1. Introduction

Logistics management is a major contributor to reduce operational costs as well as enhance the competitiveness and service level of the industries where the facilitation and acceleration of efficient logistics management depends on the design of the distribution network (DN) [

1]. Location allocation, routing, and inventory are the three major decisions in a distribution network design problem (DNDP). Facility location and customer allocation to facilities are constituents of the location allocation. Meanwhile, vehicle routing problems (VRPs) and inventory control problems are considered sub-areas of routing and inventory, respectively.

VRPs are extensively studied by researchers to support the planning of city logistics patterns [

2]. Most of the industries are located outside metro cities, from where line-haul vehicles need to transport huge amounts of commodities to the cities. Large-sized vehicles are used to serve this purpose, which are generally forbidden to deliver the goods inside cities due to the risk of accidents. For this purpose, the transshipment of cargo between line-haul vehicles and inside city delivery vehicles is mandatory [

3], creating the necessity of supply chain modeling for the distribution of products in cities. At the first level, cargo is transported to specific points in the outskirts of cities, and from there it is transported to the distribution centers at various places within those cities.

A similar concept is used for electric power transmission within cities. Electric power transmission and distribution systems are applied for the supply of electric power to end users. The transmission of the electricity from power generation sites to consumers is conducted through transmission lines, which traverse long distances [

4].

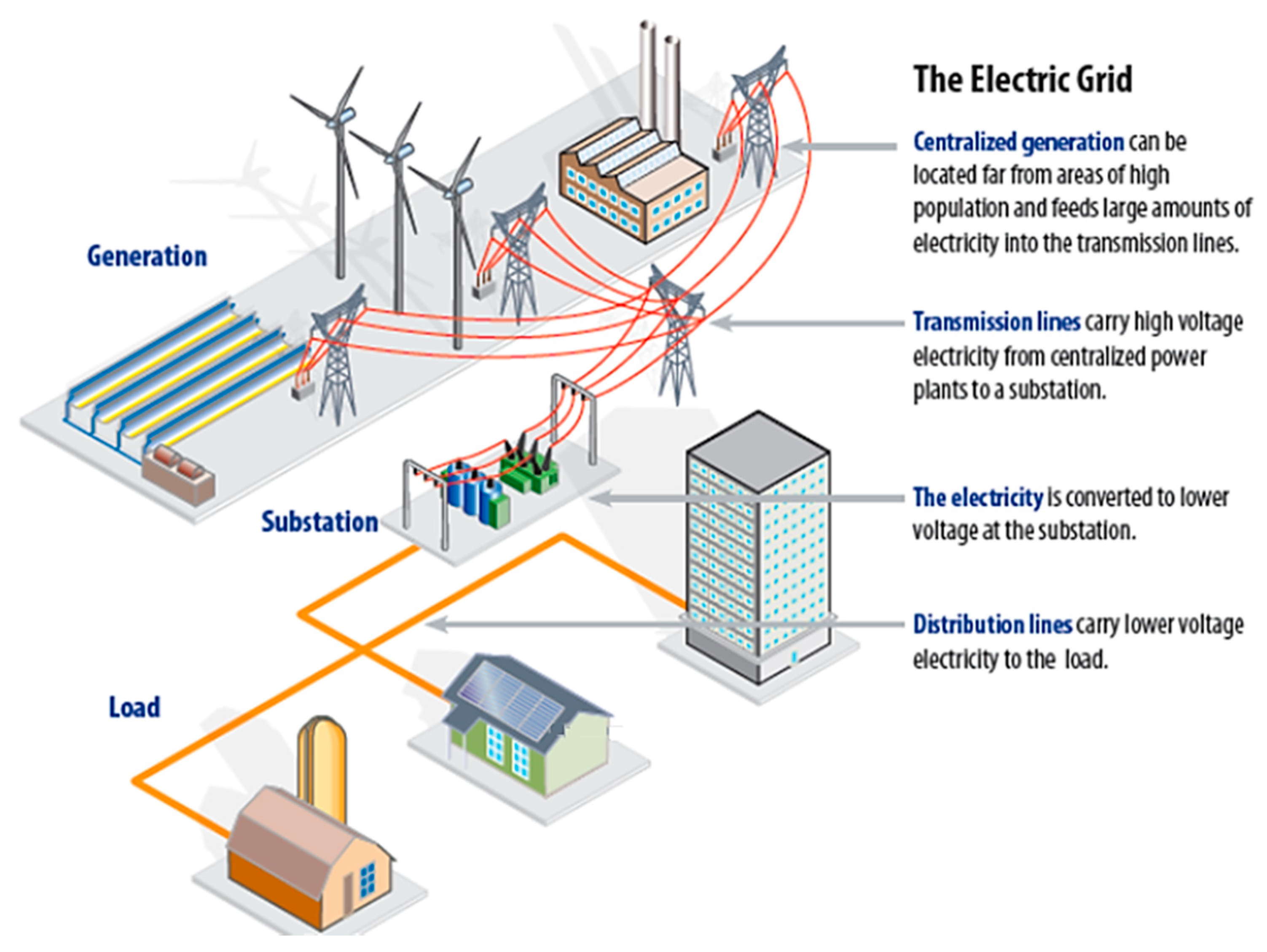

Figure 1 shows the general transmission and distribution flow of electric power from power generation stations to consumer locations. High-voltage electric power cables transmit electric power to grid stations which are located at the outskirts of cities, and from there the stepped-down electric power is distributed to different zones of those cities.

This phenomenon can be thought of as a two-tier distribution network, as heavy transportation vehicles deliver goods to the depots located outside cities, and light vehicles subsequently carry the products to the distribution centers or retailers located in different areas of those cities. Several heuristics to solve the variants of vehicle routing and distribution center location problems are available in the supply chain literature, most of which bear limited generic application. In addition, every manufacturing or distribution organization cannot necessarily afford research and development centers to design optimal routes and supply chain cost minimization procedures. For instance, some manufacturers of small electrical components (household bulbs and tube-lights) may not be able to afford a research and development segment in their hierarchical structure.

The accelerated development and extended usage of the internet and e-commerce has drawn the attention of businesses towards the integration of online and offline sales channels. The integration of offline and online channels is often termed as a multichannel context [

5]. Traditional enterprises can deliver diverse types of products and services by the incorporation of online sales channels in their businesses. The number of companies taking advantage of this opportunity is growing rapidly. This enables potential customers to browse the product catalogs, price information, availability of the product, and even order the products prior to visiting the physical stores. Therefore, online sales channels can positively improve the sales of physical (offline) stores. This effective mode of sales is titled as online to offline (O2O) commerce [

6]. Recently, a case study conducted by Chang et al. [

7] provided factual proof of the effectiveness of the integration of offline and online sales channels to increase the sales order.

Further, for the O2O sales channel, the customer acquisition cost is required to convince the potential consumer or customer to purchase a specific product; this cost is considered a primary business metric. It determines the worth of the end customer to the business and, through it, the return on investment from the customers can be obtained. This enables businesses to evaluate their investment decisions on a single customer in order to improve profitability [

8]. Organizations make investments for online marketing as well as offline marketing of their products. Then, to compute the customer acquisition cost, each customer who buys the product or service is asked about the channel of information through which he came to know about that product. A handful of data is collected for a specific period, and customer acquisition cost for both types of channels is obtained as follows:

Empirical evidence has proved that the customer acquisition cost plays a vital role for value creation in the business strategy. This cost has several components including online and offline marketing, subsidies, dealer commissions, administration costs, and bonuses. Most importantly, successful investment in the customer acquisition cost is directly associated with future corporate profits. It determines the customer retention, technology adoption, and improved market shares [

9]. To incorporate an e-commerce strategy, this study considers a supply chain management model that acquires customers through the O2O channel and takes into account a certain customer acquisition cost for its O2O channel to enhance the future profitability of the system.

In this context, this paper develops a modified product distribution approach towards cost optimization through delivery network design for a small-scale electrical components manufacturer. The proposed model considers that the firm’s target O2O market is available retailers in specific cities, and their manufacturing facilities are located at a distance from those cities. The company owns a fleet of large transport vehicles (trucks) for delivering goods to its main distribution center located near the outskirts of the cities, from where company-owned small-sized transportation vehicles distribute the commodities to sub-distribution centers (retailers) located inside various zones of those cities. This paper provides a solution to this supply chain model by considering it as an electric power transmission and distribution network. Terminologies of the electric power distribution are used to model the situation in order to provide ease in its applicability by the management of companies that have limited knowledge of supply chain management (SCM) techniques.

The structure of the paper is as follows:

Section 2 presents a brief review of the relevant literature. The mathematical model is developed in

Section 3, and

Section 4 provides a numerical illustration of the model. Finally,

Section 5 highlights the important concluding remarks and further research directions for the proposed model.

2. Literature Review

All the activities included in the flow of commodities from vendors/suppliers to the end users are part of the supply chain management (SCM). Developing an efficient flow of products in a supply chain with acceptable service level and minimum costs requires optimization plans falling in the category of SCM [

10]. Various quantitative methods to manage multi-echelon SCM have been reported in the literature since the seminal work by Clark and Scarf [

11]. Sabri and Beamon [

12] developed an SCM model by the combination of planning decisions and strategic design using an iterative solution procedure. Nozick and Turnquist [

13] used a linear function to determine the safety stock and then combined it with a facility location problem. Sarrafha et al. [

14] provided a network design for a multi-echelon supply chain by integrating procurement, production, and deliveries in their model.

Transshipments in SCM helps to reduce risks due to shortages and stock-out conditions. Much of the literature takes transshipment into consideration. Most researchers have focused on optimal control strategies of transshipments without capacity constraints. Common supplier multi-retailer supply chain models with transshipments between retailers were considered by Rudi et al. [

15], Olsson [

16], and Tang and Yen [

17] with the consideration of infinite capacity of the central supplier. Axsäter et al. [

18] developed a transshipment model for

n retailers with stock out case, when the transshipments are made from the outside backup warehouse. Liao et al. [

19] as well as Noham and Tzur [

20] considered emergency orders and multiple items without capacity constraints, whereas Lee and Park [

21] studied some incentives for each retailer to inflate the order in equilibrium in the presence of transshipments opportunity.

A major objective of VRPs found in the literature is the distance minimization, where the distance among each pair of retailers is kept constant in a classical VRP, and the total distance of the supply chain is calculated as the sum of all inter-customer distances on the route of a designated vehicle [

22]. Crainic et al. [

3] developed a VRP variant with time windows at the corresponding customers. Perboli et al. [

23] presented three sets of two-echelon VRPs with four satellites and 50 customers. Their branch and cut algorithm can solve instances up to 21 customers to near-optimal solutions. Jepsen et al. [

24] formulated a branch and cut procedure to solve VRPs with the constraint of a limited number of vehicles per satellite, and solved 47 out of 93 instances to their near-optimal solutions. Martínez-Salazar et al. [

25] formulated a routing problem with the objective of minimizing customer waiting time. Breunig et al. [

26] proposed a hybrid metaheuristic for two-echelon location routing and two-echelon vehicle routing problems.

Generally, distribution centers (DCs) function as inventory storage as well as transfer locations. Thus, the optimization of DC locations and their capacities under the influence of market demands is among the vital decisions of SCM [

27]. Apte and Viswanathan [

28] discussed some techniques to improve the overall efficiencies of logistics and distribution networks. Murali et al. [

29] integrated the pre-positioning of the relief goods and facility location to determine the number of humanitarian aid centers needed, and their locations, after a disaster has occurred. Chaiwuttisak et al. [

30] presented an integer programming model considering the allocation problem to improve the supply of blood products by reducing distribution centers and transportation cost.

The electric power system consists of a large-scale network of several electrical components to transmit and utilize electric power, where the optimal power flow (OPF) to obtain a steady-state operation point with minimum cost is the area of interest for researchers [

31]. The classical method of OPF has the basics provided by power flow solutions in Newton’s method [

32] and the interior point method [

33]. Several studies in recent years have used non-conventional approaches to obtain the OPF. Bose et al. [

34] solved the convex dual OPF problem through tree networks. Sivasubramani and Swarup [

35] presented a differential evolution algorithm and sequential quadratic programming for efficient solutions of OPF. Divshali et al. [

36] used a particle swarm optimization technique to solve OPF with dynamic security constraints in deregulated power systems.

5. Concluding Remarks

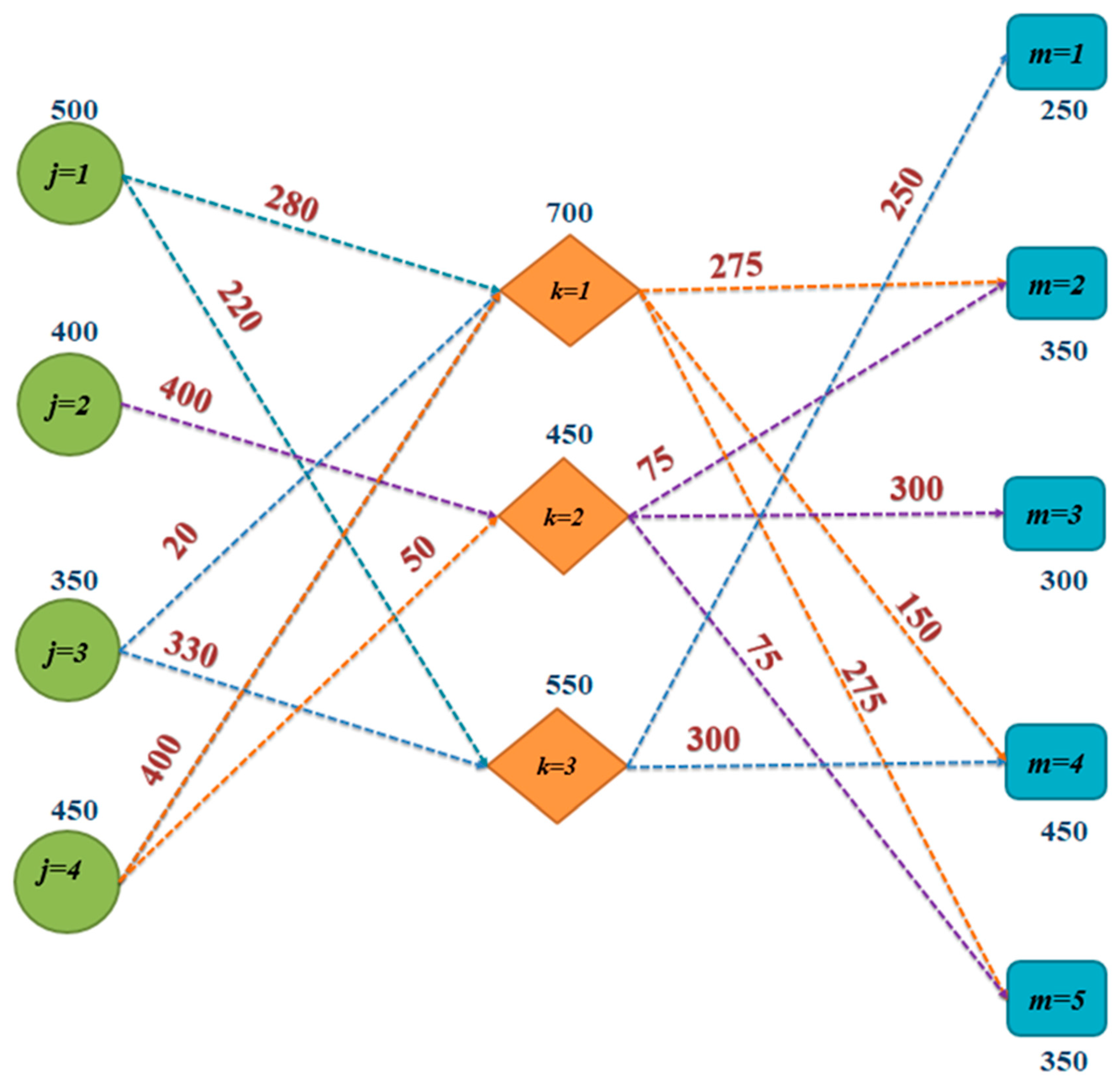

This research work developed a model for the O2O supply chain management of a household electric components manufacturer for delivering goods to its distribution centers and retailers. In the proposed model, electric power transshipment and distribution is considered as product distribution network and is solved using power transmission terminologies. A supply chain management model for a household electric switches manufacturing group having various manufacturing plants in industrial zones outside a specific city was proposed. From these manufacturing facilities, the commodities are shipped to company-owned warehouses in the outskirts of the city. Commodities are then delivered to various retail stores within the city area through small trucks. These multi-retailers are the clients of the product that are acquired by making investments in O2O e-commerce. The model considers the manufacturing capacity of each facility as the power generation capacity, the distance between nodes as the length of the electric power transmission wires, the product quantity transferred from one node to another as the amount of power transmitted, and the retail store demand as the load of a consumer zone.

A numerical experiment for the mixed integer linear programming model was carried out using LINGO optimization software. Analysis of the results verified that the model successfully satisfied the retailer demand of each consumer zone while also minimizing the total cost of the supply chain. The model can be extended to several different scenarios, including the consideration of shortages that are backordered [

37,

38,

39,

40], controllable production rate [

41,

42,

43,

44,

45], optimal trade credit policies [

46,

47,

48,

49], quantity allocation problems [

50,

51], different defective rework options [

46], and variable deterioration [

47]. An immediate possible extension to this paper could be the incorporation of an uncertain defective rate [

52,

53] in the supply chain.