Corrosion-Fatigue Life Prediction Modeling for RC Structures under Coupled Carbonation and Repeated Loading

Abstract

:1. Introduction

2. Corrosion-Fatigue Life Prediction Modeling

2.1. Concrete Carbonation

2.2. Carbonation-Induced Reinforcing Bar Corrosion

2.3. Corrosion-Fatigue Life Prediction

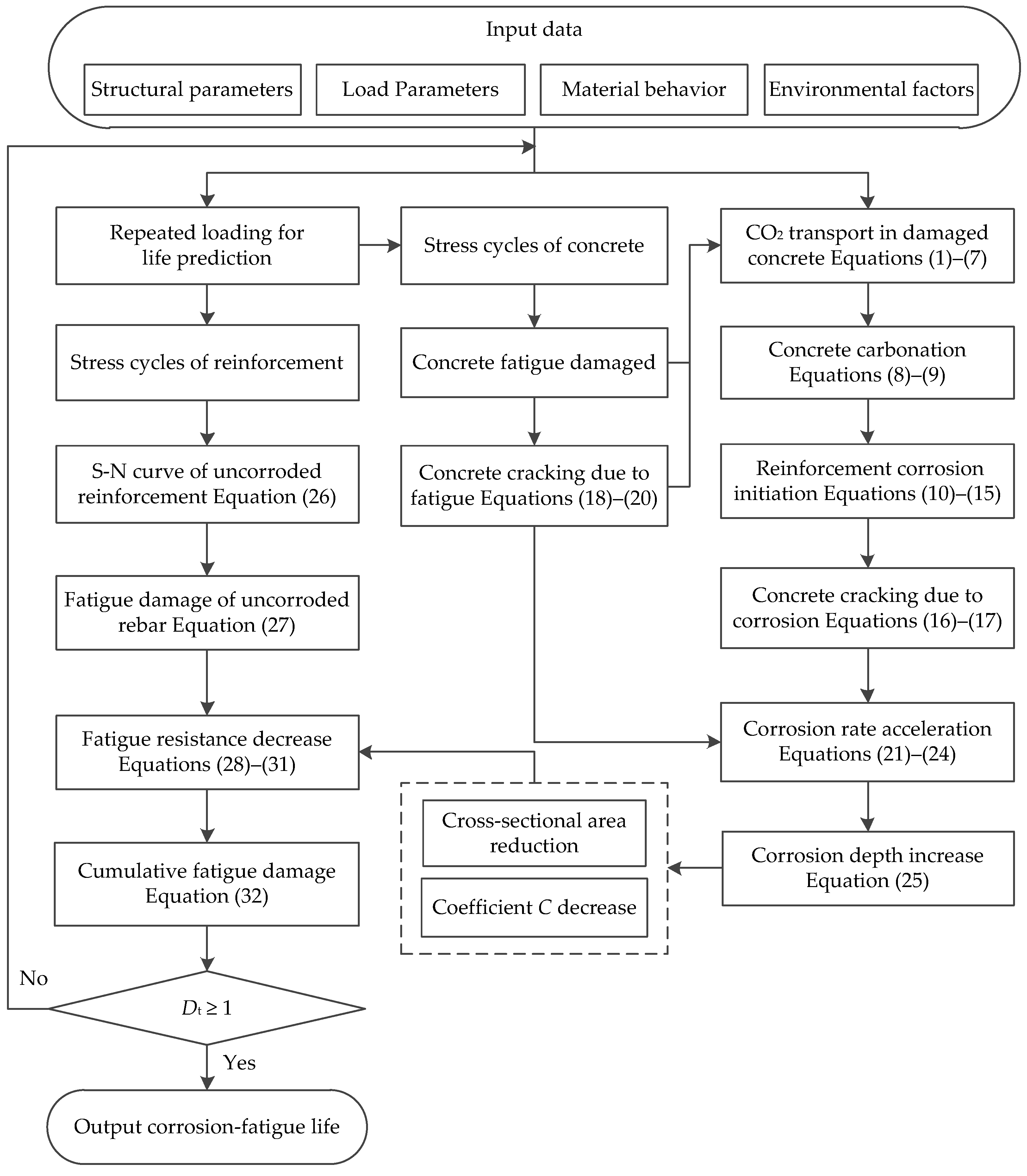

2.4. Corrosion-Fatigue Life Prediction Flowchart

- (1)

- Input the structural parameters, load parameters, material behavior, and environmental factors. Then, calculate the reinforcement and concrete stress cycles due to repeated loading.

- (2)

- Determine the CO2 transport in fatigue damaged process through Equations (1)–(7).

- (3)

- Obtain the carbonation process of fatigue-damaged concrete through Equations (8) and (9).

- (4)

- Estimate the reinforcement corrosion initiation time and the corrosion rate before concrete cracking through Equations (11)–(15).

- (5)

- Compute the concrete cracking time and the corrosion rate after concrete cracking through Equations (16)–(24).

- (6)

- Calculate the reinforcement corrosion depth and corrosion ratio through Equations (10) and (25).

- (7)

- Obtain the fatigue resistance and fatigue damage of uncorroded reinforcement through Equations (26) and (27).

- (8)

- Determine the fatigue resistance decrease behavior through Equations (28)–(31).

- (9)

- Calculate the cumulative fatigue damage Dt through Equation (32),

- (10)

- Output the corrosion-fatigue life by judging whether Dt reaches 1.

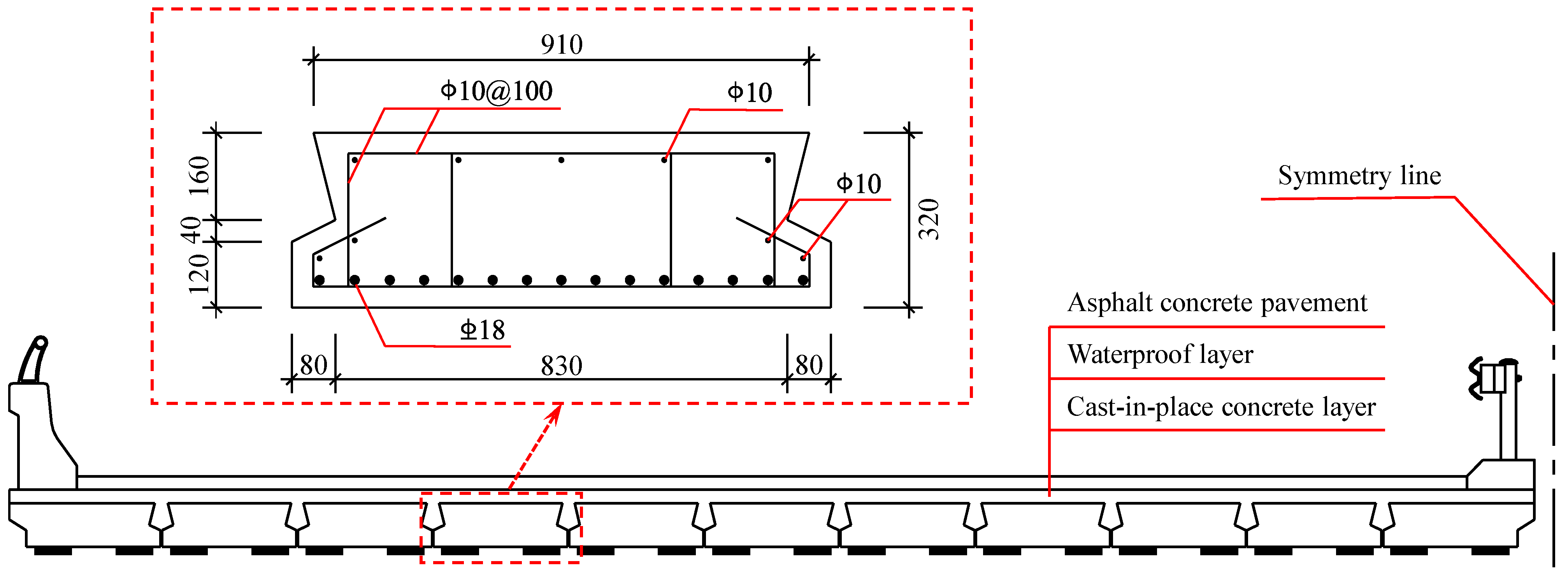

3. Model Application

4. Results and Discussion

4.1. Corrosion-Fatigue Life Prediction

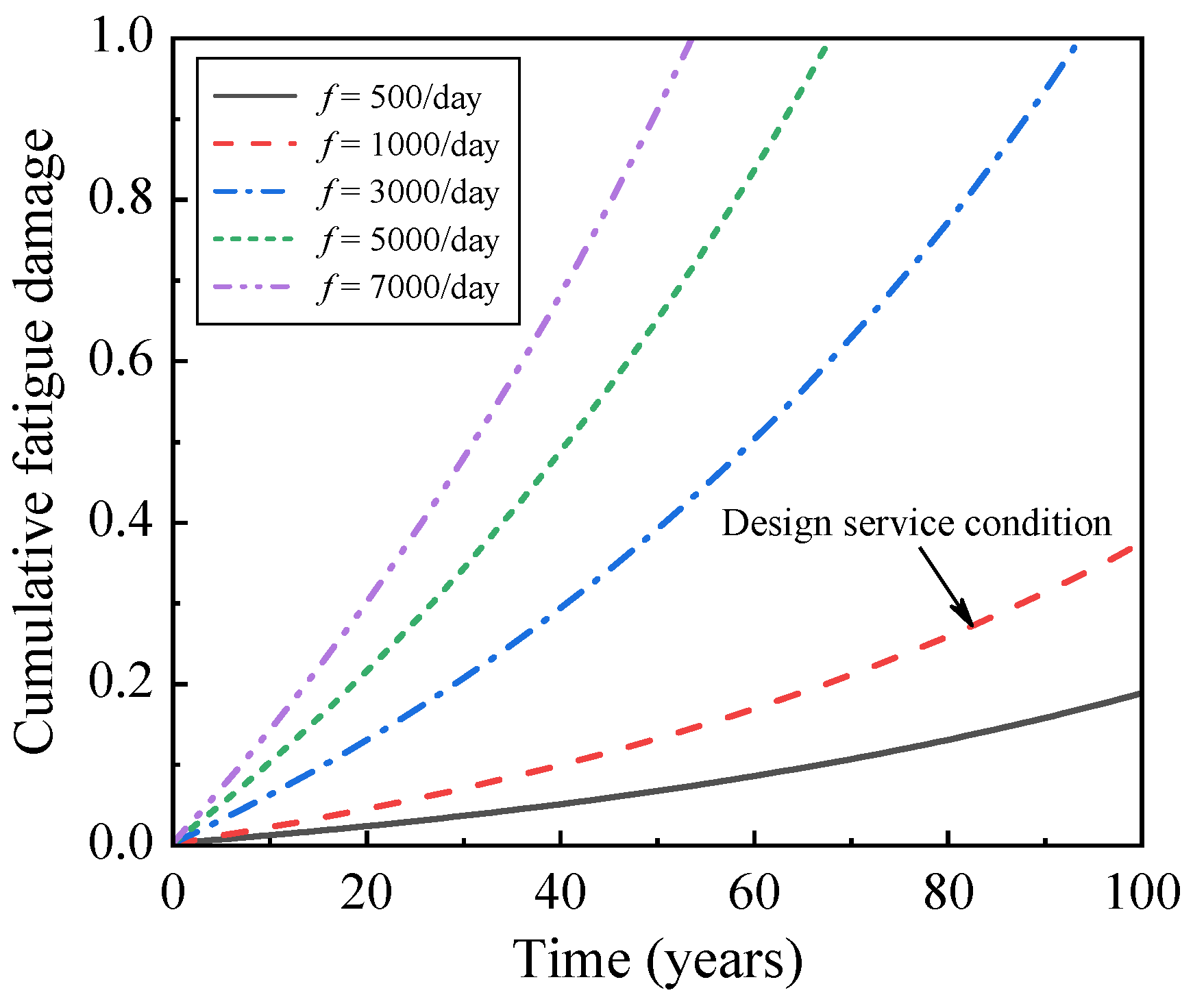

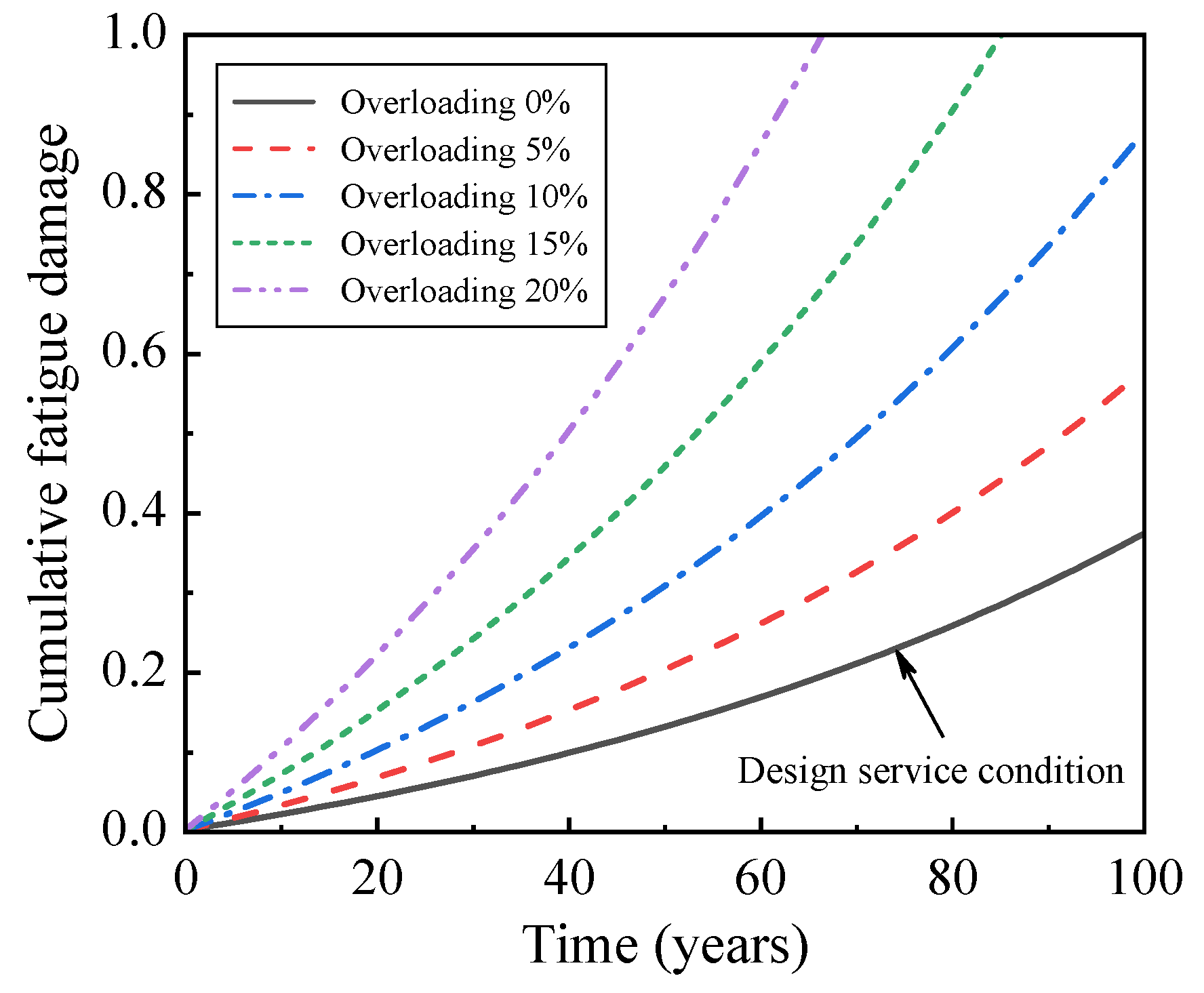

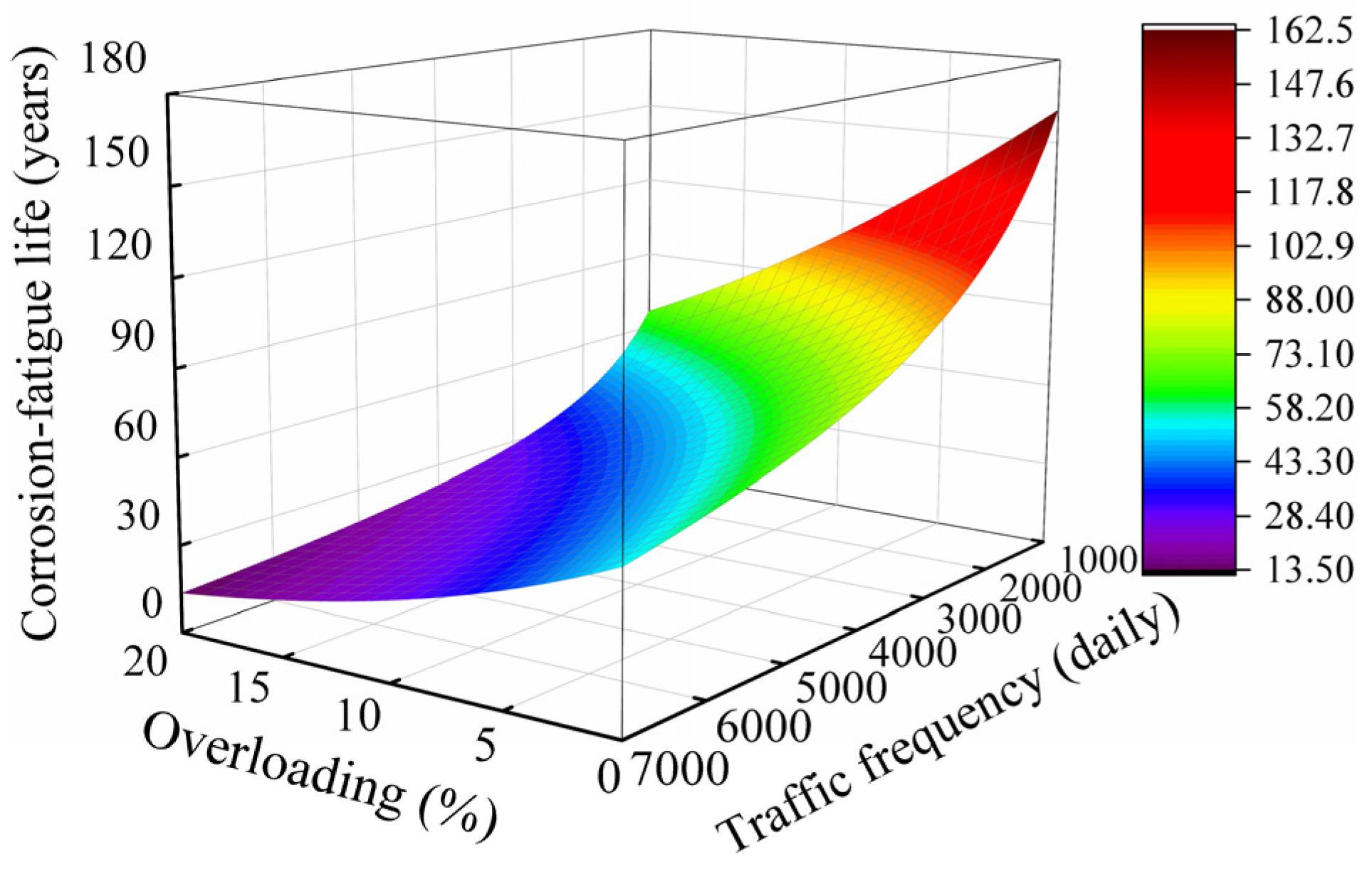

4.2. Effect of Traffic Frequency and Overloading

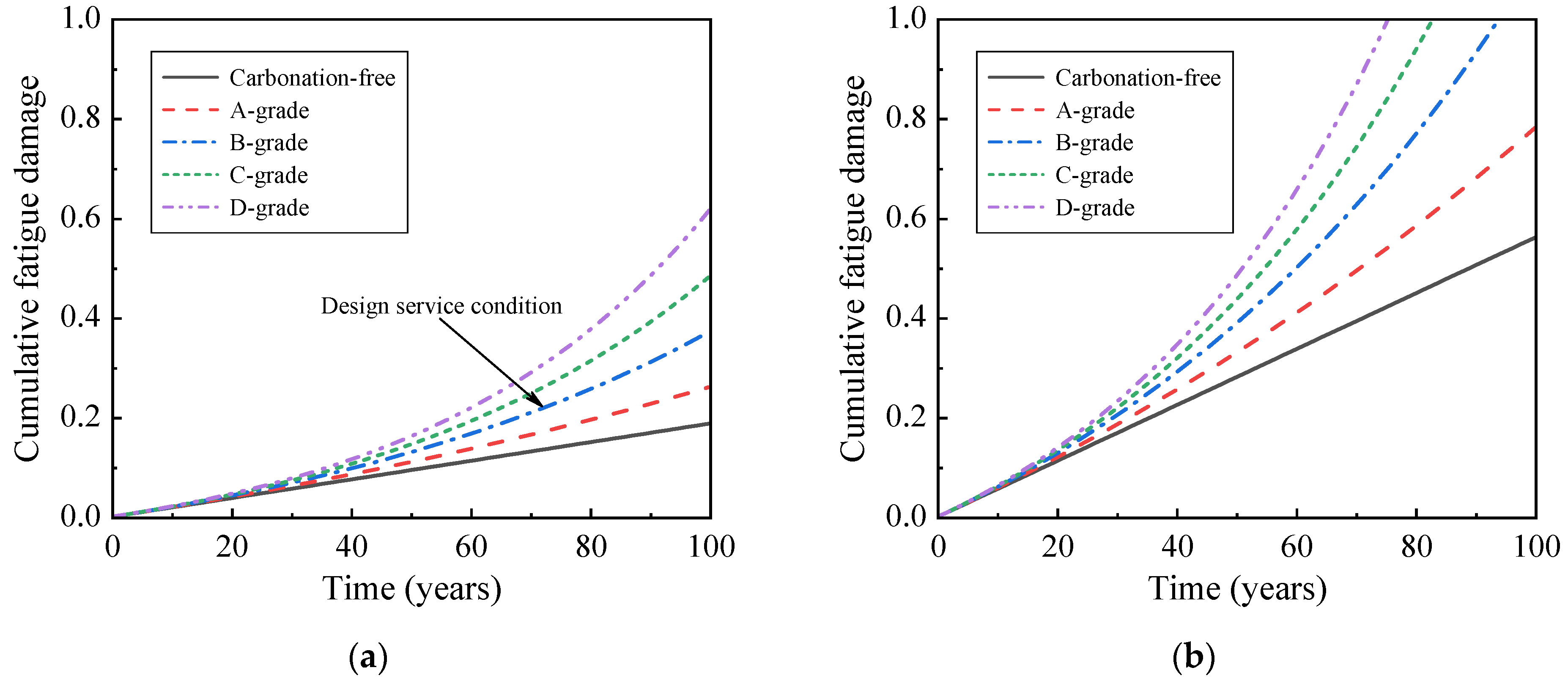

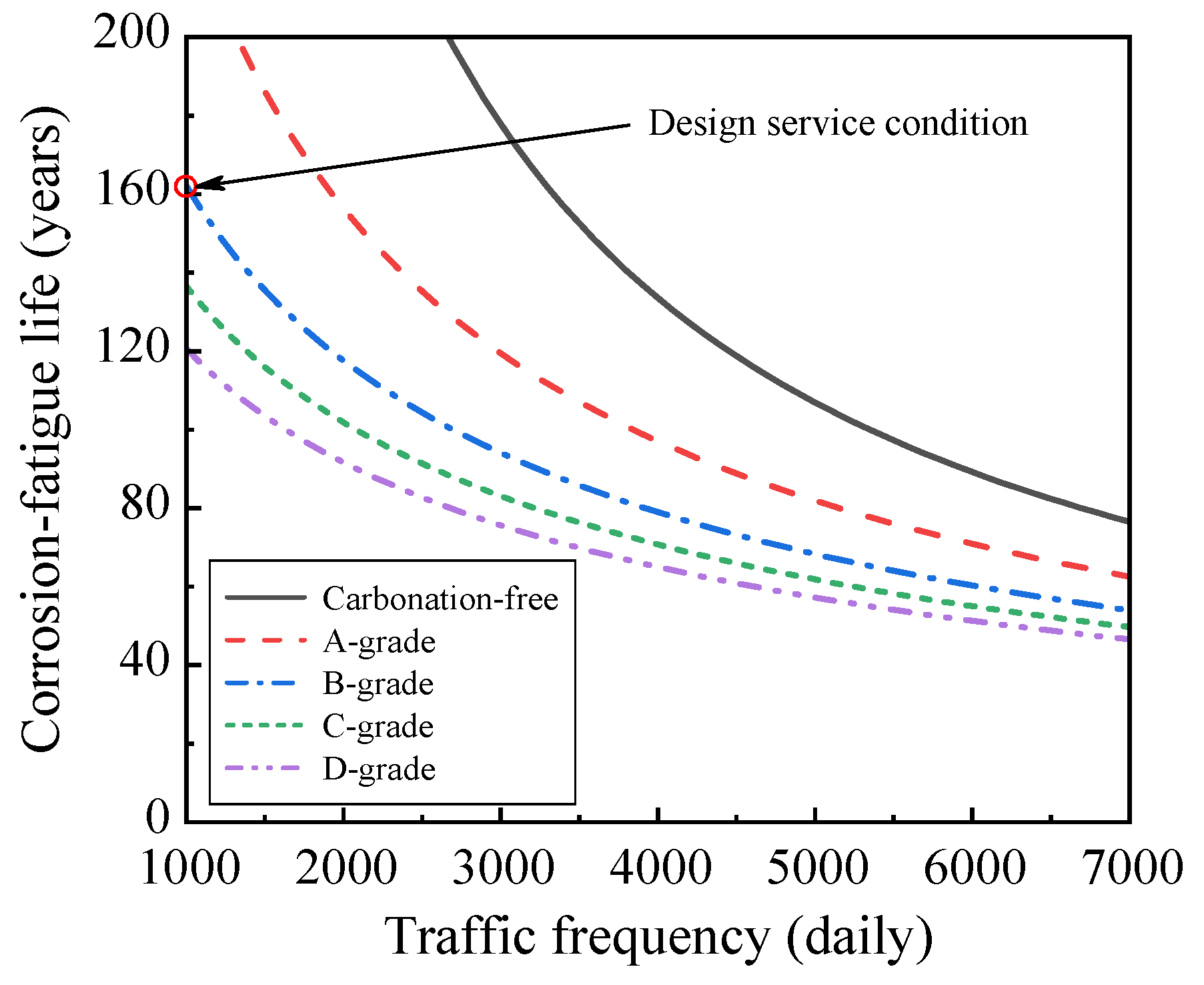

4.3. Effect of Carbonation Environment Grade

4.4. Effect of Environmental Temperature and Relative Humidity

5. Conclusions

- (1)

- The proposed corrosion-fatigue life prediction model can predict the corrosion-fatigue life simply and conveniently for RC structures under coupled carbonation and repeated loading.

- (2)

- Under the design service condition, the corrosion-fatigue performance of the 6 m-span RC slab is satisfactory. The cumulative fatigue damage in the tensile reinforcement at the slab bottom is 0.372 when the bridge is operated to the design service life, and the corrosion-fatigue life of the RC slab is 162.1 years.

- (3)

- The increase of traffic frequency and overloading ratio will reduce the corrosion-fatigue life of the 6 m-span RC slab. When the traffic frequency increases from 1000/day to 7000/day, the corrosion-fatigue life will decrease by 66.86%. When the overloading ratio increases from 0% to 20%, the corrosion-fatigue life will decrease by 58.90%.

- (4)

- The corrosion-fatigue life of the 6 m-span RC slab decreases with the increase of carbonation environment grade. Compared with the carbonation-free environment, the four carbonation environments grades A, B, C, and D will reduce the corrosion-fatigue life by 56.48%, 69.67%, 74.46%, and 77.45%, respectively.

- (5)

- The increase of environmental temperature and relative humidity will reduce the corrosion-fatigue life of the 6 m-span RC slab. Under the four different carbonation environment grades of A to D, the increase of environmental temperature and relative humidity can reduce the corrosion-fatigue life by up to 41.76%, 44.95%, 44.16%, and 41.87%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hrabová, K.; Lehner, P.; Ghosh, P.; Konečný, P.; Teplý, B. Sustainability Levels in Comparison with Mechanical Properties and Durability of Pumice High-Performance Concrete. Appl. Sci. 2021, 11, 4964. [Google Scholar] [CrossRef]

- Bheel, N.; Tafsirojjaman, T.; Liu, Y.; Awoyera, P.; Kumar, A.; Keerio, M.A. Experimental Study on Engineering Properties of Cement Concrete Reinforced with Nylon and Jute Fibers. Buildings 2021, 11, 454. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, W.; Li, S.; Tang, M. Effects of simultaneous fatigue loading and corrosion on the behavior of reinforced beams. Constr. Build. Mater. 2018, 181, 85–93. [Google Scholar] [CrossRef]

- Song, L.; Hou, J.; Yu, Z. Fatigue and post-fatigue monotonic behaviour of partially prestressed concrete beams. Mag. Concrete Res. 2016, 68, 109–117. [Google Scholar] [CrossRef]

- Lantsoght, E.O.L.; Koekkoek, R.; Vander, V.C.; Sliedrecht, H. Fatigue Assessment of Prestressed Concrete Slab-Between-Girder Bridges. Appl. Sci. 2019, 9, 2312. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V. Protection of steel reinforcement for concrete—A review. Corros. Rev. 1998, 16, 317–358. [Google Scholar] [CrossRef]

- Lee, H.; Lee, H.; Min, S.; Lim, S.; Singh, J. Carbonation-induced corrosion initiation probability of rebars in concrete with/without finishing materials. Sustainability 2018, 10, 3814. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Diao, B.; Xu, J.; Zhang, R.; Zhang, W. Effects of the reinforcement ratio and chloride corrosion on the fatigue behavior of RC beams. Int. J. Fatigue 2020, 131, 105299. [Google Scholar] [CrossRef]

- Song, L.; Yu, Z. Fatigue performance of corroded reinforced concrete beams strengthened with CFRP sheets. Constr. Build. Mater. 2015, 90, 99–109. [Google Scholar] [CrossRef]

- Blikharskyy, Y.; Selejdak, J.; Kopiika, N. Corrosion fatigue damages of rebars under loading in time. Materials 2021, 14, 3416. [Google Scholar] [CrossRef]

- Bigaud, D.; Ali, O. Time-variant flexural reliability of RC beams with externally bonded CFRP under combined fatigue-corrosion actions. Reliab. Eng. Syst. Saf. 2014, 131, 257–270. [Google Scholar] [CrossRef] [Green Version]

- Koh, T.; Kim, M.; Yang, K.; Yoon, Y.; Kwon, S. Service life evaluation of RC T-girder under carbonation considering cold joint and loading effects. Constr. Build. Mater. 2019, 226, 106–116. [Google Scholar] [CrossRef]

- Kwon, S.; Na, U. Prediction of durability for RC columns with crack and joint under carbonation based on probabilistic approach. Int. J. Concr. Struct. Mater. 2011, 5, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Z.; Gu, X.; Huang, Q.; Zhang, W. Statistical analysis of concrete carbonation depths considering different coarse aggregate shapes. Constr. Build. Mater. 2019, 229, 116856. [Google Scholar] [CrossRef]

- Song, L.; Liu, J.; Cui, C.; Yu, Z.; Fan, Z.; Hou, J. Carbonation process of reinforced concrete beams under the combined effects of fatigue damage and environmental factors. Appl. Sci. 2020, 10, 3981. [Google Scholar] [CrossRef]

- Liu, Z.; Philip, V.D.H.; Belie, N.D. Effect of the mechanical load on the carbonation of concrete: A review of the underlying mechanisms, test methods, and results. Materials 2021, 14, 4407. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Zhang, R.; Diao, B.; Zhang, W.; Xu, J. Effects of pre-fatigue damage on high-cycle fatigue behavior and chloride permeability of RC beams. Int. J. Fatigue 2019, 122, 9–18. [Google Scholar] [CrossRef]

- Ma, Y.; Xiang, Y.; Wang, L.; Zhang, J.; Liu, Y. Fatigue life prediction for aging RC beams considering corrosive environments. Eng. Struct. 2014, 79, 211–221. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Shao, W.; Zhang, J.; Liao, S.; Fernandez-Steeger, T.M. Service life prediction and lateral bearing capacity analysis of piles considering coupled corrosion-temperature deterioration processes. J. Mar. Sci. Eng. 2021, 9, 614. [Google Scholar] [CrossRef]

- Sun, J.; Ding, Z.; Huang, Q. Corrosion fatigue life prediction for steel bar in concrete based on fatigue crack propagation and equivalent initial flaw size. Constr. Build. Mater. 2019, 195, 208–217. [Google Scholar] [CrossRef]

- Yang, D.; Yi, T.; Li, H. Coupled fatigue-corrosion failure analysis and performance assessment of RC bridge deck slabs. J. Bridge Eng. 2017, 22, 4017077. [Google Scholar] [CrossRef]

- Wang, X. Effects of crack and climate change on service life of concrete subjected to carbonation. Appl. Sci. 2018, 8, 572. [Google Scholar] [CrossRef] [Green Version]

- Marques, P.F.; Costa, A. Service life of RC structures: Carbonation induced corrosion. Prescriptive vs. performance-based methodologies. Constr. Build. Mater. 2010, 24, 258–265. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, P.; Yu, Z. Effects of environmental factors on concrete carbonation depth and compressive strength. Materials 2018, 11, 2167. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Zheng, W.; Zhao, Y.; Zhang, X. Time-varying reliability evaluation of concrete based on carbonation Depth. Appl. Sci. 2019, 9, 5116. [Google Scholar] [CrossRef] [Green Version]

- Rastayesh, S.; Mankar, A.; Dalsgaard Sørensen, J.; Bahrebar, S. Development of stochastic fatigue model of reinforcement for reliability of concrete structures. Appl. Sci. 2020, 10, 604. [Google Scholar] [CrossRef] [Green Version]

- Al-Rousan, R.; Issa, M. Fatigue performance of reinforced concrete beams strengthened with CFRP sheets. Constr. Build. Mater. 2011, 25, 3520–3529. [Google Scholar] [CrossRef]

- Ganesh, P.; Ramachandra Murthy, A. Fatigue performance of damaged RC beams rehabilitated with GGBS based ultra high performance concrete. Int. J. Fatigue 2020, 138, 105707. [Google Scholar] [CrossRef]

- Sun, J.; Ding, Z.; Huang, Q. Development of EIFS-based corrosion fatigue life prediction approach for corroded RC beams. Eng. Fract. Mech. 2019, 209, 1–16. [Google Scholar] [CrossRef]

- Li, S.; Tang, H.; Gui, Q.; Ma, Z. Fatigue behavior of naturally corroded plain reinforcing bars. Constr. Build. Mater. 2017, 152, 933–942. [Google Scholar] [CrossRef]

- Jiang, C.; Huang, Q.; Gu, X.; Zhang, W. Experimental investigation on carbonation in fatigue-damaged concrete. Cement. Concrete Res. 2017, 99, 38–52. [Google Scholar] [CrossRef]

- Jiang, C.; Huang, Q.; Gu, X.; Zhang, W. Modeling the effects of fatigue damage on concrete carbonation. Constr. Build. Mater. 2018, 191, 942–962. [Google Scholar] [CrossRef]

- Zhang, W.; Ye, Z.; Gu, X.; Liu, X.; Li, S. Assessment of fatigue life for corroded reinforced concrete beams under uniaxial bending. J. Struct. Eng. 2017, 143, 4017048. [Google Scholar] [CrossRef]

- Verma, M.; Mishra, S.S. Coupled fatigue-corrosion life estimation of reinforced concrete beam: Numerical versus experimental approach. Struct. Concrete 2019, 20, 2194–2205. [Google Scholar] [CrossRef]

- Bastidas-Arteaga, E.; Bressolette, P.; Chateauneuf, A.; Sanchez-Silva, M. Probabilistic lifetime assessment of RC structures under coupled corrosion-fatigue deterioration processes. Struct. Saf. 2009, 31, 84–96. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Xu, J.; Diao, B.; Jin, L.; Du, X. Fatigue life prediction for the reinforced concrete (RC) beams under the actions of chloride attack and fatigue. Eng. Struct. 2021, 242, 112543. [Google Scholar] [CrossRef]

- Ge, B.; Kim, S. Probabilistic service life prediction updating with inspection information for RC structures subjected to coupled corrosion and fatigue. Eng. Struct. 2021, 238, 112260. [Google Scholar] [CrossRef]

- Song, L.; Cui, C.; Liu, J.; Yu, Z.; Jiang, L. Corrosion-fatigue life assessment of RC plate girder in heavy-haul railway under combined carbonation and train loads. Int. J. Fatigue 2021, 151, 106368. [Google Scholar] [CrossRef]

- Zhang, Q. Mathematical modeling and numerical study of carbonation in porous concrete materials. Appl. Math. Comput. 2016, 281, 16–27. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Fardis, M.N.; Vayenas, C.G. Effect of composition, environmental factors and cement-lime mortar coating on concrete carbonation. Mater. Struct. 1992, 25, 293–304. [Google Scholar] [CrossRef]

- Song, H.; Kwon, S.; Byun, K.; Park, C. Predicting carbonation in early-aged cracked concrete. Cement. Concrete Res. 2006, 36, 979–989. [Google Scholar] [CrossRef]

- GB50010-2010. Code for Design of Concrete Structures; China Architecture & Building Press: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Papadakis, V.G.; Vayenas, C.G.; Fardis, M.N. Fundamental modeling and experimental investigation of concrete carbonation. ACI Mater. J. 1991, 88, 363–373. [Google Scholar]

- Wang, X.; Zhang, W.; Gu, X.; Dai, H. Determination of residual cross-sectional areas of corroded bars in reinforced concrete structures using easy-to-measure variables. Constr. Build. Mater. 2013, 38, 846–853. [Google Scholar] [CrossRef]

- GB/T 51355-2019. Standard for Durability Assessment of Existing Concrete Structures; China Architecture & Building Press: Beijing, China, 2019. (In Chinese) [Google Scholar]

- Li, J. Study on Fatigue Mechanics Behavior of Prestressed Concrete Bridges. Ph.D. Thesis, Central South University, Changsha, China, 2013. (In Chinese). [Google Scholar]

- Miner, M.A. Cumulative damage in fatigue. J. Appl. Mech. 1945, 12, A159–A164. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, G.; Su, X.; Wang, L.; Zhang, J. Experimental and modelling of the flexural performance degradation of corroded RC beams under fatigue load. Constr. Build. Mater. 2018, 191, 994–1003. [Google Scholar] [CrossRef]

- Li, H.; Frangopol, D.M.; Soliman, M.; Xia, H. Fatigue reliability assessment of railway bridges based on probabilistic dynamic analysis of a coupled train-bridge system. J. Struct. Eng. 2016, 142, 4015158. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Ren, W. Time-Dependent Reliability Assessment of Reinforced Concrete Bridge under Fatigue Loadings. China Railw. Sci. 2009, 30, 49–53. (In Chinese) [Google Scholar]

- EN 1992-1-1 Eurocode 2: Design of Concrete Structures. General Rules. Rules for Buildings; European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- Yan, D.; Luo, Y.; Lu, N.; Yuan, M.; Beer, M. Fatigue stress spectra and reliability evaluation of short-to medium-span bridges under stochastic and dynamic traffic loads. J. Bridge Eng. 2017, 22, 04017102. [Google Scholar] [CrossRef] [Green Version]

- Deng, L.; Yan, W.; Nie, L. A simple corrosion fatigue design method for bridges considering the coupled corrosion-overloading effect. Eng. Struct. 2019, 178, 309–317. [Google Scholar] [CrossRef]

- Bastidas-Arteaga, E. Reliability of reinforced concrete structures subjected to corrosion-fatigue and climate change. Int. J. Concr. Struct. Mater. 2018, 12, 77–89. [Google Scholar] [CrossRef] [Green Version]

| Grade of Carbonation Environment | Description | mef |

|---|---|---|

| A | A general indoor environment or a general outdoor environment without rain and pollution. | 1.0–1.2 |

| B | An indoor humid environment, an indoor dry and wet alternative environment, or a slightly polluted environment without rain. | 1.2–2.5 |

| C | An outdoor rain environment, an acid rain environment, a general freezing-thawing environment, or a heavily polluted environment. | 2.5–4.0 |

| D | An outdoor rain environment in a humid and hot area. | 4.0–4.5 |

| Parameter | Value | Description |

|---|---|---|

| fcu | 30 MPa | Cubic compressive strength of concrete |

| fc | 20.1 MPa | Compressive strength of concrete |

| ft | 1.43 MPa | Tensile strength of concrete |

| Ec | 3 × 104 MPa | Elastic modulus of concrete |

| vc | 0.2 | Poisson’s ratio of concrete |

| fy | 335 MPa | Yield strength of tensile reinforcement |

| Es | 2 × 105 MPa | Elastic modulus of tensile reinforcement |

| d0 | 18 mm | Diameter of tensile reinforcement |

| c | 50 mm | Thickness of concrete cover |

| γ | 25 kN/m3 | Weight of reinforced concrete |

| mef | 2.5 | B-grade carbonation environment factor |

| T | 15 °C | Environmental temperature |

| RH | 65% | Environmental relative humidity |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, C.; Song, L.; Liu, J.; Yu, Z. Corrosion-Fatigue Life Prediction Modeling for RC Structures under Coupled Carbonation and Repeated Loading. Mathematics 2021, 9, 3296. https://doi.org/10.3390/math9243296

Cui C, Song L, Liu J, Yu Z. Corrosion-Fatigue Life Prediction Modeling for RC Structures under Coupled Carbonation and Repeated Loading. Mathematics. 2021; 9(24):3296. https://doi.org/10.3390/math9243296

Chicago/Turabian StyleCui, Chenxing, Li Song, Jinliang Liu, and Zhiwu Yu. 2021. "Corrosion-Fatigue Life Prediction Modeling for RC Structures under Coupled Carbonation and Repeated Loading" Mathematics 9, no. 24: 3296. https://doi.org/10.3390/math9243296