Deterioration Model for Reinforced Concrete Bridge Girders Based on Survival Analysis

Abstract

:1. Introduction

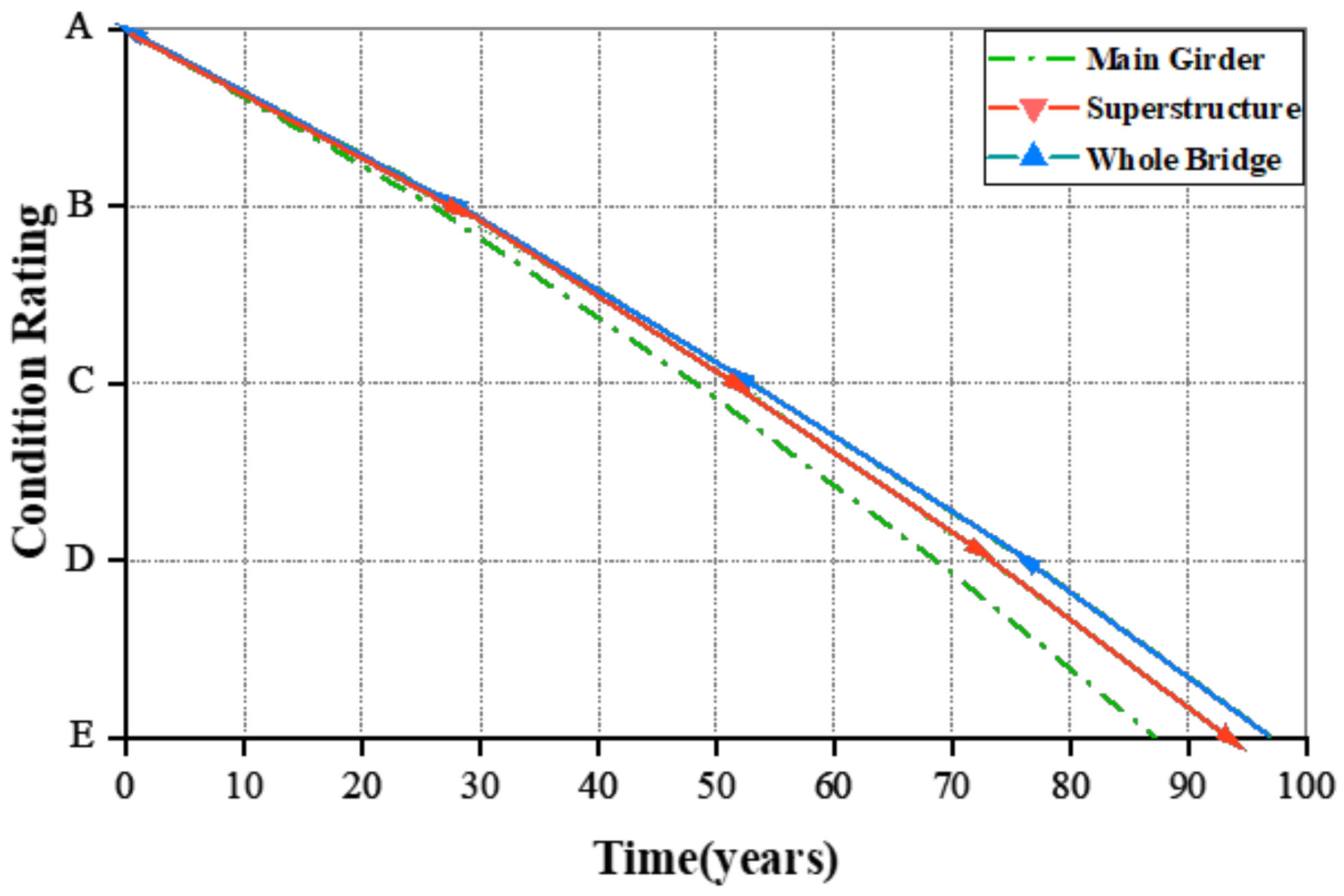

- To analyze the deterioration of the main girder under different CRs and assess the service life of the main girder;

- To seek the deterioration pattern of the performance of the main girders under different influencing factors;

- To compare the deterioration of the performance of the main girders with that of the superstructure and the whole bridge.

2. Literature Review

3. Methods

3.1. Survival Analysis

3.2. Cox Regression Analysis

3.3. Weibull Distribution

4. Data Preparation

4.1. Data Profile

4.2. Data Pre-processing

- According to Table 2, convert BCI scores to CRs.

- Locate null values in the dataset.

- Check the CR values of the year before and after the year in which the null value is located, and if they are all the same, replace the null value with that CR value. Otherwise, consider the record invalid and deleted it from the dataset.

- If the CR values change from D or E to A in the adjacent year, reset the age of the bridge after the change to 1. That is, consider the bridge as new after major repairs or reconstruction because bridges in D and E must undergo major repairs or reconstruction according to Shanghai’s bridge management regulations.

- If the CR values of adjacent years do not have a monotonically decreasing trend without a maintenance record, delete the record because the fluctuation of CR value at this time may be an inspection error or even a mistake.

- Set a reasonable range for the deterioration rate of bridge performance based on engineering experience [20]. (For example, urban bridges in China are generally designed for a life of 50–100 years [65]; hence, a bridge rating that deteriorates from grade A to grade D is typically no less than 20 years, and it is unlikely that a bridge CR will maintain an A rating for more than 40 years.).

- Mark the censored data in the inspection record dataset.

5. Results and Discussion

5.1. Processed Dataset

5.2. Parameter Estimation for Weibull Distribution

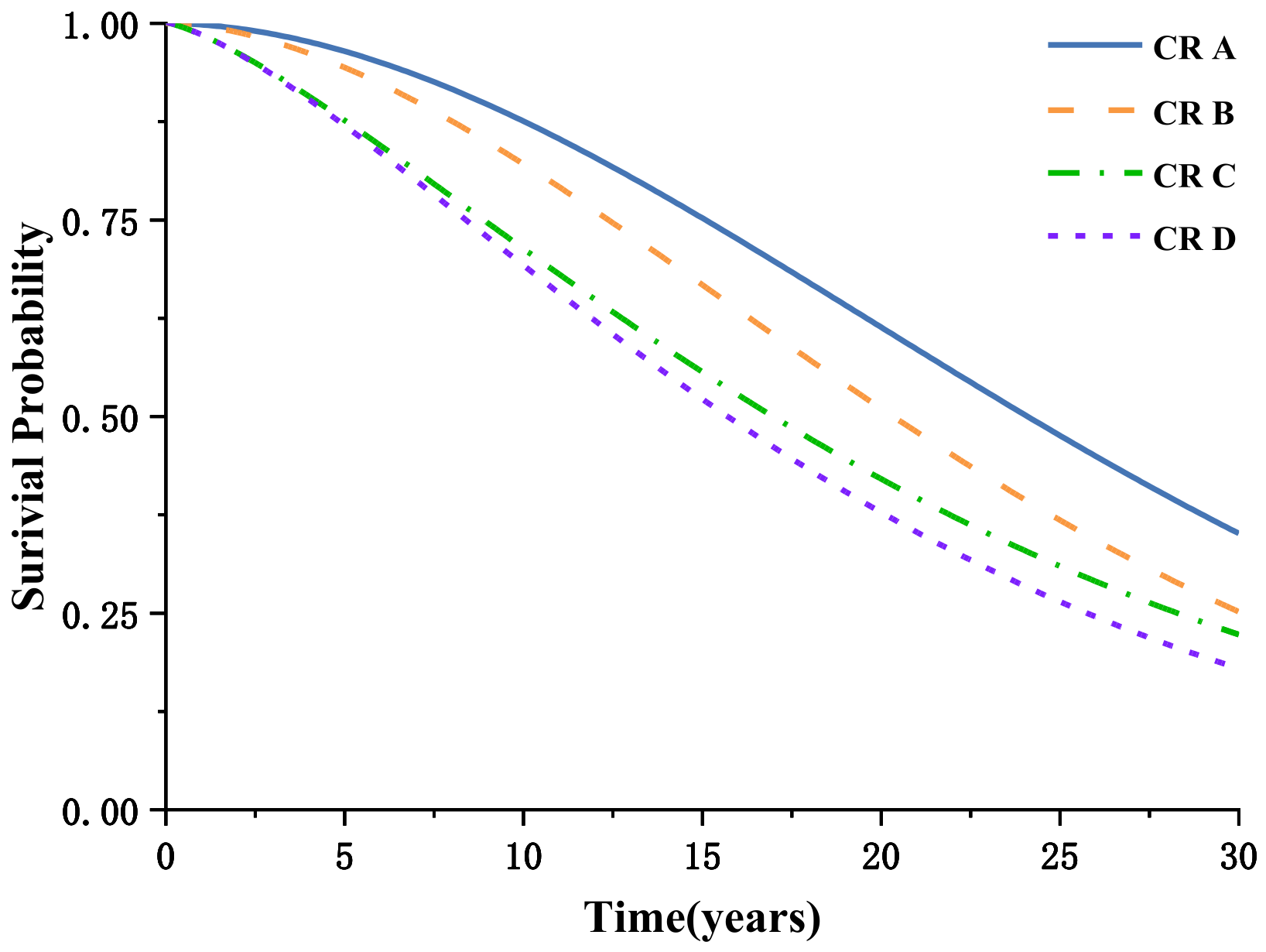

5.3. Survival Curve and Analysis

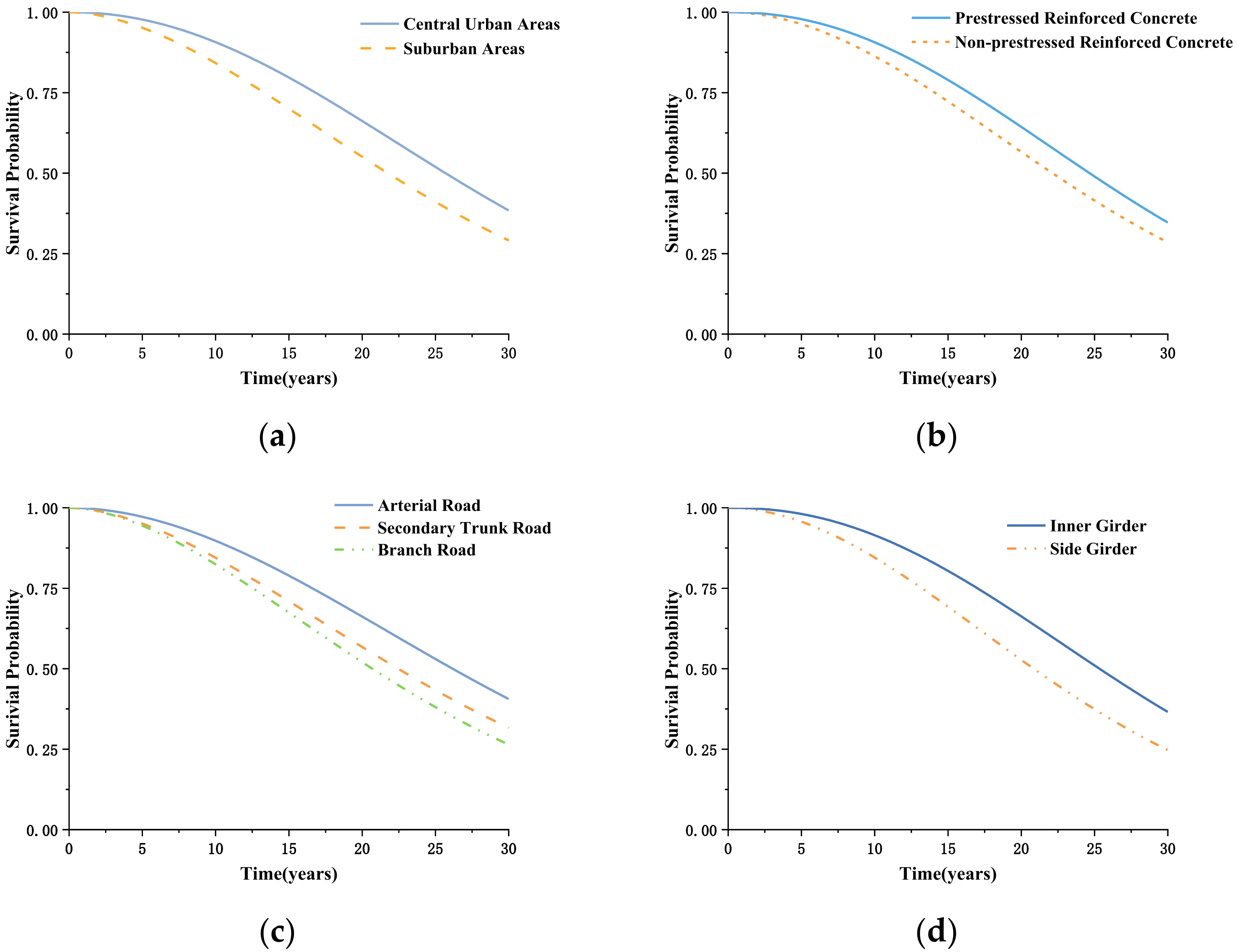

- Area factor: the area in which the bridge is located (suburban or central urban areas, which may reflect different maintenance budget levels).

- Structure factor: the structural type of the main girder (prestressed or non-prestressed reinforced concrete).

- Road factor: the grade of the road on which the bridge is located (usually related to traffic level, higher road grade means more traffic).

- Position factor: whether the main girder is located on the outer side of the superstructure (reflecting the degree of contact between the main girder and the atmospheric environment).

5.4. Cox Model Parameters

5.5. Life Prediction

6. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mirzaei, Z.; Adey, B.T. Investigation of the use of three existing methodologies to determine optimal life-cycle activity profiles for bridges. Struct. Infrastruct. Eng. 2015, 11, 1484–1509. [Google Scholar] [CrossRef]

- Calvert, G.; Neves, L.; Andrews, J.; Hamer, M. Multi-defect modelling of bridge deterioration using truncated inspection records. Reliab. Eng. Syst. Saf. 2020, 200, 106962. [Google Scholar] [CrossRef]

- Archilla, A.R.; Destefano, P.D.; Grivas, D. Method for Estimating Transition Probability in Bridge Deterioration Models. J. Infrastruct. Syst. 1999, 4, 56–62. [Google Scholar] [CrossRef]

- Nurmuhametov, K.; Zinnurov, T.; Sadykov, D. Implementation of the Decision-Making Algorithm in the Bridge Management System. In Proceedings of the International Scientific Conference on Socio-Technical Construction and Civil Engineering, Kazan, Russia, 21–28 April 2021. [Google Scholar]

- Madanat, S.M.; Karlaftis, M.G.; Mccarthy, P.S. Probabilistic Infrastructure Deterioration Models with Panel Data. J. Infrastruct. Syst. 1997, 3, 4–9. [Google Scholar] [CrossRef]

- Medina, P.A.; González, J.L. Reinforced concrete long-term deterioration prediction for the implementation of a Bridge Management System. Mater. Today Proc. 2022, 58, 1265–1271. [Google Scholar] [CrossRef]

- Hawk, H.; Small, E.P. The BRIDGIT Bridge Management System. Struct. Eng. Int. 2008, 8, 309–314. [Google Scholar] [CrossRef]

- Stevens, N.A.; Lydon, M.; Marshall, A.H.; Taylor, S. Identification of Bridge Key Performance Indicators Using Survival Analysis for Future Network-Wide Structural Health Monitoring. Sensors 2020, 20, 6894. [Google Scholar] [CrossRef]

- Dekelbab, W.; Al-Wazeer, A.; Harris, B. History Lessons from the National Bridge Inventory. Public Roads 2008, 71, 30. [Google Scholar]

- Markiz, N.; Jrade, A. Integrating fuzzy-logic decision support with a bridge information management system (BrIMS) at the conceptual stage of bridge design. J. Inf. Technol. Constr. 2018, 23, 92–121. [Google Scholar]

- Bu, G.P.; Lee, J.H.; Guan, H.; Loo, Y.C.; Blumenstein, M. Prediction of Long-Term Bridge Performance: Integrated Deterioration Approach with Case Studies. J. Perform. Constr. Facil. 2015, 29, 04014089. [Google Scholar] [CrossRef] [Green Version]

- Bolukbasi, M.; Mohammadi, J.; Arditi, D. Estimating the Future Condition of Highway Bridge Components Using National Bridge Inventory Data. Pract. Period. Struct. Des. Constr. 2004, 9, 16–25. [Google Scholar] [CrossRef]

- Kong, J.S.; Frangopol, D.M. Life-Cycle Reliability-Based Maintenance Cost Optimization of Deteriorating Structures with Emphasis on Bridges. J. Struct. Eng. 2003, 129, 818–828. [Google Scholar] [CrossRef]

- Tabatabai, H.; Sobolev, K.; Ghorbanpoor, A.; Nabizadeh, A.; Lee, C.W.; Lind, M. Evaluation of Thin Polymer Overlays for Bridge Decks. In Proceedings of the Structural Faults and Repair Conference, Edinburgh, UK, 11 May 2018. [Google Scholar]

- Yang, D.Y.; Frangopol, D.M. Life-cycle management of deteriorating bridge networks with network-level risk bounds and system reliability analysis. Struct. Saf. 2020, 83, 101911. [Google Scholar] [CrossRef]

- Ibrahim, N.; Yunus, M.Z.M. Bridge monitoring and management system using GIS. IOP Conf. Ser. Mater. Sci. Eng. 2019, 527, 12076. [Google Scholar] [CrossRef]

- Wellalage, N.K.W.; Zhang, T.; Dwight, R. Calibrating Markov Chain–Based Deterioration Models for Predicting Future Conditions of Railway Bridge Elements. J. Bridge Eng. 2014, 20, 04014060. [Google Scholar] [CrossRef] [Green Version]

- Emoto, H.; Takahashi, J.; Widyawati, R.; Miyamoto, A. Performance Evaluation and Remaining Life Prediction of an Aged Bridge by J-BMS. Procedia Eng. 2014, 95, 65–74. [Google Scholar] [CrossRef] [Green Version]

- Li, C.Z. Development and application of Highway Bridge Management System (CBMS2000). J. Highw. Transp. Res. Dev. 2003, 20, 84–90. (In Chinese) [Google Scholar]

- Fang, Y.; Sun, L.J. Developing A Semi-Markov Process Model for Bridge Deterioration Prediction in Shanghai. Sustainability 2019, 11, 5524. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.H. Artificial neural network model of bridge deterioration. J. Perform. Constr. Facil. 2010, 24, 597–602. [Google Scholar] [CrossRef]

- Zayed, T.M.; Chang, L.M.; Fricker, J.D. Life-Cycle Cost Analysis using Deterministic and Stochastic Methods: Conflicting Results. J. Perform. Constr. Facil. 2002, 16, 63–74. [Google Scholar] [CrossRef]

- Morcous, G. Performance Prediction of Bridge Deck Systems Using Markov Chains. J. Perform. Constr. Facil. 2006, 20, 146–155. [Google Scholar] [CrossRef]

- Zambon, I.; Vidovic, A.; Strauss, A.; Matos, J. Condition Prediction of Existing Concrete Bridges as a Combination of Visual Inspection and Analytical Models of Deterioration. Appl. Sci. 2019, 9, 148. [Google Scholar] [CrossRef] [Green Version]

- Ng, S.K.; Moses, F. Bridge deterioration modelling using semi-Markov theory. In Proceedings of the Structural Safety and Reliability, Shiraishi, Shinozuka and Wen, Rotterdam, The Netherlands, 1 January 1998. [Google Scholar]

- Kleiner, Y. Scheduling Inspection and Renewal of Large Infrastructure Assets. J. Infrastruct. Syst. 2001, 7, 136–143. [Google Scholar] [CrossRef]

- Bortot, F.; Zonta, D.; Zandonini, R. A Bridge Management strategy based on future reliability and semi-markov deterioration models. In Proceedings of the 3rd International ASRA Net Colloquium, Glasgow, UK, 10–12 July 2006. [Google Scholar]

- Mauch, M.; Madanat, S. Semiparametric hazard rate models of reinforced concrete bridge deck deterioration. J. Infrastruct. Syst. 2001, 7, 49–57. [Google Scholar] [CrossRef]

- Mishalani, R.G.; Madanat, S.M. Computation of Infrastructure Transition Probabilities Using Stochastic Duration Models. J. Infrastruct. Syst. 2002, 8, 139–148. [Google Scholar] [CrossRef]

- Bu, G.P.; Lee, J.; Guan, H.; Blumenstein, M.; Loo, Y.C. Development of an integrated method for probabilistic bridge-deterioration modeling. J. Perform. Constr. Facil. 2014, 28, 330–340. [Google Scholar] [CrossRef] [Green Version]

- Cox, C.; Chu, H.; Schneider, M.F.; Munoz, A. Parametric survival analysis and taxonomy of hazard functions for the generalized gamma distribution. J. Stat. Med. 2010, 26, 4352–4374. [Google Scholar] [CrossRef]

- Ying, N.Y.; Kumaraswamy, M.M.; Pam, H.J.; Xie, H.M. Integrating semiparametric and parametric models in survival analysis of bridge element deterioration. J. Infrastruct. Syst. 2013, 19, 176–185. [Google Scholar] [CrossRef]

- Nakat, Z.S.; Madanat, S.M. Stochastic duration modeling of pavement overlay crack initiation. J. Infrastruct. Syst. 2008, 14, 185–192. [Google Scholar] [CrossRef]

- Madanat, S.; Park, S.; Kuhn, K. Adaptive Optimization and Systematic Probing of Infrastructure System Maintenance Policies under Model Uncertainty. J. Infrastruct. Syst. 2006, 12, 192–198. [Google Scholar] [CrossRef] [Green Version]

- Tabatabai, H.; Tabatabai, M.; Lee, C.W. Reliability of bridge decks in Wisconsin. J. Bridge Eng. 2011, 16, 53–62. [Google Scholar] [CrossRef]

- Loizos, A.; Karlaftis, M.G. Prediction of Pavement Crack Initiation from In-Service Pavements: A Duration Model Approach. Transp. Res. Rec. J. Transp. Res. Board 2005, 1940, 38–42. [Google Scholar] [CrossRef]

- Dehghan, A.; McManus, K.J.; Gad, E.F. Probabilistic Failure Prediction for Deteriorating Pipelines: Nonparametric Approach. J. Perform. Constr. Facil. 2008, 22, 45–53. [Google Scholar] [CrossRef]

- Nabizadeh, A.; Tabatabai, H.; Tabatabai, M.A. Survival Analysis of Bridge Superstructures in Wisconsin. Appl. Sci. 2018, 8, 2079. [Google Scholar] [CrossRef] [Green Version]

- Tabatabai, H.; Tabatabai, M. Survival Analyses for Bridge Decks in Northern United States. Civ. Environ. Eng. Fac. Artic. 2016, 7, 1–30. [Google Scholar]

- Agrawal, A.K.; Kawaguchi, A.; Chen, Z. Deterioration Rates of Typical Bridge Elements in New York. J. Bridge Eng. 2010, 15, 419–429. [Google Scholar] [CrossRef]

- Nasrollahi, M.; Washer, G. Estimating Inspection Intervals for Bridges Based on Statistical Analysis of National Bridge Inventory Data. J. Bridge Eng. 2015, 20, 04014104. [Google Scholar] [CrossRef]

- Manafpour, A.; Guler, L.; Radlinska, A.; Rajabipour, F. Stochastic Analysis and Time-Based Modeling of Concrete Bridge Deck Deterioration. J. Bridge Eng. 2018, 23, 04018066. [Google Scholar] [CrossRef]

- Hong, T.H.; Chung, S.H.; Han, S.W.; Lee, S.Y. Service Life Estimation of Concrete Bridge Decks. KSCE J. Civ. Eng. 2006, 10, 233–241. [Google Scholar] [CrossRef]

- Tabatabai, H.; Lee, C.W.; Tabatabai, M.A. Reliability of bridge decks in the United States. Bridge Struct. Assess. Des. Constr. 2015, 11, 75–85. [Google Scholar] [CrossRef] [Green Version]

- Liang, M.T.; Lan, J.J. Reliability analysis for the existing reinforced concrete pile corrosion of bridge substructure. Cem. Concr. Res. 2005, 35, 540–550. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Department of PRC. Technical Code of Maintenance for City Bridges (CJJ 99-2017); China Architecture Publishing & Media Co., Ltd.: Beijing, China, 2017. [Google Scholar]

- Wakchaure, S.S.; Jha, K.N. Determination of bridge health index using analytical hierarchy process. Constr. Manag. Econ. 2012, 30, 133–149. [Google Scholar] [CrossRef]

- Fereshtehnejad, E.; Hur, J.; Shafieezadeh, A.; Brokaw, B. Ohio Bridge Condition Index: Multilevel Cost-Based Performance Index for Bridge Systems. Transp. Res. Rec. J. Transp. Res. Board 2017, 2612, 152–160. [Google Scholar] [CrossRef]

- Solovyov, L.; Solovyov, A. Thermal Method in the Control of Fatigue Cracks in Welded Bridge Superstructures. Transp. Res. Procedia 2021, 54, 355–361. [Google Scholar] [CrossRef]

- Saeed, T.U.; Moomen, M.; Ahmed, A.; Murillo-Hoyos, J.; Volovski, M.; Labi, S. Performance Evaluation and Life Prediction of Highway Concrete Bridge Superstructure across Design Types. J. Perform. Constr. Facil. 2017, 31, 04017052. [Google Scholar] [CrossRef]

- Black, M.; Brint, A.T.; Brailsford, J.R. A semi-Markov approach for modelling asset deterioration. J. Oper. Res. Soc. 2005, 56, 1241–1249. [Google Scholar] [CrossRef]

- Fleischhacke, A.; Ghonima, O.; Schumacher, T. Bayesian Survival Analysis for US Concrete Highway Bridge Decks. J. Infrastruct. Syst. 2020, 26, 04020001. [Google Scholar] [CrossRef]

- Chen, L.P. Semiparametric estimation for cure survival model with left-truncated and right-censored data and covariate measurement error. Stat. Probab. Lett. 2019, 154, 108547. [Google Scholar] [CrossRef] [Green Version]

- Lee, E.T.; Go, O.T. Survival analysis in public health research. Annu. Rev. Public Health 1997, 18, 105–134. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Li, L.; Ni, D.H. Comparative Univariate and Regression Survival Analysis of Lane-Changing Duration Characteristic for Heavy Vehicles and Passenger Cars. J. Transp. Eng. Part A Syst. 2022, 148, 04022109. [Google Scholar] [CrossRef]

- Thackham, M.; Ma, J. On maximum likelihood estimation of the semi-parametric Cox model with time-varying covariates. J. Appl. Stat. 2020, 47, 1511–1528. [Google Scholar] [CrossRef]

- Kohout, J. Three-parameter Weibull distribution with upper limit applicable in reliability studies and materials testing. Microelectron. Reliab. 2022, 137, 114769. [Google Scholar] [CrossRef]

- Li, L.; Li, F.; Chen, Z.; Sun, L.J. Use of Markov Chain Model Based on Actual Repair Status to Predict Bridge Deterioration in Shanghai, China. Transp. Res. Rec. 2016, 2550, 106–114. [Google Scholar] [CrossRef]

- Li, L.; Sun, L.J.; Ning, G.B. Deterioration Prediction of Urban Bridges on Network Level Using Markov-Chain Model. Math. Probl. Eng. 2014, 7, 728107. [Google Scholar] [CrossRef]

- Beng, S.S.; Matsumoto, T. Survival analysis on bridges for modeling bridge replacement and evaluating bridge performance. Struct. Infrastruct. Eng. 2012, 8, 251–268. [Google Scholar] [CrossRef] [Green Version]

- Dabous, S.A. A Decision Support Methodology for Rehabilitation Management of Concrete Bridges. Ph.D. Thesis, Concordia University, Montréal, QC, Canada, 2008. [Google Scholar]

- Martinez, P.; Mohamed, E.; Mohsen, O.; Mohamed, Y. Comparative Study of Data Mining Models for Prediction of Bridge Future Conditions. J. Perform. Constr. Facil. 2020, 34, 04019108. [Google Scholar] [CrossRef]

- Chen, Z. Research on Technology Structure of Transportation Infrastructure Management System. Ph.D. Thesis, Tongji University, Shanghai, China, July 2005. [Google Scholar]

- Bush, S.J.W.; Henning, T.F.P.; Raith, A.; Ingham, J.M. Development of a Bridge Deterioration Model in a Data-Constrained Environment. J. Perform. Constr. Facil. 2017, 31, 04017080. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Department of PRC. Code for Design of the Municipal Bridges (CJJ 11-2011); China Architecture Publishing & Media Co., Ltd.: Being, China, 2019. [Google Scholar]

| Bridge Type | Bridge Parts | Weight |

|---|---|---|

| Girder bridge | Deck System | 0.15 |

| Superstructure | 0.40 | |

| Substructure | 0.45 |

| Rating | State | BCI Score | Maintenance Recommendations |

|---|---|---|---|

| A | Intact | [90, 100] | Routine maintenance |

| B | Good | [80, 90) | Routine maintenance or minor repair |

| C | Qualified | [66, 80) | Minor repair |

| D | Bad | [50, 66) | Medium or major repair |

| E | Dangerous | [0, 50) | Major repair or reconstruction |

| Year | Overall Data Records | Valid Data Records |

|---|---|---|

| 2007 | 1211 | 841 |

| 2008 | 2731 | 2356 |

| 2009 | 2641 | 2276 |

| 2010 | 3003 | 2566 |

| 2011 | 2939 | 2582 |

| 2012 | 2889 | 2498 |

| 2013 | 3166 | 2708 |

| 2014 | 3103 | 2683 |

| 2015 | 3170 | 2730 |

| 2016 | 3342 | 2871 |

| 2017 | 3252 | 2779 |

| 2018 | 3313 | 2853 |

| 2019 | 3359 | 2764 |

| 2020 | 3332 | 2817 |

| Total | 41,451 | 35,324 |

| CR | Complete Records | Right-Censored | Left-Censored |

|---|---|---|---|

| A | 1898 | 1545 | 89 |

| B | 1602 | 673 | 67 |

| C | 1312 | 477 | 35 |

| D | 623 | 103 | 31 |

| CR | Average Expectation | Standard Deviation | ||

|---|---|---|---|---|

| A | 29.292 | 1.878 | 26.003 | 14.386 |

| B | 25.016 | 1.771 | 22.266 | 12.992 |

| C | 22.240 | 1.358 | 20.372 | 15.167 |

| D | 20.402 | 1.402 | 18.591 | 13.436 |

| Variable | Regression Coefficient | HR | Confidence Interval of HR |

|---|---|---|---|

| Central Urban Area vs. Suburban | −0.318 | 0.728 | [0.624, 0.832] |

| Prestressed vs. Non-prestressed | 0.151 | 1.163 | [1.071, 1.255] |

| Arterial Road vs. Branch Road | −0.445 | 0.641 | [0.495, 0.787] |

| Secondary Trunk Road vs. Branch Road | −0.124 | 0.884 | [0.779, 0.989] |

| Side Girder vs. Inner Girder | 0.369 | 1.446 | [1.374, 1.518] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Lu, Y.; Peng, M. Deterioration Model for Reinforced Concrete Bridge Girders Based on Survival Analysis. Mathematics 2022, 10, 4436. https://doi.org/10.3390/math10234436

Li L, Lu Y, Peng M. Deterioration Model for Reinforced Concrete Bridge Girders Based on Survival Analysis. Mathematics. 2022; 10(23):4436. https://doi.org/10.3390/math10234436

Chicago/Turabian StyleLi, Li, Yu Lu, and Miaojuan Peng. 2022. "Deterioration Model for Reinforced Concrete Bridge Girders Based on Survival Analysis" Mathematics 10, no. 23: 4436. https://doi.org/10.3390/math10234436

APA StyleLi, L., Lu, Y., & Peng, M. (2022). Deterioration Model for Reinforced Concrete Bridge Girders Based on Survival Analysis. Mathematics, 10(23), 4436. https://doi.org/10.3390/math10234436