Implementation of Voltage Sag Relative Location and Fault Type Identification Algorithm Using Real-Time Distribution System Data

Abstract

:1. Introduction

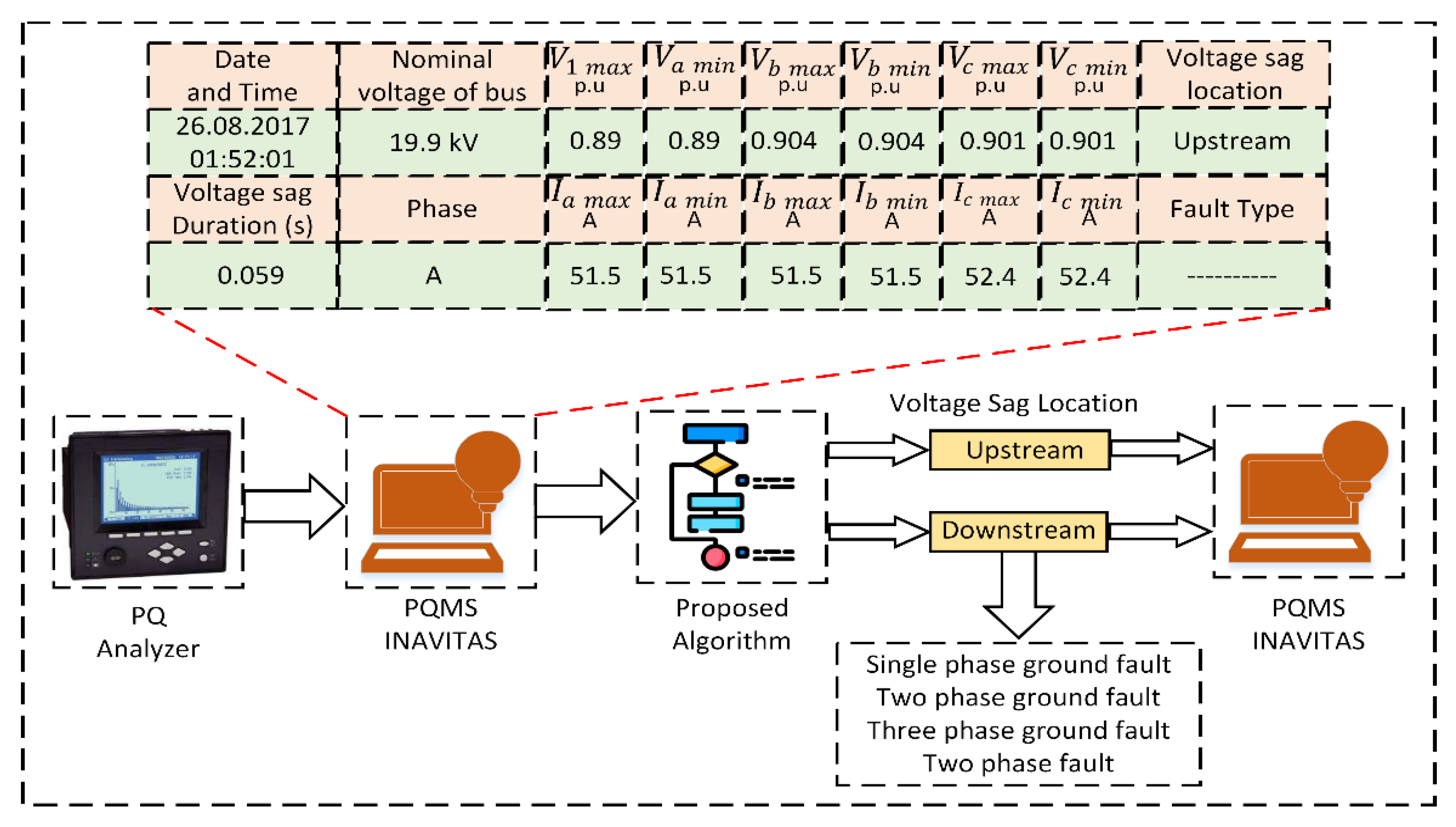

- This paper proposes a novel algorithm to determine voltage sag location and fault type using voltage and current magnitude before and during the voltage sag recorded by PQMS in the actual distribution system company.

- The proposed algorithm is integrated into PQMS, making it valuable for engineering applications. Moreover, it can help the solving disagreement regarding voltage sag location between different operators.

1.1. Problem Definition

1.2. Problem Solution

2. Proposed Method

2.1. Scoring Algorithm

2.2. Fault Type Identification

2.3. Implementation of the Proposed Algorithm into PQMS

- For events 1–4, the algorithm determines the voltage sag relative location as a DS, and fault type is classified as SFGL. When the current and voltage waveforms shown in Figure A1, Figure A2, Figure A3 and Figure A4 are investigated, a voltage sag has occurred in one phase, and overcurrent is observed in this phase.

- For event 5, when the current and voltage waveform demonstrated in Figure A5 is examined, it is observed that there is voltage sag in phases a and b, and the current in these phases increases. While the proposed algorithm classifies the voltage sag direction as DS, the fault type is determined as LLGF.

- For event 6, Figure A6 shows the voltage and current waveform recorded by the PQ analyzer. As can be seen from Figure A6, it is encountered with voltage sag in three phases, and the excessive current is drawn from three phases. The presented algorithm detects the voltage sag relative location and fault type as DS and LLLGF, respectively.

- For events 7–8, when the voltage and the current waveforms represented in Figure A7 and Figure A8 are analyzed, although there is voltage collapse in some phases, it has been observed that there is no increase in the currents drawn from these phases. The algorithm detects the direction of voltage sag as US.

3. Simulation Study

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- IEEE. IEEE Recommended Practice for Monitoring Electric Power Quality; IEEE: Piscataway, NJ, USA, 1995; Volume 2019, ISBN 978-0-7381-5940-9. [Google Scholar]

- Hartings, R.; Andersson, T.; Sveanät, V.; Ceder, Å. Test and Evaluation of Voltage Dip Immunity; STRI: Bingley, UK, 2002. [Google Scholar]

- McGranaghan, M.F.; Mueller, D.R.; Samotyj, M.J. Voltage Sags in Industrial Systems. IEEE Trans. Ind. Appl. 1993, 29, 397–403. [Google Scholar] [CrossRef]

- Heine, P.; Pohjanheimo, P.; Lehtonen, M.; Lakervi, E. A Method for Estimating the Frequency and Cost of Voltage Sags. IEEE Trans. Power Syst. 2002, 17, 290–296. [Google Scholar] [CrossRef]

- Samotyj, M.J.; Mielczarski, W.; Wasiluk-Hassa, M.M. Electric Power for the Digital Age. Proc. Int. Conf. Harmon. Qual. Power ICHQP 2002, 1, 276–282. [Google Scholar] [CrossRef]

- Yi, T.; Jie, H.; Hao, L.; Lei, W. Method for Voltage Sag Source Location Based on the Internal Resistance Sign in a Single-Port Network. IET Gener. Transm. Distrib. 2016, 10, 1720–1727. [Google Scholar] [CrossRef]

- Meral, M.E.; Teke, A.; Bayindir, K.C.; Tumay, M. Power Quality Improvement with an Extended Custom Power Park. Electr. Power Syst. Res. 2009, 79, 1553–1560. [Google Scholar] [CrossRef]

- Yalman, Y.; Celik, O.; Tan, A.; Bayindir, K.C.; Cetinkaya, U.; Yesil, M.; Akdeniz, M.; Tinajero, G.D.A.; Chaudhary, S.K.; Guerrero, J.M.; et al. Impacts of Large-Scale Offshore Wind Power Plants Integration on Turkish Power System. IEEE Access 2022, 10, 83265–83280. [Google Scholar] [CrossRef]

- De Santis, M.; Noce, C.; Varilone, P.; Verde, P. Analysis of the Origin of Measured Voltage Sags in Interconnected Networks. Electr. Power Syst. Res. 2018, 154, 391–400. [Google Scholar] [CrossRef]

- Moradi, M.H.; Mohammadi, Y. Voltage Sag Source Location: A Review with Introduction of a New Method. Int. J. Electr. Power Energy Syst. 2012, 43, 29–39. [Google Scholar] [CrossRef]

- Parsons, A.C.; Grady, W.M.; Powers, E.J.; Soward, J.C. A Direction Finder for Power Quality Disturbances Based upon Disturbance Power and Energy. IEEE Trans. Power Deliv. 2000, 15, 1081–1086. [Google Scholar] [CrossRef]

- Kong, W.; Dong, X.; Chen, Z. Voltage Sag Source Location Based on Instantaneous Energy Detection. Electr. Power Syst. Res. 2008, 78, 1889–1898. [Google Scholar] [CrossRef]

- Li, C.; Tayjasanant, T.; Xu, W.; Liu, X. Method for Voltage-Sag-Source Detection by Investigating Slope of the System Trajectory. IEE Proc. Commun. 2003, 150, 367–372. [Google Scholar] [CrossRef]

- Hamzah, N.; Mohamed, A.; Hussain, A. A New Approach to Locate the Voltage Sag Source Using Real Current Component. Electr. Power Syst. Res. 2004, 72, 113–123. [Google Scholar] [CrossRef]

- Moradi, M.H.; Mohammadi, Y. A New Current-Based Method for Voltage Sag Source Location Using Directional Overcurrent Relay Information. Int. Trans. Electr. Energy Syst. 2013, 23, 270–281. [Google Scholar] [CrossRef]

- Polajžer, B.; Štumberger, G.; Dolinar, D. Detection of Voltage Sag Sources Based on the Angle and Norm Changes in the Instantaneous Current Vector Written in Clarke’s Components. Int. J. Electr. Power Energy Syst. 2015, 64, 967–976. [Google Scholar] [CrossRef]

- Polajžer, B.; Štumberger, G.; Seme, S.; Dolinar, D. Detection of Voltage Sag Sources Based on Instantaneous Voltage and Current Vectors and Orthogonal Clarke’s Transformation. IET Gener. Transm. Distrib. 2008, 2, 219–226. [Google Scholar] [CrossRef]

- Blanco-Solano, J.; Petit-Suárez, J.F.; Ordóñez-Plata, G. Methodology for Relative Location of Voltage Sag Source Using Voltage Measurements Only. DYNA 2015, 82, 94–100. [Google Scholar] [CrossRef]

- Leborgne, R.; Karlsson, D. Voltage Sag Source Location Based on Voltage Measurements Only. Electr. Power Qual. Util. 2008, XIV, 25–30. [Google Scholar]

- Tayjasanant, T.; Li, C.; Xu, W. A Resistance Sign-Based Method for Voltage Sag Source Detection. IEEE Trans. Power Deliv. 2005, 20, 2544–2551. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Leborgne, R.C. A New Approach for Voltage Sag Source Relative Location in Active Distribution Systems with the Presence of Inverter-Based Distributed Generations. Electr. Power Syst. Res. 2020, 182, 106222. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Leborgne, R.C. Relative Location of Voltage Sags Source at the Point of Common Coupling of Constant Power Loads in Distribution Systems. Int. Trans. Electr. Energy Syst. 2020, 30, 1–15. [Google Scholar] [CrossRef]

- Yalman, Y.; Uyanık, T.; Atlı, İ.; Tan, A.; Bayındır, K.Ç.; Karal, Ö.; Golestan, S.; Guerrero, J.M. Prediction of Voltage Sag Relative Location with Data-Driven. Energies 2022, 15, 6641. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Salarpour, A.; Chouhy Leborgne, R. Comprehensive Strategy for Classification of Voltage Sags Source Location Using Optimal Feature Selection Applied to Support Vector Machine and Ensemble Techniques. Int. J. Electr. Power Energy Syst. 2020, 124, 106363. [Google Scholar] [CrossRef]

- Kazemi, A.; Mohamed, A.; Shareef, H.; Raihi, H. Accurate Voltage Sag-Source Location Technique for Power Systems Using GACp and Multivariable Regression Methods. Int. J. Electr. Power Energy Syst. 2014, 56, 97–109. [Google Scholar] [CrossRef]

- Kazemi, A.; Mohamed, A.; Shareef, H. Tracking the Voltage Sag Source Location Using Multivariable Regression Model. Int. Rev. Electr. Eng. 2011, 6, 1853–1861. [Google Scholar]

- Liao, H.; Anani, N. Fault Identification-Based Voltage Sag State Estimation Using Artificial Neural Network. Energy Procedia 2017, 134, 40–47. [Google Scholar] [CrossRef]

- Turović, R.; Dragan, D.; Gojić, G.; Petrović, V.B.; Gajić, D.B.; Stanisavljević, A.M.; Katić, V.A. An End-to-End Deep Learning Method for Voltage Sag Classification. Energies 2022, 15, 2898. [Google Scholar] [CrossRef]

- Liao, H.; Milanovic, J.V.; Rodrigues, M.; Shenfield, A. Voltage Sag Estimation in Sparsely Monitored Power Systems Based on Deep Learning and System Area Mapping. IEEE Trans. Power Deliv. 2018, 33, 3162–3172. [Google Scholar] [CrossRef]

- Borges, F.A.S.; Rabelo, R.A.L.; Fernandes, R.A.S.; Araujo, M.A. Methodology Based on Adaboost Algorithm Combined with Neural Network for the Location of Voltage Sag Disturbance. Proc. Int. Jt. Conf. Neural Netw. 2019, 1–7. [Google Scholar] [CrossRef]

- Deng, Y.; Liu, X.; Jia, R.; Huang, Q.; Xiao, G.; Wang, P. Sag Source Location and Type Recognition via Attention-Based Independently Recurrent Neural Network. J. Mod. Power Syst. Clean Energy 2021, 9, 1018–1031. [Google Scholar] [CrossRef]

- Lv, G.; Sun, W. Voltage Sag Source Location Based on Pattern Recognition. J. Energy Eng. 2013, 139, 136–141. [Google Scholar] [CrossRef]

- Liu, J.; Song, H.; Zhou, L. Identification and Location of Voltage Sag Sources Based on Multi-Label Random Forest. In Proceedings of the IEEE Sustainable Power and Energy Conference (iSPEC), Beijing, China, 21–23 November 2019; pp. 2025–2030. [Google Scholar] [CrossRef]

- Enerji Yönetim Sistemi|Inavitas (EMS). Available online: https://www.inavitas.com/tr/ (accessed on 15 August 2022).

| Rule 1: if (V1min ≤ 0.9 and V2max ≥ 1.1 and V3min > 0.9 and V3max < 1.1) then D1 = V3min − V1min, D2 = V2max − V3max Rule 2: if (V1min ≤ 0.9 and V2max < 1.1 and V2min > 0.9 and V3max ≥ 1.1) then D1 = V2min − V1min, D2 = V3max − V2max Rule 3: if (V1min > 0.9 and V1max < 1.1 and V2min <= 0.9 and V3max ≥ 1.1) then D1 = V1min − V2min, D2 = V3max − V1max Rule 4: if (V1min > 0.9 and V1max < 1.1 and V2max ≥ 1.1 and V3min ≤ 0.9) then D1 = V1min − V3min, D2 = V2max − V1max Rule 5: if (V1max ≥ 1.1 and V2min ≤ 0.9 and V3min > 0.9 and V3max < 1.1) then D1 = V3min − V2min, D2 = V1max − V3max Rule 6: if (V1max ≥ 1.1 and V2min > 0.9 and V2max < 1.1 and V3min < 0.9) then D1 = V2min − V3min, D2 = V1max − V2max Rule 7: if (V1min ≤ 0.9 and V2min > 0.9 and V2max < 1.1 and V3min > 0.9 and V3max < 1.1) then D1 = V3min − V1min, D2 = V2min – V1min Rule 8: if (V1min > 0.9 and V1max < 1.1 and V2min ≤ 0.9 and V3min > 0.9 and V3max < 1.1)) then D1 = V3min − V2min, D2 = V1min − V2min Rule 9: if (V1min > 0.9 and V1max < 1.1 and V2min ≤ 0.9 and V3min > 0.9 and V3max < 1.1) then D1 = V2min − V3min, D2 = V1min – V3min Rule 10: if (V1min ≤ 0.9 and V2max ≥ 1.1 and V3max ≥ 1.1) then D1 = V1min − 0.9, D2 = V2max − 1.1, D3 = V3max − 1.1 Rule 11: if (V1max ≥ 1.1 and V2min ≤ 0.9 and V3max ≤ 1.1) then D1 = V1max − 1.1, D2 = V2min − 0.9, D3 = V3max − 1.1 Rule 12: if (V1max ≥ 1.1 and V2max ≥ 1.1 and V3min ≤ 0.9) then D1 = V1max − 1.1, D2 = V2max − 1.1, D3 = V3min − 0.9 Rule 13: if (V1min ≤ 0.9 and V2min ≤ 0.9 and V3max < 1.1 and V3min > 0.9) then D1 = V3min − V1min, D2 = V3min − V2min Rule 14: if (V1min ≤ 0.9 and V2min > 0.9 and V2max < 1.1 and V3min ≤ 0.9) then D1 = V2min − V1min, D2 = V2min − V3min Rule 15: if (V1min > 0.9 and V1max < 1.1 and V2min ≤ 0.9 and V3min ≤ 0.9) then D1 = V1min − V2min, D2 = V1min − V3min Rule 16: if (V1min ≤ 0.9 and V2min ≤ 0.9 and V3max ≥ 1.1) then D1 = V1min − 0.9, D2 = V2min − 0.9, D3 = V3max − 1.1 Rule 17: if (V1min ≤ 0.9 and V2max ≥ 1.1 and V3min ≤ 0.9) then D1 = V1min − 0.9, D2 = V2max − 1.1, D3 = V3min − 0.9 Rule 18: if (V1max ≥ 1.1 and V2min ≤ 0.9 and V3min ≤ 0.9)) then D1 = V1min − 0.9, D2 = V2max − 1.1, D3 = V3min − 0.9 Rule 19: if (V1min ≤ 0.9 and V2min ≤ 0.9 and V3min ≤ 0.9)) then D1 = V1min − 0.9, D2 = V2min − 0.9, D3 = V3min − 0.9 Rule 20: if (V1max ≥ 1.1 and V2min > 0.9 and V2max < 1.1 and V3min > 0.9 and V3max < 1.1) then D1 = V1max − V2max, D2 = V1max − V3max Rule 21: if (V1min > 0.9 and V1max < 1.1 and V2max ≥ 1.1 and V3min > 0.9 and V3max < 1.1) then D1 = V2max − V1max, D2 = V2max − V3max Rule 22: if (V1min > 0.9 and V1max < 1.1 and V2max < 1.1 and V2min > 0.9 and V3max ≥ 1.1) then D1 = V3max − V1max, D2 = V3max − V2max Rule 23: if (V1max ≥ 1.1 and V2max ≥ 1.1 and V3min > 0.9 and V3max < 1.1) then D1 = V1max − V3max, D2 = V2max −V3max Rule 24: if (V1max ≥ 1.1 and V2max < 1.1 and V2min > 0.9 and V3max ≥ 1.1) then D1 = V1max − V2max, D2 = V3max − V2max Rule 25: if (V1min > 0.9 and V1max < 1.1 and V2max ≥ 1.1 and V3max ≥ 1.1) then D1 = V2max − V1max, D2 = V3max − V1max Rule 26: if (V1max ≥ 1.1 and V2max ≥1.1 and V3max ≥ 1.1) then D1 = V1max − 1.1, D2 = V2max − 1.1, D3 = V3max − 1.1 |

| if (D1 ≥ 0.5 or D2 ≥ 0.5) then Si = 5 if (0.3 ≥ D1 > 0.2 or 0.3 ≥ D2 > 0.2) then Si = 3 if (0.2 ≥ D1 > 0.1 or 0.2 ≥ D2 > 0.1) then Si = 2 if (0.1 ≥ D1 > 0 or 0.1 ≥ D2 > 0) then Si = 1 if (D1 ≥ 0.5 or D2 ≥ 0.5 or D3 ≥ 0.5) then Si = 5 if (0.3 ≥ D1 > 0.2 or 0.3 ≥ D2 > 0.2 or 0.3 ≥ D3 > 0.2) then Si = 3 if (0.2 ≥ D1 > 0.1 or 0.2 ≥ D2 > 0.1 or 0.2 ≥ D3 > 0.1) then Si = 2 if (0.1 ≥ D1 > 0 or 0.1 ≥ D2 > 0 or 0.1 ≥ D3 > 0) then Si = 1 if ((V1max − V1min ≤ 0.02) and (V2max − V2min ≤ 0.02) and (V3max − V3min ≤ 0.02)) then Si = −5 if (MV > 0.5) then Si = 5) if (0.5 > MV > 0.4) then Si = 4) if (0.4 > MV > 0.3) then Si = 3) if (0.3 > MV > 0.2) then Si = 2) if (MV < 0.2) then Si = 0) if (C1 > 1.3 or C2 > 1.3 or C3 > 1.3) and if (C1 > 5 and C2 > 5 and C3 > 5) then Si = 5 if (C1 > 1.3 or C2 > 1.3 or C3 > 1.3 then Si = 4 if () then Si = 4 |

| if (V1min ≤ 0.9 and V2max ≥ 1.1 and V3min > 0.9 and V3max < 1.1) then SLGF if (V1min ≤ 0.9 and V2max < 1.1 and V2min > 0.9 and V3max ≥ 1.1) then SLGF if (V1min > 0.9 and V1max < 1.1 and V2min ≤ 0.9 and V3max ≥ 1.1) then SLGF if (V1min > 0.9 and V1max < 1.1 and V2max ≥ 1.1 and V3min <= 0.9) then SLGF if (V1max ≥ 1.1 and V2min ≤ 0.9 and V3min > 0.9 and V3max < 1.1) then SLGF if (V1max ≥ 1.1 and V2min > 0.9 and V2max < 1.1 and V3min < 0.9) then SLGF if (V1min ≤ 0.9 and V2min > 0.9 and V2max < 1.1 and V3min > 0.9 and V3max < 1.1) then SLGF if (V1min > 0.9 and V1max < 1.1 and V2min ≤ 0.9 and V3min > 0.9 and V3max < 1.1) then SLGF if (V1min > 0.9 and V1max < 1.1 and V2min > 0.9 and V2max < 1.1 and V3min ≤ 0.9) then SLGF if (V1min ≤ 0.9 and V2max ≥ 1.1 and V3max ≥ 1.1) then SLGF if (V1max ≥ 1.1 and V2min ≤ 0.9 and V3max ≥ 1.1) then SLGF if (V1max ≥ 1.1 and V2max ≥ 1.1 and V3min ≤ 0.9) then SLGF if (V1min ≤ 0.9 and V2min ≤ 0.9 and V3max < 1.1 and V3min > 0.9) then LLF if (V1min ≤ 0.9 and V2min > 0.9 and V2max < 1.1 and V3min ≤ 0.9) then LLF if (V1min > 0.9 and V1max < 1.1 and V2min ≤ 0.9 and V3min ≤ 0.9) then LLF if (V1min ≤ 0.9 and V2min ≤ 0.9 and V3max ≥ 1.1) then LLGF if (V1min ≤ 0.9 and V2max ≥ 1.1 and V3min ≤ 0.9) then LLGF if (V1max ≥ 1.1 and V2min ≤ 0.9 and V3min ≤ 0.9) then LLGF if (V1min ≤ 0.9 and V2min ≤ 0.9 and V3min ≤ 0.9) then LLLGF |

| Event ID | Event Direction | Fault Type | V-I Data |

|---|---|---|---|

| 1 | DS | SLGF | Figure A1 |

| 2 | DS | SLGF | Figure A2 |

| 3 | DS | SLGF | Figure A3 |

| 4 | DS | SLGF | Figure A4 |

| 5 | DS | LLGF | Figure A5 |

| 6 | DS | LLLGF | Figure A6 |

| 7 | US | --------------- | Figure A7 |

| 8 | US | --------------- | Figure A8 |

| Fault Location | Monitoring Point | |||

|---|---|---|---|---|

| MP1 | MP2 | MP3 | MP4 | |

| F1 | Downstream | Upstream | Upstream | Upstream |

| F2 | Upstream | Upstream | Downstream | Upstream |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yalman, Y.; Uyanık, T.; Tan, A.; Bayındır, K.Ç.; Terriche, Y.; Su, C.-L.; Guerrero, J.M. Implementation of Voltage Sag Relative Location and Fault Type Identification Algorithm Using Real-Time Distribution System Data. Mathematics 2022, 10, 3537. https://doi.org/10.3390/math10193537

Yalman Y, Uyanık T, Tan A, Bayındır KÇ, Terriche Y, Su C-L, Guerrero JM. Implementation of Voltage Sag Relative Location and Fault Type Identification Algorithm Using Real-Time Distribution System Data. Mathematics. 2022; 10(19):3537. https://doi.org/10.3390/math10193537

Chicago/Turabian StyleYalman, Yunus, Tayfun Uyanık, Adnan Tan, Kamil Çağatay Bayındır, Yacine Terriche, Chun-Lien Su, and Josep M. Guerrero. 2022. "Implementation of Voltage Sag Relative Location and Fault Type Identification Algorithm Using Real-Time Distribution System Data" Mathematics 10, no. 19: 3537. https://doi.org/10.3390/math10193537