Testing of an Adaptive Algorithm for Estimating the Parameters of a Synchronous Generator Based on the Approximation of Electrical State Time Series

Abstract

1. Introduction

2. Literature Review

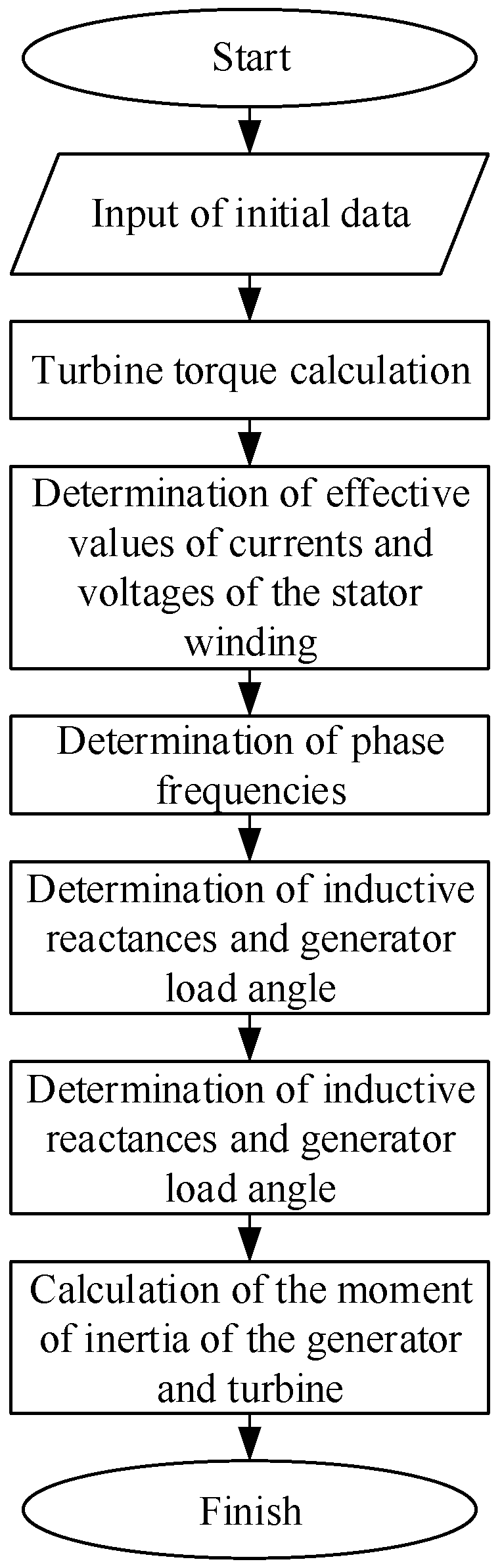

3. Algorithm of the Synchronous Machine Parameters Estimation

- Torsion of SG shaft is zero.

- Active power losses are found by re-adjusting experimental results to the current state of the SG.

- The device of direct speed measurement is installed on the rotor of the SG.

- 4.

- Load angle.

- 5.

- Reactance of d-axis and q-axis.

- 6.

- Inertia moment of a turbine and rotating parts of the SG.

- Rated parameters of the SG (rated active power capacity, power factor, number of pole pairs, rated voltage of stator winding, rated current of the stator winding, rated voltage of rotor winding, and rated current of rotor winding).

- Instantaneous values of stator voltage and stator current.

- Instantaneous values of field voltage and field current.

- Angular frequency of the rotor.

4. Model Testing Results

5. Results of Real Physical Model Testing

5.1. Description of the Real Physical Model and Measurement System

- The technical results obtained during the testing confirmed the logger’s operability and provision of the required quality indicators of measurements such as measurement errors, high measurement sampling rate (57.8 kHz), and measurement synchronization accuracy—up to 1 μs.

- Logger operating experience has confirmed its technical and design solutions in terms of establishing optical communications between its central part (the logger control unit) and remote units (measurement transducers). It can allow the central part of the recorder to be placed on premises remotely from power equipment.

- The prospects for the further use of the logger should be associated with the development of the hardware platform development and the modernization of the measuring communications infrastructure.

5.2. Estimation of the Parameters of the Synchronous Machines

6. Conclusions

- SG load angle;

- d-axis reactance Xd and q-axis reactance Xq for a known value of the torque angle;

- Inertia moment.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Saeed, M.H.; Fangzong, W.; Kalwar, B.A.; Iqbal, S. A Review on Microgrids’ Challenges & Perspectives. IEEE Access 2021, 9, 166502–166517. [Google Scholar] [CrossRef]

- Fereidouni, A.; Susanto, J.; Mancarella, P.; Hong, N.; Smit, T.; Sharafi, D. Online Security Assessment of Low-Inertia Power Systems: A Real-Time Frequency Stability Tool for the Australian South-West Interconnected System. In Proceedings of the 31st Australasian Universities Power Engineering Conference (AUPEC), Virtual, 26–30 September 2021; pp. 1–9. [Google Scholar] [CrossRef]

- Moiseichenkov, A.N.; Kovalenko, P.Y.; Senyuk, M.D.; Mukhin, V.I. Synchronous Machine Adaptive Model for Power System Emergency Control and Technical State Diagnostic. In Proceedings of the 2020 Ural Smart Energy Conference (USEC), Ekaterinburg, Russia, 13–15 November 2020; pp. 147–150. [Google Scholar] [CrossRef]

- Adkins, B.; Harley, R.G. The General Theory of Alternating Current Machines: Applications to Practical Problems; Springer: New York, NY, USA, 1975. [Google Scholar]

- Standard 115-1995; IEEE Guide: Test Procedures for Synchronous Machines. IEEE: New York, NY, USA, 1995.

- IEC-60034-4; Rotating Electrical Machines—Part 4: Methods for Determining Synchronous Machine Quantities from Tests, IEC Standard. IEC Central Office: Geneva, Switzerland, 2008.

- Bortoni, E.D.C.; Jardini, J. Identification of synchronous machine parameters using load rejection test data. IEEE Trans. Energy Convers. 2002, 17, 242–247. [Google Scholar] [CrossRef]

- Bortoni, E.; Jardini, J. A Standstill Frequency Response Method for Large Salient Pole Synchronous Machines. IEEE Trans. Energy Convers. 2004, 19, 687–691. [Google Scholar] [CrossRef]

- Vandoorn, T.L.; De Belie, F.M.; Vyncke, T.J.; Melkebeek, J.A.; Lataire, P. Generation of Multisinusoidal Test Signals for the Identification of Synchronous-Machine Parameters by Using a Voltage-Source Inverter. IEEE Trans. Ind. Electron. 2009, 57, 430–439. [Google Scholar] [CrossRef]

- Arjona, M.A.; Cisneros-Gonzalez, M.; Hernandez, C. Parameter Estimation of a Synchronous Generator Using a Sine Cardinal Perturbation and Mixed Stochastic–Deterministic Algorithms. IEEE Trans. Ind. Electron. 2010, 58, 486–493. [Google Scholar] [CrossRef]

- Arjona, M.; Hernandez, C.; Cisneros-Gonzalez, M.; Escarela-Perez, R. Estimation of synchronous generator parameters using the standstill step-voltage test and a hybrid Genetic Algorithm. Int. J. Electr. Power Energy Syst. 2012, 35, 105–111. [Google Scholar] [CrossRef]

- Hasni, M.; Touhami, O.; Ibtiouen, R.; Fadel, M.; Caux, S. Estimation of synchronous machine parameters by standstill tests. Math. Comput. Simul. 2010, 81, 277–289. [Google Scholar] [CrossRef]

- Kou, P.; Zhou, J.; Wang, C.; Xiao, H.; Zhang, H.; Li, C. Parameters identification of nonlinear state space model of synchronous generator. Eng. Appl. Artif. Intell. 2011, 24, 1227–1237. [Google Scholar] [CrossRef]

- Cisneros-González, M.; Hernandez, C.; Morales-Caporal, R.; Bonilla-Huerta, E.; Arjona, M.A. Parameter Estimation of a Synchronous-Generator Two-Axis Model Based on the Standstill Chirp Test. IEEE Trans. Energy Convers. 2013, 28, 44–51. [Google Scholar] [CrossRef]

- Wamkeue, R.; Baetscher, F.; Kamwa, I. Hybrid-State-Model-Based Time-Domain Identification of Synchronous Machine Parameters from Saturated Load Rejection Test Records. IEEE Trans. Energy Convers. 2008, 23, 68–77. [Google Scholar] [CrossRef]

- Wamkeue, R.; Jolette, C.; Mabwe, A.B.M.; Kamwa, I. Cross-Identification of Synchronous Generator Parameters from RTDR Test Time-Domain Analytical Responses. IEEE Trans. Energy Convers. 2011, 26, 776–786. [Google Scholar] [CrossRef]

- Rodríguez, G.G.; Silva, A.S.e.; Zeni, N. Identification of synchronous machine parameters from field flashing and load rejection tests with field voltage variations. Electr. Power Syst. Res. 2017, 143, 813–824. [Google Scholar] [CrossRef]

- Giesbrecht, M.; Meneses, L.A.E. Detailed derivation and experimental validation of a method for obtaining load con-ditions for salient pole synchronous machine quadrature axis parameters determination. IEEE Trans. Ind. Electron. 2019, 66, 5049–5056. [Google Scholar] [CrossRef]

- Zaker, B.; Gharehpetian, G.B.; Karrari, M. Improving Synchronous Generator Parameters Estimation Using d-q Axes Tests and Considering Saturation Effect. IEEE Trans. Ind. Inform. 2017, 14, 1898–1908. [Google Scholar] [CrossRef]

- Faria, V.A.; Bernardes, J.; Bortoni, E.C. Parameter estimation of synchronous machines considering field voltage variation during the sudden short-circuit test. Int. J. Electr. Power Energy Syst. 2019, 114, 105421. [Google Scholar] [CrossRef]

- Brkovic, B.; Petrovic, D.; Vasic, R. Determination of synchronous generator parameters using the field current wave-form. In Proceedings of the 18th International Symposium on Power Electronics, Novi Sad, Serbia, 28–30 October 2015; pp. 1–8. [Google Scholar]

- Micev, M.; Ćalasan, M.; Petrović, D.S.; Ali, Z.M.; Quynh, N.V.; Aleem, S.H.A. Field current waveform-based method for estimation of synchronous generator parameters using adaptive black widow optimization algorithm. IEEE Access 2020, 8, 207537–207550. [Google Scholar] [CrossRef]

- González-Cagigal, M.; Macías, J.A.R.; Gómez-Expósito, A. Parameter estimation of fully regulated synchronous generators using Unscented Kalman Filters. Electr. Power Syst. Res. 2018, 168, 210–217. [Google Scholar] [CrossRef]

- Rouhani, A.; Abur, A. Constrained Iterated Unscented Kalman Filter for Dynamic State and Parameter Estimation. IEEE Trans. Power Syst. 2017, 33, 2404–2414. [Google Scholar] [CrossRef]

- Ahmadzadeh-Shooshtari, B.; Torkzadeh, R.; Kordi, M.; Marzooghi, H.; Eghtedarnia, F. SG parameters estimation based on synchrophasor data. IET Gener. Transm. Distrib. 2018, 12, 2958–2967. [Google Scholar] [CrossRef]

- Zaker, B.; Gharehpetian, G.B.; Karrari, M.; Moaddabi, N. Simultaneous parameter identification of synchronous generator and excitation system using onlinemeasurements. IEEE Trans. Smart Grid 2016, 7, 1230–1238. [Google Scholar] [CrossRef]

- Xu, Y.; Mili, L.; Korkali, M.; Chen, X. An Adaptive Bayesian Parameter Estimation of a Synchronous Generator Under Gross Errors. IEEE Trans. Ind. Inform. 2019, 16, 5088–5098. [Google Scholar] [CrossRef]

- Zimmer, V.; Decker, I.; Silva, A.e. A Robust approach for the identification of synchronous machine parameters and dynamic states based on PMU data. Electr. Power Syst. Res. 2018, 165, 167–178. [Google Scholar] [CrossRef]

- Kyriakides, E.; Heydt, G.; Vittal, V. Online Parameter Estimation of Round Rotor Synchronous Generators Including Magnetic Saturation. IEEE Trans. Energy Convers. 2005, 20, 529–537. [Google Scholar] [CrossRef]

- Karayaka, H.; Keyhani, A.; Heydt, G.; Agrawal, B.; Selin, D. Synchronous generator model identification and parameter estimation from operating data. IEEE Trans. Energy Convers. 2003, 18, 121–126. [Google Scholar] [CrossRef]

- Melgoza, J.; Heydt, G.; Keyhani, A.; Agrawal, B.; Selin, D. Synchronous machine parameter estimation using the Hartley series. IEEE Trans. Energy Convers. 2001, 16, 49–54. [Google Scholar] [CrossRef]

- Valverde, G.; Kyriakides, E.; Heydt, G.T.; Terzija, V. Nonlinear Estimation of Synchronous Machine Parameters Using Operating Data. IEEE Trans. Energy Convers. 2011, 26, 831–839. [Google Scholar] [CrossRef]

- Ghahremani, E.; Karrari, M.; Malik, O. Synchronous generator third-order model parameter estimation using online experimental data. IET Gener. Transm. Distrib. 2008, 2, 708–719. [Google Scholar] [CrossRef]

- Huang, J.; Corzine, K.; Belkhayat, M. Online Synchronous Machine Parameter Extraction From Small-Signal Injection Techniques. IEEE Trans. Energy Convers. 2009, 24, 43–51. [Google Scholar] [CrossRef]

- Hutchison, G.; Zahawi, B.; Harmer, K.; Gadoue, S.; Giaouris, D. Non-invasive identification of turbo-generator parameters from actual transient network data. IET Gener. Transm. Distrib. 2015, 9, 1129–1136. [Google Scholar] [CrossRef]

- Beordo, L.; Cari, E.P.T.; Landgraf, T.G.; Alberto, L.F.C. A comparative validation of a synchronous generator by trajectory sensitivity and offline methods. Int. Trans. Electr. Energy Syst. 2016, 27, e2255. [Google Scholar] [CrossRef]

- Sellschopp, F.S. A tool for extracting synchronous machines parameters from the dc flux decay test. Comput. Electr. Eng. 2005, 31, 56–68. [Google Scholar] [CrossRef]

- Dehghani, M.; Karrari, M.; Rosehart, W.; Malik, O. Synchronous machine model parameters estimation by a time-domain identification method. Int. J. Electr. Power Energy Syst. 2009, 32, 524–529. [Google Scholar] [CrossRef]

- Oteafy, A.M.; Chiasson, J.N.; Ahmed-Zaid, S. Development and application of a standstill parameter identification technique for the synchronous generator. Int. J. Electr. Power Energy Syst. 2016, 81, 222–231. [Google Scholar] [CrossRef]

- Kyriakides, E.; Heydt, G.; Vittal, V. On-Line Estimation of Synchronous Generator Parameters Using a Damper Current Observer and a Graphic User Interface. IEEE Trans. Energy Convers. 2004, 19, 499–507. [Google Scholar] [CrossRef]

- Kundur, P. Power System Stability and Control; McGraw-Hill, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Kovalenko, P.Y.; Moiseichenkov, A. Comparing the techniques of defining the synchronous machine load angle. J. Phys. Conf. Ser. 2017, 870, 12013. [Google Scholar] [CrossRef]

- Kovalenko, P.Y.; Senyuk, M.D.; Dmitrieva, A.A. Determination of The Instantaneous Electrical Operating Parameters with an Increased Sampling Rate. In Proceedings of the 2020 International Conference on Electrotechnical Complexes and Systems (ICOECS), Ufa, Russia, 27–30 October 2020; pp. 1–4. [Google Scholar]

| Method | Advantages | Disadvantages |

|---|---|---|

| Adaptive model of a synchronous generator [3] | High adaptability to a set of input measurements, and high accuracy | The complexity of setting and determining the parameters of the algorithm |

| Least-squares method [14] | Productivity | High sensitivity to ejections in the original data |

| Kalman filter [23] | High resistance to noise in raw data, high accuracy | Significant computing power is required |

| The interior point method [16] | Effective work with small data samples | Insufficient reliability, the possible discrepancy between the iterative procedure for finding the optimum |

| The Levenberg–Marquardt method [11] | Productivity | Insufficient reliability, the possible discrepancy between the iterative procedure for finding the optimum |

| The maximum likelihood algorithm [37] | Productivity | Data samples of considerable length are required to perform the operation of the method |

| Parameter | Value |

|---|---|

| SG 8 | |

| Rotor type | Salient pole |

| Rated apparent capacity | 15 kVA |

| Power factor | 0.8 |

| Rated voltage | 230 V |

| Rated stator current | 37.5 A |

| Base impedance | 3.52 Ω |

| SG 42 | |

| Rotor type | Nonsalient pole |

| Rated apparent capacity | 5 kVA |

| Power factor | 0.8 |

| Rated voltage | 230 V |

| Rated stator current | 12.55 A |

| Base impedance | 10.58 Ω |

| SG 47 | |

| Rotor type | Nonsalient pole |

| Rated apparent capacity | 5 kVA |

| Power factor | 0.8 |

| Rated voltage | 230 V |

| Rated stator current | 12.55 A |

| Base impedance | 10.58 Ω |

| SG 64 | |

| Rotor type | Nonsalient pole |

| Rated apparent capacity | 5 kVA |

| Power factor | 0.8 |

| Rated voltage | 230 V |

| Rated stator current | 12.55 A |

| Base impedance | 10.58 Ω |

| Parameter | Calculated Values, Ω | Reference Values, Ω | Error, % |

|---|---|---|---|

| Xd | 14.43 | 13.30 | 7.25 |

| Xd′ | 1.25 | 1.30 | 4.00 |

| Xd″ | 0.76 | 0.69 | 9.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senyuk, M.; Beryozkina, S.; Berdin, A.; Moiseichenkov, A.; Safaraliev, M.; Zicmane, I. Testing of an Adaptive Algorithm for Estimating the Parameters of a Synchronous Generator Based on the Approximation of Electrical State Time Series. Mathematics 2022, 10, 4187. https://doi.org/10.3390/math10224187

Senyuk M, Beryozkina S, Berdin A, Moiseichenkov A, Safaraliev M, Zicmane I. Testing of an Adaptive Algorithm for Estimating the Parameters of a Synchronous Generator Based on the Approximation of Electrical State Time Series. Mathematics. 2022; 10(22):4187. https://doi.org/10.3390/math10224187

Chicago/Turabian StyleSenyuk, Mihail, Svetlana Beryozkina, Alexander Berdin, Alexander Moiseichenkov, Murodbek Safaraliev, and Inga Zicmane. 2022. "Testing of an Adaptive Algorithm for Estimating the Parameters of a Synchronous Generator Based on the Approximation of Electrical State Time Series" Mathematics 10, no. 22: 4187. https://doi.org/10.3390/math10224187

APA StyleSenyuk, M., Beryozkina, S., Berdin, A., Moiseichenkov, A., Safaraliev, M., & Zicmane, I. (2022). Testing of an Adaptive Algorithm for Estimating the Parameters of a Synchronous Generator Based on the Approximation of Electrical State Time Series. Mathematics, 10(22), 4187. https://doi.org/10.3390/math10224187