Two-Step Adaptive Control for Planar Type Docking of Autonomous Underwater Vehicle

Abstract

:1. Introduction

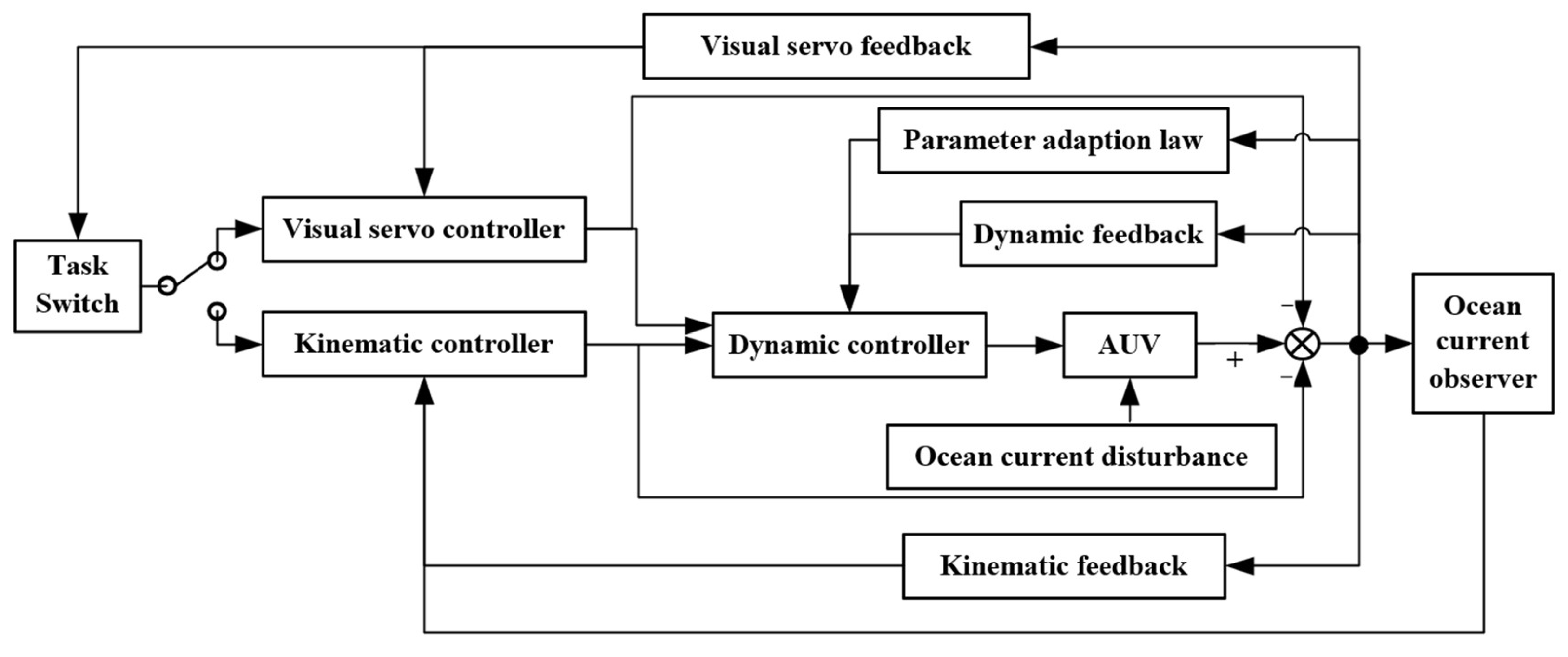

- The two-step docking method takes full advantage of the omnidirectional feature of the planar type docking station. A seamless combination of dynamic positioning and three-dimensional (3D) visual servo is made to achieve a stable and accurate docking control.

- The controller perfectly matches up with the underactuated feature of the prototype AUV, where a roll motion adjustment is adopted to rapidly compensate for the visual error and gradually reduce the actual positioning error during the descending docking process.

- Practical issues are fully considered in the controller design and simulation validation, including hardware limitations, unknown ocean current disturbance, inevitable positioning error and model parameter uncertainties.

2. Problem Statement

2.1. Planar Type Docking Task

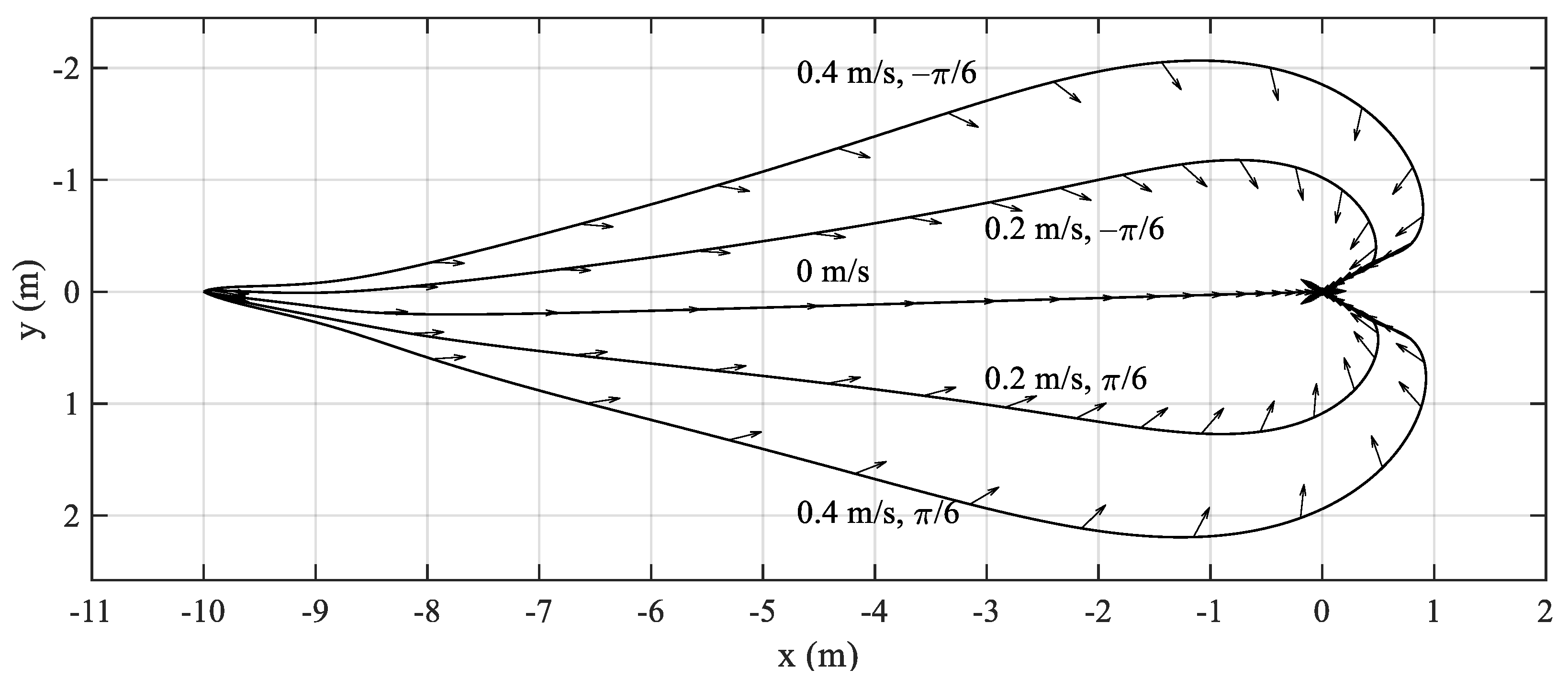

- Pre-docking horizontal dynamic positioning step. The AUV returns to the station at a constant depth and dynamically stops on the top of the platform. In the presence of an ocean current, it aligns itself in an antiparallel direction with the current so that the disturbance can be easily canceled by the surge motion.

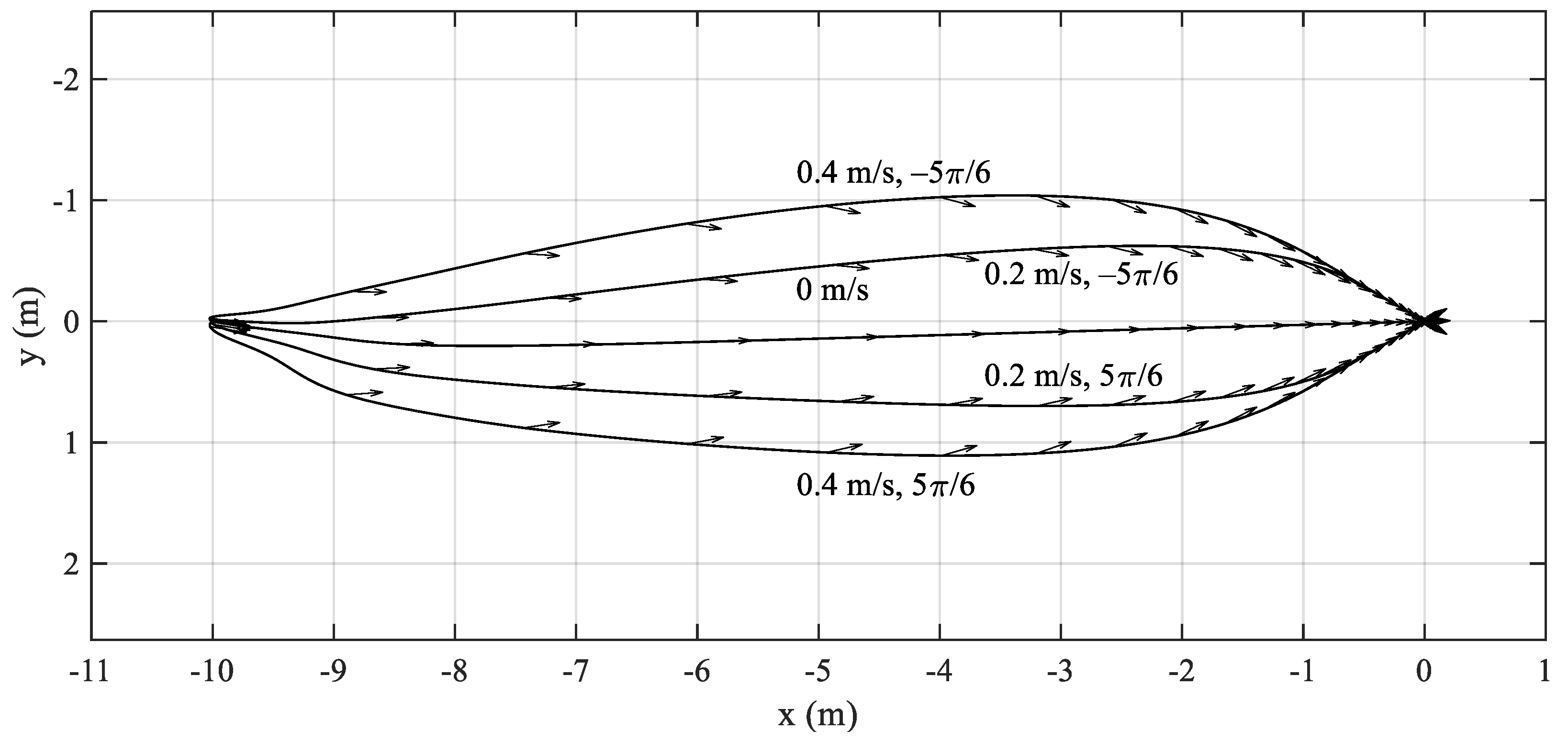

- Vertical visual servo landing and docking step. The AUV descends and lands on the platform center using a 3D visual servo strategy. Since the docking station allows an arbitrary landing direction of the AUV, the heading angle of the AUV merely depends on the current direction, which brings much convivence and stability of the docking process.

2.2. Kinematic Model

2.3. Dynamic Model

3. Controller Design

3.1. Pre-Docking Step

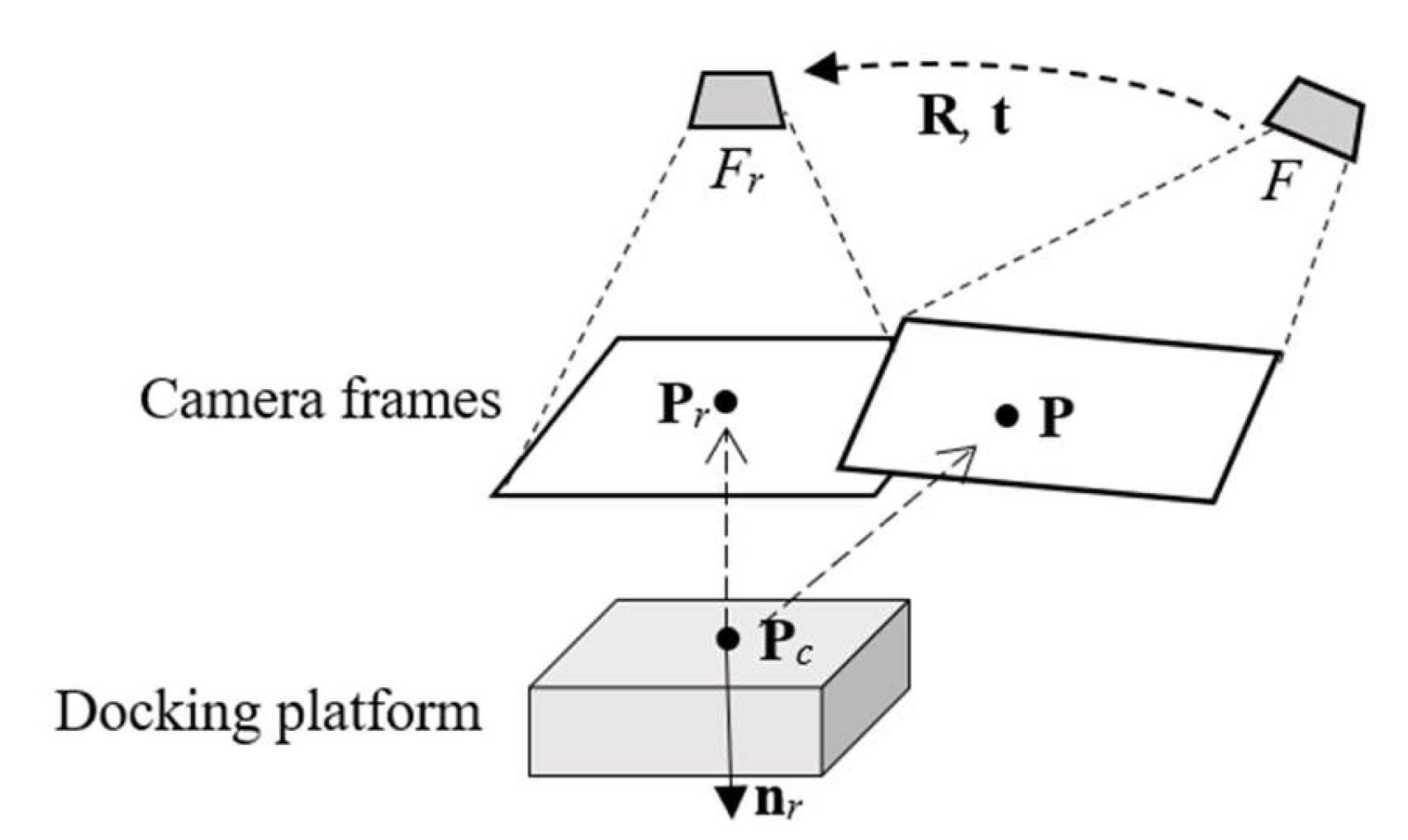

3.2. Visual Servo Docking Step

4. Simulation and Analysis

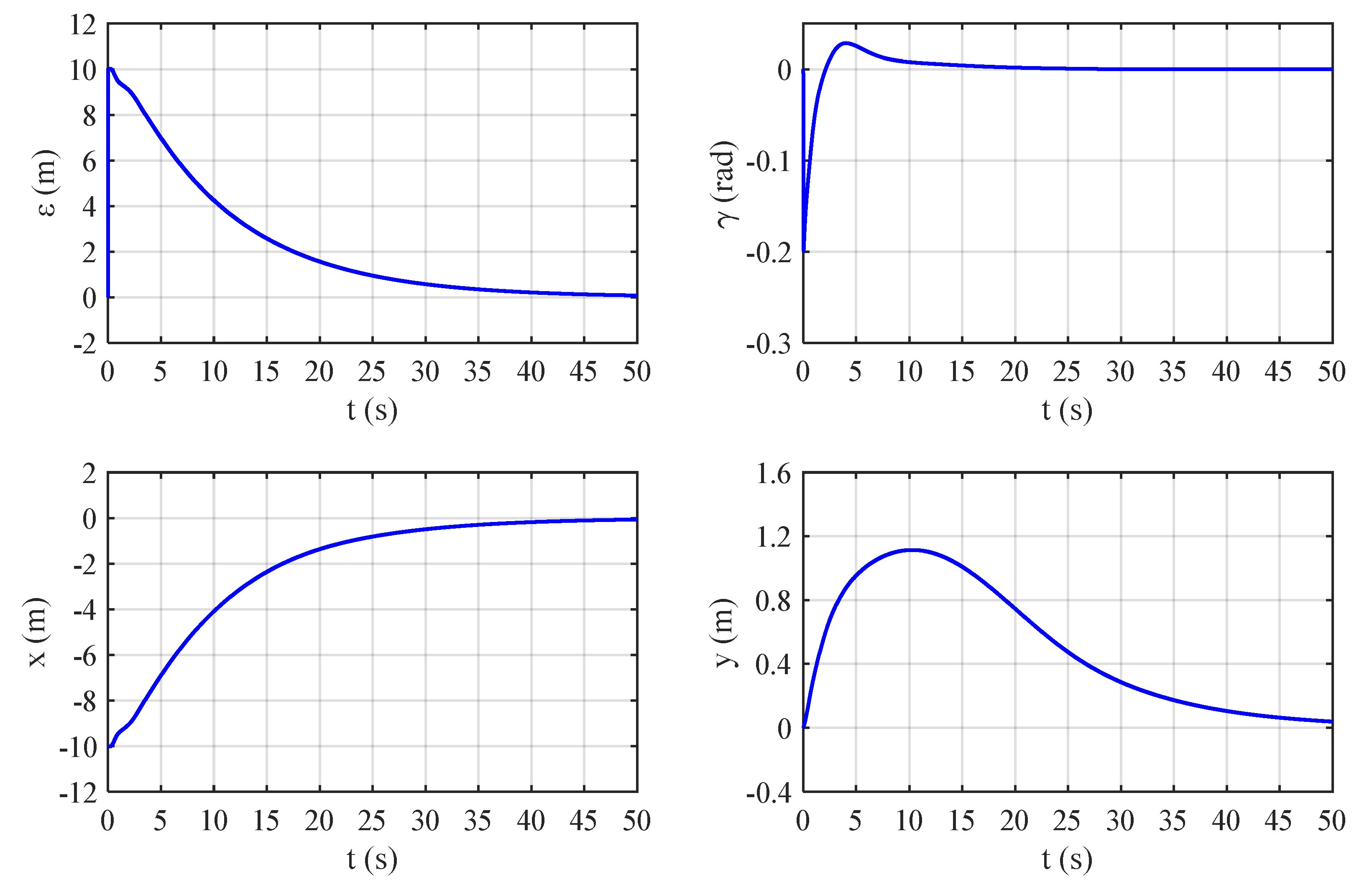

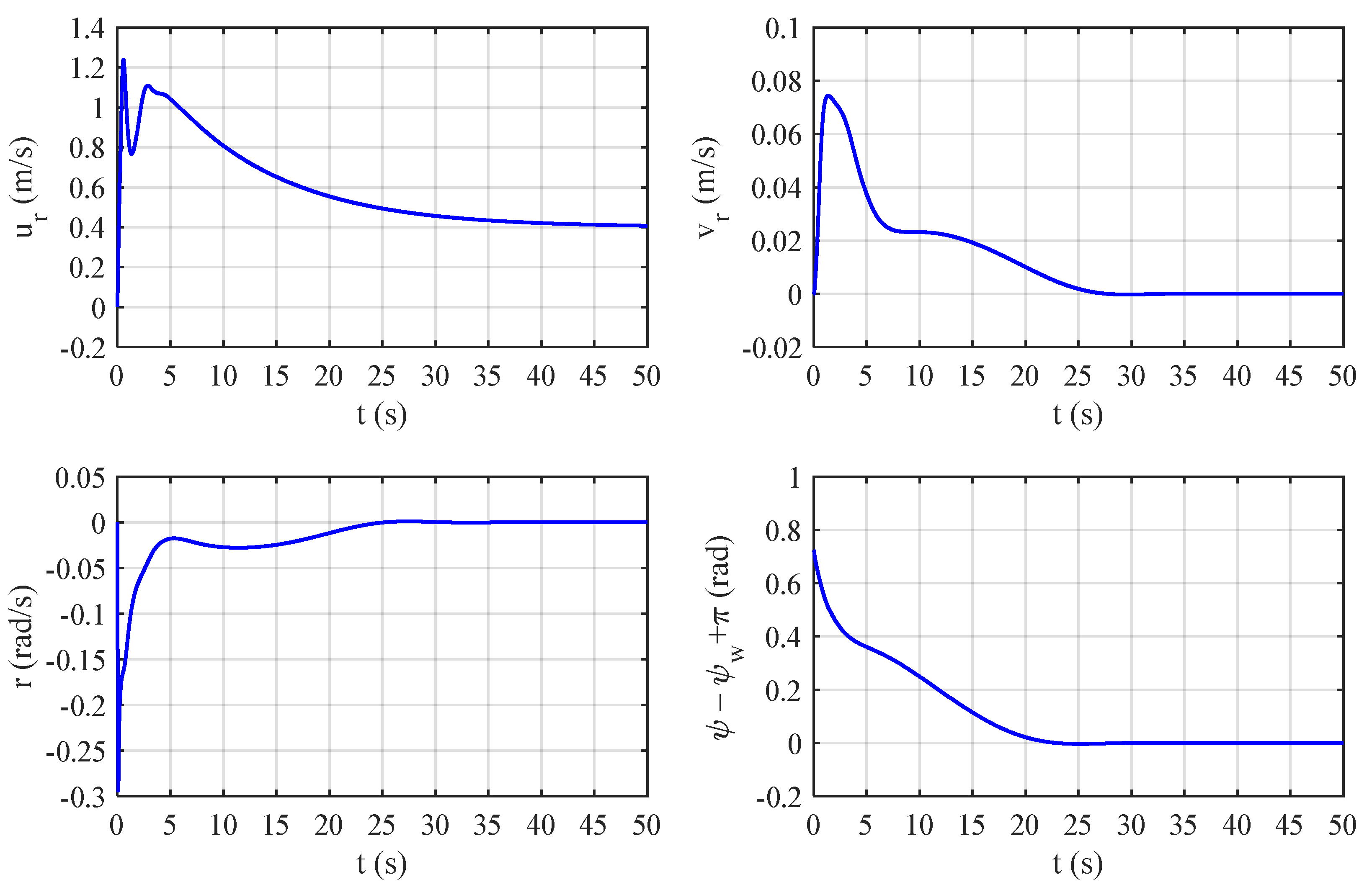

4.1. Pre-Docking Process

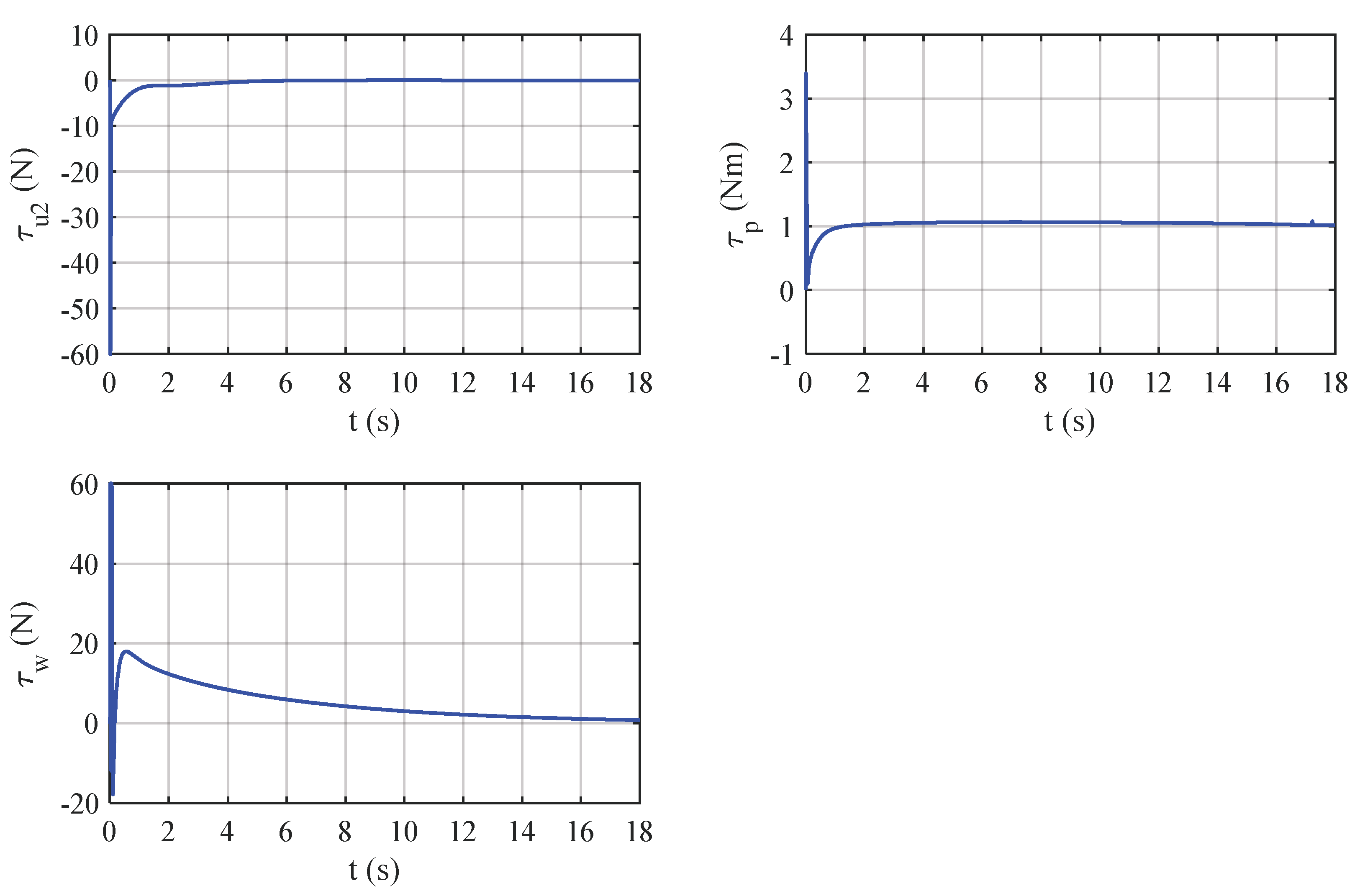

4.2. Visual Servo Docking Process

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Ta, X.; Xiao, R.; Wei, Y.; An, D.; Li, D. Survey of underwater robot positioning navigation. Appl. Ocean Res. 2019, 90, 101845. [Google Scholar] [CrossRef]

- Sahoo, A.; Dwivedy, S.K.; Robi, P. Advancements in the field of autonomous underwater vehicle. Ocean Eng. 2019, 181, 145–160. [Google Scholar] [CrossRef]

- Nayak, N.; Das, S.R.; Panigrahi, T.K.; Das, H.; Nayak, S.R.; Singh, K.K.; Askar, S.S.; Abouhawwash, M. Overshoot Reduction Using Adaptive Neuro-Fuzzy Inference System for an Autonomous Underwater Vehicle. Mathematics 2023, 11, 1868. [Google Scholar] [CrossRef]

- Yazdani, A.; Sammut, K.; Yakimenko, O.; Lammas, A. A survey of underwater docking guidance systems. Robot. Auton. Syst. 2020, 124, 103382. [Google Scholar] [CrossRef]

- Stokey, R.; Purcell, M.; Forrester, N.; Austin, T.; Goldsborough, R.; Allen, B.; von Alt, C. A Docking System for REMUS, an Autonomous Underwater Vehicle. In Proceedings of the IEEE/MTS OCEANS 1997 Conference, Halifax, NS, Canada, 6–9 October 1997; pp. 1132–1136. [Google Scholar]

- Teeneti, C.R.; Truscott, T.T.; Beal, D.N.; Pantic, Z. Review of Wireless Charging Systems for Autonomous Underwater Vehicles. IEEE J. Ocean. Eng. 2019, 46, 68–87. [Google Scholar] [CrossRef]

- Li, H.; Huang, F.; Chen, Z. Virtual-reality-based online simulator design with a virtual simulation system for the docking of unmanned underwater vehicle. Ocean Eng. 2022, 266, 112780. [Google Scholar] [CrossRef]

- Lin, M.; Lin, R.; Yang, C.; Li, D.; Zhang, Z.; Zhao, Y.; Ding, W. Docking to an underwater suspended charging station: Systematic design and experimental tests. Ocean Eng. 2022, 249, 110766. [Google Scholar] [CrossRef]

- Palomeras, N.; Vallicrosa, G.; Mallios, A.; Bosch, J.; Vidal, E.; Hurtos, N.; Carreras, M.; Ridao, P. AUV homing and docking for remote operations. Ocean Eng. 2018, 154, 106–120. [Google Scholar] [CrossRef]

- Palomer, A.; Ridao, P.; Ribas, D. Inspection of an underwater structure using point-cloud SLAM with an AUV and a laser scanner. J. Field Robot. 2019, 36, 1333–1344. [Google Scholar] [CrossRef]

- Allibert, G.; Hua, M.-D.; Krupínski, S.; Hamel, T. Pipeline following by visual servoing for Autonomous Underwater Vehicles. Control Eng. Pract. 2019, 82, 151–160. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, L.-H.; Hua, M.-D.; Allibert, G.; Hamel, T. A Homography-Based Dynamic Control Approach Applied to Station Keeping of Autonomous Underwater Vehicles Without Linear Velocity Measurements. IEEE Trans. Control Syst. Technol. 2020, 29, 2065–2078. [Google Scholar] [CrossRef]

- Kimball, P.W.; Clark, E.B.; Scully, M.; Richmond, K.; Flesher, C.; Lindzey, L.E.; Harman, J.; Huffstutler, K.; Lawrence, J.; Lelievre, S.; et al. The Artemis under-ice AUV docking system. J. Field Robot. 2018, 35, 299–308. [Google Scholar] [CrossRef]

- Myint, M.; Yonemori, K.; Lwin, K.N.; Yanou, A.; Minami, M. Dual-eyes Vision-based Docking System for Autonomous Underwater Vehicle: An Approach and Experiments. J. Intell. Robot. Syst. 2018, 92, 159–186. [Google Scholar] [CrossRef]

- Wang, T.; Zhao, Q.; Yang, C. Visual navigation and docking for a planar type AUV docking and charging system. Ocean Eng. 2021, 224, 108744. [Google Scholar] [CrossRef]

- Akinyele, O.; Choi, J.W.; Yu, C.H. Improving Response Performance of Quadrant-detector-navigated Unmanned Underwater Vehicle in Underwater Docking Operations. Int. J. Control Autom. Syst. 2021, 19, 1013–1025. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, J.; Chen, Y.; Bian, C.; Zhang, F.; Liang, Q. Adaptive neural network control for visual docking of an autonomous underwater vehicle using command filtered backstepping. Int. J. Robust Nonlinear Control 2022, 32, 4716–4738. [Google Scholar] [CrossRef]

- Xie, T.; Li, Y.; Jiang, Y.; Pang, S.; Wu, H. Turning circle based trajectory planning method of an underactuated AUV for the mobile docking mission. Ocean Eng. 2021, 236, 109546. [Google Scholar] [CrossRef]

- Ren, R.; Zhang, L.; Liu, L.; Yuan, Y. Two AUVs Guidance Method for Self-Reconfiguration Mission Based on Monocular Vision. IEEE Sens. J. 2021, 21, 10082–10090. [Google Scholar] [CrossRef]

- Yan, Z.; Zhang, J.; Tang, J. Whale optimization algorithm based on lateral inhibition for image matching and vision-guided AUV docking. J. Intell. Fuzzy Syst. 2021, 40, 4027–4038. [Google Scholar] [CrossRef]

- Aguiar, A.P.; Pascoal, A.M. Dynamic positioning and way-point tracking of underactuated AUVs in the presence of ocean currents. Int. J. Control 2007, 80, 1092–1108. [Google Scholar] [CrossRef]

- Panagou, D.; Kyriakopoulos, K.J. Dynamic positioning for an underactuated marine vehicle using hybrid control. Int. J. Control 2014, 87, 264–280. [Google Scholar] [CrossRef]

- Wang, Y.-L.; Han, Q.-L.; Fei, M.-R.; Peng, C. Network-Based T–S Fuzzy Dynamic Positioning Controller Design for Unmanned Marine Vehicles. IEEE Trans. Cybern. 2018, 48, 2750–2763. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, J.; Liu, C.; Proctor, A. Nonlinear model predictive dynamic positioning control of an underwater vehicle with an onboard USBL system. J. Mar. Sci. Technol. 2016, 21, 57–69. [Google Scholar] [CrossRef]

- Elmokadem, T.; Zribi, M.; Youcef-Toumi, K. Control for Dynamic Positioning and Way-point Tracking of Underactuated Autonomous Underwater Vehicles Using Sliding Mode Control. J. Intell. Robot. Syst. 2019, 95, 1113–1132. [Google Scholar] [CrossRef]

- Peng, Y.; Guo, L.; Meng, Q.; Chen, H. Research on Hover Control of AUV Uncertain Stochastic Nonlinear System Based on Constructive Backstepping Control Strategy. IEEE Access 2022, 10, 50914–50924. [Google Scholar] [CrossRef]

- Benhimane, S.; Malis, E. Homography-based 2D Visual Tracking and Servoing. Int. J. Robot. Res. 2007, 26, 661–676. [Google Scholar] [CrossRef]

- van der Zwaan, S.; Bernardino, A.; Santos-Victor, J. Visual station keeping for floating robots in unstructured environments. Robot. Auton. Syst. 2002, 39, 145–155. [Google Scholar] [CrossRef] [Green Version]

- Krupinski, S.; Allibert, G.; Hua, M.-D.; Hamel, T. An Inertial-Aided Homography-Based Visual Servo Control Approach for (Almost) Fully Actuated Autonomous Underwater Vehicles. IEEE Trans. Robot. 2017, 33, 1041–1060. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Zhang, G.; Wu, P.; Zhao, X.; Wang, T.; Yan, W. Model Predictive Visual Servoing of Fully-Actuated Underwater Vehicles With a Sliding Mode Disturbance Observer. IEEE Access 2019, 7, 25516–25526. [Google Scholar] [CrossRef]

- Wang, N.; He, H. Extreme Learning-Based Monocular Visual Servo of an Unmanned Surface Vessel. IEEE Trans. Ind. Informatics 2020, 17, 5152–5163. [Google Scholar] [CrossRef]

- Gao, J.; Proctor, A.A.; Shi, Y.; Bradley, C. Hierarchical Model Predictive Image-Based Visual Servoing of Underwater Vehicles With Adaptive Neural Network Dynamic Control. IEEE Trans. Cybern. 2015, 46, 2323–2334. [Google Scholar] [CrossRef] [PubMed]

- Fossen, T.I. Handbook of Marine Craft Hydrodynamics and Motion Control; Wiley: New York, NY, USA, 2011. [Google Scholar]

| D = diag (Dv, Dω) | ||

| = diag(15, 15, 15) (kg) | (kg·m) | Dv = diag(8, 20, 30) (kg·s−1) |

| = diag(0.7, 0.55, 0.5) (kg·m2) | (kg·m2) | Dω = diag(1.5, 2.8, 3) (kg·m2·s−1) |

| (kg·m) | (kg·m) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Sun, Z.; Ke, Y.; Li, C.; Hu, J. Two-Step Adaptive Control for Planar Type Docking of Autonomous Underwater Vehicle. Mathematics 2023, 11, 3467. https://doi.org/10.3390/math11163467

Wang T, Sun Z, Ke Y, Li C, Hu J. Two-Step Adaptive Control for Planar Type Docking of Autonomous Underwater Vehicle. Mathematics. 2023; 11(16):3467. https://doi.org/10.3390/math11163467

Chicago/Turabian StyleWang, Tianlei, Zhenxing Sun, Yun Ke, Chaochao Li, and Jiwei Hu. 2023. "Two-Step Adaptive Control for Planar Type Docking of Autonomous Underwater Vehicle" Mathematics 11, no. 16: 3467. https://doi.org/10.3390/math11163467