1. Introduction

In the past decades, nanotechnology has been used more and more widely in thermoelectric devices, which makes the study of heat conduction theory extremely important. Generally, the phonon Boltzmann transport equation (BTE) can characterize thermal transport well in nanostructures. In order to solve the BTE, researchers have made a lot of progress [

1,

2,

3,

4,

5,

6,

7,

8]. The Gray model is commonly used [

2]; however, solving the BTE in this way sometimes leads to inaccurate solutions that cannot be ignored. The different lattice Boltzmann methods have also been developed by the methods mentioned in references [

3,

4,

5,

6]. However, the lattice Boltzmann methods still have some shortcomings. For example, they are used for non-physical prediction in the ballistic state [

5,

6]. There is another method that can directly solve the BTE by using the finite difference method, namely the discrete ordinate method [

7]. However, in addition to requiring a large amount of memory to solve the equation, this method also shows a slow convergence near the diffusion limit. Moreover, the discrete unified gas dynamics scheme [

8] has been proven to be effective and deliver high-precision for low-dimensional thermal phonon transport, but it has not been used to solve the BTE in three-dimensional geometry. The state-space strategies are the basis of the novel theory of control and its advantage is the characterization of approaches of importance through the BTE in favoring transport functions. However, for this method, in the previous duration the processes were sufficient for them with only one differential equation for a reasonably low order [

9]. The main step of the finite element method for solving the BTE is obtaining the equations of motion for the finite elements [

10]. However, this method is very time consuming and it cannot handle the infinite domain problems well. So far, the Monte Carlo (MC) simulation has been proved to be an efficient method for solving the BTE. Two typical MC methods are used, of which the ensemble MC method is employed to calculate the effective thermal conductivity in many kinds of nanostructures, for example, silicon structures [

11,

12] and even composites [

13,

14]. The other method, the phonon tracing MC method, simulates the trajectories of phonons independently which reduces the computation time greatly [

15,

16]. Therefore, both the ensemble MC and the phonon tracing MC are suitable methods used for phonon transport in many kinds of nanostructures with a larger size, and they can also solve the BTE with high accuracy and minimum calculation time [

1].

Recently, Yu-Chao Hua and Bing-Yang Cao proposed an efficient two-step Monte Carlo method for heat conduction in nanostructures [

1]. However, it is difficult to calculate the effective thermal conductivity of complex structures with different pore shapes. Effective medium theory (EMT) is a widely used analytical method to study the optical responses of subwavelength periodic structures [

17,

18,

19] and it can achieve similar functions of the whole system by defining the average value of materials with effective parameters [

20]. The Maxwell-Garnett theory and the Bruggeman EMT are based on the material characteristics of each component in the mixture, which play an important role in effective medium methods. The composition of dielectric materials usually shows different structural properties. To calculate the thermal conductivity of these materials, EMT should be a favored method; for a given material and geometric structure, the EMT method can calculate the thermal conductivity by achieving the functions of the given system [

21]. Due to these characteristics of EMT, it has many applications in electrical conductivity and related issues [

22,

23,

24,

25,

26].

At nanoscale, the size characteristics of phononic crystals are very close to or even smaller than the mean free path (MFP) of phonons, and the heat conduction no longer obeys the Fourier law. Therefore, in order to deeply understand phonon transport in thermoelectric phononic crystals, the correct models and methods are required to simulate the phonon transport. The EMT method can effectively calculate the effective thermal conductivity, and the value of the effective thermal conductivity only depends on the porosity. However, the EMT method is not the best method to calculate the effective thermal conductivity of complex geometry. The MC method mainly calculates the effective thermal conductivity through the MC model, which can reduce the calculation time without damaging the accuracy. However, this method still has problems in calculating the effective thermal conductivity of complex pore shapes. The general effective medium theory can calculate the effective thermal conductivity of different pore shapes by implementing the suppression function. Therefore, we combine the MC method with the general effective medium theory method to develop a novel method for calculating the effective thermal conductivity of complex pore shapes as effectively as these two methods. In this paper, a novel Monte Carlo method based on the universal effective medium theory is developed to calculate the thermal conductivity in nanoscale thermoelectric phononic crystals with complex geometries, which is the creativity point in this paper. The outline of this paper is as follows. In

Section 2, the method description is introduced. In addition, the numerical experiments are conducted to numerically illustrate some properties of the present method in

Section 3, followed by a summary in

Section 4. In this paper, the MCBU method is compared with the EMT method and it is found that the MCBU method can effectively and accurately calculate the effective thermal conductivity of different geometric shapes, while the EMT method cannot deal with it well, which is the main focus of this paper.

3. Results and Discussions

In this section, the accuracy of the MCBU method is checked and the results are compared with those of the two-step MC method and the MC model in Reference [

1]. The two-step MC method calculates the thermal conductivity through the formula

, where Δ

L is the length of simulation unit,

l0 is the average MFP and

p0 is the initial phonon transmittance,

pi is the internal phonon transmittance. The MC model calculates the thermal conductivity through the formula

, where

Rp is the pore radius and

ε is the porosity.

The deviation between

p0 and

pi can be ignored. Therefore, when calculating the effective thermal conductivity by the two-step MC method,

pi can be replaced by

p0.

Figure 2 illustrates the effective thermal conductivity varying with

Lc. It is found that the effective thermal conductivity increases with increasing

Lc, and the results obtained by the MCBU method agree well with those predicted by the two-step MC method; the deviation between them decreases with increasing

Lc. In addition, the results obtained by the two methods are both slightly less than those obtained by the MC model, and approach the value predicted by the MC model.

In the following, numerical experiments are conducted to show the effectiveness of the MCBU method, and the comparison between the MCBU method and effective medium theory (EMT) method is discussed in detail. First, the results are illustrated in

Table 1 and

Figure 3. In

Table 1,

ks is denoted as the thermal conductivity of rectangle pores in the MCBU method,

km as the thermal conductivity of the EMT method; and

ts is denoted as the computation time of the MCBU method, and

tm as the computation time of the EMT method. From

Table 1, we can see that the MCBU method is consistent with the EMT method with a deviation of less than 12%. In the AlN with rectangular pore shape, when the porosity is 0.35 and 0.4, the MCBU method is consistent with the EMT method, with a deviation of about 3%. In addition, the deviation of the computation time between the two methods can be ignored.

Figure 3 shows that the effective thermal conductivity decreases with the increase of porosity, and the deviation between the MCBU method and EMT method in rectangular and circular holes decreases sharply with the increase of porosity. For triangular and rhombic pores, the deviation between the two methods decreases with the decrease of porosity. With the change of pore shapes, the same value is obtained by using the EMT method, which indicates that the EMT method may have some problems in calculating the effective thermal conductivity of complex geometric pore shapes. Therefore, when calculating the effective thermal conductivity of pores with complex geometry, the MCBU method is a more suitable and quicker method.

Next, based on other influencing factors, we compare the results between the MCBU method and the EMT method in detail. From

Table 2, we can conclude that when the characteristic MFP Λ

0 is equal to 0.1 till 0.35, the effective thermal conductivity of rectangular pores is consistent with the EMT method, with a deviation of less than 20%, or even less than 5%. In addition, we find that the calculation time deviation between the two methods can be ignored, which shows the superiority of our method. In other words, it can accurately calculate more complex geometry than the effective medium theory in almost the same time.

Figure 4 illustrates that the effective thermal conductivity calculated by the EMT method does not change with the changing of pore shapes and Λ

0. Moreover, from

Figure 4, we can conclude that at the porosity of 0.25, the effective thermal conductivity in four kinds of shapes decreases with the increase of the characteristic MFP, and the deviation between the MCBU method and the EMT method decreases when the characteristic MFP decreases. In this figure, the effective thermal conductivity of rectangle pores is the closest to the EMT method.

Then, we analyze the influence of

S(0) on the effective thermal conductivity in AlN, at 300 k, and compare the results between MCBU method and the EMT method. From

Table 3, we can conclude that the MCBU method is consistent with the effective medium theory method. With the increase of

S(0), the deviation will be less than 15%. In addition, we can see that the difference in calculation time between the two methods can be ignored, which again shows the superiority of our method.

Figure 5 illustrates that the effective thermal conductivity in four kinds of pore shapes calculated by the MCBU method, and the effective thermal conductivity calculated by the EMT method increases with the increase of

S(0) and the deviation between the MCBU method and the EMT method decreases with the increase of

S(0).

In the following, we analyze the influence of

Lc/

L on the effective thermal conductivity in AlN, at 300k, with four kinds of pore shapes and compare the results of the MCBU method and the EMT method. As shown in

Table 4, the MCBU method agrees with the EMT method with a deviation between them of less than 20%. Except for the cases where

Lc/

L equals to 1.8 and 2.0, the deviation between the two methods decreases with the increase of

Lc/

L, and when

Lc/

L ≥ 1.7, the deviation between the two methods is less than 16.2%. From

Figure 6, we can see that the two curves increase with the increase of

Lc/

L.

Then we calculate the effective thermal conductivity in rectangle pores and compare it with the EMT method. From

Table 5, we can conclude that the MCBU method agrees with the EMT method with the deviation between them being less than 18%, and except for the cases where

Lc/

L equals to 1.6 and 1.7, the deviation between the two methods decreases with the increase of

Lc/

L and when 1.9 ≤

Lc/

L ≤ 2.0, the deviation between the two methods is less than 16%. Compared with

Table 4, we can conclude that

ks is larger than

kc for all the values of

Lc/

L. From

Figure 7, we can conclude that the two curves increase with the increase of

Lc/

L.

Next, we calculate the effective thermal conductivity in triangle pores and compare it with the EMT and we denote

kt as the thermal conductivity of the MCBU method and

km as the thermal conductivity of the EMT method. From

Table 6 and

Figure 8, we can conclude that the effective thermal conductivity increases with the increase of

Lc/

L. From

Table 6, we can conclude that MCBU method agrees with the EMT method with the deviation between them less than 18% and except for the cases where

Lc/

L equals to 1.6, the deviation between the two methods decreases with the increase of

Lc/

L and when 1.9 ≤

Lc/

L ≤ 2.0, the deviation between the two method is less than 15%. Compared with

Table 4,

Table 5 and

Table 6, we have

kc <

kt <

ks for all the values of

Lc/

L.

Last, we calculate the effective thermal conductivity in rhombus pores and compare it with the EMT and we denote

kr as the thermal conductivity of the MCBU method and

km as the thermal conductivity of the EMT method. From

Table 7 and

Figure 9, we can see that the effective thermal conductivity increases with the increase of

Lc/

L, and from

Table 7, we can conclude that the MCBU method agrees with the EMT method with the deviation between them less than 19% and except for this, cases where

Lc/

L equals to 1.7, the deviation between the two methods decreases with the increase of

Lc/

L and when 1.7 ≤

Lc/

L ≤ 2.0, the deviation between the two method is less than 16.6%. Compared with

Table 4,

Table 5 and

Table 6, we can conclude that

kc <

kr <

kt <

ks for all the values of

Lc/

L.

Finally, a detailed analysis of influences of geometric parameters is conducted and discussed. In previous studies, the influences of porosity on thermal conductivity have been studied. However, little work has been done on the effects of different porosities on periodic nanoscale structures. In this paper, the effects of porosities on periodic nanostructures in different pore shapes are studied and shown in

Figure 10. The black line denotes the circle pores, the blue line denotes the rectangle pores, the green line denotes the triangle pores and the red line denotes the rhombus pores. From

Figure 10, it can be observed that the effective thermal conductivity decreases when the porosity increases and this is because the greater the porosity, the more loss of the heat flux passthrough to the material. The effective thermal conductivity of the triangle pore shapes is the most affected and it decreases most rapidly with the increase of the porosity. The thermal conductivity of the rectangle pore shapes is the least affected. With the increase of the porosity, the effective thermal conductivity of the rectangle pores decreases the slowest, followed by the circle pores and the rhombus pores. Let

kc,

ks,

kt,

kr be the effective thermal conductivity of circle pores, rectangle pores, triangle pores, and rhombus pores, respectively. It is clear that under the same porosity and the same temperature, we always have

ks >

kc >

kr >

kt as shown in

Figure 10.

To evaluate the influence of the temperature, we calculate the effective thermal conductivity in different temperatures. When the temperature increases, no matter what the shape of the pore and the porosity, the effective thermal conductivity increases too. Without the loss of generality, we calculated the effective thermal conductivity with square shapes in at 200 k, 300 k, 400 k and 500 k, respectively, as shown in

Figure 11. From this figure, we can conclude that at the same temperature, the trend of the effective thermal conductivity is dropping while the porosity is increasing and under the same porosity, the trend of conductivity is increasing while the temperature increasing. That is because when the temperature increases, the heat flux increases too and that causes the effective thermal conductivity increase.

To study the influence of the materials, we calculate the effective thermal conductivity with different pore shapes in four materials: AlAs, AlN, GaAs and Si. Without the loss of generality, we calculate the effective thermal conductivity in rectangle shapes in at 300 k. As shown in

Figure 12, we can see that under the same porosity and the same temperature, the effective thermal conductivity in material made of AlN is the highest while, at the same time, the effective thermal conductivity in material made of Si is the lowest; the effective thermal conductivity in material made of GaAs is higher than that made of AlAs. Moreover, the thermal conductivity in material made of AlN and GaAs differs slightly but the conductivity in materials made of Si is significantly lower than the former, and this conclusion will not change with the change of the pore shapes. From this result, we can say that in materials made of AlN, there will be less loss of heat flux while in materials made of Si, there will be more loss of heat flux.

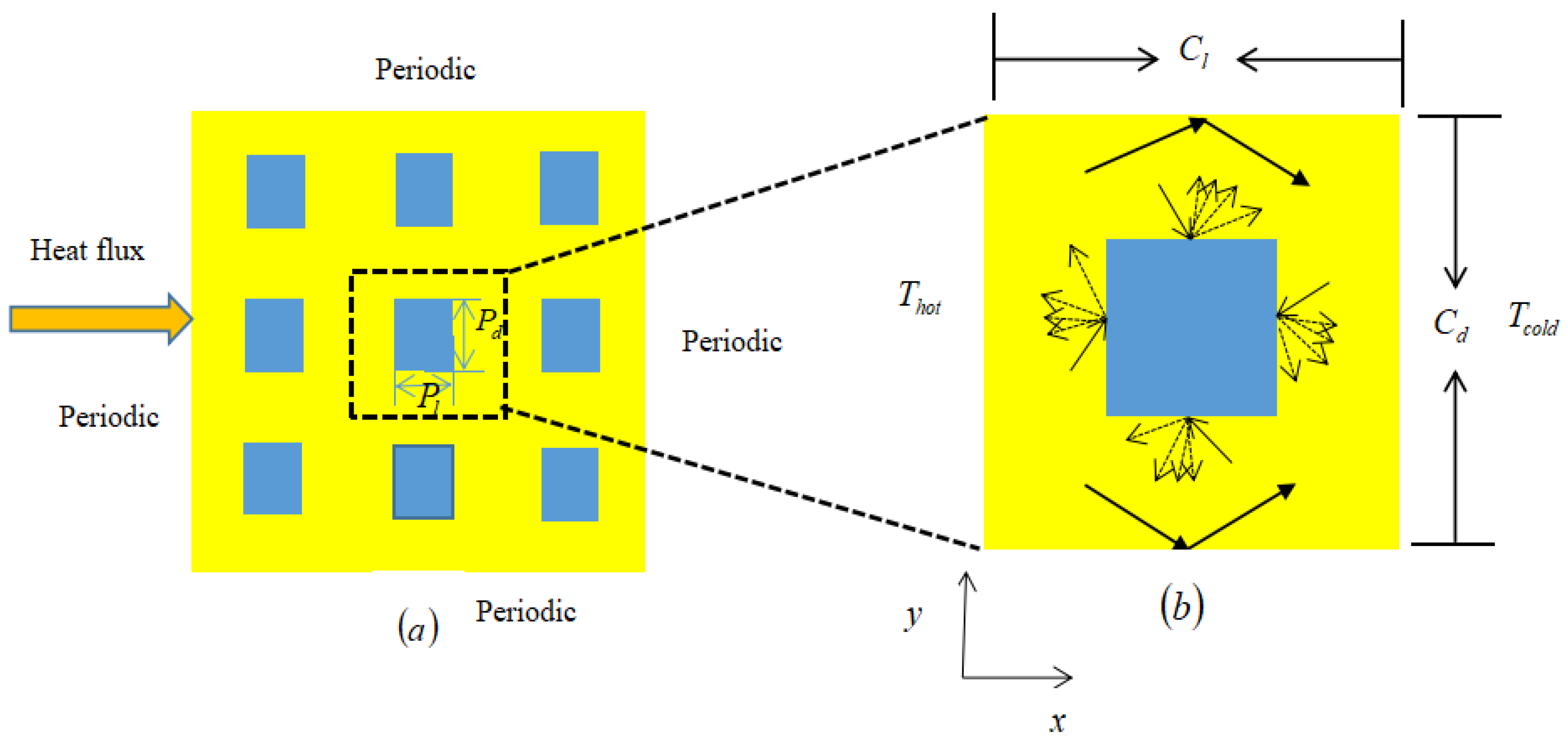

In order to evaluate the influence of the location of pore shapes, we calculate the effective thermal conductivity in material made of AlAs for two kinds of rectangles. For one kind of rectangle, we set the parameter as

Pl = 2

Pd which means the aspect ratio of the rectangle is 2 and for the other kind of the rectangle, we set the parameter as

Pd = 2

Pl which means the aspect ratio of the rectangle is 0.5, as shown in

Figure 13. From this figure, it can be clearly seen that the effective thermal conductivity of the rectangle with

Pl = 2

Pd structure is always higher than the rectangle with

Pd = 2

Pl structure and the gap between the two line widens with the growth of the porosity. From this result, we can see that the locations of the pores block the heat flux through the materials, changing the direction of the heat flux and affecting the effective thermal conductivity.