Hydro-Mechanical Coupling of Cement-Based Slurry Grouting in Saturated Geomaterials

Abstract

:1. Introduction

2. Governing Equations for Cement-Based Slurry Grouting

2.1. Mass Conservation Equations

2.2. Momentum Balance Equations

2.3. The Final Equations for Grouting

3. Discretization and Solving

3.1. Bézier Extraction Operator

3.2. Discretization for Governing Equations

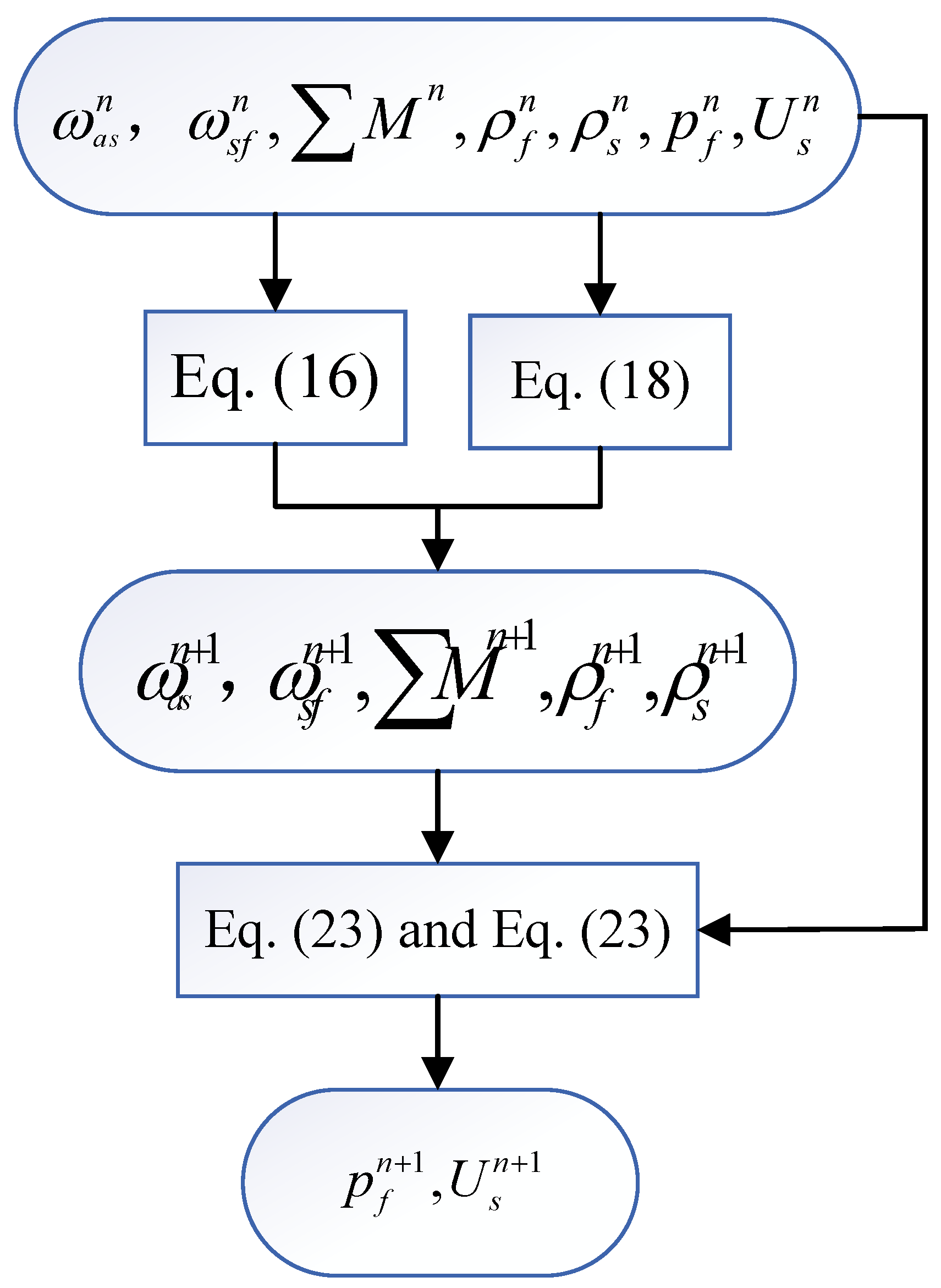

3.3. Solving Implementation

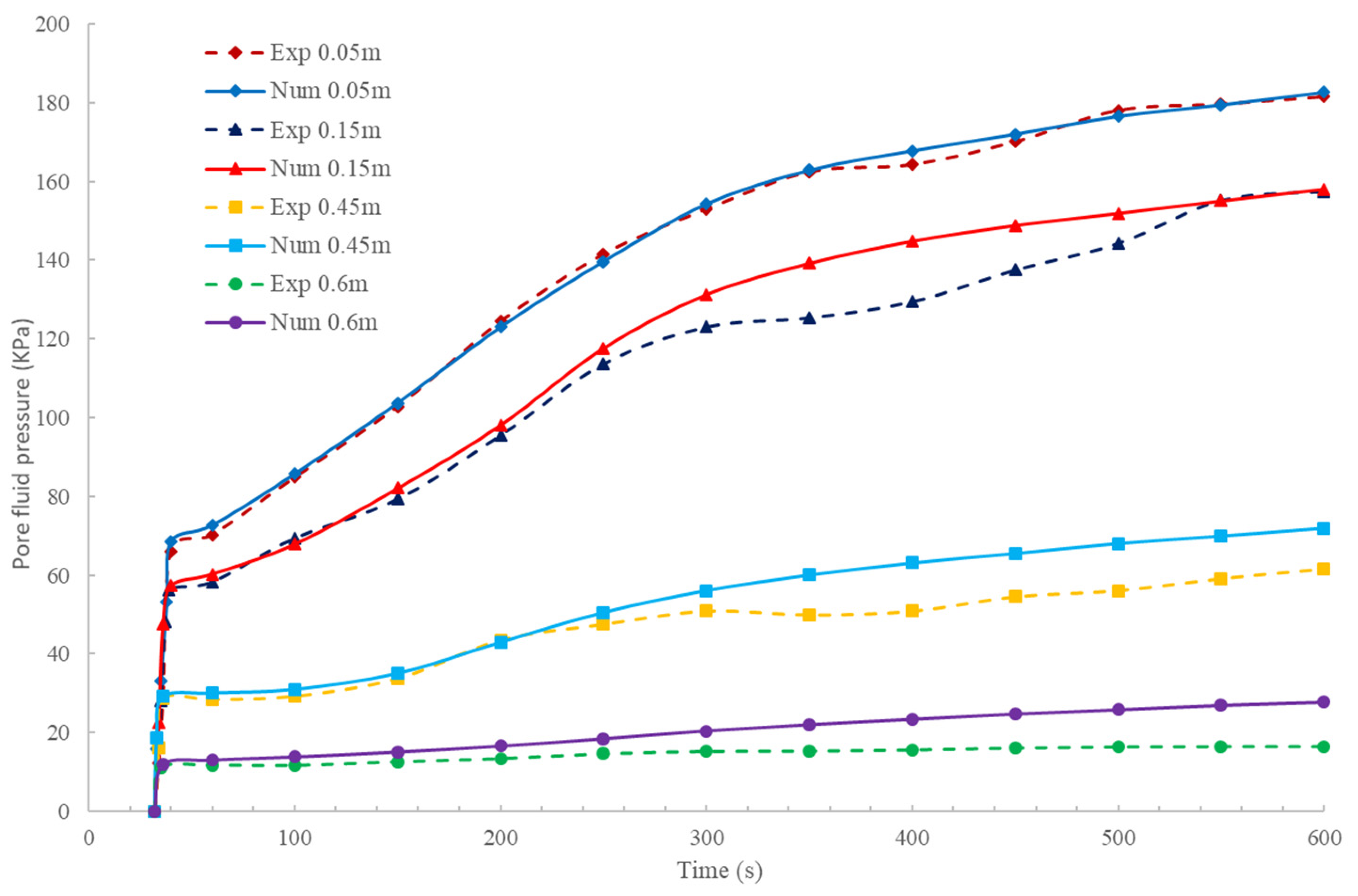

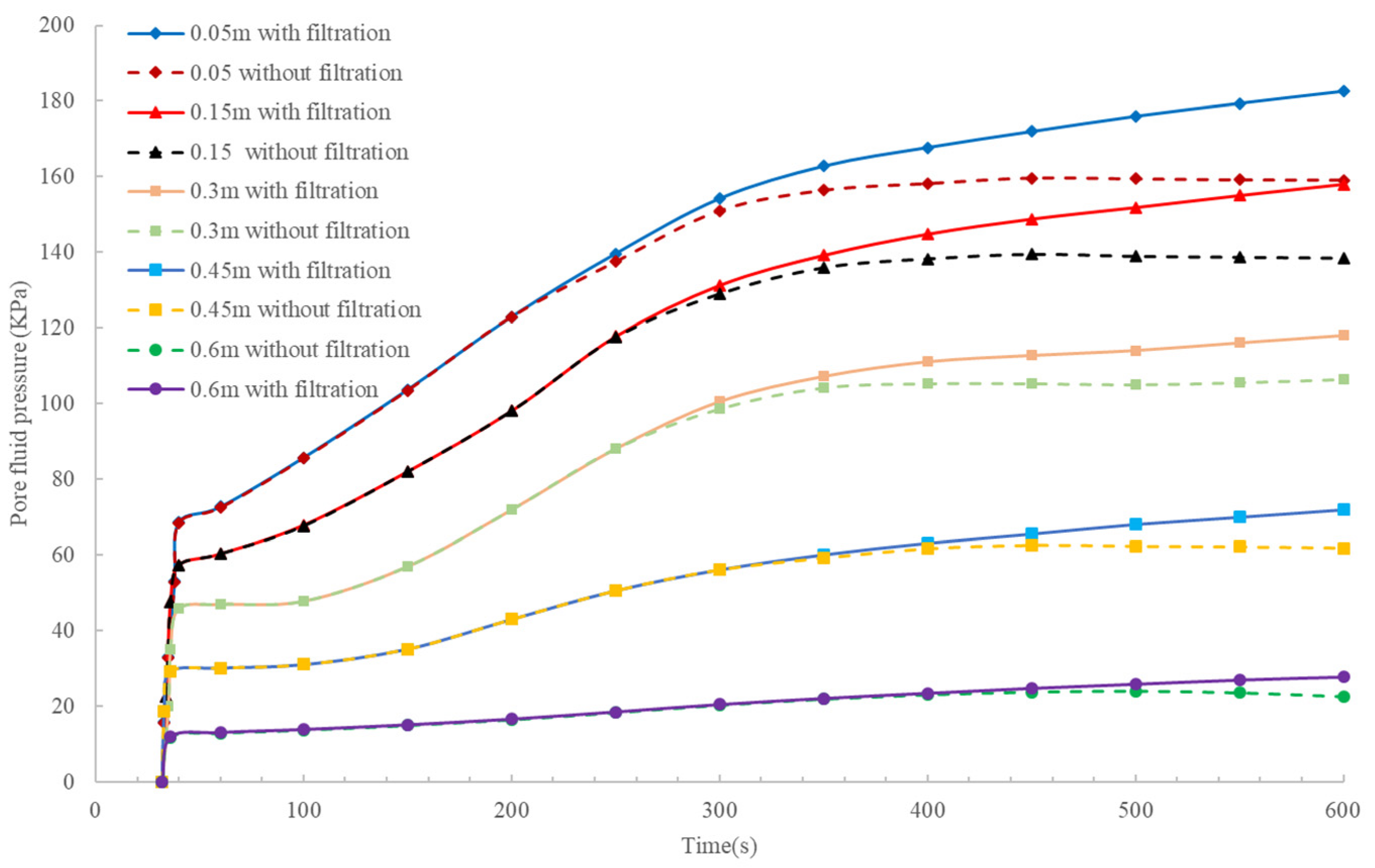

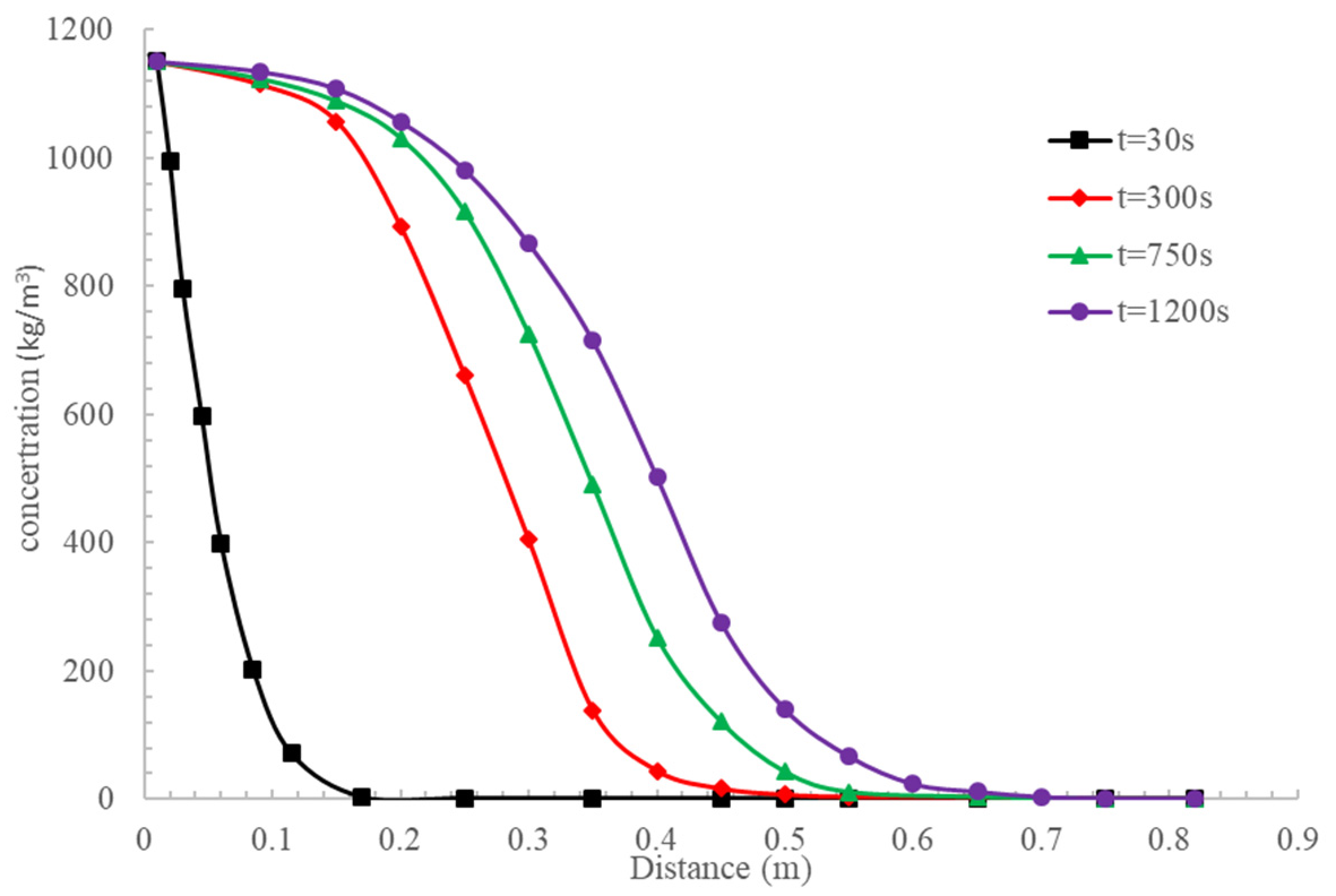

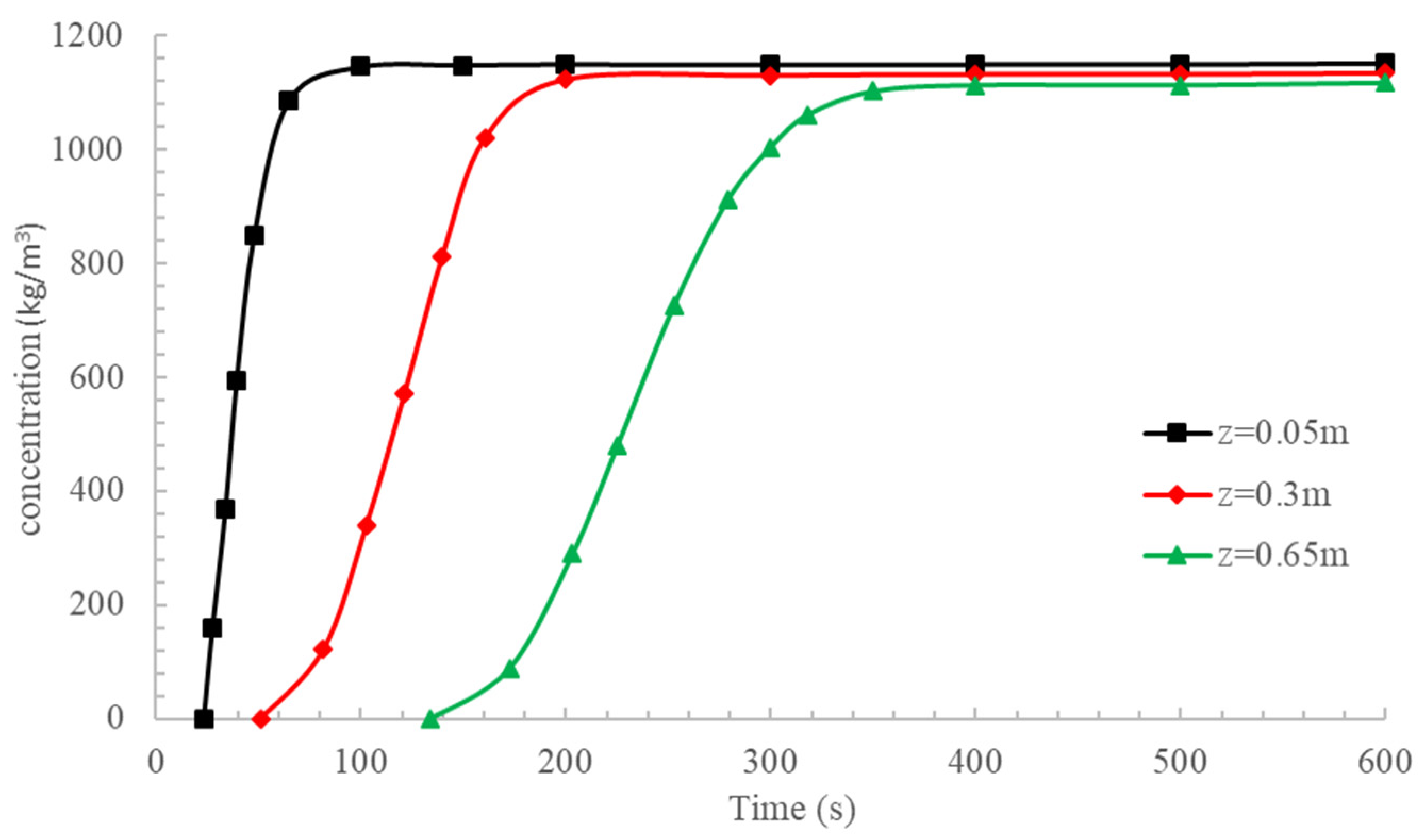

4. Validation and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bouchelaghem, F.; Vulliet, L. Mathematical and numerical filtration–advection–dispersion model of miscible grout propagation in saturated porous media. Int. J. Numer. Anal. Met. 2001, 25, 1195–1227. [Google Scholar] [CrossRef]

- Mohammadmoradi, P.; Taheri, S.; Bryant, S.L.; Kantzas, A. Solvent diffusion and dispersion in partially saturated porous media: An experimental and numerical pore-level study. Chem. Eng. 2018, 191, 300–317. [Google Scholar] [CrossRef]

- Nadimi, S.; Shahriar, K. Experimental creep tests and prediction of long-term creep behavior of grouting material. Arab. J. Geosci. 2014, 7, 3251–3257. [Google Scholar] [CrossRef]

- Ding, W.; Duan, C.; Zhu, Y.; Zhao, T.; Huang, D.; Li, P. The behavior of synchronous grouting in a quasi-rectangular shield tunnel based on a large visualized model test. Tunn. Undergr. Space Technol. 2019, 83, 409–424. [Google Scholar] [CrossRef]

- Li, H.; Ji, X.M.; Zhou, P. Study on the Microscopic Mechanism of Grouting in Saturated Water-Bearing Sand Stratum Based on VOF-DEM Method. Processes 2022, 10, 1447. [Google Scholar] [CrossRef]

- Lin, Y.X.; Wang, X.; Ma, J.; Huang, L.C. A finite-discrete element-based approach for modelling the hydraulic fracturing of rocks with irregular inclusions. Eng. Fract. Mech. 2022, 261, 108209. [Google Scholar] [CrossRef]

- Lin, Y.X.; Lai, Z.S.; Ma, J.J.; Huang, L.C.; Lei, M.F. A FDEM approach to study mechanical and fracturing responses of geo-materials with high inclusion contents using a novel reconstruction strategy. Eng. Fract. Mech. 2023, 282, 109171. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, I.M.; Jang, J.H.; Choi, H. Grout ability of cement-based grout with consideration of viscosity and filtration phenomenon. Int. J. Numer. Anal. Meth. Geomech. 2009, 33, 1771–1797. [Google Scholar] [CrossRef]

- Chupin, O.; Saiyouri, N.; Hicher, P.-Y. Modeling of a semi-real injection test in sand. Comput. Geotech. 2009, 36, 1039–1048. [Google Scholar] [CrossRef] [Green Version]

- Kou, L.; Miao, R.; Miao, F. Fractal analysis of non-Newton fluid grouting through soil composed of arbitrary cross-sectional capillaries. Fractals 2021, 29, 2150139. [Google Scholar] [CrossRef]

- Li, L.; Huang, Q.; Zuo, X.; Wu, J.; Wei, B.; He, Y.; Zhang, W.; Zhang, J. Study on the Slurry Diffusion Law of Fluidized Filling Gangue in the Caving Goaf of Thick Coal Seam Fully Mechanized Caving Mining. Energies 2022, 15, 8164. [Google Scholar] [CrossRef]

- Saada, Z.; Canou, J.; Dormieux, L.; Dupla, J.; Maghous, S. Modelling of cement suspension flow in granular porous media. Int. J. Numer. Anal. Methods Geomech. 2005, 29, 691–711. [Google Scholar] [CrossRef]

- Srinivasacharya, D.; Bhuvanavijaya, R.; Mallikarjuna, B. Dispersion effects on mixed convection over a vertical wavy surface in a porous medium with variable properties. Procedia Eng. 2015, 127, 271–278. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.Z.; Yan, X.; Han, W.Q.; Ma, G.W.; Zhang, Y.M. Simulating the Filtration Effects of Cement-Grout in Fractured Porous Media with the 3D Unified Pipe-Network Method. Processes 2019, 7, 46. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.H.; Zhang, X.H.; Wu, D.; Di, H.G. Mathematical Modeling of Slurry Infiltration and Particle Dispersion in Saturated Sand. Transp. Porous Med. 2017, 124, 91–116. [Google Scholar] [CrossRef]

- Francesco, P.; Schrefler, B.A.; Sciumè, G. Multiphase Flow in Deforming Porous Media: A Review. Arch. Computat. Methods Eng. 2017, 24, 423–448. [Google Scholar] [CrossRef]

- Gray, W.G.; Miller, C.T. Introduction to the Thermodynamically Constrained Averaging Theory for Porous Medium Systems; Springer: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Gray, W.G.; Miller, C.T. Thermodynamically constrained averaging theory approach for heat transport in single-fluid-phase porous media systems. J. Heat Transf. 2009, 131, 101002. [Google Scholar] [CrossRef]

- Jackson, A.S.; Rybak, I.; Helmig, R.; Gray, W.G.; Miller, C.T. Thermodynamically constrained averaging theory approach for modeling flow and transport phenomena in porous medium systems:9. Transition region models. Adv. Water Resour. 2012, 42, 71–90. [Google Scholar] [CrossRef]

- Rybak, I.V.; Gray, W.G.; Miller, C.T. Modeling of two-fluid-phase flow and species transport in porous media. J. Hydrol. 2015, 521, 565–581. [Google Scholar] [CrossRef] [Green Version]

- Kremheller, J.; Vuong, A.T.; Yoshihara, W.; Schrefler, B.; Wall, W. A monolithic multiphase porous medium framework for (a-)vascular tumor growth. Comput. Methods Appl. Mech. Eng. 2018, 340, 657–683. [Google Scholar] [CrossRef]

- Sciumè, G. Mechanistic modeling of vascular tumor growth: An extension of Biot’s theory to hierarchical bi-compartment porous medium systems. Acta Mech. 2021, 232, 1445–1478. [Google Scholar] [CrossRef]

- Hughes, T.J.R.; Cottrell, J.A.; Bazilevs, Y. Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput. Methods Appl. Mech. Eng. 2015, 194, 4135–4195. [Google Scholar] [CrossRef] [Green Version]

- Bhardwaj, G.; Singh, I.V.; Mishra, B.K.; Bui, Q.T. Numerical simulation of functionally graded cracked plates using NURBS based XIGA under different loads and boundary conditions. Compos. Struct. 2015, 126, 347–359. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Calo, V.M.; Hughes, T.J.R.; Zhang, Y. Isogeometric fluid-structure interaction: Theory, algorithms, and computations. Comput. Mech. 2008, 43, 3–37. [Google Scholar] [CrossRef]

- Yu, T.T.; Yin, S.H.; Bui, T.Q.; Hirose, S. A simple FSDT-based isogeometric analysis for geometrically nonlinear analysis of functionally graded plates. Finite Elem. Anal. Des. 2015, 96, 1–10. [Google Scholar] [CrossRef]

- Irzal, F.; Remmers, J.J.; Verhoosel, C.V.; Borst, R. Isogeometric finite element analysis of poroelasticity. Int. J. Numer. Anal. Meth. Geomech. 2013, 37, 1891–1907. [Google Scholar] [CrossRef]

- Nguyen, M.N.; Bui, T.Q.; Yu, T.; Hirose, S. Isogeometric analysis for unsaturated flow problems. Comput. Geotech. 2014, 62, 257–267. [Google Scholar] [CrossRef]

- Bekele, Y.W.; Kyokawa, H.; Kvarving, A.M.; Kvamsdal, T.; Nordal, S. Isogeometric analysis of THM coupled processes in ground freezing. Comput. Geotech. 2017, 88, 129–145. [Google Scholar] [CrossRef]

- Shahrokhabadi, S.; Cao, T.D.; Vahedifarda, F. Thermo-hydro-mechanical modeling of unsaturated soils using isogeometric analysis: Model development and application to strain localization simulation. Int. J. Numer. Anal. Methods Geomech. 2020, 44, 261–292. [Google Scholar] [CrossRef] [Green Version]

- Borden, M.J.; Scott, M.A.; Evans, J.A.; Hughes, T.J. Isogeometric finite element data structures based on Bézier extraction of NURBS. Int. J. Numer. Meth. Eng. 2011, 87, 15–47. [Google Scholar] [CrossRef]

- Scott, M.A.; Borden, M.J.; Verhoosel, C.V.; Sederberg, T.W.; Hughes, T.J. Isogeometric finite element data structures based on Bézier extraction of T-splines. Int. J. Numer. Meth. Eng. 2011, 88, 126–156. [Google Scholar] [CrossRef]

- Irzal, F.; Remmers, J.J.; Verhoosel, C.V.; Borst, R. An Isogeometric analysis Bézier interface element for mechanical and poromechanical fracture problems. Int. J. Numer. Meth. Eng. 2014, 97, 608–628. [Google Scholar] [CrossRef] [Green Version]

- Shahrokhabadi, S.; Cao, T.D.; Vahedifarda, F. Isogeometric analysis through Bézier extraction for thermo-hydromechanical modeling of saturated porous media. Comput. Geotech. 2019, 107, 176–188. [Google Scholar] [CrossRef]

- Vo-Minh, T.; Nguyen-Son, L.; Nguyen-Van, G.; Thai-Phuong, T. Upper bound limit analysis of circular tunnel in cohesive-frictional soils using isogeometric analysis based on Bézier extraction. Tunn. Undergr. Space Technol. 2021, 114, 103995. [Google Scholar] [CrossRef]

- Borst, R.D.; Crisfield, M.A.; Remmers, J.J.; Verhoosel, C.V. Nonlinear Finite Element Analysis of Solids And structures; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Kou, L.; Zhu, H. Hydro-Mechanical Coupling of Cement-Based Slurry Grouting in Saturated Geomaterials. Mathematics 2023, 11, 2877. https://doi.org/10.3390/math11132877

Wang H, Kou L, Zhu H. Hydro-Mechanical Coupling of Cement-Based Slurry Grouting in Saturated Geomaterials. Mathematics. 2023; 11(13):2877. https://doi.org/10.3390/math11132877

Chicago/Turabian StyleWang, Haitao, Lei Kou, and Hongkang Zhu. 2023. "Hydro-Mechanical Coupling of Cement-Based Slurry Grouting in Saturated Geomaterials" Mathematics 11, no. 13: 2877. https://doi.org/10.3390/math11132877