1. Introduction

In public health emergencies, the supply of rescue materials has a significant impact on the efficiency of rescue and epidemic control. Local rescue supply cannot meet the demand of residents during severe outbreak, such as COVID-19. Consequently, the government must organize the transportation of rescue materials far from the epidemic area to address the material shortage. To ensure the rapid and extensive supply of rescue materials, multiple modes of transportation should be used. How to optimize the route for multimodal transportation is a key challenge in material allocation tasks. Previous studies have addressed this challenge by proposing various models and structures. For example, Maghfiroh et al. [

1] proposed a multi-modal distribution model considering land, air and ship within a three-tier relief network. Chen et al. [

2] proposed a three-tier multimodal transport network structure for the cross-regional dispatch of emergency supplies. The objective of these studies was to minimize rescue time and maximize rescue utility. However, in the context of public health emergencies, material allocation should consider the demand priority for curbing the spread of the epidemic effectively. Tofighi et al. [

3] determined the priority of demand points based on the degree of earthquake damage and social conditions. In the case of shortage of relief resources, demand points with higher priorities were assigned first. Zhu et al. [

4] used the tolerable pain duration of victims during transportation to characterize the rescue priority of victims with different degrees of injury. They constructed an emergency rescue path model that considered the same and different degrees of injury. Considering the psychological pain and fairness of affected individuals is a crucial aspect of humanitarian relief operations, especially from the perspective of the psychological state of the affected people. Cotes et al. [

5] proposed a facility siting model with prepositioned supplies. Their model specifically takes into account the cost of deprivation, an estimate used to quantify the human suffering caused by scarcity. Jamali et al. [

6] proposed a stochastic programming model considering different scenarios to weigh relief costs, deprivation costs and carbon emissions in humanitarian logistics. The cost of deprivation was affected by the severity of the different injuries of the patients, aiming to strike a balance between different aspects of sustainability. These studies highlight the importance of considering the psychological pain cost in the rescue material allocation to alleviate the psychological trauma of the affected people and improve the rescue efficiency.

To the best of our knowledge, there have been no studies focusing on the trade-off between psychological pain cost and the demand priority in the allocation of rescue material. Therefore, this paper formulates a mixed integer programming model, which takes the psychological pain costs and material allocation costs as the decision-making objectives. The psychological pain costs are divided into absolute and relative pain costs. The absolute pain cost is an economic valuation of the psychological pain of those affected by a public health emergency without rescue material supply. The relative pain cost is expressed by the absolute value of the deviation between the two absolute pain costs, characterizing the fairness and timeliness in rescue operations. To highlight the priority requirements of emergency rescue, we introduce demand priority to represent the urgency of different epidemic areas that affect the material allocation sequence. To solve the proposed model, we have developed an improved genetic algorithm. A set of case studies is conducted to illustrate the influence of the demand priority and psychological pain on the rescue material allocation. This study can provide theoretical guidance and decision-making support for emergency supplies in public health emergencies, ultimately improving the efficiency of emergency rescue efforts.

The rest of this paper is organized as follows:

Section 2 reviews the literature related to the problem of rescue material allocation.

Section 3 proposes the mixed integer programming model for the rescue material allocation problem.

Section 4 presents a modified genetic algorithm to solve the proposed model.

Section 5 conducts case studies to evaluate the performance of the solution algorithm and draw managerial insights.

Section 6 applies the proposed model and algorithm to a real case. Finally,

Section 7 concludes the paper and discusses the direction for future research.

2. Literature Review

The allocation of emergency materials is an indispensable part of responding to public health emergencies, natural disasters and other emergencies. In the field of emergency material allocation, early research focused on single-level logistics networks, where emergency materials are distributed from the distribution center to the demand. For example, Hu et al. [

7] considered the situation of dispatching from a single emergency material supply point to multiple emergency points and explored the application of container intermodal transportation in the distribution of emergency materials to optimize the path of the emergency material supply chain. In contrast, Zhang et al. [

8] considered the dispatching of multiple emergency warehouses to multiple emergency points and minimized the total time of material dispatching as the goal. Abounacer et al. [

9] further studied the multi-objective siting–transportation problem for disaster response, aiming to determine the number, location and tasks of distribution centers and optimize material distribution. Lyu et al. [

10] focused on the shortage of materials at multiple supply points and multiple disaster-affected points in the early post-disaster period, taking into account efficiency and fairness, and built an emergency material distribution model to efficiently solve the problem of emergency material allocation under scarcity. Zhu et al. [

11] considered the heterogeneous psychological pain of the affected people in post-disaster emergency rescue and constructed a dynamic scheduling model of emergency supplies with two levels of heterogeneous behavior. These studies focused on the single-level allocation of emergency materials from different perspectives. However, the multi-level allocation of emergency materials is common in real emergencies, and it is necessary to consider the decision-making coordination between multiple levels to obtain a reasonable distribution scheme of emergency materials.

Research on multi-level emergency material allocation has gradually attracted attention in recent years. In this type of network, emergency materials need to be transported from the central warehouse to the distribution center, and then delivered to the demand point. Such a multi-level material allocation problem makes it more complicated to optimize the transportation routes and quantities of emergency materials. Tofighi et al. [

3] studied the problem of a two-stage humanitarian logistics network design, including central warehouses, local distribution centers and demand points, and developed a two-stage scenario planning approach. This method involves determining the location of the central warehouse and the local distribution center in the first stage, and developing relief plans according to different situations in the second stage. At the same time, Pradhananga et al. [

12] considered the deprivation cost caused by the delay in the delivery of emergency supplies and proposed an integrated three-level network model of emergency preparation, emergency supplies distribution and response to ensure the efficient distribution of supplies. Noham et al. [

13] studied the two-level humanitarian supply chain design problem, considering pre-disaster and post-disaster scenarios, where the optimal warehouse location was determined before the disaster and the distribution of materials at the demand point is determined after the disaster to improve the performance of the entire supply chain. Song et al. [

14] considered the waiting situation of emergency vehicles in the emergency distribution centers, and proposed a multi-material, multi-level distribution emergency material allocation plan optimization model to determine whether vehicles need to wait. Wang et al. [

15] proposed a three-level distribution network dynamic allocation model of emergency supplies with multiple collection and distribution points, multiple distribution centers and multiple disaster points by introducing the proportion of material demand shortage into the exponential utility function to measure fairness. It aims to consider efficiency and fairness in the multi-stage distribution of large-scale disaster emergency relief materials, and further reduce costs. While these studies provide new ideas and methods for multi-level emergency material scheduling, further research is needed considering the real emergency. For example, Erbeyoğlu et al. [

16] proposed a two-level relief network design model under humanitarian logistics to achieve feasible, efficient and equitable post-disaster distribution plans under different disaster scenarios. Shan et al. [

17] studied the cross-regional distribution of center–distribution and center–demand point three-level dynamic material dispatching network considering factors such as timeliness differences, geographical dispersion and capital consumption of emergency materials across regions. Kawase et al. [

18] study multi-level relief stock allocation strategies in humanitarian logistics, posing a dynamic stochastic optimization problem.

Considering the requirements for efficient allocation and cost of rescue materials in emergencies, multimodal transportation is used to transport emergency materials based on the characteristics and complementarities of different transportation modes. Thus, optimizing the allocation routes in a multimodal transportation network should consider the coordination and conversion between different transportation modes, as well as factors such as transportation costs and speeds of different transportation modes. Xiong et al. [

19] conducted a comprehensive study that considered time window constraints, road damage and mixed loading of various emergency materials. They focused on the multi-level location routing problem of multimodal transportation distribution of emergency materials after the earthquake, to achieve the timely and fair distribution of emergency materials. On this basis, Ning T. et al. [

20] proposed a two-stage joint transportation method of medical supplies considering capacity constraints. In the first stage, temporary transfer points are determined, and the construction of a “helicopter-vehicle” joint transportation network structure for medical supplies is considered; The second stage determines the transport routes based on clustering; effectively reducing the number of vehicles. To further optimize the scheduling strategy, Zhang et al. [

21] established a two-tier optimal scheduling model for emergency supplies considering multimodal transport. The upper-level model considered multimodal transport and aimed at the shortest transportation time; the lower-level model emphasized the fairness in emergency material distribution, aiming to minimize the variance in material allocation at each demand point, ensuring the timeliness and fairness of emergency material dispatch. Additionally, Gao et al. [

22] studied the site selection-combined transportation problem of large-scale emergency material deployment after an earthquake, taking into account timeliness and fairness, and considering the coordinated combined transportation of emergency materials by road, aviation and railway. Furthermore, Li et al. [

23] established a multimodal transport hub-radiation comprehensive emergency rescue material transportation network to determine the location of candidate hub nodes and transportation plans for different modes of transportation. This made it possible to ensure the timely guarantee of basic living materials and minimize the transportation cost of the transportation company. To address uncertainties, Liu et al. [

24] comprehensively considered the dual uncertainties of demand and transportation environment and established an optimization model for the multimodal transportation of emergency supplies with the goal of maximum reliability. The aim is to deliver emergency supplies to their destinations on time and reliably.

Early studies primarily focused on optimizing rescue operations in terms of timeliness and cost-effectiveness. However, in recent years, more and more studies have turned their focus on humanitarian logistics and consider the psychological conditions of the affected people. They introduce the economic value valuation of the psychological pain caused by the disaster-affected people’s inability to obtain materials into the objective function. For example, Cotes et al. [

5] incorporated the loss caused by people’s inability to obtain life-sustaining materials as deprivation costs into the decision-making target, and developed a facility siting model with transportation costs, inventory costs, fixed costs of facilities and deprivation costs as targets. Considering the dynamic features, Zhu et al. [

25] used risk perception theory and fairness aversion function to quantify the risk perception satisfaction and distribution fairness of the disaster victims regarding the delivery time and quantity of emergency supplies and constructed a multi-stage scheduling model based on psychological perception for emergency supplies allocation, aiming to improve the satisfaction of the disaster victims with the rescue outcomes. Zhu et al. [

26] constructed the relative deprivation cost based on the deprivation cost of disaster victims as one of the decision objectives. They studied the dynamic allocation problem of emergency supplies considering fairness to mitigate the trauma of disaster victims and enhanced the rescue fairness by alleviating the psychological trauma of disaster victims. Moreover, Zhang et al. [

27] measured the loss of disaster victims waiting for emergency supplies using the deprivation cost function. They integrated emergency facility location, emergency supplies reserve and allocation based on scenarios, to reduce human suffering during and after disasters. Gong et al. [

28] considered the psychological factors of disaster victims under an uncertain environment and proposed to construct a risk perception function to describe the psychological risk perception degree of disaster victims for obtaining relief supplies. They developed a multi-period dynamic allocation optimization decision model for emergency supplies, so that decision-makers can choose their attitude toward cost and psychological loss of disaster victims. It is worth noting that Gao et al. [

22] proposed to construct a pain cost function to depict the psychological pain degree of disaster victims, with the minimum psychological pain cost and emergency logistics cost of disaster victims as the objective. They constructed a multi-objective programming model for emergency supplies allocation location and intermodal transport. On this basis, Khodaee et al. [

29] proposed a humanitarian supply chain model for vaccine distribution during the COVID-19 pandemic, regarded the human injury degree caused by the inability to obtain vaccines and other key items in critical situations such as deprivation function and included them in the decision objectives, with transportation cost, shortage cost, deprivation cost and holding cost as objectives, to minimize human suffering and death toll. Sun et al. [

30] took the total deprivation cost and total operation cost caused by delayed access to medical services as objectives and studied a scenario-based robust optimization model, which integrated medical facility location, casualty transportation and material allocation. The objective was to save lives and alleviate human suffering.

However, most of the existing studies on the allocation of emergency supplies are on natural disasters, and there are relatively few studies on the allocation of emergency supplies in the context of public health emergencies. Considering the damage to facilities and roads caused by natural disaster emergencies and the uncertainty of material demand due to the uncertainty of the number of people affected by the disaster, most of the studies on the allocation of natural disaster-related emergency materials consider the stochasticity and uncertainty of some of the parameters in the scheduling process, and there are more studies on the vehicle routing problem and the site selection-routing problem, among others. Meanwhile, the existing literature mainly focuses on the reduction in the cost or time of emergency supplies allocation and the improvement of subjective and objective fairness, and there are fewer studies on the portrayal and reduction of the psychological pain of the disaster victims under the complex rescue scenarios. They have underestimated the combined effects of demand prioritization and psychological distress on the distribution of supplies. Thus, this paper introduces both the demand priority and psychological pain into the multi-type rescue materials allocation under a multimodal transportation network to trade off the priority and fairness of the demand. The aim of our study is to design optimal transportation routes that minimize the total cost of emergency material allocation, including the average psychological pain cost of the affected residents, transportation cost, loading cost and transfer cost. To illustrate the shortcomings of this study and our contribution,

Table 1 provides a comparative table of modeling studies of emergency supplies allocation.

4. Modified Genetic Algorithm

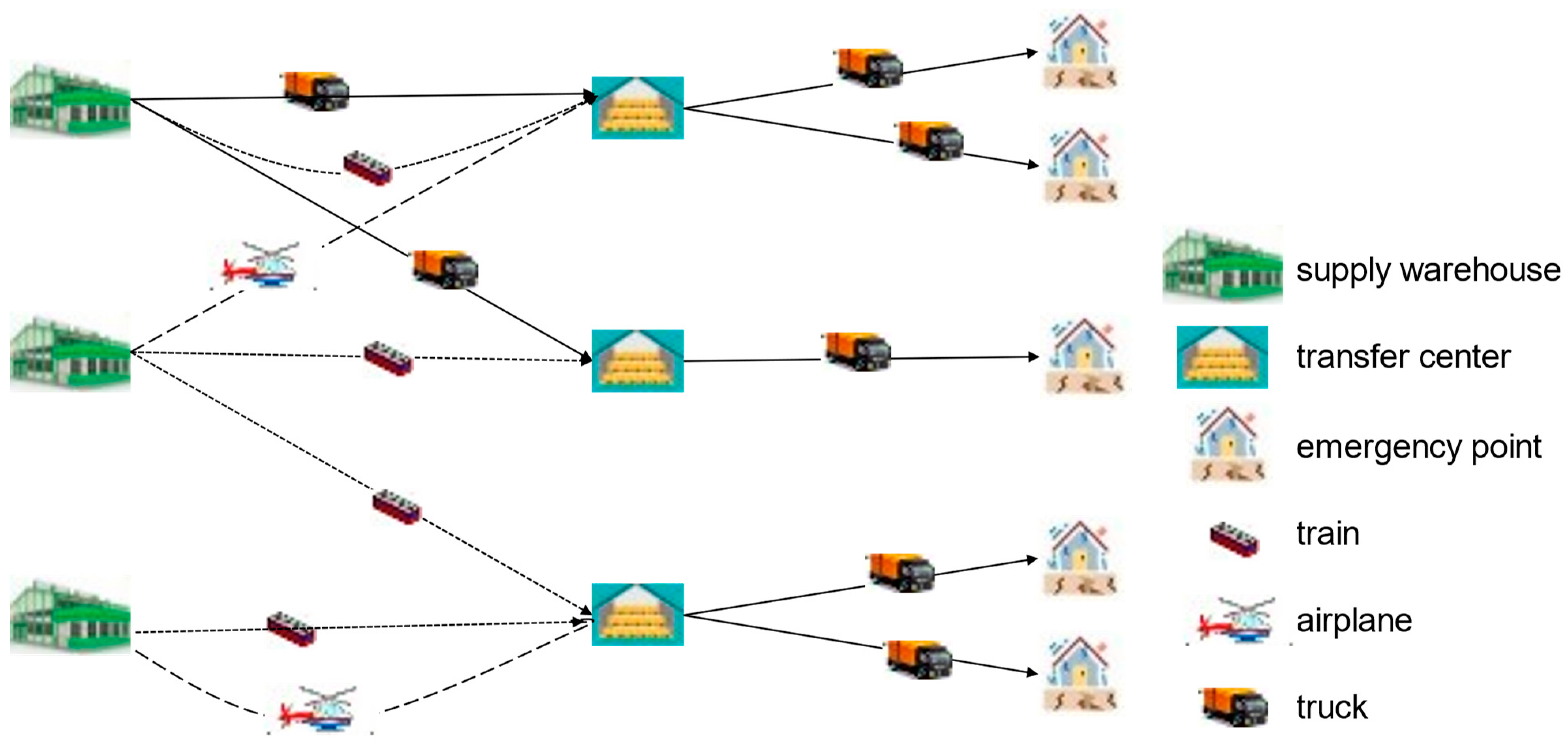

Our proposed model addresses the allocation and transportation problem of emergency materials for multiple categories within the network including multiple supply warehouses, multiple transfer centers and multiple emergency points. The scheduling network is complex and involves a large number of variables, posing significant challenges for solving the difficult problem to solve.

Genetic algorithms are intelligent optimization algorithms that apply Darwin’s natural evolutionary rule of “survival of the fittest” to solve computational problems. Compared with other algorithms, the genetic algorithm has a strong global search ability, can search for the optimal solution in a large-scale solution space and is suitable for solving complex optimization problems. In addition, the genetic algorithm is encoded in a more flexible way and is able to represent a variety of complex solution spaces. In this paper, the flowchart of the modified genetic algorithm for solving the proposed model of allocation of emergency materials is shown in

Figure 3.

(1) Parameter Initialization: The input parameters of the genetic algorithm in this model mainly include relevant parameters such as the supply and demand of materials, emergency priorities of emergency points and more. Additionally, the algorithm parameters mainly include population size, number of iterations, crossover rate and mutation rate among others.

(2) Chromosome Coding: The chromosome coding method in this paper is as follows: In the emergency material dispatching model, it is assumed that the number of supply warehouses, transfer centers, emergency points and material types are n1, n2, n3 and n4, respectively, and the number of transportation methods is M = 3. The chromosome is divided into two segments. The first segment represents the quantity of materials allocated from the supply warehouse to the transfer center. It adopts the decimal four-dimensional encoding method. () represents the gene index, where represents the index of the supply warehouse, and represents the transfer center index, represents the material type index, and represents the transport mode index. Chromosome () indicates the quantity of emergency supplies allocated to transfer center by supply warehouse using transportation mode , and contains n1 × n2 × n4 × M genes in total. The second paragraph indicates the quantity of materials allocated from the transfer center to the emergency point, and adopts the decimal three-dimensional coding method. () represents the gene index, where represents the index of the transfer center, represents the index of the material type and represents the emergency point index. Chromosome () indicates the number of emergency supplies allocated to emergency point by transfer center , including n2 × n3 × n4 genes in total.

(3) Population Initialization: Since the chromosomes generated when the population is initialized are usually random, this paper adjusts the initialized chromosomes so that the chromosomes generated through initialization meet the constraints in the scheduling model.

(4) Fitness Function: Fitness indicates the degree of adaptation of an individual to the environment. The genetic algorithm selects the new generation of individuals mainly based on the chromosomal fitness function value to realize the selection of the best and the worst, and the chromosomal genes with high fitness function are inherited to the next generation of individuals. In this algorithm, all the individuals in each generation are sorted according to the fitness value, and then the newly generated individuals are replaced by the next ones in the original population. The objective function of the model in this paper is to minimize the suffering cost of disaster victims and the minimum total cost of emergency supplies deployment. After converting the objective function into a single objective function, set the fitness function to the reciprocal of the transformed objective function. The smaller the value of the objective function, the larger the value of the fitness function.

(5) Select operation: The mutated chromosomes were selected using the roulette method. First calculate the probability of each chromosome being selected as , which is the cumulative fitness of the chromosome. Randomly generate any decimal, judge from the first chromosome and the first chromosome whose cumulative probability is greater than or equal to the decimal is the chromosome that performs the mutation operation.

(6) Cross-operation: The genetic algorithm usually performs a crossover operation on two bodies. However, due to the violation of the demand constraint of the research problem and the inflow and outflow equality constraints of the transfer center, it is not feasible to perform crossover on two bodies. In order to avoid the problems of the above-mentioned common crossover strategy, the crossover operation used in this algorithm is to exchange two random position indices on the second segment of the chromosome in a selected individual, and then adjust the first segment of the chromosome to meet the constraints. The crossover strategy is shown in

Figure 4. The basic rule of crossover is to randomly select two individuals

and

that serve different emergency points from different transfer centers, exchange the two different transfer centers to obtain new individuals

and

, and then adjust the first segment of the chromosome so that the constraints are satisfied.

(7) Mutation Operation: For the structural settings of the three-dimensional gene fragment and the four-dimensional gene fragment in this paper, the mutation operation will produce a large number of infeasible solutions. Therefore, according to the design rules of the non-completely random mutation operator in the genetic algorithm, the chromosome after each mutation is guaranteed to be optimal by designing the mutation operator. This algorithm randomly selects a location for the first segment of the chromosome to mutate the transport mode. The mutation strategy is shown in

Figure 5. For the second segment of the chromosome, a transfer center

is randomly selected that is different from the transfer center

, reducing the allocation of transfer centers

. A part of the emergency materials

for the emergency point

is added to the emergency materials

distributed by the transfer center

to the emergency point

. Due to the limitation of the minimum satisfaction rate of material supply and demand, the exchange quantity is not completely random but subject to certain constraints.

, seen in equation (30) includes

, which is the minimum satisfaction,

, which is the demand,

, which is the total supply of materials

and

, which is the total distribution of materials

. The mutation strategy is shown in

Figure 6.

(8) Elimination of Infeasible Solutions: The model needs to meet the constraints of the number of vehicles and the throughput of the transfer center. Individuals that do not meet the above constraints will be eliminated.

(9) Termination Principle: According to the set maximum number of iterations, when iteration reaches the maximum number of generations, calculation is terminated, and the scheme produced by the chromosome with the largest fitness value is selected as the optimal solution.

The whole model solution framework is given in Algorithm 1.

| Algorithm 1: Modified Genetic Algorithm |

| Input: All parameter values involved in the model. |

| Output: Material distribution transportation program and objective function value. |

- 1.

Fit←zeros (populationSize, 1)% Store the fitness value for each individual - 2.

Chrom1←zeros (M,N,I,J, populationSize)% Storing each individual - 3.

Chrom2←zeros (N,J,K, populationSize)

|

- 4.

for n←1 to populationSize - 5.

flag←false - 6.

While not flag do - 7.

Chrom1, Chrom2←Initialize()

|

- 8.

flag←isfeasible (Chrom1, Chrom2)

|

- 9.

End - 10.

Obj←calculateObj ()

|

- 11.

Fit←1/Obj

|

- 12.

End - 13.

maxF←0% Record the optimal fitness value - 14.

bestsolution1←zeros (M,N,I,J)% Record the optimal solution - 15.

bestsolution2←zeros (N,J,K) - 16.

gen←1 - 17.

solution←zeros (1,maxGen)% Record the optimal objective function value for each generation - 18.

Ns←populationSize *Ps

|

- 19.

while gen < = maxGen do

|

- 20.

Fit←calculateFitness (Chrom1, Chrom2)

|

- 21.

If max(Fit) > maxF

|

- 22.

bestsolution1←Chrom1

|

- 23.

bestsolution2←Chrom2 - 24.

maxF←max (Fit) - 25.

solution←1/maxF

|

- 26.

End - 27.

Sort(Fit, Chrom1,Chrom2)

|

- 28.

Selchrom1, Selchromy1←Selection (Chrom1, Chrom2,Ns)

|

- 29.

Selchrom1, Selchromy1←Cross (Selchrom1, Selchromy1)

|

- 30.

Selchrom1, Selchromy1←Mutation (Selchrom1, Selchromy1)

|

- 31.

StoreNewIndividuals (Chrom1, Chrom2, Selchrom1, Selchromy1)

|

- 32.

gen←gen + 1

|

- 33.

end

|

- 34.

return bestsolution1, bestsolution2, solution

|

7. Conclusions

In this paper, we propose a multimodal transportation optimization research method for the allocation of emergency rescue materials that considers the psychological pain cost and the demand priority of emergency points. To highlight the requirements of timeliness, fairness and economy, we take the psychological pain cost of residents and the logistics cost of emergency materials as the decision-making targets. To characterize the rescue priority more accurately, we determine the node loading order by setting the urgency. Then, we construct an emergency allocation model to improve the rescue effectiveness and design a modified genetic algorithm for solving the model. Taking the Wenchuan earthquake as the background, we solve different instances to verify the effectiveness of our proposed algorithm. It was found that, for small-scale instances , the algorithm produces consistent results with Gurobi. As the instance size increases , Gurobi can only find feasible solutions within 1800 s. When , Gurobi is unable to find feasible solutions within the specified time limit. The algorithm has a significant advantage in terms of runtime for large-scale instances. Our model can help to better determine the route of material supply in the public health emergency, thereby alleviating residents’ psychological pain and reducing budgets. We also conducted sensitivity analysis to observe the influence of relative pain cost coefficient, transportation modes and loading and unloading capacity of nodes on the objective function. Moreover, the model and algorithm have been applied successfully to the 2020 Wuhan COVID-19 outbreak.

There are some limitations in the research on emergency material allocation discussed in this paper. For example, this study only considers the static emergency material allocation problem. Future research could incorporate supply and demand dynamics. Another important idea is that future research can employ the model to actual emergency rescue scenarios, so as to verify its practicability and continuously improve the model. Specifically, we can try to incorporate the psychological pain cost and demand priority into the optimization decision-making of relief material supply routes under public health emergencies, so as to achieve more effective disaster relief. In addition, further exploration can be conducted on the trade-off between psychological pain cost and demand priority in the allocation of rescue materials through multi-objective optimization, as well as the development of new measurement methods for psychological pain cost.