Dynamic Green Growth Assessment of China’s Industrial System with an Improved SBM Model and Global Malmquist Index

Abstract

:1. Introduction

2. Literature Review

3. Modelling

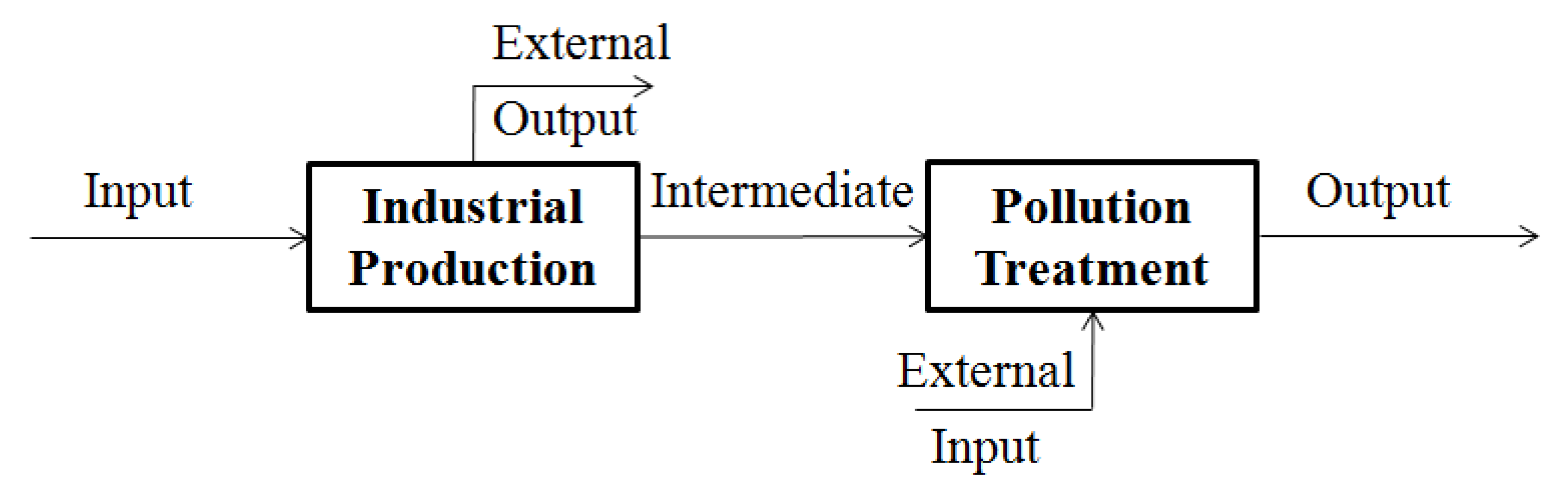

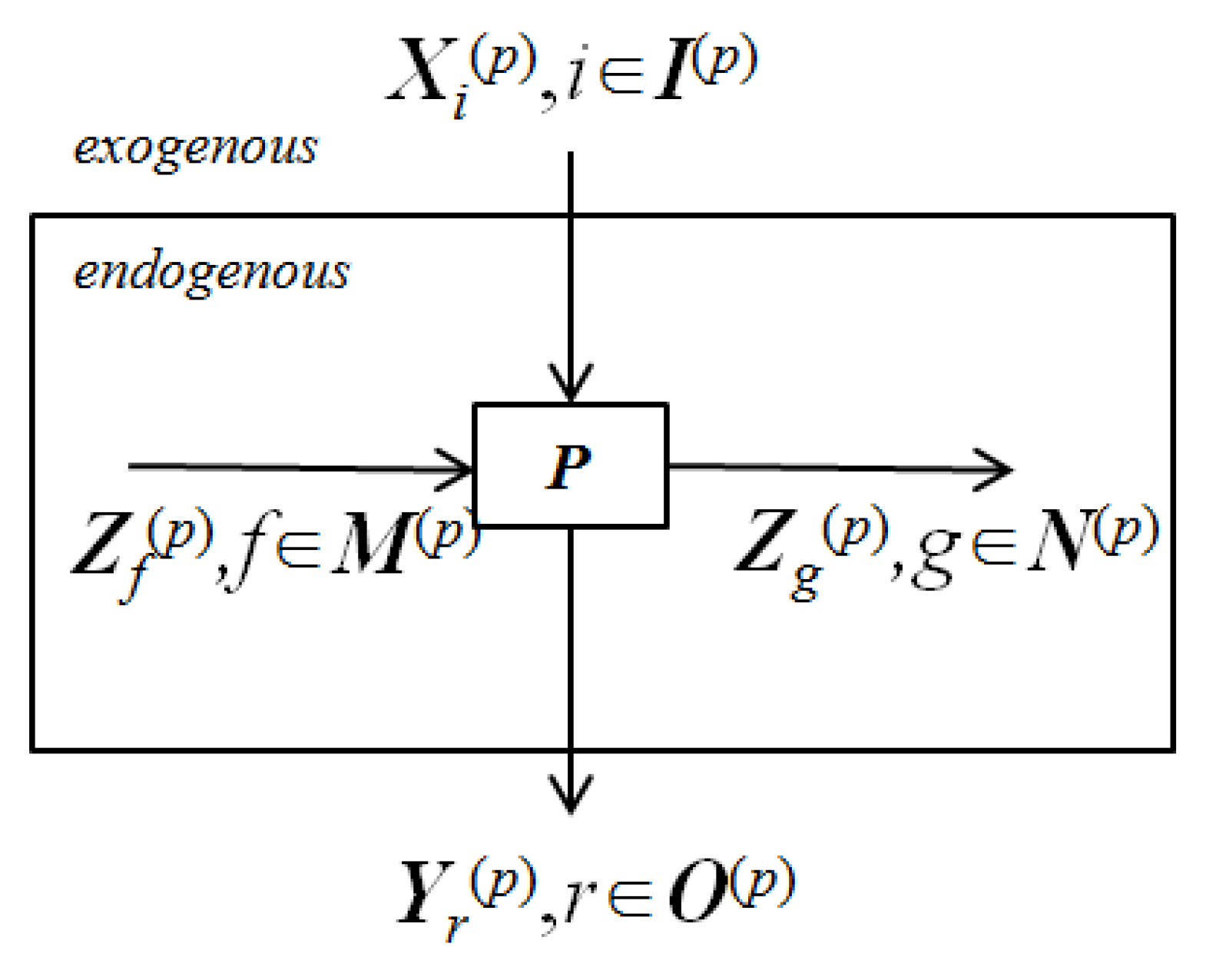

3.1. Basic Network SBM

3.2. Improved Network SBM

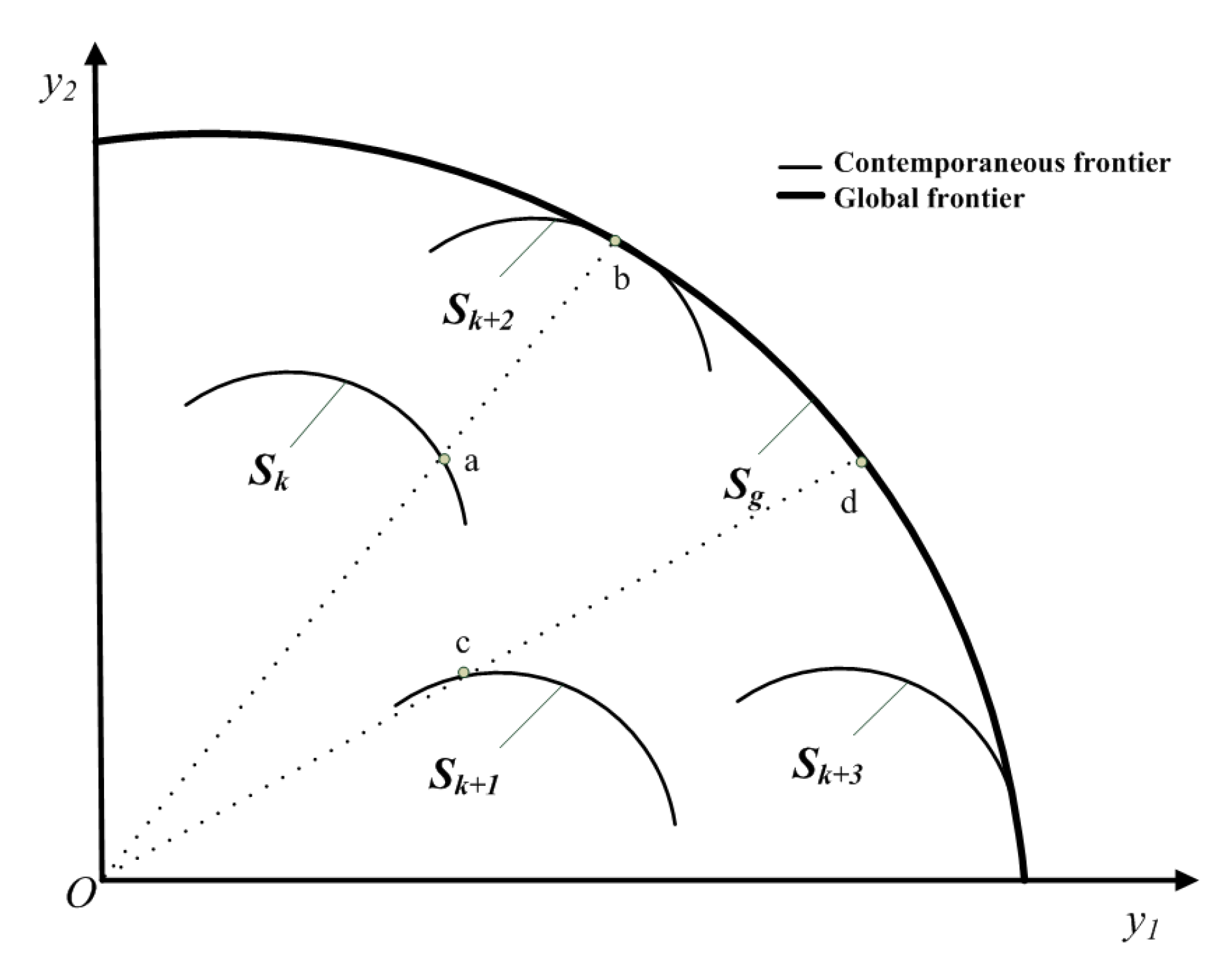

3.3. Global MI

4. Application

4.1. Data and Variables

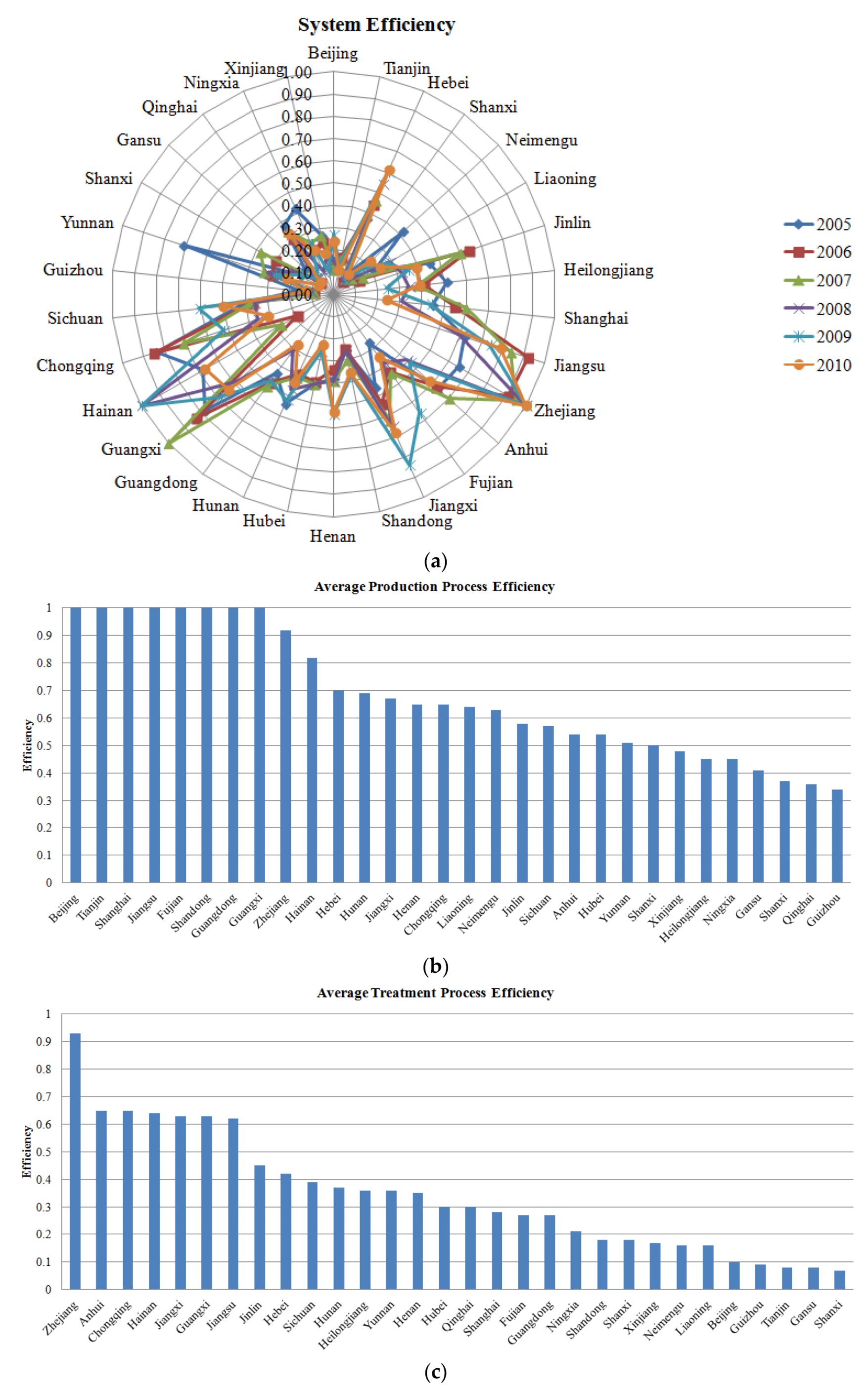

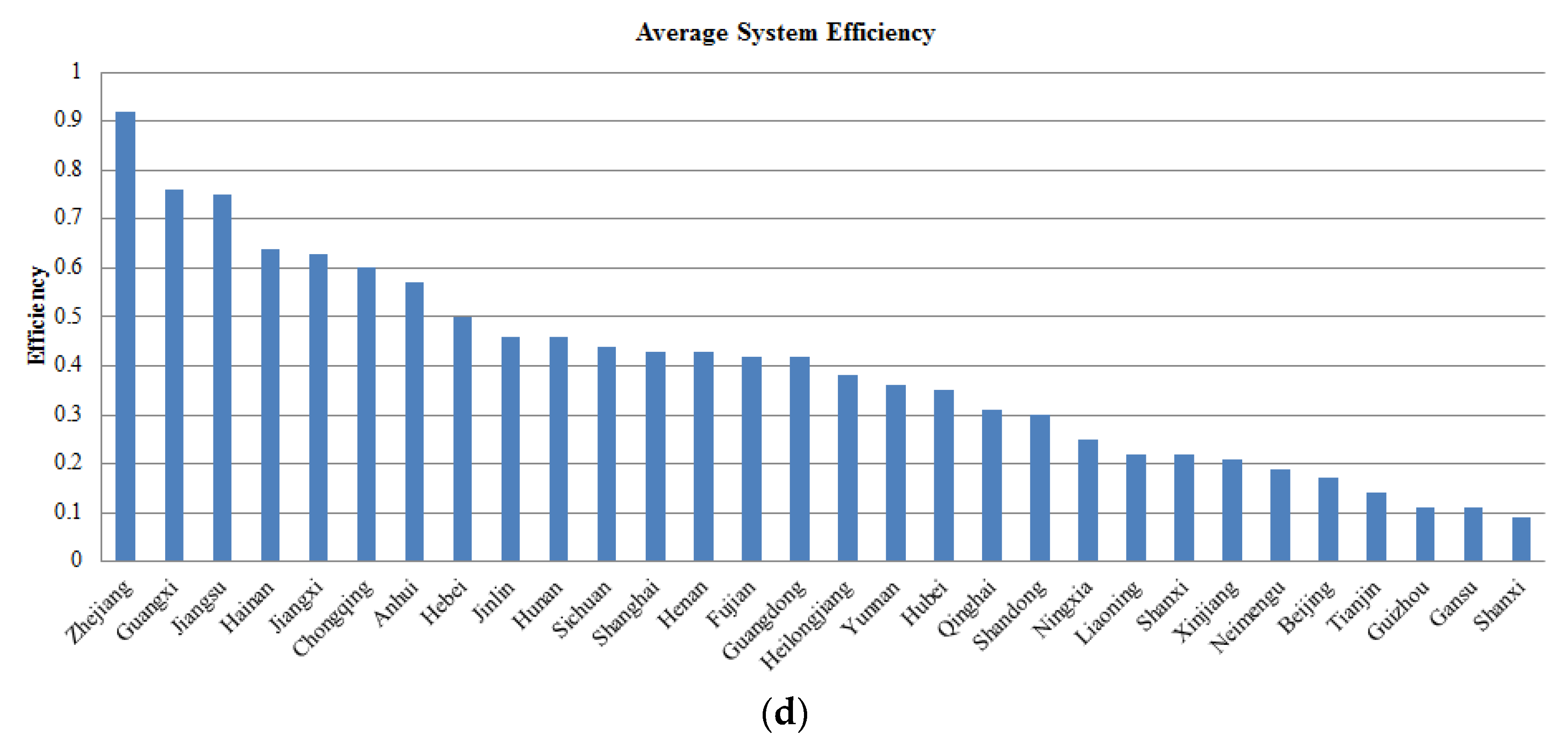

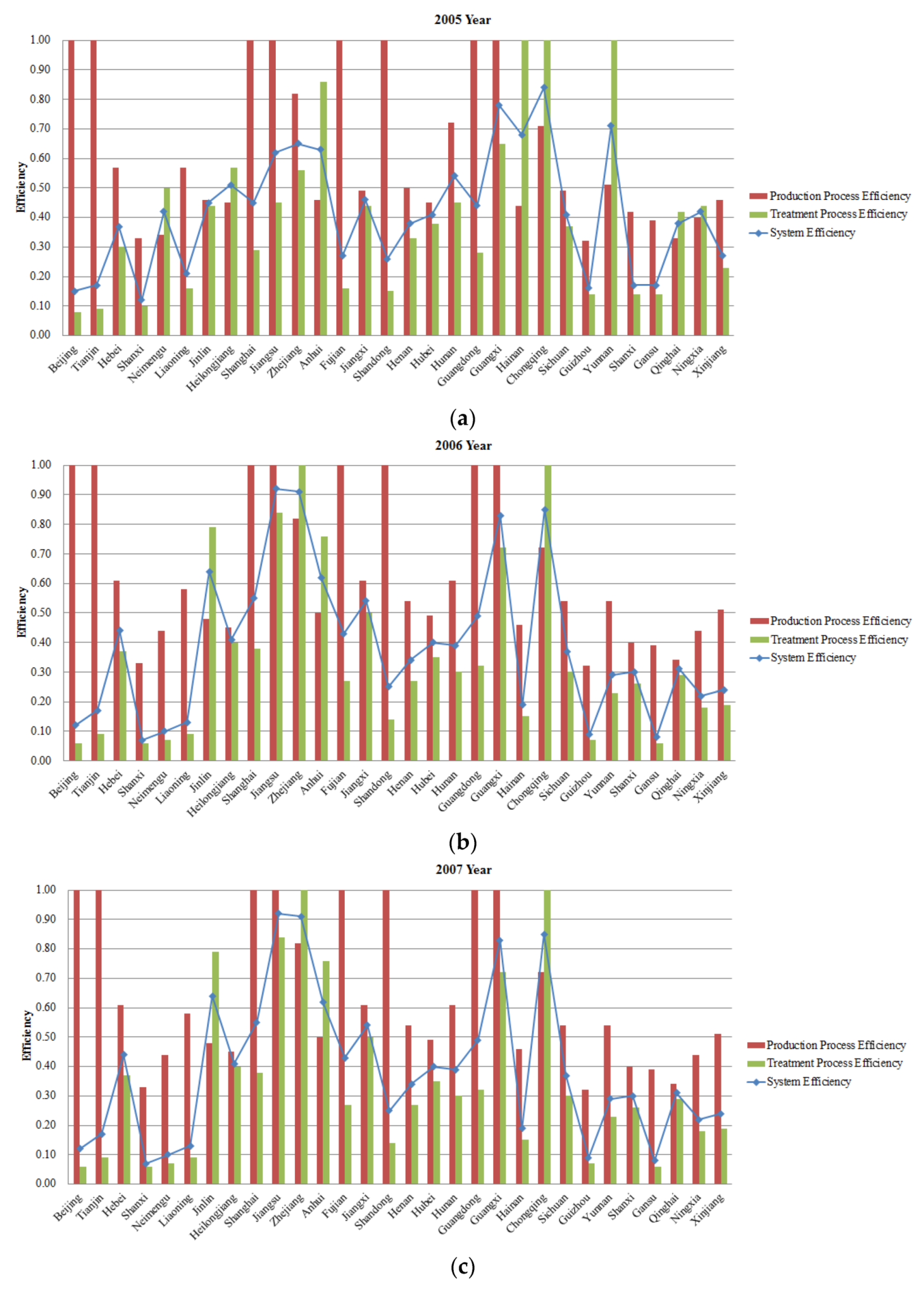

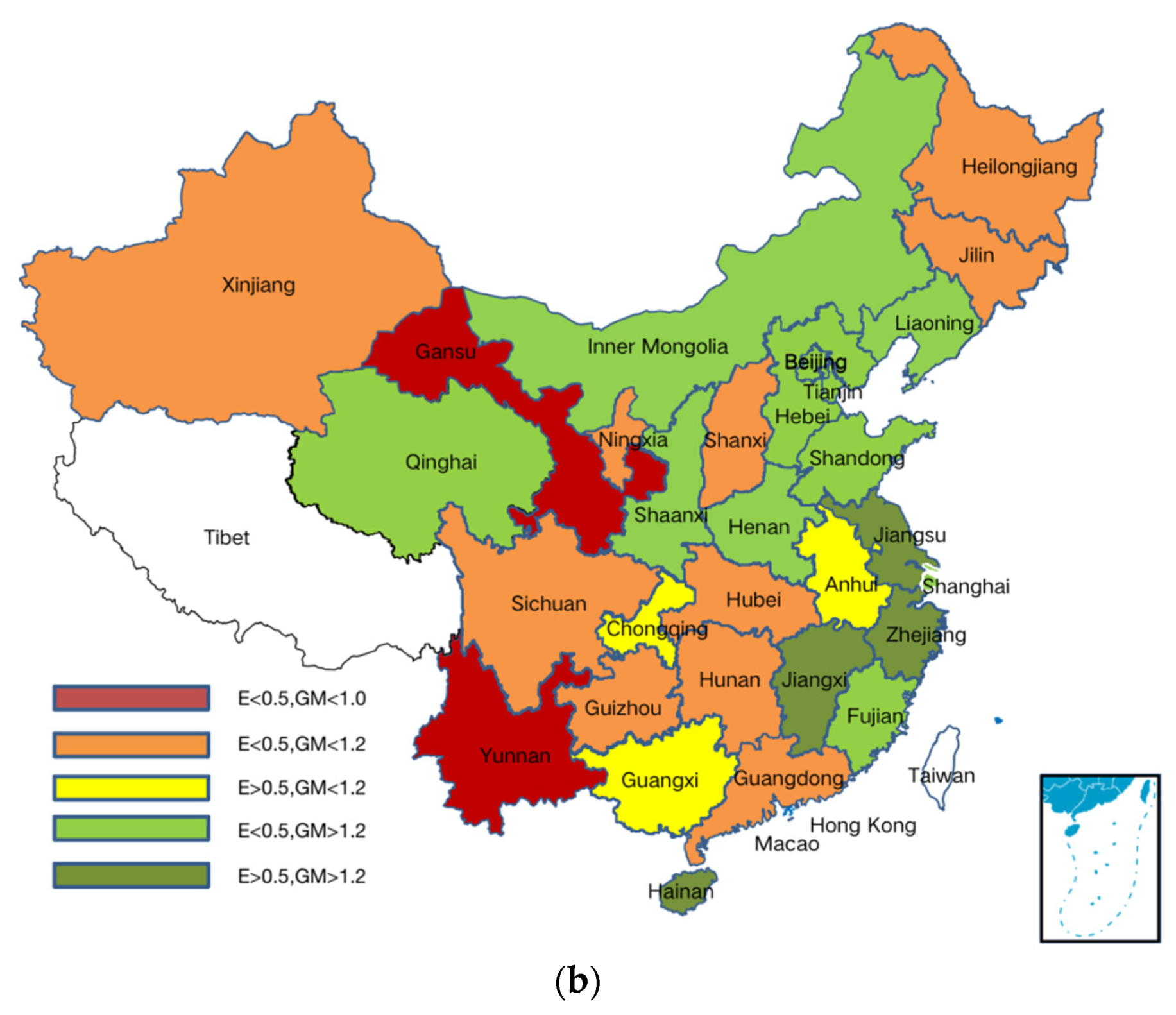

4.2. Analytical Results of Efficiency

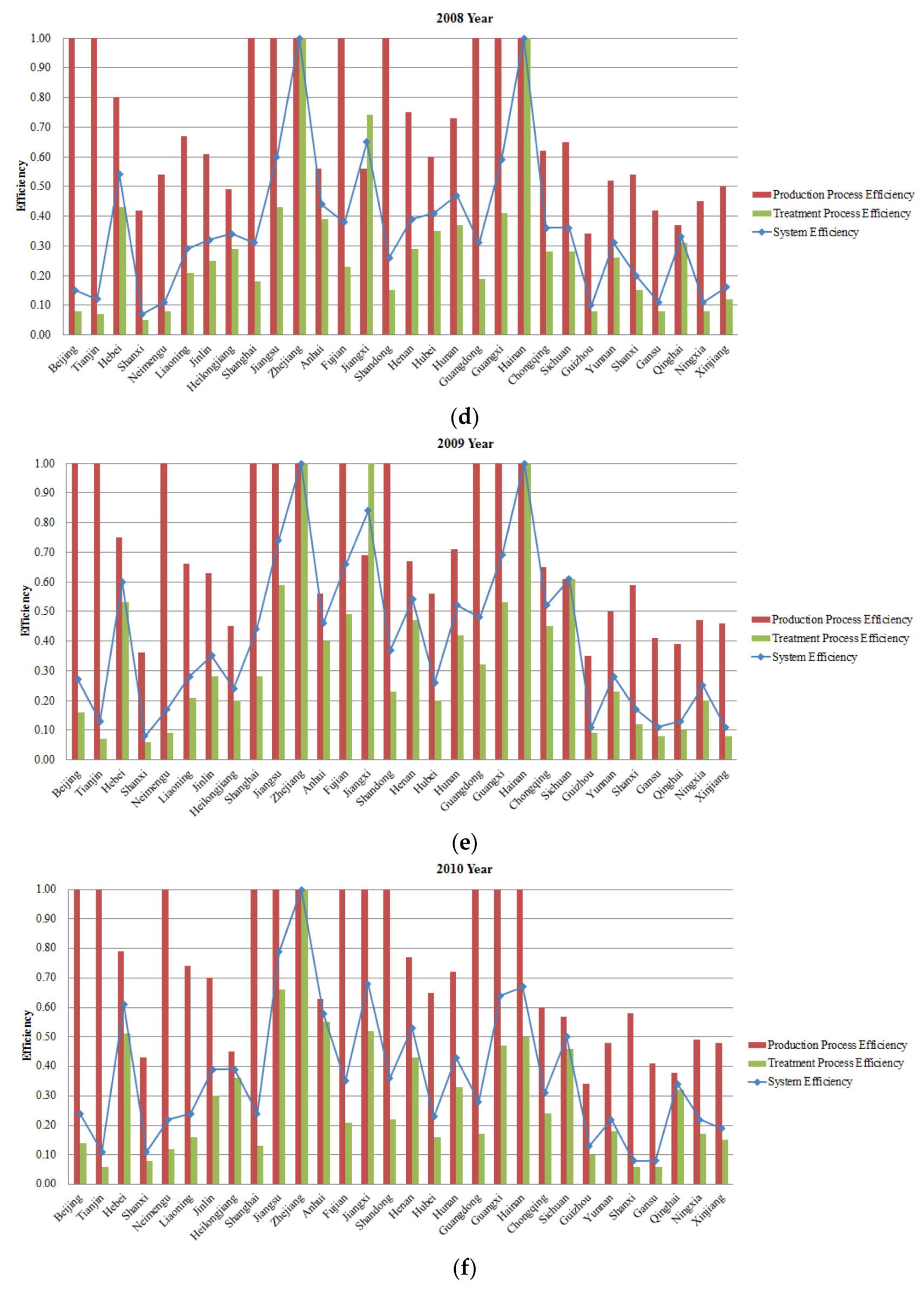

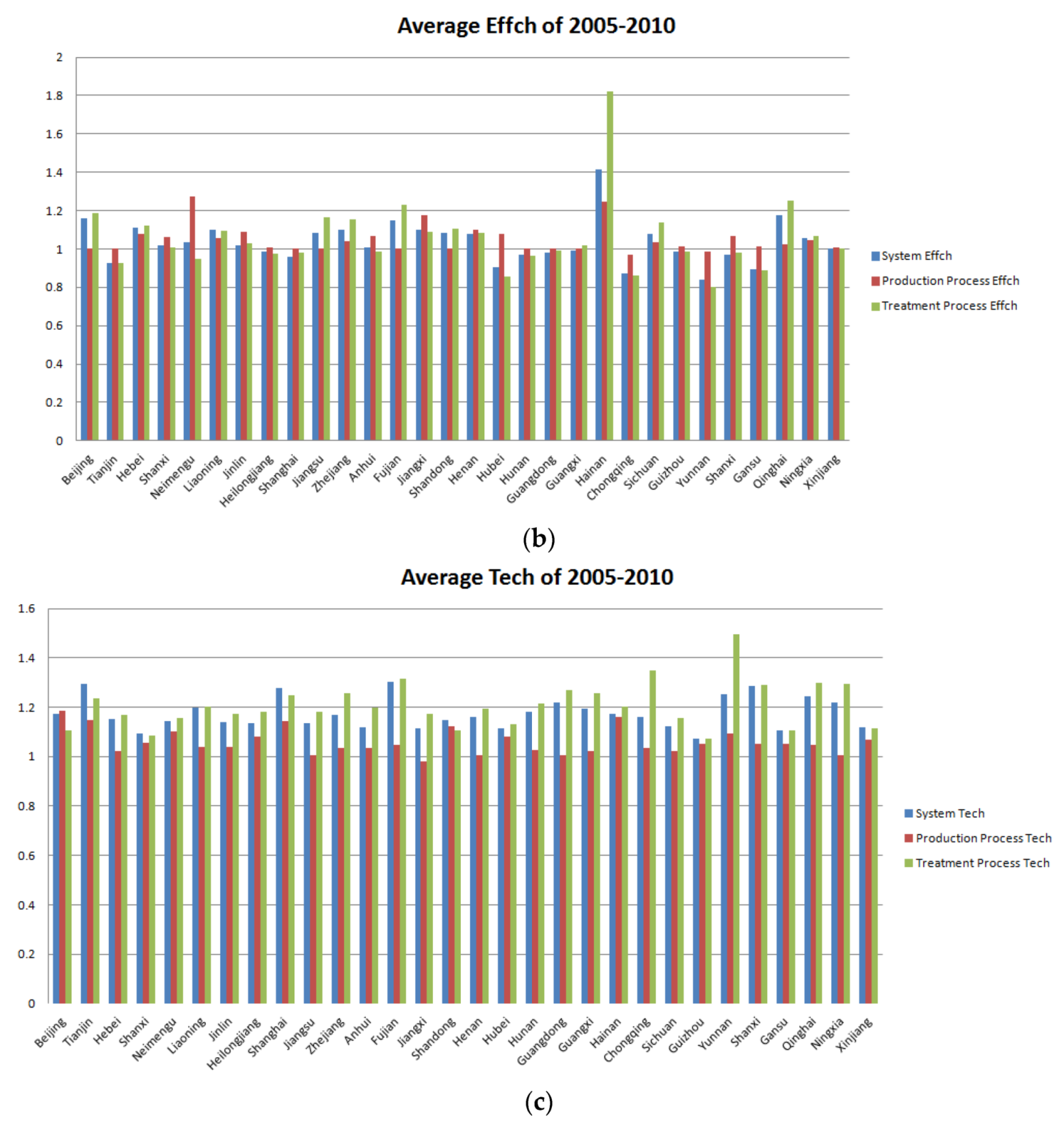

4.3. Analytical Results of MI

5. Conclusions and Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Variables | Units | Mean | Variance | Max | Min | Source | |

|---|---|---|---|---|---|---|---|

| Industrial Production Process | |||||||

| Input(X1) | Labour | 10,000 persons | 274.06 | 96,310.70 | 1568.00 | 12.00 | China Statistical Yearbook |

| Capital | CNY 100,000,000 | 4896.31 | 17,727,655.33 | 21,781.92 | 348.53 | China Statistical Yearbook | |

| Energy consumption per industrial added value | Ton/CNY 10,000 | 2.57 | 2.37 | 9.03 | 0.58 | China Industrial Economic Statistical Yearbook | |

| Output(Y1) | Industrial GDP | CNY 100,000,000 | 15,151.71 | 321,448,650.85 | 92,056.48 | 473.06 | China Statistical Yearbook |

| Intermediate product(Z) | Industrial wastewater emission | 10,000 tons | 80,163.44 | 4,842,511,262.48 | 29,6318.00 | 5782.00 | China Industrial Economic Statistical Yearbook |

| Pollution Treatment Process | |||||||

| Input(X2) | Pollution treatment investment | CNY 10,000 | 156,016.66 | 18,391,993,784.43 | 844,159.00 | 3563.00 | China Environmental Statistical Yearbook |

| Output(Y2) | Industrial wastewater emission on standard | 10,000 tons | 74,230.08 | 4,410,758,276.27 | 288,936.00 | 3396.00 | China Environmental Statistical Yearbook |

| Comprehensive value from three-waste reutilisation | CNY 10,000 | 452,306.61 | 271,598,713,023.71 | 2,863,867.20 | 5289.70 | China Environmental Statistical Yearbook | |

| Item | 2005 | 2006 | 2007 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| System | Stage 1 | Stage 2 | System | Stage 1 | Stage 2 | System | Stage 1 | Stage 2 | |

| Beijing | 0.15 | 1.00 | 0.08 | 0.12 | 1.00 | 0.06 | 0.11 | 1.00 | 0.06 |

| Tianjin | 0.17 | 1.00 | 0.09 | 0.17 | 1.00 | 0.09 | 0.16 | 1.00 | 0.09 |

| Hebei | 0.37 | 0.57 | 0.30 | 0.44 | 0.61 | 0.37 | 0.46 | 0.65 | 0.39 |

| Shanxi | 0.12 | 0.33 | 0.10 | 0.07 | 0.33 | 0.06 | 0.09 | 0.35 | 0.07 |

| Neimenggu | 0.42 | 0.34 | 0.50 | 0.10 | 0.44 | 0.07 | 0.11 | 0.48 | 0.08 |

| Liaoning | 0.21 | 0.57 | 0.16 | 0.13 | 0.58 | 0.09 | 0.15 | 0.60 | 0.11 |

| Jilin | 0.45 | 0.46 | 0.44 | 0.64 | 0.48 | 0.79 | 0.60 | 0.57 | 0.61 |

| Heilongjiang | 0.51 | 0.45 | 0.57 | 0.41 | 0.45 | 0.40 | 0.38 | 0.42 | 0.36 |

| Shanghai | 0.45 | 1.00 | 0.29 | 0.55 | 1.00 | 0.38 | 0.60 | 1.00 | 0.43 |

| Jiangsu | 0.62 | 1.00 | 0.45 | 0.92 | 1.00 | 0.84 | 0.84 | 1.00 | 0.72 |

| Zhejiang | 0.65 | 0.82 | 0.56 | 0.91 | 0.82 | 1.00 | 0.95 | 0.90 | 1.00 |

| Anhui | 0.63 | 0.46 | 0.86 | 0.62 | 0.50 | 0.76 | 0.70 | 0.51 | 0.92 |

| Fujian | 0.27 | 1.00 | 0.16 | 0.43 | 1.00 | 0.27 | 0.44 | 1.00 | 0.28 |

| Jiangxi | 0.46 | 0.49 | 0.44 | 0.54 | 0.61 | 0.50 | 0.62 | 0.68 | 0.59 |

| Shandong | 0.26 | 1.00 | 0.15 | 0.25 | 1.00 | 0.14 | 0.30 | 1.00 | 0.18 |

| Henan | 0.38 | 0.50 | 0.33 | 0.34 | 0.54 | 0.27 | 0.39 | 0.69 | 0.30 |

| Hubei | 0.41 | 0.45 | 0.38 | 0.40 | 0.49 | 0.35 | 0.41 | 0.50 | 0.37 |

| Hunan | 0.54 | 0.72 | 0.45 | 0.39 | 0.61 | 0.30 | 0.41 | 0.63 | 0.33 |

| Guangdong | 0.44 | 1.00 | 0.28 | 0.49 | 1.00 | 0.32 | 0.51 | 1.00 | 0.35 |

| Guangxi | 0.78 | 1.00 | 0.65 | 0.83 | 1.00 | 0.72 | 1.00 | 1.00 | 1.00 |

| Hainan | 0.68 | 0.44 | 1.00 | 0.19 | 0.46 | 0.15 | 0.27 | 1.00 | 0.16 |

| Chongqing | 0.84 | 0.71 | 1.00 | 0.85 | 0.72 | 1.00 | 0.71 | 0.57 | 0.90 |

| Sichuan | 0.41 | 0.49 | 0.37 | 0.37 | 0.54 | 0.30 | 0.38 | 0.54 | 0.31 |

| Guizhou | 0.16 | 0.32 | 0.14 | 0.09 | 0.32 | 0.07 | 0.09 | 0.34 | 0.07 |

| Yunnan | 0.71 | 0.51 | 1.00 | 0.29 | 0.54 | 0.23 | 0.33 | 0.51 | 0.28 |

| Shanxi | 0.17 | 0.42 | 0.14 | 0.30 | 0.40 | 0.26 | 0.38 | 0.44 | 0.35 |

| Gansu | 0.17 | 0.39 | 0.14 | 0.08 | 0.39 | 0.06 | 0.09 | 0.44 | 0.07 |

| Qinghai | 0.38 | 0.33 | 0.42 | 0.31 | 0.34 | 0.29 | 0.35 | 0.34 | 0.36 |

| Ningxia | 0.42 | 0.40 | 0.44 | 0.22 | 0.44 | 0.18 | 0.25 | 0.43 | 0.21 |

| Xinjiang | 0.27 | 0.46 | 0.23 | 0.24 | 0.51 | 0.19 | 0.27 | 0.48 | 0.22 |

| Beijing | 0.15 | 1.00 | 0.08 | 0.27 | 1.00 | 0.16 | 0.24 | 1.00 | 0.14 |

| Tianjin | 0.12 | 1.00 | 0.07 | 0.13 | 1.00 | 0.07 | 0.11 | 1.00 | 0.06 |

| Hebei | 0.54 | 0.80 | 0.43 | 0.60 | 0.75 | 0.53 | 0.61 | 0.79 | 0.51 |

| Shanxi | 0.07 | 0.42 | 0.05 | 0.08 | 0.36 | 0.06 | 0.11 | 0.43 | 0.08 |

| Neimenggu | 0.11 | 0.54 | 0.08 | 0.17 | 1.00 | 0.09 | 0.22 | 1.00 | 0.12 |

| Liaoning | 0.29 | 0.67 | 0.21 | 0.28 | 0.66 | 0.21 | 0.24 | 0.74 | 0.16 |

| Jilin | 0.32 | 0.61 | 0.25 | 0.35 | 0.63 | 0.28 | 0.39 | 0.70 | 0.30 |

| Heilongjiang | 0.34 | 0.49 | 0.29 | 0.24 | 0.45 | 0.20 | 0.39 | 0.45 | 0.36 |

| Shanghai | 0.31 | 1.00 | 0.18 | 0.44 | 1.00 | 0.28 | 0.24 | 1.00 | 0.13 |

| Jiangsu | 0.60 | 1.00 | 0.43 | 0.74 | 1.00 | 0.59 | 0.79 | 1.00 | 0.66 |

| Zhejiang | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Anhui | 0.44 | 0.56 | 0.39 | 0.46 | 0.56 | 0.40 | 0.58 | 0.63 | 0.55 |

| Fujian | 0.38 | 1.00 | 0.23 | 0.66 | 1.00 | 0.49 | 0.35 | 1.00 | 0.21 |

| Jiangxi | 0.65 | 0.56 | 0.74 | 0.84 | 0.69 | 1.00 | 0.68 | 1.00 | 0.52 |

| Shandong | 0.26 | 1.00 | 0.15 | 0.37 | 1.00 | 0.23 | 0.36 | 1.00 | 0.22 |

| Henan | 0.39 | 0.75 | 0.29 | 0.54 | 0.67 | 0.47 | 0.53 | 0.77 | 0.43 |

| Hubei | 0.41 | 0.60 | 0.35 | 0.26 | 0.56 | 0.20 | 0.23 | 0.65 | 0.16 |

| Hunan | 0.47 | 0.73 | 0.37 | 0.52 | 0.71 | 0.42 | 0.43 | 0.72 | 0.33 |

| Guangdong | 0.31 | 1.00 | 0.19 | 0.48 | 1.00 | 0.32 | 0.28 | 1.00 | 0.17 |

| Guangxi | 0.59 | 1.00 | 0.41 | 0.69 | 1.00 | 0.53 | 0.64 | 1.00 | 0.47 |

| Hainan | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 0.67 | 1.00 | 0.50 |

| Chongqing | 0.36 | 0.62 | 0.28 | 0.52 | 0.65 | 0.45 | 0.31 | 0.60 | 0.24 |

| Sichuan | 0.36 | 0.65 | 0.28 | 0.61 | 0.61 | 0.61 | 0.50 | 0.57 | 0.46 |

| Guizhou | 0.10 | 0.34 | 0.08 | 0.11 | 0.35 | 0.09 | 0.13 | 0.34 | 0.10 |

| Yunnan | 0.31 | 0.52 | 0.26 | 0.28 | 0.50 | 0.23 | 0.22 | 0.48 | 0.18 |

| Shanxi | 0.20 | 0.54 | 0.15 | 0.17 | 0.59 | 0.12 | 0.08 | 0.58 | 0.06 |

| Gansu | 0.11 | 0.42 | 0.08 | 0.11 | 0.41 | 0.08 | 0.08 | 0.41 | 0.06 |

| Qinghai | 0.33 | 0.37 | 0.31 | 0.13 | 0.39 | 0.10 | 0.34 | 0.38 | 0.32 |

| Ningxia | 0.11 | 0.45 | 0.08 | 0.25 | 0.47 | 0.20 | 0.22 | 0.49 | 0.17 |

| Xinjiang | 0.16 | 0.50 | 0.12 | 0.11 | 0.46 | 0.08 | 0.19 | 0.48 | 0.15 |

| (a) | |||||||||||||||

| Item | 2005–2006 | 2006–2007 | 2007–2008 | 2008–2009 | 2009–2010 | ||||||||||

| System | System | System | System | System | |||||||||||

| Malm | Effch | Tech | Malm | Effch | Tech | Malm | Effch | Tech | Malm | Effch | Tech | Malm | Effch | Tech | |

| Beijing | 1.05 | 0.79 | 1.32 | 0.93 | 0.96 | 0.97 | 1.36 | 1.38 | 0.99 | 1.90 | 1.81 | 1.05 | 1.35 | 0.87 | 1.54 |

| Tianjin | 1.84 | 1.00 | 1.84 | 0.81 | 0.94 | 0.86 | 0.93 | 0.79 | 1.18 | 1.13 | 1.06 | 1.06 | 1.31 | 0.85 | 1.54 |

| Hebei | 1.50 | 1.20 | 1.25 | 1.18 | 1.05 | 1.12 | 1.17 | 1.16 | 1.01 | 1.17 | 1.13 | 1.04 | 1.35 | 1.01 | 1.34 |

| Shanxi | 0.59 | 0.58 | 1.02 | 1.37 | 1.22 | 1.13 | 0.73 | 0.81 | 0.90 | 1.18 | 1.09 | 1.08 | 1.88 | 1.40 | 1.34 |

| Neimenggu | 0.22 | 0.23 | 0.93 | 1.53 | 1.10 | 1.40 | 1.01 | 1.06 | 0.95 | 1.27 | 1.51 | 0.84 | 2.05 | 1.28 | 1.59 |

| Liaoning | 0.80 | 0.64 | 1.25 | 1.40 | 1.15 | 1.22 | 2.02 | 1.87 | 1.08 | 1.01 | 0.98 | 1.03 | 1.22 | 0.86 | 1.42 |

| Jilin | 1.49 | 1.43 | 1.04 | 1.14 | 0.93 | 1.22 | 0.57 | 0.54 | 1.04 | 1.16 | 1.09 | 1.07 | 1.46 | 1.11 | 1.32 |

| Heilongjiang | 0.95 | 0.81 | 1.17 | 0.94 | 0.91 | 1.03 | 1.00 | 0.89 | 1.12 | 0.72 | 0.73 | 0.99 | 2.17 | 1.59 | 1.37 |

| Shanghai | 1.50 | 1.22 | 1.22 | 1.40 | 1.08 | 1.29 | 0.66 | 0.52 | 1.28 | 1.36 | 1.44 | 0.94 | 0.87 | 0.53 | 1.65 |

| Jiangsu | 1.56 | 1.48 | 1.06 | 1.08 | 0.91 | 1.18 | 0.75 | 0.72 | 1.04 | 1.33 | 1.24 | 1.08 | 1.39 | 1.07 | 1.31 |

| Zhejiang | 1.29 | 1.39 | 0.93 | 1.19 | 1.04 | 1.14 | 1.41 | 1.06 | 1.34 | 0.85 | 1.00 | 0.85 | 1.58 | 1.00 | 1.58 |

| Anhui | 1.03 | 0.98 | 1.05 | 1.22 | 1.12 | 1.09 | 0.69 | 0.64 | 1.09 | 1.06 | 1.03 | 1.04 | 1.69 | 1.27 | 1.33 |

| Fujian | 1.98 | 1.58 | 1.25 | 1.14 | 1.02 | 1.11 | 1.48 | 0.86 | 1.72 | 1.64 | 1.75 | 0.94 | 0.79 | 0.53 | 1.50 |

| Jiangxi | 1.38 | 1.19 | 1.17 | 1.23 | 1.16 | 1.07 | 1.18 | 1.04 | 1.14 | 1.33 | 1.29 | 1.03 | 0.95 | 0.81 | 1.17 |

| Shandong | 1.12 | 0.95 | 1.18 | 1.27 | 1.22 | 1.04 | 0.81 | 0.84 | 0.97 | 1.66 | 1.46 | 1.14 | 1.36 | 0.96 | 1.41 |

| Henan | 1.05 | 0.89 | 1.17 | 1.17 | 1.13 | 1.04 | 1.19 | 1.00 | 1.19 | 1.44 | 1.39 | 1.04 | 1.35 | 0.99 | 1.37 |

| Hubei | 1.12 | 0.97 | 1.15 | 1.07 | 1.04 | 1.03 | 0.99 | 1.00 | 0.99 | 0.63 | 0.63 | 1.01 | 1.22 | 0.88 | 1.39 |

| Hunan | 0.94 | 0.72 | 1.30 | 1.18 | 1.06 | 1.12 | 1.25 | 1.13 | 1.11 | 1.15 | 1.11 | 1.03 | 1.11 | 0.83 | 1.34 |

| Guangdong | 1.24 | 1.11 | 1.12 | 1.17 | 1.05 | 1.11 | 0.88 | 0.61 | 1.44 | 1.37 | 1.53 | 0.89 | 0.91 | 0.59 | 1.54 |

| Guangxi | 1.20 | 1.06 | 1.13 | 1.78 | 1.20 | 1.48 | 0.56 | 0.59 | 0.95 | 1.02 | 1.18 | 0.87 | 1.42 | 0.92 | 1.54 |

| Hainan | 0.21 | 0.28 | 0.74 | 1.59 | 1.40 | 1.14 | 4.95 | 3.72 | 1.33 | 1.01 | 1.00 | 1.01 | 1.10 | 0.67 | 1.65 |

| Chongqing | 1.61 | 1.00 | 1.61 | 0.61 | 0.84 | 0.72 | 0.55 | 0.50 | 1.09 | 1.41 | 1.44 | 0.98 | 0.84 | 0.59 | 1.41 |

| Sichuan | 1.00 | 0.90 | 1.12 | 0.99 | 1.04 | 0.96 | 1.06 | 0.93 | 1.14 | 1.83 | 1.70 | 1.07 | 1.08 | 0.82 | 1.32 |

| Guizhou | 0.66 | 0.55 | 1.19 | 0.95 | 0.97 | 0.97 | 1.04 | 1.14 | 0.91 | 1.18 | 1.09 | 1.09 | 1.43 | 1.18 | 1.21 |

| Yunnan | 0.81 | 0.41 | 1.98 | 1.14 | 1.12 | 1.02 | 0.95 | 0.95 | 1.00 | 1.02 | 0.91 | 1.12 | 0.91 | 0.80 | 1.14 |

| Shanxi | 2.76 | 1.70 | 1.62 | 1.49 | 1.29 | 1.15 | 0.64 | 0.54 | 1.19 | 0.80 | 0.83 | 0.96 | 0.74 | 0.49 | 1.52 |

| Gansu | 0.56 | 0.48 | 1.15 | 1.24 | 1.13 | 1.10 | 1.12 | 1.17 | 0.96 | 1.13 | 0.99 | 1.14 | 0.82 | 0.69 | 1.18 |

| Qinghai | 1.05 | 0.80 | 1.31 | 1.55 | 1.15 | 1.35 | 1.09 | 0.93 | 1.18 | 0.35 | 0.39 | 0.89 | 3.92 | 2.61 | 1.50 |

| Ningxia | 0.63 | 0.53 | 1.18 | 1.16 | 1.13 | 1.02 | 0.62 | 0.43 | 1.45 | 2.13 | 2.30 | 0.93 | 1.35 | 0.89 | 1.51 |

| Xinjiang | 0.89 | 0.91 | 0.98 | 1.20 | 1.10 | 1.10 | 0.66 | 0.60 | 1.10 | 0.72 | 0.71 | 1.01 | 2.38 | 1.69 | 1.40 |

| (b) | |||||||||||||||

| Item | 2005–2006 | 2006–2007 | 2007–2008 | 2008–2009 | 2009–2010 | ||||||||||

| Stage 1 | Stage 1 | Stage 1 | Stage 1 | Stage 1 | |||||||||||

| Malm | Effch | Tech | Malm | Effch | Tech | Malm | Effch | Tech | Malm | Effch | Tech | Malm | Effch | Tech | |

| Beijing | 1.14 | 1.00 | 1.14 | 1.20 | 1.00 | 1.20 | 1.08 | 1.00 | 1.08 | 1.09 | 1.00 | 1.09 | 1.41 | 1.00 | 1.41 |

| Tianjin | 1.13 | 1.00 | 1.13 | 1.08 | 1.00 | 1.08 | 1.13 | 1.00 | 1.13 | 0.95 | 1.00 | 0.95 | 1.45 | 1.00 | 1.45 |

| Hebei | 1.05 | 1.08 | 0.97 | 1.08 | 1.06 | 1.02 | 1.11 | 1.24 | 0.90 | 0.93 | 0.93 | 1.00 | 1.30 | 1.07 | 1.22 |

| Shanxi | 1.09 | 0.99 | 1.11 | 1.14 | 1.09 | 1.05 | 1.15 | 1.19 | 0.97 | 0.89 | 0.85 | 1.04 | 1.33 | 1.19 | 1.11 |

| Neimenggu | 1.59 | 1.30 | 1.23 | 1.16 | 1.10 | 1.06 | 1.19 | 1.13 | 1.05 | 1.15 | 1.85 | 0.62 | 1.54 | 1.00 | 1.54 |

| Liaoning | 1.05 | 1.02 | 1.03 | 1.11 | 1.05 | 1.06 | 1.02 | 1.12 | 0.91 | 1.03 | 0.98 | 1.05 | 1.30 | 1.12 | 1.15 |

| Jilin | 0.93 | 1.05 | 0.89 | 1.29 | 1.19 | 1.09 | 1.10 | 1.06 | 1.04 | 1.07 | 1.03 | 1.04 | 1.26 | 1.11 | 1.13 |

| Heilongjiang | 1.27 | 0.99 | 1.29 | 0.97 | 0.93 | 1.04 | 1.08 | 1.19 | 0.91 | 0.94 | 0.91 | 1.04 | 1.14 | 1.01 | 1.13 |

| Shanghai | 1.07 | 1.00 | 1.07 | 1.19 | 1.00 | 1.19 | 1.12 | 1.00 | 1.12 | 0.94 | 1.00 | 0.94 | 1.40 | 1.00 | 1.40 |

| Jiangsu | 0.97 | 1.00 | 0.97 | 1.02 | 1.00 | 1.02 | 0.83 | 1.00 | 0.83 | 1.09 | 1.00 | 1.09 | 1.12 | 1.00 | 1.12 |

| Zhejiang | 1.03 | 1.00 | 1.03 | 1.12 | 1.09 | 1.03 | 0.94 | 1.12 | 0.84 | 0.93 | 1.00 | 0.93 | 1.34 | 1.00 | 1.34 |

| Anhui | 1.10 | 1.09 | 1.01 | 1.06 | 1.03 | 1.03 | 1.12 | 1.09 | 1.03 | 1.06 | 1.01 | 1.05 | 1.17 | 1.12 | 1.05 |

| Fujian | 0.99 | 1.00 | 0.99 | 1.07 | 1.00 | 1.07 | 1.08 | 1.00 | 1.08 | 0.88 | 1.00 | 0.88 | 1.21 | 1.00 | 1.21 |

| Jiangxi | 1.11 | 1.25 | 0.89 | 1.24 | 1.12 | 1.11 | 0.76 | 0.83 | 0.92 | 1.25 | 1.23 | 1.01 | 1.42 | 1.45 | 0.98 |

| Shandong | 1.05 | 1.00 | 1.05 | 1.11 | 1.00 | 1.11 | 1.08 | 1.00 | 1.08 | 1.10 | 1.00 | 1.10 | 1.27 | 1.00 | 1.27 |

| Henan | 1.08 | 1.08 | 1.00 | 1.19 | 1.29 | 0.92 | 1.03 | 1.08 | 0.95 | 0.97 | 0.89 | 1.09 | 1.24 | 1.16 | 1.07 |

| Hubei | 1.13 | 1.10 | 1.03 | 1.32 | 1.01 | 1.30 | 1.07 | 1.20 | 0.90 | 0.96 | 0.94 | 1.02 | 1.34 | 1.15 | 1.16 |

| Hunan | 0.89 | 0.85 | 1.05 | 1.08 | 1.02 | 1.05 | 1.04 | 1.16 | 0.89 | 1.02 | 0.97 | 1.05 | 1.10 | 1.01 | 1.09 |

| Guangdong | 0.90 | 1.00 | 0.90 | 1.12 | 1.00 | 1.12 | 1.00 | 1.00 | 1.00 | 0.89 | 1.00 | 0.89 | 1.12 | 1.00 | 1.12 |

| Guangxi | 0.80 | 1.00 | 0.80 | 1.25 | 1.00 | 1.25 | 1.00 | 1.00 | 1.00 | 0.79 | 1.00 | 0.79 | 1.26 | 1.00 | 1.26 |

| Hainan | 1.29 | 1.05 | 1.22 | 1.35 | 2.18 | 0.62 | 1.06 | 1.00 | 1.06 | 1.00 | 1.00 | 1.00 | 1.91 | 1.00 | 1.91 |

| Chongqing | 0.98 | 1.01 | 0.97 | 0.91 | 0.80 | 1.15 | 1.06 | 1.09 | 0.97 | 1.05 | 1.05 | 1.00 | 0.99 | 0.91 | 1.09 |

| Sichuan | 1.14 | 1.09 | 1.05 | 1.04 | 1.01 | 1.03 | 1.02 | 1.20 | 0.85 | 0.93 | 0.94 | 1.00 | 1.09 | 0.93 | 1.17 |

| Guizhou | 1.04 | 1.01 | 1.03 | 1.13 | 1.06 | 1.06 | 1.06 | 1.00 | 1.06 | 0.99 | 1.01 | 0.98 | 1.10 | 0.98 | 1.12 |

| Yunnan | 1.30 | 1.06 | 1.23 | 1.05 | 0.95 | 1.10 | 1.04 | 1.02 | 1.02 | 0.94 | 0.95 | 0.99 | 1.08 | 0.96 | 1.13 |

| Shanxi | 1.07 | 0.93 | 1.14 | 1.16 | 1.12 | 1.04 | 1.09 | 1.22 | 0.90 | 1.12 | 1.10 | 1.02 | 1.12 | 0.97 | 1.15 |

| Gansu | 1.04 | 1.01 | 1.04 | 1.20 | 1.14 | 1.06 | 1.01 | 0.95 | 1.06 | 0.94 | 0.97 | 0.97 | 1.12 | 1.00 | 1.12 |

| Qinghai | 1.11 | 1.01 | 1.09 | 1.10 | 1.02 | 1.09 | 1.13 | 1.07 | 1.05 | 0.95 | 1.06 | 0.89 | 1.07 | 0.97 | 1.11 |

| Ningxia | 0.96 | 1.10 | 0.88 | 1.11 | 0.99 | 1.12 | 1.08 | 1.04 | 1.04 | 0.95 | 1.05 | 0.90 | 1.13 | 1.04 | 1.09 |

| Xinjiang | 1.16 | 1.11 | 1.05 | 1.03 | 0.93 | 1.10 | 1.12 | 1.04 | 1.08 | 0.89 | 0.93 | 0.96 | 1.19 | 1.04 | 1.14 |

| (c) | |||||||||||||||

| Item | 2005–2006 | 2006–2007 | 2007–2008 | 2008–2009 | 2009–2010 | ||||||||||

| Stage 2 | Stage 2 | Stage 2 | Stage 2 | Stage 2 | |||||||||||

| Malm | Effch | Tech | Malm | Effch | Tech | Malm | Effch | Tech | Malm | Effch | Tech | Malm | Effch | Tech | |

| Beijing | 1.00 | 0.78 | 1.29 | 0.87 | 0.95 | 0.91 | 1.34 | 1.41 | 0.95 | 1.94 | 1.94 | 1.00 | 1.17 | 0.86 | 1.37 |

| Tianjin | 1.81 | 1.00 | 1.81 | 0.77 | 0.94 | 0.82 | 0.88 | 0.77 | 1.14 | 1.16 | 1.07 | 1.08 | 1.11 | 0.84 | 1.32 |

| Hebei | 1.58 | 1.24 | 1.27 | 1.18 | 1.05 | 1.12 | 1.16 | 1.10 | 1.06 | 1.28 | 1.24 | 1.03 | 1.32 | 0.97 | 1.36 |

| Shanxi | 0.56 | 0.56 | 1.01 | 1.35 | 1.21 | 1.12 | 0.69 | 0.76 | 0.91 | 1.23 | 1.15 | 1.07 | 1.80 | 1.37 | 1.32 |

| Neimenggu | 0.15 | 0.15 | 1.04 | 1.50 | 1.07 | 1.40 | 0.95 | 1.02 | 0.94 | 1.23 | 1.18 | 1.04 | 1.80 | 1.32 | 1.37 |

| Liaoning | 0.78 | 0.60 | 1.29 | 1.38 | 1.14 | 1.20 | 2.15 | 1.95 | 1.10 | 1.00 | 0.99 | 1.01 | 1.12 | 0.79 | 1.42 |

| Jilin | 1.69 | 1.79 | 0.94 | 1.06 | 0.78 | 1.36 | 0.48 | 0.41 | 1.17 | 1.16 | 1.09 | 1.06 | 1.44 | 1.08 | 1.34 |

| Heilongjiang | 0.90 | 0.70 | 1.29 | 0.93 | 0.91 | 1.03 | 0.97 | 0.81 | 1.21 | 0.69 | 0.70 | 0.99 | 2.44 | 1.76 | 1.38 |

| Shanghai | 1.53 | 1.31 | 1.17 | 1.38 | 1.12 | 1.23 | 0.59 | 0.43 | 1.37 | 1.46 | 1.56 | 0.94 | 0.72 | 0.47 | 1.53 |

| Jiangsu | 1.80 | 1.88 | 0.96 | 1.10 | 0.85 | 1.29 | 0.75 | 0.60 | 1.25 | 1.42 | 1.38 | 1.03 | 1.53 | 1.11 | 1.38 |

| Zhejiang | 1.37 | 1.78 | 0.77 | 1.18 | 1.00 | 1.18 | 1.76 | 1.00 | 1.76 | 0.80 | 1.00 | 0.80 | 1.77 | 1.00 | 1.77 |

| Anhui | 1.00 | 0.88 | 1.13 | 1.33 | 1.22 | 1.09 | 0.57 | 0.42 | 1.37 | 1.06 | 1.04 | 1.01 | 1.91 | 1.36 | 1.40 |

| Fujian | 2.08 | 1.74 | 1.20 | 1.11 | 1.03 | 1.08 | 1.50 | 0.83 | 1.80 | 1.97 | 2.12 | 0.93 | 0.67 | 0.43 | 1.56 |

| Jiangxi | 1.40 | 1.15 | 1.23 | 1.22 | 1.18 | 1.03 | 1.47 | 1.25 | 1.18 | 1.40 | 1.35 | 1.03 | 0.72 | 0.52 | 1.39 |

| Shandong | 1.11 | 0.94 | 1.18 | 1.25 | 1.26 | 0.99 | 0.77 | 0.82 | 0.94 | 1.70 | 1.56 | 1.09 | 1.26 | 0.95 | 1.32 |

| Henan | 1.02 | 0.82 | 1.25 | 1.12 | 1.09 | 1.02 | 1.21 | 0.96 | 1.26 | 1.61 | 1.66 | 0.97 | 1.33 | 0.90 | 1.47 |

| Hubei | 1.10 | 0.91 | 1.21 | 1.05 | 1.06 | 1.00 | 0.96 | 0.94 | 1.03 | 0.59 | 0.57 | 1.03 | 1.11 | 0.81 | 1.38 |

| Hunan | 0.98 | 0.67 | 1.45 | 1.17 | 1.08 | 1.08 | 1.29 | 1.13 | 1.14 | 1.18 | 1.15 | 1.03 | 1.09 | 0.79 | 1.38 |

| Guangdong | 1.35 | 1.14 | 1.19 | 1.13 | 1.07 | 1.05 | 0.86 | 0.54 | 1.60 | 1.53 | 1.70 | 0.90 | 0.84 | 0.52 | 1.61 |

| Guangxi | 1.44 | 1.11 | 1.30 | 1.99 | 1.40 | 1.43 | 0.43 | 0.41 | 1.04 | 1.16 | 1.28 | 0.91 | 1.43 | 0.89 | 1.61 |

| Hainan | 0.13 | 0.15 | 0.88 | 1.50 | 1.02 | 1.46 | 7.57 | 6.44 | 1.18 | 1.00 | 1.00 | 1.00 | 0.75 | 0.50 | 1.50 |

| Chongqing | 2.37 | 1.00 | 2.37 | 0.44 | 0.90 | 0.48 | 0.45 | 0.32 | 1.44 | 1.49 | 1.57 | 0.95 | 0.80 | 0.53 | 1.51 |

| Sichuan | 0.98 | 0.80 | 1.22 | 0.97 | 1.06 | 0.92 | 1.06 | 0.88 | 1.20 | 2.19 | 2.20 | 1.00 | 1.08 | 0.75 | 1.44 |

| Guizhou | 0.63 | 0.52 | 1.21 | 0.92 | 0.96 | 0.96 | 1.02 | 1.15 | 0.89 | 1.20 | 1.09 | 1.10 | 1.44 | 1.20 | 1.20 |

| Yunnan | 0.75 | 0.23 | 3.22 | 1.15 | 1.18 | 0.98 | 0.93 | 0.93 | 1.00 | 1.05 | 0.91 | 1.15 | 0.86 | 0.77 | 1.12 |

| Shanxi | 2.92 | 1.88 | 1.55 | 1.50 | 1.35 | 1.11 | 0.58 | 0.44 | 1.34 | 0.76 | 0.78 | 0.97 | 0.69 | 0.46 | 1.49 |

| Gansu | 0.53 | 0.45 | 1.18 | 1.20 | 1.09 | 1.10 | 1.12 | 1.20 | 0.93 | 1.16 | 1.01 | 1.16 | 0.78 | 0.68 | 1.15 |

| Qinghai | 1.04 | 0.70 | 1.48 | 1.62 | 1.24 | 1.31 | 1.07 | 0.86 | 1.25 | 0.31 | 0.33 | 0.94 | 4.72 | 3.13 | 1.51 |

| Ningxia | 0.60 | 0.41 | 1.46 | 1.14 | 1.17 | 0.98 | 0.58 | 0.38 | 1.55 | 2.32 | 2.52 | 0.92 | 1.35 | 0.86 | 1.57 |

| Xinjiang | 0.84 | 0.85 | 0.98 | 1.22 | 1.15 | 1.06 | 0.61 | 0.54 | 1.12 | 0.73 | 0.70 | 1.04 | 2.44 | 1.77 | 1.38 |

References

- China National Bureau of Statistics. Available online: http://www.stats.gov.cn/ (accessed on 14 May 2021).

- Bian, Y. Eco-efficiency evaluation of non-cooperative game two-stage production system. J. Manag. Sci. China 2012, 7, 11–19. [Google Scholar]

- Tu, Z.; Shen, R. Does environment technology efficiency measured by traditional method underestimate environment governance efficiency? From the evidence of China’s industrial provincial panel data using environmental directional distance function based on the network DEA. Econ. Rev. 2013, 5, 89–99. [Google Scholar]

- Wu, J.; Yin, P.; Sun, J.; Chu, J.; Liang, L. Evaluating the environmental efficiency of a two-stage system with undesired outputs by a DEA approach: An interest preference perspective. Eur. J. Oper. Res. 2016, 254, 1047–1062. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Su, Q.; Chen, K.; Liao, L. The Impact of Land Use Change on Disaster Risk from the Perspective of Efficiency. Sustainability 2021, 13, 3151. [Google Scholar] [CrossRef]

- Seo, Y.; Umeda, S. Evaluating Farm Management Performance by the Choice of Pest-Control Sprayers in Rice Farming in Japan. Sustainability 2021, 13, 2618. [Google Scholar] [CrossRef]

- Tone, K.; Tsutsui, M. Network DEA: A slacks-based measure approach. Eur. J. Oper. Res. 2009, 197, 243–252. [Google Scholar] [CrossRef] [Green Version]

- Färe, R.; Grosskopf, S. Productivity and intermediate products: A frontier approach. Econ. Lett. 1996, 50, 65–70. [Google Scholar] [CrossRef]

- Lewis, H.F.; Sexton, T.R. Network DEA: Efficiency analysis of organizations with complex internal structure. Comput. Oper. Res. 2004, 31, 1365–1410. [Google Scholar] [CrossRef]

- Hwang, S.N.; Kao, T.L. Measuring managerial efficiency in non-life insurance companies: An application of two-stage data envelopment analysis. Int. J. Manag. 2006, 23, 699–720. [Google Scholar]

- Kao, C.; Hwang, S.-N. Efficiency decomposition in two-stage data envelopment analysis: An application to non-life insurance companies in Taiwan. Eur. J. Oper. Res. 2008, 185, 418–429. [Google Scholar] [CrossRef]

- Seiford, L.M.; Zhu, J. Profitability and Marketability of the Top 55 U.S. Commercial Banks. Manag. Sci. 1999, 45, 1270–1288. [Google Scholar] [CrossRef] [Green Version]

- Sexton, T.R.; Lewis, H.F. Two-Stage DEA: An Application to Major League Baseball. J. Prod. Anal. 2003, 19, 227–249. [Google Scholar] [CrossRef]

- Lo, S.-F.; Lu, W.-M. An integrated performance evaluation of financial holding companies in Taiwan. Eur. J. Oper. Res. 2009, 198, 341–350. [Google Scholar] [CrossRef]

- Huang, C.-W.; Chiu, Y.-H.; Fang, W.-T.; Shen, N. Assessing the performance of Taiwan’s environmental protection system with a non-radial network DEA approach. Energy Policy 2014, 74, 547–556. [Google Scholar] [CrossRef]

- Chen, Y.; Cook, W.D.; Kao, C.; Zhu, J. Network DEA pitfalls: Divisional efficiency and frontier projection. In Data Envelopment Analysis; Springer: Boston, MA, USA, 2014. [Google Scholar]

- Fukuyama, H.; Mirdehghan, S. Identifying the efficiency status in network DEA. Eur. J. Oper. Res. 2012, 220, 85–92. [Google Scholar] [CrossRef]

- Kao, C. Efficiency decomposition in network data envelopment analysis. In Data Envelopment Analysis; Springer: New York, NY, USA, 2014. [Google Scholar]

- Prieto, A.M.; Zofío, J.L. Network DEA efficiency in input–output models: With an application to OECD countries. Eur. J. Oper. Res. 2007, 178, 292–304. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some models for estimating technical and scale inefficiencies in data envelopment analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef] [Green Version]

- Färe, R.; Lovell, C.K. Measuring the technical efficiency of production. J. Econ. Theory 1978, 19, 150–162. [Google Scholar] [CrossRef]

- Pastor, J.T.; Ruiz, J.L.; Sirvent, I. An enhanced DEA Russell graph efficiency measure. Eur. J. Oper. Res. 1999, 115, 596–607. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of super-efficiency in data envelopment analysis. Eur. J. Oper. Res. 2002, 143, 32–41. [Google Scholar] [CrossRef] [Green Version]

- Hernández-Sancho, F.; Molinos-Senante, M.; Sala-Garrido, R. Energy efficiency in Spanish wastewater treatment plants: A non-radial DEA approach. Sci. Total Environ. 2011, 409, 2693–2699. [Google Scholar] [CrossRef] [PubMed]

- Kao, C. Efficiency decomposition for parallel production systems. J. Oper. Res. Soc. 2012, 63, 64–71. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Roos, P. Productivity and quality changes in Swedish pharmacies. Int. J. Prod. Econ. 1995, 39, 137–144. [Google Scholar] [CrossRef]

- Christina, B.; George, H. Dynamics of productivity taking into consideration the impact of energy consumption and environmental degradation. Energy Policy 2018, 120, 276–283. [Google Scholar]

- Rath, B.N.; Akram, V.; Bai, D.P.; Mahalik, M.K. Do fossil fuel and renewable energy consumption affect total factor productivity growth? Evidence from cross-country data with policy insights. Energy Policy 2019, 127, 186–199. [Google Scholar] [CrossRef]

- Löthgren, M.; Tambour, M. Productivity and customer satisfaction in Swedish pharmacies: A DEA network model. Eur. J. Oper. Res. 1999, 115, 449–458. [Google Scholar] [CrossRef]

- Jahantighi, M.A.; Moghaddas, Z.; Ghasemi, M.V. Two-stage malmquist productivity index with intermediate products. Int. J. Ind. Math. 2012, 4, 31–40. [Google Scholar]

- Pouryusef, M.; Tohidi, G.; Razavian, S. Malmquist productivity index for decision making units with two-stage structure. Proc. World Acad. Sci. Eng. Technol. 2011, 80, 317–319. [Google Scholar]

- Kao, C.; Hwang, S.-N. Multi-period efficiency and Malmquist productivity index in two-stage production systems. Eur. J. Oper. Res. 2014, 232, 512–521. [Google Scholar] [CrossRef]

- Degl’Innocenti, M.; Kourtzidis, S.A.; Sevic, Z.; Tzeremes, N.G. Bank productivity growth and convergence in the European Union during the financial crisis. J. Bank. Finance 2016, 75, 184–199. [Google Scholar] [CrossRef] [Green Version]

- Lotfi, F.H.; Jahanshahloo, G.R.; Vaez-Ghasemi, M.; Moghaddas, Z. Evaluation progress and regress of balanced scorecards by multi-stage Malmquist Productivity Index. J. Ind. Prod. Eng. 2013, 30, 345–354. [Google Scholar] [CrossRef]

- Fukuyama, H.; Weber, W.L. Measuring bank performance with a dynamic network Luenberger indicator. Ann. Oper. Res. 2015, 250, 85–104. [Google Scholar] [CrossRef]

- Kao, C. Measurement and decomposition of the Malmquist productivity index for parallel production systems. Omega 2017, 67, 54–59. [Google Scholar] [CrossRef]

- Wu, J.; Li, M.; Zhu, Q.; Zhou, Z.; Liang, L. Energy and environmental efficiency measurement of China’s industrial sectors: A DEA model with non-homogeneous inputs and outputs. Energy Econ. 2019, 78, 468–480. [Google Scholar] [CrossRef]

- An, Q.; Tao, X.; Dai, B.; Li, J. Modified Distance Friction Minimization Model with Undesirable Output: An Application to the Environmental Efficiency of China’s Regional Industry. Comput. Econ. 2019, 55, 1047–1071. [Google Scholar] [CrossRef]

- Chen, F.; Zhao, T.; Wang, J. The evaluation of energy–environmental efficiency of China’s industrial sector: Based on Super-SBM model. Clean Technol. Environ. Policy 2019, 21, 1397–1414. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, W. DEA models with undesirable inputs, intermediates, and outputs. In Data Envelopment Analysis: A Handbook of Models and Methods; Zhu, J., Ed.; Springer: New York, NY, USA, 2015; pp. 415–446. [Google Scholar]

- Charnes, A.; Cooper, W.W. Programming with linear fractional functionals. Nav. Res. Logist. Q. 1962, 9, 181–186. [Google Scholar] [CrossRef]

- Pastor, J.T.; Lovell, C.K. A global Malmquist productivity index. Econ. Lett. 2005, 88, 266–271. [Google Scholar] [CrossRef]

- Liu, H.; Yang, R.; Wu, D.; Zhou, Z. Green productivity growth and competition analysis of road transportation at the provincial level employing Global Malmquist-Luenberger Index approach. J. Clean. Prod. 2021, 279, 123677. [Google Scholar] [CrossRef]

- Lv, C.; Shao, C.; Lee, C.C. Green technology innovation and financial development: Do environmental regulation and innovation output matter? Energy Econ. 2021, 98, 105237. [Google Scholar] [CrossRef]

- Bian, Y.; Yan, S.; Xu, H. Efficiency evaluation for regional urban water use and wastewater decontamination systems in China: A DEA approach. Resour. Conserv. Recycl. 2014, 83, 15–23. [Google Scholar] [CrossRef]

- Wu, H.-Q.; Shi, Y.; Xia, Q.; Zhu, W.-D. Effectiveness of the policy of circular economy in China: A DEA-based analysis for the period of 11th five-year-plan. Resour. Conserv. Recycl. 2014, 83, 163–175. [Google Scholar] [CrossRef]

- Capusneanu, S.; Topor, D.I.; Hint, M.S.; Ionescu, C.A.; Coman, M.D.; Paschia, L.; Nicolau, N.L.G.; Ivan, O.R. Mathematical model for identifying and quantifying the overall environmental cost. J. Bus. Econ. Manag. 2020, 21, 1307–1328. [Google Scholar] [CrossRef]

- Yang, Z. A two-stage DEA model to evaluate the overall performance of Canadian life and health insurance companies. Math. Comput. Model. 2006, 43, 910–919. [Google Scholar] [CrossRef]

- Malik, M.; Efendi, S.; Zarlis, M. Data Envelopment Analysis (DEA) Model in Operation Management. In Proceedings of the 4th International Conference on Operational Research (InteriOR), Medan, Indonesia, 21–23 August 2017. [Google Scholar]

- Stefko, R.; Gavurova, B.; Kocisova, K. Healthcare efficiency assessment using DEA analysis in the Slovak Republic. Health Econ. Rev. 2018, 8, 6. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Dai, B.; Wu, Q. Dynamic Green Growth Assessment of China’s Industrial System with an Improved SBM Model and Global Malmquist Index. Mathematics 2021, 9, 2594. https://doi.org/10.3390/math9202594

Li F, Dai B, Wu Q. Dynamic Green Growth Assessment of China’s Industrial System with an Improved SBM Model and Global Malmquist Index. Mathematics. 2021; 9(20):2594. https://doi.org/10.3390/math9202594

Chicago/Turabian StyleLi, Fenfen, Bo Dai, and Qifan Wu. 2021. "Dynamic Green Growth Assessment of China’s Industrial System with an Improved SBM Model and Global Malmquist Index" Mathematics 9, no. 20: 2594. https://doi.org/10.3390/math9202594