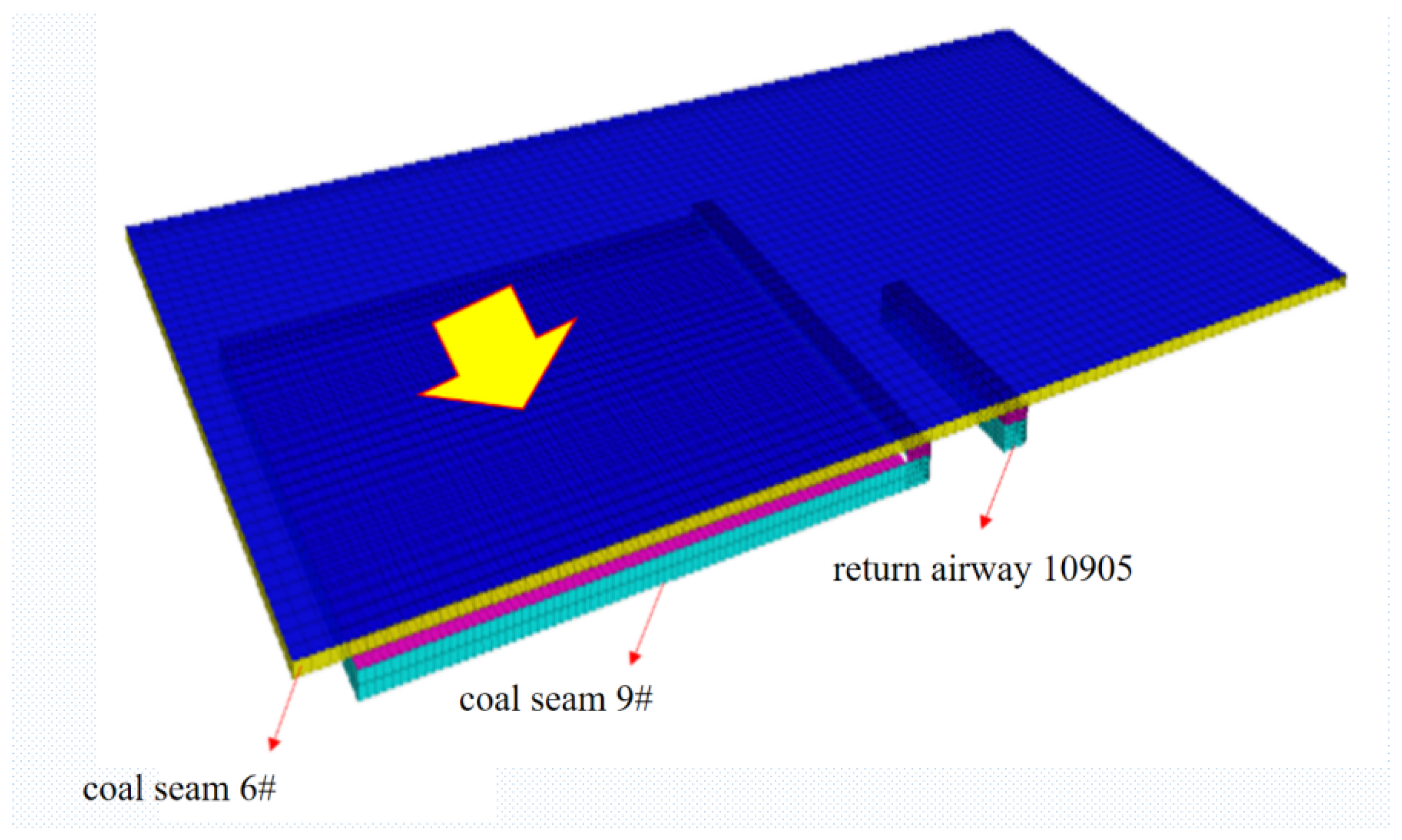

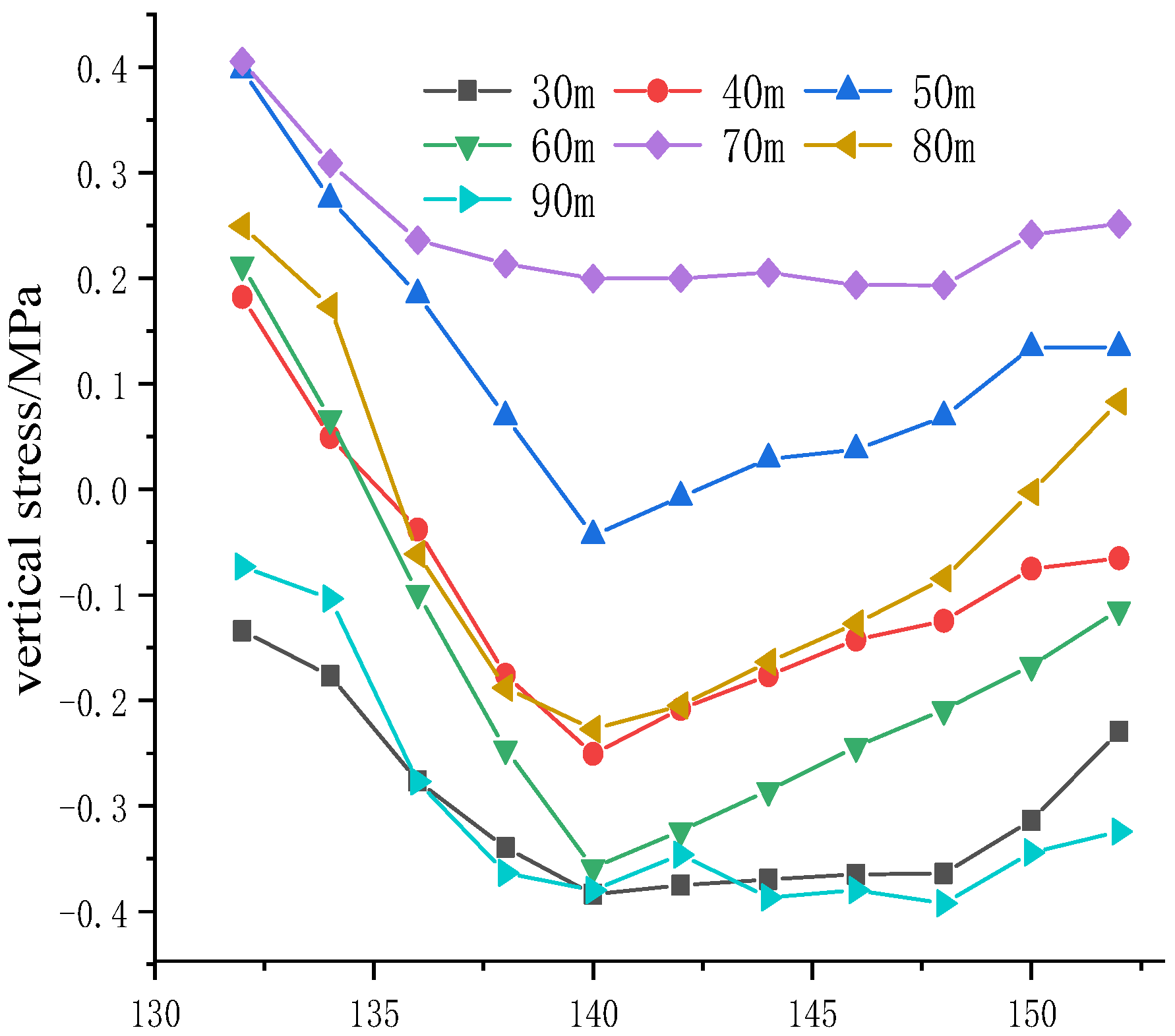

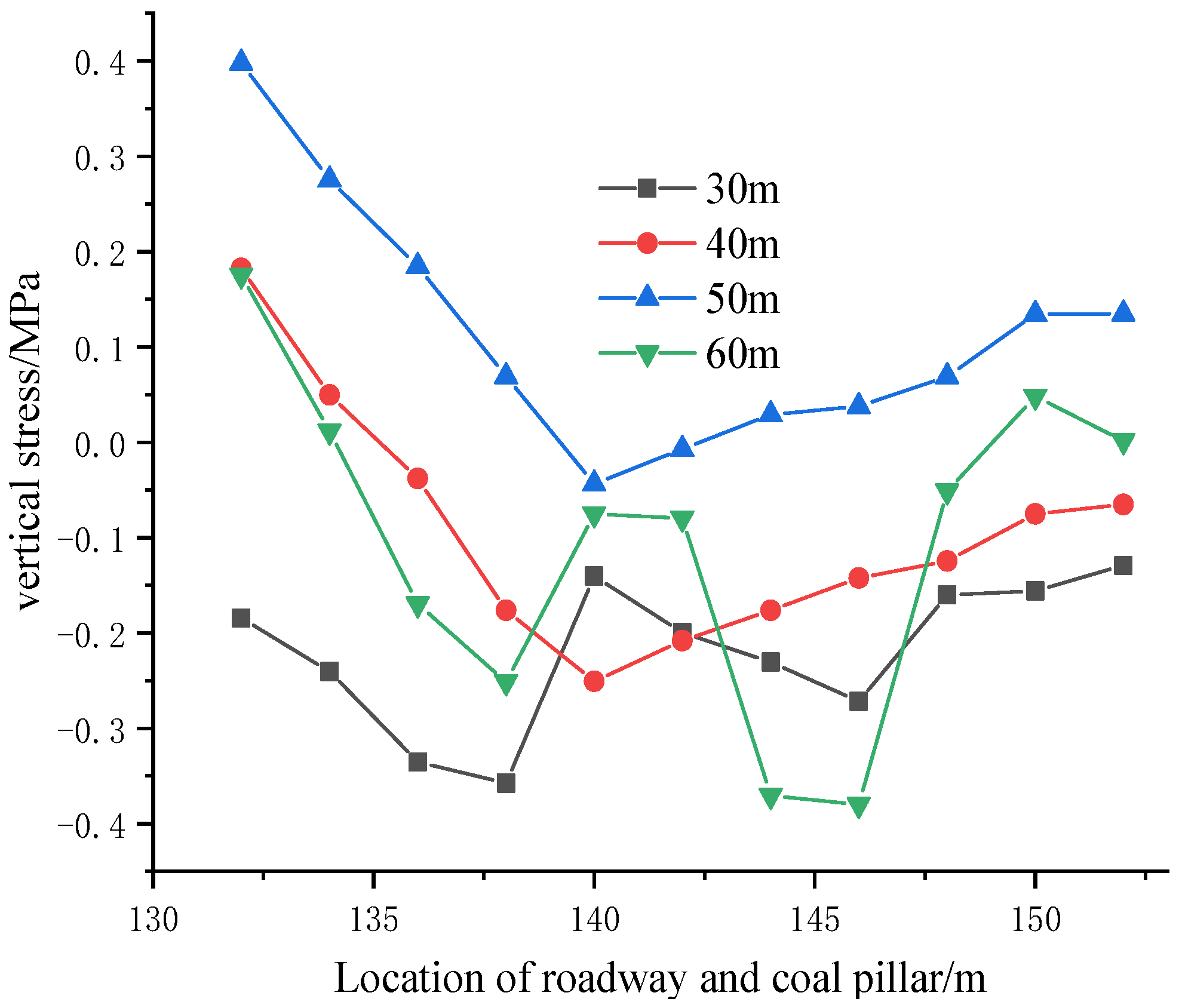

4.2.1. Stress Evolution Law

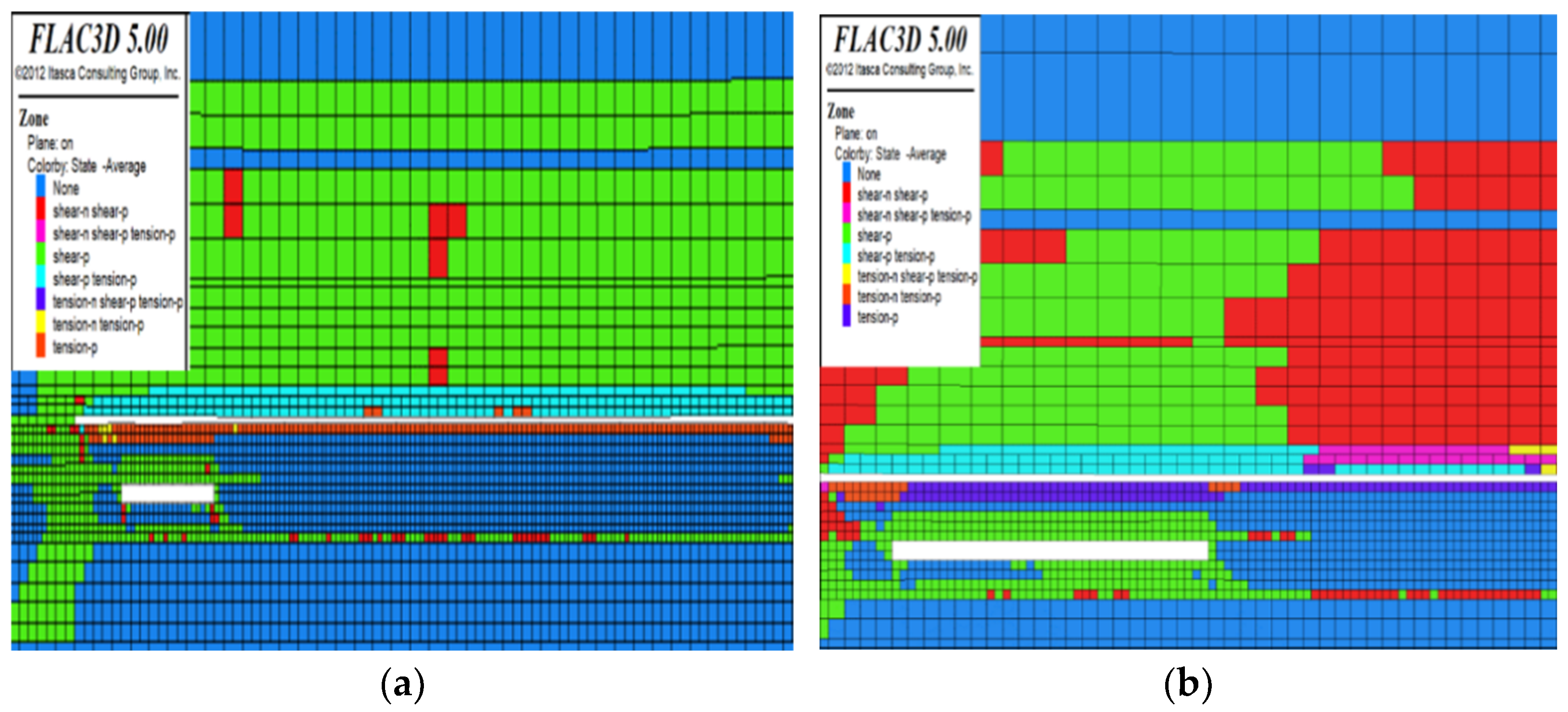

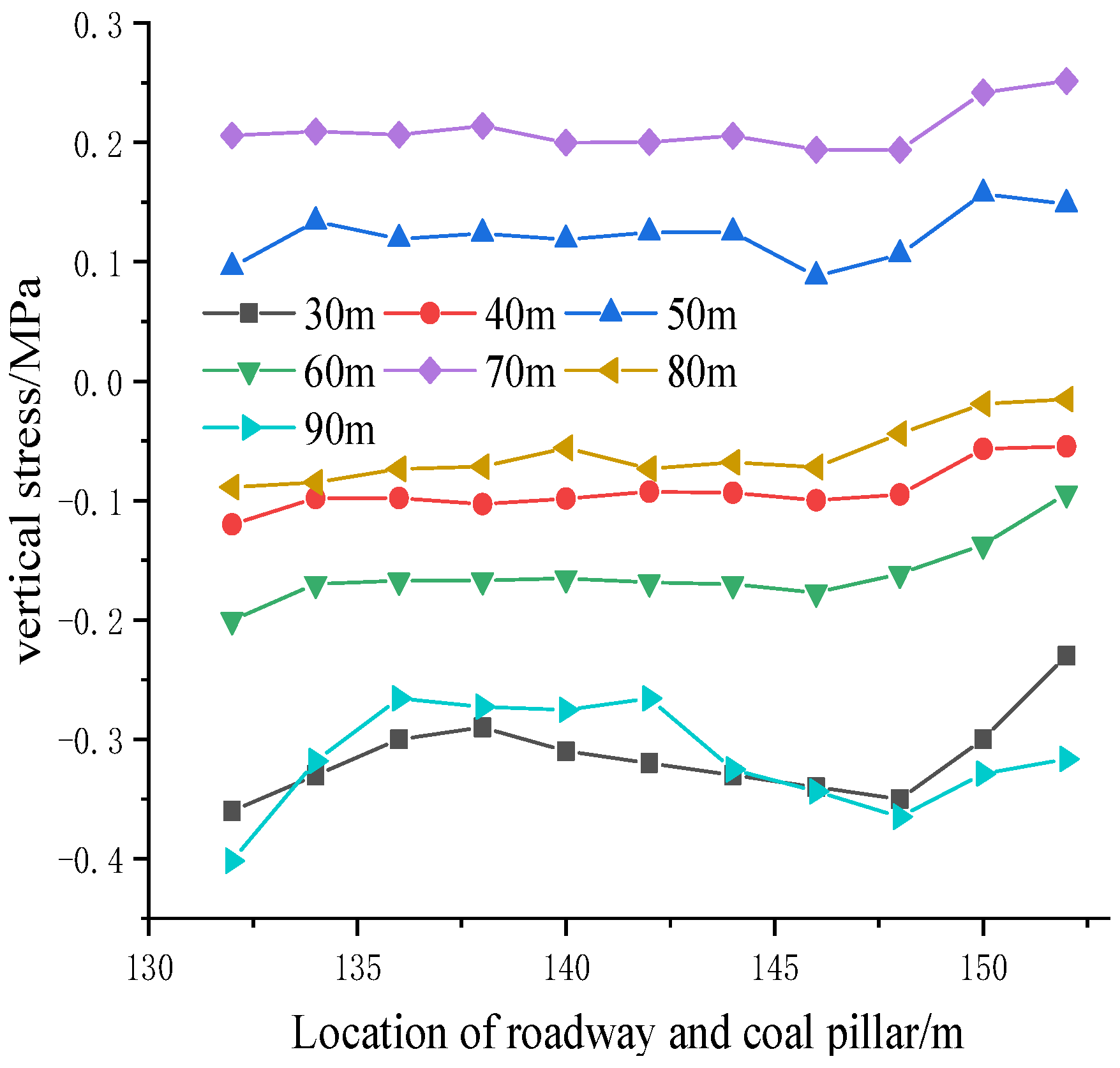

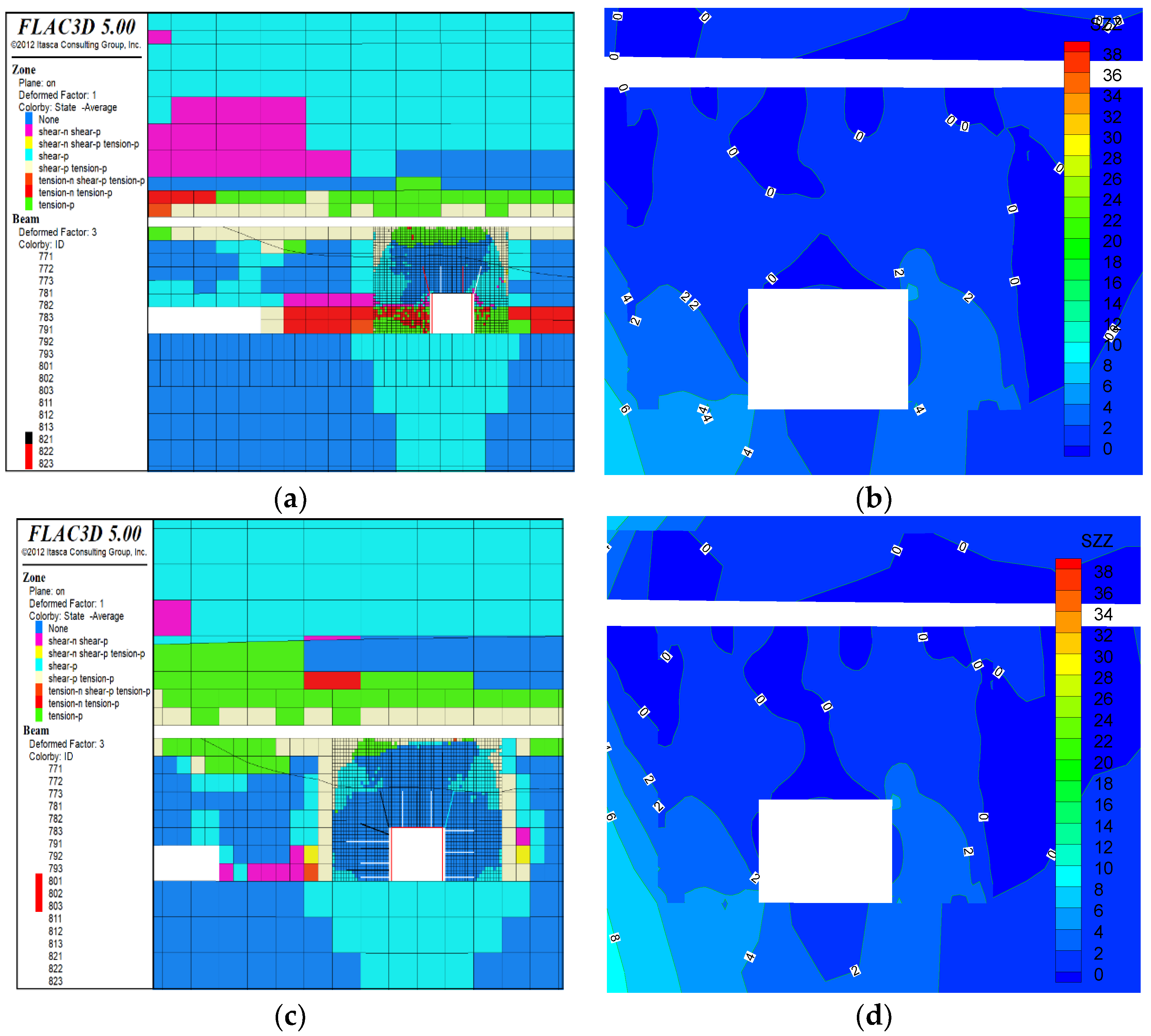

4.2.2. Evolution Law of Plastic Zone

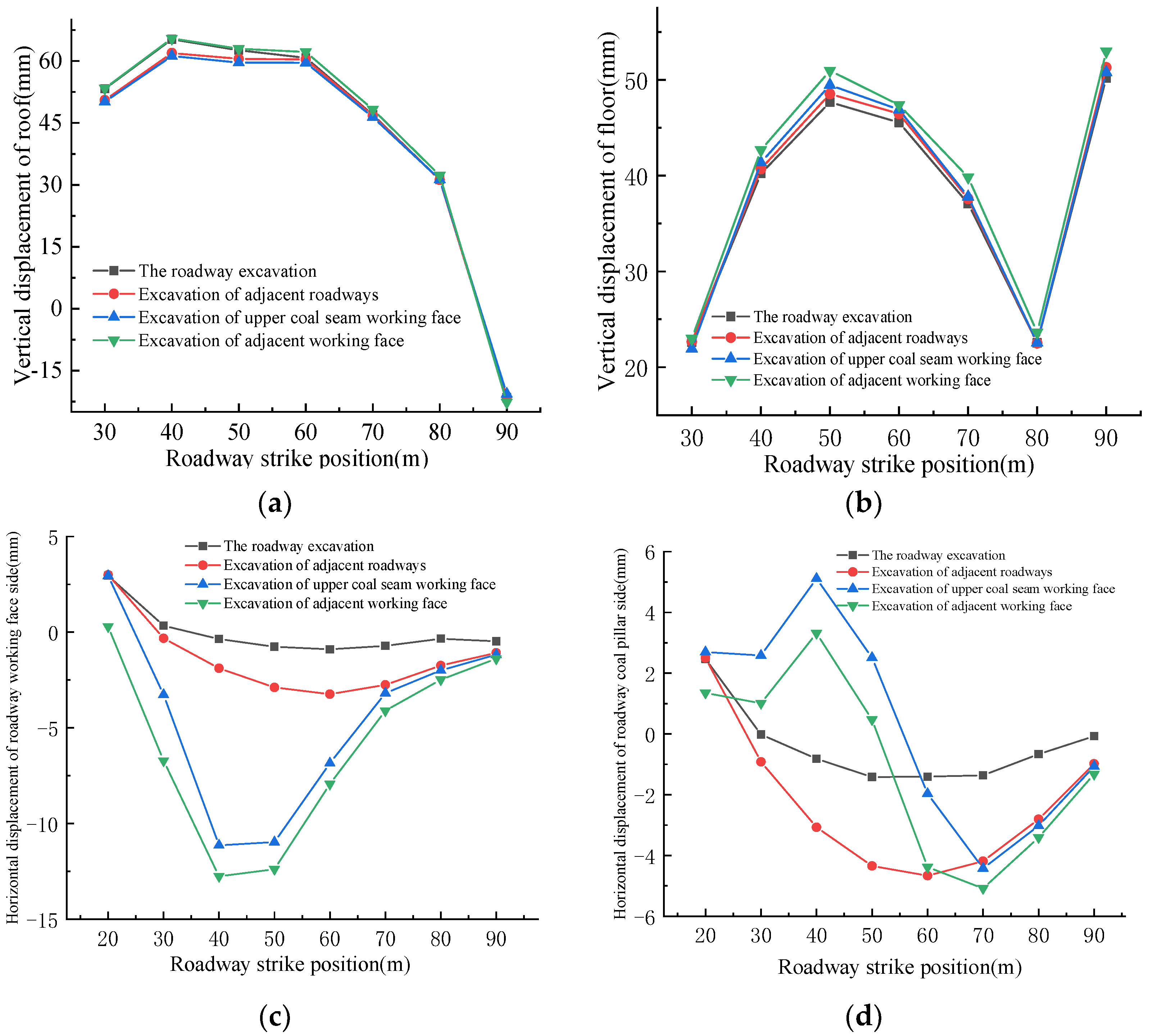

4.3. Stress and Deformation Evolution Law of Surrounding Rock under Repeated Mining

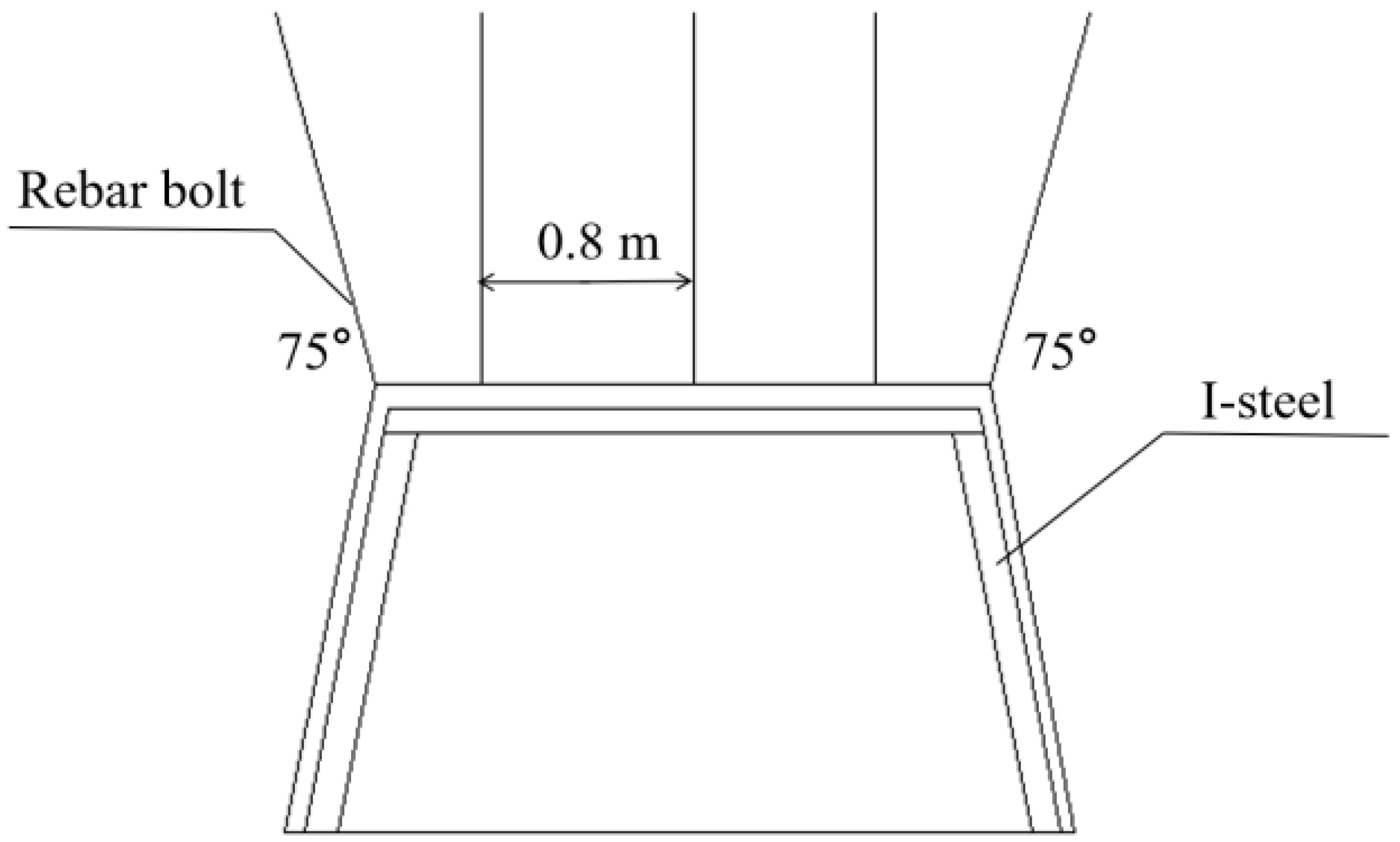

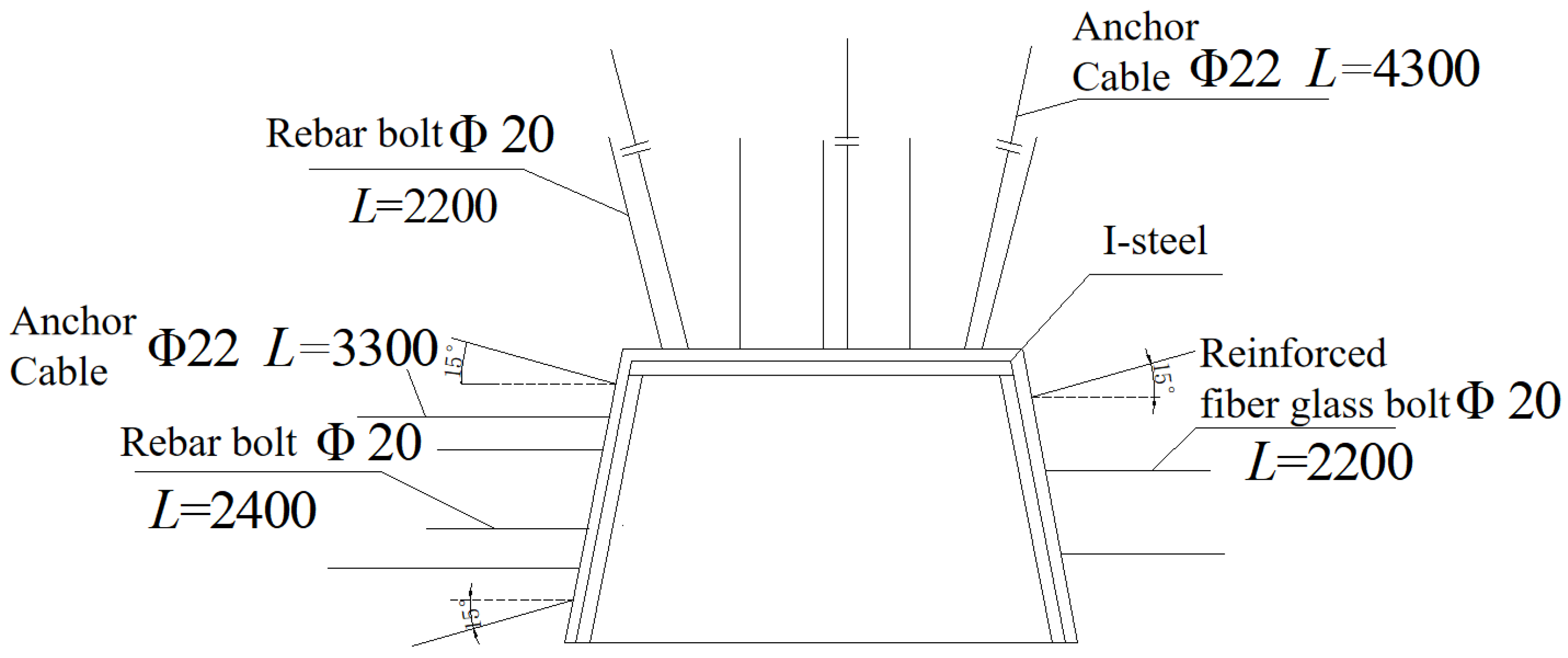

5. Support Measurements Numerical Simulation Analysis

5.1. Influence of Fracture Angle on Unconfined Compressive Strength

5.2. Comparative Analysis of Supporting Effect in Numerical Simulation

5.3. Engineering Practices

6. Conclusions

- (1)

- Through field investigation and data observation, the surrounding rock of the roadway presents the asymmetric evolution characteristics of cracks. The expression of floor failure depth caused by upper coal seam mining is obtained through the elastic-plastic theory. Combined with the geological conditions of coal seam #6, the floor failure depth caused by coal seam #6 is 4.63 m.

- (2)

- According to the results of numerical simulation, the stress concentration in working face 10905 and roadway without a residual coal pillar is in a low stress environment. After repeated mining, the deformation of the overall surrounding rock of the roadway increases with the increase of mining times. In particular, the horizontal displacement of the roadway coal pillar side changes greatly, and the actual damage degree is the largest. The deformation variables of the two sides are prone to asymmetric situations during mining, and the stability maintenance of the coal pillar side needs to be emphasized.

- (3)

- The asymmetric anchor cable + I-steel support scheme is proposed to effectively prevent the deformation and fracture of the roadway roof in this study. And the bolt-cable timely support plays a controlling role on the surrounding rock of the roadway. In addition, the plastic zone of the surrounding rock of the roadway is the least, and the bearing capacity of surrounding rock in the roadway increases from 0–2 MPa to 2–4 MPa.

- (4)

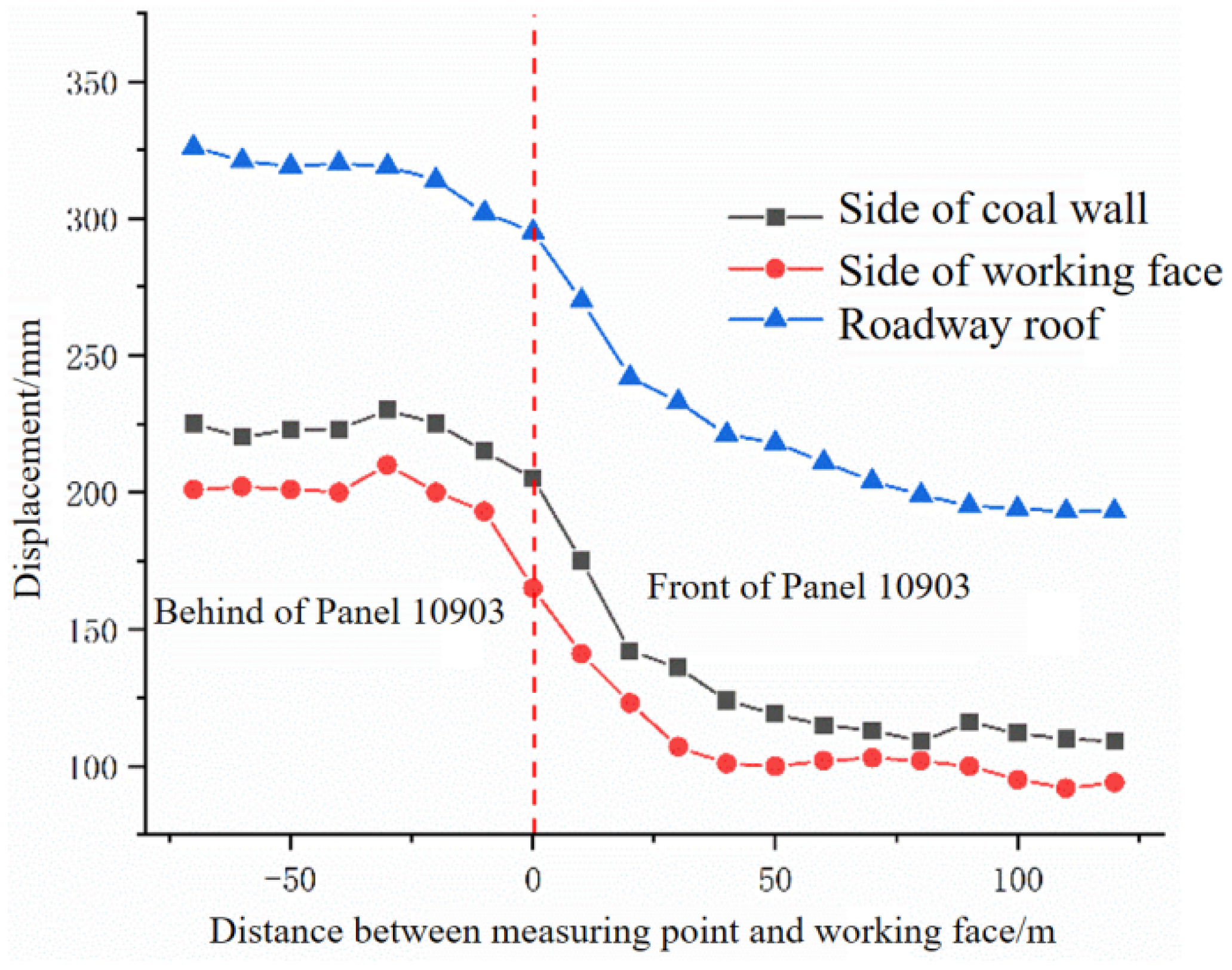

- Through the field observation of the surrounding rock deformation of the roadway in the test section, the maximum displacement of the roadway roof, coal pillar side and working face side is 326 mm, 225 mm and 201 mm, respectively. Moreover, the deformation on both sides of the roadway is asymmetric in distribution, and its deformation rate is the largest in the range of +20 m to −40 m from the working face. The overall displacement of the roadway is within the controllable range as a result of using the optimized support scheme.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kong, D.; Cheng, Z.; Zheng, S. Study on the failure mechanism and stability control measures in a large-cutting-height coal mining face with a deep-buried seam. Bull. Eng. Geol. Environ. 2019, 78, 6143–6157. [Google Scholar] [CrossRef]

- Xiong, Y.; Kong, D.; Cheng, Z.; Wu, G.; Zhang, Q. The Comprehensive Identification of Roof Risk in a Fully Mechanized Working Face Using the Cloud Model. Mathematics 2021, 9, 2072. [Google Scholar] [CrossRef]

- Liu, F.; Guo, Z.; Lv, H.; Cheng, Z. Test and analysis of blast wave in mortar test block. Int. J. Rock Mech. Min. Sci. 2018, 108, 80–85. [Google Scholar] [CrossRef]

- Klemetti, T.M.; Van Dyke, M.A.; Evanek, N.; Compton, C.C.; Tulu, I.B. Insights into the Relationships Among the Roof, Rib, Floor, and Pillars of Underground Coal Mines. Min. Met. Explor. 2021, 38, 531–538. [Google Scholar] [CrossRef]

- Maleki, H. Coal pillar mechanics of violent failure in U.S. Mines. Int. J. Min. Sci. Technol. 2017, 27, 387–392. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, J.; Ranjith, P.G.; Zhang, Z.; Gao, F.; Wang, S. Experimental investigation on the nonlinear characteristics of energy evolution and failure characteristics of coal under different gas pressures. Bull. Eng. Geol. Environ. 2022, 81, 38. [Google Scholar] [CrossRef]

- Xie, J.; Xu, J.; Wang, F.; Guo, J.; Liu, D. Deformation effect of lateral roof roadway in close coal seams after repeated mining. Int. J. Min. Sci. Technol. 2014, 24, 597–601. [Google Scholar] [CrossRef]

- Kong, D.; Xiong, Y.; Cheng, Z.; Wang, N.; Wu, G.; Liu, Y. Stability analysis of coal face based on coal face-support-roof system in steeply inclined coal seam. Geomech. Eng. 2021, 25, 233–243. [Google Scholar] [CrossRef]

- Lv, H.; Cheng, Z.; Dong, Y.; Zhang, J.; Ma, Y. Numerical simulation on the crack initiation and propagation of coal with combined defects. Struct. Eng. Mech. 2021, 79, 237–245. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, J.; Liang, X.; Wang, S. Ecological risk assessment of soil and water loss by thermal enhanced methane recovery: Numerical study using two-phase flow simulation. J. Clean. Prod. 2022, 334, 130183. [Google Scholar] [CrossRef]

- Xiong, Y.; Kong, D.; Cheng, Z.; Wen, Z.; Ma, Z.; Wu, G.; Liu, Y. Instability Control of Roadway Surrounding Rock in Close-Distance Coal Seam Groups under Repeated Mining. Energies 2021, 14, 5193. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, Z.; Lv, H. Study on failure and subsidence law of frozen soil layer in coal mine influenced by physical conditions. Geomech. Eng. 2019, 18, 97–109. [Google Scholar] [CrossRef]

- Liu, X.; Cheng, Z. Changes in subsidence-field surface movement in shallow-seam coal mining. J. S. Afr. Inst. Min. Metal. 2019, 119, 201–206. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.K.; Agrawal, H.; Singh, A.P. Rib stability: A way forward for safe coal extraction in India. Int. J. Min. Sci. Technol. 2017, 27, 1087–1091. [Google Scholar] [CrossRef]

- Lv, H.; Cheng, Z.; Liu, F. Study on the mechanism of a new fully mechanical mining method for extremely thick coal seam. Int. J. Rock Mech. Min. Sci. 2021, 142, 104788. [Google Scholar] [CrossRef]

- Cheng, Z.; Geng, X. Soil consistency and interparticle characteristics of various biopolymer types stabilization of clay. Geomech. Eng. 2021, 27, 103–113. [Google Scholar] [CrossRef]

- Liu, X.; Ning, J.; Tan, Y.; Xu, Q.; Fan, D. Coordinated supporting method of gob-side entry retainingin coal mines and a case study with hard roof. Geomech. Eng. 2018, 15, 1173–1182. [Google Scholar] [CrossRef]

- Yu, J.; Liu, G.; Cai, Y.; Zhou, J.; Liu, S.; Tu, B. Time-Dependent Deformation Mechanism for Swelling Soft-Rock Tunnels in Coal Mines and Its Mathematical Deduction. Int. J. Geomech. 2020, 20, 04019186. [Google Scholar] [CrossRef]

- Lv, H.; Tang, Y.; Zhang, L.; Cheng, Z.; Zhang, Y. Analysis for mechanical characteristics and failure models of coal specimens with non-penetrating single crack. Geomech. Eng. 2019, 17, 355–365. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, L.; Zhang, Y. Laboratory investigation of the mechanical properties of coal–rock combined body. Bull. Eng. Geol. Environ. 2020, 79, 1947–1958. [Google Scholar] [CrossRef]

- Cheng, Z.; Pan, W.; Li, X.; Sun, W. Numerical simulation on strata behaviours of TCCWF influenced by coal-rock combined body. Geomech. Eng. 2019, 19, 269–282. [Google Scholar] [CrossRef]

- Cheng, Z.; Yang, S.; Li, L.; Zhang, L. Support working resistance determined on top-coal caving face based on coal-rock combined body. Geomech. Eng. 2019, 19, 255–268. [Google Scholar] [CrossRef]

- Wang, D.; Barakos, G.; Cheng, Z.; Mischo, H.; Zhao, J. Numerical simulation of pressure profile of mining backfill fly-ash slurry in an L-shaped pipe using a validated Herschel-Bulkley model. J. Sustain. Cem. Based 2021, 1–15. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, G.; Liu, Y.; Cheng, Z. Study on Overlying Strata Movement and Surface Subsidence of Coal Workfaces with Karst Aquifer Water. Mathematics 2022, 10, 169. [Google Scholar] [CrossRef]

- Yang, S.; Chen, M.; Jing, H.; Chen, K.; Meng, B. A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng. Geol. 2017, 217, 89–101. [Google Scholar] [CrossRef]

- Lv, H.; Wang, D.; Cheng, Z.; Zhang, Y.; Zhou, T. Study on mechanical characteristics and failure modes of coal-mudstone combined body with prefabricated crack. Mathematics 2022, 10, 177. [Google Scholar] [CrossRef]

- Wang, D.; Cheng, Z.; Shi, Q.; Zhao, J.; Mischo, H. Simulation Study of the Velocity Profile and Deflection Rate of Non-Newtonian Fluids in the Bend Part of the Pipe. Geofluids 2022, 2022, 7885556. [Google Scholar] [CrossRef]

- Xu, C.; Xia, C. A new large strain approach for predicting tunnel deformation in strain-softening rock mass based on the generalized Zhang-Zhu strength criterion. Int. J. Rock Mech. Min. 2021, 143, 104786. [Google Scholar] [CrossRef]

| Rock Name | Volumetric Weight g/cm3 | Compressive Strength/MPa | Tensile Strength/MPa | Poisson’s Ratio | Cohesion/MPa | Internal Friction Angle/° |

|---|---|---|---|---|---|---|

| Coal #6 | 1.29 | 13.25 | 0.33 | 0.32 | 1.18 | 25.16 |

| Mudstone-1 | 2.13 | 38.90 | 0.88 | 0.31 | 1.78 | 23.40 |

| Argillaceous Sandstone | 2.32 | 79.65 | 1.57 | 0.28 | 3.80 | 34.00 |

| Silty Mudstone | 2.44 | 62.18 | 1.23 | 0.21 | 3.30 | 30.05 |

| Coal #9 | 1.30 | 11.89 | 0.26 | 0.36 | 1.42 | 24.50 |

| Mudstone-2 | 2.00 | 38.20 | 0.82 | 0.29 | 1.80 | 24.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, Y.; Kong, D.; Pu, S.; Xiong, Y.; Li, Q.; Cheng, Z. Study on Failure Characteristics and Control Technology of Roadway Surrounding Rock under Repeated Mining in Close-Distance Coal Seam. Mathematics 2022, 10, 2166. https://doi.org/10.3390/math10132166

Shang Y, Kong D, Pu S, Xiong Y, Li Q, Cheng Z. Study on Failure Characteristics and Control Technology of Roadway Surrounding Rock under Repeated Mining in Close-Distance Coal Seam. Mathematics. 2022; 10(13):2166. https://doi.org/10.3390/math10132166

Chicago/Turabian StyleShang, Yuqi, Dezhong Kong, Shijiang Pu, Yu Xiong, Qiang Li, and Zhanbo Cheng. 2022. "Study on Failure Characteristics and Control Technology of Roadway Surrounding Rock under Repeated Mining in Close-Distance Coal Seam" Mathematics 10, no. 13: 2166. https://doi.org/10.3390/math10132166

APA StyleShang, Y., Kong, D., Pu, S., Xiong, Y., Li, Q., & Cheng, Z. (2022). Study on Failure Characteristics and Control Technology of Roadway Surrounding Rock under Repeated Mining in Close-Distance Coal Seam. Mathematics, 10(13), 2166. https://doi.org/10.3390/math10132166