1. Introduction

As the world opts for using more green energy, solar energy is one of the forerunners as clean energy to replace fossil fuel and conventional energy sources. A solar collector is the main tool that is used to harness the sun’s energy and increasing its efficiency is a main concern and a focus of researchers in the discipline of energy development. Back in 1995, a new group of fluids emerged named nanofluids [

1], displaying interesting thermophysical properties; using them in a solar collector as working fluids contributed to increasing the its efficient. Thus, a considerable number of studies were done on exergy efficiency and entropy generation of solar collectors that were employing nanofluids. Alklaibi et al. [

2], Joseph et al. [

3], and Eltaweel et al. [

4] analyzed these parameters experimentally inside a flat plate solar collector employing diamond/H

2O nanofluid, PTSC applying SiO

2/Ag-CuO NF, and an abandoned tube solar collector manipulating MWCNT/H

2O NF. For further reading see Singh et al. [

5], Kaya et al. [

6], and Olfian et al. [

6]. A wide range of fluids hold important positions in manufacturing procedures. Nonetheless, these liquids have slight small thermal conductivity. As a result, they do not use large thermal exchange rates in thermal management devices. Using extremely small-sized solid molecules that are dispersed in broad liquids to improve heat conductivity is one technique to overcome this barrier. NF is the presence of nano-sized molecules (1–100 nm) in a traditional base fluid. NFs have improved stability, rheological properties, and much greater thermal conductivity [

7]. The use of NFs in collectors and water heaters is being studied from the standpoints of effects, economics, and the environment; some studies on the thermal conductivity and optical properties of NFs have been published [

8]. SCs are a sort of heat converter that converts the power from solar radiations to the stored internal power in the working liquid. These devices suck up incoming solar energy, convert it to heat, and transmit the heat to a liquid running across the SC; the gathered energy is generated by the working fluid. Solar water heaters are among the most practical solar energy gadgets.

In recent years, NF has been extended to hybrid nanofluids to enhance fluid characteristics. The dispersion of two diverse kinds of nanomolecules in the standard liquid is an operating concept of HBNFs. This improves the heat transmission capacities of regular fluids and results in a higher heat exponent when compared to nanofluids [

9,

10]. Devi and Devi [

11] were among the first to develop computational models for HBNF model. Since then, other researchers have investigated HBNFs; however, to the best of the authors’ expertise, no analysis has been conducted on hybrid nanofluids rotating flow.

To study these problems numerically and analytically, a special set of fluid and heat models and boundary conditions must be applied to arrive at satisfiable results. A scientific postulate states that the heat exchange process is attributable to a temperature imbalance between two systems or within the same system. In 1822, the French scientist and researcher named Joseph Fourier printed the book “The Analytical Theory of Heat” [

12] in which he introduced Fourier’s law of thermal conductivity which characterizes how the phenomenon of heat exchange has been studied since. Nevertheless, this model is not flawless in the sense that the complete scheme can be affected by any preliminary disruption. Cattaneo [

13] addressed this issue and extend Fourier’s relation of thermal conductivity by combining the thermal recreation time. Christov [

14] also contributed to Cattaneo model by adding Oldroyd’s upper-convective derivatives for time. And thus, a recent heat fluxing model emerged CCM which characterizes the transfer of heat via the spreading of thermal waves at a restricted speed and has the material-invariant formulation. So instead of using Fourier’s law, some researchers opted to employ CCM coupled with various fluid models, for example in studies of 3D fluid flowing over an elongating plate- such as the Jeffrey fluid model [

15], Prandtl fluid model [

16], second grade fluid model [

17], and in Hayat et al. [

18] where the Eyring–Powell model had been used in addition to the presence of chemical processes. From the results, we can conclude that increasing the thermal relaxation parameter will negatively affect the temperature fields. Ahmed et al. [

19] examined a developed flow of Maxwell nanofluid. Their study was time-dependent, three-dimensional, and characterized by using modified CCM. Hayat et al. [

20] studied the consequence of using CCM on the Maxwell liquid bounder-layer flowing over an extending plate with changing thickener. Mahanthesh et al. [

21] probed the influence of internal heat generating that was susceptible to stratification and exponential space on NF that was flowing via a horizontal melting surface. However, instead of using the Maxwell model they used the upper-convected Maxwell model. Alebraheem et al. [

22] studied the mass and heat transmission of Casson NF flow via a swirling cylindrical pipe. The study was carried out with the existence of gyrotactic microbes in the nanofluid. The entropy generation of this type of nanofluid bounder-layer flowing via a porous expanding plate is explored by Asif et al. [

23]. Shah et al. [

24] examined the heat transmition performance of electroconductive magnetohydrodynamics flowing of a Casson ferro-fluid via an extending plate sheet. All the previously-mentioned studies used CCM to assess the impact of thermal relaxing time on the boundary layer.

Recently, many researchers have discussed global warming which is a subject that has been effectively debated in recent years. Global warming, likewise described as a greenhouse influence, occurs after CO

2 and more harmful emissions in the environment trapping of heat for years in the planet’s atmosphere, causing the world to grow substantially warmer. Alternate power generation methods will be necessary to reduce the influence on the environment [

8]. In SCs, NF is more efficient than regular fluid as an operating liquid. The thermodynamic influence of a flat plate solar collector was investigated by Chaji et al. [

25]. The study [

26] probed an accomplishment of PTSC mirrors. Sharma and Kundan [

27] probed a nanofluid that was based on PTSC concentration. Buongiorno [

28] depicted that when NFs are in greater contact with a solid surface, they generate more stability. Afzal et al. [

29] probed the heat transmission of unsteady magneto-slippage NFs in sunny environments. Hussain et al. [

30] investigated heat transport with Navier’s partial slippage and thermal jumping constraints. Other research [

31] investigated the effectiveness of NFs with variable viscid and thermal conductivity. In this regard, the analysis [

32] investigated the effects of penetrable materials and nanomolecules. Using NF-based fluid that directly absorbed sunlight, the research [

33] investigated the influence of the sun’s radiation on the forced convection of NFs flow depending on the immediate absorbing progress. Subramani et al. [

34] demonstrated the effect of heat transfer improvements in a PTSC.

Despite heat exchange implying energy flowing, certain undesirable motions happen as a result of actual reasons such as liquid combining, liquid molecular vibrating, frictional movement, chemical reactions, electric reluctance, and so on, which eventually causes energy annihilation and the development of entropy. Furthermore, sustainable energy from solar energy is fairly low when compared to the organizational point of view because immutability that is created inside the system causes damage to the available work, which must be reduced. As a result, a second law-based approach to research is necessary to provide guideline for improving the thermal performance of solar-powered systems [

35,

36]. Entropy denotes the device’s incapacity to use 100 percent of valuable effort. SCs exergy and energy have been investigated [

37,

38], which depicts the influence of immutability on the thermal performance accountancy rate. Ghanbarpour et al. [

39] evaluated a short loop heating pipeline and contrasted the entropy production rate and thermal resistance, revealing a net improvement of 34.6 and 24% utilizing a graphene nanofluid over a water-based fluid and effectively achieving entropy creation reduction. Khan et al. [

40] explored the thermohydraulic effectiveness on the swiveling flow in RHT, as well as entropy creation by employing hybridized NF and the development of thermal entropy, radioactivity, and entropy. Wang et al. [

41] assessed distilled water to the thermo-hydraulic and entropy generation and the implementation of SC using NFs (Al

2O

3, Fe

2O

3, Cu nanomolecules). They discovered that nanofluid is a more effective heat transmitting material. They effectively reduced the total entropy production by 29%, 32%, and 41% for Al

2O

3, Fe

2O

3, and copper with a fractional size of 0.12% associated with H

2O as a standard liquid, repspectively. Suzuki et al. [

42] investigated the exergy by comparing analyses among the uses of a flatness duct and chamber pipe in SCs. Gbadeyan et al. [

43] investigated the effect of changing the viscosity and thermal conductivity on MHD Casson NF boundary layer movement. The results showed that raising the following parameters boosts the rapidity while decreasing the temperature and nanomolecules concentricity. Using a two-phase technique, Mahdy et al. [

44] addressed the entropy generation in a time-dependent magneto that was combined convective flowing around a spinning sphere of Casson NF. The results revealed that the entropic production is enhanced by increasing the number of parameters such as thermophoresis, magnetic field, and non-Newtonian Casson parameters. Kamran et al. [

45] investigated computational Casson NF MHD flow via a horizontally extending plate with the effect of Joule heating. They found that raising the Eckert number enhances the Sherwood number whereas the Nusselt number diminishes. Shankar et al. [

46] established a numerical analysis to research the impact of heat generation on the unsteady magneto natural convective flow of Casson liquid over perpendicular oscillation porous platter. Concurrently, Farhat et al. [

47] evaluated the optimal mass flowing rate, SC plate area, and the cooling capacity of a flat plate collector. Furthermore, entropy evaluation of SC may be found in the next publications [

48,

49,

50,

51,

52].

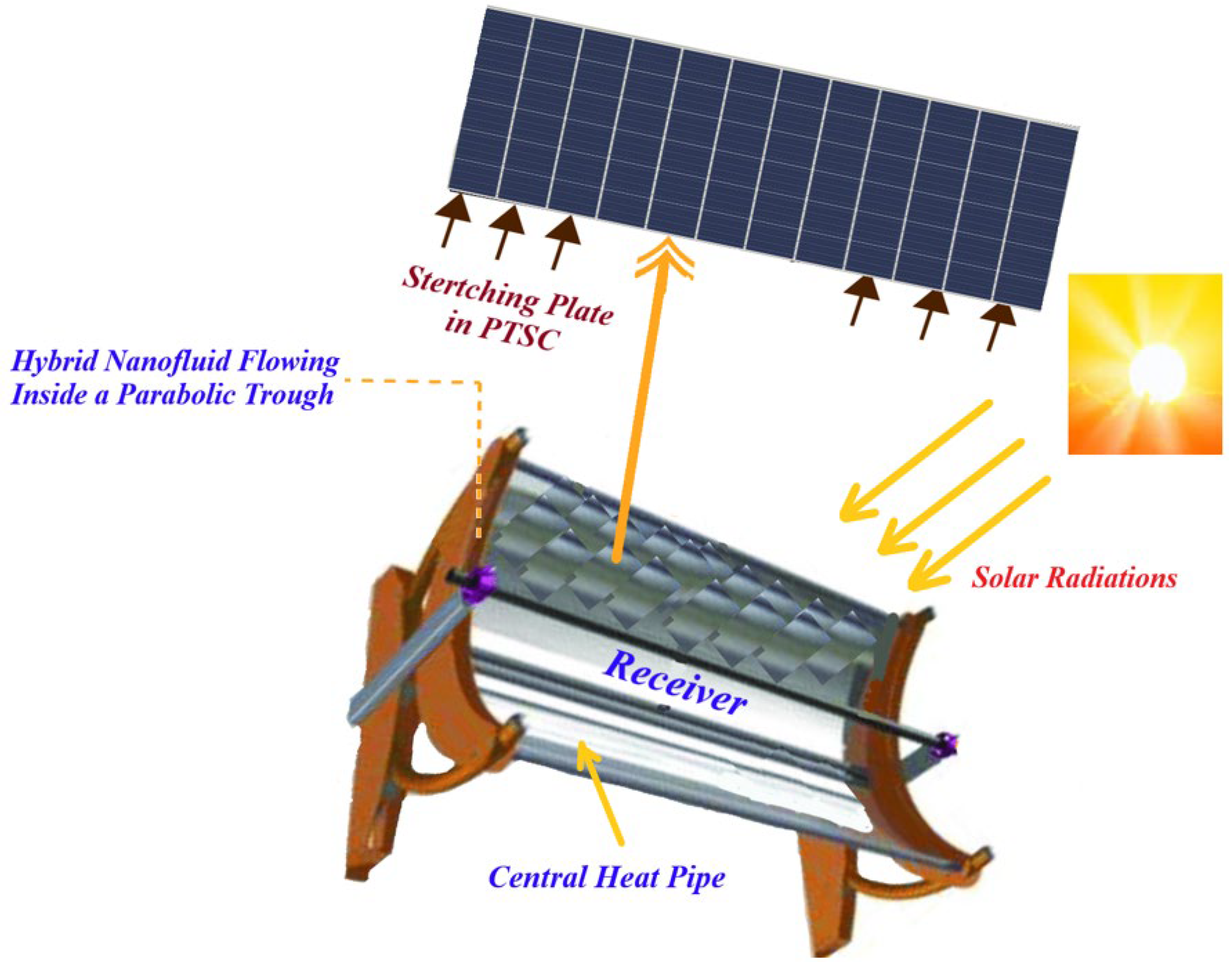

Figure 1 represents a PTSC diagram.

It is worth noting that the effects of an applied magneto transverse direction on the form factor and heat transmission characteristics of Newtonianism HBNF rotational flow on porous flat surfaces have never been studied in the literature when employing two types of nanomolecules, which we used for our study: copper (Cu) and alumina (Al2O3), with Newtonianism water (H2O) as the fluid. As a result, the purpose of this study is to provide scientific solutions to the following research issues:

To what extent does increasing rapidity outline the temperatures contour within the boundary-layer, drag force factor, and the quantity of Nusselt provided?

How do heat transfer rates alter with increasing the magnetization impact and nanoparticles volume fractions in hybridity and mono nanofluid dynamics?

What are the differences between the use of a hybrid nanofluid and a neutral nanofluid in terms of thermal and electrical conductivities?

To what extent does rotational motion affect the velocity patterns and heat transfer rates of the nanofluids that were used in the investigation.

Does the porosity of the surrounding medium as well as the permeability of surfaces have a role in changing the flow rapidity and heat transmission rates of the used nanofluids that were under study?

2. Mathematical Modelling

Consider the stable hybridity nanofluid flowing between two horizontal parallel similar surfaces whenever the nanoliquid and the plates rotate with an angular velocity

around the

axis normal to the plates. The

axis is parallel to the surface, the

axis is normal to it, and the

axis is normal to the

plane in a Cartesian coordinates system (see

Figure 2). The plates may be found at

and

. Two equal and opposite pressures stretch the lower surface, keeping the location of the point (0, 0, 0) constant. This paper examined a three-dimensional continuous magneto-spin flow of HBNF (Cu-Al

2O

3/H

2O) among 2-surfaces that were operating with angular speed

under heat transmission. The bottom plate’s stretched speed is

, but the top surface has penetrability. The flow field’s speed is

. In the

axis path, a constant magneto field

is used. An induced magnetic field is neglected when the magnetism Reynolds amount is assumed to be below.

Figure 2 depicts the mathematical model of the flowing field as well as the coordinate system.

The conveyed relevant system of equalities for rotating flowing can be expressed as [

53]:

in which

is heat fluxing. CCM [

15] allows one to write:

The elements form of regulating model is offered as the subsequent [

52]:

in which

signifies a thermal diffusion of HBNF and

signifies a changed pressure. Instead of Al

2O

3/H

2O and Cu-Al

2O

3/H

2O), the expressions are given in

Table 1 and

Table 2.

In the case of uniform suction/injection, the

rapidity element stays stable at a higher surface due to porosity. The temperature change is recognized through HBNF. An upper plate has heat

and the bottom plate has heat

such that

. The physical thermal characteristics of Al

2O

3, Cu, and H

2O are described in

Table 3.

The following are the destination constraints at the upper and lower plates:

in which positive

implies the suction and negative

implies the injection at the upper wall. Consider similarity transformation [

56] as:

The resulting nondimensional system of ODEs is offered by:

having the following non-dimensional endpoint conditions:

The nondimensional factors that are associated with nondimensional formulas are stated as:

The frictional force factor

and the Nusselt quantity

are given in dimensional form the next relationships [

57]:

in which

signifies the shearing stress and

denotes the heat fluxing at the surface. The dimensionless manner of Equation (17) via similarity transformations that were before declared in Equation (11) are expressed as follows:

in which

expresses the Reynolds quantity.

5. Results and Discussions

The current section is dedicated to analyzing the influence of varied dimensionless parameters on speed, rotational, and energy fields. The impact of the nanoparticles fractional size on wall frictional factor and RHT are numerically calculated and exhibited in tabular and graph structures.

Table 5 reflects the impression of distinguished amounts of the fractional size of the nanomolecules on the wall frictional factor in the situation of Al

2O

3/H

2O NF and Cu-Al

2O

3/H

2O HBNF, respectively. It is extremely obvious that an amplification in the nanoparticles fractional size reduces a wall frictional force. The consistency of NF lessens by the virtue of growth of

retards the NF rapidity. The wall frictional factor increases at low plate surface

in contrast to a higher stretchy plate

. The NF rapidity reduces the amount of fluid traveling away from the bottom plate. The wall frictional force of Al

2O

3/H

2O MNF exhibits progressive behavior at

when compared to Cu-Al

2O

3/H

2O HBNF, and the frictional force of stretched plate is located at

.

Table 6 sketched the influence of

on

. The insertion of a mix of nanomolecules Cu-Al

2O

3 in the base liquid magnifies the RHT in comparison to the Al

2O

3/H

2O-based nanofluid. The heat transmission is much better at the lower plate at

in comparison to the plate that is located at

. A conducting of the fluid is enhanced with hybridized nanomolecules. Hybrid nanoparticles Cu-Al

2O

3 are considered the best thermal conductor in contrast to Al

2O

3 nanoparticles based on the purpose of heat transfer. Likewise, the amplifying comportment of average heat transmission in

Table 4 will go ahead to improve the performance and efficacy of PTSC. A thickener of the thermal bounder-layer augments as the temperature amplifies.

Figure 5a–c display an influence of the fractional size of nanomolecules factors

and

of traditional and HBNFs on the velocities

and

and the temperature outline

, respectively. It is noted that a magnification in

amplifies the consistency of the nanoparticles. The viscidness of a liquid escalates due to an augmentation in

which impedes the movement of NF and a thickening of a motion boundary-layer too, and due to this,

drops. An effect of nanomolecules concentricity

on the microrotation field

is interpreted in

Figure 5b. It manifests that enlargement in

expands

. Physically, a positive alteration in

topples the rotating percentage via a sheet enlarging rate and mostly supports less opposition to NF flow via the expandable plate. Intriguingly, the oscillating movement of the liquid is amplified as a result of magnifying

quantities, which raises

. The temperature of NF is proportional to

. The temperature boundary-layer thickener improves as a result of enrichment in

quantities. More heat is created within, escalating the heat transfer phenomena and temperature domain

. Physically, the reason for the increase in the speed, especially near the boundary layer, as well as the temperature is that the increase in nanoparticles improves the thermal conducting, which increases the movement of particles within the fluid, and thus boosts the random movement in it.

Figure 6a–c exhibit the influence of sucking factor

on

,

, and

. The speed of the liquid increases due to an incremental change in

. The speed of the fluid accelerates as a result of enrichment in

, which uplifts

. The rotating influence of the liquid augmentation is due to a development in a suction factor. In the scenario of suction, the fluid that is present at free-streaming platter constraints is near a surface. Due to the thickener, the temperature boundary-layer diminishes and RHT decreases owing to magnification in

. From these graphs, it is clear that Cu-Al

2O

3/H

2O HBNF has superior thermal conductance in comparison to Al

2O

3/H

2O MNF. This is because the heat source works to increase the random motion of particles in the fluid which acts to enhance the rapidity of the nanofluid.

Figure 7a–c expose the influence of Reynold’s number

on

,

, and

, respectively. It is noted that the inertial powers topple the viscidness forces on the behalf of augmentation in

. The viscous powers decrease by the virtue of an increase in

. A thickener of the momentum boundary-layer increases, and the NF consistency decreases as

increases, which reduces NF movement and flow rapidity

. A progressive change in

reduces the NF angular momentum and provides greater resistance to the NF that is moving. A steady shift in

alters the NF behavior from stable to unstable, and the rotating impact reduces and devalued

. The viscidity of the material is proportional to

. It is obvious that increasing

reduces the NF viscidness, which raises the temperature. The thickening of the temperature boundary-layer besides heat transmission increases by the advantage of magnification in

. The physical reason for this is that

is inversely proportional with

. Whilst

boosts that means, the viscidity diminishes which means that the rapidity is improved, and the temperature is reduced.

The influence of the rotation parameter

on

,

as well as

are displayed in

Figure 8a–c, which indicate that a fortification in

lessens

then enriches

and

. It is discovered that the rotational rate exceeds the stretchable rate and, as a result, brings additional restrictions to the NF flowing movement, thus slowing the NF rapidity

. The NF’s rotating quickness develops for a progressive shift in

, which raises

. The apparent viscidity declines due to a fortifying in

that amplifies the temperature outline. It has been shown that heat transfer is considerably better in Cu-Al

2O

3/H

2O HBNF than in Al

2O

3/H

2O MNF. The thermal conductivity and thermal boundary-layer thickener of HBNF are elevated by hybridized nanomolecules.

Figure 9a–c emphasize the performing of electrically-conducting liquid magneto parameter

,

, and

. An improvement shift in

devalues the liquid rapidity. It is empirically validated that an electrical current in the occurrence of magnetism force releases a force called Lorentz forces. This Lorentz power is basic and offers endurance to a liquid flowing action. The speed of a liquid retards and is unsettled to an improvement shift in

which reduces the thickener in terms of impetus boundary-layer also. Additionally, a magnification in

provides elevated friction effects that have the capacity to contract the liquid rapidity and lessen the nanoliquid rotating occurrence

. It is remarkable that a non-negative shift in

releases a powerful Lorentz effect that ultimately magnifies RHT. The temperature boundary-layer thickening improves in a state of stronger Lorentz powers. HBNF delivers better heat and amplifies the temperature much better in contrast to a Al

2O

3 nanoparticles-based fluid. The effects of

,

, and

on the thermal field are determined in

Figure 10a–c for the case of hybrid nanoparticles and conventional nanoparticles. For increasing

, the temperature

gets augmented for Cu-Al

2O

3/H

2O as well as for Al

2O

3/H

2O along with the thermal boundary-layer. Physically, the enlargement in the thermal temperature profile is because of the heat transfer to fluid mixture particles by a boost in

. The temperature profile for different

for Cu-Al

2O

3/H

2O and Al

2O

3/H

2O are displayed in

Figure 10b. The increase in

diminishes the temperature field for both the nanomaterial and the hybrid nanomaterial. This is based on the fact that as

increases, material particles need additional time to transmit the energy to their nearby molecules. As for greater amounts of

, the fluid mixture demonstrates a non-conducting behavior. An improvement shift in

denigrates NF temperature. Thermal diffusivity shows dominating behavior for

which leads to a reduction in the temperature profile.

The effects of

,

,

, and

on the Nusselt quantity are delineated in

Figure 11a–d at the state of hybridized nanomolecules when

. A magnification in

booms the thermal transport trend. The temperature of a liquid escalates in response to an amplification in the hybridized nanoparticles fractional size. This promotes sucking occurrence for an increase in the temperature that is soaked up by the liquid directly to an amplification in

which uplifts RHT. The inertial powers decrease the viscidness, and because of a growing shift in

, it declines the liquid viscidness and additionally impedes liquid activity. RHT increases in the case of

and

when the volume percentage of hybrid nanoparticles is increased. Heat transmission is inversely linked to fluidity. The fluid’s shearing thickener temperature rises, increasing the heat transfer phenomena. A magnified hybridized nanomolecules fractional size produces a liquid that is heavier, reducing the rotating phenomena

and RHT. A non-negative shift in

reduces the heat exchange phenomena. Lorentz power operates as a frictional force, slowing the rapidity of the liquid and magnifying Nusselt quantity.

A disparity in Nusselt quantity in the case of incremental change in

,

,

, and

is displayed in

Figure 12a–d at

.The incremental change in the hybridized nanomolecules expands a liquid temperature at the wall but the liquid temperature lessens when moving away from the wall at

. The sucking capability of a liquid is devalued, causing the thermal transport process to decline. A magnification in

strengthens the inertial power in comparison to viscidity; it minimizes a liquid viscidness and boosts thermal transmit happening. It is clear that such a rotating manifestation of the liquid is a significantly more powerful intermediate zone than the distance from the plate

; it devalues the heat transmit occurrence. The heat transmission disasters are caused by an increase in

at

. The Lorentz power is less efficient at

, it reduces the influence of the skin friction factor and enhances the heat exchange process. An enhancement of RHT phenomena enhances PTSC productivity and effectiveness.

Stream lined variation in the case of the sucking (injection) variable

is exhibited in

Figure 13a–c. Stream lines depict the behavior of liquid via a stretchable plate. When sucking is

, in comparison to the injection scenario

, the intervals among streaming lines are not effectively eliminated. Whilst the streaming lines are close enough, the liquid movement is comparatively high, as seen in the case of

against

and

.