Validating Measurement Structure of Checklist for Evaluating Ergonomics Risks in Heavy Mobile Machinery Cabs

Abstract

:1. Introduction

2. Background

3. Materials and Methods

4. Results

4.1. Descriptive Statistics

4.2. Reliability and Exploratory Factor Analysis

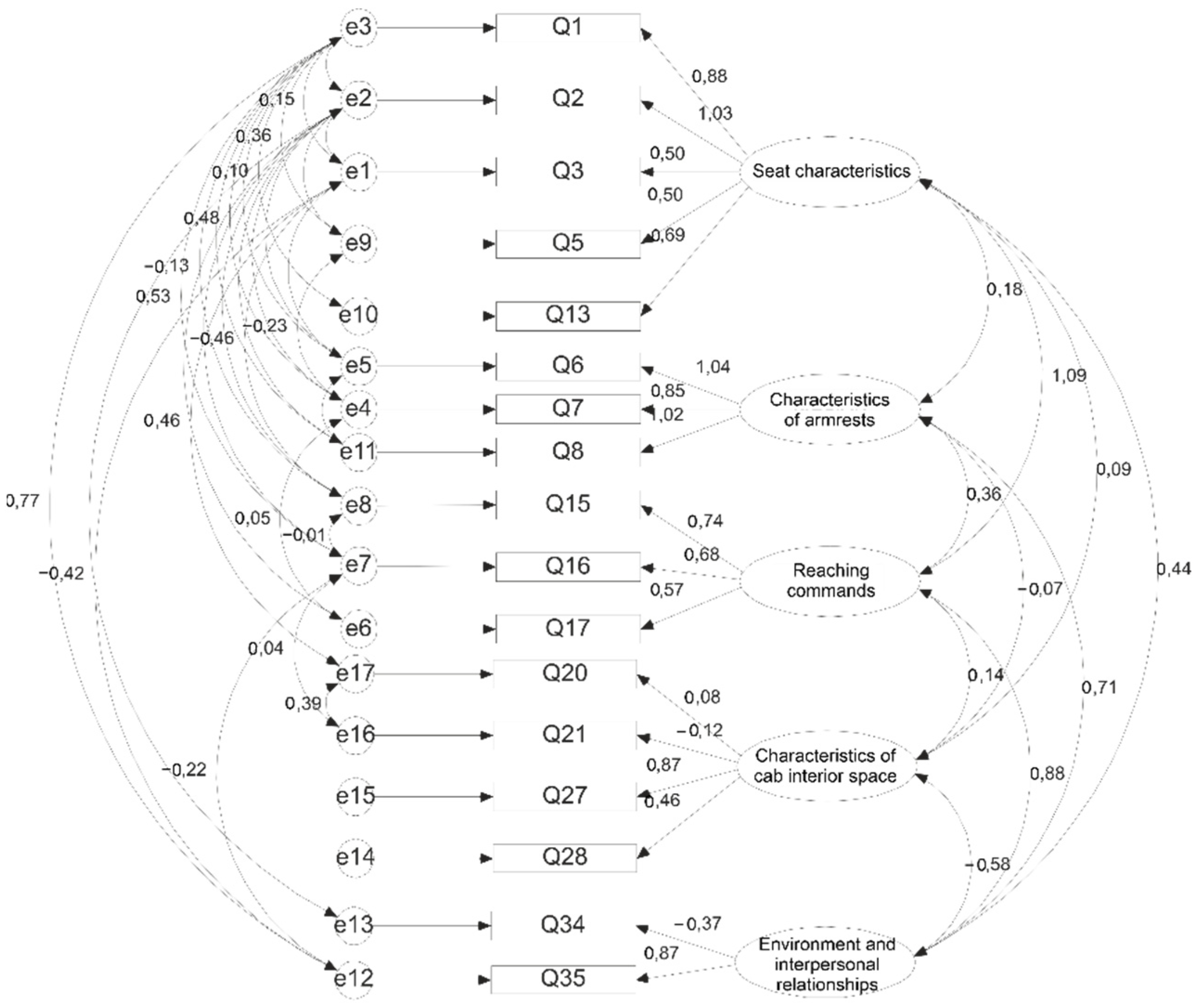

4.3. Confirmatory Factor Analysis

5. Discussion

6. Conclusions

- Designers should put special attention to 17 characteristics (the seat’s vertical and horizontal adjustability, the seat height, the possibility that the seat can be tilted back, and its lumbar support; armrests should exist and should be adjustable and put to an appropriate height; the location of the controls or levers should be adjustable, and should be easily reached and moved; the cab interior space should be large enough and enable good visibility from the cab in all directions, while both the entrance and exit into the cab need to be carefully solved; working conditions and especially exhaust gases and dust are important in cab design to prevent the operators’ absence from work). These are grouped as seat characteristics, characteristics of armrests, reaching commands, characteristics of cab interior space, and environmental factors.

- In the current examined designs, whole-body vibration issues and controls according to the model obtained seem well solved.

- Special attention should be drawn to the horizontal adjustment of the seat, armrests are a must, and they should be put at the appropriate height.

- Since all groups of questions are positively correlated (which means that improvements in one area lead to improvements in another), besides the characteristics of armrests and environment and interpersonal relationships vs. cab interior space, special attention should be paid to the design of armrests and environment and interpersonal relationships.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- Age of the operator

- Operator height (cm)

- Operator weight (kg)

- Years of work experience

- Machine-operated type and producer

- Age of the machine operated (years)

| 1. Is the seat height adjustable? | 1 | 2 | 3 | 4 | 5 |

| 2. Can the seat be adjusted horizontally? | 1 | 2 | 3 | 4 | 5 |

| 3. Is the seat set at the appropriate height? | 1 | 2 | 3 | 4 | 5 |

| 4. Does the seat have back support? | 1 | 2 | 3 | 4 | 5 |

| 5. Does the seat have lumbar support? | 1 | 2 | 3 | 4 | 5 |

| 6. Are there armrests? | 1 | 2 | 3 | 4 | 5 |

| 7. Are the armrests adjustable? | 1 | 2 | 3 | 4 | 5 |

| 8. Are the armrests set at the appropriate height? | 1 | 2 | 3 | 4 | 5 |

| 9. Do you feel vibrations over the seat? | 1 | 2 | 3 | 4 | 5 |

| 10. Do you feel vibrations over the floor? | 1 | 2 | 3 | 4 | 5 |

| 11. Do you feel the vibrations through the controls? | 1 | 2 | 3 | 4 | 5 |

| 12. Is the seat firmly attached to the cab floor? | 1 | 2 | 3 | 4 | 5 |

| 13. Can the seat be tilted back? | 1 | 2 | 3 | 4 | 5 |

| 14. Can the seat rotate? | 1 | 2 | 3 | 4 | 5 |

| 15. Can the location of the controls or levers be adjusted? | 1 | 2 | 3 | 4 | 5 |

| 16. Can you easily reach the controls or levers? | 1 | 2 | 3 | 4 | 5 |

| 17. Can you easily move the controls or levers? | 1 | 2 | 3 | 4 | 5 |

| 18. Can you easily reach the pedal? | 1 | 2 | 3 | 4 | 5 |

| 19. Can you use the pedal easily? | 1 | 2 | 3 | 4 | 5 |

| 20.Is the cabin large/spacious enough for you? | 1 | 2 | 3 | 4 | 5 |

| 21. Do you have enough visibility in all directions? | 1 | 2 | 3 | 4 | 5 |

| 22. Is your view of ongoing operation obstructed by obstacles? | 1 | 2 | 3 | 4 | 5 |

| 23. Do you hear noise in the cabin? | 1 | 2 | 3 | 4 | 5 |

| 24. Can you control the temperature in the cabin? | 1 | 2 | 3 | 4 | 5 |

| 25. Does the cabin equipment have sills? | 1 | 2 | 3 | 4 | 5 |

| 26. Does the equipment have handrails? | 1 | 2 | 3 | 4 | 5 |

| 27. Can you easily open/close the cabin door? | 1 | 2 | 3 | 4 | 5 |

| 28. Can you easily get in/out of the cab? | 1 | 2 | 3 | 4 | 5 |

| 29. Do you have the proper equipment to enter the cabin? | 1 | 2 | 3 | 4 | 5 |

| 30. Do you have the proper equipment to get out of the cabin? | 1 | 2 | 3 | 4 | 5 |

| 31. Do you have good visibility and a general view of the work area? | 1 | 2 | 3 | 4 | 5 |

| 32. Are the cabin windows without distraction? | 1 | 2 | 3 | 4 | 5 |

| 33. Is there a device that allows better visibility of the working field? | 1 | 2 | 3 | 4 | 5 |

| 34. Due to poor working conditions, I am often absent from work (sick leaves). | 1 | 2 | 3 | 4 | 5 |

| 35. Do exhaust gases and dust bother you? | 1 | 2 | 3 | 4 | 5 |

| 36. Do you mind pollution that is part of working conditions? | 1 | 2 | 3 | 4 | 5 |

| 37. The atmosphere of cooperation and togetherness prevails among the operators. | 1 | 2 | 3 | 4 | 5 |

| 38. Managers motivate and reward us. | 1 | 2 | 3 | 4 | 5 |

| 39. Machine failures are very often caused by human and organizational factors. | 1 | 2 | 3 | 4 | 5 |

References

- McCann, M. Heavy equipment and truck-related deaths on excavation work sites. J. Saf. Res. 2006, 37, 511–517. [Google Scholar] [CrossRef] [PubMed]

- Patterson, J.M.; Shappell, S.A. Operator error and system deficiencies: Analysis of 508 mining incidents and accidents from Queensland, Australia using HFACS. Accid. Anal. Prev. 2010, 42, 1379–1385. [Google Scholar] [CrossRef] [PubMed]

- Hinze, J.W.; Teizer, J. Visibility-related fatalities related to construction equipment. Saf. Sci. 2011, 49, 709–718. [Google Scholar] [CrossRef]

- Shao, B.; Hu, Z.; Liu, Q.; Chen, S.; He, W. Fatal accident patterns of building construction activities in China. Saf. Sci. 2018, 111, 253–263. [Google Scholar] [CrossRef]

- Spasojević Brkić, V.K.; Klarin, M.M.; Brkić, A.D. Ergonomic design of crane cabin interior: The path to improved safety. Saf. Sci. 2015, 73, 43–51. [Google Scholar] [CrossRef]

- Zunjic, A.; Brkic, V.S.; Klarin, M.; Brkic, A.; Krstic, D. Anthropometric assessment of crane cabins and recommendations for design: A case study. Work 2015, 52, 185–194. [Google Scholar] [CrossRef]

- Krishna, O.B.; Maiti, J.; Ray, P.K.; Mandal, S. Assessment of Risk of Musculoskeletal Disorders among Crane Operators in a Steel Plant: A Data Mining-Based Analysis. Hum. Factors Ergon. Manuf. Serv. Ind. 2014, 25, 559–572. [Google Scholar] [CrossRef]

- Burdorf, A.; Zondervan, H. An epidemiological study of low-back pain in crane operators. Ergonomics 1990, 33, 981–987. [Google Scholar] [CrossRef]

- Bovenzi, M.; Pinto, I.; Stacchini, N. Low back pain in port machinery operators. J. Sound Vib. 2002, 253, 3–20. [Google Scholar] [CrossRef]

- Kittusamy, N.K. A Checklist for Evaluating Cab Design of Construction Equipment. Appl. Occup. Environ. Hyg. 2003, 18, 721–723. [Google Scholar] [CrossRef]

- Jorgensen, M.J.; Kittusamy, N.K.; Aedla, P.B. Repeatability of a Checklist for Evaluating Cab Design Characteristics of Heavy Mobile Equipment. J. Occup. Environ. Hyg. 2007, 4, 913–922. [Google Scholar] [CrossRef]

- Kurtz, L.A.; Vi, P.; Verma, D.K. Case Study: Occupational Exposures to Hand-Arm Vibration, Whole-Body Vibration, and Noise Among Crane Operators in Construction: A Pilot Study. J. Occup. Environ. Hyg. 2012, 9, D117–D122. [Google Scholar] [CrossRef] [PubMed]

- Lutz, E.A.; Reed, R.J.; Lee, V.S.; Burgess, J.L. Occupational Exposures to Emissions from Combustion of Diesel and Alternative Fuels in Underground Mining—A Simulated Pilot Study. J. Occup. Environ. Hyg. 2015, 12, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Kushwaha, D.K.; Kane, P.V. Ergonomic assessment and workstation design of shipping crane cabin in steel industry. Int. J. Ind. Ergon. 2016, 52, 29–39. [Google Scholar] [CrossRef]

- Dondur, N.; Spasojević-Brkić, V.; Brkić, A. Crane Cabins with Integrated Visual Systems fot the Detection and Interpretation of Environment–Economic Appaisal. J. Appl. Eng. Sci. 2012, 10. Available online: https://aseestant.ceon.rs/index.php/jaes/article/view/2516 (accessed on 18 February 2022). [CrossRef] [Green Version]

- Fang, Y.; Chen, J.; Cho, Y.K.; Kim, K.; Zhang, S.; Perez, E. Vision-based load sway monitoring to improve crane safety in blind lifts. J. Struct. Integr. Maint. 2018, 3, 233–242. [Google Scholar] [CrossRef]

- Hoffmann, E.R.; Chan, A.H. Review of compatibility and selection of multiple lever controls used in heavy machinery. Int. J. Ind. Ergon. 2018, 65, 93–102. [Google Scholar] [CrossRef]

- Jeripotula, S.K.K.; Mangalpady, A.; Mandela, G.R.R. Assessment of Exposure to Whole-Body Vibration of Dozer Operators Based on Postural Variability. Mining Met. Explor. 2020, 37, 813–820. [Google Scholar] [CrossRef]

- Forde, M.S.; Punnett, L.; Wegman, D.H. Pathomechanisms of work-related musculoskeletal disorders: Conceptual issues. Ergonomics 2002, 45, 619–630. [Google Scholar] [CrossRef]

- Marras, W.S. The Complex Spine: The Multidimensional System of Causal Pathways for Low-Back Disorders. Hum Factors 2012, 54, 881–889. [Google Scholar] [CrossRef]

- Brkić, V.S.; Veljković, Z.; Brkić, A. Crane Cabins Development-Are there Innovations Needed? E3S Web Conf. 2019, 95, 01006. [Google Scholar] [CrossRef]

- Spasojević-Brkić, V.K.; Milazzo, M.F.; Brkić, A.; Maneski, T. Emerging risks in smart process industry cranes survey: SAF€RA research project SPRINCE. Serb. J. Manag. 2015, 10, 247–254. [Google Scholar] [CrossRef] [Green Version]

- Spasojevic Brkic, V.; Dondur, N.; Brkic, A.; Perisic, M. Economic Implications of Innovative Visual Guidance System for Crane Cabins. In Advances in Human Factors and Systems Interaction; Nunes, I.L., Ed.; Springer International Publishing: Cham, The Netherlands, 2020; pp. 133–139. [Google Scholar]

- Cheberiachko, S.; Cheberiachko, Y.; Sotskov, V.; Tytov, O. National Technical University Dnipro Polytechnic Analysis of the factors influencing the level of professional health and the biological age of miners during underground mining of coal seams. Min. Miner. Depos. 2018, 12, 87–96. [Google Scholar] [CrossRef] [Green Version]

- Virtanen, K.; Mansikka, H.; Kontio, H.; Harris, D. Weight watchers: NASA-TLX weights revisited. Theor. Issues Ergon. Sci. 2022, 23, 725–748. [Google Scholar] [CrossRef]

- Munro, D.M.; Govers, M.E.; Oliver, M.L. Physical demands of overhead crane operation. Int. J. Ind. Ergon. 2021, 86, 103200. [Google Scholar] [CrossRef]

- Kobzev, K.O.; Shamshura, S.A.; Chukarin, A.N.; Buryanov, A.I.; Kasyanov, V.E. Substantiation of the parameters of vibration systems in the cab of the gantry crane at the workplace of crane operators. MATEC Web Conf. 2018, 226, 01023. [Google Scholar] [CrossRef] [Green Version]

- Spasojević-Brkić, V.K.; Veljković, Z.; Brkić, A. Crane Cabins′ Safety and Ergonomics Characteristics Evaluation Based on Data Collected in Sweden Port. J. Appl. Eng. Sci. 2015, 13. Available online: https://aseestant.ceon.rs/index.php/jaes/article/view/9564 (accessed on 18 February 2022).

- Mandal, B.B.D.; Manwar, V.D. Prevalence of musculoskeletal disorders among heavy earth moving machinery operators exposed to whole-body vibration in opencast mininglence of musculoskeletal disorders among heavy earth moving machinery operators exposed to whole-body vibration in opencast mining. Int. J. Commun. Med. Public Health 2017, 4, 1566–1572. [Google Scholar]

- Charles, L.E.; Ma, C.C.; Burchfiel, C.M.; Dong, R.G. Vibration and Ergonomic Exposures Associated With Musculoskeletal Disorders of the Shoulder and Neck. Saf. Health. Work 2017, 9, 125–132. [Google Scholar] [CrossRef]

- Eger, T.; Stevenson, J.; Callaghan, J.; Grenier, S.; Vibration Research Group. Predictions of health risks associated with the operation of load-haul-dump mining vehicles: Part 2—Evaluation of operator driving postures and associated postural loading. Int. J. Ind. Ergon. 2007, 38, 801–815. [Google Scholar] [CrossRef]

- Kittusamy, N.K.; Buchholz, B. Assessment of Ergonomic Exposures among Operators of Construction Equipment. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2000, 44, 173–176. [Google Scholar] [CrossRef]

- Ray, P.K.; Tewari, V. Ergonomic design of crane cabins: A case study from a steel plant in India. Work 2012, 41, 5972–5976. [Google Scholar] [CrossRef] [PubMed]

- Finnes, A.; Enebrink, P.; Ghaderi, A.; Dahl, J.; Nager, A.; Öst, L.-G. Psychological treatments for return to work in individuals on sickness absence due to common mental disorders or musculoskeletal disorders: A systematic review and meta-analysis of randomized-controlled trials. Int. Arch. Occup. Environ. Health 2018, 92, 273–293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kuijt-Evers, L.; Krause, F.; Vink, P. Aspects to improve cabin comfort of wheel loaders and excavators according to operators. Appl. Ergon. 2003, 34, 265–271. [Google Scholar] [CrossRef] [PubMed]

- Carayon, P.; Smith, M.J.; Haims, M.C. Work Organization, Job Stress, and Work-Related Musculoskeletal Disorders. Hum. Factors 1999, 41, 644–663. [Google Scholar] [CrossRef] [PubMed]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson Education Limited: Harlow, UK, 2014. [Google Scholar]

- Hardesty, D.M.; Bearden, W.O. The use of expert judges in scale development: Implications for improving face validity of measures of unobservable constructs. J. Bus. Res. 2004, 57, 98–107. [Google Scholar] [CrossRef]

- Malik, S.; Amin, J.; Sharf, M.; Yasmin, M.; Kadry, S.; Anjum, S. Fractured Elbow Classification Using Hand-Crafted and Deep Feature Fusion and Selection Based on Whale Optimization Approach. Mathematics 2022, 10, 3291. [Google Scholar] [CrossRef]

- Legendre, P. Species associations: The Kendall coefficient of concordance revisited. J. Agric. Biol. Environ. Stat. 2005, 10, 226–245. [Google Scholar] [CrossRef]

- Bekesiene, S.; Hošková-Mayerová, Š.; Becherová, O. Accidents and Emergency Events in Railway Transport while Transporting Hazardous Items. In Proceedings of the 20th International Scientific Conference Transport Means: Kaunas University of Technology, Kaunas, Juodkrantė, Lithuania, 5–7 October 2016; pp. 936–941. [Google Scholar]

- Goretzko, D.; Pham, T.T.H.; Bühner, M. Exploratory factor analysis: Current use, methodological developments and recommendations for good practice. Curr. Psychol. 2019, 40, 3510–3521. [Google Scholar] [CrossRef]

- Lukić, J.; Misita, M.; Milanović, D.D.; Borota-Tišma, A.; Janković, A. Determining the Risk Level in Client Analysis by Applying Fuzzy Logic in Insurance Sector. Mathematics 2022, 10, 3268. [Google Scholar] [CrossRef]

| N | Mean | Med | Min | Max | SD | Cv (%) | |

|---|---|---|---|---|---|---|---|

| Age of operator [year] | 102 | 38.23 | 37 | 19 | 55 | 9.827 | 25.7 |

| Height [cm] | 102 | 177.65 | 178 | 165 | 190 | 6.170 | 3.5 |

| Weight [kg] | 102 | 89.47 | 87.5 | 60 | 150 | 15.007 | 16.8 |

| Working experience [year] | 102 | 13.69 | 12 | 1 | 38 | 9.809 | 71.7 |

| Age of machine [year] | 102 | 14.22 | 9 | 0 | 40 | 14.449 | 101.6 |

| Items/Indicators | Cronbach’s Alpha | Spearman-Brown Coefficient | Kendall W Coefficient | Factor Loadings | |

|---|---|---|---|---|---|

| Equal Length | Unequal Length | ||||

| Q1 | 0.833 | 0.785 | 0.791 | 0.127 | 0.902 |

| Q2 | 0.904 | ||||

| Q3 | 0.819 | ||||

| Q5 | 0.486 | ||||

| Q13 | 0.744 | ||||

| Q6 | 0.972 | 0.957 | 0.961 | 0.000 | 0.983 |

| Q7 | 0.973 | ||||

| Q8 | 0.963 | ||||

| Q15 | 0.767 | 0.790 | 0.806 | 0.238 | 0.687 |

| Q16 | 0.887 | ||||

| Q17 | 0.898 | ||||

| Q20 | 0.810 | 0.810 | 0.813 | 0.104 | 0.825 |

| Q21 | 0.777 | ||||

| Q27 | 0.778 | ||||

| Q28 | 0.807 | ||||

| Q34 | 0.730 | 0.730 | 0.730 | 0.091 | 0.887 |

| Q35 | 0.887 | ||||

| Fit Indices | Recommended Values [37,42] | Values in the Model |

|---|---|---|

| χ2 | - | 118.3 |

| df | - | 66 |

| χ2 significance p | ≤0.001 | 0.0000 |

| χ2/df | <3.0 “good” <5.0 “permissible” | 1.7924 |

| GFI (Goodness of Fit) | >0.9 or >0.8 | 0.918 |

| AGFI (Adjusted Goodness of Fit) | >0.9 or >0.8 | 0.817 |

| NFI (Normed Fit Index) | >0.90 | 0.901 |

| CFI (Comparative Fit Index) | >0.90 | 0.963 |

| TLI (Tucker–Lewis Index) | >0.90 | 0.929 |

| RMSEA (Root Mean Square Error of Approximation) | ≤0.05 “very good fit” 0.05–0.08 “good fit” 0.08–0.10 “moderate fit” >0.10 “bad fit” | 0.070 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spasojević Brkić, V.; Misita, M.; Perišić, M.; Brkić, A.; Veljković, Z. Validating Measurement Structure of Checklist for Evaluating Ergonomics Risks in Heavy Mobile Machinery Cabs. Mathematics 2023, 11, 23. https://doi.org/10.3390/math11010023

Spasojević Brkić V, Misita M, Perišić M, Brkić A, Veljković Z. Validating Measurement Structure of Checklist for Evaluating Ergonomics Risks in Heavy Mobile Machinery Cabs. Mathematics. 2023; 11(1):23. https://doi.org/10.3390/math11010023

Chicago/Turabian StyleSpasojević Brkić, Vesna, Mirjana Misita, Martina Perišić, Aleksandar Brkić, and Zorica Veljković. 2023. "Validating Measurement Structure of Checklist for Evaluating Ergonomics Risks in Heavy Mobile Machinery Cabs" Mathematics 11, no. 1: 23. https://doi.org/10.3390/math11010023

APA StyleSpasojević Brkić, V., Misita, M., Perišić, M., Brkić, A., & Veljković, Z. (2023). Validating Measurement Structure of Checklist for Evaluating Ergonomics Risks in Heavy Mobile Machinery Cabs. Mathematics, 11(1), 23. https://doi.org/10.3390/math11010023