1. Introduction

The inverse problem of determining the cause, condition, or input from the effect, performance, or output has been proposed in many fields of scientific research and is commonly referred to as a “mathematical-physical inverse problem” [

1]. The importance and necessity of studying inverse problems have been recognized, driven by the needs of natural science and engineering applications. In recent decades, inverse problems have found extensive applications in fields such as geophysics [

2,

3,

4], resource exploration [

5,

6], ocean engineering [

7], mechanics [

8,

9,

10], acoustics [

11,

12], and others.

Traditional mechanical inverse analysis methods usually employ a combination of numerical methods and optimization algorithms. An optimization algorithm is a mathematical method that minimizes or maximizes an objective function by adjusting model parameters or design variables [

13]. In mechanical inverse analysis, optimization algorithms are used to adjust model parameters or design variables to minimize the error between simulation results and actual observed or desired results. Traditional mechanical inverse analysis methods typically employ iterative optimization algorithms to incrementally enhance the model, with commonly used algorithms including gradient descent [

14], genetic algorithms [

15], and particle swarm optimization [

16]. However, these conventional optimization algorithms have limitations such as the tendency to converge to local optima and slow convergence speeds. Consequently, numerous novel optimization algorithms have emerged to address these drawbacks. Examples include the Arithmetic Optimization Algorithm [

17], the IbI Logic Algorithm [

18], and the modified Sooty Tern Optimization Algorithm [

13].

Many researchers have effectively utilized numerical methods and optimization algorithms for the identification of mechanical parameters in elastoplastic materials. For example, De-Carvalho et al. [

14] employed two optimization algorithms, namely, the gradient-based Levenberg–Marquardt algorithm and the real search space evolution algorithm, to perform inverse analysis on the constitutive parameters of three different models: the elastic-plastic hardening model, the hyperelastic model, and the elastic-viscoplastic model. The objective was to minimize the disparity between the physical experimental results and the numerical simulation results [

14]. Furthermore, a significant number of studies have utilized probability-based parameter estimation methods for mechanical parameter identification. For instance, Khodadadian et al. [

19] developed a Bayesian parameter estimation framework to identify the uncertain parameters associated with the phase field fracture problem. Reliable results are obtained by their proposed Bayesian inversion method, even when relatively coarse grids are employed instead of real data [

19]. Similarly, Noii et al. [

20] applied Bayesian inversion techniques to identify mechanical parameters in various scenarios, including linear elasticity, elastoplasticity, and fracture problems of different materials. They extensively investigated the complex coupled multi-field marginal value problem and shared the open source code of their Bayesian inversion method [

20].

However, traditional mechanical inverse analysis methods suffer from cumbersome inversion processes, large computations, and slow convergence efficiencies. The rapid development of artificial intelligence techniques, particularly the impressive capabilities of deep learning in handling high-dimensional complex structural data, have made them powerful tools for solving both forward and inverse problems in mechanics [

9,

21,

22,

23,

24]. For instance, Liu et al. [

21,

22] proposed a two-way neural network for solving both forward and inverse problems in mechanics, which they combined with nonlinear finite elements to accurately identify the constitutive parameters of hyperelastic materials. Potrzeszcz-Sut et al. [

9] utilized a backpropagation neural network in conjunction with indentation test data to efficiently determine the elastic-plastic material parameters described by Ramberg–Osgood’s law. Pichler et al. [

24] employed artificial neural networks to approximate finite element analysis and combined them with genetic algorithms to determine optimal parameter estimates for unknown parameter identification. In a similar vein, Liu et al. [

25] introduced a surrogate model based on orthogonal decomposition and artificial neural networks. They further integrated this surrogate model with Bayesian theory to achieve the efficient inversion of geotechnical parameters.

Despite the great strides made in deep learning, it cannot be overlooked that its current achievements rely heavily on large, high-quality datasets. However, in practical engineering problems, obtaining a significant amount of high-quality data is often challenging due to measurement difficulties, high costs, and measurement errors. As a result, the accuracy of the computational results may be low or difficult to solve directly using purely data-driven deep learning methods.

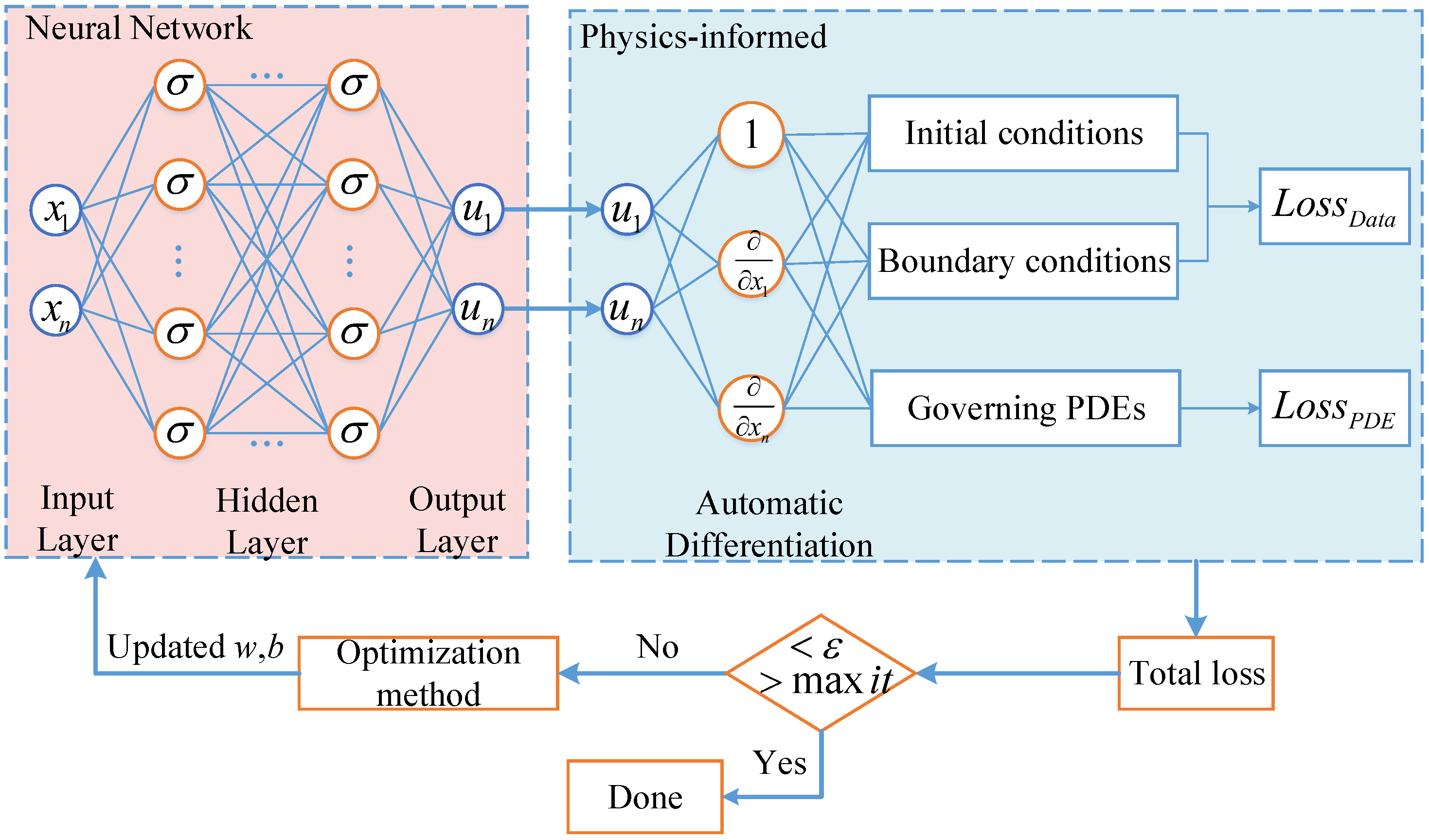

In the latest research work, the physics-informed deep learning method proposed by Professor Karniadakis constructs interpretable neural network models by incorporating relevant physical laws or constraints [

26]. Physics-informed deep learning guarantees the generalization and validity of the model, even when there is a small amount of data or when noise observation bias, or other such factors are present. This approach enables the model predictions to comply with objective physical constraints [

26], ensuring their accuracy and reliability. A typical example of this is the Physics-Informed Neural Network (PINN), which shows great promise in solving both the forward and inverse problems of partial differential equations (PDEs). This is due to its ability to integrate data and PDEs [

27,

28,

29], making it a powerful tool for researchers in the field. PINNs have proven to be effective in solving many inverse problems of PDEs due to their ease of implementation. This is because the code used for solving the forward problem can be applied to the solution of the inverse problem with minimal modifications [

8,

30,

31,

32].

For example, Fallah et al. [

30] utilized PINN to invert the natural frequency of TDFG porous beams on an elastic foundation. They then used this information to solve for the bending and free vibrations of TDFG porous beams using PINN. Depina et al. [

31] applied PINNs to the inverse problem of unsaturated groundwater flow. Their research demonstrated that PINNs are capable of accurately identifying the van Genuchten constitutive parameters. Xu et al. [

32] improved the training efficiency and accuracy of neural networks for linear elastic and hyperelastic inverse problems by incorporating uncertainty-weighted multi-task learning methods and transfer learning strategies based on PINN. Lu et al. [

8] employed physics-informed deep learning to improve the accuracy and efficiency of the inversion process for the mechanical properties of elastic-plastic materials.

Due to the challenges associated with acquiring real measurement data, researchers often resort to numerical methods to synthesize data used to train PINNs when tackling inverse problems involving PDEs. These trained PINNs are subsequently applied to real-world engineering problems where only limited measurement data are available [

8,

32]. The computational errors arising from numerical methods can be regarded as measurement errors, and PINNs demonstrate robustness in handling such errors. The Finite Element Method (FEM) is commonly employed as the primary numerical method. However, it has certain limitations, such as its high dependency on mesh quality, its inability to handle mesh distortion, and its susceptibility to volume locking issues [

33]. To address these problems, the Smoothed Finite Element Method (S-FEM) has been developed. S-FEM is an extension of the FEM that incorporates the smoothing strain technique, enabling it to handle mesh distortion effectively. Moreover, S-FEM offers improved computational accuracy compared to FEM [

33,

34,

35]. Due to the geometric complexity and irregularity of practical engineering problems, achieving high computational accuracy with quadrilateral cells in the discretization process becomes challenging. In contrast, triangular cells in the S-FEM offer better accuracy when properly adapted to the geometry. Therefore, the use of triangular cells reduces computational complexity while ensuring a better adaptation to real engineering problems [

36].

In practical engineering applications, there is a growing need to invert various material parameters. However, traditional machine learning is typically designed for specific tasks, requiring reconstruction of the model after changing the dataset. This can result in a significant increase in computational cost. Transfer learning involves utilizing knowledge from a previously trained model for a new task [

37]. For instance, the weights and biases from a pre-trained neural network can be used as initial values for a neural network trained on a similar problem. By avoiding random initialization of the neural network, the training process can converge more quickly.

The combination of transfer learning with PINN for parameter inversion has received relatively little attention in research. Haghighat et al. [

38] proposed a PINN framework for solving inverse problems in solid mechanics, but only briefly mentioned its potential for transfer learning without conducting significant analysis or research on the topic. Xu et al. [

32] proposed a transfer learning-based PINN method for inverting different loading systems of linear-elastic and hyperelastic structures. However, due to the characteristics of transfer learning, the method presented in [

32] still requires a significant amount of data in the pre-training phase.

In this paper, we propose a transfer learning-based coupling of S-FEM and PINN approach to invert different material parameters, with the goal of improving the accuracy and efficiency of the inversion process. The proposed approach involves utilizing S-FEM to generate a small dataset of high quality, which is then combined with PINN for pre-training purposes. The resulting pre-trained model parameters are saved and utilized as the initial state for the PINN model when inverting the material parameters of a new dataset. To assess the accuracy and efficiency of the proposed method during the pre-training phase, validation will be conducted using an elastic-plastic material parameter inversion problem. Subsequently, the inversion of various material parameters, encompassing linear elasticity and elastoplasticity, will be performed by employing the coupling of S-FEM and PINN, both with and without transfer learning.

The contributions of this paper can be summarized as follows:

- (1)

A transfer learning-based coupling of the S-FEM and PINN methods for the inversion of different material parameters is proposed.

- (2)

The proposed approach improves the convergence efficiency of the inversion by at least a factor of two over the method without transfer learning and also provides a degree of improvement in the accuracy of the inversion.

- (3)

The proposed method requires only a small amount of data in the pre-training phase of the model to achieve high accuracy.

This paper is organized as follows. The backgrounds of the S-FEM, PINN, and elastic-plastic problems are presented in

Section 2. The PDEs involved in the elastoplastic inversion problem and the specific implementation of our proposed approach are illustrated in

Section 3. The results of our proposed method to invert different material parameters are presented in

Section 4. The advantages and disadvantages of our proposed method and the future research work are discussed in

Section 5. Finally, a summary of the paper is presented.

5. Discussion

The transfer learning-based coupling of S-FEM and PINN proposed in this paper has the advantage of achieving high computational accuracy using only a small dataset in the pre-training phase. This is particularly useful in practical engineering applications where obtaining a large amount of monitoring data can be difficult due to the high measurement cost or measurement difficulty. The proposed method is well-suited for the inversion of material parameters for small datasets. The use of coupling S-FEM and PINN to pre-train the model allows for higher computational accuracy and efficiency compared to using traditional FEM and PINN to pre-train the model. The robustness of PINN to noise in the data ensures the validity of the model even in the presence of errors. However, the findings of this study demonstrate that coupling PINN with high-quality synthetic data can lead to a significant improvement in computational accuracy. The strain smoothing technique utilized in the S-FEM enables the synthesis of data in low-order linear elements with greater computational accuracy compared to the FEM in bilinear elements [

35]. By coupling S-FEM with PINN, we were able to enhance the accuracy of the computational results for the elastic-plastic inverse problem without increasing the computational cost.

The computational results presented in

Section 4.2 demonstrate that our proposed method, incorporating transfer learning, exhibits a minimum twofold increase in computational efficiency compared to the approach without transfer learning. By employing coupled S-FEM with PINN during the pre-training phase, our method successfully mitigates computational errors to approximately 2%. Although the improvement in computational accuracy of our method is not significant in some cases, the reduction in computational cost is still significant. Transfer learning leverages pre-trained models to enable neural networks to acquire generic physics knowledge from related physical problems. This process enhances their ability to formulate and model new problems effectively. By incorporating a priori knowledge acquired during the pre-training phase, transfer learning facilitates more accurate and reliable inversion results in the solution process for the new problem. Additionally, the utilization of a pre-trained model enables the provision of a favorable initial state for the new problem, thereby expediting the convergence process. This paper adopts a strategy where the neural network parameters obtained during the pre-training stage are preserved as the initial parameters for the new model. Therefore, when applied to a new dataset, the model converges quickly to the optimal solution.

While the transfer learning-based S-FEM coupled PINN method proposed in this paper demonstrates remarkable performance in the inversion of various elastoplastic material parameters, it is essential to address the challenge of avoiding negative transfer in the transfer learning process. Transfer learning algorithms typically rely on the assumption that the source and target domains possess some level of interrelation [

37,

68]. However, if this assumption does not hold, negative transfer can occur, potentially resulting in inferior performance compared to scenarios where no transfer learning is employed [

37,

68]. In this paper, we assume that the models requiring parameter inversion share identical properties and conditions, except for the material parameters. This assumption ensures the correlation between the source and target domains, which is fundamental for effective transfer learning. Furthermore, the dataset necessary for the inversion using PINN is synthesized using S-FEM. It is important to acknowledge that, like any numerical method, S-FEM relies on certain assumptions and simplifications when compared to the actual problem. Therefore, there will be inherent limitations when synthesizing data using different numerical methods.

One of the key advantages of PINN lies in its ability to incorporate both physical information and data constraints during training, leading to solutions that satisfy both aspects. However, a challenge arises from the presence of multiple loss terms in PINN, which encompass both data-driven and physically driven components. The weights assigned to these loss terms significantly impact the computational results [

26,

69]. In this paper, we employ a fine-tuning approach to adjust the weights of the loss terms based on the computational results. However, for more complex problems, adopting a better weighting scheme, particularly an adaptive one, can be advantageous in enhancing overall convergence. Additionally, PINN, similar to other deep learning models, is specifically designed for particular problems. Developing effective neural network architectures often relies on user experience, which can be a time-intensive process. Furthermore, it is crucial to consider that a design approach successful in one problem scenario may not yield the same results in other problems. Thus, the impact of various design approaches on the results should be uniformly considered [

26,

69].

In our future research work, we intend to explore and investigate more combinations of numerical methods with PINN to solve various mechanical inverse problems. We aim to compare the applicable scenarios of different methods and avoid the limitation of the scope of application of a single numerical method to synthesize data. Moreover, we plan to incorporate an adaptive weighting strategy to enhance the overall convergence of the method. This integration will enable the proposed method to be effectively applied to complex problems. Furthermore, we aspire to apply our method to a real engineering case, providing an opportunity to evaluate its practical utility and efficacy in real-world scenarios. These future research directions will contribute to a deeper understanding of the capabilities and limitations of the proposed method, as well as its potential for real-world applications.