Route Optimization of Hazardous Material Railway Transportation Based on Conditional Value-at-Risk Considering Risk Equity

Abstract

1. Introduction

- We introduce CVaR into risk assessment in railway transportation scenarios for risk aversion routes and dispatch decisions;

- Taking into account the risk unfairness of the external public, we added a risk equity goal to the CVaR-based assessment, and proposed a new model named CVaRE;

- We introduce a practical example and use the k-shortest CVaRE algorithm to solve the problem model, generating the optimal solution. This can serve as a guide and reference for railway hazardous material transportation dispatch decision-makers.

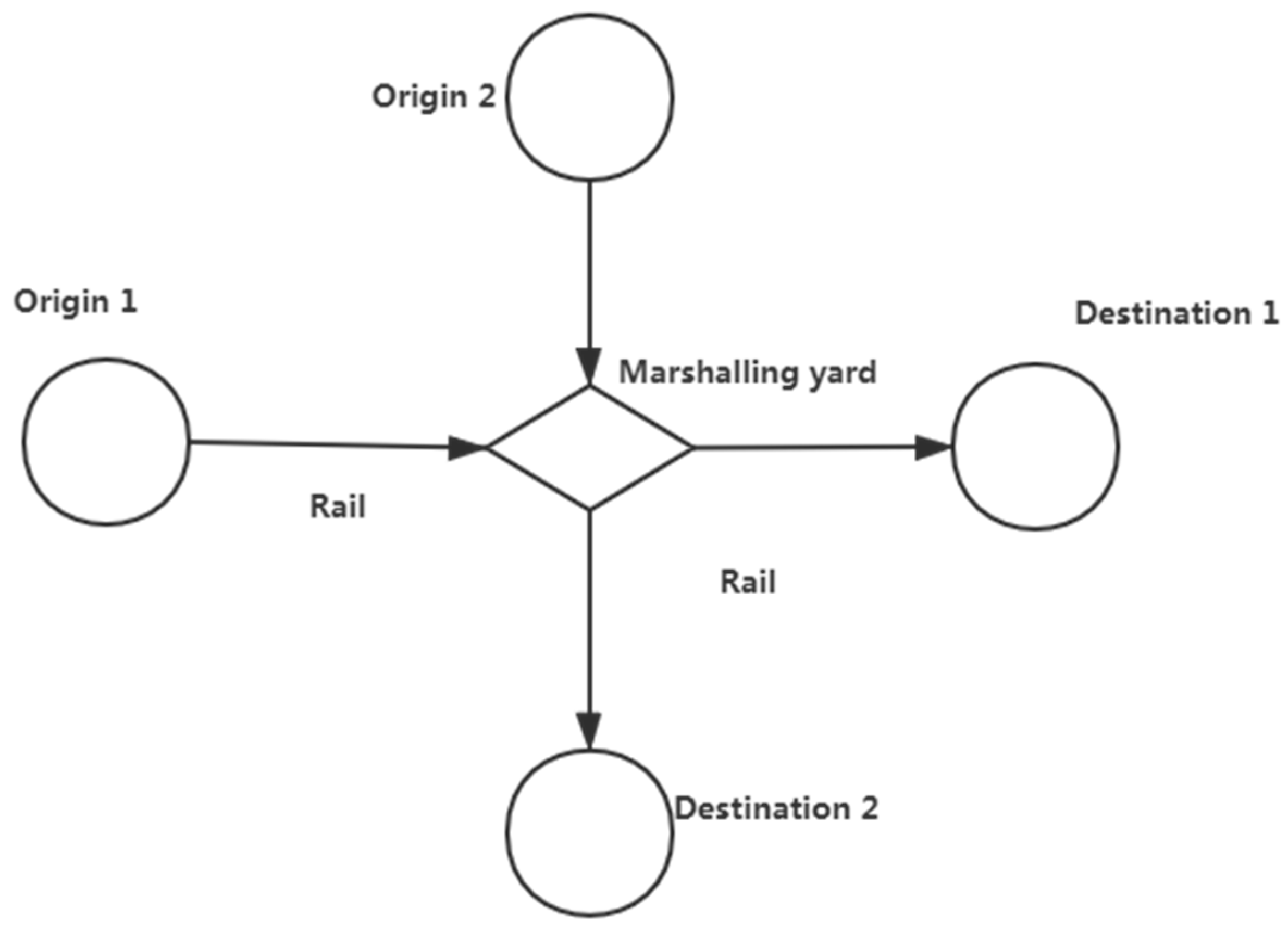

2. Problem Description

2.1. Assumptions and Notations

2.1.1. Model Assumptions

- Fixed transportation network: The railway infrastructure, including yards and routes, is predefined and does not change dynamically.

- Probability-based risk estimation: Accident probabilities and consequences are derived from historical incident reports and regulatory guidelines.

- Travel times and accident probabilities: Assumed to be known and constant, ensuring computational efficiency but ignoring real-world uncertainties.

- Time window constraints: Predefined operational time windows are enforced to ensure safe and timely railway arrivals, maintaining scheduling reliability while balancing efficiency and risk management.

- Generalized hazmat risk representation: Risk estimation is based on historical data and predefined exposure factors, without differentiating between Hazmat types.

2.1.2. Notations

| Set of yards, indexed by i, j, k | |

| Set of marshalling yards, indexed by k, | |

| Set of arcs in the network, indexed by (i, j), (k, j) | |

| Set of railway shipments between railway yards (or yard and marshalling yards), indexed by v | |

| Set of yards in service of shipment v | |

| Set of arcs in service of shipment v |

| Cost of moving a Hazmat container on arc (i, j) in shipment v | |

| Exposure risk of moving a Hazmat container on arc (i, j) in shipment v | |

| Exposure risk of using yard k for a Hazmat container in shipment v | |

| Origin of shipment v | |

| Destination of shipment v | |

| Non-negative integer, number of Hazmat containers in shipment v | |

| Confidence level, but also represents the level of risk aversion of suppliers | |

| Risk consequences in shipment v on arc (i, j) in shipment v | |

| Accident probability on arc (i, j) in shipment v | |

| Risk consequences of using yard k for Hazmat shipment v | |

| Probability of accident in using yard k | |

| Select Route VaR Threshold Under CVaR* | |

| 0–1 variable, whether to select arc (i, j) in shipment v as transportation section | |

| 0–1 variable, whether to select yard k as railway yard in shipment v | |

| Number of containers in shipment v unload at Marshalling yard k | |

| Delivery time associated with shipment v | |

| Time for handling containers at marshalling yard k | |

| Time for running on the railway route | |

| Impact radius of Hazmat accident | |

| Maximum population density of the area passed through by arc (i, j) | |

| Population density of the area where yard k is located |

2.2. Hazmat Risk Measurement Formulation Based on VaR and CVaR

3. Model Establishment

3.1. Mathematical Model

3.1.1. Model Based on CVaR of Direct Transportation Case (Base Case)

3.1.2. Model Based on CVaRE of Transfer Transportation Case Considering Risk Equity

3.2. Solution Methodology

4. Computational Analysis

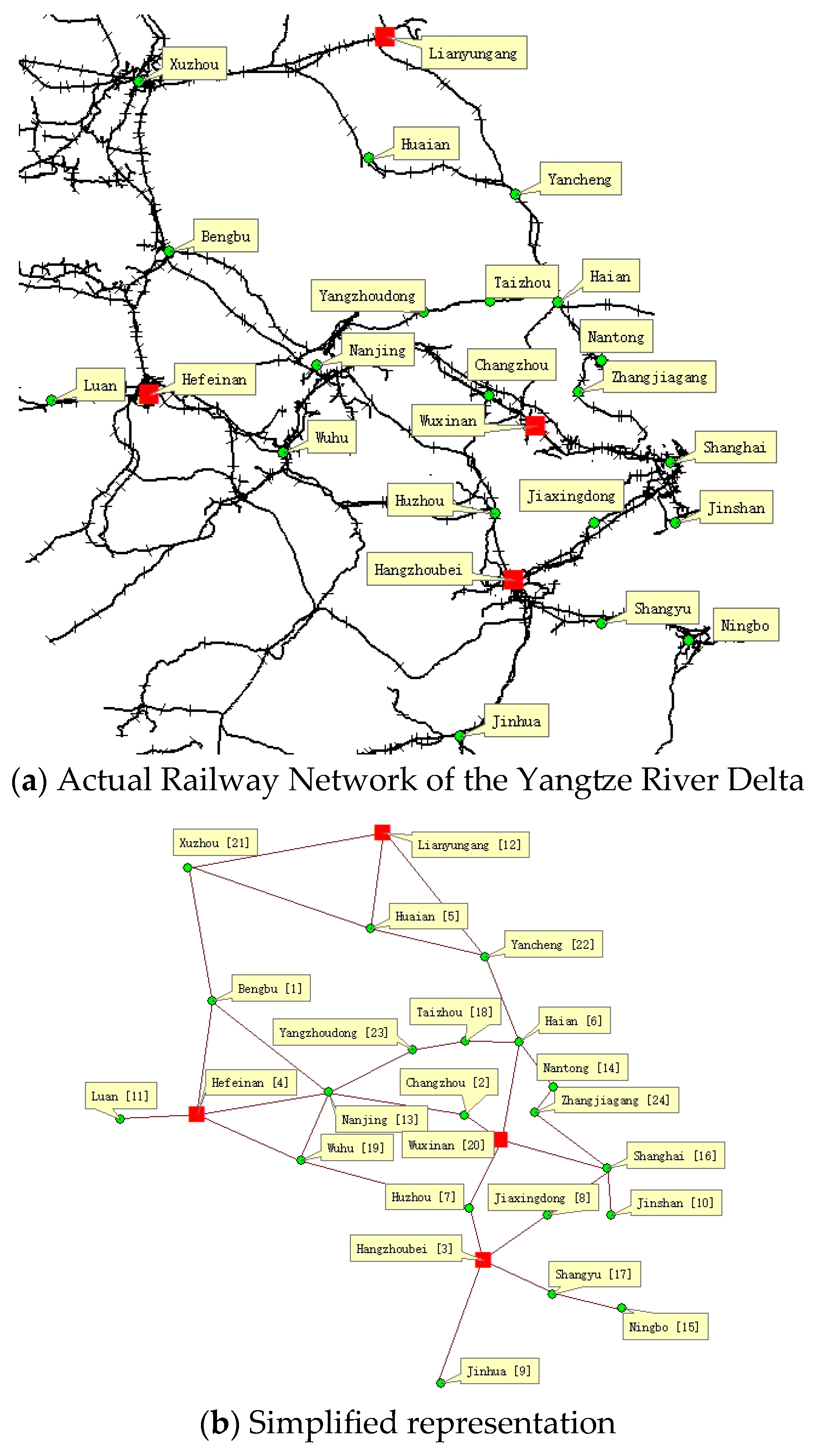

4.1. Problem Setting

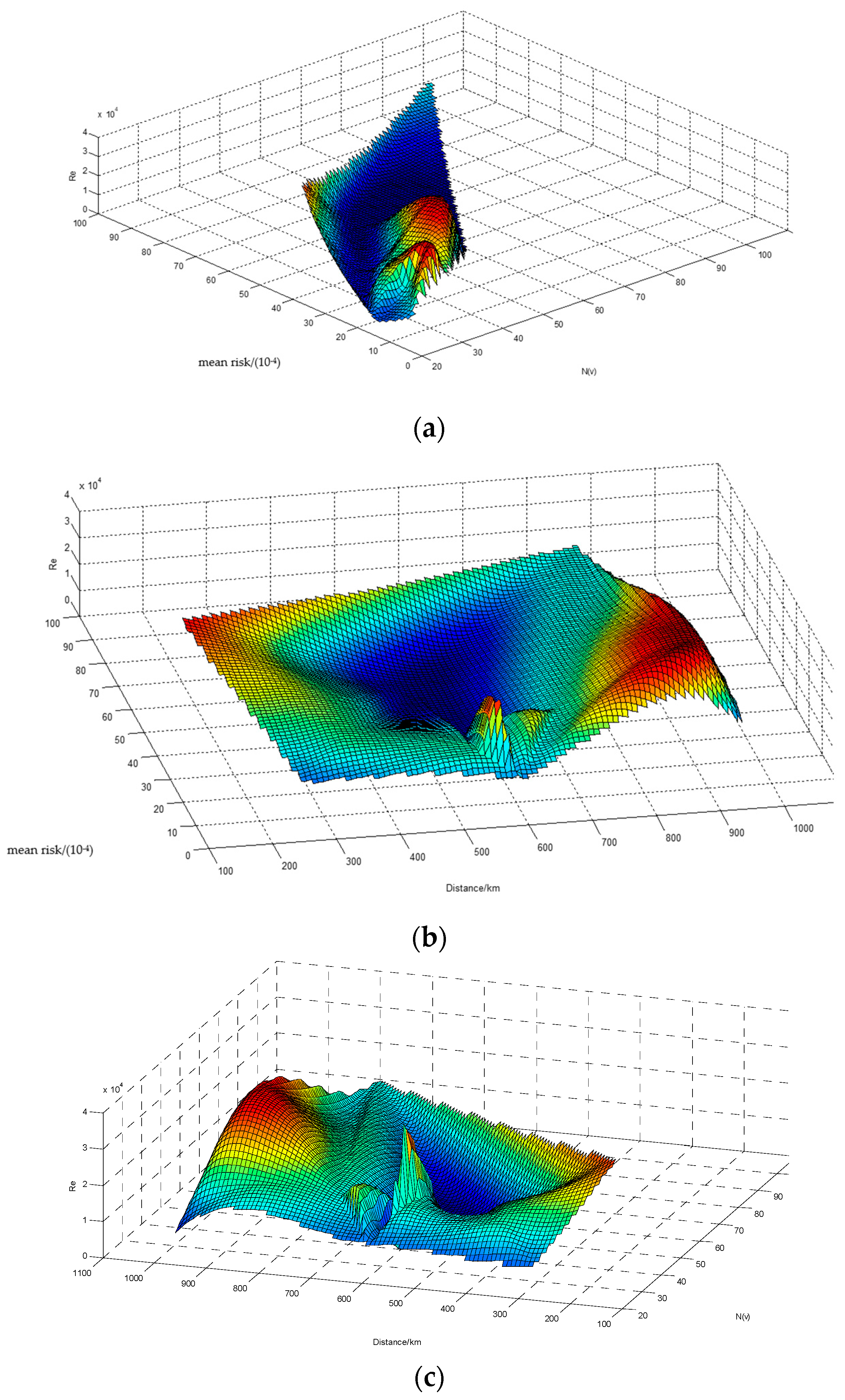

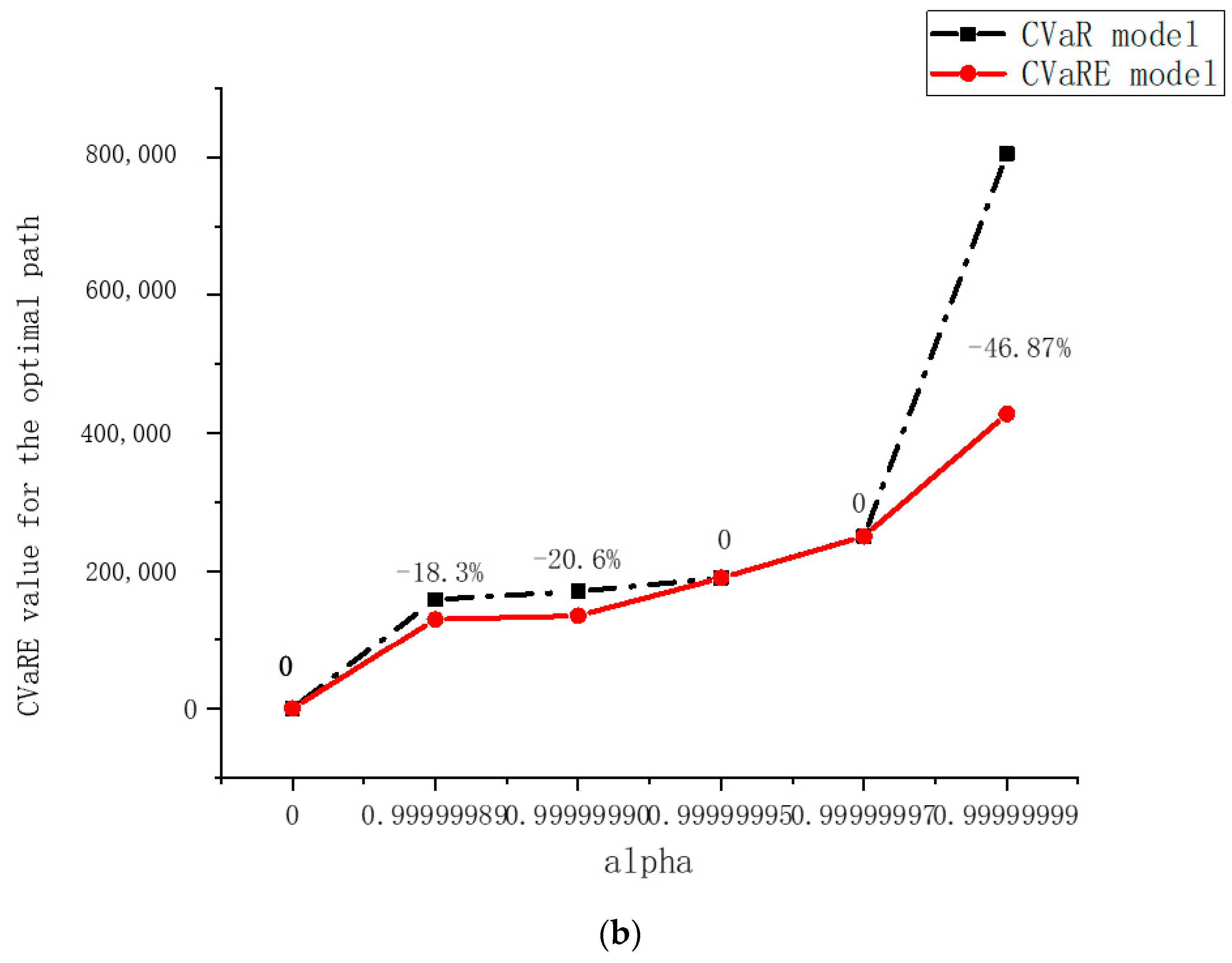

4.2. Data Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Federal Railroad Administration Office of Safety Analysis. Available online: https://safetydata.fra.dot.gov/ (accessed on 20 January 2025).

- China Federation of Logistics and Purchasing. 2022 China Hazardous Chemicals Logistics. In China Logistics Yearbook; He, L.M., Ed.; China Fortune Publishing Co., Ltd.: Beijing, China, 2023; pp. 282–283. [Google Scholar]

- Bubbico, R.; Maschio, G.; Mazzarotta, B.; Milazzo, M.F.; Parisi, E. Risk management of road and rail transport of hazardous materials in Sicily. J. Loss Prev. Process Ind. 2006, 19, 32–38. [Google Scholar] [CrossRef]

- Abkowitz, M.; Lepofsky, M.; Cheng, P. Selecting criteria for designating hazardous materials highway routes. Transp. Res. Rec. 1992, 1333, 30–35. [Google Scholar]

- Erkut, E.; Ingolfsson, A. Catastrophe avoidance models for hazardous materials route planning. Transp. Sci. 2000, 34, 165–179. [Google Scholar] [CrossRef]

- Liu, L.; Wu, Q.; Li, S.; Li, Y.; Fan, T. Risk Assessment of Hazmat Road Transportation Considering Environmental Risk under Time-Varying Conditions. Int. J. Environ. Res. Public Health 2021, 18, 9780. [Google Scholar] [CrossRef] [PubMed]

- Qi, J.; Wang, S. LNG Bunkering Station Deployment Problem—A Case Study of a Chinese Container Shipping Network. Mathematics 2023, 11, 813. [Google Scholar] [CrossRef]

- Androutsopoulos, K.N.; Zografos, K.G. Modeling and solving the fuel distribution problem with unloading precedence and loading sequence considerations. Ann. Oper. Res. 2023, 332, 909–947. [Google Scholar] [CrossRef]

- Sun, Y. A Fuzzy Multi-Objective Routing Model for Managing Hazardous Materials Door-to-Door Transportation in the Road-Rail Multimodal Network with Uncertain Demand and Improved Service Level. IEEE Access 2020, 8, 172808–172828. [Google Scholar] [CrossRef]

- Ke, G.Y. Managing rail-truck intermodal transportation for hazardous materials with random yard disruptions. Ann. Oper. Res. 2020, 309, 457–483. [Google Scholar] [CrossRef]

- Assadipour, G.; Ke, G.Y.; Verma, M. Planning and managing intermodal transportation of hazardous materials with capacity selection and congestion. Transp. Res. Part E Logist. Transp. Rev. 2015, 76, 45–57. [Google Scholar] [CrossRef]

- Kang, Y.; Batta, R.; Kwon, C. Value-at-risk model for hazardous material transportation. Ann. Oper. Res. 2014, 222, 361–387. [Google Scholar] [CrossRef]

- Fang, K.; Fu, E.; Huang, D.; Ke, G.Y.; Verma, M. A value-at-risk based approach to the routing problem of multi-hazmat railcars. Eur. J. Oper. Res. 2025, 320, 132–145. [Google Scholar] [CrossRef]

- Toumazis, I.; Kwon, C. Routing hazardous materials on time-dependent networks using conditional value-at-risk. Transp. Res. Part C Emerg. Technol. 2013, 37, 73–92. [Google Scholar] [CrossRef]

- Faghih-Roohi, S.; Ong, Y.-S.; Asian, S.; Zhang, A.N. Dynamic conditional value-at-risk model for routing and scheduling of hazardous material transportation networks. Ann. Oper. Res. 2015, 247, 715–734. [Google Scholar] [CrossRef]

- Andersson, F.; Mausser, H.; Rosen, D.; Uryasev, S. Credit risk optimization with conditional value-at-risk criterion. Math. Program. 2001, 89, 273–291. [Google Scholar] [CrossRef]

- Huang, D.; Pang, J.; Liu, L.; Wu, S.; Huang, T. An Emergency Quantity Discount Contract with Supplier Risk Aversion under the Asymmetric Information of Sales Costs. Mathematics 2022, 10, 919. [Google Scholar] [CrossRef]

- Ma, S.; Cai, J.; Wang, G.; Ge, X.; Teng, Y.; Jiang, H. Research on Decision Analysis with CVaR for Supply Chain Finance Based on Blockchain Technology. Mathematics 2024, 12, 438. [Google Scholar] [CrossRef]

- Hosseini, S.D.; Verma, M. Conditional value-at-risk (CVaR) methodology to optimal train configuration and routing of rail hazmat shipments. Transp. Res. Part B Methodol. 2018, 110, 79–103. [Google Scholar] [CrossRef]

- Zhong, S.; Cheng, R.; Jiang, Y.; Wang, Z.; Larsen, A.; Nielsen, O.A. Risk-averse optimization of disaster relief facility location and vehicle routing under stochastic demand. Transp. Res. Part E Logist. Transp. Rev. 2020, 141, 102015. [Google Scholar] [CrossRef]

- Su, L.; Kwon, C. Risk-averse network design with behavioral conditional value-at-risk for hazardous materials transportation. Transp. Sci. 2020, 54, 184–203. [Google Scholar] [CrossRef]

- Hosseini, S.D.; Verma, M. Equitable routing of rail hazardous materials shipments using CVaR methodology. Comput. Oper. Res. 2021, 129, 105222. [Google Scholar] [CrossRef]

- Fang, K.; Ke, G.Y.; Verma, M. A routing and scheduling approach to rail transportation of hazardous materials with demand due dates. Eur. J. Oper. Res. 2017, 261, 154–168. [Google Scholar] [CrossRef]

- Carotenuto, P.; Giordani, S.; Ricciardelli, S.; Rismondo, S. A tabu search approach for scheduling hazmat shipments. Comput. Oper. Res. 2007, 34, 1328–1350. [Google Scholar] [CrossRef]

- Liu, L.; Li, J.; Zhou, L.; Fan, T.; Li, S. Research on Route Optimization of Hazardous Materials Transportation Considering Risk Equity. Sustainability 2021, 13, 9427. [Google Scholar] [CrossRef]

- Bianco, L.; Caramia, M.; Giordani, S.; Piccialli, V. A game-theoretic approach for regulating hazmat transportation. Transp. Sci. 2016, 50, 424–438. [Google Scholar] [CrossRef]

- Fontaine, P.; Crainic, T.G.; Gendreau, M.; Minner, S. Population-based risk equilibration for the multimode hazmat transport network design problem. Eur. J. Oper. Res. 2020, 284, 188–200. [Google Scholar] [CrossRef]

- Liu, L.; Liu, C. Design of hazardous materials transportation network considering risk equity under uncertain demand. J. Syst. Manag. 2024, 33, 1218–1230. [Google Scholar]

- Liu, L.; Gan, X.; Wu, Q.; Sun, Z. Route Optimization of Hazardous Material (Hazmat) Transportation with Risk Equity and Time-Varying Risk. Transp. Res. Rec. J. Transp. Res. Board 2024, 2678, 901–918. [Google Scholar] [CrossRef]

- Rockafellar, R.T.; Uryasev, S. Conditional value-at-risk for general loss distributions. J. Bank. Financ. 2002, 26, 1443–1471. [Google Scholar] [CrossRef]

- Sarykalin, S.; Serraino, G.; Uryasev, S. Value-at-Risk vs. Conditional Value-at-Risk in Risk Management and Optimization. In State-of-the-Art Decision-Making Tools in the Information-Intensive Age; Informs: Catonsville, MD, USA, 2008; pp. 270–294. [Google Scholar]

- Verma, M. Railroad transportation of dangerous goods: A conditional exposure approach to minimize transport risk. Transp. Res. Part C Emerg. Technol. 2011, 19, 790–802. [Google Scholar] [CrossRef]

| Origin | Destination | N(v) | CVaR * | Route | |

|---|---|---|---|---|---|

| 1 | 12 | 30 | 20,256.98 | [1, 21, 12] | 17 |

| 1 | 3 | 59 | 45,842.12 | [1, 4, 19, 7, 3] | 23 |

| 4 | 14 | 39 | 49,434.77 | [4, 13, 23, 18, 6, 14] | 9 |

| 4 | 3 | 74 | 34,381.59 | [4, 19, 7, 3] | 23 |

| 4 | 12 | 54 | 30,385.47 | [4, 1, 21, 12] | |

| 5 | 14 | 23 | 27,984.10 | [5, 22, 6, 14] | 10 |

| 5 | 13 | 35 | 30,385.47 | [5, 21, 1, 13] | 17 |

| 7 | 1 | 25 | 31,266.28 | [7, 19, 4, 1] | 8 |

| 7 | 15 | 37 | 30,606.14 | [7, 3, 17, 15] | 11 |

| 9 | 13 | 31 | 44,517.62 | [9, 3, 7, 19, 13] | 6 |

| 10 | 7 | 20 | 69,064.39 | [10, 16, 8, 3, 7] | 1 |

| 11 | 14 | 24 | 46,753.52 | [11, 4, 13, 23, 18, 6, 14] | 1 |

| 13 | 10 | 38 | 129,906.74 | [13, 19, 7, 3, 8, 16, 10] | 23 |

| 15 | 3 | 54 | 18,733.65 | [15, 17, 3] | 11 |

| 15 | 9 | 27 | 26,859.05 | [15, 17, 3, 9] | 6 |

| 15 | 19 | 40 | 45,842.12 | [15, 17, 3, 7, 19] | 23 |

| 16 | 21 | 102 | 186,583.81 | [16, 8, 3, 7, 19, 4, 1, 21] | 25 |

| 16 | 13 | 54 | 115,262.50 | [16, 8, 3, 7, 19, 13] | 23 |

| 16 | 23 | 30 | 100,118.54 | [16, 8, 3, 7, 19, 13, 23] | 9 |

| 16 | 9 | 31 | 64,910.37 | [16, 8, 3, 9] | 6 |

| 17 | 16 | 36 | 72,276.81 | [17, 3, 8, 16] | 11 |

| 18 | 20 | 48 | 43,250.94 | [18, 6, 20] | 28 |

| 18 | 16 | 37 | 112,363.00 | [18, 6, 14, 24, 16] | 21 |

| 20 | 11 | 30 | 38,540.30 | [20, 2, 13, 4, 11] | 1 |

| 20 | 5 | 18 | 36,919.47 | [20, 6, 22, 5] | 3 |

| 22 | 24 | 12 | 25,710.35 | [22, 6, 14, 24] | 1 |

| 22 | 16 | 29 | 96,069.21 | [22, 6, 14, 24, 16] | 10 |

| 24 | 10 | 39 | 78,724.22 | [24, 16, 10] | 32 |

| 3 | 12 | 52 | 117,998.97 | [3, 7, 19, 4, 1, 21, 12] | 23 |

| O-D Pair | N(v) | Distance (P) | ||

|---|---|---|---|---|

| (1, 12) | 30 | 374 | 16,906.03 | 25.36 |

| (1, 3) | 59 | 553 | 0 | 34.35 |

| (4, 14) | 39 | 550 | 15,532.25 | 15.20 |

| (5, 13) | 35 | 581 | 36,197.46 | 15.85 |

| (9, 13) | 31 | 587 | 14,621.13 | 18.92 |

| (10, 7) | 20 | 274 | 7886.06 | 15.21 |

| (11, 14) | 24 | 606 | 8364.41 | 8.39 |

| (13, 10) | 38 | 586 | 1880.56 | 40.45 |

| (16, 13) | 54 | 544 | 0 | 63.04 |

| (16, 21) | 102 | 878 | 14,254.90 | 99.60 |

| (16, 23) | 30 | 645 | 20,646.36 | 22.06 |

| (18, 16) | 37 | 709 | 15,214.80 | 31.11 |

| (22, 16) | 29 | 1002 | 2822.4 | 29.48 |

| (24, 10) | 39 | 176 | 32,237.57 | 61.71 |

| (3, 12) | 52 | 927 | 34,307.54 | 34.83 |

| Model | Confidence Level | Risk-Measure Value | Route Properties | |||

|---|---|---|---|---|---|---|

| CVaRE * | CVaR * | VaR * | Number of Arcs | Distance (km) | ||

| CVaR | 0 | 0.0189 | 0.0124 | 0 | 4 | 303 |

| 0.99999989 | 158,818.48 | 106,068.99 | 10,755.56 | 4 | 303 | |

| 0.99999990 | 170,387.44 | 112,363.00 | 10,807.08 | 4 | 303 | |

| 0.99999995 | 190,079.78 | 159,650.17 | 11,460.53 | 7 | 709 | |

| 0.99999997 | 250,355.35 | 199,639.35 | 17,737.43 | 7 | 709 | |

| 0.99999999 | 804,905.68 | 118,086.33 | 39,362.11 | 3 | 297 | |

| CVaRE | 0 | 0.0189 | 0.0124 | 0 | 4 | 303 |

| 0.99999989 | 129,759.72 | 115,928.08 | 10,755.56 | 7 | 709 | |

| 0.99999990 | 135,202.78 | 119,987.98 | 10,807.08 | 7 | 709 | |

| 0.99999995 | 190,079.78 | 159,650.17 | 11,460.53 | 7 | 709 | |

| 0.99999997 | 250,355.35 | 199,639.35 | 17,737.43 | 7 | 709 | |

| 0.99999999 | 427,682.78 | 275,534.77 | 39,362.11 | 7 | 709 | |

| Cost (CNY) | |||

|---|---|---|---|

| Direct transportation(base case) | 1,721,712.71 | 2,234,020.54 | 2,349,421.56 |

| Transfer transportation | 1,848,079.10 | 2,777,571.41 | 2,361,436.20 |

| Min cost (P) | 1,906,528.87 | 3,014,526.37 | 2,169,930.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Sun, S.; Li, S. Route Optimization of Hazardous Material Railway Transportation Based on Conditional Value-at-Risk Considering Risk Equity. Mathematics 2025, 13, 803. https://doi.org/10.3390/math13050803

Liu L, Sun S, Li S. Route Optimization of Hazardous Material Railway Transportation Based on Conditional Value-at-Risk Considering Risk Equity. Mathematics. 2025; 13(5):803. https://doi.org/10.3390/math13050803

Chicago/Turabian StyleLiu, Liping, Shilei Sun, and Shuxia Li. 2025. "Route Optimization of Hazardous Material Railway Transportation Based on Conditional Value-at-Risk Considering Risk Equity" Mathematics 13, no. 5: 803. https://doi.org/10.3390/math13050803

APA StyleLiu, L., Sun, S., & Li, S. (2025). Route Optimization of Hazardous Material Railway Transportation Based on Conditional Value-at-Risk Considering Risk Equity. Mathematics, 13(5), 803. https://doi.org/10.3390/math13050803