A Mathematical Programming Model for Minimizing Energy Consumption on a Selective Laser Melting Machine

Abstract

:1. Introduction

- The energy-saving potential of nesting and scheduling decisions on a single SLM machine is studied. Based on an accurate energy consumption model, we propose a mixed-integer linear programming (MILP) model considering alternative build orientations for the nesting and scheduling problem;

- Through numerical experiments, the performance of the proposed model is tested and validated by comparison with commercial 3D printing software. The MILP model achieves significant energy savings compared to the commercial software. The percentage of energy savings tends to increase with the number of alternative build orientations of the parts.

2. Literature Review

2.1. Energy-Aware Scheduling

2.2. Nesting and Scheduling on AM Machines

2.3. Research Gap

3. Problem Description

- For any part , any optional build orientation can satisfy the quality requirement of the part j.

- Each part is represented by its minimum bounding box, and thus, the projection of any part is a rectangle on the build platform.

- There is a minimum distance requirement between any parts placed on the build platform. Without loss of generality, it is assumed that this distance has been included in the size of each part.

- The process parameters (e.g., laser power, layer thickness, hatching distance) are identical for all parts.

- The power of each subsystem of the SLM machine is assumed to be constant during a subprocess.

4. Energy Consumption Model

4.1. Energy Consumption Calculation

4.2. Processing Time of Subprocesses

4.3. Power of Subsystems

4.4. State of Subsystems

5. Mathematical Programming Model

5.1. MILP Model

- J: set of parts.

- : set of subsystems. bs is the basic system, ht is the heater, wc is the water circulation system, co is the water cooling unit, lsb is the laser unit for scanning border, lfc is the laser unit for filling contour, lvh is the laser unit for volume hatching, lss is the laser unit for scanning supporting structure, rm is the recoater motor, ev stands for the electric values, gp is the gas circulation pump motor.

- : set of subprocesses. ph is the preheating, sb is the scanning border, fc is the filling contour, vh is volume hatching, ss is the building of support structure, rc is the recoating, co is the cooling.

- : set of alternative build orientations of part j.

- B: set of available batches on machine.

- : volume of part j.

- : surface area of part j.

- D: the minimum allowed distance from the parts to the platform boundary.

- d: the minimum allowed distance between parts.

- : recoating speed of machine.

- : length, width, and height of the build platform.

- : height, length, width, and supporting structure volume of the k-th orientation of part j.

- : number of lasers.

- : speed for scanning border.

- : speed for filling contour.

- : build-up rate for the part.

- : build-up rate for the support.

- : layer thickness.

- : power of the subsystem f.

- : the time spent in the preheating subprocess.

- : the time spent in the cooling subprocess.

- : the power coefficient of the subsystem f in the subprocess l, means that the subsystem f is not active in the subprocess l, means that the subsystem f is fully active during the subprocess l; means that the subsystem f is intermittently running during the subprocess l, that is, where represents the measured power of subsystem f in subprocess l.

- : equals 1 if part j is assigned to the b-th batch, 0 otherwise;

- : equals 1 if part j selects the k-th optional build orientation, 0 otherwise;

- : coordinates of the left-bottom point of part j’s projection on the platform;

- : equals 1 if part j is placed such that its length is parallel to that of the platform.

- : equals 1 if the b-th batch on machine is formed, 0 otherwise;

- : equals 1 if part j’s right–top point is placed to the left of part j’s left–bottom point in the same batch, 0 otherwise;

- : equals 1 if part j’s right–top point is placed below part j’s left–bottom point in the same batch, 0 otherwise;

- : height of the b-th batch;

- : the energy consumption of the b-th batch;

- : the processing time of the subprocess l in the b-th batch;

- M: a large number.

5.2. Model Improvements

5.3. Model Parameter: The Number of Available Batches

- Step 1:

- Set label is unnecessary and can be removed. Answer: Confirmed, we have removed the bold. , where ;

- Step 2:

- Solve the MILP model with the current value of ;

- Step 3:

- If the model is infeasible or if the obtained solution includes opened batches, then increment by 1 and return to Step 2. Otherwise, proceed to the next step;

- Step 4:

- Terminate and output the results.

6. Numerical Results

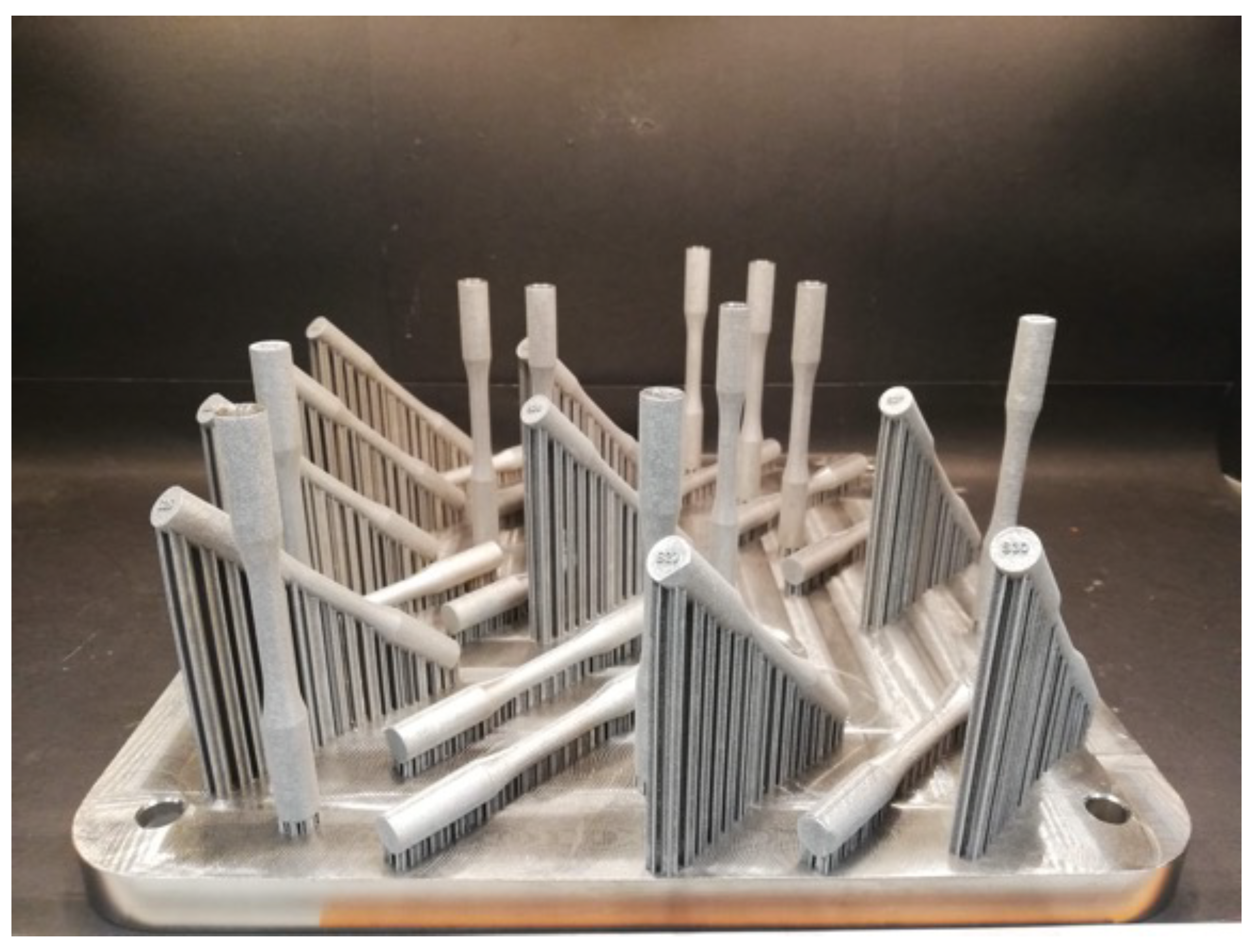

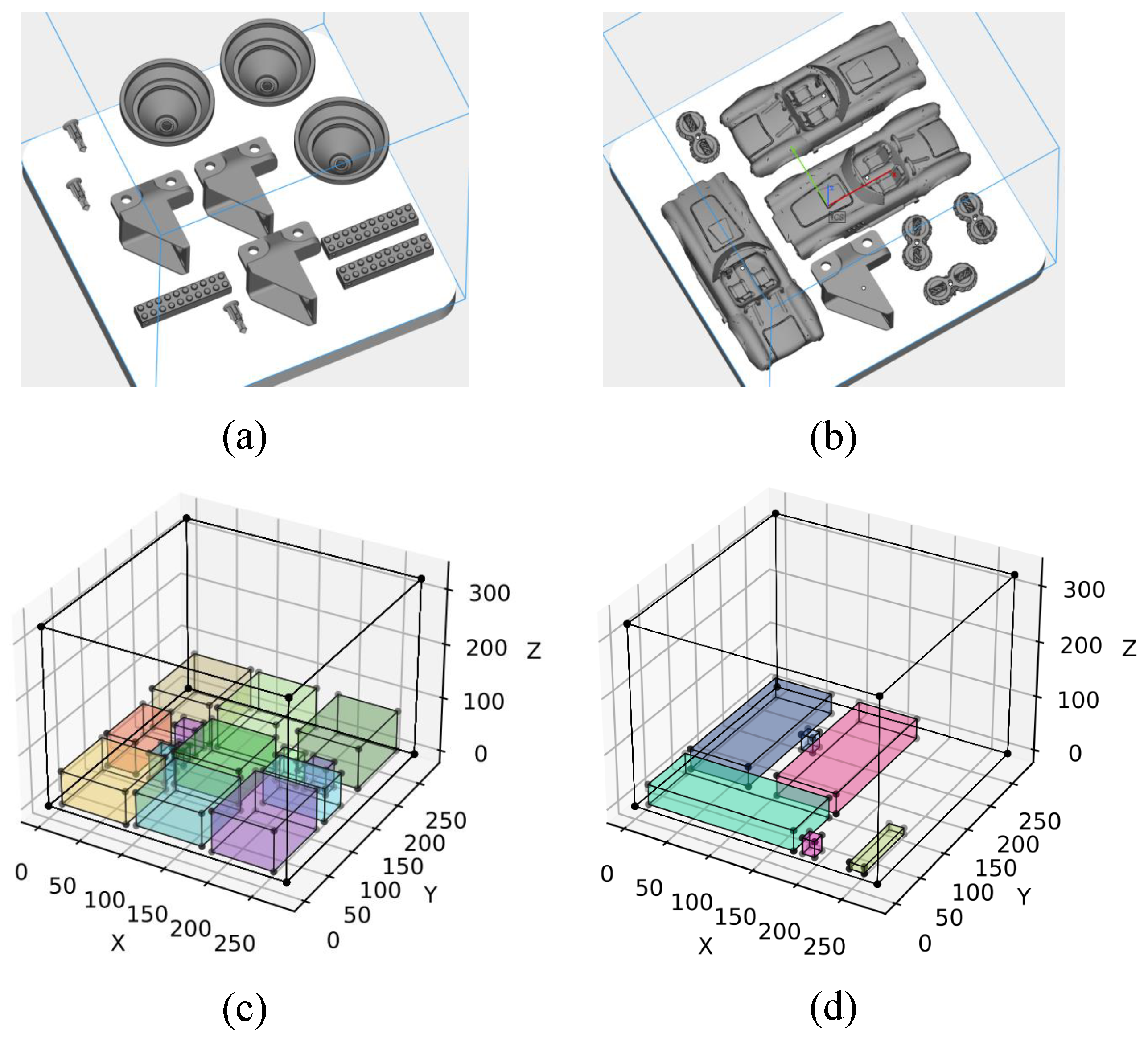

6.1. Test Instance

6.2. Machine and Process Parameters

6.3. Experiment Setup

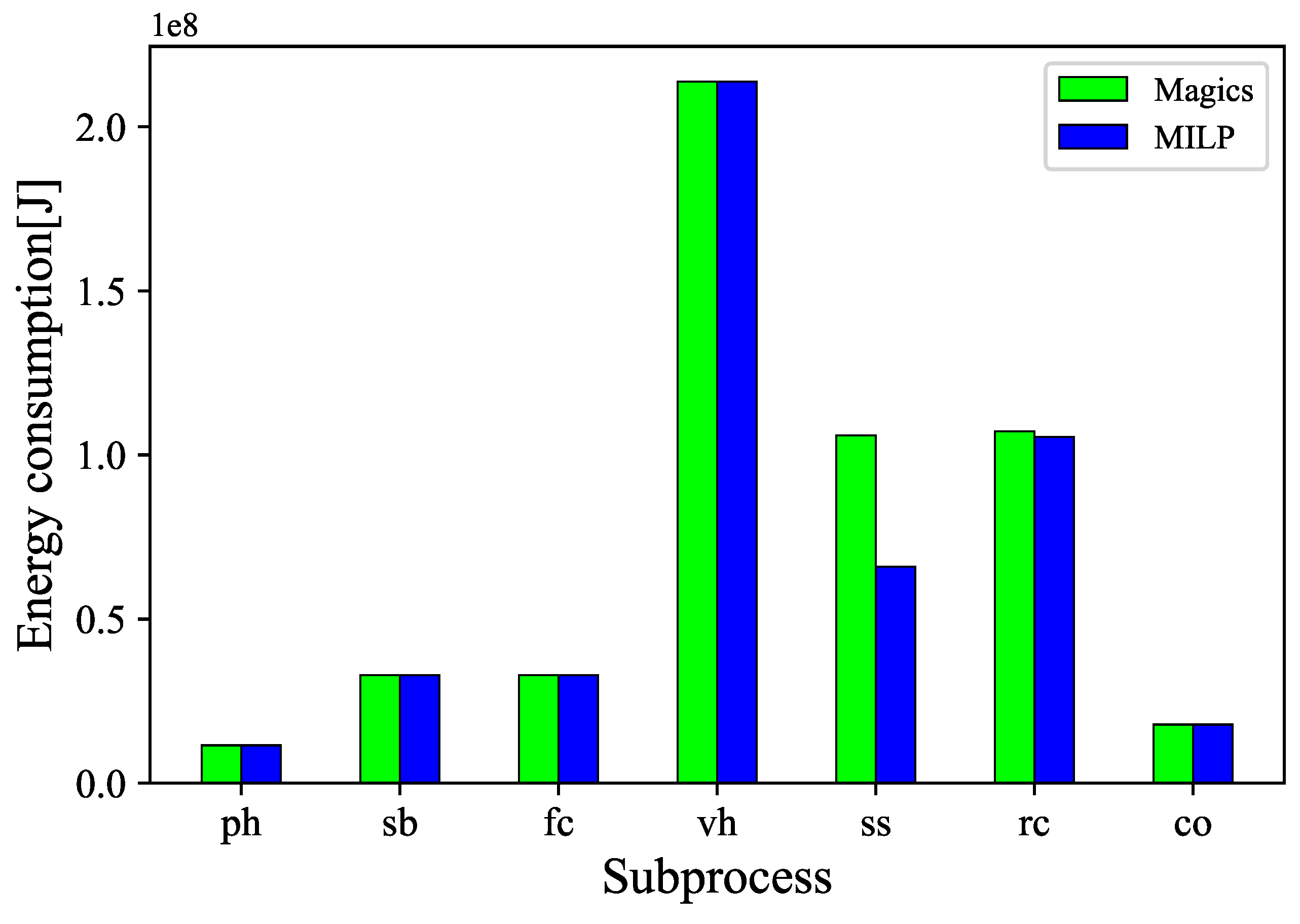

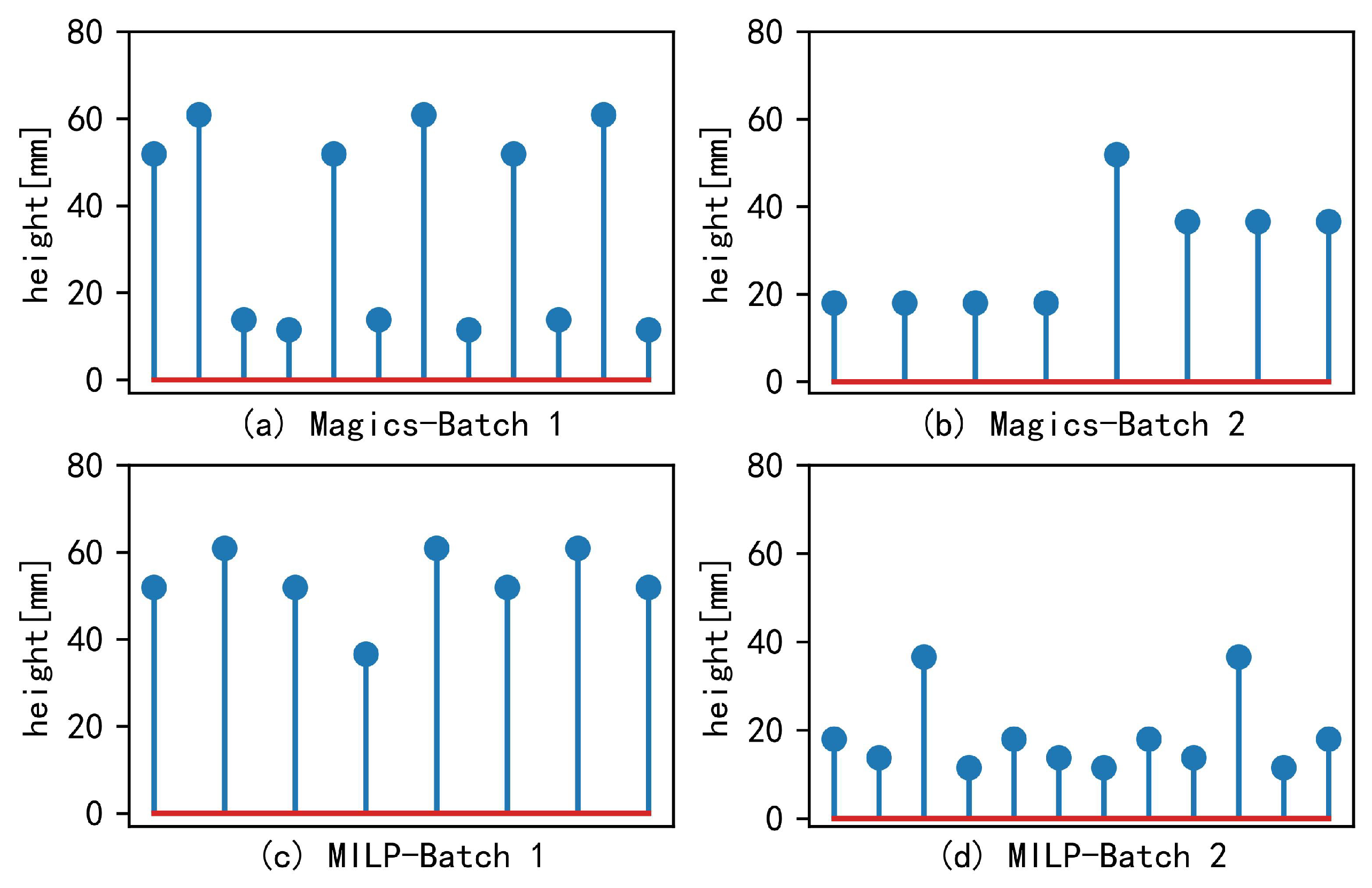

- Experiment 1: The first numerical experiment compares the energy consumption of printing a set of 20 parts when MILP and Magics are applied for the nesting and scheduling. Magics uses the default build orientation for each part, which corresponds to the smallest Z axis height. For MILP, we assume that each part has five different alternative build orientations, which are provided by the Magics software according to different rules. The MILP model is solved by the Gurobi solver (ver 9.5.2) with a maximum CPU runtime of 7200 s.

- Experiment 2: A design of experiments is performed with the following factors and levels: number of parts—{20, 25, 30}, number of alternative build orientations—{1, 3, 5, 7}. This results in 12 experiments. We analyze the impact of the number of parts and alternative build orientations on the energy consumption of the MILP model.

6.4. Results Analysis

6.4.1. Experiment 1

6.4.2. Experiment 2

- Increasing the build orientation of parts can reduce energy consumption to some extent, but it also complicates the model and increases the optimality gap.

- Increasing the number of printed parts can lead to reduced energy consumption compared to Magics, but it also makes the model more challenging to solve.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Part Information

| Part Type | Build Orientation | Volume [] | Surface Area [ | Supporting Structure Volume [] | Length [mm] | Width [mm] | Heigth [mm] |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 6744.00 | 8607.80 | 1724.00 | 57.50 | 24.60 | 18.00 |

| 2 | 6744.00 | 8607.80 | 2596.00 | 38.80 | 24.50 | 41.70 | |

| 3 | 6744.00 | 8607.80 | 2174.00 | 22.10 | 32.00 | 46.00 | |

| 4 | 6744.00 | 8607.80 | 1489.00 | 18.00 | 24.50 | 47.60 | |

| 5 | 6744.00 | 8607.80 | 2667.00 | 42.10 | 28.10 | 36.50 | |

| 6 | 6744.00 | 8607.80 | 2162.00 | 40.38 | 24.72 | 39.98 | |

| 7 | 6744.00 | 8607.80 | 2545.00 | 40.38 | 27.74 | 40.05 | |

| 2 | 1 | 37,635.00 | 17,532.00 | 23,352.00 | 73.00 | 64.00 | 51.90 |

| 2 | 37,635.00 | 17,532.00 | 14,668.00 | 78.30 | 72.70 | 76.40 | |

| 3 | 37,635.00 | 17,532.00 | 3396.00 | 87.70 | 70.50 | 74.40 | |

| 4 | 37,635.00 | 17,532.00 | 15,453.00 | 73.00 | 74.00 | 64.00 | |

| 5 | 37,635.00 | 17,532.00 | 13,779.00 | 69.00 | 56.90 | 76.70 | |

| 6 | 37,635.00 | 17,532.00 | 3694.00 | 73.17 | 85.90 | 74.03 | |

| 7 | 37,635.00 | 17,532.00 | 2025.00 | 73.17 | 62.49 | 78.14 | |

| 3 | 1 | 1029.00 | 1017.00 | 98.00 | 28.30 | 13.80 | 13.80 |

| 2 | 1029.00 | 1017.00 | 142.00 | 24.90 | 13.80 | 25.10 | |

| 3 | 1029.00 | 1017.00 | 376.00 | 21.80 | 15.90 | 26.90 | |

| 4 | 1029.00 | 1017.00 | 0.00 | 13.70 | 13.80 | 28.30 | |

| 5 | 1029.00 | 1017.00 | 536.00 | 26.70 | 14.90 | 22.40 | |

| 6 | 1029.00 | 1017.00 | 155.00 | 24.87 | 13.75 | 24.87 | |

| 7 | 1029.00 | 1017.00 | 138.55 | 19.77 | 21.95 | 25.14 | |

| 4 | 1 | 105,909.00 | 45,458.30 | 36,239.00 | 69.00 | 169.00 | 36.60 |

| 2 | 105,909.00 | 45,458.30 | 10,143.00 | 75.70 | 165.70 | 101.00 | |

| 3 | 105,909.00 | 45,458.30 | 34,743.00 | 139.00 | 93.20 | 155.70 | |

| 4 | 105,909.00 | 45,458.30 | 44,612.00 | 69.80 | 36.60 | 169.00 | |

| 5 | 105,909.00 | 45,458.30 | 47,096.00 | 90.60 | 147.40 | 136.20 | |

| 6 | 105,909.00 | 45,458.30 | 13,352.00 | 85.35 | 158.36 | 122.65 | |

| 7 | 105,909.00 | 45,458.30 | 20,212.00 | 141.10 | 90.55 | 157.22 | |

| 5 | 1 | 28,588.10 | 20,398.80 | 1183.00 | 77.00 | 77.00 | 60.90 |

| 2 | 28,588.10 | 20,398.80 | 5542.00 | 77.00 | 77.00 | 60.90 | |

| 3 | 28,588.10 | 20,398.80 | 25,217.00 | 76.70 | 60.90 | 76.70 | |

| 4 | 28,588.10 | 20,398.80 | 25,150.00 | 69.70 | 74.60 | 76.70 | |

| 5 | 28,588.10 | 20,398.80 | 12,042.00 | 73.20 | 74.10 | 71.10 | |

| 6 | 28,589.10 | 20,398.80 | 25,145.00 | 72.45 | 73.73 | 76.90 | |

| 7 | 28,589.10 | 20,398.80 | 25,145.00 | 74.02 | 72.47 | 76.74 | |

| 6 | 1 | 6310.00 | 9792.00 | 3908.00 | 16.60 | 79.70 | 11.50 |

| 2 | 6310.00 | 9792.00 | 3726.00 | 34.70 | 71.20 | 60.60 | |

| 3 | 6310.00 | 9792.00 | 5187.00 | 27.20 | 37.20 | 80.40 | |

| 4 | 6310.00 | 9792.00 | 2425.00 | 16.60 | 11.50 | 79.70 | |

| 5 | 6310.00 | 9792.00 | 3737.00 | 29.60 | 73.20 | 57.40 | |

| 6 | 6310.00 | 9792.00 | 2439.00 | 30.78 | 16.17 | 81.23 | |

| 7 | 6310.00 | 9792.00 | 3267.00 | 26.36 | 62.57 | 65.43 |

References

- Huang, R.; Riddle, M.; Graziano, D.; Warren, J.; Das, S.; Nimbalkar, S.; Cresko, J.; Masanet, E. Energy and emissions saving potential of additive manufacturing: The case of lightweight aircraft components. J. Clean. Prod. 2016, 135, 1559–1570. [Google Scholar] [CrossRef]

- Yoon, H.; Lee, J.; Kim, H.; Kim, M.; Kim, E.; Shin, Y.; Chu, W.; Ahn, S. A comparison of energy consumption in bulk forming, subtractive, and additive processes: Review and case study. Int. J. Precis. Eng. Manuf.-Green Technol. 2014, 1, 261–279. [Google Scholar] [CrossRef]

- Karimi, S.; Kwon, S.; Ning, F. Energy-aware production scheduling for additive manufacturing. J. Clean. Prod. 2021, 278, 123183. [Google Scholar] [CrossRef]

- Jia, Z.; Zhang, Y.; Leung, J.; Li, K. Bi-criteria ant colony optimization algorithm for minimizing makespan and energy consumption on parallel batch machines. Appl. Soft Comput. 2017, 55, 226–237. [Google Scholar] [CrossRef]

- Zhou, S.; Li, X.; Du, N.; Pang, Y.; Chen, H. A multi-objective differential evolution algorithm for parallel batch processing machine scheduling considering electricity consumption cost. Comput. Oper. Res. 2018, 96, 55–68. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.; Yu, J.; Ma, S.; Liu, M. Bi-objective identical parallel machine scheduling to minimize total energy consumption and makespan. J. Clean. Prod. 2018, 193, 424–440. [Google Scholar] [CrossRef]

- Kruth, J.P.; Vandenbroucke, B.; Van Vaerenbergh, J.; Mercelis, P. Benchmarking of different SLS/SLM processes as rapid manufacturing techniques. In Proceedings of the International Conference Polymers & Moulds Innovations PMI, Gent, Belgium, 20–23 April 2005. [Google Scholar]

- Lv, J.; Peng, T.; Zhang, Y.; Wang, Y. A novel method to forecast energy consumption of selective laser melting processes. Int. J. Prod. Res. 2021, 59, 2375–2391. [Google Scholar] [CrossRef]

- Faludi, J.; Baumers, M.; Maskery, I.; Hague, R. Environmental impacts of selective laser melting: Do printer, powder, or power dominate? J. Ind. Ecol. 2017, 21, S144–S156. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, X.; Li, Y. Improved evolutionary algorithm for parallel batch processing machine scheduling in additive manufacturing. Int. J. Prod. Res. 2020, 58, 2263–2282. [Google Scholar] [CrossRef]

- Lodi, A.; Martello, S.; Vigo, D. Recent advances on two-dimensional bin packing problems. Discret. Appl. Math. 2002, 123, 379–396. [Google Scholar] [CrossRef]

- Agrawal, P.; Rao, S. Energy-aware scheduling of distributed systems. IEEE Trans. Autom. Sci. Eng. 2014, 11, 1163–1175. [Google Scholar] [CrossRef]

- Bruzzone, A.; Anghinolfi, D.; Paolucci, M.; Tonelli, F. Energy-aware scheduling for improving manufacturing process sustainability: A mathematical model for flexible flow shops. CIRP Ann. 2012, 61, 459–462. [Google Scholar] [CrossRef]

- Che, A.; Zhang, S.; Wu, X. Energy-conscious unrelated parallel machine scheduling under time-of-use electricity tariffs. J. Clean. Prod. 2017, 156, 688–697. [Google Scholar] [CrossRef]

- Schulz, S.; Neufeld, J.; Buscher, U. A multi-objective iterated local search algorithm for comprehensive energy-aware hybrid flow shop scheduling. J. Clean. Prod. 2019, 224, 421–434. [Google Scholar] [CrossRef]

- Che, A.; Zeng, Y.; Lyu, K. An efficient greedy insertion heuristic for energy-conscious single machine scheduling problem under time-of-use electricity tariffs. J. Clean. Prod. 2016, 129, 565–577. [Google Scholar] [CrossRef]

- Abikarram, J.; McConky, K.; Proano, R. Energy cost minimization for unrelated parallel machine scheduling under real time and demand charge pricing. J. Clean. Prod. 2019, 208, 232–242. [Google Scholar] [CrossRef]

- Paul, R.; Anand, S. Process energy analysis and optimization in selective laser sintering. J. Manuf. Syst. 2012, 31, 429–437. [Google Scholar] [CrossRef]

- Verma, A.; Rai, R. Sustainability-induced dual-level optimization of additive manufacturing process. Int. J. Adv. Manuf. Technol. 2017, 88, 1945–1959. [Google Scholar] [CrossRef]

- Oh, Y.; Witherell, P.; Lu, Y.; Sprock, T. Nesting and scheduling problems for additive manufacturing: A taxonomy and review. Addit. Manuf. 2020, 36, 101492. [Google Scholar] [CrossRef]

- Pinto, M.; Silva, C.; Thürer, M.; Moniz, S. Nesting and scheduling optimization of additive manufacturing systems: Mapping the territory. Comput. Oper. Res. 2024, 165, 106592. [Google Scholar] [CrossRef]

- Chergui, A.; Hadj-Hamou, K.; Vignat, F. Production scheduling and nesting in additive manufacturing. Comput. Ind. Eng. 2018, 126, 292–301. [Google Scholar] [CrossRef]

- Alicastro, M.; Ferone, D.; Festa, P.; Fugaro, S.; Pastore, T. A reinforcement learning iterated local search for makespan minimization in additive manufacturing machine scheduling problems. Comput. Oper. Res. 2021, 131, 105272. [Google Scholar] [CrossRef]

- Li, X.; Zhang, K. Single batch processing machine scheduling with two-dimensional bin packing constraints. Int. J. Prod. Econ. 2018, 196, 113–121. [Google Scholar] [CrossRef]

- Che, Y.; Hu, K.; Zhang, Z.; Lim, A. Machine scheduling with orientation selection and two-dimensional packing for additive manufacturing. Comput. Oper. Res. 2021, 130, 105245. [Google Scholar] [CrossRef]

- Yu, C.; Matta, A.; Semeraro, Q.; Lin, J. Mathematical models for minimizing total tardiness on parallel additive manufacturing machines. IFAC-PapersOnLine 2022, 55, 1521–1526. [Google Scholar] [CrossRef]

- Zipfel, B.; Neufeld, J.; Buscher, U. An iterated local search for customer order scheduling in additive manufacturing. Int. J. Prod. Res. 2024, 62, 605–625. [Google Scholar] [CrossRef]

- Nascimento, P.J.; Silva, C.; Antunes, C.H.; Moniz, S. Optimal decomposition approach for solving large nesting and scheduling problems of additive manufacturing systems. Eur. J. Oper. Res. 2024, 317, 92–110. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Wildman, R.; Ashcroft, I.; Hague, R. Energy inputs to additive manufacturing: Does capacity utilization matter? In Proceedings of the International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2011; University of Texas at Austin: Austin, TX, USA, 2011. [Google Scholar]

- Piili, H.; Happonen, A.; Väistö, T.; Venkataramanan, V.; Partanen, J.; Salminen, A. Cost estimation of laser additive manufacturing of stainless steel. Phys. Procedia 2015, 78, 388–396. [Google Scholar] [CrossRef]

- Lin, J.; Yu, C.; Lu, J. A bi-objective optimization method to minimize the makespan and energy consumption on parallel SLM machines. In Proceedings of the 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE), Auckland, New Zealand, 26–30 August 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J.R. Environmental dimensions of additive manufacturing: Mapping application domains and their environmental implications. J. Ind. Ecol. 2017, 21, S49–S68. [Google Scholar] [CrossRef]

- Yi, L.; Krenkel, N.; Aurich, J.C. An energy model of machine tools for selective laser melting. Procedia CIRP 2018, 78, 67–72. [Google Scholar] [CrossRef]

- Ingarao, G.; Priarone, P.; Deng, Y.; Paraskevas, D. Environmental modelling of aluminium based components manufacturing routes: Additive manufacturing versus machining versus forming. J. Clean. Prod. 2018, 176, 261–275. [Google Scholar] [CrossRef]

| Subsystem | Power [W] |

|---|---|

| Basic subsystem | |

| Platform heater | |

| Water circulation unit | |

| Water-cooling unit | |

| Laser-scanning border | |

| Laser-filling contour | |

| Laser volume hatching | |

| Laser support structure | |

| Recoater motor | |

| Electric valves | |

| Gas circulation pump motor |

| Constraints | Big-M Value |

|---|---|

| (12) | |

| (21) | |

| (25) (28) | |

| (26) (27) | |

| (29) | |

| (30) | |

| (31) | |

| (32) | |

| (43) |

| Subsystem | Power [W] | Pre Heating | Scan Border | Fill Contour | Volume Hatching | Support Structure | Re Coating | Cooling |

|---|---|---|---|---|---|---|---|---|

| Basic subsystem | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Platform heater | 1 | 0 | ||||||

| Water circulation unit | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Water-cooling unit | ||||||||

| Laser-scanning border | 0 | 1 | 0 | 0 | 0 | 0 | 0 | |

| Laser-filling contour | 0 | 0 | 1 | 0 | 0 | 0 | 0 | |

| Laser volume hatching | 0 | 0 | 0 | 1 | 0 | 0 | 0 | |

| Laser support structure | 0 | 0 | 0 | 0 | 1 | 0 | 0 | |

| Recoater motor | 0 | 0 | 0 | 0 | 0 | 1 | 0 | |

| Electric valves | 1 | 1 | 1 | 1 | 1 | 1 | 0 | |

| Gas circulation pump motor | 0 | 1 | 1 | 1 | 1 | 1 | 0 |

| Process Parameter | Scan Border | Fill Contour | Volume Hatching | Support Structure |

|---|---|---|---|---|

| Power of the laser [W] | 300 | 300 | 350 | 350 |

| Scanning speed [mm/s] | 730 | 730 | 1650 | 1000 |

| Layer thickness [mm] | 0.03 | 0.03 | 0.03 | 0.03 |

| Hatching distance [mm] | - | - | 0.13 | 0.13 |

| Parameters | Magics | MILP | ||||

|---|---|---|---|---|---|---|

| Batch 1 | Batch 2 | Total | Batch 1 | Batch 2 | Total | |

| Surface area [] | 220,689 | 382,340 | 603,029 | 276,929 | 326,100 | 603,029 |

| Part volume [] | 146,217 | 188,334 | 334,551 | 186,356 | 148,195 | 334,551 |

| Support volume [] | 108,969 | 141,951 | 250,920 | 43,618 | 112,625 | 156,243 |

| Number of slices | 2031 | 1729 | 3760 | 2481 | 1220 | 3701 |

| Utilization rate | 47.63% | 57.84% | 52.7% | 63.72% | 47.70% | 55.7% |

| Number of parts | 12 | 8 | 20 | 14 | 6 | 20 |

| Makespan [s] | 63,749 | 77,965 | 141,714 | 68,851 | 63,448 | 132,299 |

| Total energy consumption [MJ] | 225.66 | 296.59 | 522.25 | 241.84 | 238.72 | 480.56 |

| Machine Subsystem | Energy Saving [MJ] | Percentage [%] |

|---|---|---|

| 1-Basic subsystem | 5.36 | 12.86 |

| 2-Platform heater | 5.1 | 12.24 |

| 3-Water circulation unit | 6.72 | 16.13 |

| 4-Water cooling unit | 5.78 | 13.87 |

| 5-Laser for support structure | 17.73 | 42.55 |

| 6-Recoater motor | 0.03 | 0.07 |

| 7-Electric valves | 0.3 | 0.72 |

| 8-Gas circulation pump motor | 0.65 | 1.56 |

| Total energy saving | 41.67 | 100 |

| Machine Subprocess | Energy Saving [MJ] | Percentage [%] |

|---|---|---|

| 1-Preheating | 0 | 0 |

| 2-Scan border | 0 | 0 |

| 3-Fill contour | 0 | 0 |

| 4-Volumne hatching | 0 | 0 |

| 5-Support structure | 40.00 | 95.99 |

| 6-Recoating | 1.67 | 4.01 |

| 7-Cooling | 0 | 0 |

| Total energy saving | 41.67 | 100 |

| Instance | EC [MJ] | EV [J/] | ES [%] | Gap [%] | B |

|---|---|---|---|---|---|

| ins_20_1 | 507.73 | 841.97 | 3.46 | 0.00 | 2 |

| ins_20_3 | 481.06 | 797.74 | 8.53 | 5.17 | 2 |

| ins_20_5 | 480.56 | 796.91 | 8.62 | 5.34 | 2 |

| ins_20_7 | 479.91 | 795.83 | 8.75 | 6.46 | 2 |

| ins_25_1 | 625.23 | 839.38 | 5.81 | 7.66 | 3 |

| ins_25_3 | 602.57 | 808.96 | 9.22 | 5.32 | 3 |

| ins_25_5 | 577.11 | 774.78 | 13.06 | 1.58 | 2 |

| ins_25_7 | 570.31 | 765.65 | 14.08 | 1.59 | 2 |

| ins_30_1 | 782.87 | 840.81 | 11.37 | 7.40 | 3 |

| ins_30_3 | 746.03 | 801.25 | 15.54 | 12.29 | 3 |

| ins_30_5 | 745.24 | 800.40 | 15.63 | 15.76 | 3 |

| ins_30_7 | 769.41 | 826.36 | 12.89 | 20.21 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, C.; Lin, J. A Mathematical Programming Model for Minimizing Energy Consumption on a Selective Laser Melting Machine. Mathematics 2024, 12, 2507. https://doi.org/10.3390/math12162507

Yu C, Lin J. A Mathematical Programming Model for Minimizing Energy Consumption on a Selective Laser Melting Machine. Mathematics. 2024; 12(16):2507. https://doi.org/10.3390/math12162507

Chicago/Turabian StyleYu, Chunlong, and Junjie Lin. 2024. "A Mathematical Programming Model for Minimizing Energy Consumption on a Selective Laser Melting Machine" Mathematics 12, no. 16: 2507. https://doi.org/10.3390/math12162507

APA StyleYu, C., & Lin, J. (2024). A Mathematical Programming Model for Minimizing Energy Consumption on a Selective Laser Melting Machine. Mathematics, 12(16), 2507. https://doi.org/10.3390/math12162507