Quasi-Packing Different Spheres with Ratio Conditions in a Spherical Container

Abstract

:1. Introduction

- (1)

- A novel class of sphere packing in a spherical container with partial overlapping, quasi-containment and ratio conditions.

- (2)

- A mixed-integer nonlinear programming model for the ratio quasi-packing of spheres.

- (3)

- A heuristic for large problem instances consisting of finding feasible starting points in an open dimension continuous optimization problem to obtain reasonable feasible solutions.

- (4)

- Numerical experiments for small problem instances with exact solutions obtained using the global solver BARON.

- (5)

- Numerical experiments for larger problem instances with good feasible solutions obtained by the heuristic using the local solver IPOPT for open dimension problems.

2. Problem Formulation

- (partial overlapping condition) for ,

- (quasi-containment condition) for ,

- for (ratio condition),

Mixed-Integer Nonlinear Programming Model for RQPS

- The model (1)–(4) is a mixed-integer nonlinear mathematical programming problem (MINLP—Mixed-Integer Nonlinear Programming).

- The objective function (1) is linear.

- The total number of variables is ( binary and continuous variables).

- The solution space is defined by + nonlinear constraints of the form (2), (3) and linear inequalities in (4).

3. Heuristic Approach

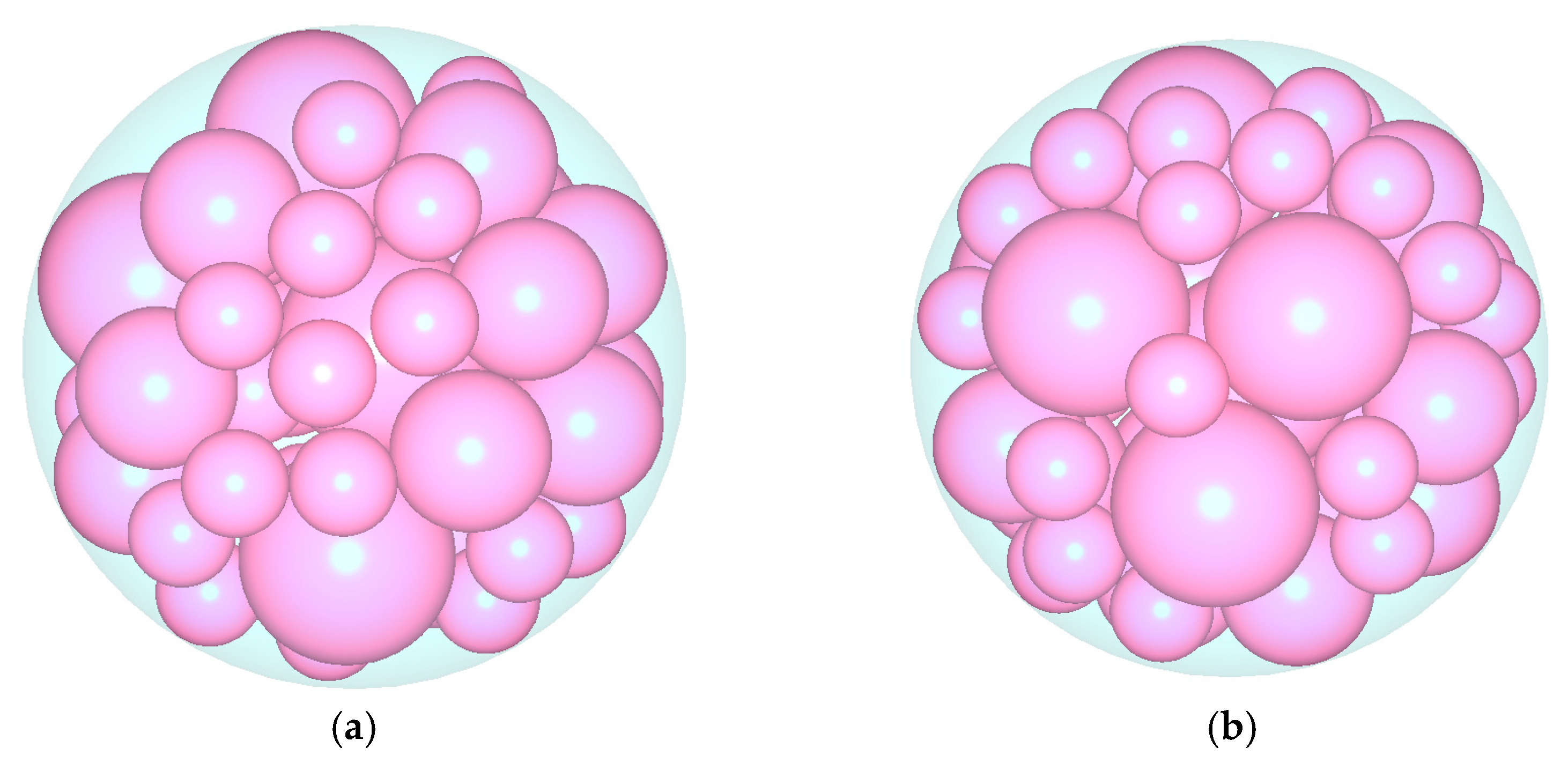

- (a)

- , , ;

- (b)

- and .

4. Computational Results

4.1. Results for Small Instances Using BARON

4.2. Results Obtained by the Heuristic

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Hifi, M.; M’Hallah, R. A literature review on circle and sphere packing problems: Models and methodologies. Adv. Oper. Res. 2009, 2009, 150624. [Google Scholar] [CrossRef]

- Cremer, T.; Cremer, M. Chromosome territories. Cold Spring Harb. Perspect. Biol. 2010, 2, a003889. [Google Scholar] [CrossRef] [PubMed]

- Raj, A.; Chen, Y.-H. The wiring economy principle: Connectivity determines anatomy in the human brain. PLoS ONE 2011, 6, e14832. [Google Scholar] [CrossRef] [PubMed]

- Rivera-Alba, M.; Vitaladevuni, S.N.; Mishchenko, Y.; Lu, Z.; Takemura, S.-Y.; Scheffer, L.; Meinertzhagen, I.A.; Chklovskii, D.B.; de Polavieja, G.G. Wiring economy and volume exclusion determine neuronal placement in the Drosophila brain. Curr. Biol. 2011, 21, 2000–2005. [Google Scholar] [CrossRef] [PubMed]

- Karklin, Y.; Simoncelli, E.P. Efficient coding of natural images with a population of noisy Linear-Nonlinear neurons. Adv. Neural Inf. Process. Syst. 2011, 24, 999–1007. [Google Scholar]

- Sutou, A.; Day, Y. Global optimization approach to unequal sphere packing problems in 3D. J. Optim. Theory Appl. 2002, 114, 671–694. [Google Scholar] [CrossRef]

- Wang, J. Packing of unequal spheres and automated radiosurgical treatment planning. J. Combin. Optim. 1999, 3, 453–463. [Google Scholar] [CrossRef]

- Burtseva, L.; Pestryakov, A.; Romero, R.; Valdez, B.; Petranovskii, V. Some aspects of computer approaches to simulation of bimodal sphere packing in material engineering. Adv. Mater. Res. 2014, 1040, 585–591. [Google Scholar] [CrossRef]

- Duriagina, Z.; Lemishka, I.; Litvinchev, I.; Marmolejo, J.A.; Pankratov, A.; Romanova, T.; Yaskov, G. Optimized filling of a given cuboid with spherical powders for additive manufacturing. J. Oper. Res. Soc. China 2021, 9, 853–868. [Google Scholar] [CrossRef]

- Frenkel, D. Computer simulation of hard-core models for liquid crystals. Mol. Phys. 1987, 60, 1–20. [Google Scholar] [CrossRef]

- Yamada, S.; Kanno, J.; Miyauchi, M. Multi-sized sphere packing in containers: Optimization formula for obtaining the highest density with two different sized spheres. IPSJ Online Trans. 2011, 4, 126–133. [Google Scholar] [CrossRef]

- Araujo, L.J.P.; Ozcan, E.; Atkin, J.A.D.; Baumers, M. Analysis of irregular three-dimensional packing problems in additive manufacturing: A new taxonomy and dataset. Intern. J. Prod. Res. 2019, 57, 5920–5934. [Google Scholar] [CrossRef]

- Romanova, T.; Stoyan, Y.; Pankratov, A.; Litvinchev, I.; Yanchevsky, I.; Mozgova, I. Optimal Packing in Additive Manufacturing. IFAC-PapersOnLine 2019, 52, 2758–2763. [Google Scholar] [CrossRef]

- Romanova, T.; Stoyan, Y.; Pankratov, A.; Litvinchev, I.; Avramov, K.; Chernobryvko, M.; Yanchevskyi, I. Optimal layout of ellipses and its application for additive manufacturing. Int. J. Prod. Res. 2021, 59, 560–575. [Google Scholar] [CrossRef]

- Halkarni, S.S.; Sridharan, A.; Prabhu, S.V. Experimental investigation on effect of random packing with uniform sized spheres inside concentric tube heat exchangers on heat transfer coefficient and using water as working medium. Int. J. Therm. Sci. 2018, 133, 341–356. [Google Scholar] [CrossRef]

- Mueller, G.E. Numerically packing spheres in cylinders. Powder Technol. 2005, 159, 105–110. [Google Scholar] [CrossRef]

- Flaischlen, S.; Wehinger, G.D. Synthetic packed-bed generation for CFD simulations: Blender vs. STAR-CCM+. ChemEngineering 2019, 3, 52. [Google Scholar] [CrossRef]

- Castillo, I.; Kampas, F.J.; Pintér, J.D. Solving circle packing problems by global optimization: Numerical results and industrial applications. Eur. J. Oper. Res. 2008, 191, 786–802. [Google Scholar] [CrossRef]

- Miyazawa, F.K.; Wakabayashi, Y. Techniques and results on approximation algorithms for packing circles. São Paulo J. Math. Sci. 2022, 16, 585–615. [Google Scholar] [CrossRef]

- Martinez, L.; Andrade, R.; Birgin, E.G.; Martinez, J.M. Packmol: A package for building initial configurations for molecular dynamics simulations. J. Comput. Chem. 2009, 30, 2157–2164. [Google Scholar] [CrossRef]

- Amore, P. Circle packing in regular polygons. Phys. Fluids 2023, 35, 027130. [Google Scholar] [CrossRef]

- Stoyan, Y.; Yaskov, G.; Romanova, T.; Litvinchev, I.; Yakovlev, S.; Cantu, J.M.V. Optimized packing multidimensional hyperspheres: A unified approach. Math. Biosci. Eng. 2020, 17, 6601–6630. [Google Scholar] [CrossRef] [PubMed]

- Toledo, F.M.B.; Carravilla, M.A.; Ribeiro, C.; Oliveira, J.F.; Gomes, A.M. The dotted-board model: A new MIP model for nesting irregular shapes. Int. J. Prod. Econ. 2013, 145, 478–487. [Google Scholar] [CrossRef]

- Galiev, S.I.; Lisafina, M.S. Linear models for the approximate solution of the problem of packing equal circles into a given domain. Eur. J. Oper. Res. 2013, 230, 505–514. [Google Scholar] [CrossRef]

- Litvinchev, I.; Infante, L.; Ozuna Espinosa, E.L. Approximate Circle Packing in a Rectangular Container: Integer Programming Formulations and Valid Inequalities. In Computational Logistics. ICCL 2014; Lecture Notes in Computer Science; González-Ramírez, R.G., Schulte, F., Voß, S., Ceroni Díaz, J.A., Eds.; Springer: Cham, Switzerland, 2014; Volume 8760, pp. 47–60. [Google Scholar] [CrossRef]

- Litvinchev, I.; Ozuna, E.L. Integer programming formulations for approximate packing circles in a rectangular container. Math. Probl. Eng. 2014, 2014, 317697. [Google Scholar] [CrossRef]

- He, K.; Tole, K.; Ni, F.; Yuan, Y.; Liao, L. Adaptive large neighborhood search for solving the circle bin packing problem. Comput. Oper. Res. 2021, 127, 105140. [Google Scholar] [CrossRef]

- Yuan, Y.; Tole, K.; Ni, F.; He, K.; Xiong, Z.; Liu, J. Adaptive simulated annealing with greedy search for the circle bin packing problem. Comput. Oper. Res. 2022, 144, 105826. [Google Scholar] [CrossRef]

- Morales, A.; Fierrez, J.; Acien, A.; Tolosana, R.; Serna, I. SetMargin loss applied to deep keystroke biometrics with circle packing interpretation. Pattern Recognit. 2022, 122, 108283. [Google Scholar] [CrossRef]

- Lai, X.; Hao, J.K.; Yue, D.; Lü, Z.; Fu, Z.H. Iterated dynamic thresholding search for packing equal circles into a circular container. Eur. J. Oper. Res. 2022, 299, 137–153. [Google Scholar] [CrossRef]

- von Seckendorff, J.; Achterhold, K.; Pfeiffer, F.; Fischer, R.; Hinrichsen, O. Experimental and numerical analysis of void structure in random packed beds of spheres. Powder Technol. 2021, 380, 613–628. [Google Scholar] [CrossRef]

- Hifi, M.; Yousef, L. A local search-based method for sphere packing problems. Eur. J. Oper. Res. 2019, 274, 482–500. [Google Scholar] [CrossRef]

- Hifi, M.; Youssouf, A.M.; Yousef, L.A. Population-Based Algorithm for the Sphere Packing Problem. In Proceedings of the 2022 8th International Conference on Control, Decision and Information Technologies (CoDIT), Istanbul, Turkey, 17 May 2022; Volume 1, pp. 1455–1460. [Google Scholar]

- Uhler, C.; Wright, S.J. Packing ellipsoids with overlap. SIAM Rev. 2013, 55, 671–706. [Google Scholar] [CrossRef]

- DeVries, S.H.; Baylor, D.A. Mosaic arrangement of ganglion cell receptive fields in rabbit retina. J. Neurophysiol. 1997, 78, 2048–2060. [Google Scholar] [CrossRef]

- McDonnell, M.D.; Stocks, N.G. Maximally informative stimuli and tuning curves for sigmoidal Rate-Coding neurons and populations. Phys. Rev. Lett. 2008, 101, 058103. [Google Scholar] [CrossRef]

- Iglesias-Ham, M.; Kerber, M.; Uhler, C. Sphere Packing with Limited Overlap. In Proceedings of the 26th Canadian Conference on Computational Geometry, CCCG 2014, Halifax, NS, Canada, 11–13 August 2014. [Google Scholar]

- Blunt, M.J. Multiphase Flow in Permeable Media: A Pore-Scale Perspective; Cambridge University Press: Cambridge, UK, 2017; p. 500. [Google Scholar] [CrossRef]

- Gerke, K.M.; Korost, D.V.; Karsanina, M.V.; Korost, S.P.; Vasiliev, R.V.; Lavrukhin, V.R.; Gafurova, D.R. Modern approaches to pore space scale digital modeling of core structure and multiphase flow. Georesursy 2021, 23, 197–213. [Google Scholar] [CrossRef]

- Sedaghat, M.H.; Gerke, K.; Azizmohammadi, S.; Matthai, S.K. Simulation-based determination of relative permeability in laminated rocks. Energy Procedia 2016, 97, 433–439. [Google Scholar] [CrossRef]

- Eichheimer, P.; Thielmann, M.; Popov, A.; Golabek, G.J.; Fujita, W.; Kottwitz, M.O.; Kaus, B.J.P. Pore-scale permeability prediction for Newtonian and non-Newtonian fluids. Solid Earth 2019, 10, 1717–1731. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Hou, J.; Zhang, Z.; Chen, Z. Multi-thermal fluid assisted gravity drainage process: A new improved-oil-recovery technique for thick heavy oil reservoir. J. Pet. Sci. Eng. 2015, 133, 1–11. [Google Scholar] [CrossRef]

- Al-Nakhli, A.; Tariq, Z.; Mahmoud, M.; Abdulraheem, A.; Al-Shehri, D. A Novel Thermochemical Fracturing Approach to Reduce Fracturing Pressure of High Strength Rocks. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, SPE-197593-MS, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar] [CrossRef]

- Duriagina, Z.A.; Lemishka, I.A.; Trostianchyn, A.M.; Kulyk, V.V.; Svachko, S.G.; Tepla, T.L.; Pleshakov, E.I.; Kovbasyuk, T.M. The effect of morphology and particle-size distribution of VT20 titanium alloy powders on the mechanical properties of deposited coatings. Powder Metall. Met. Ceram. 2019, 57, 697–702. [Google Scholar] [CrossRef]

- Ning, J.; Wang, W.; Zamorano, B.; Liang, S.Y. Analytical modeling of lack-of-fusion porosity in metal additive manufacturing. Appl. Phys. A 2019, 125, 797. [Google Scholar] [CrossRef]

- Romanova, T.; Stoyan, Y.; Pankratov, A.; Litvinchev, I.; Marmolejo, J.A. Decomposition Algorithm for Irregular Placement Problems. In Intelligent Computing and Optimization ICO 2019; Advances in Intelligent Systems and Computing; Vasant, P., Zelinka, I., Weber, G.W., Eds.; Springer: Cham, Switzerland, 2020; Volume 1072, pp. 214–221. [Google Scholar]

- Kilinc, M.R.; Sahinidis, N.V. Exploiting integrality in the global optimization of mixed integer nonlinear programming problems with BARON. Optim. Methods Softw. 2018, 33, 540–562. [Google Scholar] [CrossRef]

- Sahinidis, N. BARON User Manual V. Available online: http://www.minlp.com/downloads/docs/baronmanual.pdf (accessed on 3 November 2022).

- Tawarmalani, M.; Sahinidis, N.V. A polyhedral branch-and-cut approach to global optimization. Math. Program. 2005, 103, 225–249. [Google Scholar] [CrossRef]

- NEOS Server: State-of-the-Art Solvers for Numerical Optimization. Available online: https://neos-server.org/neos/ (accessed on 11 January 2023).

- Fourer, R.; Gay, D.M.; Kernighan, B.W. AMPL: A Modeling Language for Mathematical Programming, 2nd ed.; Thomson Learning: Chicago, IL, USA, 2002. [Google Scholar]

- IPOPT: Documentation. Available online: https://coin-or.github.io/Ipopt/ (accessed on 14 January 2023).

- Litvinchev, I.; Ozuna, E.L. Approximate packing circles in a rectangular container: Valid inequalities and nesting. J. Appl. Res. Technol. 2014, 12, 716–723. [Google Scholar] [CrossRef]

- Michaelis, A.; Scheithauer, U.; Moritz, T.; Weingarten, S.; Abel, J.; Schwarzer, E.; Kunz, W. Advanced Manufacturing for Advanced Ceramics. Procedia CIRP 2020, 95, 18–22. [Google Scholar] [CrossRef]

- Abel, J.; Scheithauer, U.; Janics, T.; Hampel, S.; Cano, S.; Müller-Köhn, A.; Günther, A.; Kukla, C.; Moritz, T. Fused Filament Fabrication (FFF) of Metal-Ceramic Components. J. Vis. Exp. 2018, 143, e57693. [Google Scholar]

- Stoyan, Y.G.; Romanova, T.E.; Pankratov, O.V.; Stetsyuk, P.I.; Stoyan, Y.E. Sparse balanced layout of spherical voids in three-dimensional domains. Cybern. Syst. Anal. 2021, 57, 542–551. [Google Scholar] [CrossRef]

- Zhao, B.; An, X.; Wang, Y.; Zhao, H.; Shen, L.; Sun, X.; Zou, R. Packing of different shaped tetrahedral particles: DEM simulation and experimental study. Powder Technol. 2020, 360, 21–32. [Google Scholar] [CrossRef]

- Zhao, B.; An, X.; Zhao, H.; Gou, D.; Shen, L.; Sun, X. DEM simulation on random packings of binary tetrahedron-sphere mixtures. Powder Technol. 2020, 361, 160–170. [Google Scholar] [CrossRef]

- Stoyan, Y.; Pankratov, A.; Romanova, T. Placement Problems for Irregular Objects: Mathematical Modeling, Optimization and Applications. In Optimization Methods and Applications; Springer Optimization and Its Applications, Butenko, S., Pardalos, P., Shylo, V., Eds.; Springer: Cham, Switzerland, 2017; Volume 130, pp. 521–559. [Google Scholar] [CrossRef]

- Stoyan, Y.; Pankratov, A.; Romanova, T.; Fasano, G.; Pintér, J.D.; Stoian, Y.E.; Chugay, A. Optimized Packings in Space Engineering Applications: Part I Modeling and Optimization in Space Engineering; Springer Optimization and Its Applications, Fasano, G., Pintér, J., Eds.; Springer: Cham, Switzerland, 2019; Volume 144, pp. 395–437. [Google Scholar] [CrossRef]

- Pankratov, A.; Romanova, T.; Litvinchev, I. Packing ellipses in an optimized convex polygon. J. Glob. Optim. 2019, 75, 495–522. [Google Scholar] [CrossRef]

- Romanova, T.; Litvinchev, I.; Pankratov, A. Packing ellipsoids in an optimized cylinder. Eur. J. Oper. Res. 2020, 285, 429–443. [Google Scholar] [CrossRef]

- Romanova, T.E.; Stetsyuk, P.I.; Chugay, A.M.; Shekhovtsov, S.B. Parallel computing technologies for solving optimization problems of geometric design. Cybern. Syst. Anal. 2019, 55, 894–904. [Google Scholar] [CrossRef]

- Stoyan, Y.G.; Romanova, T.E.; Pankratov, O.V.; Stetsyuk, P.I.; Maksimov, S.V. Sparse balanced layout of ellipsoids. Cybern. Syst. Anal. 2021, 57, 864–873. [Google Scholar] [CrossRef]

| Example | Radius of {ik} | |||||

|---|---|---|---|---|---|---|

| 1 | 1 | 11 | 1.1 | −1 | 0.2 | 0.2 |

| 2 | 10 | 1.2 | −1 | 0.2 | 0.2 | |

| 3 | 10 | 1.3 | −1 | 0.2 | 0.2 | |

| 4 | 12 | 1.4 | −1.1 | 0.2 | 0.2 | |

| 5 | 14 | 1.5 | −1.2 | 0.2 | 0.2 | |

| 2 | 1 | 10 | 1.1 | −1 | 0.1 | 0.3 |

| 2 | 9 | 1.2 | −1 | 0.1 | 0.3 | |

| 3 | 9 | 1.3 | −1 | 0.1 | 0.3 | |

| 4 | 13 | 1.4 | −1.1 | 0.1 | 0.3 | |

| 5 | 12 | 1.5 | −1.2 | 0.1 | 0.3 |

| Example | Radius of {ik} | |||||

|---|---|---|---|---|---|---|

| 3 | 1 | 24 | 1.2 | −0.7 | 0.6 | 0.6 |

| 2 | 15 | 1.3 | −1 | 0.2 | 0.2 | |

| 3 | 10 | 1.4 | −1.1 | 0.2 | 0.2 | |

| 4 | 1 | 24 | 1.2 | −0.7 | 0.5 | 0.7 |

| 2 | 15 | 1.3 | −1 | 0.1 | 0.3 | |

| 3 | 10 | 1.4 | −1.1 | 0.1 | 0.3 |

| Example | Radius of {ik} | |||||

|---|---|---|---|---|---|---|

| 5 | 1 | 10 | 2 | −1.8 | 1/7 | 1/7 |

| 2 | 20 | 1.5 | −1.35 | 2/7 | 2/7 | |

| 3 | 40 | 1 | −0.9 | 4/7 | 4/7 | |

| 6 | 1 | 10 | 2 | −2 | 1/7 − 0.01 | 1/7 + 0.01 |

| 2 | 20 | 1.5 | −1.5 | 2/7 − 0.01 | 2/7 + 0.01 | |

| 3 | 40 | 1 | −0.9 | 4/7 − 0.01 | 4/7 + 0.01 |

| Example | Radius of {ik} | |||||

|---|---|---|---|---|---|---|

| 7, 14 | 1 | 50 | 2 | −2 | 1/7 | 1/7 |

| 2 | 100 | 1.5 | −1.5 | 2/7 | 2/7 | |

| 3 | 200 | 1 | −1 | 4/7 | 4/7 | |

| 8, 15 | 1 | 50 | 2 | −2 | 1/7 − 0.01 | 1/7 + 0.01 |

| 2 | 100 | 1.5 | −1.5 | 2/7 − 0.01 | 2/7 + 0.01 | |

| 3 | 200 | 1 | −1 | 4/7 − 0.01 | 4/7 + 0.01 | |

| 9, 11, 13, 16, 18, 20 | 1 | 50 | 2 | −1.8 | 1/7 | 1/7 |

| 2 | 100 | 1.5 | −1.35 | 2/7 | 2/7 | |

| 3 | 200 | 1 | −0.9 | 4/7 | 4/7 | |

| 10, 12, 17, 19 | 1 | 50 | 2 | −1.8 | 1/7 − 0.01 | 1/7 + 0.01 |

| 2 | 100 | 1.5 | −1.35 | 2/7 − 0.01 | 2/7 + 0.01 | |

| 3 | 200 | 1 | −0.9 | 4/7 − 0.01 | 4/7 + 0.01 |

| Example | Radius of {ik} | |||||

|---|---|---|---|---|---|---|

| 21 | 1 | 50 | 2 | 0.2 | 1/7 | 1/7 |

| 2 | 100 | 1.5 | 0.15 | 2/7 | 2/7 | |

| 3 | 200 | 1 | 0.1 | 4/7 | 4/7 | |

| 22 | 1 | 50 | 2 | 0.2 | 1/7 − 0.01 | 1/7 + 0.01 |

| 2 | 100 | 1.5 | 0.15 | 2/7 − 0.01 | 2/7 + 0.01 | |

| 3 | 200 | 1 | 0.1 | 4/7 − 0.01 | 4/7 + 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fischer, A.; Litvinchev, I.; Romanova, T.; Stetsyuk, P.; Yaskov, G. Quasi-Packing Different Spheres with Ratio Conditions in a Spherical Container. Mathematics 2023, 11, 2033. https://doi.org/10.3390/math11092033

Fischer A, Litvinchev I, Romanova T, Stetsyuk P, Yaskov G. Quasi-Packing Different Spheres with Ratio Conditions in a Spherical Container. Mathematics. 2023; 11(9):2033. https://doi.org/10.3390/math11092033

Chicago/Turabian StyleFischer, Andreas, Igor Litvinchev, Tetyana Romanova, Petro Stetsyuk, and Georgiy Yaskov. 2023. "Quasi-Packing Different Spheres with Ratio Conditions in a Spherical Container" Mathematics 11, no. 9: 2033. https://doi.org/10.3390/math11092033

APA StyleFischer, A., Litvinchev, I., Romanova, T., Stetsyuk, P., & Yaskov, G. (2023). Quasi-Packing Different Spheres with Ratio Conditions in a Spherical Container. Mathematics, 11(9), 2033. https://doi.org/10.3390/math11092033