Mesh Free Radial Point Interpolation Based Displacement Recovery Techniques for Elastic Finite Element Analysis

Abstract

:1. Introduction

2. Elastic Problem Statement

3. Least Square Interpolation Technique for Displacement Recovery

4. Radial Point Interpolation Method (RPIM) for Displacement Recovery

4.1. Multi-Quadrics Radial Function (MQ)

4.2. Gaussian (Exponential) Radial Basis Function (Exp)

4.3. Thin Plate Splint (TPS) Radial Basis Function (Exp)

5. Measurement of Errors

6. Elastic Plate Problems

6.1. Square Plate Problem

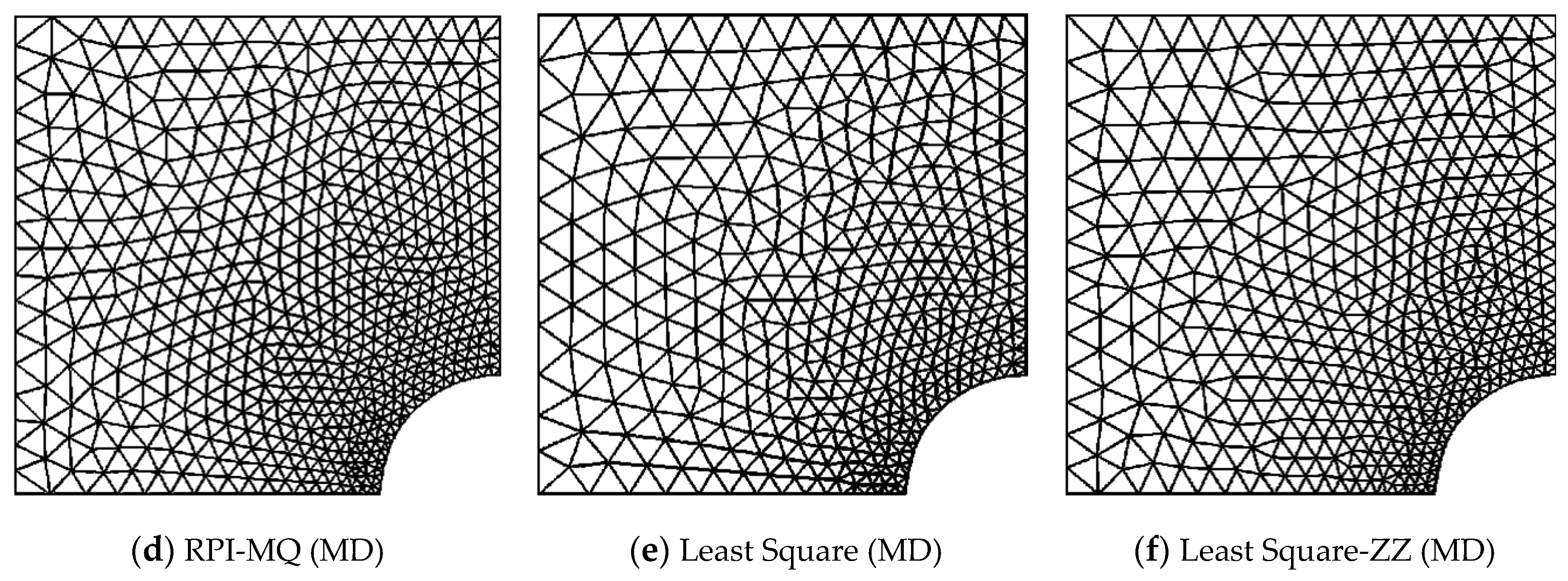

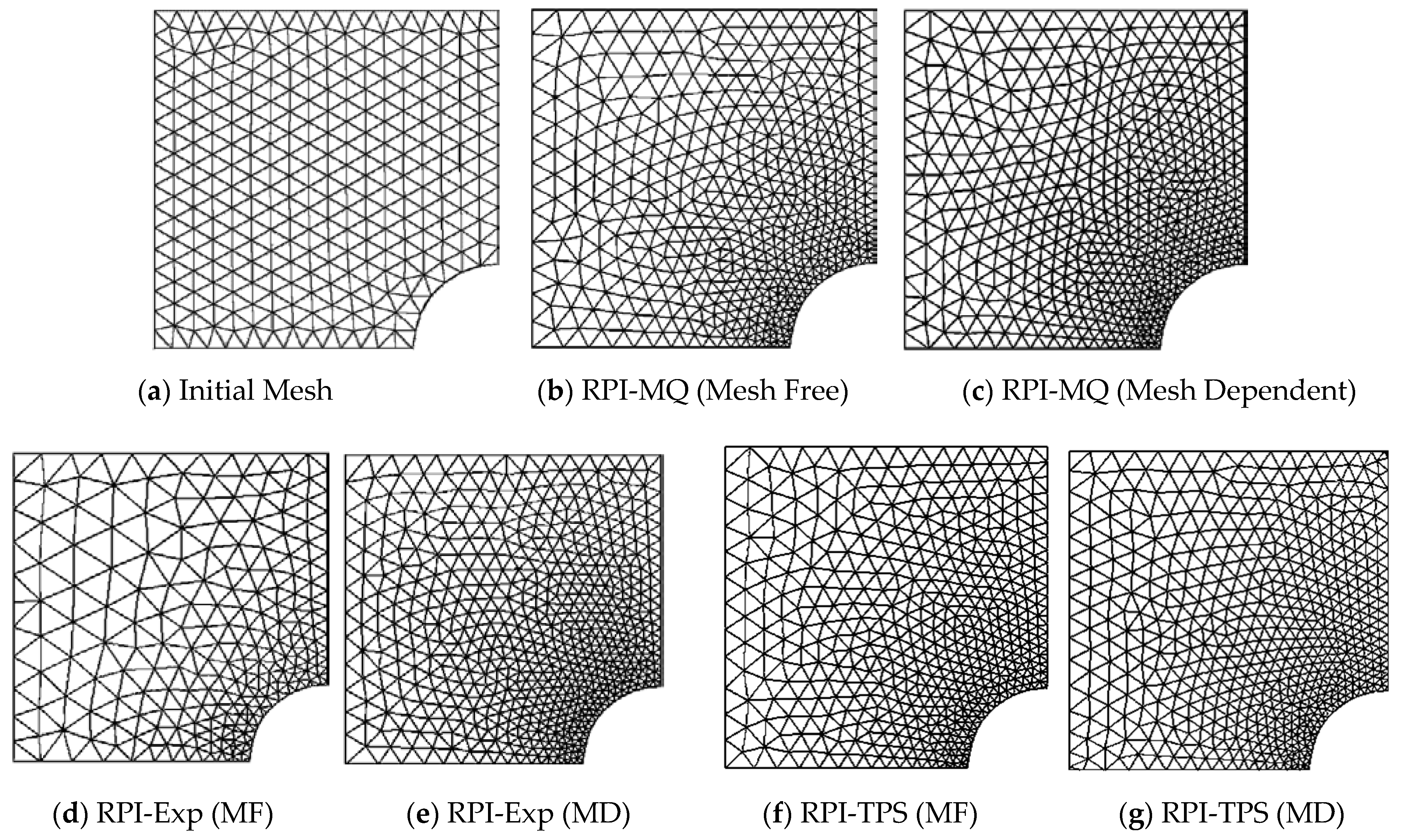

6.1.1. Mesh Free and Mesh Dependent Displacement Recovery Techniques

6.1.2. RPI Recovery Technique and Radial Basis Function Type

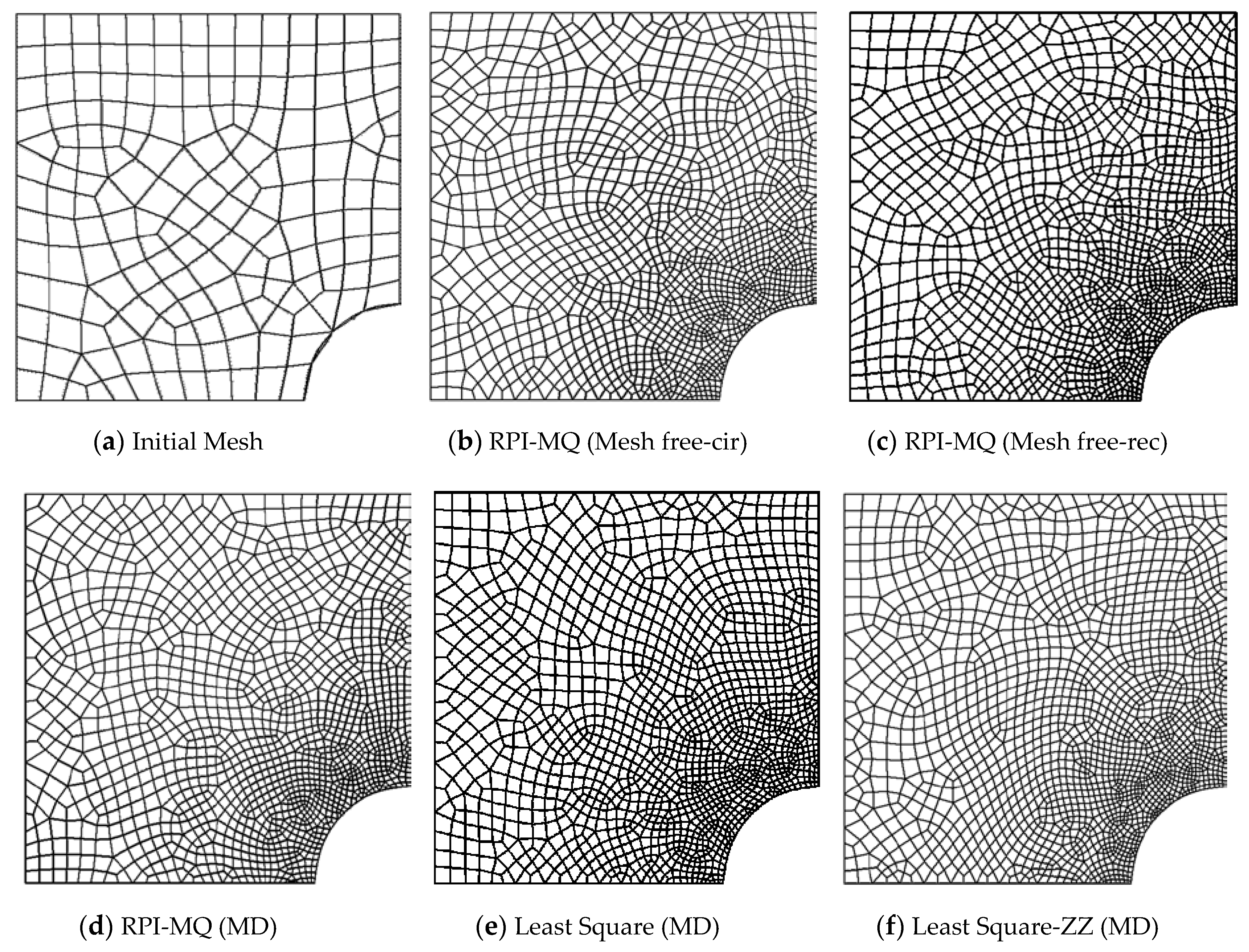

6.1.3. RPI Recovery Technique and Patch Configuration

6.2. Square Plate with Opening Problem

7. Discussion

8. Present Study Limitations and Future Research Work

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taus, M.; Rodin, G.J.; Hughes, T.J.R.; Scott, M.A. Isogeometric boundary element methods and patch tests for linear elastic problems: Formulation, numerical integration, and applications. Comput. Methods Appl. Mech. Eng. 2019, 357, 112591. [Google Scholar] [CrossRef]

- Cen, S.; Wu, C.J.; Li, Z.; Shang, Y.; Li, C. Some advances in high-performance finite element methods. Eng. Comput. 2019, 36, 2811–2834. [Google Scholar] [CrossRef]

- Grosse, I.; Katragadda, P.; Benoit, J. An adaptive accuracy-based a posteriori error estimator. Finite Elem. Anal. Des. 1992, 12, 75–90. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Zhu, J.Z. The superconvergent patch recovery anda posteriori error estimates. Part 1: The recovery technique. Int. J. Numer. Methods Eng. 1992, 33, 1331–1364. [Google Scholar] [CrossRef]

- Niu, Q.; Shephard, M.S. Super-convergent Extraction Techniques for Finite Element Analysis. Int. J. Num. Meth. Eng. 1993, 36, 811–836. [Google Scholar] [CrossRef]

- Li, X.; Wiberg, N.-E. A posteriori error estimate by element patch post-processing, adaptive analysis in energy and L2 norms. Comput. Struct. 1994, 53, 907–919. [Google Scholar] [CrossRef]

- Ubertini, F. Patch recovery based on complementary energy. Int. J. Numer. Methods Eng. 2004, 59, 1501–1538. [Google Scholar] [CrossRef]

- Ullah, Z.; Coombs, W.; Augarde, C. An adaptive finite element/meshless coupled method based on local maximum entropy shape functions for linear and nonlinear problems. Comput. Methods Appl. Mech. Eng. 2013, 267, 111–132. [Google Scholar] [CrossRef] [Green Version]

- Chung, H.-J.; Belytschko, T. An error estimate in the EFG method. Comput. Mech. 1998, 21, 91–100. [Google Scholar] [CrossRef]

- Yang, C.S.; Lee, F.B.; Kao, S.-P.; Hung, P.-S. Twelve different interpolation methods: A case study of Surfer 8.0. In Proceedings of the XXth ISPRS Congress, Istanbul, Turkey, 12–23 July 2004; pp. 778–785. [Google Scholar]

- Chen, X.L.; Liu, G.R.; Lim, S.P. The effects of the enforcement of compatibility in the radial point interpolation method for analyzing mindlin plates. In Advances in Meshfree and X-FEM Methods; World Scientific: Singapore, 2002; pp. 84–89. [Google Scholar]

- Liu, G.R.; Zhang, G.Y.; Dai, K.Y.; Wang, Y.Y.; Zhong, Z.H.; Li, G.Y.; Han, X. A linearly conforming point interpolation method (lc-pim) for 2d solid mechanics problems. Int. J. Comput. Methods 2005, 2, 645–665. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.R.; Zhang, G.Y. A novel scheme of strain-constructed point interpolation method for static and dynamic mechanics problems. Int. J. Appl. Mech. 2009, 1, 233–258. [Google Scholar] [CrossRef] [Green Version]

- Mirzaei, D. Analysis of moving least squares approximation revisited. J. Comput. Appl. Math. 2015, 282, 237–250. [Google Scholar] [CrossRef]

- Hamrani, A.; Belaidi, I.; Monteiro, E.; Lorong, P. On the Factors Affecting the Accuracy and Robustness of Smoothed-Radial Point Interpolation Method. Adv. Appl. Math. Mech. 2016, 9, 43–72. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; Wang, Y.; Jiang, Y.; Jiang, Y.; Zong, Z. A combination of singular cell-based smoothed radial point inter-polation method and FEM in solving fracture problem. Int. J. Comput. Methods 2018, 15, 1850079. [Google Scholar] [CrossRef]

- Ahmed, M.; Singh, D.; Desmukh, M.N. Interpolation type stress recovery technique based error estimator for elasticity problems. Mechanika 2018, 24, 672–679. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, M.; El Ouni, M.H.; Singh, D.; Kahla, N.B. A parametric study of meshfree interpolation based recovery techniques in finite element elastic analysis. CMES Comput. Model. Engg. Sci. 2019, 121, 687–786. [Google Scholar]

- Ahmed, M. A Comparative study of mesh-free radial point interpolation method and moving least squares method-based error estimation in elastic finite element analysis. Arab. J. Sci. Eng. 2020, 45, 3541–3557. [Google Scholar] [CrossRef]

- Gong, J.; Zou, D.; Kong, X.; Qu, Y.; Zhou, Y. A Non-Matching Nodes Interface Model with Radial Interpolation Function for Simulating 2D Soil–Structure Interface Behaviors. Int. J. Comput. Methods 2020, 18, 2050023. [Google Scholar] [CrossRef]

- Liu, G.R.; Gu, Y.T. A local radial point interpolation method (LR-PIM) for free vibration analyses of 2-D solids. J. Sound Vib. 2001, 246, 29–46. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Liu, G. On the optimal shape parameters of radial basis functions used for 2-D meshless methods. Comput. Methods Appl. Mech. Eng. 2002, 191, 2611–2630. [Google Scholar] [CrossRef]

- Wang, J.; Liu, G.R. A point interpolation meshless method based on radial basis functions. Int. J. Numer. Methods Eng. 2002, 54, 1623–1648. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Zhu, J.Z. A simple error estimator and adaptive procedure for practical engineering analysis. Int. J. Numer. Methods Eng. 1987, 24, 337–357. [Google Scholar] [CrossRef]

| Mesh Size (1/h) | FEM Error (×10−3) | RPI (Mesh Free) | RPI (Mesh Dependent) | LS (Mesh Dependent) | |||

|---|---|---|---|---|---|---|---|

| Error (×10−3) | Effectivity | Error (×10−3) | Effectivity | Error (×10−3) | Effectivity | ||

| 1/4 | 5.365 | 3.084 | 0.63004 | 2.429 | 0.76209 | 3.791 | 0.70817 |

| 1/16 | 0.378 | 0.192 | 0.64754 | 0.140 | 0.83318 | 0.181 | 0.67755 |

| 1/32 | 0.0951 | 0.047 | 0.64615 | 0.034 | 0.84088 | 0.043 | 0.67375 |

| Rate of Conv. | 1.93939 | 2.01685 | 2.06494 | 2.15207 | |||

| Mesh Size (1/h) | FEM Error (×10−3) | RPI (Mesh Free) | RPI (Mesh Dependent) | LS (Mesh Dependent) | |||

|---|---|---|---|---|---|---|---|

| Error (×10−3) | Effectivity | Error (×10−3) | Effectivity | Error (×10−3) | Effectivity | ||

| 1/4 | 0.24501 | 0.24755 | 1.30050 | 0.14612 | 0.95302 | 1.03015 | 4.24214 |

| 1/12 | 0.00842 | 0.00224 | 1.02195 | 0.00202 | 1.00023 | 0.01930 | 2.44485 |

| 1/24 | 0.00104 | 0.00014 | 1.01017 | 0.00014 | 1.00494 | 0.00132 | 1.58496 |

| Rate of Conv. | 3.04733 | 4.16168 | 3.86833 | 3.721499 | |||

| Mesh Size (1/h) | FEM Error (×10−3) | RPI (Mesh Free) | RPI (Mesh Dependent) | LS (Mesh Dependent) | |||

|---|---|---|---|---|---|---|---|

| Error (×10−3) | Effectivity | Error (×10−3) | Effectivity | Error (×10−3) | Effectivity | ||

| 1/4 | 2.032 | 2.280 | 1.64355 | 2.839 | 2.02455 | 1.840 | 1.83209 |

| 1/16 | 0.124 | 0.097 | 1.55565 | 0.176 | 2.28836 | 0.111 | 1.82651 |

| 1/32 | 0.031 | 0.028 | 1.51151 | 0.044 | 2.31024 | 0.028 | 1.82654 |

| Rate of Conv. | 2.01223 | 2.26171 | 2.00883 | 2.01729 | |||

| Mesh Size (1/h) | FEM Error (×10−3) | RPI (Mesh Free) | RPI (Mesh Dependent) | LS (Mesh Dependent) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MQ | Exp | TSP | MQ | Exp | Error (×10−3) | θ | |||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | ||||

| 1/4 | 93.749 | 17.114 | 0.9469 | 58.476 | 0.8568 | 30.079 | 0.92276 | 26.233 | 0.8933 | 51.106 | 0.9096 | 58.478 | 0.9300 |

| 1/16 | 24.441 | 1.307 | 0.9931 | 7.385 | 0.9389 | 1.563 | 0.98496 | 1.586 | 1.0038 | 8.298 | 1.0860 | 4.462 | 0.9896 |

| 1/32 | 12.248 | 0.335 | 0.9975 | 2.684 | 0.9310 | 0.561 | 0.98924 | 0.425 | 1.0092 | 3.847 | 1.1195 | 1.158 | 0.9970 |

| Rate of Conv. | 0.97875 | 1.89163 | 1.48183 | 1.91524 | 1.98282 | 1.24389 | 1.89225 | ||||||

| Mesh Size (1/h) | FEM Error (×10−3) | RPI (Mesh Free) | RPI (Mesh Dependent) | LS (Mesh Dependent) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MQ | Exp | TSP | MQ | Exp | Error (×10−3) | θ | |||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | ||||

| 1/4 | 13.168 | 7.493 | 1.1596 | 35.032 | 2.8637 | 5.782 | 1.10655 | 3.941 | 1.0294 | 4.445 | 1.0548 | 12.258 | 1.2556 |

| 1/12 | 1.515 | 0.184 | 1.0135 | 0.560 | 1.0853 | 0.199 | 1.01836 | 0.174 | 1.0093 | 0.257 | 1.0162 | 0.529 | 1.0405 |

| 1/24 | 0.380 | 0.025 | 1.0057 | 0.0678 | 1.0275 | 0.023 | 1.00292 | 0.026 | 1.0053 | 0.0613 | 1.0116 | 0.070 | 1.0127 |

| Rate of Conv. | 1.97848 | 3.1910 | 3.48633 | 3.09017 | 2.76963 | 2.39122 | 2.88449 | ||||||

| Mesh Size (1/h) | FEM Error (×10−3) | RPI (Mesh Free) | RPI (Mesh Dependent) | LS (Mesh Dependent) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MQ | Exp | TSP | MQ | Exp | Error (×10−3) | θ | |||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | ||||

| 1/4 | 60.262 | 13.249 | 1.0541 | 52.222 | 0.8173 | 27.595 | 1.0121 | 23.053 | 1.0263 | 46.792 | 0.8560 | 13.667 | 1.0810 |

| 1/16 | 15.015 | 0.797 | 0.9967 | 7.272 | 1.0063 | 1.272 | 0.9805 | 1.294 | 1.0130 | 6.593 | 0.9669 | 0.813 | 1.0051 |

| 1/32 | 7.506 | 0.201 | 0.9967 | 2.536 | 1.0191 | 0.622 | 0.9615 | 0.323 | 1.0164 | 2.303 | 0.9782 | 0.201 | 1.0013 |

| Rate of Conv. | 1.00169 | 2.01497 | 1.45472 | 1.82359 | 2.05275 | 1.44822 | 2.02723 | ||||||

| Mesh Size | FEM (Exact Error) (×10−3) | RPI (MQ) Recovery | LS Recovery | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Circular Mesh Free Patch | Rectangular Mesh Free Patch | Mesh Dependent Patch | Mesh Dependent Patch | |||||||

| Elem. | DOF | |||||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | |||

| 103 | 136 | 1.534 | 0.630 | 0.83865 | 0.635 | 0.82329 | 0.603 | 0.83264 | 0.915 | 0.88585 |

| 470 | 530 | 0.282 | 0.117 | 0.93473 | 0.116 | 0.91067 | 0.115 | 0.97121 | 0.141 | 0.93646 |

| 1887 | 2004 | 0.070 | 0.029 | 0.94503 | 0.029 | 0.91226 | 0.028 | 0.99068 | 0.029 | 0.91340 |

| Mesh Size | FEM (Exact Error) (×10−3) | RPI (MQ) Recovery | LS Recovery | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Circular Mesh Free Patch | Rectangular Mesh Free Patch | Mesh Dependent Patch | Mesh Dependent Patch | |||||||

| Elem. | DOF | |||||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | |||

| 103 | 476 | 0.056 | 0.039 | 0.95236 | 0.034 | 0.94796 | 0.032 | 0.87951 | 0.121 | 2.38461 |

| 470 | 1998 | 0.247 | 0.0028 | 0.96288 | 0.0025 | 0.96605 | 0.0025 | 0.90108 | 0.0073 | 1.66566 |

| 1887 | 7780 | 0.059 | 0.00033 | 0.98617 | 0.00030 | 0.98079 | 0.00031 | 0.93046 | 0.00054 | 1.27775 |

| Mesh Size | FEM (Exact Error) (×10−3) | RPI (MQ) Recovery | LS Recovery | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Circular Mesh Free Patch | Rectangular Mesh Free Patch | Mesh Dependent Patch | Mesh Dependent Patch | |||||||

| Elem. | DOF | |||||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | |||

| 186 | 432 | 0.356 | 0.303 | 1.43564 | 0.298 | 1.43444 | 0.299 | 1.48273 | 0.249 | 1.40829 |

| 593 | 1282 | 0.133 | 0.094 | 1.38343 | 0.092 | 1.36857 | 0.093 | 1.38133 | 0.075 | 1.28740 |

| 1333 | 2806 | 0.054 | 0.040 | 1.37238 | 0.040 | 1.36711 | 0.041 | 1.38847 | 0.034 | 1.30001 |

| Mesh Size | FEM (Exact Error) (×10−3) | RPI (MQ) Recovery | LS Recovery | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Circular Mesh Free Patch | Rectangular Mesh Free Patch | Mesh Dependent Patch | Mesh Dependent Patch | |||||||

| Elem. | DOF | |||||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | |||

| 186 | 432 | 22.764 | 8.269 | 1.04925 | 8.349 | 1.04267 | 8.579 | 1.08869 | 6.305 | 1.06260 |

| 593 | 1282 | 13.917 | 3.859 | 1.07186 | 4.348 | 1.05353 | 4.089 | 1.08202 | 1.821 | 1.01123 |

| 1813 | 3790 | 7.994 | 2.410 | 1.05454 | 2.452 | 1.03180 | 2.635 | 1.08825 | 1.011 | 1.00801 |

| Mesh Size | FEM (Exact Error) (×10−3) | RPI (MQ) Recovery | LS Recovery (Mesh Dependent) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Circular Zone | Rectangular Zone | Mesh Dependent Patch | Element Patch | Node Patch (ZZ) [18] | ||||||||

| Elem. | DOF | |||||||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | |||

| 155 | 194 | 12.905 | 7.636 | 0.78552 | 7.768 | 0.78485 | 8.253 | 0.73122 | 11.206 | 0.80541 | 13.231 | 1.01807 |

| 548 | 618 | 8.504 | 4.442 | 0.91893 | 4.402 | 0.94074 | 4. 814 | 0.89851 | 5.495 | 0.90648 | 7.913 | 1.12593 |

| 1585 | 1700 | 5.171 | 2.251 | 0.93567 | 2.450 | 0.96781 | 2.244 | 0.93447 | 2.572 | 0.90042 | 4.672 | 1.14923 |

| Mesh Size | FEM Error (×10−3) | RPI (Exp) | RPI (TPS) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mesh Free | Mesh Dependent | Mesh Free | Mesh Dependent | |||||||

| Elem. | DOF | |||||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | |||

| 155 | 194 | 12.905 | 11.739 | 1.06061 | 10.845 | 1.20390 | 8.256 | 0.79118 | 13.611 | 0.92793 |

| 548 | 618 | 8.504 | 7.297 | 0.89907 | 6.587 | 1.29955 | 4.653 | 0.91835 | 5.926 | 0.88131 |

| 1585 | 1700 | 5.171 | 8.108 | 1.55389 | 4.783 | 0.95750 | 2.157 | 0.92439 | 4.095 | 0.95173 |

| Mesh Size | FEM (Exact Error) (×10−3) | RPI (MQ) Recovery | LS Recovery (Mesh Dependent) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Circular Mesh free | Mesh Dependent Patch | Element Patch | Node Patch (ZZ) [18] | |||||||

| Elem. | DOF | |||||||||

| Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | Error (×10−3) | θ | |||

| 179 | 414 | 8.085 | 5.377 | 1.01183 | 5.377 | 0.92632 | 7.286 | 0.94018 | 9.262 | 1.40135 |

| 578 | 1254 | 4.291 | 2.196 | 0.94201 | 2.420 | 0.94167 | 2.949 | 0.99933 | 2.404 | 0.89920 |

| 1842 | 3854 | 2.882 | 1.604 | 0.94551 | 1.696 | 0.89699 | 1.703 | 0.94552 | 1646 | 0.91160 |

| Recovery Type | Linear Triangle (Uniform Mesh Having 548 Elements and 618 DOF) | Linear Quadrilateral (Uniform Mesh Having 179 Elements and 414 DOF) | ||||||

|---|---|---|---|---|---|---|---|---|

| FEM Error | Proj. Error | Adaptive Mesh (2%) | FEM Error | Proj. Error | Adaptive Mesh (2%) | |||

| N | DOF | N | DOF | |||||

| LS (Mesh Dependent) | 6.84 | 6.22 | 781 | 866 | 6.50 | 6.14 | 1444 | 3032 |

| LS (Mesh Dependent-ZZ) | 6.84 | 7.66 | 922 | 1012 | 6.50 | 9.25 | 1816 | 3784 |

| RPI (Mesh Free-MQ-Cir.) | 6.84 | 6.32 | 1004 | 1098 | 6.50 | 6.42 | 1468 | 3082 |

| RPI (Mesh Free-MQ-Rec.) | 6.84 | 6.47 | 1050 | 1140 | 6.50 | 5.96 | 1422 | 2990 |

| RPI (Mesh Dependent-MQ) | 6.84 | 6.18 | 1175 | 1274 | 6.50 | 6.39 | 1452 | 3028 |

| RPI (Mesh Free-Exp.-Cir.) | 6.84 | 6.14 | 417 | 486 | ||||

| RPI (Mesh Dependent-Exp.) | 6.84 | 8.90 | 1155 | 1242 | ||||

| RPI (Mesh Free-TSP-Cir.) | 6.84 | 6.31 | 945 | 1038 | ||||

| RPI (Mesh Dependent-TSP) | 6.84 | 6.06 | 1100 | 1200 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.; Singh, D.; AlQadhi, S.; Alrefae, M.A. Mesh Free Radial Point Interpolation Based Displacement Recovery Techniques for Elastic Finite Element Analysis. Mathematics 2021, 9, 1900. https://doi.org/10.3390/math9161900

Ahmed M, Singh D, AlQadhi S, Alrefae MA. Mesh Free Radial Point Interpolation Based Displacement Recovery Techniques for Elastic Finite Element Analysis. Mathematics. 2021; 9(16):1900. https://doi.org/10.3390/math9161900

Chicago/Turabian StyleAhmed, Mohd., Devinder Singh, Saeed AlQadhi, and Majed A. Alrefae. 2021. "Mesh Free Radial Point Interpolation Based Displacement Recovery Techniques for Elastic Finite Element Analysis" Mathematics 9, no. 16: 1900. https://doi.org/10.3390/math9161900