Concurrent Control Chart Pattern Recognition: A Systematic Review

Abstract

1. Introduction

2. Methodology

2.1. Search Strategy

2.2. Selection Process

- Criterion 1: The full text is not available in the databases.

- Criterion 2: The paper does not present a methodological approach.

- Criterion 3: The paper does not pertain to SPC problems.

- Criterion 4: The paper does not discuss a problem of CCP recognition.

- Criterion 5: The paper only addresses single CCP recognition.

2.3. Bias Assessment

- Is the research problem clearly defined? (Yes/No)

- Is the proposed solution clearly stated? (Yes/No)

- Does the research detail the tools applied in the proposed solution? (Yes/No)

- Are the assumptions or considerations framing the study presented? (Yes/No)

- Is the development of the solution methodology clearly explained? (Yes/No)

- Does the research have a clear definition of the main findings and results? (Yes/No)

- Are future lines of research presented? (Yes/No)

2.4. Classification Scheme

- What type of approach is used to identify concurrent CCPs? Articles are grouped according to their methodology for recognising concurrent CCPs based on their preprocessing, training, classification, and testing approaches. SP refers to a simple pattern, while CP refers to a concurrent one.

- (I)

- Decomposition–Training SP–Classifier SP–Testing SP (Approach 1): A decomposition procedure separates concurrent patterns into simple ones. Classifiers are trained for simple pattern recognition.

- (II)

- Training SP–Classifier SP–Testing SP/CP (Approach 2): Classifiers are trained for simple pattern recognition, and concurrent pattern classification is achieved using a threshold value. Testing evaluates both concurrent and simple pattern.

- (III)

- Training SP/CP–Classifier SP–Testing SP/CP (Approach 3): Classifiers are designed for simple pattern recognition, and concurrent pattern classification is achieved using a threshold value. However, both training and testing procedures consider concurrent patterns.

- (IV)

- Training SP/CP–Classifier SP/CP–Testing SP/CP (Approach 4): Classifiers are designed for both simple and concurrent pattern recognition. Both training and testing are performed with simple and concurrent patterns.

- (V)

- Training CP–Classifier CP–Testing CP (Approach 5): Classifiers are designed for concurrent pattern recognition. Both training and testing are performed with concurrent patterns.

- (VI)

- Statistical methods (Approach 6): The classification is performed using statistical data analysis.

- Which classification techniques are applied? Articles are grouped according to the classification technique used to differentiate control chart patterns.

- (I)

- Artificial neural networks (ANN): A classification algorithm inspired by the neural structures of the human brain.

- (II)

- Decision tree (DT): A classification algorithm that separates a dataset following a branch–leaf structure.

- (III)

- Extreme learning machine (ELM): A learning paradigm for single-hidden-layer feed-forward neural networks.

- (IV)

- Fitted cosine curve (FCC): A technique that uses a cosine curve to decom-pose a signal into several independent components.

- (V)

- Fitted line analysis (FLA): A technique that specialises in recognising shift and trend patterns.

- (VI)

- Sparse representation-based classification (SRC): A technique employed for detecting active basic patterns.

- (VII)

- Multivariate adaptive regression splines (MARS): A classification algorithm based on a divide and conquer strategy.

- (VIII)

- Statistical correlation coefficient (SCC): A technique that uses the statistical correlation coefficient as a similarity measure to determine the pattern type.

- (IX)

- Support vector machine (SVM): A classification algorithm that maps points in space to separate the data that belongs to different categories using a hyperplane and the largest distance between the nearest training-data points of each class.

- (X)

- Random forest (RF): A classification algorithm that builds an ensemble of classification trees.

- (XI)

- Rough set (RS): A classification tool for systems characterised by inexact, uncertain, or vague information.

- (XII)

- Deep neural networks (DNN): An ANN with at least two layers.

- What are the assumptions of the data model? This category describes the assumptions about the data model based on the nature of the process.

- (I)

- Normally distributed data: The process data follow a normal distribution.

- (II)

- Non-normally distributed data: In some cases, the normality assumption is not tenable, so the data are assumed to follow a non-normal distribution.

- (III)

- (Autocorrelated process data: The variable is correlated with itself over successive time intervals.

- What data preprocessing procedures are applied? This category groups articles according to preprocessing procedures applied to the data before the classification task.

- (I)

- Independent component analysis (ICA): A procedure applied to separate a multivariate signal into independent subcomponents.

- (II)

- Multi-resolution wavelet analysis (MRWA): A procedure applied to de-compose a series of data into a time–frequency space.

- (III)

- Scaling/standardisation/codification (S/ST/CO): Methods for data scaling, standardization, and codification.

- (IV)

- Singular spectrum analysis (SSA): A nonparametric method that decomposes a time series into a sum of components such as trends, oscillatory components, and noise.

- (V)

- Sparse representation-based source separation (SRSS): An approach based on sparse coding.

- (VI)

- Engineering process control (EPC): Methods applied to transform controllable variables and compensate for the effects of process disturbances.

- (VII)

- Extreme-point symmetric mode (ESMD): An empirically-based data-analysis method that decomposes a signal into several independent components whose sum is the original signal.

- (VIII)

- Principal component analysis (PCA): A multivariate statistical analysis method that uses linear transformation.

- (IX)

- Second-order blind source separation (SO-BSS) techniques: Approaches applied for separating the sources, assuming that there exists a temporal correlation between the observed data.

- (X)

- Spectral-based processing approach (SPA): method based on spectral analysis for data transformation and dimensionality reduction.

- (XI)

- Resampling (RSA): A preprocessing method to resize an image or a signal without losing information or adding noise.

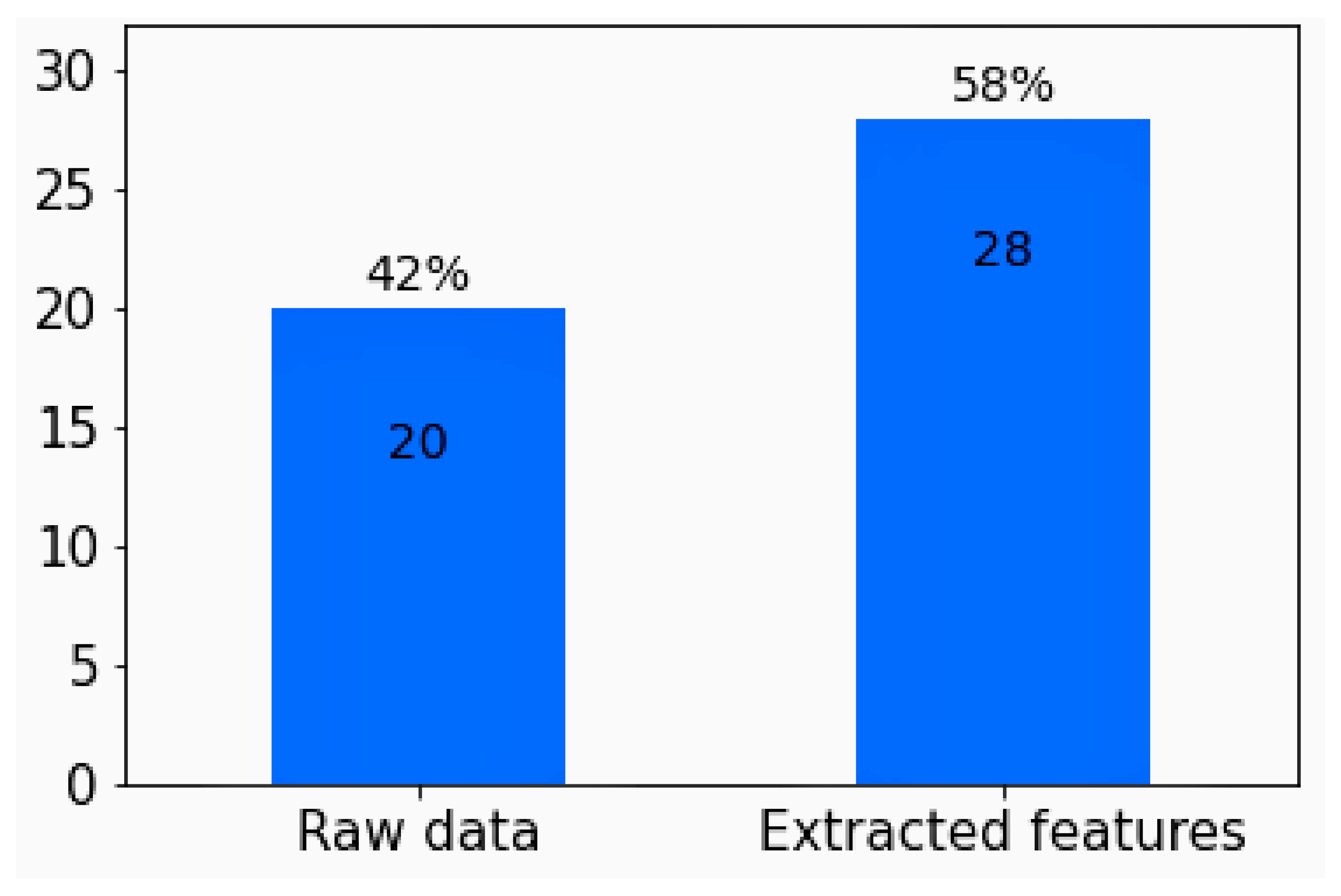

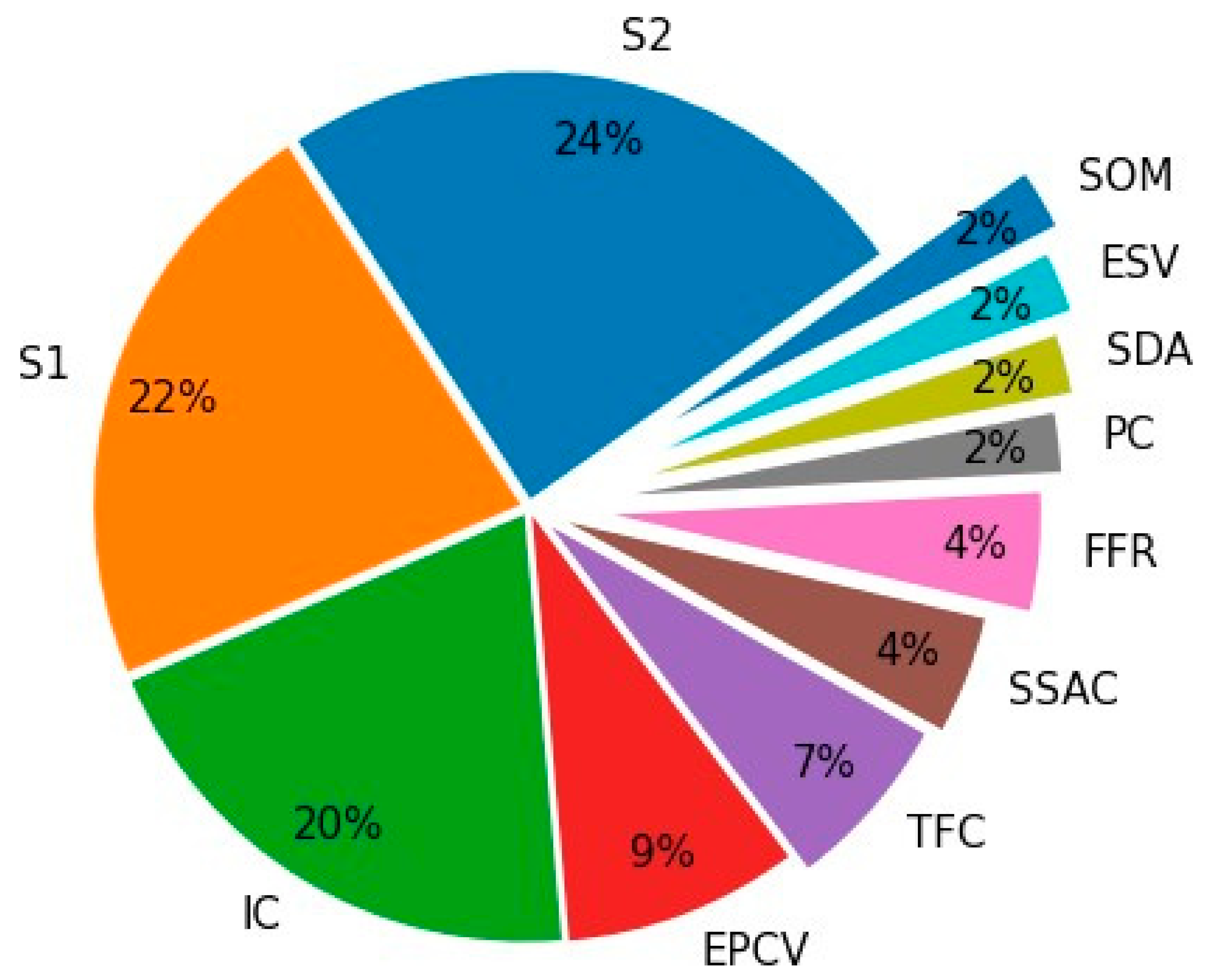

- What type of input data is considered? Research papers are grouped according to the type of data that are fed into the classification methods to identify the pattern type.

- (I)

- Raw data: Unprocessed input data or processed data using simple preprocessing techniques such as scaling and standardization.

- (II)

- Extracted features: Extraction of features is performed to obtain relevant information hidden in raw data that may improve classification results.

- (a)

- Statistical features (S1).

- (b)

- Shape features (S2).

- (c)

- Independent components (IC): Non-Gaussian and statistically independent additive subcomponents resulting from an ICA.

- (d)

- SSA components (SSAC): Independent components resulting from the application of an SSA.

- (e)

- Time–frequency localized coefficients (TFC): Time–frequency signal representations originated from a wavelet transformation.

- (f)

- Principal component (PC): Principal components resulting from PCA.

- (g)

- Fusion feature reduction variables (FFR): Features extracted from FFR methods.

- (h)

- Sub-dictionary atoms (SDA): Sources resulting from SRSS methods.

- (i)

- Engineering process control variables (EPCV): Adjusted variables resulting from EPC.

- (j)

- Extreme-point symmetric variables (ESV): Decomposed signals resulting from ESMD methods.

- (k)

- Second-order matrix (SOM): Unitary matrix resulting from SO-BSS.

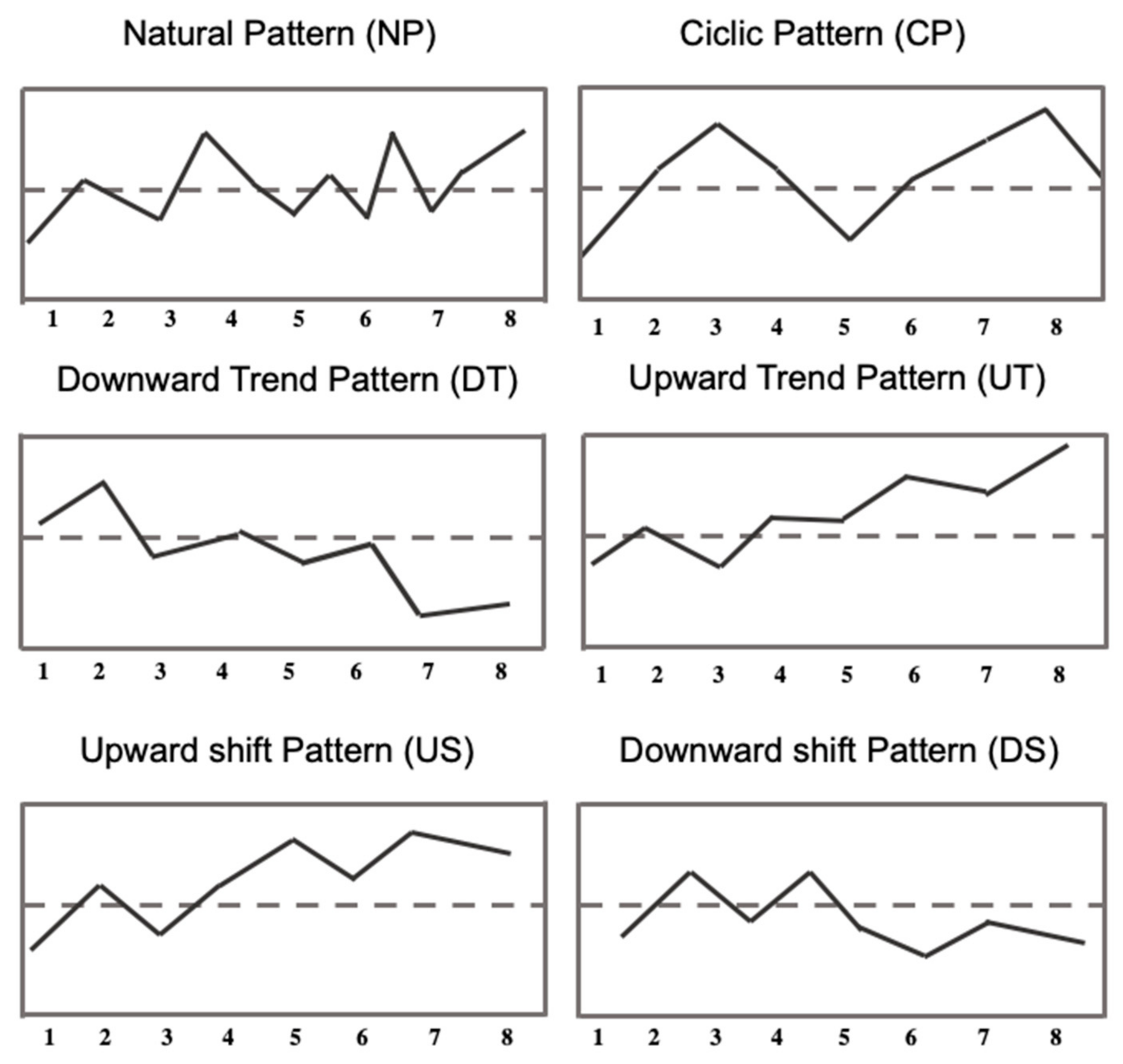

- Which concurrent CCPs are studied? This category classifies reviewed articles according to the concurrent control chart patterns that are subject to study.

- (I)

- Cyclic–systematic.

- (II)

- Shift–cyclic.

- (III)

- Shift–normal.

- (IV)

- Shift–systematic.

- (V)

- Shift–trend.

- (VI)

- Mean–variance.

- (VII)

- Trend–cyclic.

- (VIII)

- Trend–normal.

- (IX)

- Trend–systematic.

- (X)

- Stratification–normal.

- (XI)

- Systematic–normal.

- (XII)

- Cyclic–normal.

- (XIII)

- Stratification–trend.

- (XIV)

- Stratification–shift.

- (XV)

- Stratification–cyclic.

- (XVI)

- Stratification–systematic.

- (XVII)

- Trend–trend.

- (XVIII)

- Shift–shift.

- (XIX)

- Three patterns at the same time.

- (XX)

- Four patterns at the same time.

- (XXI)

- Five patterns at the same time.

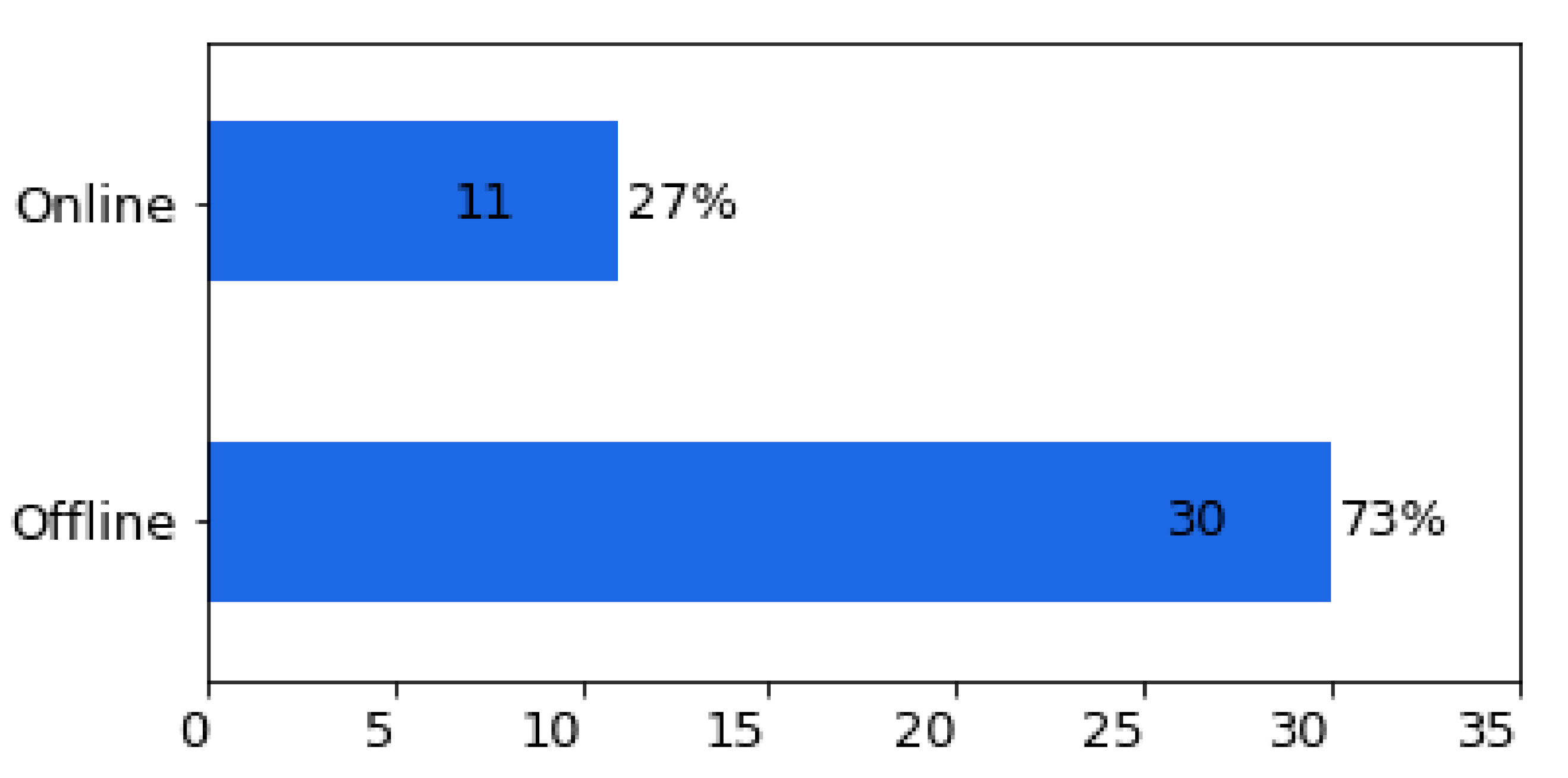

- What is the evaluation approach used? This category considers whether the authors included an evaluation approach where new samples are gradually added to the analysis window, i.e., a new sample is added to the window and the oldest sample is removed.

- (I)

- Online: The unnatural pattern appears gradually in the analysis window.

- (II)

- Offline: The natural pattern does not appear incrementally within the analysis window; it is usually completely shown in the window.

- What type of evaluation metrics are applied? This category considers what type of evaluation metrics were applied by the authors during the proposal construction process.

- (I)

- Detection speed: Metrics that measure how rapidly the alternating pat tern was identified. These metrics include the out-of-control average run length (ARL1 or ARL), average target pattern run length (ATPRL), type II error (β), average run length index (ARLIDX), average both patterns run length (ABPRL), and average time to signal (ATTS).

- (II)

- Detection accuracy: Metrics that measure how accurate the identification of the considered patterns is; includes natural and unnatural patterns. These metrics include the classification rate (CLR), correct recognition (CR), classification accuracy (CA), recognition accuracy (RA), the percentage of correctly identified concurrent CCPs (CIC), precision (PR), recall (RE), and F1-score (F1).

- (III)

- False alarms: Metrics that measure the identification of unnatural patterns when the process is under a natural pattern. These metrics include the false alarm (FA), in-control average run length (ARL0), and type I error (α).

- What type of data does the model use? This category classifies research according to the type of data used during the proposal testing process.

- (I)

- Real data: This category groups together research that uses data obtained from the monitoring of a real process.

- (II)

- Simulated data: This category groups research that uses data generated through established mathematical functions.

- How is the window size determined? This category determines whether the window size is obtained through an optimisation process.

- (I)

- Window size analysis: Research that performed some optimisation process to select the input data window size is considered.

- (II)

- No window size analysis: Research that is based on other authors or establishes the window size without greater rigour is considered.

- What is the amount of data per pattern? This category establishes whether the proposal considers an unbalanced number of patterns.

- (I)

- Unbalanced dataset: Research that considers the high imbalance of patterns in the actual monitoring processes.

- (II)

- Balanced dataset: Research that does not consider the high imbalance of patterns in the actual monitoring process.

3. Bibliometric Analysis

3.1. Publication Numbers

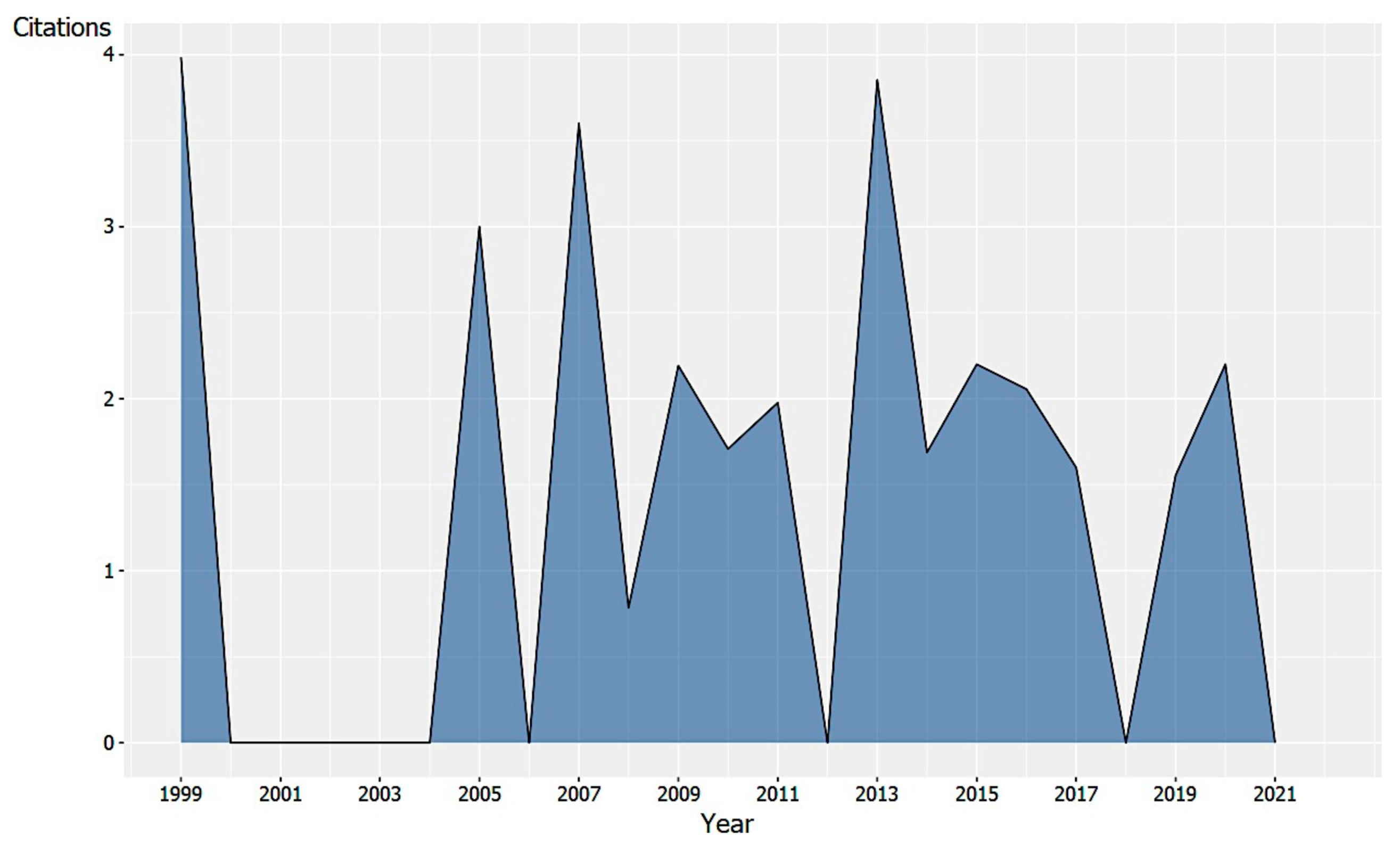

3.2. Average Citations per Year

3.3. Relevant Sources

3.4. Country Collaboration

3.5. Historical Direct Citation Network

3.6. Network of Authors Keywords

4. Results and Discussion

4.1. Concurrent Pattern Recognition Approach

4.2. Classification Techniques

4.3. Assumptions of the Data Model

4.4. Data Preprocessing Procedures

4.5. Type of Input Data

4.6. Concurrent Control Chart Patterns Studied

4.7. Evaluation Approach

4.8. Type of Evaluation Metrics

4.9. Type of Data for Testing Process

4.10. Window Size Optimisation

4.11. Amount of Data per Pattern

5. Difficulties and Challenges for Concurrent Control Chart Pattern Recognition

5.1. Design and Conceptualisation of the Proposed Algorithms or Methods

5.2. Validation and Performance Indicators

5.3. Implementation and Application of the Proposed Methods

6. Conclusions and Future Research Lines

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| α | Type I error |

| β | Type II error |

| ABPRL | Average both patterns run length ANN |

| ANN | Artificial neural networks |

| ARL | Average run length |

| ARL0 | In-control average run length |

| ARLIDX | Average run length index |

| ATPRL | Average target pattern run length |

| ATTS | Average time to signal |

| CA | Classification accuracy |

| CIC | Percentage of correctly identified concurrent CCPs |

| CP | Concurrent pattern |

| CCP | Control chart pattern |

| CLR | Classification rate |

| CR | Correct recognition |

| DNN | Deep neural networks |

| DT | Decision tree |

| ELM | Extreme learning machine |

| EPC | Engineering process control |

| EPCV | Engineering process control variables |

| ESMD | Extreme-point symmetric mode |

| ESV | Extreme-point symmetric variables |

| F1 | F1-score |

| FA | False alarm |

| FCC | Fitted cosine curve |

| FFR | Fusion feature reduction variables |

| FLA | Fitted line analysis |

| IC | Independent components |

| ICA | Independent component analysis |

| MARS | Multivariate adaptive regression splines |

| MRWA | Multi-resolution wavelet analysis |

| PC | Principal component |

| PCA | Principal component analysis |

| PR | Precision |

| RA | Recognition accuracy |

| RE | Recall |

| RF | Random forest |

| RSA | Resampling |

| RS | Rough set |

| S1 | Statistical features |

| S2 | Shape features |

| S/ST/CO | Scaling/standardisation/codification |

| SCC | Statistical correlation coefficient |

| SDA | Sub-dictionary atoms |

| SO-BSS | Second-order blind source separation techniques |

| SOM | Second-order matrix |

| SP | Simple pattern |

| SPA | Spectral-based processing approach |

| SPC | Statistical Process Control |

| SRC | Sparse representation-based classification |

| SRSS | Sparse representation-based source separation |

| SSA | Singular spectrum analysis |

| SSAC | SSA components |

| SVM | Support vector machine |

References

- Shewhart, W.A. Economic Control of Quality of Manufactured Product; Macmillan and Co., Ltd.: London, UK, 1931. [Google Scholar]

- Wang, J.; Kochhar, A.; Hannam, R. Pattern recognition for statistical process control charts. Int. J. Adv. Manuf. Technol. 1998, 14, 99–109. [Google Scholar] [CrossRef]

- Pelegrina, G.D.; Duarte, L.T.; Jutten, C. Blind source separation and feature extraction in concurrent control charts pattern recognition: Novel analyses and a comparison of different methods. Comput. Ind. Eng. 2016, 92, 105–114. [Google Scholar] [CrossRef]

- Shang, C.; You, F. Data analytics and machine learning for smart process manufacturing: Recent advances and perspectives in the big data era. Engineering 2019, 5, 1010–1016. [Google Scholar] [CrossRef]

- Xu, J.; Lv, H.; Zhuang, Z.; Lu, Z.; Zou, D.; Qin, W. Control Chart Pattern Recognition Method Based on Improved One-dimensional Convolutional Neural Network. IFAC-PapersOnLine 2019, 52, 1537–1542. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, X.; Wang, H.; Xiong, G.; Cheng, W. Features Fusion Exaction and KELM With Modified Grey Wolf Optimizer for Mixture Control Chart Patterns Recognition. IEEE Access 2020, 8, 42469–42480. [Google Scholar] [CrossRef]

- Chiu, J.E.; Tsai, C.H. On-line concurrent control chart pattern recognition using singular spectrum analysis and random forest. Comput. Ind. Eng. 2021, 159, 107538. [Google Scholar] [CrossRef]

- Maged, A.; Xie, M. Recognition of abnormal patterns in industrial processes with variable window size via convolutional neural networks and AdaBoost. J. Intell. Manuf. 2022, 1–23. [Google Scholar] [CrossRef]

- Paolanti, M.; Frontoni, E. Multidisciplinary pattern recognition applications: A review. Comput. Sci. Rev. 2020, 37, 100276. [Google Scholar] [CrossRef]

- Xie, L.; Gu, N.; Li, D.; Cao, Z.; Tan, M.; Nahavandi, S. Concurrent control chart patterns recognition with singular spectrum analysis and support vector machine. Comput. Ind. Eng. 2013, 64, 280–289. [Google Scholar] [CrossRef]

- Shao, Y.E.; Chang, P.Y.; Lu, C.J. Applying two-stage neural network based classifiers to the identification of mixture control chart patterns for an SPC-EPC process. Complexity 2017, 2017, 2323082. [Google Scholar] [CrossRef]

- Lesany, S.; Ghomi, S.F.; Koochakzadeh, A. Development of fitted line and fitted cosine curve for recognition and analysis of unnatural patterns in process control charts. Pattern Anal. Appl. 2019, 22, 747–765. [Google Scholar] [CrossRef]

- Hachicha, W.; Ghorbel, A. A survey of control-chart pattern-recognition literature (1991–2010) based on a new conceptual classification scheme. Comput. Ind. Eng. 2012, 63, 204–222. [Google Scholar] [CrossRef]

- Guh, R.S.; Tannock, J. Recognition of control chart concurrent patterns using a neural network approach. Int. J. Prod. Res. 1999, 37, 1743–1765. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef] [PubMed]

- Company, W.E. Statistical Quality Control Handbook; Western Electric: Rossville, GA, USA, 1958. [Google Scholar]

- Pritchard, A. Statistical bibliography or bibliometrics. J. Doc. 1969, 25, 348–349. [Google Scholar]

- Tandon, A.; Kaur, P.; Mäntymäki, M.; Dhir, A. Blockchain applications in management: A bibliometric analysis and literature review. Technol. Forecast. Soc. Chang. 2021, 166, 120649. [Google Scholar] [CrossRef]

- Guh, R.S.; Hsieh, Y.C. A neural network based model for abnormal pattern recognition of control charts. Comput. Ind. Eng. 1999, 36, 97–108. [Google Scholar] [CrossRef]

- Guh, R.S.; Tannock, J. A neural network approach to characterize pattern parameters in process control charts. J. Intell. Manuf. 1999, 10, 449–462. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, S.; Lam, S. A hybrid system for SPC concurrent pattern recognition. Adv. Eng. Inform. 2007, 21, 303–310. [Google Scholar] [CrossRef]

- Lu, C.J.; Shao, Y.E.; Li, P.H. Mixture control chart patterns recognition using independent component analysis and support vector machine. Neurocomputing 2011, 74, 1908–1914. [Google Scholar] [CrossRef]

- Du, S.; Huang, D.; Lv, J. Recognition of concurrent control chart patterns using wavelet transform decomposition and multiclass support vector machines. Comput. Ind. Eng. 2013, 66, 683–695. [Google Scholar] [CrossRef]

- Al-Assaf, Y. Multi-resolution wavelets analysis approach for the recognition of concurrent control chart patterns. Qual. Eng. 2004, 17, 11–21. [Google Scholar] [CrossRef]

- Yang, J.H.; Yang, M.S. A control chart pattern recognition system using a statistical correlation coefficient method. Comput. Ind. Eng. 2005, 48, 205–221. [Google Scholar] [CrossRef]

- Wang, X. Hybrid abnormal patterns recognition of control chart using support vector machining. In Proceedings of the 2008 International Conference on Computational Intelligence and Security, Washington, DC, USA, 13–17 December 2008; IEEE: Piscataway, NJ, USA, 2008; Volume 2, pp. 238–241. [Google Scholar]

- Jiang, P.; Liu, D.; Zeng, Z. Recognizing control chart patterns with neural network and numerical fitting. J. Intell. Manuf. 2009, 20, 625. [Google Scholar] [CrossRef]

- Wang, C.H.; Dong, T.P.; Kuo, W. A hybrid approach for identification of concurrent control chart patterns. J. Intell. Manuf. 2009, 20, 409–419. [Google Scholar] [CrossRef]

- Guh, R.S. Simultaneous process mean and variance monitoring using artificial neural networks. Comput. Ind. Eng. 2010, 58, 739–753. [Google Scholar] [CrossRef]

- Lu, C.J.; Shao, Y.E.; Li, P.H.; Wang, Y.C. Recognizing mixture control chart patterns with independent component analysis and support vector machine. In Advances in Neural Networks—ISNN 2010, Proceedings of the 7th International Symposium on Neural Networks, Shanghai, China, 6–9 June 2010; Springer: Berlin/Heidelberg, Germany, 2010; pp. 426–431. [Google Scholar]

- Ghomi, S.F.; Lesany, S.; Koochakzadeh, A. Recognition of unnatural patterns in process control charts through combining two types of neural networks. Appl. Soft Comput. 2011, 11, 5444–5456. [Google Scholar] [CrossRef]

- Lu, C.J.; Shao, Y.E.; Chang, C.L. Applying ica and svm to mixture control chart patterns recognition in a process. In Advances in Neural Networks—ISNN 2011, Proceedings of the 8th International Symposium on Neural Networks, Guilin, China, 29 May–1 June 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 278–287. [Google Scholar]

- Shao, Y.E.; Lin, Y.; Chan, Y.C. Integrated use of ICA and ANN to recognize the mixture control chart patterns in a process. In Advances in Data Mining. Applications and Theoretical Aspects, Proceedings of the 11th Industrial Conference on Data Mining, New York, NY, USA, 30 August–3 September 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 218–227. [Google Scholar]

- Gu, N.; Cao, Z.; Xie, L.; Creighton, D.; Tan, M.; Nahavandi, S. Identification of concurrent control chart patterns with singular spectrum analysis and learning vector quantization. J. Intell. Manuf. 2013, 24, 1241–1252. [Google Scholar] [CrossRef]

- Lesany, S.; Koochakzadeh, A.; Fatemi Ghomi, S. Recognition and classification of single and concurrent unnatural patterns in control charts via neural networks and fitted line of samples. Int. J. Prod. Res. 2014, 52, 1771–1786. [Google Scholar] [CrossRef]

- Lu, C.J.; Shao, Y.E.; Li, C.C. Recognition of concurrent control chart patterns by integrating ICA and SVM. Appl. Math. Inf. Sci. 2014, 8, 681–689. [Google Scholar] [CrossRef]

- Chompu-inwai, R.; Thaiupathump, T. Improved ICA-based mixture control chart patterns recognition using shape related features. In Proceedings of the 2015 IEEE Conference on Control Applications (CCA), Sydney, Australia, 21–23 September 2015; IEEE: Piscataway, NJ, USA; pp. 484–489. [Google Scholar]

- Thaiupathump, T.; Chompu-Inwai, R. Impact of kurtosis on performance of mixture control chart patterns recognition using Independent Component Analysis and neural networks. In Proceedings of the 2015 4th International Conference on Advanced Logistics and Transport (ICALT), Valenciennes, France, 20–22 May 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 94–99. [Google Scholar]

- Yang, W.A.; Zhou, W.; Liao, W.; Guo, Y. Identification and quantification of concurrent control chart patterns using extreme-point symmetric mode decomposition and extreme learning machines. Neurocomputing 2015, 147, 260–270. [Google Scholar] [CrossRef]

- Zhang, M.; Cheng, W. Recognition of mixture control chart pattern using multiclass support vector machine and genetic algorithm based on statistical and shape features. Math. Probl. Eng. 2015, 2015, 382395. [Google Scholar] [CrossRef]

- Zhang, M.; Cheng, W.; Guo, P. Intelligent recognition of mixture control chart pattern based on quadratic feature extraction and SVM with AMPSO. J. Coast. Res. 2015, 73, 304–309. [Google Scholar] [CrossRef]

- Mozafari, A.S.; Aminnayeri, M. Concurrent Control Chart Pattern Recognition Using a Novel Source Separation Method based on Sparse Representation. In Proceedings of the 46th International Conference on Computers & Industrial Engineering 2016 (CIE46), Tianjin, China, 29–31 October 2016. [Google Scholar]

- Shao, Y.E.; Chiu, C.C. Applying emerging soft computing approaches to control chart pattern recognition for an SPC–EPC process. Neurocomputing 2016, 201, 19–28. [Google Scholar] [CrossRef]

- Hong, Z.; Li, Y.; Zeng, Z. Convolutional neural network for control chart patterns recognition. In Proceedings of the 3rd International Conference on Computer Science and Application Engineering, Sanya, China, 22–24 October 2019; pp. 1–9. [Google Scholar]

- Miao, Z.; Yang, M. Control chart pattern recognition based on convolution neural network. In Smart Innovations in Communication and Computational Sciences; Springer: Berlin/Heidelberg, Germany, 2019; pp. 97–104. [Google Scholar]

- Kadakadiyavar, S.; Ramrao, N.; Singh, M.K. Efficient mixture control chart pattern recognition using adaptive RBF neural network. Int. J. Inf. Technol. 2020, 12, 1271–1280. [Google Scholar] [CrossRef]

- Kao, L.J.; Chiu, C.C. Application of integrated recurrent neural network with multivariate adaptive regression splines on SPC-EPC process. J. Manuf. Syst. 2020, 57, 109–118. [Google Scholar] [CrossRef]

- Shao, Y.E.; Hu, Y.T. Using machine learning classifiers to recognize the mixture control chart patterns for a multiple-input multiple-output process. Mathematics 2020, 8, 102. [Google Scholar] [CrossRef]

- Zhang, M.; Yuan, Y.; Wang, R.; Cheng, W. Recognition of mixture control chart patterns based on fusion feature reduction and fireworks algorithm-optimized MSVM. Pattern Anal. Appl. 2020, 23, 15–26. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, M. Control chart recognition based on the parallel model of CNN and LSTM with GA optimization. Expert Syst. Appl. 2021, 185, 115689. [Google Scholar] [CrossRef]

- Cheng, C.S.; Chen, P.W.; Ho, Y. Control Chart Concurrent Pattern Classification Using Multi-Label Convolutional Neural Networks. Appl. Sci. 2022, 12, 787. [Google Scholar] [CrossRef]

- Chang, C.C.; Lin, C.J. LIBSVM: A library for support vector machines. ACM Trans. Intell. Syst. Technol. (TIST) 2011, 2, 1–27. [Google Scholar] [CrossRef]

- Torng, C.C.; Hwang, C.H. Recognition of Concurrent Control Chart Patterns in Autocorrelated Processes Using Support Vector Machine. Proc. Eng. Technol. Innov. 2016, 3, 22–24. [Google Scholar]

- Huberts, L.C.; Schoonhoven, M.; Goedhart, R.; Diko, M.D.; Does, R.J. The performance of control charts for large non-normally distributed datasets. Qual. Reliab. Eng. Int. 2018, 34, 979–996. [Google Scholar] [CrossRef]

- Psarakis, S.; Papaleonida, G. SPC procedures for monitoring autocorrelated processes. Qual. Technol. Quant. Manag. 2007, 4, 501–540. [Google Scholar] [CrossRef]

- Chen, S.; Yu, J. Deep recurrent neural network-based residual control chart for autocorrelated processes. Qual. Reliab. Eng. Int. 2019, 35, 2687–2708. [Google Scholar] [CrossRef]

- Ranaee, V.; Ebrahimzadeh, A. Control chart pattern recognition using a novel hybrid intelligent method. Appl. Soft Comput. 2011, 11, 2676–2686. [Google Scholar] [CrossRef]

- Cheng, H.P.; Cheng, C.S. Control chart pattern recognition using wavelet analysis and neural networks. J. Qual. 2009, 16, 311–321. [Google Scholar]

- Guh, R.S. Integrating artificial intelligence into on-line statistical process control. Qual. Reliab. Eng. Int. 2003, 19, 1–20. [Google Scholar] [CrossRef]

- Du, S.; Lv, J.; Xi, L. An integrated system for on-line intelligent monitoring and identifying process variability and its application. Int. J. Comput. Integr. Manuf. 2010, 23, 529–542. [Google Scholar] [CrossRef]

- Asadi, A.; Farjami, Y. Online mean shift detection in multivariate quality control using boosted decision tree learning. J. Syst. Manag. 2019, 5, 81–106. [Google Scholar]

- Lu, Z.; Wang, M.; Dai, W. A condition monitoring approach for machining process based on control chart pattern recognition with dynamically-sized observation windows. Comput. Ind. Eng. 2020, 142, 106360. [Google Scholar] [CrossRef]

- Albers, W.; Kallenberg, W.C. Empirical non-parametric control charts: Estimation effects and corrections. J. Appl. Stat. 2004, 31, 345–360. [Google Scholar] [CrossRef]

- Yu, J. Gaussian mixture models-based control chart pattern recognition. Int. J. Prod. Res. 2012, 50, 6746–6762. [Google Scholar] [CrossRef]

- Fuqua, D.; Razzaghi, T. A cost-sensitive convolution neural network learning for control chart pattern recognition. Expert Syst. Appl. 2020, 150, 113275. [Google Scholar] [CrossRef]

- Ramaker, H.J.; van Sprang, E.N.; Westerhuis, J.A.; Smilde, A.K. The effect of the size of the training set and number of principal components on the false alarm rate in statistical process monitoring. Chemom. Intell. Lab. Syst. 2004, 73, 181–187. [Google Scholar] [CrossRef]

- Kang, J.H.; Kim, S.B. False alarm classification for multivariate manufacturing processes of thin film transistor–liquid crystal displays. J. Process Control 2015, 35, 21–29. [Google Scholar] [CrossRef]

- Sohaimi, N.A.M.; Masood, I.; Nor, D.M. Bivariate SPC Chart Pattern Recognition Using Modular-Neural Network. J. Phys. Conf. Ser. 2018, 1049, 012096. [Google Scholar]

- Wuest, T.; Weimer, D.; Irgens, C.; Thoben, K.D. Machine learning in manufacturing: Advantages, challenges, and applications. Prod. Manuf. Res. 2016, 4, 23–45. [Google Scholar] [CrossRef]

- Guh, R.S.; Zorriassatine, F.; Tannock, J.; O’Brien, C. On-line control chart pattern detection and discrimination—A neural network approach. Artif. Intell. Eng. 1999, 13, 413–425. [Google Scholar] [CrossRef]

- Gauri, S.K.; Chakraborty, S. A study on the various features for effective control chart pattern recognition. Int. J. Adv. Manuf. Technol. 2007, 34, 385–398. [Google Scholar] [CrossRef]

- Cheng, Z.; Ma, Y. A research about pattern recognition of control chart using probability neural network. In Proceedings of the 2008 ISECS International Colloquium on Computing, Communication, Control, and Management, Guangzhou, China, 3–4 August 2008; IEEE: Piscataway, NJ, USA, 2008; Volume 2, pp. 140–145. [Google Scholar]

- Awadalla, M.H.; Sadek, M.A. Spiking neural network-based control chart pattern recognition. Alex. Eng. J. 2012, 51, 27–35. [Google Scholar] [CrossRef][Green Version]

- Cheng, C.S.; Ho, Y.; Chiu, T.C. End-to-end control chart pattern classification using a 1D convolutional neural network and transfer learning. Processes 2021, 9, 1484. [Google Scholar] [CrossRef]

- Zan, T.; Su, Z.; Liu, Z.; Chen, D.; Wang, M.; Gao, X. Pattern Recognition of Different Window Size Control Charts Based on Convolutional Neural Network and Information Fusion. Symmetry 2020, 12, 1472. [Google Scholar] [CrossRef]

- Khan, S.H.; Hayat, M.; Bennamoun, M.; Sohel, F.A.; Togneri, R. Cost-sensitive learning of deep feature representations from imbalanced data. IEEE Trans. Neural Netw. Learn. Syst. 2017, 29, 3573–3587. [Google Scholar] [PubMed]

- Ünlü, R. Cost-oriented LSTM methods for possible expansion of control charting signals. Comput. Ind. Eng. 2021, 154, 107163. [Google Scholar] [CrossRef]

- Xanthopoulos, P.; Razzaghi, T. A weighted support vector machine method for control chart pattern recognition. Comput. Ind. Eng. 2014, 70, 134–149. [Google Scholar] [CrossRef]

- Apsemidis, A.; Psarakis, S.; Moguerza, J.M. A review of machine learning kernel methods in statistical process monitoring. Comput. Ind. Eng. 2020, 142, 106376. [Google Scholar] [CrossRef]

- Xin-chun, C.; Peng, D.; Nai-qing, Y.; Meng-xue, B. Study on discrete manufacturing quality control technology based on big data and pattern recognition. Math. Probl. Eng. 2021, 2021, 8847094. [Google Scholar] [CrossRef]

- Tran, P.H.; Ahmadi Nadi, A.; Nguyen, T.H.; Tran, K.D.; Tran, K.P. Application of Machine Learning in Statistical Process Control Charts: A Survey and Perspective. In Control Charts and Machine Learning for Anomaly Detection in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2022; pp. 7–42. [Google Scholar]

- Zan, T.; Liu, Z.; Su, Z.; Wang, M.; Gao, X.; Chen, D. Statistical process control with intelligence based on the deep learning model. Appl. Sci. 2020, 10, 308. [Google Scholar] [CrossRef]

- Viharos, Z.J.; Jakab, R. Reinforcement Learning for Statistical Process Control in Manufacturing. Measurement 2021, 182, 109616. [Google Scholar] [CrossRef]

- Chen, X.W.; Lin, X. Big data deep learning: Challenges and perspectives. IEEE Access 2014, 2, 514–525. [Google Scholar] [CrossRef]

- Haghtalab, S.; Xanthopoulos, P.; Madani, K. A robust unsupervised consensus control chart pattern recognition framework. Expert Syst. Appl. 2015, 42, 6767–6776. [Google Scholar] [CrossRef]

- Khormali, A.; Addeh, J. A novel approach for recognition of control chart patterns: Type-2 fuzzy clustering optimized support vector machine. ISA Trans. 2016, 63, 256–264. [Google Scholar] [CrossRef] [PubMed]

- Zaman, M.; Hassan, A. Improved statistical features-based control chart patterns recognition using ANFIS with fuzzy clustering. Neural Comput. Appl. 2019, 31, 5935–5949. [Google Scholar] [CrossRef]

- Golilarz, N.A.; Addeh, A.; Gao, H.; Ali, L.; Roshandeh, A.M.; Munir, H.M.; Khan, R.U. A new automatic method for control chart patterns recognition based on ConvNet and harris hawks meta heuristic optimization algorithm. IEEE Access 2019, 7, 149398–149405. [Google Scholar] [CrossRef]

- De la Torre Gutierrez, H.; Pham, D. Estimation and generation of training patterns for control chart pattern recognition. Comput. Ind. Eng. 2016, 95, 72–82. [Google Scholar] [CrossRef]

- Hassan, A.; Baksh, M.S.N.; Shaharoun, A.M.; Jamaluddin, H. Improved SPC chart pattern recognition using statistical features. Int. J. Prod. Res. 2003, 41, 1587–1603. [Google Scholar] [CrossRef]

- Quintero-Arteaga, C.; Peñabaena-Niebles, R.; Vélez, J.I.; Jubiz-Diaz, M. Statistical design of an adaptive synthetic X control chart for autocorrelated processes. Qual. Reliab. Eng. Int. 2022, 2022, 9629170. [Google Scholar] [CrossRef]

| Author(s) | A | B | C | D | E | F | G | H | I | J | K |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Guh and Tannock [14] | II, III | I | I | III | I | II, V, VII | I | I, II, III | II | I | II |

| Guh and Hsieh [19] | II | I | I | III | I | VII | II | I, II, III | II | II | II |

| Guh and Tannock [20] | II | I | I | III | I | VII | II | I, II, III | II | II | II |

| Al-Assaf [24] | II, III | I | I | II, III | II (e) | II, V, VII | II | II, III | II | II | II |

| Yang and Yang [25] | VI | VIII | I | - | I | II, V, VII | I | I, II, III | II | I | II |

| Chen et al. [21] | I | I | I | II | II (a, e) | VII | I | II, III | II | II | II |

| Wang [26] | II | IX | I | - | I | II, V, VII | II | II | II | II | II |

| Jiang et al. [27] | II, VI | I, V | I | III | I | II, V | II | II | II | II | II |

| Wang et al. [28] | I, VI | II, VIII | I | I | II (b, c) | I, II, IV, V, VII, IX | II | II | II | II | II |

| Guh [29] | III | I | I | III | III | II, V, VI, VII, XVII, | I | I, II, III, XVIII | II | II | II |

| Lu et al. [30] | I | IX | I | I | II (c) | III, VIII, X, XI, XII | II | II | II | II | II |

| Ghomi et al. [31] | IV | I | I | - | I | II, V, VII | I | I, II | II | II | II |

| Lu et al. [22] | I | IX | I | I | II (c) | III, VIII, X, XI, XII | II | II | II | II | II |

| Lu et al. [32] | I | IX | I | I | II (c) | III, VII, IX-XI, | II | II | II | II | II |

| XVI-XIX | |||||||||||

| Shao et al. [33] | I | I | I | I | II (c) | IX, XVI, XVII | II | II | II | II | II |

| Du et al. [23] | I, VI | VIII, IX | I | II | II (e) | II, IV, V, VII | I | II | II | I | II |

| Gu et al. [34] | I | I | I | IV | II (d) | I, II, IV, VII, IX | II | II | I, II | II | II |

| Xie et al. [10] | I | IX | I | IV | II (d) | I, II, IV, VII, IX | II | I, II | II | II | II |

| Lesany et al. [35] | II, VI | I, V | I | III | I | II, IV, V, VII, IX, XIX | II | II | II | II | II |

| Lu et al. [36] | I | IX | I | I | II (c) | I, II, IV, V, VII, IX | II | II | II | II | II |

| Chompu-inwai and | I | I, II | I | I | II (b, c) | I, II, IV, V, VII, IX | II | II | II | II | II |

| Thaiupathump [37] | |||||||||||

| Thaiupathump and | I | I | I | I | II (c) | I, II, IV, V, VII, | II | II | II | II | II |

| Chompu-inwai [38] | IX, XVII, XVIII | ||||||||||

| Yang et al. [39] | I | III | I | III, II | II (j) | I, II, IV, V, VII, IX | I | I, II | II | I | II |

| Zhang and Cheng [40] | IV | IX | I | - | II (a, b) | II, V, VII, XIX | II | II | II | II | II |

| Zhang et al. [41] | IV | IX | I | VIII | II (a, b, f) | II, V, VII, XIX | II | II | II | II | II |

| Mozafari and | I | VI | I | V | II (h) | I, II, IV, V, VII, IX | II | II | II | II | II |

| Aminnayeri [42] | |||||||||||

| Pelegrina et al. [3] | I | IX | I | I, IX | II (a, b, c, k) | III, VIII, XI, XII | II | II | II | II | I, II |

| Shao and Chiu [43] | V | I, III, | III | VI | I, II (i) | I, II, IV, V, VII, IX, XIII, | II | II | II | II | II |

| X, XI | XIV-XVI, XIX-XXI | ||||||||||

| Shao et al. [11] | IV | I, VII, IX | III | VI | I, II (i) | I, II, IV, XIX | II | I, II, III | II | II | II |

| Hong et al. [44] | IV | XII | I | III | I | I, II, IV, V, VII, IX | II | II | II | II | II |

| Lesany et al. [12] | VI | IV, V | I | III | I | II, IV, V, VII, IX, XIX | II | II | II | II | II |

| Miao and Yang [45] | - | XII | I | III | II (a, b) | II, V, VI | II | II | II | II | II |

| Kadakadiyavar et al. [46] | IV | I | I | - | I | II, V, VII, XIX | II | II | II | I | II |

| Kao and Chiu [47] | V | III, X, XII | III | VI | II (i) | I, II, IV, V, VII, IX, XIII, | I | II | II | I | II |

| XIV, XV, XIX, XX, XXI | |||||||||||

| Shao and Hu [48] | IV | I, III, VII, IX | III | VI | I, II (i) | I, II, IV, XIV, XV, XVI, XIX | II | II | II | II | II |

| Zhang et al. [6] | IV | III | I | X | I, II (a, b, g) | II, V, VII, XIX | II | II | II | II | II |

| Zhang et al. [49] | IV | IX | I | VIII | I, II (a, b, g) | II, V, VII, XIX | II | II | II | II | II |

| Chiu and Tsai [7] | I | X | III | IV, VI | II (a, b) | I, II, IV, VII, IX, XIII, | I | I, II | II | II | II |

| XIV, XV, XVI | |||||||||||

| Yu and Zhang [50] | IV | XII | I | III | I, II (a, b) | II, V, VII, XIX | II | I, II | II | II | II |

| Cheng et al. [51] | III | XII | I | III | I | II, V, VI, XX | I | II | I, II | II | II |

| Maged and Xie [8] | IV | XII | I | II, XI | I | II, V, VI | I | II | I, II | I | II |

| Approach | Algorithms | Description | Advantage | Disadvantage |

|---|---|---|---|---|

| Supervised | Support vector machine, | Techniques trained | Models easier to interpret | Many real problems lack |

| learning | artificial neural networks, | from labelled data | thanks to labels that allow | labelled data, including |

| random forest, and others | performance evaluation | monitoring processes | ||

| Unsupervised | Spectral clustering, | Techniques trained | No labelled data required | Models are difficult to in- |

| learning | K-means, hierarchical | from unlabelled data | terpret and are sensitive | |

| clustering, and others | to the selected clustering | |||

| method, i.e., methods are | ||||

| based on different distance | ||||

| or similarity metrics | ||||

| Semi supervised | Transductive support | Techniques trained | Allows the building of models | Highly error-sensitive mo- |

| learning | vector machine, generative | from mixed data | when there are not enough | dels because they label |

| models, and others | (labelled and unlabelled) | labels for a supervised model | unlabelled samples from | |

| labelled samples | ||||

| Deep learning | Convolutional neural network, | Technique used to auto- | Allows the building of models with | High computational requi- |

| long short-term memory neural network, | matically extract complex | high volumes of data [84] | rement, computer memory | |

| auto encoder, and others | features from data; can be | and running time [84] | ||

| supervised or unsupervised |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García, E.; Peñabaena-Niebles, R.; Jubiz-Diaz, M.; Perez-Tafur, A. Concurrent Control Chart Pattern Recognition: A Systematic Review. Mathematics 2022, 10, 934. https://doi.org/10.3390/math10060934

García E, Peñabaena-Niebles R, Jubiz-Diaz M, Perez-Tafur A. Concurrent Control Chart Pattern Recognition: A Systematic Review. Mathematics. 2022; 10(6):934. https://doi.org/10.3390/math10060934

Chicago/Turabian StyleGarcía, Ethel, Rita Peñabaena-Niebles, Maria Jubiz-Diaz, and Angie Perez-Tafur. 2022. "Concurrent Control Chart Pattern Recognition: A Systematic Review" Mathematics 10, no. 6: 934. https://doi.org/10.3390/math10060934

APA StyleGarcía, E., Peñabaena-Niebles, R., Jubiz-Diaz, M., & Perez-Tafur, A. (2022). Concurrent Control Chart Pattern Recognition: A Systematic Review. Mathematics, 10(6), 934. https://doi.org/10.3390/math10060934