Abstract

Modeling the pre-extraction of coalbed methane presents a significant mathematical challenge due to the complex interplay of multiple physical fields. This paper presents a robust mathematical model based on a thermo-hydro-mechanical damage (THMD) framework to describe this process. The model is formulated as a system of coupled, non-linear partial differential equations (PDEs) that integrate governing equations for heat transfer, fluid seepage, and solid mechanics with a damage evolution law derived from continuum damage mechanics. A key contribution of this work is the integration of this multi-physics model, solved numerically using the Finite Element Method (FEM), with a statistical modeling approach using Response Surface Methodology (RSM) and Analysis of Variance (ANOVA). This integrated framework allows for a systematic analysis of the model’s parameter space and a rigorous quantification of sensitivities. The ANOVA results reveal that the model’s damage output is most sensitive to the borehole diameter (F = 2531.51), while the effective extraction radius is predominantly governed by the initial permeability (F = 4219.59). This work demonstrates the power of combining a PDE-based multi-physics model with statistical metamodeling to provide deep, quantitative insights for optimizing gas extraction strategies in deep, low-permeability coal seams.

Keywords:

gas extraction; COMSOL multiphysics numerical simulation; sensitivity analysis; pre-pumping law MSC:

86-08; 86-10

1. Introduction

As the cornerstone of China’s energy system, the safe and efficient extraction of coal is of strategic importance to national energy security [1,2]. Coal seam gas (mainly CH4) present in coal seams is not only a major hazard restricting safe production in coal mines but also a valuable, relatively clean energy resource [3]. However, China’s coal seam geological conditions are complex. Particularly with the shift in mining focus to deeper levels, coal seams commonly exhibit characteristics of “three highs and one low”: high gas content, high in situ stress, high geothermal temperature, and low permeability [4,5]. Due to their direct penetration of the coal seam and wide range of influence, along-layer boreholes (often referred to as horizontal boreholes in a broader context) have become a core technical means for gas pre-extraction and regional control in low-permeability coal seams, especially in deep mines. However, enhancing their extraction efficiency heavily relies on a profound understanding of deep coal mechanics, gas transport laws, and complex multi-field coupling effects.

Due to its widespread engineering application and the unique deep environment, along-layer gas extraction in deep coal seams has always been a research focus in gas management. Scholars have conducted extensive research on the factors restricting the effectiveness of along-layer extraction under deep conditions of high stress, high gas pressure, high temperature, and low permeability. To accurately model this process, it is essential to recognize that the deep coal mass behaves as a complex geological medium subject to fundamental principles of rock mechanics and multi-physics coupling. The thermal-mechanical (TM) coupling effect is particularly pronounced. The principles of thermal degradation observed in various deep geological formations are directly applicable to the deep coal environment. For example, experimental studies on other rock types like sandstone [6] and granite [7] have conclusively shown that elevated temperatures under high confinement significantly degrade key mechanical properties such as strength and stiffness. This provides a strong rationale for incorporating temperature-dependent mechanical behaviors in any realistic model of deep coal seams. Furthermore, thermal processes can fundamentally alter the hydraulic properties of porous rocks. Research on shale, a sedimentary rock with characteristics comparable to coal, has demonstrated that heating modifies the pore network and connectivity, which in turn greatly influences permeability [8]. This highlights the critical need to consider thermo-hydraulic (TH) coupling when modeling gas transport in coal. Feng Gao et al. [9] developed a fully coupled thermo-hydro-mechanical (THM) model to investigate the sensitivities of gas extraction from slotted boreholes. H. Li et al. [10] established a theoretical model for coalbed methane (CBM) extraction that considers various proppant distribution forms, which was validated against field production results. Xianyang Zou et al. [11] stablished a new hydro-mechanics coupling model that sufficiently considers the effects of slippage and tortuosity on gas seepage. Tenglong Rong et al. [12] formulated an anisotropic coal permeability model that incorporates damage to systematically examine dynamic changes in directional flow during gas extraction. J. Peng et al. [13] applied Translation-invariant Wavelet Threshold Denoising (TIWTD) to improve the processing of coal and gas outburst risk index data, addressing issues that hinder ac-curate prediction. Chao Sun et al. [14] introduced microwave stimulation technology into the gas extraction area of coal seams for the first time and established a new coupled electromagnetic-thermo-hydro-mechanical model for coal seam gas recovery. Feng Du et al. [15] developed a fluid-solid coupling model to explore the efficiency of N2 injection for enhancing gas extraction from coal seams (N2-ECGE). Although these studies have greatly advanced the technology of along-layer gas extraction in deep coal seams, the complex “three highs and one low” environment makes the coal body response and gas flow behavior more intricate, and the multi-physics coupling effects are more significant. This poses higher demands on the refined understanding of the along-layer extraction mechanism and the accuracy of predictive models.

The gas extraction process is inherently a result of multi-physics interactions. Therefore, constructing a mathematical model that accurately describes these coupling effects is crucial. At the fundamental fluid-solid (HM) coupling level, J.G. Wang et al. [16], Yaoyao Zhao et al. [17], and Lei Zhang et al. [18] have, respectively, established models describing the interaction of stress and seepage fields under conditions of directional compaction, time-dependent deformation, and creep effects. To describe coal properties more accurately, B. Hu et al. [19] introduced a new method for quantitatively characterizing the absolute methane adsorption isotherm, while Xiao jun Feng et al. [20] examined how moisture content affects pressure-dependent gas diffusion. In the area of damage mechanics and constitutive relations, Mingtian Zhang et al. [21] used acoustic emission to study the response characteristics of load damage precursor information for gas-containing coals, and S. Dazhao et al. [22] employed nuclear magnetic resonance (NMR) to study the resistivity evolution law during the damage process of gas-bearing coal. Integrating damage with fluid-solid coupling is a key focus of recent research. This is particularly critical because engineering activities such as borehole drilling act as significant disturbances to the in situ stress state of the deep coal mass. The concept that initial disturbances can induce damage that governs the long-term creep and stability of deep rock masses has been explored in detail by Zhao et al. [23]. Applying this principle to coal extraction necessitates the inclusion of a damage (D) component to accurately capture the material degradation and permeability evolution around the borehole. This complexity underscores the inadequacy of simple linear models and reflects a broader trend across geomechanics towards employing sophisticated elasto-plastic or damage-based solutions to capture non-linear responses, a trend also evident in complex fields like tunneling engineering [24]. Menglin Du et al. [25] developed a thermo-hydro-mechanical coupling damage model that explicitly incorporates frost-heaving effects from liquid nitrogen (LN2) fracturing. L. Peng et al. [26] studied strata movement control in deep mining areas, which involves damage mechanics. Furthermore, Xuexi Chen et al. [27] developed a composite fissure leakage model for surrounding rock and boreholes using heterogeneous geostatistical modeling. Chao Xu et al. [28] constructed a coupled mechanics-damage-seepage model (MDS) considering the non-homogeneous characteristics of coal. Li Jia et al. [29] conducted a systematic analysis of the energy storage characteristics of reservoir fluids. Finally, Erhui Zhang et al. [30] carried out a microseismic monitoring simulation experiment of coal and gas outbursts to study their microseismic response characteristics. At a more complex multi-field coupling level, Lin et al. [31] constructed a THMD model for liquid nitrogen fracturing and applied it to gas extraction research. These models provide important tools for understanding the complex mechanisms of gas extraction. However, how to comprehensively and dynamically integrate these coupling effects, especially damage evolution, into a model for the entire process of gas extraction from along-layer boreholes, while fully considering the specifics of the deep environment, remains a key research focus.

Despite significant progress in deep coal seam gas extraction technology and multi-field coupling theory, a critical research gap persists. There is a lack of research on fully coupled dynamic simulations of the THMD four-field process specifically for deep along-layer boreholes. While many studies focus on individual coupling effects, few have integrated these complex, bidirectional feedbacks—especially damage evolution—into a unified model and, more importantly, systematically quantified the sensitivity of extraction outcomes to key geological and engineering parameters. Research that finely characterizes the heterogeneity, multiple gas transport mechanisms, and the feedback loops between damage and other physical fields in this specific engineering context remains insufficient.

To address this gap, this paper aims to construct a comprehensive numerical model that reflects the THMD four-field coupling effects during the gas extraction process from along-layer boreholes in deep, low-permeability coal seams. The specific objectives of this study are threefold: (1) to establish a robust THMD coupled model by introducing constitutive relationships and control equations that describe the characteristics of deep coal seams; (2) to systematically investigate the spatiotemporal evolution of the temperature, seepage, stress, and damage fields around boreholes under various parameters using the COMSOL6.2 Multiphysics platform; and (3) to identify and rank the most critical factors influencing gas extraction efficiency through a statistical sensitivity analysis.

The main contribution of this work lies not only in the development of the coupled THMD model itself but in the novel integration of this deterministic numerical model with a statistical framework based on Response Surface Methodology (RSM). This integrated approach allows us to move beyond simple simulation to a quantitative analysis of parameter interactions and their impact on extraction effectiveness (i.e., the effective extraction radius and the damage zone area). This provides a more refined theoretical guidance and direct technical support for optimizing high-efficiency gas extraction schemes, enhancing the scientific basis for borehole design and ensuring safe production in coal mines.

This paper is organized as follows: Section 2 presents the physical system and the governing equations of the fully coupled THMD mathematical model. Section 3 details the numerical methodology, including the geometric model, boundary conditions, finite element implementation, and computational details. Section 4 presents and discusses the simulation results, including the validation of the model and the multi-factor sensitivity analysis. Finally, Section 5 summarizes the main conclusions, acknowledges the study’s limitations, and suggests directions for future research.

2. A Coupled THMD Model Considering Coal Matrix Damage

2.1. Physical System and Conceptual Model

The Wanfu Coal Mine, located in Heze City, Shandong Province, primarily mines the 3# coal seam. The 1305 headgate working face has a relatively stable coal seam, is fully mineable, with a thickness of 5.39–6.96 m (average 6.34 m), and a dip angle of 0–3° (average 1°). The average temperature is 330 K.

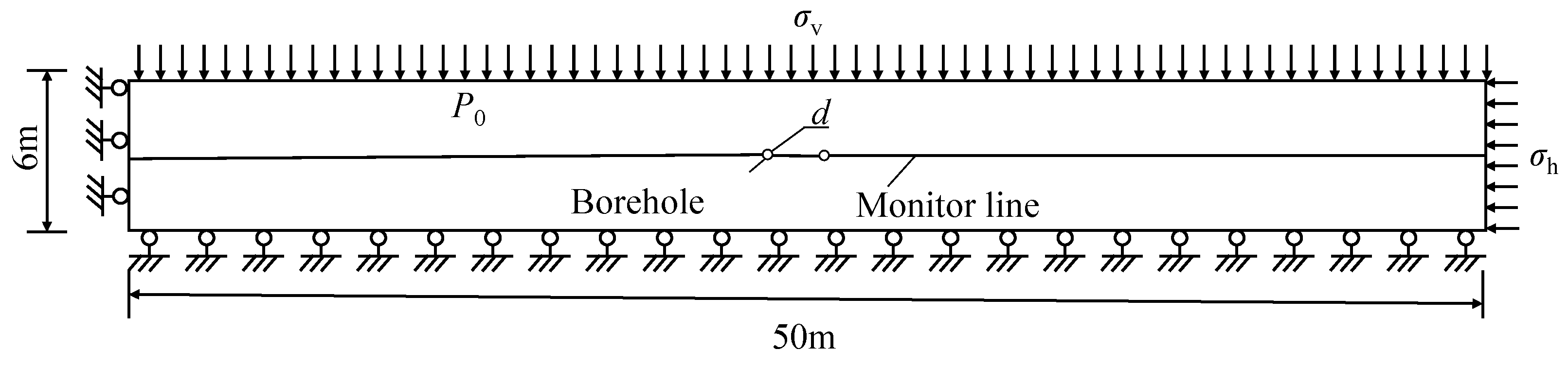

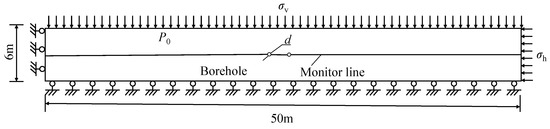

Pre-extraction from along-layer boreholes is a highly complex physical process. This study focuses on a representative section of a deep coal seam where two parallel boreholes are drilled along the seam’s layer for gas extraction. The physical domain for our model is a 2D cross-section perpendicular to the borehole axis, representing a simplified yet effective way to capture the primary physics of the system. Figure 1 illustrates this conceptual model, showing the geometric dimensions, the applied stress field, and the location of the boreholes. The model aims to simulate the changes in temperature, gas pressure, coal body stress, and damage evolution around these boreholes over time.

Figure 1.

Two-dimensional physical model.

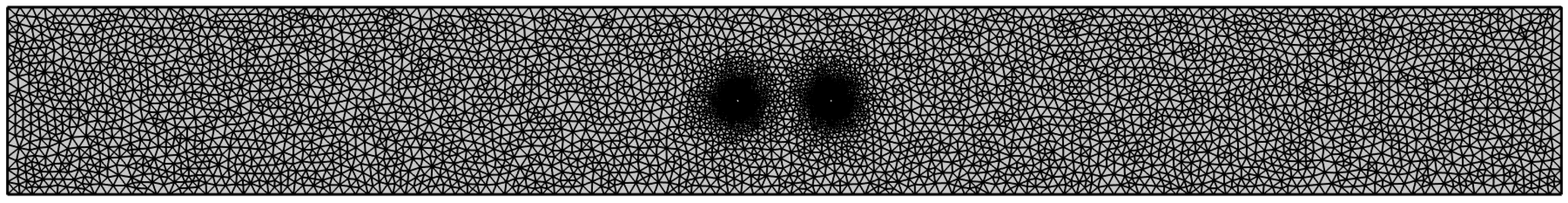

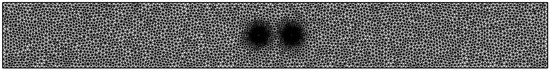

Two parallel along-layer boreholes are arranged in the coal seam (simulating the minimum extraction unit). The model is meshed with free triangular elements, with refinement near the boreholes (element size 0.001). A total of 29,780 elements are generated, with a minimum mesh quality of 0.4958. The value of 0.4958 indicates that even the most poorly shaped element in our mesh is of acceptable quality, far from the degenerate case, ensuring the reliability of our simulation results (see Figure 2).

Figure 2.

Finite element mesh.

2.2. The Thermo-Hydro-Mechanical Damage Coupled Model

2.2.1. Basic Assumptions

Pre-extraction from along-layer boreholes is a highly complex physical process. Before establishing its mathematical differential equations and performing numerical simulations, the model needs to be simplified with the following assumptions, drawing upon the work of other researchers: (1) The coal body is treated as a continuous, heterogeneous material, with its physical properties following a Weibull distribution. (2) At the microscopic elemental scale, the coal is considered a homogeneous, isotropic, linear elastic material that satisfies the small deformation assumption. Under loading, macroscopic damage follows damage theory, and parameters like mechanical strength, permeability, and thermal conductivity change with damage. (3) The coal and gas are in a state of thermal equilibrium, and thermal radiation is not considered. (4) Gas flow within the coal seam obeys Darcy’s law, and the effect of the coal’s water content is ignored [31,32]. In addition to these physical assumptions, we define the mathematical domain for the model. Let Ω ⊂ R2 represent the two-dimensional spatial domain of the model. The governing equations are solved over the time interval [0, T]. This space–time domain, on which the entire coupled model is formulated, is denoted by .

2.2.2. Coal Body Energy Conservation Equation

According to the laws of thermodynamics, the coal body satisfies energy conservation during gas extraction. Considering the heat exchange between the coal and gas, as well as the heat released from coal deformation, the energy conservation equation for the coal body is expressed as [33,34]:

where ρm, Cm and λm are the density (kg/m 3), specific heat capacity (J/(kg·K)), and thermal conductivity (W/(m·K)) of the gas-bearing coal, respectively; ρg, Cg, and λg are the density, specific heat capacity, and thermal conductivity of the gas; ρc, Cc, and λc are the density, specific heat capacity, and thermal conductivity of the coal; p is the gas pressure (Pa); T is the coal temperature (K); μg is the dynamic viscosity of the gas (Pa·s); k is the coal permeability (m2); K is the bulk modulus of the gas-bearing coal (GPa), K = E/(3(1 − 2ν)); ν is the Poisson’s ratio of the coal; E is the elastic modulus of the coal (GPa); φ is the coal porosity (%); βt is the thermal expansion coefficient of the coal (1/K); εv is the volumetric strain of the coal, εv = εxx + εyy + εzz, where εxx, εyy, εzz are the strains in the three directions; and the heat source (W/m3). Qh is the heat source (W/m2).

The initial temperature of the entire model domain is set to 330 K. A convective heat transfer boundary condition is applied to the borehole peripheries with an external temperature of 290 K to simulate the cooling effect of gas expansion and flow, while the outer boundaries are treated as thermally insulated.

2.2.3. Gas Seepage Equation

To ensure mine safety and efficient extraction, a thorough understanding of gas seepage laws is necessary.

where Qm is the mass source term (kg/(m3·s)).

The initial gas pressure in the coal seam is assumed to be uniform at 0.46 MPa. The borehole surfaces are set as a pressure boundary with an extraction vacuum pressure of 13 kPa. The outer boundaries of the model are defined as no-flow boundaries.

2.2.4. Control Equation of Coal Body Deformation Field

Coal is a porous medium, internally composed of many fractures and pores. Mechanically, it can be considered a composite material made of a solid skeleton and a porous medium. Considering the thermal stress and fracture pressure during extraction, the governing equations for coal deformation based on the thermo-poroelastic constitutive relationship are [35,36]:

The terms in Equation (5) are defined as follows: G is the shear modulus of the coal (GPa), G = E/2(1 + ν); p is the fracture pressure (MPa); Fi (i = 1, 2, 3) is the body force (MPa); ui,j is the displacement tensor and α is the Biot coefficient of the coal.

The maximum tensile stress criterion and the Mohr-Coulomb criterion are used to determine the degree of damage in the coal near the extraction borehole. It should be noted that both damage determination and evolution are based on the coal matrix. When the stress state of the coal matrix meets the above criteria, it is considered that the coal matrix has undergone tensile or shear damage (tensile is positive, compressive is negative). The criteria [37,38] are expressed as:

where F1, F2 are the threshold functions for determining tensile and shear failure (Pa); σ1, σ3 are the maximum and minimum principal stresses (Pa); ft0, fc0 are the uniaxial tensile and compressive strengths of the coal matrix (MPa) and θ is the internal friction angle (°).

Tensile damage is always prioritized in any stress state. To quantitatively describe the damage state of the coal matrix, a damage variable D is introduced, calculated as follows [39,40]:

where ε1, ε3 are the maximum and minimum principal strains; εt0, εc0 are the ultimate tensile and compressive principal strains at which tensile and shear damage occur and n is the coal strength constitutive coefficient, taken as 2, dF1 < 0 or dF2 < 0 indicates that the coal matrix is not damaged, and the damage variable retains its value from the previous time step. F1 = 0, dF1 > 0 indicates tensile failure, and the damage variable increases. F2 = 0, dF2 > 0 indicates shear failure, and the damage variable increases.

For the mechanical field, a uniformly distributed load of 20 MPa is applied to the top of the model to simulate the overlying rock stress, with a horizontal stress of 10 MPa applied to the right boundary (based on a lateral pressure coefficient of 0.5). The bottom and left sides of the model are defined with roller supports, allowing vertical and horizontal movement, respectively.

2.3. Damage Evolution Equations

2.3.1. Impact of Damage on Coal Body

During gas pre-extraction, the coal around the borehole undergoes plastic failure. Meanwhile, changes in gas pressure cause varying degrees of damage to the coal. Assuming the damage process is continuous, the evolution of the elastic modulus can be described as [41]:

where E0 is the initial elastic modulus of the coal (MPa); D is the damage variable.

As a porous medium, the coal’s volume is composed of solid and pore volumes. The dynamic evolution of porosity under external loads, temperature, and fracture pressure is given by [42,43,44]:

During coal seam gas extraction, permeability is related to porosity changes. The permeability evolution equation considering damage is [45]:

where k0 is the initial permeability (m2) and φ0 is the initial porosity (%).

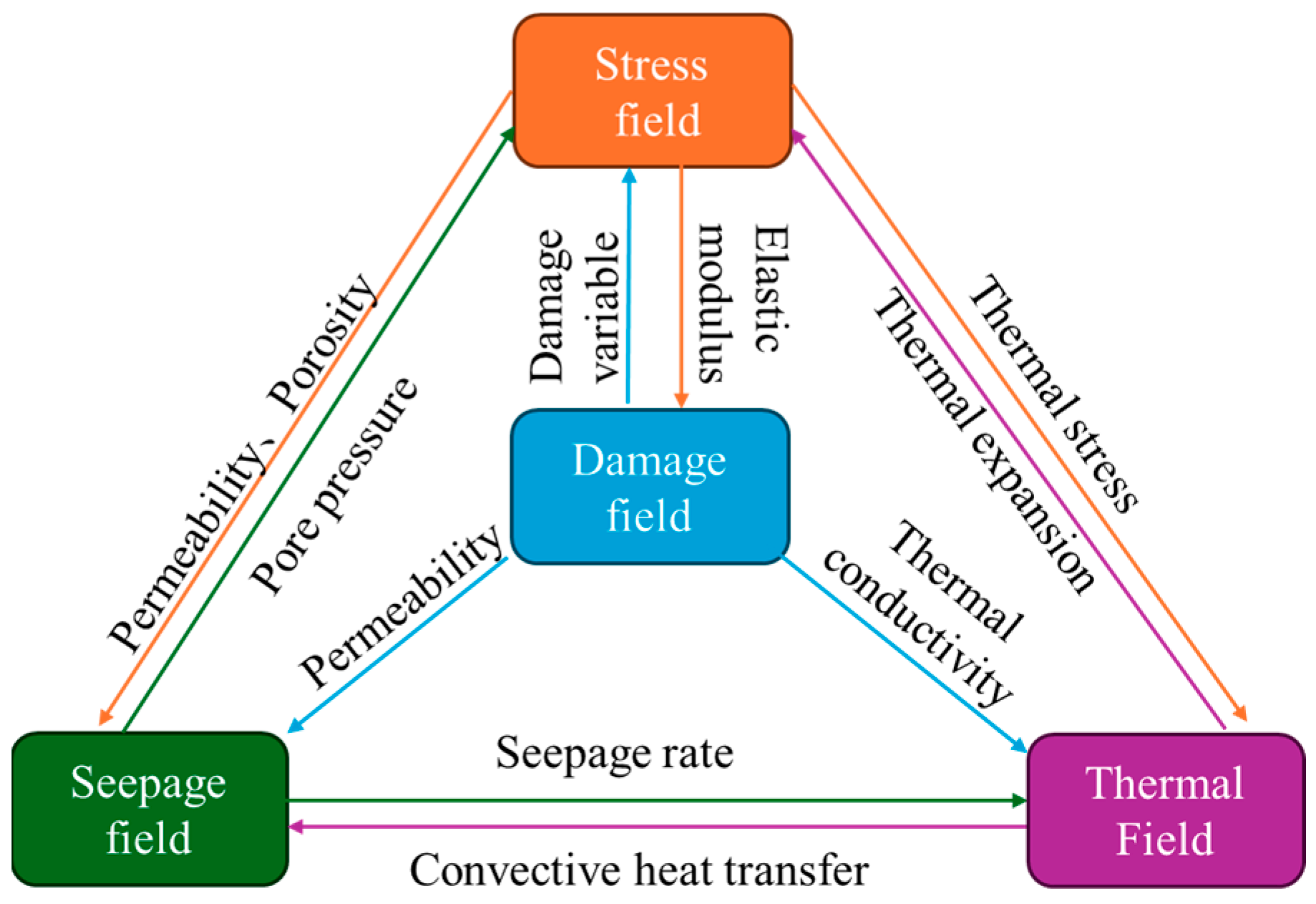

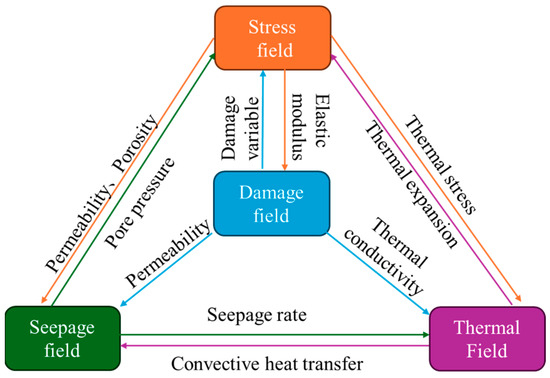

2.3.2. Thermo-Hydro-Mechanical Damage Coupling Relationship

The changes in various physical fields during gas extraction from a coal seam can be quantitatively described by Equations (1)–(11). The coupling of these fields is achieved through these equations, as illustrated in Figure 3. This THMD coupling framework is consistent with the state-of-the-art in coupled geomechanical modeling for deep underground engineering. For instance, Liu et al. [32] developed a similar THMD framework to investigate the complex reservoir responses to cold-water injection in deep geothermal systems. A central tenet of this approach, which we have adopted here, is the recognition that rock damage is not just an output but a critical mediator that dynamically links the thermal, hydraulic, and mechanical fields. The key coupling pathways in our model are as follows.

Figure 3.

Coupled Relationship of Thermo-Hydro-Mechanical Damage during Coalbed Methane Extraction.

Stress-Seepage (H-M) Coupling: The two fields are bidirectionally coupled. Gas pressure from the Seepage Field acts as pore pressure, reducing the effective stress in the Solid Mechanics equations (Equation (5)). Conversely, the coal deformation (strain) calculated by the Stress Field modifies the coal’s porosity (Equation (10)) and, subsequently, its permeability (Equation (11)), which in turn governs the gas flow in the Seepage Field (Equation (4)).

Temperature-Stress (T-M) Coupling: Temperature changes from the Thermal Field induce thermal expansion or contraction, generating thermal stress within the Stress Field, as captured by the βt term in Equation (5).

Damage-Mediated Couplings: The Damage Field acts as a central mediator. Mechanical stress and strain from the Stress Field can cause material damage according to the criteria in Equations (6)–(8). This damage variable (D) then directly impacts other fields: it degrades the Elastic Modulus of the Stress Field (Equation (9)) and significantly increases the Permeability of the Seepage Field (Equation (11)), creating a critical feedback loop.

3. Numerical Methodology

3.1. Finite Element Implementation

The fully coupled THMD model was implemented and solved using the commercial finite element software COMSOL Multiphysics. Specifically, the Heat Transfer in Porous Media module was used for the thermal field, the Darcy’s Law interface for the hydraulic field, and the Solid Mechanics module for the mechanical field. The damage evolution equations were implemented as user-defined variables using the Domain ODEs and DAEs interface.

The spatial discretization of the governing partial differential equations was performed using the Galerkin finite element method. To ensure high accuracy for the field variables, second-order Lagrange triangular elements were employed. The entire system of coupled, non-linear equations was solved monolithically using a PARDISO direct solver, which was chosen for its efficiency and robustness in handling the strong coupling between the different physical fields.

3.2. Numerical Model Construction

3.2.1. Construction of Heterogeneous Coal Bodies

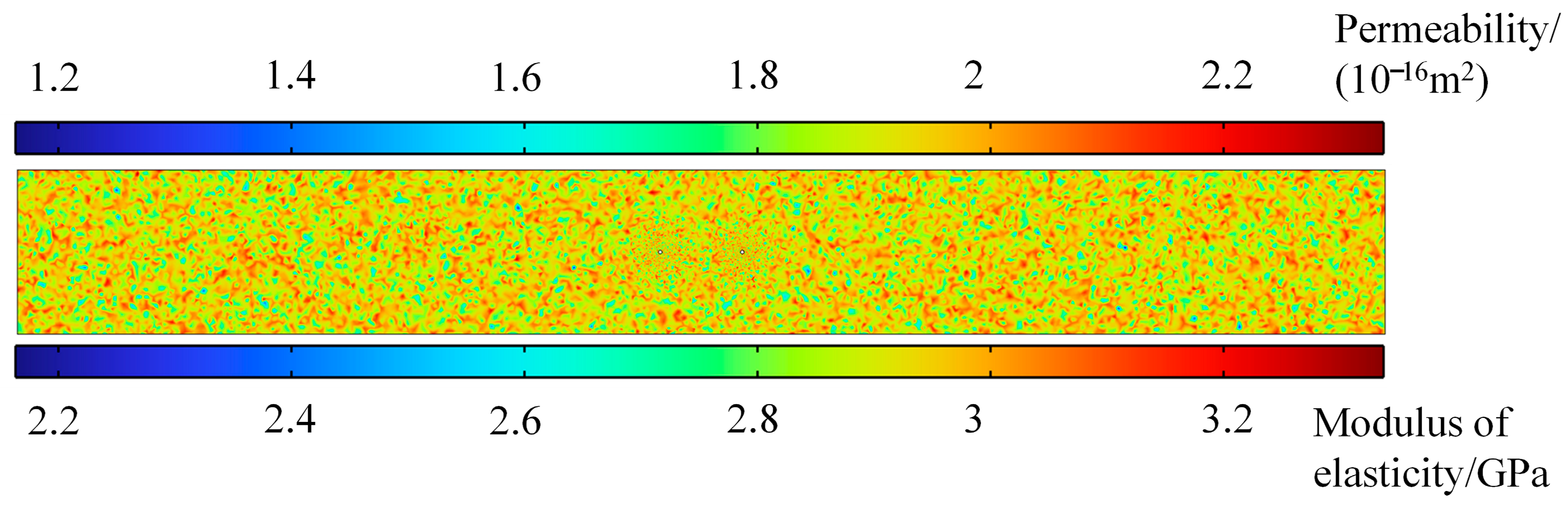

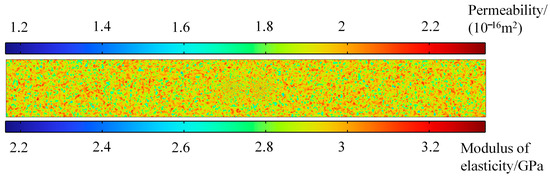

This paper uses the Weibull distribution to characterize the heterogeneity of parameters such as mechanical strength, permeability, and thermal expansion coefficient. The probability density function is defined as [46]:

where ω is a physical property of the coal (e.g., elastic modulus), ω0 is the average value of this property, and m is the Weibull homogeneity index. The specific situation is shown in Figure 4.

Figure 4.

Heterogeneous Distribution of Physical Parameters of Coal Body.

3.2.2. Model Calculation Parameters

The parameters for the along-layer borehole gas pre-extraction model were obtained from field and laboratory tests. The specific parameters are shown in Table 1.

Table 1.

Model Calculation Parameters.

3.3. Model Validation

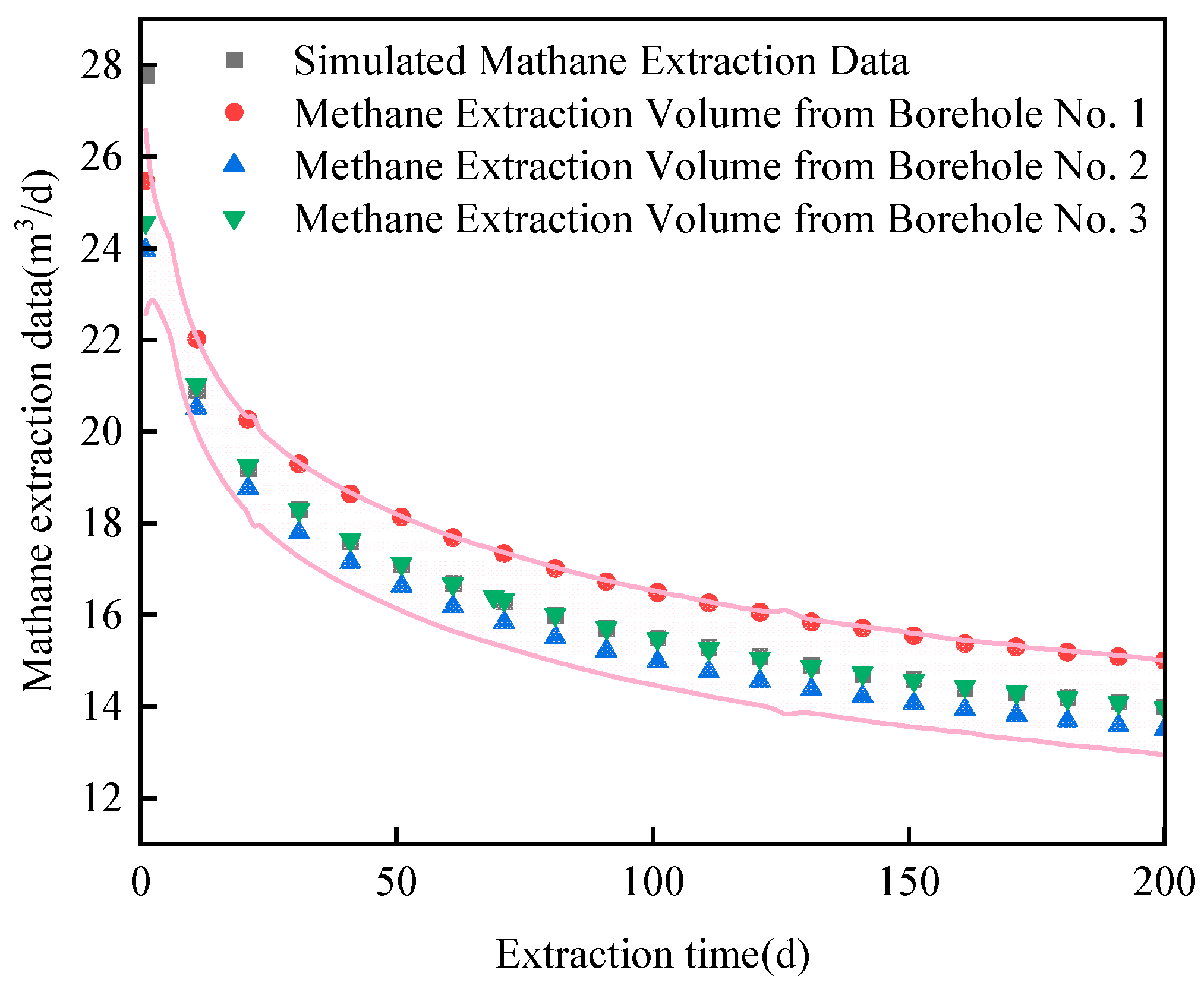

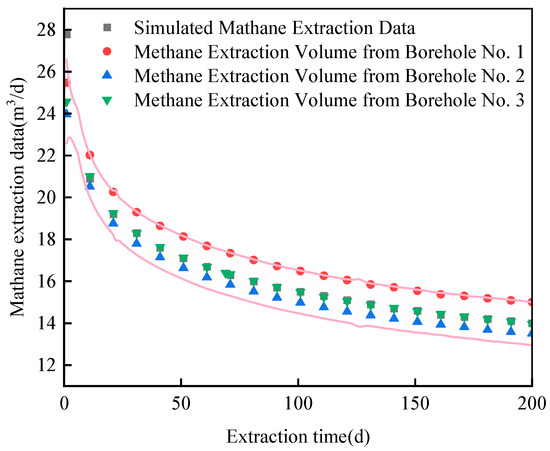

To ascertain the predictive capability and practical applicability of the developed THMD model, a rigorous validation was performed by comparing simulation results against on-site gas extraction data from a deep coal mine, the specific results are shown in Figure 5. The field experiment involved three parallel along-layer boreholes with a diameter of 94 mm, a length of 120 m, and a spacing of 6 m. The pure methane extraction rate from each borehole was continuously monitored over an extended period, providing a robust dataset for comparison.

Figure 5.

Simulated Coalbed Methane Extraction Data and On-site Coalbed Methane Extraction Data. The pink area represents the confidence interval.

As seen from the monitored pure gas extraction rates, the rates for the three boreholes decreased rapidly from initial values of 25.46, 22.96, and 24.57 m3/d to 16.63, 14.13, and 15.63 m3/d, respectively, then gradually declined to stable values of 14.99, 12.49, and 13.95 m3/d. By comparing the monitored rates with the numerical simulation results, we can conclude that throughout the extraction period, the monitored rates fluctuate around the simulated rate. The difference is larger in the initial phase but decreases over time, with the four curves eventually converging. The overall data falls within the confidence interval. The simulated borehole extraction rate stabilized from an initial peak of 27.77 m3/d to 13.99 m3/d, with an average relative error of 4.1% compared to the measured values (12.49–14.99 m3/d). This indicates that the difference between the monitored and simulated rates is small, showing good consistency and thus validating the reliability of the model.

3.4. Simulation Results

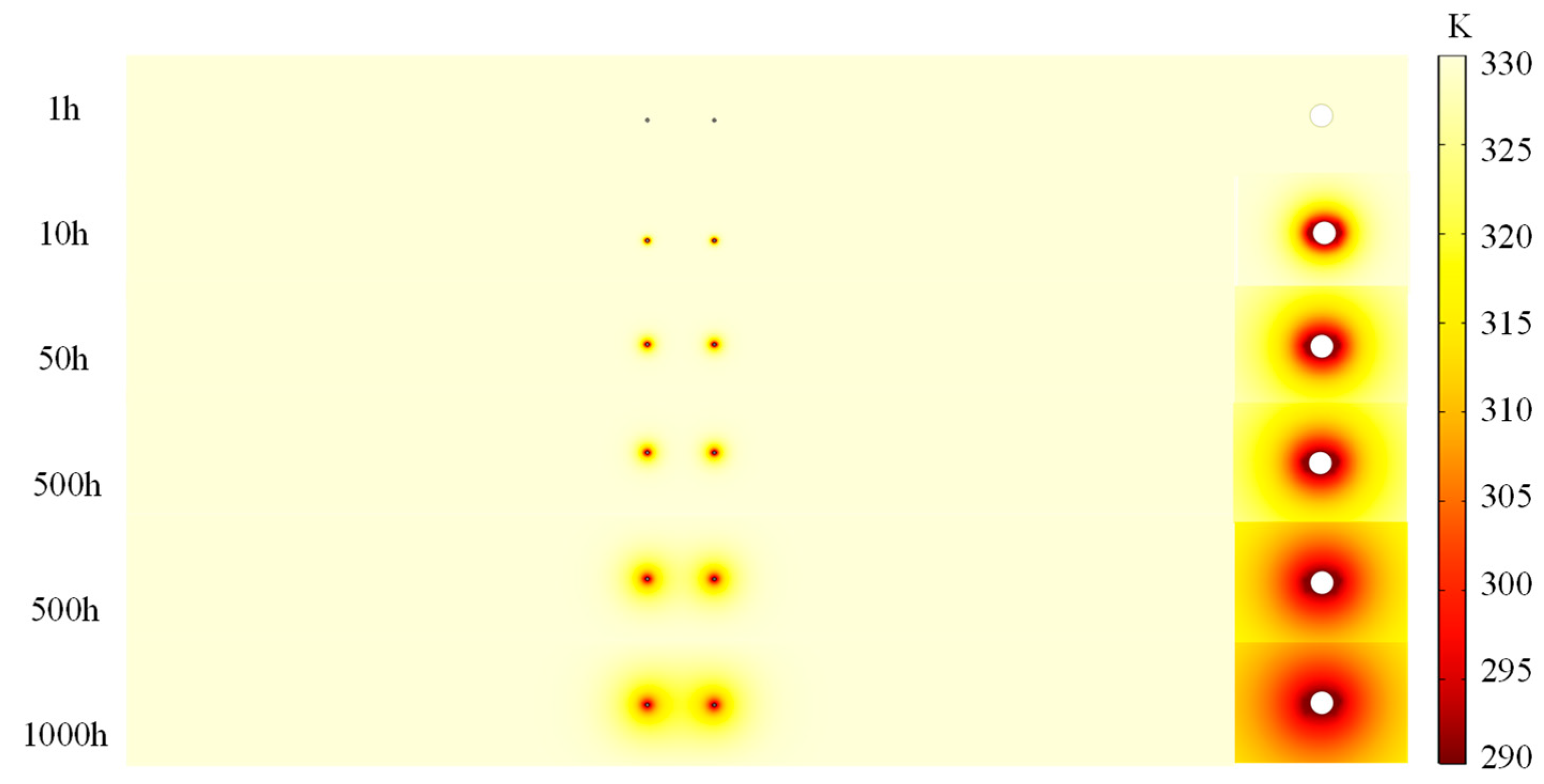

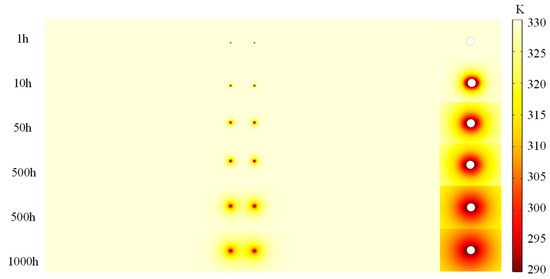

3.4.1. Temperature Distribution

An analysis of temperature changes in the coal seam throughout the THMD-coupled extraction process is presented in this section. Figure 6 displays the temperature distribution at various stages. A rapid drop in the temperature of the surrounding coal occurs when the borehole surface is first exposed to extraction (1 h), which establishes a low-temperature zone at the center of the borehole. This low-temperature area continues to expand as extraction time progresses to 1000 h, giving rise to a significant temperature gradient around the boreholes. At 1000 h, the heat exchange between the boreholes and the surrounding coal begins to affect the temperature distribution, causing fluctuations to appear in the isothermal contours around the boreholes. The temperature of the coal layer surrounding the boreholes continues to decrease for the duration of the gas extraction process.

Figure 6.

Variation in coal seam temperature with time.

From a practical engineering perspective, this significant temperature drop, driven by the Joule-Thomson effect during gas expansion, is not merely a thermal phenomenon. It induces thermal stress in the surrounding coal matrix, which can lead to the creation of new micro-fractures or the propagation of existing ones. This process can create a localized zone of enhanced permeability around the borehole, which is a beneficial effect that can improve the efficiency of gas drainage over time.

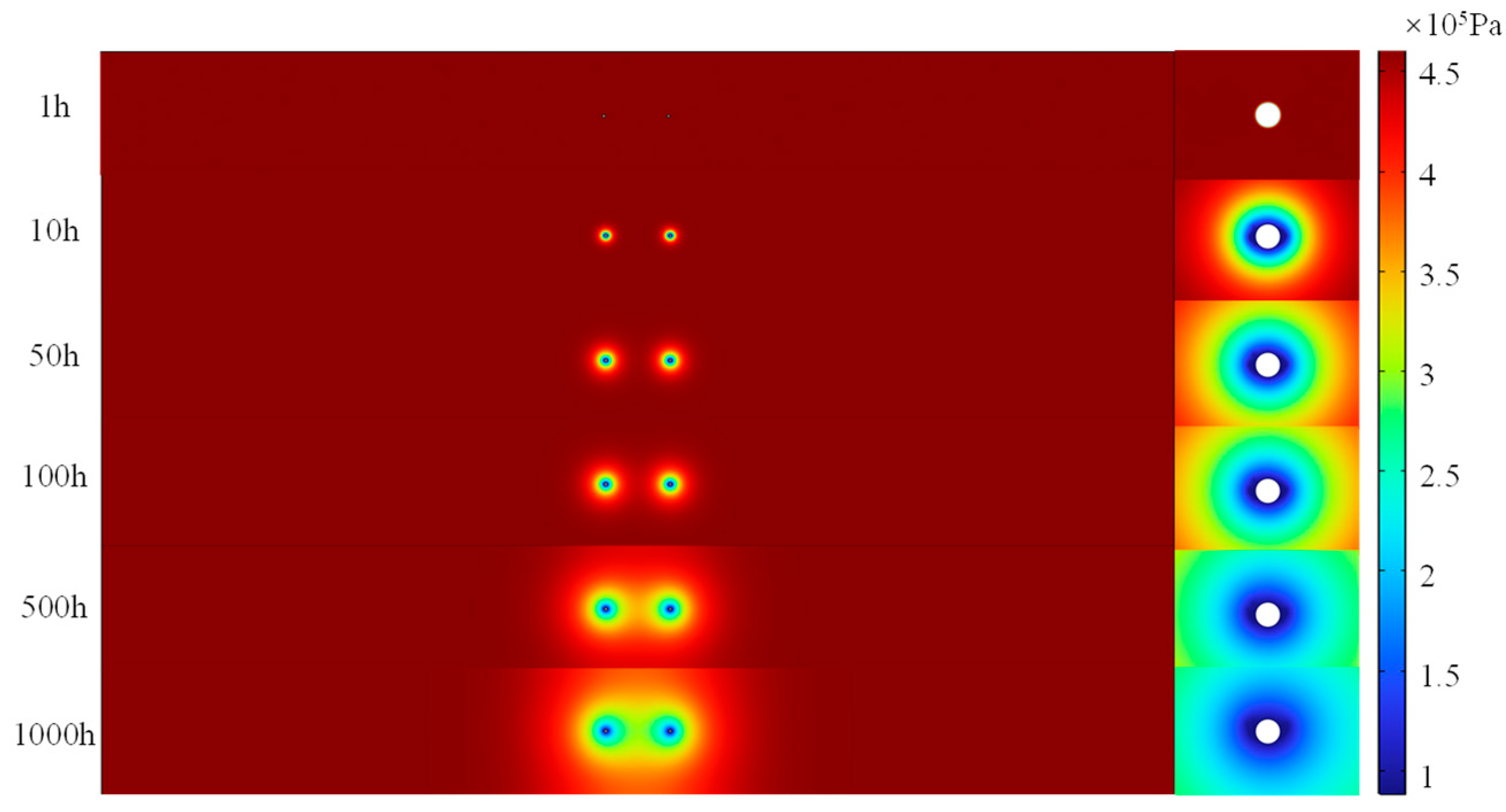

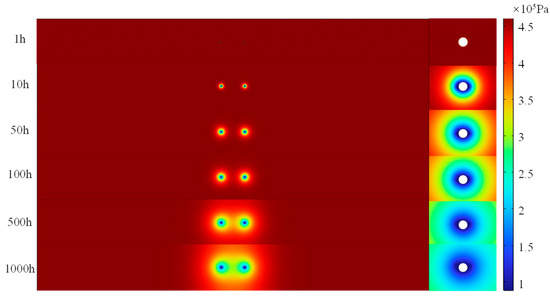

3.4.2. Gas Pressure Distribution

Figure 7 shows the change in gas pressure in the coal seam at different extraction times. From the gas pressure cloud map, it is clear that after 1000 h of extraction, the gas pressure has changed significantly. As extraction proceeds, the gas pressure in the coal seam gradually decreases. The pressure is higher further away from the boreholes, approaching the original reservoir pressure. The closer to the boreholes, the lower the gas pressure. After 1000 h, the pressure influence zones of the two boreholes have overlapped, indicating effective gas extraction between them.

Figure 7.

Variation in gas pressure with time.

The visualization of these pressure influence zones has direct engineering applications. The successful overlap of the pressure funnels between the two boreholes, as seen at 1000 h, is the primary goal of borehole pattern design. It provides a visual confirmation that the coal mass between the boreholes is being effectively degasified. Engineers can use such models to optimize borehole spacing, ensuring that no high-pressure ‘dead zones’ remain, which would otherwise pose a significant safety risk during subsequent mining operations.

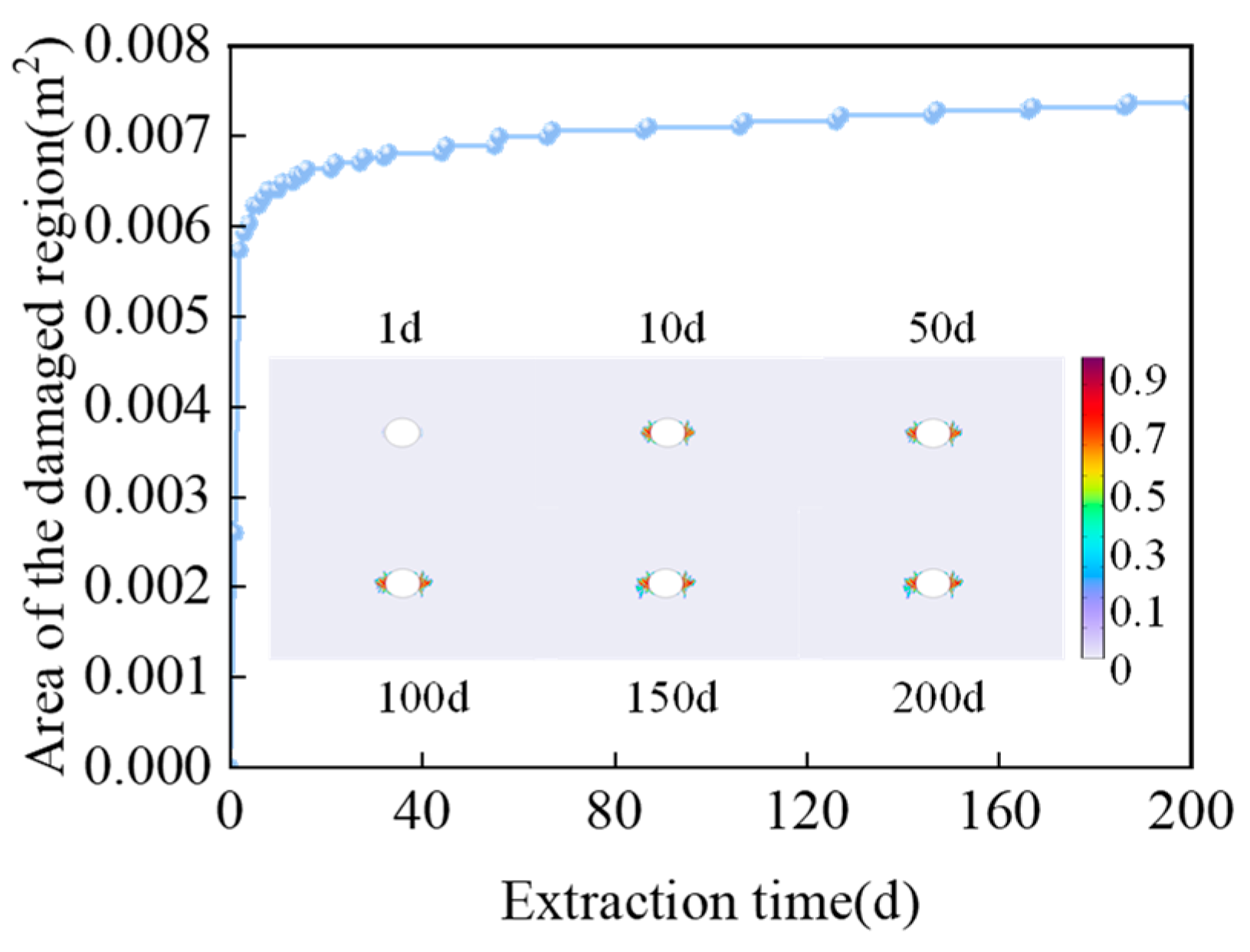

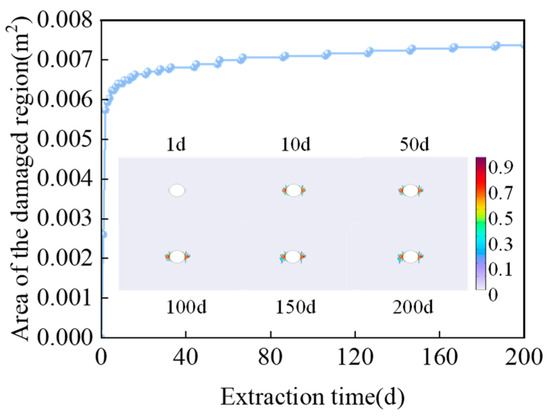

3.4.3. Borehole Damage Zone Area

Figure 8 shows the change in the damaged area near the boreholes at different extraction times. At the beginning of extraction, significant damage occurred near the boreholes. This is because the negative pressure in the boreholes and the reservoir gas pressure created large gas pressure and temperature gradients initially, leading to significant changes in effective stress and causing a damage zone to form. As extraction continued, the damaged area increased slightly, growing by only 0.53% from 10 h to 1000 h. This is because the changes in pore pressure and thermal stress due to extraction cause continuous damage generation near the boreholes, but the gradient is not as large as in the initial phase.

Figure 8.

Variation in damage zone area with time.

In an engineering context, the formation of this damage zone presents a critical trade-off. On one hand (a positive effect), the damaged region acts as a high-permeability channel, facilitating the flow of gas from the coal matrix into the borehole, thereby increasing extraction efficiency. On the other hand (a negative risk), an excessively large or unstable damage zone can lead to borehole instability, potential collapse, and blockages, which would halt production and could increase safety risks. Therefore, a key application of this model is to help engineers predict and control the extent of this damage zone to optimize this balance—maximizing permeability enhancement while maintaining borehole integrity.

4. Multi-Factor Sensitivity Analysis of Borehole Pre-Extraction Effectiveness

4.1. Effective Extraction Radius

The effective extraction radius is a crucial engineering parameter for designing along-layer borehole layouts, as it directly dictates the spacing required to ensure an area is safe for mining. To enhance the practical applicability of our simulation, we define this radius not by an arbitrary value, but by a formal safety threshold derived from established regulatory standards.

The theoretical basis for this criterion comes directly from Article 190 of the “Coal Mine Safety Regulations” of China, a legally mandated standard for coal mine operations. This regulation stipulates that for pre-extraction to be considered effective and the area safe, the residual gas content must be reduced to less than 70% of its original value. To translate this safety requirement into a measurable pressure threshold, we use the widely accepted parabolic relationship between gas pressure p and gas content X [47]:

where X is the coal seam gas content (m3/t); a is the gas content coefficient (m3/(t·MPa0.5)); p is the reservoir pressure (MPa).

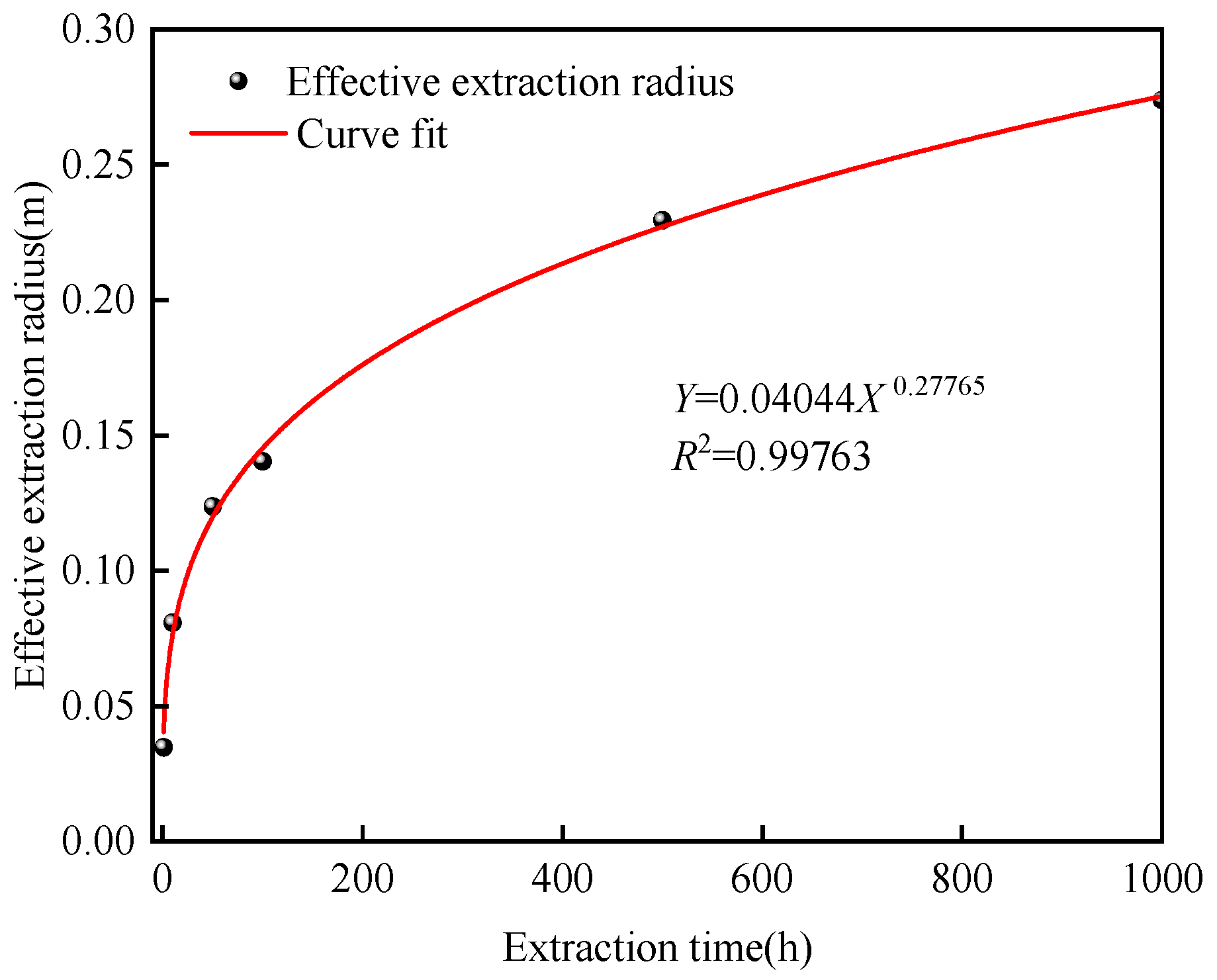

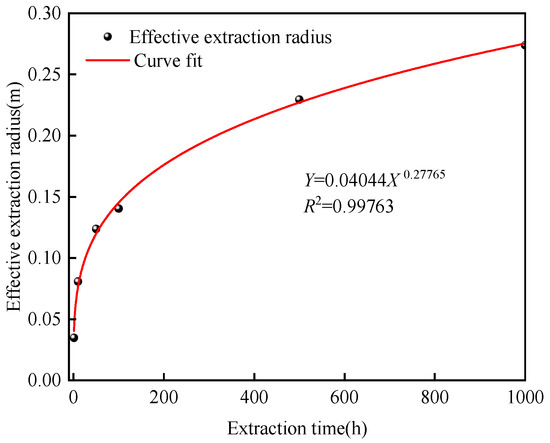

Based on this relationship, a residual gas content of 70% corresponds to a residual gas pressure of (0.7)2 = 49% of the original reservoir pressure. Therefore, our “effective extraction radius” is defined as the distance from the borehole at which the gas pressure has dropped by at least 51%. This approach ensures that our simulation results are directly tied to a practical, safety-driven engineering benchmark. The evolution of this safety-compliant effective radius over time is calculated and presented in Figure 9. This radius serves as an actionable guideline for determining the maximum allowable spacing between boreholes to meet safety standards before mining operations commence.

Figure 9.

Variation in effective extraction radius with time.

Figure 9 illustrates the temporal evolution of the effective extraction radius. The radius experiences a phase of rapid initial growth, reaching 0.0347 m after 1 h and 0.0808 m after 10 h. As the extraction period extends, the expansion of the radius follows a power-law function (Y = 0.04044X0.27765). However, during the later stages of extraction, the rate of increase decelerates. This slowdown is attributed to the continuous decline in gas seepage capacity as the pressure front advances further from the borehole. Ultimately, the radius’s range of influence stabilizes, attaining a final value of 0.2739 m after 1000 h.

4.2. Sensitivity Analysis of Effective Extraction Radius and Damage Zone Area

4.2.1. Response Surface Analysis Method

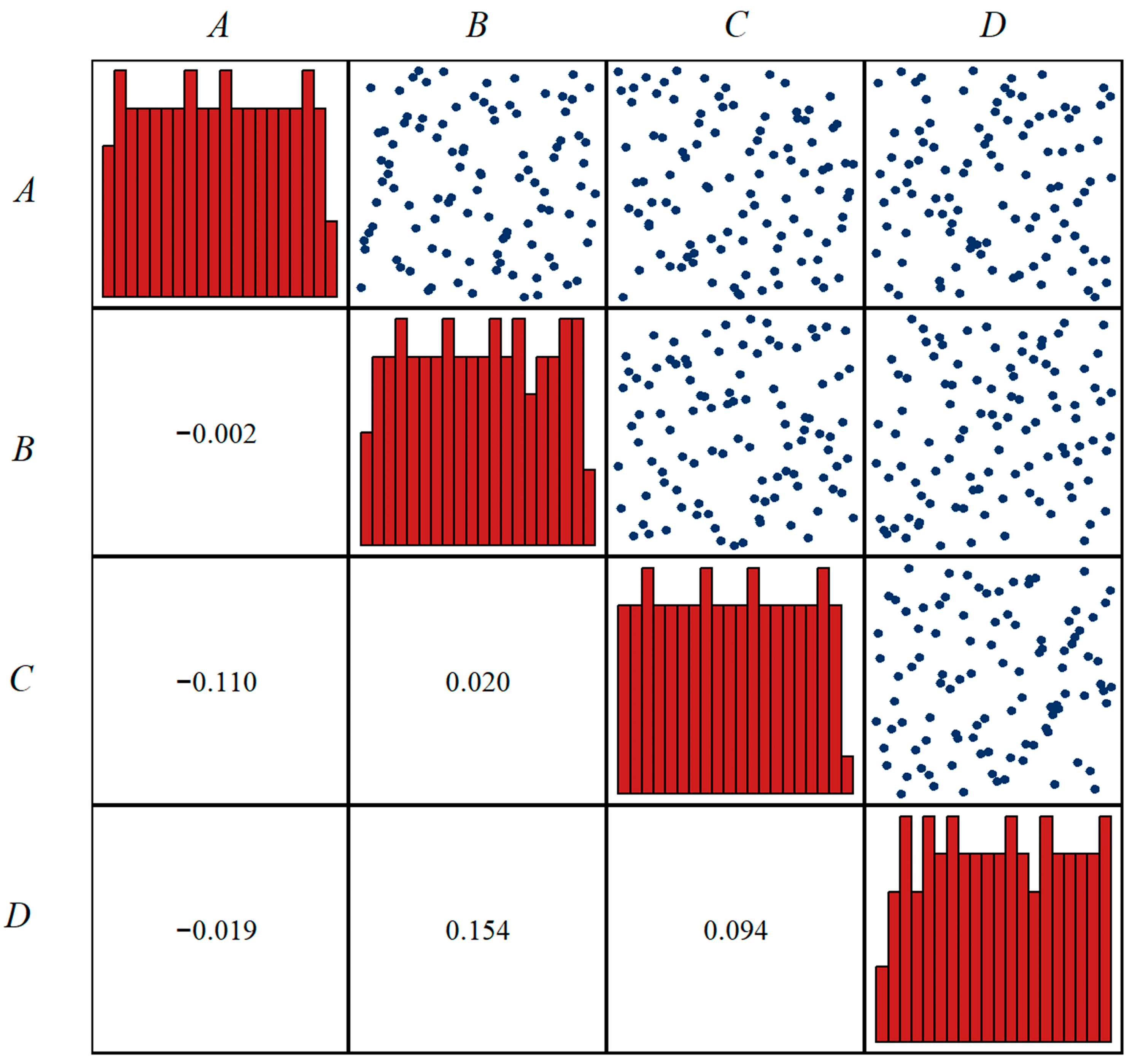

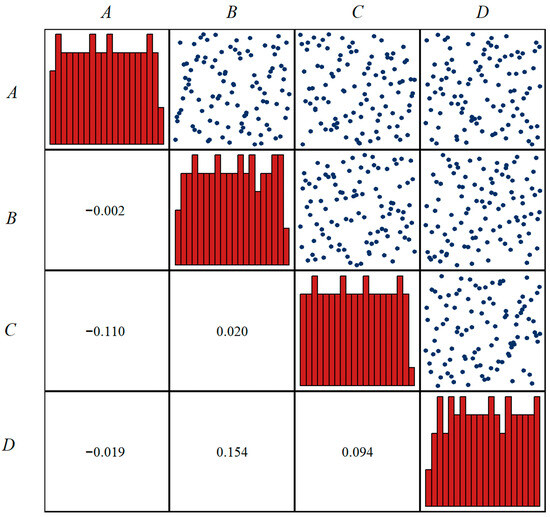

A sensitivity analysis based on the Response Surface Method (RSM) was performed to analyze how different parameters affect the effective extraction radius and damage zone area [48,49]. The goal of this analysis is to identify extraction parameters that enhance safety while minimizing costs and the risk of failure. RSM relies on statistical models to map the relationship between system inputs and outputs, making the precision of these models critical for a successful analysis [50]. Prior to conducting the sensitivity analysis, we validated the performance of the applied algorithm and confirmed the required number of numerical simulation designs. For the sampling strategy, Uniform Latin Hypercube (ULH) was chosen for its efficiency; it ensures a uniform spread of random samples across the parameter space, which reduces computational demands and time [51,52]. Figure 10 shows the scatter matrix chart of input parameters. The probability density functions of all input variables are less than 0.1 or around 0.1, and no strong correlation among the four input variables is observed. Therefore, the design space can be considered satisfactory to perform the screening analysis of those four input parameters in terms of the dependent variable.

Figure 10.

Scatter matrix plot of input parameter screening and analysis.

This study selected four input parameters: borehole diameter (A), extraction negative pressure (B), borehole spacing (C), and initial permeability (D). A Box–Behnken Design (BBD) with 29 simulation runs was designed to study their effects on the effective extraction radius and damage zone area. The design and results are shown in Table 2 and Table 3.

Table 2.

Factors and Their Corresponding Levels in the Experimental Design.

Table 3.

Design Layout for the Response Surface Experiment and Observed Outcomes.

Subsequently, quadratic polynomial equations were established to represent the relationship between the effective extraction radius, damage zone area, and the independent variables to obtain predicted responses. The fitted regression equations based on coded factors are shown in (14) and (15).

Y1 = 1.38818 − 0.0176082 × A − 0.0285878 × B + 0.0287832 × C − 0.0484686 × D − 0.00100343 × AB + 0.000178737 × AC + 5.57585 × 10−5 × AD + 0.00271026 × BC − 0.000727419 × BD + 0.00227463 × CD + 0.000112577 × A2 + 0.0267106 × B2 + 0.00510274 × C2 + 0.00127279 × D2

Y2 = 0.00514518 − 1.85139 × 10−5 × A − 7.27883 × 10−6 × B − 0.000129481 × C − 0.000249719 × D − 1.89888 × 10−6 × AB

− 3.5091 × 10−7 × AC + 1.14099 × 10−6 × AD + 2.23757 × 10−5 × BC + 7.3526 × 10−6× BD + 2.71634 × 10−6 × CD + 6.48457 × 10−7 × A2

− 2.78064 × 10−5 × B2 − 4.06081 × 10−8 × C2 + 3.43143 × 10−6 × D2

− 3.5091 × 10−7 × AC + 1.14099 × 10−6 × AD + 2.23757 × 10−5 × BC + 7.3526 × 10−6× BD + 2.71634 × 10−6 × CD + 6.48457 × 10−7 × A2

− 2.78064 × 10−5 × B2 − 4.06081 × 10−8 × C2 + 3.43143 × 10−6 × D2

The coefficient of determination, R2, was used to quantify the agreement between the response surface model and the actual data. With values approaching 1 indicating a stronger correlation, the obtained R2 values of 0.9968 and 0.9946 confirm that the predicted values are in excellent agreement with the results from the numerical simulations. Furthermore, the adjusted R2 values for the effective extraction radius and damage zone area were 0.9937 and 0.9893, respectively, satisfying the criteria for robust regression model performance [53].

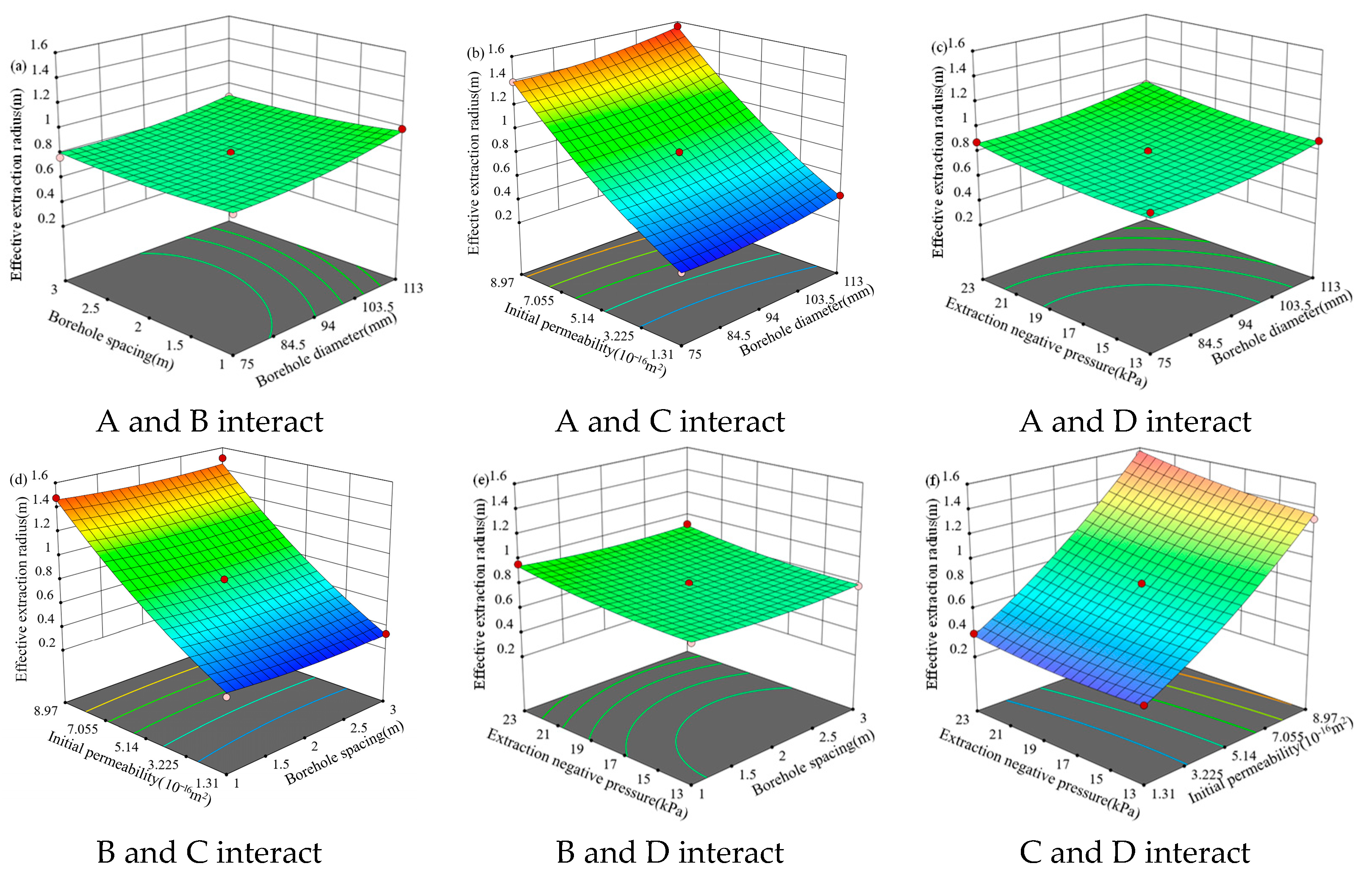

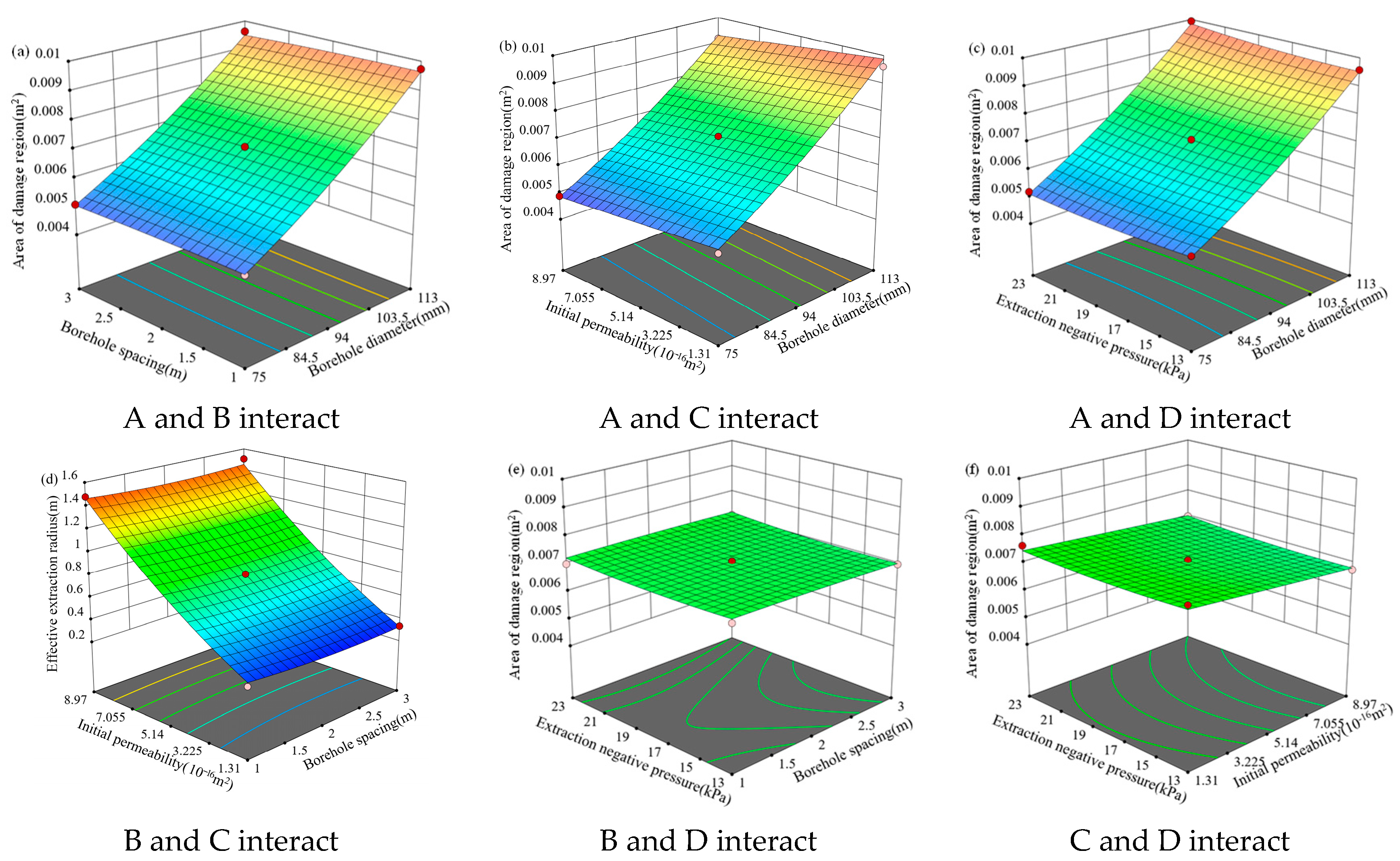

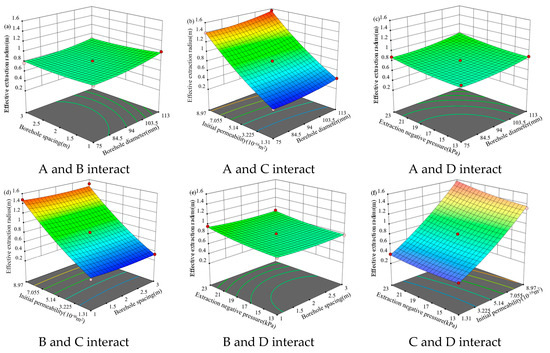

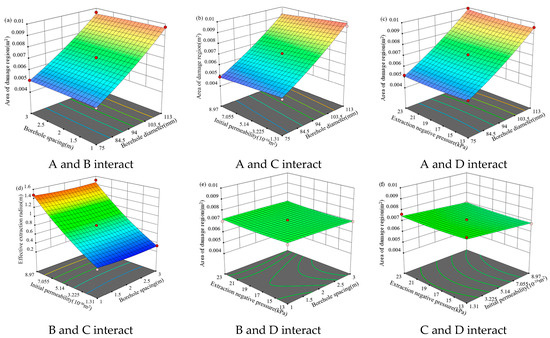

The response surface plots in Figure 11 and Figure 12 illustrate that both the effective extraction radius (Y1) and the area of the damage region (Y2) are governed by the complex interactions between multiple factors. A comparative analysis reveals that initial permeability and borehole diameter have the most pronounced positive effects on both response variables, as indicated by the consistently steep gradients of their respective response surfaces. Conversely, borehole spacing has a negligible impact on both Y1 and Y2, which is evident from the nearly flat surfaces and parallel, widely spaced contour lines across its interaction plots (Figure 11a and Figure 12a).

Figure 11.

Changes in Y1 (Effective Extraction Radius) under the influence of the interaction effects of different factors.

Figure 12.

Changes in Y2 (Area of Damage Region) under the influence of the interaction effects of different factors.

Notably, the most significant interaction for the effective extraction radius (Y1) occurs between initial permeability and extraction negative pressure (Figure 11f), characterized by a sharply curved surface and dense, elliptical contours. For the area of the damage region (Y2), the strongest interaction is observed between borehole diameter and initial permeability (Figure 12b). In summary, initial permeability and borehole diameter are the dominant controlling factors, while borehole spacing exerts a minimal influence on both the extraction radius and the damage area.

4.2.2. Sensitivity Analysis

To understand how the model outputs are affected by changes in the input variables, a sensitivity analysis (SA) was conducted. This analysis relies on the results from the analysis of variance (ANOVA), shown in Table 4, which provides a quantitative measure of sensitivity for each parameter. The statistical importance of each term is indicated by its corresponding F-value and p-value.

Table 4.

Analysis of variance of the effective extraction radius and area of damage region response surface model.

For the effective extraction radius (Y1), the ANOVA results reveal a clear hierarchy of influence among the parameters. The most significant factor by a substantial margin is initial permeability (C), with an overwhelming F-value of 4219.59 (p < 0.0001). This is followed by borehole diameter (A) (F = 60.02, p < 0.0001) and extraction negative pressure (D) (F = 56.77, p < 0.0001), both of which are also highly significant. In contrast, the effect of borehole spacing (B) is statistically not significant (p = 0.0953) within the tested range. Among the interaction terms, the coupling between initial permeability and extraction negative pressure (CD) (F = 8.72, p = 0.0105) was also found to be significant.

For the area of the damage region (Y2), the analysis presents a different sensitivity ranking. Borehole diameter (A) is overwhelmingly the most dominant factor, with an exceptionally high F-value of 2531.51 (p < 0.0001). Initial permeability (C) also shows a statistically significant effect (F = 35.22, p < 0.0001). However, both borehole spacing (B) and extraction negative pressure (D) were found to be not statistically significant in influencing the damage zone area. Furthermore, the quadratic term for borehole diameter (A2) (F = 14.83, p = 0.0018) is also significant, highlighting a strong and non-linear influence on damage formation.

In summary, the sensitivity analysis indicates that enhancing the effective extraction radius is primarily dependent on the geological factor of initial permeability, with key operational parameters like borehole diameter and extraction pressure also playing significant roles. Conversely, controlling or predicting the damage zone area is almost entirely dictated by the geometric parameter of the borehole diameter, with initial permeability as a secondary, but still significant, factor. These findings are crucial for optimizing borehole layout and extraction schemes in engineering practice, as they clearly distinguish the factors that govern drainage efficiency from those that control borehole stability.

From a practical mining engineering perspective, these statistical findings provide clear, actionable guidance. The overwhelming significance of initial permeability (C) on the effective extraction radius (F-value of 4219.59) statistically confirms a fundamental field observation: geological conditions are the primary determinant of drainage effectiveness. This implies that in low-permeability seams, engineering interventions aimed at enhancing permeability (e.g., hydraulic fracturing) will likely yield the highest return on investment for expanding the gas drainage area. Conversely, the analysis reveals that the borehole diameter (A) is the single most dominant factor influencing the damaged region’s size (F-value of 2531.51). This provides a direct directive for safety management: to control the stability of the surrounding coal mass and mitigate risks associated with excessive fracturing, the precise control of borehole diameter is more critical than adjusting other operational parameters like extraction pressure within the tested range.

4.3. Limitations and Future Outlook

While this study provides valuable insights, it is important to acknowledge its limitations, which in turn illuminate promising directions for future research. The primary limitation is the model’s 2D simplification, a necessary compromise for computational feasibility that may not fully capture three-dimensional stress and flow effects. Consequently, a key avenue for future work is the development of a full 3D heterogeneous model to provide a more comprehensive representation. Furthermore, while our model incorporates macroscopic heterogeneity, it does not account for the intrinsic, fabric-related anisotropy of the coal matrix at the micro-scale (e.g., via permeability tensors). To enhance physical accuracy, future models should therefore incorporate such tensor-based anisotropy at the element level. Finally, looking beyond model enhancements, a significant advancement would be the integration of real-time field monitoring data (e.g., from microseismic sensors or distributed temperature sensing) with the model through data assimilation techniques. This would enable dynamic model calibration, greatly enhancing its site-specific predictive power and transforming it into a more powerful tool for real-world engineering applications.

5. Conclusions

In this study, a comprehensive numerical model incorporating fully coupled thermo-hydro-mechanical damage (THMD) processes was developed to simulate gas pre-extraction from along-layer boreholes. The principal contribution of this research, which distinguishes it from prior THM/THMD studies, lies in the synergistic integration of this heterogeneous material model with a statistical framework utilizing RSM and ANOVA. This fusion of methodologies advances the work beyond a conventional descriptive simulation, creating a quantitative optimization platform that can systematically identify and rank the parameters most critical to extraction efficiency. The key conclusions from this analysis are detailed below.

- (1)

- A fully coupled thermo-hydro-mechanical damage (THMD) model that accounts for the heterogeneous distribution of coal’s physical properties was established and successfully validated against field data, demonstrating good consistency.

- (2)

- The simulations revealed complex, non-uniform evolution patterns for the physical fields around the boreholes. The inherent material heterogeneity led to localized stress concentrations and preferential flow paths, confirming a more realistic response than a uniform material model would predict. The subsequent multi-factor sensitivity analysis provided a definitive, quantitative ranking of these influences. It was demonstrated that the effective extraction radius (Y1) is predominantly governed by the initial permeability (F-value of 4219.59), while the extent of the damage zone area (Y2) is overwhelmingly dictated by the borehole diameter (F-value of 2531.51), with both factors being highly significant (p < 0.0001).

- (3)

- These findings provide crucial, data-driven directives for engineering practice. To enhance the drainage radius in low-permeability seams, engineering interventions should prioritize measures that improve permeability (e.g., hydraulic fracturing), as this is the most influential factor. Conversely, to manage borehole stability and mitigate safety risks associated with excessive fracturing, the precise control of borehole diameter is the most critical lever. Ultimately, this research showcases the significant potential of integrating high-fidelity numerical modeling with statistical analysis to guide and optimize gas extraction strategies in complex deep-mining environments.

Author Contributions

Conceptualization, H.L.; Methodology, B.H., X.L., H.L. and L.W.; Validation, X.L., P.J. and C.W.; Formal analysis, B.H., X.L., L.W. and Y.D.; Investigation, P.J. and C.W.; Resources, B.H., L.Z. and H.L.; Data curation, B.H., X.L. and L.Z.; Writing—original draft, X.L.; Writing—review & editing, B.H. and P.J.; Project administration, B.H. and Y.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (No. 52574270, 52204235) and the Excellent Youth Program of Xi’an University of Science and Technology (No. 2024YQ3-15).

Data Availability Statement

The original contributions presented in this study are included in the article, further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Author Lu Zhang was employed by the company Wanfu Coal Mine of Yankuang Group. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Song, D.; Liu, Q.; Qiu, L.; Zhang, J.; Majid, K.; Peng, Y.; Zhao, Y.; Wang, M.; Guo, M.; Hong, T. Experimental Study on Resistivity Evolution Law and Precursory Signals in the Damage Process of Gas-Bearing Coal. Fuel 2024, 362, 130798. [Google Scholar] [CrossRef]

- Qiu, L.; Dang, J.; Zhang, J.; Wang, M.; Liu, Q.; Si, L.; Jiang, Z.; Khan, M. Investigating Nonlinear Resistivity Characteristics and Mechanisms of Coal during Various Loading Stages. J. Appl. Geophys. 2025, 238, 105705. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, E. Risk Identification for Coal and Gas Outburst in Underground Coal Mines: A Critical Review and Future Directions. Gas Sci. Eng. 2023, 118, 205106. [Google Scholar] [CrossRef]

- Hu, B.; Gou, R.; Song, Z.; Li, S.; Liu, S.; Liu, S.; Han, T.; Yang, W.; Shuang, H. Evolution of Overlying Strata Fractures in Variable Mining Heights of Deeply Buried Thick Coal Seams. Results Eng. 2025, 28, 107415. [Google Scholar] [CrossRef]

- Hu, B.; Ren, Z.; Li, S.; He, X.; Long, H.; Cheng, L.; Luo, R. The Distribution Characteristics of Adsorbed CH4 in Various-Sized Pore Structures of Coal Seams. Mathematics 2025, 13, 2931. [Google Scholar] [CrossRef]

- Liu, L.; Jin, J.; Liu, J.; Cheng, W.; Zhao, M.; Luo, S.; Luo, Y.; Wang, T. Mechanical Properties of Sandstone under In-Situ High-Temperature and Confinement Conditions. Int. J. Miner. Metall. Mater. 2025, 32, 778–787. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, Z.; Shen, W.; Feng, T.; Zhang, G. Mechanical Property and Thermal Degradation Mechanism of Granite in Thermal-Mechanical Coupled Triaxial Compression. Int. J. Rock Mech. Min. Sci. 2022, 160, 105270. [Google Scholar] [CrossRef]

- Dong, Z.; Tian, S.; Xue, H.; Lu, S.; Liu, B.; Erastova, V.; Wu, M.; Wu, R. Analysis of Pore Types in Lower Cretaceous Qingshankou Shale Influenced by Electric Heating. Energy Fuels 2024, 38, 20577–20590. [Google Scholar] [CrossRef]

- Gao, F.; Xue, Y.; Gao, Y.; Zhang, Z.; Teng, T.; Liang, X. Fully Coupled Thermo-Hydro-Mechanical Model for Extraction of Coal Seam Gas with Slotted Boreholes. J. Nat. Gas Sci. Eng. 2016, 31, 226–235. [Google Scholar] [CrossRef]

- Li, H.; Huang, B.; Zheng, W.; Zhao, X.; Tannant, D. Effect of Proppant Distribution in Hydraulic Fractures on Coalbed Methane Extraction. Results Eng. 2023, 20, 101550. [Google Scholar] [CrossRef]

- Zou, X.; Ma, T.; Liu, G.; Ye, D.; Wang, X.; Guo, K. A New Hydro-Mechanics Coupling Model for Gas Extraction of Coal Seam Considering Slippage Effect and Tortuosity. Phys. Fluids 2025, 37, 067106. [Google Scholar] [CrossRef]

- Rong, T.; Yang, Y.; Zhou, Y.; Zhang, S.; Niu, R.; Nan, P.; Wang, C. Development of an Anisotropic Coal Permeability Model Incorporating Damage and Its Application in Gas Drainage. Phys. Fluids 2025, 37, 053110. [Google Scholar] [CrossRef]

- Peng, J.; Shi, S.; Shi, X. Research on Prediction of Coal and Gas Outburst Risk Based on TIWTD-CNSA. Results Eng. 2023, 18, 101195. [Google Scholar] [CrossRef]

- Sun, C.; Liu, W.; Yang, R.; Ma, T. Sensitivity Analysis on the Microwave Irradiation Enhancing Coal Seam Gas Recovery: A Coupled Electromagnetic-Thermo-Hydro-Mechanical Model. J. Nat. Gas Sci. Eng. 2022, 100, 104457. [Google Scholar] [CrossRef]

- Du, F.; Zhang, Y.; Wang, K.; Sun, J.; Xu, Y. Nitrogen Injection for Enhanced Coal Seam Gas Extraction (N2-ECGE): A Simulation Study. Earth Energy Sci. 2025, 1, 193–202. [Google Scholar] [CrossRef]

- Wang, J.G.; Liu, J.; Kabir, A. Combined Effects of Directional Compaction, Non-Darcy Flow and Anisotropic Swelling on Coal Seam Gas Extraction. Int. J. Coal Geol. 2013, 109–110, 1–14. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, Y.; Zhao, Z.; Wei, M.; Wang, Z.; Zhang, J. Time Dependency of Permeability and Deformation of Coal during Gas Storage in Deep Coal Reservoirs. Int. J. Hydrog. Energy 2025, 98, 341–352. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, H.; Chang, J.; Yan, F.; Li, A.; Wang, S.; Guo, J.; Lei, Q.; Yang, S. Pressure-Relief Gas Flow Behavior in the Hydraulic Flushing Coal Mass Considering Creep Effect: Theoretical Modeling and Numerical Simulation. Gas Sci. Eng. 2025, 142, 205691. [Google Scholar] [CrossRef]

- Hu, B.; Ren, Z.; Li, S.; He, X.; Lin, H.; Bai, Y.; Yan, D.; Luo, R. A New Quantitative Characterization Method of Absolute Methane Adsorption Isotherm in Coal. Chem. Eng. J. 2025, 522, 167551. [Google Scholar] [CrossRef]

- Feng, X.; Deng, S.; Liu, Q.; Kong, X.; Zhang, X. Moisture Content Modulates Pressure-Dependent Gas Diffusion in Coal Particles: Mechanistic Insights. Int. J. Heat Mass Transf. 2025, 252, 127455. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, J.; Du, J.; Jiang, D.; Chen, J.; Yuan, Q.; Hao, L.; Wang, Y. Experimental Study on Effects of Load Damage Precursor Information and Response Characteristic of Gas-Containing Coal for Mining Safety Based on Acoustic Emission. Process Saf. Environ. Prot. 2024, 184, 993–1010. [Google Scholar] [CrossRef]

- Song, W.; Yu, S.; Rong, H. Study on the Mechanism of Structural Coal Permeability Law on Coal and Gas Outburst under Multi-Field Coupling. Phys. Fluids 2025, 37, 076641. [Google Scholar] [CrossRef]

- Zhao, J.; Jin, J.; Li, Y. Macro-Micro Failures of Shear Creep and Creep Damage Model of Deep Hard Rocks Induced by Initial Disturbances. Eng. Fract. Mech. 2025, 324, 111269. [Google Scholar] [CrossRef]

- Lin, C.; Wang, Z.; Shi, J.; Ma, B.; Liang, R.; Luo, X. Elasto-Plastic Solution for Tunnelling-Induced Nonlinear Responses of Overlying Jointed Pipelines in Sand. Tunn. Undergr. Space Technol. 2024, 152, 105953. [Google Scholar] [CrossRef]

- Du, M.; Zhou, C.; Cai, C.; Xue, Y.; Hou, P.; Gao, F.; Han, W.; Ren, R.; Ren, H.; Su, S. Damage Evolution Law and Permeability Enhancement Effect of Coal Subjected to Liquid Nitrogen Fracturing in Coalbed Methane Mining. Phys. Fluids 2025, 37, 046614. [Google Scholar] [CrossRef]

- Peng, L.; Zhang, G.; Wang, H.; Sun, S.; Zhang, Y.; Liu, Z.; Wang, Z. Research on Strata Movement Control in Deep Areas of Super-Thick and Weak-Cemented Overlying Strata during Local Backfill Mining—A Case Study Based on Yingpanhao Coal Mine. Results Eng. 2025, 27, 105579. [Google Scholar] [CrossRef]

- Chen, X.; Han, P.; Hu, J.; Yang, T.; Zhou, A.; Sun, J. Air Leakage Mechanism and Hole Sealing Technology in Directional Long-Drilled Perimeter Rock-Borehole Composite Fissures: For Gas Enrichment in Varying Coal-Seam Thickness Change Areas. Process Saf. Environ. Prot. 2024, 192, 1367–1381. [Google Scholar] [CrossRef]

- Xu, C.; Yuan, Y.; Wang, K.; Hu, Y.; Nie, Z.; Shi, Y. Coalbed Methane Extraction: Characteristics of Damage-Seepage Evolution and Dynamic Response of Methane Transport in Non-Homogeneous Coal Seams under Cavitation. Gas Sci. Eng. 2025, 142, 205689. [Google Scholar] [CrossRef]

- Jia, L.; Wang, L.; Cheng, Y.; Xu, J.; Nie, B.; Peng, S. Dynamic Evolution of Fluid Energy in Gas Extraction: Insights from Physical Simulation and Mathematical Modeling. Phys. Fluids 2025, 37, 073355. [Google Scholar] [CrossRef]

- Zhang, E.; Zhou, B.; Yang, L.; Li, C.; Li, P. Experimental Study on the Microseismic Response Characteristics of Coal and Gas Outbursts. Process Saf. Environ. Prot. 2023, 172, 1058–1071. [Google Scholar] [CrossRef]

- Lin, H.; Li, B.; Li, S.; Song, Z.; Wang, P.; Luo, R.; Wei, Z.; Qin, L. A Coupled Thermo-Hydro-Mechanical-Damage Model and Numerical Simulation for Layered Coal Subjected to Liquid Nitrogen Fracturing. Chin. J. Rock Mech. Eng. 2024, 43, 1110–1123. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y.; Cao, W.; Wang, T.; Zhang, L.; Feng, X. Coupled Thermo-Hydro-Mechanical-Damage Modeling of Cold-Water Injection in Deep Geothermal Reservoirs. J. Rock Mech. Geotech. Eng. 2025; in press. [Google Scholar] [CrossRef]

- Xi, B.; Wu, Y.; Zhao, Y. Experimental Study on the Correlation between Macroscopic Mechanical Parameters and Thermal Shock Velocity of Granite under Thermal Shock. Chin. J. Rock Mech. Eng. 2019, 38, 2194–2207. [Google Scholar] [CrossRef]

- Liu, L.; Ji, H.; Elsworth, D.; Zhi, S.; Lv, X.; Wang, T. Dual-Damage Constitutive Model to Define Thermal Damage in Rock. Int. J. Rock Mech. Min. Sci. 2020, 126, 104185. [Google Scholar] [CrossRef]

- Zhu, W.C.; Liu, J.; Sheng, J.C.; Elsworth, D. Analysis of Coupled Gas Flow and Deformation Process with Desorption and Klinkenberg Effects in Coal Seams. Int. J. Rock Mech. Min. Sci. 2007, 44, 971–980. [Google Scholar] [CrossRef]

- Liu, Q.; Cheng, Y.; Li, W.; Jin, K.; He, T.; Zhao, W. Gas-Solid Coupling Model for Coal and Gas in Deep Low-Permeability First-Mining Seams. Chin. J. Rock Mech. Eng. 2015, 34, 2749–2758. [Google Scholar] [CrossRef]

- Lin, H.; Li, B.; Li, S.; Qin, L.; Wei, Z.; Wang, P.; Luo, R. Numerical Investigation of Temperature Distribution and Thermal Damage of Heterogeneous Coal under Liquid Nitrogen Freezing. Energy 2023, 267, 126592. [Google Scholar] [CrossRef]

- Guo, T.; Tang, S.; Liu, S.; Liu, X.; Zhang, W.; Qu, G. Numerical Simulation of Hydraulic Fracturing of Hot Dry Rock under Thermal Stress. Eng. Fract. Mech. 2020, 240, 107350. [Google Scholar] [CrossRef]

- Zhu, W.C.; Tang, C.A. Numerical Simulation on Shear Fracture Process of Concrete Using Mesoscopic Mechanical Model. Constr. Build. Mater. 2002, 16, 453–463. [Google Scholar] [CrossRef]

- Zhu, W.C.; Tang, C.A. Micromechanical Model for Simulating the Fracture Process of Rock. Rock Mech. Rock Eng. 2004, 37, 25–56. [Google Scholar] [CrossRef]

- Williams, E. Hooke’s Law and the Concept of the Elastic Limit. Ann. Sci. 1956, 12, 74–83. [Google Scholar] [CrossRef]

- Hassanzadegan, A.; Blöcher, G.; Milsch, H.; Urpi, L.; Zimmermann, G. The Effects of Temperature and Pressure on the Porosity Evolution of Flechtinger Sandstone. Rock Mech. Rock Eng. 2014, 47, 421–434. [Google Scholar] [CrossRef]

- Lin, H.; Li, B.; Li, S.; Qin, L.; Wei, Z.; Wang, P.; Luo, R. Enhancing Coalbed Methane Recovery Using Liquid Nitrogen as a Fracturing Fluid: A Coupled Thermal-Hydro-Mechanical Modeling and Evaluation in Water-Bearing Coal Seam. Energy 2024, 291, 130445. [Google Scholar] [CrossRef]

- Baqer, Y.; Chen, X. A Review on Reactive Transport Model and Porosity Evolution in the Porous Media. Environ. Sci. Pollut. Res. 2022, 29, 47873–47901. [Google Scholar] [CrossRef]

- Zhu, W.C.; Wei, C.H. Numerical Simulation on Mining-Induced Water Inrushes Related to Geologic Structures Using a Damage-Based Hydromechanical Model. Environ. Earth Sci. 2011, 62, 43–54. [Google Scholar] [CrossRef]

- Qiu, Y.; Liang, W.; Li, J.; He, W. Study on Fracture Morphology of Heterogeneous Elasto-Plastic Coal under Hydraulic Fracturing. J. China Coal Soc. 2022, 47, 3668–3679. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, J.; Su, X. A New Test and Calculation Method for the Permeability Coefficient of Coal Seams. J. China Coal Soc. 2024, 49, 833–844. [Google Scholar] [CrossRef]

- Nazarpour, M.; Taghizadeh-Alisaraei, A.; Asghari, A.; Abbaszadeh-Mayvan, A.; Tatari, A. Optimization of Biohydrogen Production from Microalgae by Response Surface Methodology (RSM). Energy 2022, 253, 124059. [Google Scholar] [CrossRef]

- Qatan, H.S.O.; Ghani, W.A.W.A.K.; Said, M.S.M. Prediction and Optimization of Syngas Production from Napier Grass Air Gasification via Kinetic Modelling and Response Surface Methodology. Energy 2023, 270, 126883. [Google Scholar] [CrossRef]

- Allahyarzadeh-Bidgoli, A.; Dezan, D.J.; Salviano, L.O.; de Oliveira Junior, S.; Yanagihara, J.I. FPSO Fuel Consumption and Hydrocarbon Liquids Recovery Optimization over the Lifetime of a Deep-Water Oil Field. Energy 2019, 181, 927–942. [Google Scholar] [CrossRef]

- Deutsch, J.L.; Deutsch, C.V. Latin Hypercube Sampling with Multidimensional Uniformity. J. Stat. Plan. Inference 2012, 142, 763–772. [Google Scholar] [CrossRef]

- Posadas, H.; Real, S.; Villar, E. M3-SCoPE: Performance Modeling of Multi-Processor Embedded Systems for Fast Design Space Exploration. In Multi-Objective Design Space Exploration of Multiprocessor SoC Architectures; Silvano, C., Fornaciari, W., Villar, E., Eds.; Springer: New York, NY, USA, 2011; pp. 19–50. ISBN 978-1-4419-8836-2. [Google Scholar]

- Guo, T.; Tang, S.; Sun, J.; Gong, F.; Liu, X.; Qu, Z.; Zhang, W. A Coupled Thermal-Hydraulic-Mechanical Modeling and Evaluation of Geothermal Extraction in the Enhanced Geothermal System Based on Analytic Hierarchy Process and Fuzzy Comprehensive Evaluation. Appl. Energy 2020, 258, 113981. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).