1. Introduction

This paper presents the results of a comparative study of motion control methods from computational intelligence, applied to positioning of an object, with known moment of inertia, in the rotational movement in the plane around a central axis. Angular positioning is used among many domains such as mechatronic systems, robotics, and automotive, and on various rotating mechanisms such as solar array drive mechanisms, antenna pointing mechanisms, scientific instruments, motors, and actuators. This paper includes examples of modeling, control, and optimization in order to increase control precision and to reduce the response time. The purpose of this work is the analysis of methods of computational intelligence for positioning based on state feedback fuzzy control, neural predictive control, and neural model reference control compared with the linear control methods such as error feedback control, numerical control, and state feedback control. The significance of this study is that it allows the comparison of the values of the empirical performance criteria obtained for the tested control systems in the case of the position control of an object described by a valid general mathematical model.

In the literature there is an extremely large number of papers that addresses the issue of position control, using various control techniques. The following is a brief overview of recent works to highlight the current state of the art. In [

1], a control method is proposed to regulate the aerial manipulation position in free flight of an under-actuated quadrotor UAV. The control is made in a bilateral teleoperation manner to regulate the aerial manipulator position and the applied force. The control system may be used in hazardous conditions. An application to control the pendubot based on partial linearization and stabilization in the upright position is presented in [

2]. The paper investigates the closed loop system and its zero dynamics by simulation. The paper [

3] evaluates various techniques of modeling, analysis, and control on a simple flexible robotic arm taken as a test model. The load mass position is considered as a time-dependent parameter. A complex model is considered for the flexible arm, and the linearization is made with finite element analysis. A robust controller designed based on H-infinity technique is used. The paper [

4] presents a control solution to maintain an underwater vehicle at a desired static position under environmental disturbances. Non-linear dynamics is considered for the vehicle. The motion control is made based on the sliding mode concept. Two methods for the optimal allocation control module including the least squares method and the quadratic programming method are used. The results show stability and small steady-state error and robustness. Reference [

5] includes a series of 14 research studies that cover different sub-areas in the framework of motion planning and control. Computational intelligence refers to the ability of a system to learn a specific task from data or experimental observation. It is a set of nature-inspired computational methodologies and approaches to address complex real-world problems to which mathematical or traditional modeling can be useless for a few reasons: the processes might be too complex for mathematical reasoning, or it might contain some uncertainties during the process. The methods used are close to the human’s way of reasoning, i.e., it uses inexact and incomplete knowledge, and it is able to produce control actions in an adaptive way. Computational intelligence uses a combination of techniques: fuzzy logic, which allows the computer to understand natural language; and artificial neural networks, allowing the system to learn experimental data functioning such as the human mind. The authors in [

6] conduct a review of some mechatronic applications based on smart motion control technology. Fuzzy logic is widely used in machine control. It has the advantage that the solution to the problem can be cast in terms that human operators can understand, so that their experience can be used in the design of the controller. This makes it easier to mechanize tasks that are already successfully performed by humans. Reference [

7] presents a case study in the automotive industry of an integrated system in the design, measure, analyze, improve, and control cycle, allowing for the representation of expert knowledge. The authors in [

8] present an optimization method for a fuzzy logic controller used for a differential drive wheeled mobile robot. In [

9], a fuzzy logic controller based on an analytic activation function for the defuzzification procedure, with Gaussian shape of input fuzzy sets and a 2 D fuzzy rule base, is applied to the position control of a servo-pneumatic drive. In [

10], a fuzzy logical frame is used to control the angular momentum of left and right wheels of a robot. The solution is able to drive efficiently the robot inside curved paths, avoiding obstacles. In [

11] a complex control method based on a combination of methods—fuzzy control, time delay estimation, deep learning and a non-dominated sorting genetic algorithm—are used at the nonlinear active power train mount system. The authors in [

12] present a comparison of position control of a gyroscopic inverted pendulum using PID, fuzzy logic, and fuzzy PID controllers, and assure stabilization and disturbance rejection.

Alternative approaches to fuzzy logic such as neural networks can perform just as well as fuzzy logic in many cases. Neural networks may be applied for dynamic system identification, modeling, prediction, and control. Neural networks are deep learning computing systems characterized by the ability to learn from examples. Their use enables the behavior of complex systems to be modeled, predicted, and controlled, these tasks being achieved through training, without a priori information about the system’s structure and parameters. The model predictive control is an advanced method of process control that is used to control a process while satisfying a set of constraints. Model predictive controllers rely on dynamic models of process, obtained by system identification. The main advantage of model predictive control is the fact that it allows the current timeslot to be optimized, while keeping future timeslots into account. The authors in [

13] conduct a review of model predictive control systems from an engineering perspective. Model-based predictive control consists of a set of advanced control methods that make use of a process model to predict the future behavior of the control system. The control system solves a constrained optimization problem and determines the control law implicitly. This method allows control of processes which cannot be controlled by conventional feedback control systems. The authors in [

14] present a solution to using a neural network as a model predictive controller of a nonlinear system with constrains. The neural network works as a function approximator, and it is trained to minimize a cost function. This solution assures the construction of reduced-order and decentralized controllers with arbitrary structures. The authors in [

15] show that model predictive control may be used for control of nonlinear processes with uncertain models and for processes where the time constants are large. A deep neural network is used to implement the controller, and as an effect, the computational cost of implementing is reduced. The authors in [

16] applied a predictive algorithm based on multiple neural networks for simulation of dynamics of a ground vehicle and controlling a multi-domain battle space. The simulation was made using MATLAB/Simulink and demonstrated a reduction in wasted energy in variable operating conditions. In [

17], the authors employ statistical machine learning theory to develop a methodological framework of generalization error bounds for recurrent neural networks. The neural models are utilized to predict state evolution in model predictive controllers, under which closed-loop stability is established in a probabilistic manner. In [

18], a simplified vehicle dynamics model for a motion planner is designed based on nonlinear model predictive control. Model reference control creates a closed loop controller which tries to compare the output of the plant with a standard reference response and various parameters of the plant may change in practice. In [

19], a neural network-based model reference control of braking electric vehicles is presented. The model reference controller is capable of meeting the conflicting requirements of intensive and gradual braking scenarios at changing road surfaces. In this study, the neural network controller provides torque gradient control without a tire model, resulting in the return of maximal energy to the hybrid energy storage during braking. The authors in [

20] present a collection of references on the modeling of complex systems using artificial intelligence and computational methods. Neural identification is used in [

21] for an automotive active suspension control application, with vehicle state estimation, based on a virtual sensor. The study uses a trained neural network model to implement a virtual sensor. The process of development consisted of training, validation, and testing using datasets. The training method was the Bayesian search, and root-mean-square error was used as a metric. Spectral analysis was performed and error histograms were reported. The results demonstrate that a neural network-based sensor can estimate vehicle velocity. In [

22], the back propagation neural network is used to predict the maximum Lyapunov exponent under different parameters for robotic arms, and the study demonstrates that with this method, the robotic arm system can be identified more efficiently. The authors in [

23] address the control of the position of a magnetic levitation ball, proposing a deep neural network feedforward compensation controller. The controller has in its structure a neural network identifier, a neural network feedforward compensator, and a PID controller. The inverse model of the magnetic levitation ball is used by the neural identifier, trained online. The position control is realized by the feedforward compensator. The authors in [

24] present an application of a machine learning algorithm such as artificial networks in the control of a non-linear liquid level system to cover a wider operating range of the plant. The structure of the neural control is designed with minimization of the root-mean-square error and experimental validation. The authors in [

25] present a solution based on artificial intelligence techniques developed for real time control of a robotic arm using a neural network-based inverse kinematics solution. The obtained results were compared with the PI control characteristics. The authors in [

26] present a model reference controller approach for robot arm tracking using neural networks. The control system uses a neural network as a reference model, trained to follow the desired reference trajectory and a neural network controller, which provides the desired torque. The simulated controller tracks a desired trajectory with least tracking error and minimum control input. The authors in [

27] present a model-free predictive control solution for power electronic converters. The control structure contains a recurrent neural network used as a model, trained with particle swarm optimization. The paper demonstrates that the solution is more robust than a conventional model predictive control system. The paper [

28] presents a solution for position tracking of mobile manipulators based on two adaptive neural PD controllers. The controllers are trained using a Kalman filter, in order to obtain a faster learning speed. The application is compared with the conventional PID controller.The authors in [

29] present a control solution for Gantry robots based on a model reference adaptive controller and a fuzzy neural network as a motion compensator. The reference model is developed by reducing the tracking errors for a single axis, and the fuzzy neural compensator assures error compensations between dual servo-motors. The method efficiency is demonstrated by simulation. The authors in [

30] present a control structure of a multi-input multi-output temperature control system based on neural model reference control. The paper developed a multi-input multi-output version of a neural model reference controller. The obtained control system improves the transient response of the system and maintains a constant temperature. Simulation is made using MATLAB/Simulink. Some new and important developments in the search for analytical solitary wave solutions for PDE are presented in [

31,

32,

33,

34]. The results of this manuscript may well complement the existing literature.

The advantages of neural predictive control are as follows: great capacity in predictive models; appealing attributes of non-linear identification and control; suitability for non-mathematical and complex models; ability to manage an abundant number of data and input variables; and trustworthy prediction. In addition, the disadvantages are that the neural network needs to be trained; it takes a long time to process large neural networks; a lot of time is expended for online training; and quality predictions need large amounts of data. Analyzing the literature, it can be seen that there are numerous papers that present studies with applications of fuzzy logic, neural predictive controllers, and neural model reference controllers in motion control problems. However, each of these studies, papers, and examples presents only various particular cases. In the literature there are no comparative studies of the three chosen methods applied to a specific case, which would explicitly show a comparison of these methods. For this reason, the idea of a comparative study of several methods on a theoretical case often used in practice is necessary. The paper covers precisely this missing comparison of three methods of computational intelligence, in a particular case, on a process model often found in theory and practice—positioning of a body in a rotational motion. The paper compares these methods with each other but also compares them with classical linear adjustment solutions, such as error feedback control, digital control, and state feedback control. Some controversial and diverging hypotheses are considered. Conventional position control is carried out using as execution elements electric machines driven by cascade control systems with internal current control loops, over which overlap a speed control loop and an external position control loop. This is the natural means of control. The current and speed control loops must respond as quickly as possible. In addition, the control of the position must be done asymptotically and aperiodically. In this paper, the angular positioning of a heavy weight object in rotational movement is taken into consideration. The inertia of the actuator is not taken in consideration, because it has a very small time constant compared to the moment of inertia of the moving object. Fuzzy logic brings human reasoning into controller design, and neural networks bring learning and training.

The paper presents, in

Section 2, the information related to linear and digital position control, the mathematical model of the positioning process, the motion process model and its limitations, the linear control system by error feedback, the digital control system with limitation, and the state feedback control system, their design, transient characteristics, and performance criteria as a base for comparison. The third section presents the computational intelligence methods used for position control: state feedback fuzzy control, neural predictive control, and neural model reference control. The fuzzy variables, as state variables, were chosen as were their membership functions. A set of 27 fuzzy reasoning control rules was developed. The min–max inference method was used, and defuzzification was based on center of gravity. The structures based on neural network model reference control and neural model reference control are presented with their design. The chosen neural prediction controller was the basic model, in which the process model is implemented with the help of a feedforward neural network, and the optimization calculation is conventional. A neural model of the process was developed based on neural identification of the motion model, testing, and validation. The neural controller was also trained. The methods were modeled and simulated in MATLAB/Simulink. The results obtained with these three methods are presented in

Section 4. The characteristics obtained with the linear control methods are presented in the Appendix. The characteristics obtained by simulations are discussed, compared, and analyzed in

Section 5. The analyzed methods ensured good performance criteria: zero control error in steady-state, reduced response time and zero overshoot, and asymptotic and aperiodic behavior. The performance criteria differences between the control methods were small.

The work’s main contributions and novelty are:

- -

Comparative analysis of computational intelligence control methods, namely fuzzy control, neural prediction control, and neural model reference control in terms of performance criteria of control, in the case of adjusting the position of a body in rotation movement around a central axis, in variable angular positions, and using as a comparative base three linear control structures, namely error feedback control, digital control, and state feedback control.

- -

The chosen control structures were modeled and simulated in MATLAB/Simulink.

- -

For each chosen control method, the structure of the control system, the sizing mode, the regulator parameters, the training parameters, the testing and validation of the neural networks, the characteristics of transient and stationary regime, and the values of the regulation performance criteria are presented.

- -

This paper demonstrates that for all the analyzed control methods, good values of the regulation performance criteria can be obtained—low response time, zero overshoot, aperiodic and asymptotic variation of the position, and zero error in the steady-state.

- -

Analyzing the transient regime characteristics resulting from the six studied control methods, it can be said that the differences between the efficiency criteria of the control structures based on computational intelligence method and linear methods are small.

- -

This paper demonstrates that if the motion process has a linear model, the values of the performance criteria of the regulation have close values, and good quality of the regulation is ensured. However, if the motion process is nonlinear, with the help of fuzzy and neural control methods, better values of the control performance criteria can be obtained, ensuring robustness to the identification of the parameters and to the action of the disturbing load torque.

2. Preliminaries

2.1. Motion Equations

This work considers the adjustment of position θ of the material point with the moment of inertia

J in the rotational motion in a plane around an axis with angular velocity ω. The rotational movement takes place in the presence of friction. The equations of motion of the material point are:

where

M is mechanical torque and

kf is coefficient of friction.

A speed sensor is used, considered as a first-order delay element with a time constant

TTω:

where ω

m is the measured speed, and θ

m is the measured position. The position is measured by incrementing the measured speed.

2.2. Variable Limitations

The values of the parameters considered are: J = 450 kg·m2, kf = 120 kg·m2/s, and TTω = 0.12 s.

In the dimensioning of the control system, the limitations imposed by the actuator must be taken into account, namely the maximum power

Pm and the maximum torque

Mm that it can develop in a permanent working regime. The maximum rotational speed ω

m, which cannot be exceeded by the moving body, must also be taken into account to ensure safe operation. These limitations are introduced in the structure of control system. It is considered that the rotation of the body can take place in both directions of rotation. The maximum limit of the position it can reach is θ

m, in one direction or another.

In this case, the following maximum values were chosen: Mm = 1000 Nm, ωm = 0.3 rad/s, and θm = 180°.

Below are analyzed some position control structures based on linear control systems taken as reference models for comparing the control efficiency [

35]: linear control with error feedback; digital control; and state feedback control.

2.3. Linear Control System

A closed-loop, cascading position control system was selected as the reference control system. In this system, the speed in the inner loop and the position in the outer loop are adjusted. This mode of adjustment is the natural one. The internal speed control loop must respond faster. The position control loop must have an asymptotic aperiodic behavior. It is considered that the process has a high mechanical time constant

J/

kf and a low time constant

TTω of the sensor, and its model is approximated with a transfer function:

Taking into account this model, the speed controller is dimensioned with the symmetric criterion in Kessler’s variant [

36], which recommends a PI speed controller:

where

This design ensures a speed overshot σ1ω% = 43.5%.

The block diagram of the speed control system is shown in

Figure 1.

Where the speed ω is denoted with w, w* is the speed reference, ew is the speed error, M is the mechanical torque, and wm is the measured speed. The control system is analyzed with a unitary step signal applied at its reference input w* = 1 rad/s.

The response at the step signal applied at the input of the speed control system is presented in

Appendix A.

Since the controlled process has a purely integrative character, a position regulator of the proportional type was chosen with gain coefficient

KRθ = 0.8. The block diagram of the position linear control system is shown in

Figure 2.

The position θ is denoted with p, θ* is the position reference, θm is the measured position, and eθ is the position error.

The frequency characteristics of the position open loop are presented in

Appendix A. The position controller is designed to ensure a high phase reserve of 80°. The response at the step signal applied at the input of the speed control system is presented in

Appendix A.

The linear position control system, based on error feedback, assures good efficiency criteria: a short response time of position for a high moment of inertia; zero error in the steady state; and an asymptotic, aperiodic behavior of position at the step input signal.

2.4. Digital Control System

Due to the fact that the implementation of the regulators is done digitally, an example of numerical implementation of the conventional position control system is presented below. The speed controller is approximated with the trapezoid method:

and its function in

z results:

The sampling period h is chosen to be much shorter than the shortest time constant h = 0.01 s << TTω = 0.1 s.

The numerical algorithm for implementing the speed controller is:

where

Mk* is the torque reference at moment

tk =

k·h,

eωk is the speed error at moment

tk, and

a1 = 1877 and

a2 = −1873 are two coefficients.

The speed controller may be implemented digitally, using a simple microcontroller, with two multiplication and two summation operations and memorizing reference torque and error values at times tk and tk+1.

The block diagram of the numerical speed control system is shown in

Figure 3.

The characteristics of position and speed, in response to the step signal, for the discrete time system, are identical to those of the system in continuous time. This fact demonstrates that the dimensioning of the speed controller in discrete time, by approximation with the trapezoid method, starting from the values of the coefficients of the controller in continuous time, was correct. This control system assures the same values for the efficiency criteria as the control system with error feedback.

Closer to reality modeling of the control system includes speed, torque, and position limitations, as seen in

Figure 4.

In the control structure from

Figure 4, an anti-wind-up circuit has been introduced, in parallel with the speed controller, which also ensures the limitation of the prescribed torque. A prescribed speed limit and position limit have also been introduced.

The step responses of the variables of the digital position control system with limitations are shown in

Appendix A. It is observed that the position response time is short, as in the case of the linear control system, with zero error in the steady state and asymptotic, aperiodic behavior. The sampling period and the controller coefficients were well chosen.

Analyzing these characteristics, the following observations arise: The speed reference is limited at 0.3 rad/s, which leads to a decrease in control torque at the start. A lower torque results in a longer response time. It is observed that the position response time is still short compared to the high moment of inertia of an object in motion. Regarding the speed characteristic, it is observed that the speed is not limited at the start, but it is limited in a permanent functioning regime. So, the object rotates rapidly with a limitation in command power. Simulation of the linear control system was made considering infinite command power. In reality, the command has finite power, which leads to a longer response time. It is observed that the position response time is short, as in the case of the linear control system, with zero error in the steady state and asymptotic, aperiodic behavior. The sampling period and the controller coefficients were well chosen.

2.5. State Feedback Control System

As a preliminary treatment for fuzzy control, the state feedback control was analyzed [

35]. The structure of the position state feedback control system is presented in

Figure 5.

The state equations of systems are:

where the system matrices are:

and the command low is:

It can be seen that a third state variable

eθi was introduced at the output of an integrator block on the path of the position error. This leads to zero steady-state error:

The design of the state feedback command low is presented below. First, the controllability matrix is calculated:

The state feedback vector

f is determined with relation

where

mc3 is the third line of controllability matrix.

The poles of the closed loop control system are imposed such that the control efficiency criteria are to be ensured: overshoot

σ1% = 0 and a small response time. The characteristic polynomial μ(

s) is calculated, and

The values obtained for the feedback coefficients are, with approximation: KM = 800, Kθ = 15, Kθp = 10 and Kω = 5.

This design assures the pole-zero map presented in

Appendix A. The chosen poles assure an asymptotic aperiodic behavior of position at step input.

The step signal responses of the variables of state feedback control system are shown in

Appendix A.

It can be seen that the torque and speed are limited. The response time is shorter than in the case of the error feedback control system. So, the object rotates rapidly with a limitation in command power. It is observed that the position response time has zero error in the steady state and asymptotic, aperiodic behavior.

The linear control systems, namely error feedback control, digital control with limitation, linear state feedback control, and design with classical methods, are analyzed as a base of comparison. Their transient responses at the step input signal are presented, analyzed, and compared. The control systems analyzed have good control performance criteria: small response time compared to the high moment of inertia, and zero overshoot at an asymptotic aperiodic behavior. The differences between the efficiency criteria of the linear control structures analyzed are very small.

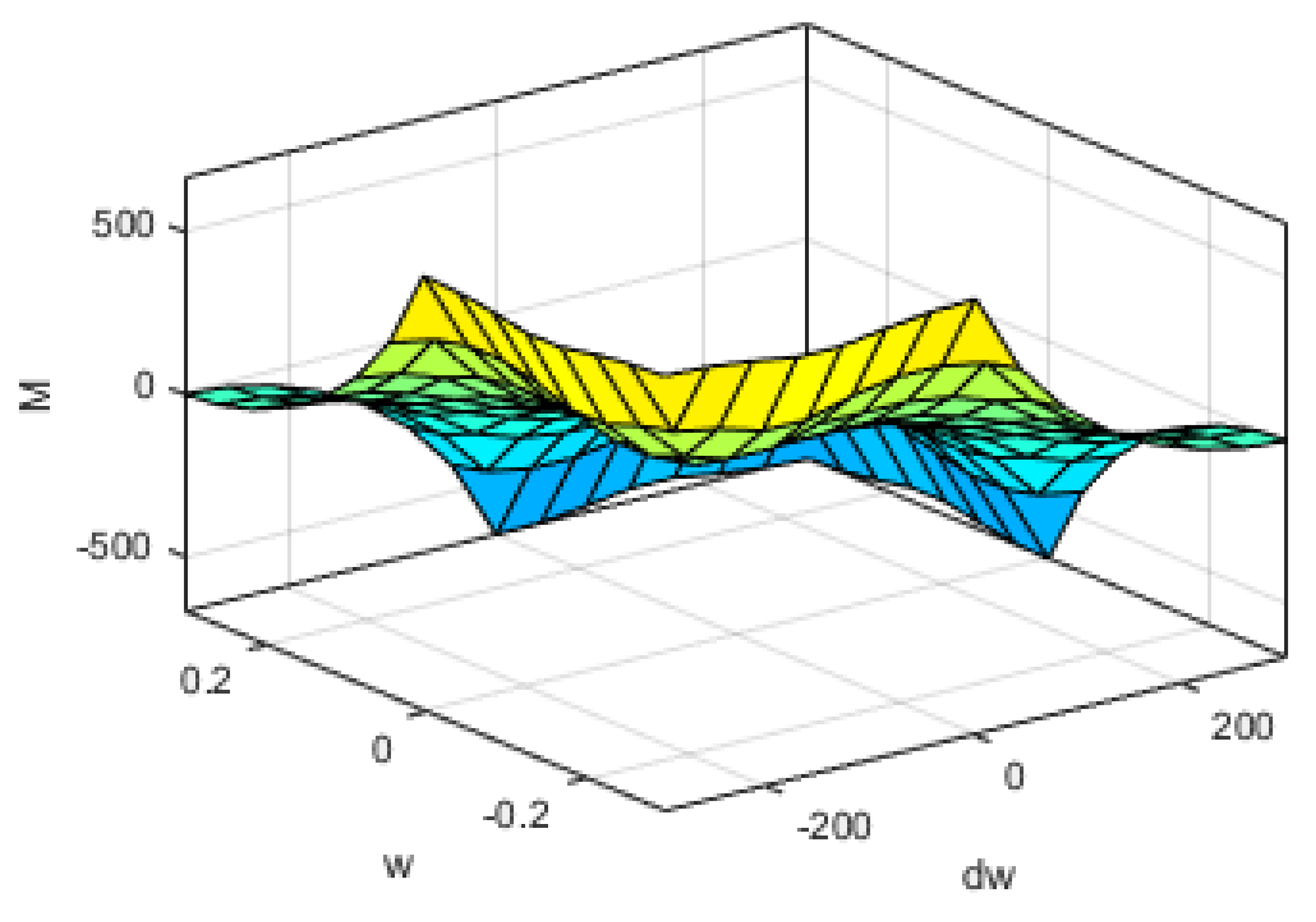

5. Discussion

The fuzzy control system is thought of as a state feedback control system, taking into account three state variables as the control variables: speed error, acceleration and rotational speed, and mechanical torque. Mamdani’s fuzzy regulator structure, triangle, and trapezoid membership functions; maximum–minimum inference method; and defuzzification method with center of gravity were chosen. This structure ensures the strongest nonlinear character of the regulator. A base with 27 rules was developed. The transient response characteristics in response to the step signal applied to the input have an asymptotic aperiodic character. The position rise time is slightly shorter than in the case of linear control. The position overshoot is zero. The control system is input–output stable. Other types of membership functions and other inference methods can be chosen as research perspectives.

The neural predictive control structure resulted after several repeated tests using various combinations of parameters and various sets of data input–output of the process for training the neural network model to obtain a small error in validating the neural model. The neural network parameters model resulted after several successive trainings, aiming to minimize the training mean squared error.

The neural model reference control structure presented resulted also after several repeated tests, using various combinations of parameters, and various sets of data input–output of the process for training the neural network model and for training the neural controller, aiming to minimize the training mean squared errors and to obtain small errors in validating the neural model and neural controller.

The response of the neural control systems to a set of random step signals applied to the input was determined. The transient response characteristics in response to the step signal applied to the input have an asymptotic aperiodic character. The position rise time is slightly shorter than in the case of linear control. The position overshoot is zero.

As research perspectives, for both neural control structures, other training parameters of the neural networks, other structures, a different number of neurons per layer, and other activation functions can be chosen in order to minimize the training errors. At each training, however, other values of weights and polarizations will be obtained.

In this study the positive aspects of deep learning include the possibility to obtain precise models of the controlled process and of the neural regulator, and that the use of these methods in regulation problems ensures obtaining good values of the performance indicators of regulation: reduced response time, zero error in stationary regime, asymptotic and aperiodic variation of the position, robustness to the identification of the process parameters and to the action of the disturbing load torque, and the possibility of use in the control of complex processes, given that with models that cannot be described mathematically, the neural networks may be developed using online or offline training. Negative issues of using deep learning can be listed: the need for a large number of training sets, the long duration of training, and the fact that the results obtained in one training are not repetitive and are not found in another training.

It is observed that for all three computational intelligence control methods, the control torque takes extreme values, both positive and negative, for printing a maximum positive acceleration and a maximum braking acceleration. The command is made in two extremely dynamic stages, specific to a dead-beat command. In permanent mode, the torque has a value of zero. In addition, the speed takes extreme values, both positive and negative, as a result of maximum acceleration. The command is made in two extremely dynamic stages, specific to a dead-beat command. In permanent mode, the speed has a value of zero. The position varies asymptotically and aperiodically, reaching permanently the prescribed value after a response time of about 6 s. Analyzing the transient regime characteristics resulting from the six studied control methods, it can be said that the differences between the efficiency criteria of the control structures based on the computational intelligence method and linear methods are small. The paper demonstrates that if the motion process has a linear model, the values of the performance criteria of the regulation have close values, and good quality of the regulation is ensured. However, if the motion process is nonlinear, with the help of fuzzy and neural control methods, better values of the control performance criteria can be obtained compared to linear methods, ensuring robustness to the identification of the parameters and to the action of the disturbing load torque.