Optimizing a Multi-State Cold-Standby System with Multiple Vacations in the Repair and Loss of Units

Abstract

:1. Introduction

2. Assumptions of the System: The State Space

The Assumptions

3. Modelling the System. The Markovian Arrival Process with Marked Arrivals

3.1. The State-Space

- For k = 1, …, R − 1for s = 1,…, k wherefor s < k

- For k = N, …, nfor s = 1,…, k wherefor s < kfor s = N,…, k wherefor s < k

3.2. Modelling the Online Unit

3.3. No Events at a Certain Time (O)

- The internal performance continues in the same phase or changes to another, equally operational state. There is no external shock (), and no inspection takes place (M). The matrix that governs this transition for the online unit is given by .

- The online undergoes an external shock but total failure does not occur (). This external shock might modify the internal performance but does not produce internal failure (). No inspection takes place (M). The matrix is .

- An inspection takes place and the time preceding the next one begins (). The inspector observes that the online unit does not need preventive maintenance and no external shock occurs (). The matrix is .

- An inspection takes place and the time preceding the next one begins (). One external shock also takes place without total failure (). This shock provokes a change in the internal performance without failure and the inspection observes minor damage (). This matrix is .

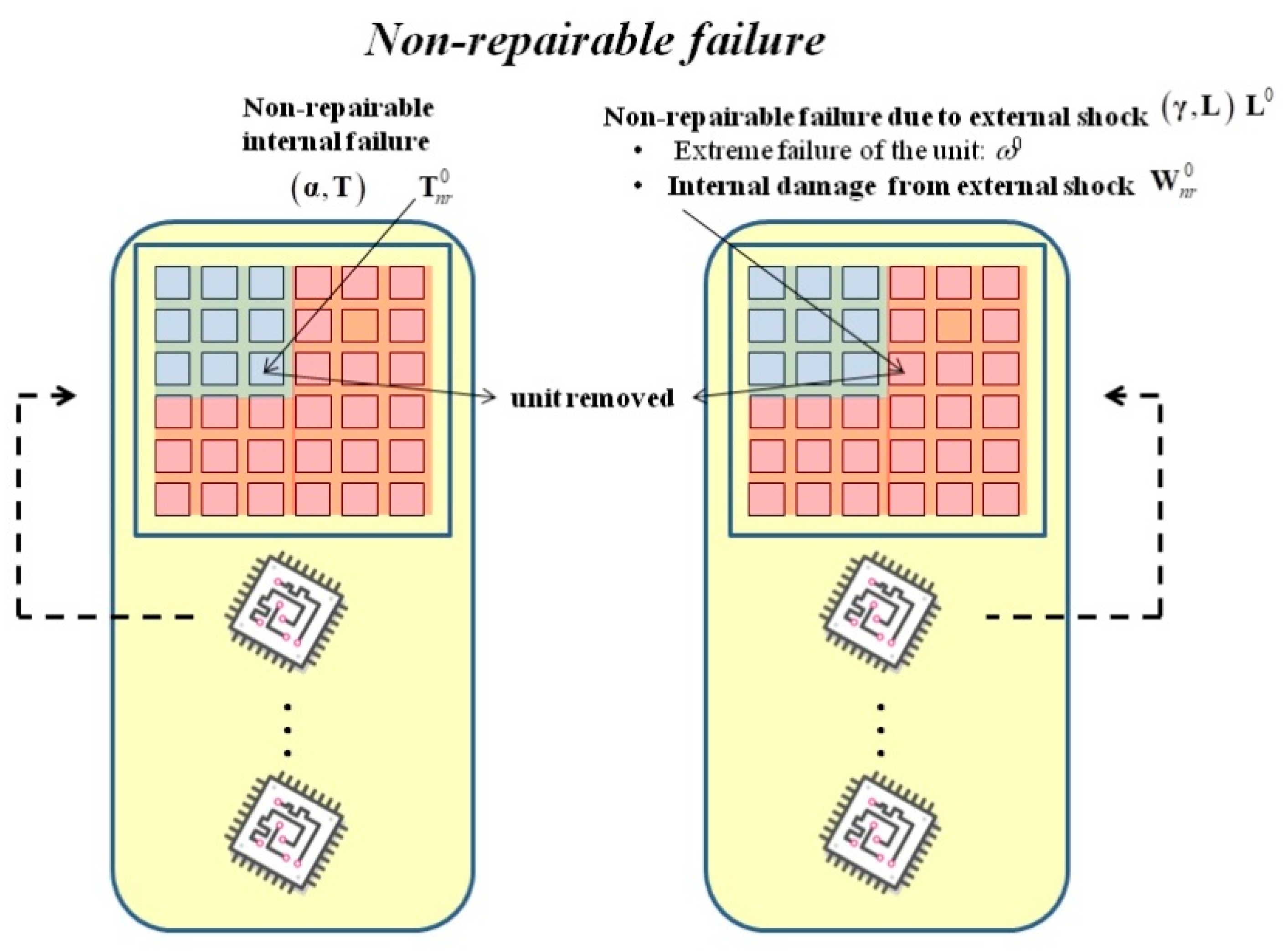

3.4. Non-Repairable Failure (C)

- An internal non-repairable failure occurs with no external shock, .

- An external shock occurs, but does not provoke total failure. This shock provokes a non-repairable internal failure or, irrespective of the shock, the online unit may experience a non-repairable internal failure. The matrix is .

- An external shock provokes total failure. In this case the internal behaviour is irrelevant. The matrix is .

3.5. The Markovian Arrival Process with Marked Arrivals (MMAP)

The Matrices DA and DB

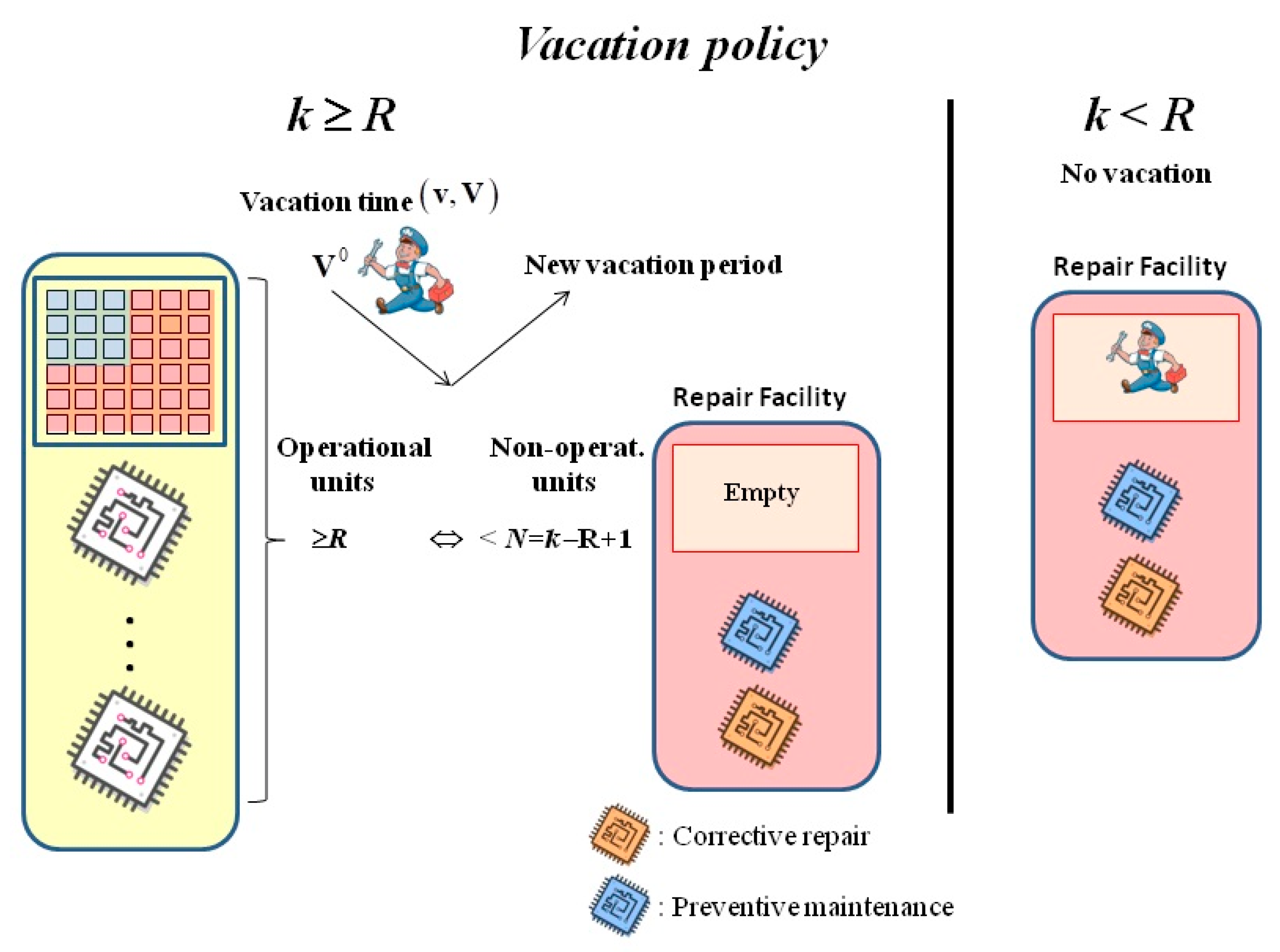

- If the number of units is less than R−1, the repairperson is always in his workplace. Then, for k = 1,…, R−1

- If the number of units is greater or equal than R, the repairperson can be on vacation or not. If the repairperson returns and there are less than R operational units then he remains at his workplace. Given that these events A and B occur when a repairable or major inspection occurs (without returning to work) then, for k = R,…, n (, the limit of the number of units in the repair facility for the repairperson to remain):

4. Measures

4.1. The Transient and the Stationary Distribution

- Proportional time that the system has k units: .

- Proportional time that the repairperson is in the workplace:.

- Proportional time that the repairperson is on vacation:

- Proportional time that the repairperson is working:

- Proportional time that the repairperson is idle:.

4.2. Availability and Mean Times

4.3. Time up to First Time That the System Is Replaced

4.4. Expected Number of Events

4.5. Mean Number of Repairable Failures

4.6. Mean Number of Major Inspections

4.7. Mean Number of Non-Repairable Failures (No Provoking System Failure)

4.8. Mean Number of Times That the Repairperson Resumes to Work

4.9. Mean Number of Times That the Repairperson Resumes and Begins a New Period of Vacation

4.10. Mean Number of New Systems

5. Rewards and Costs

5.1. Net Profit Vector

5.1.1. Online Unit

5.1.2. Repair Facility

5.2. Expected Net Profits and Total Net Profit

5.2.1. Expected Net Profit from the Online Unit Up to Time ν

5.2.2. Expected Cost from Corrective Repair and Preventive Maintenance

5.2.3. Total Net Profit

6. A Numerical Example

6.1. The System

6.2. Costs and Rewards

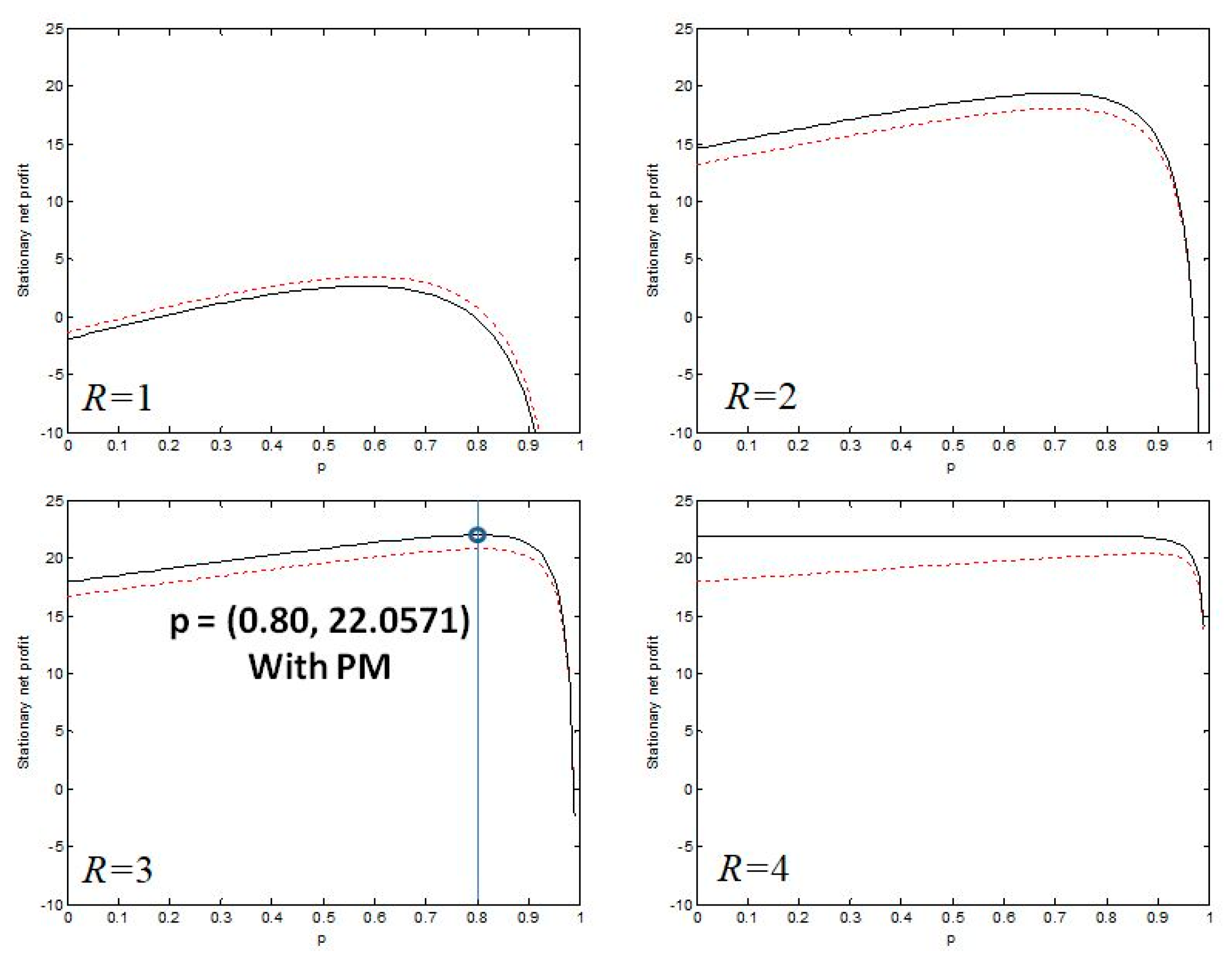

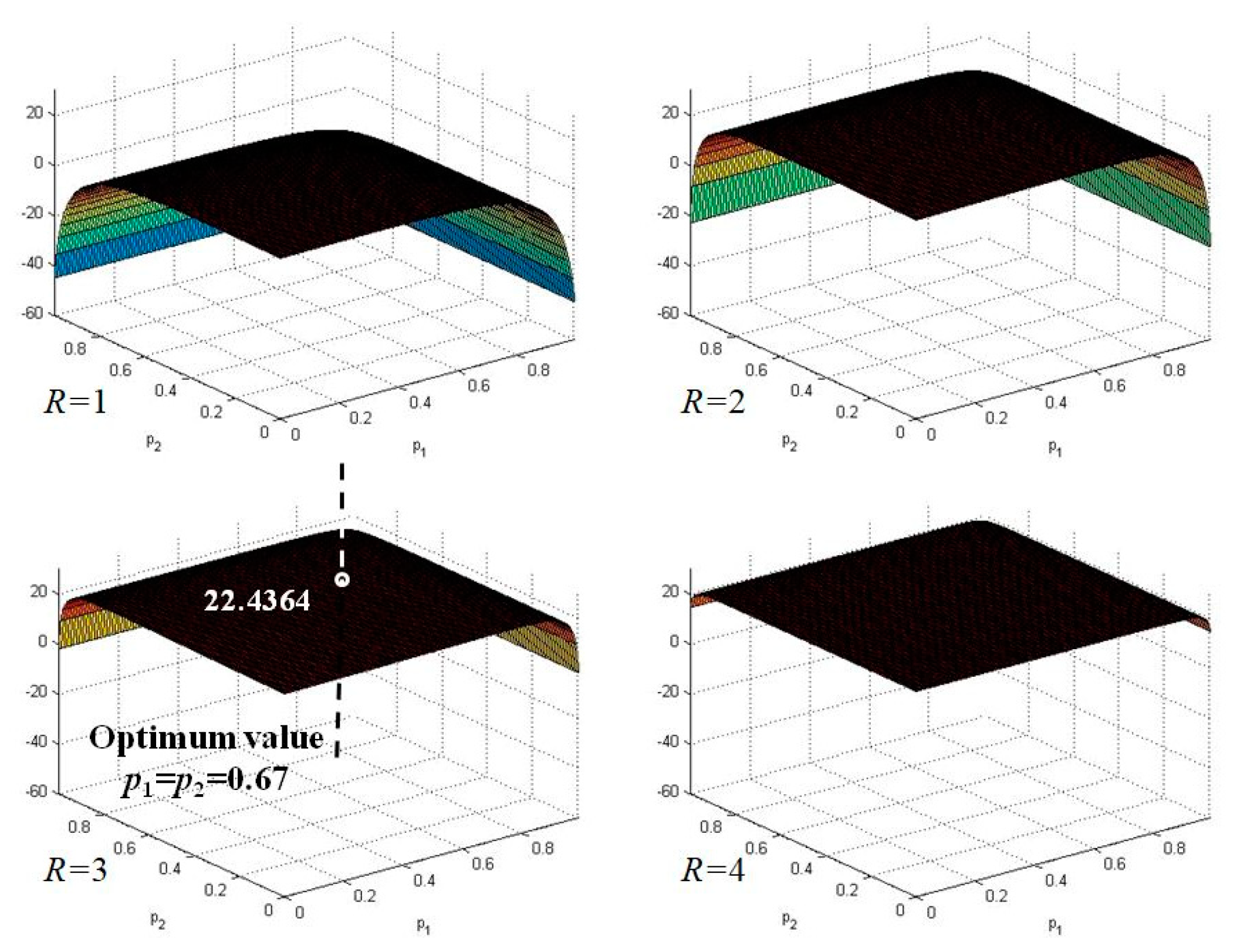

6.3. Optimization Analysis

6.3.1. The Geometric Distribution Case

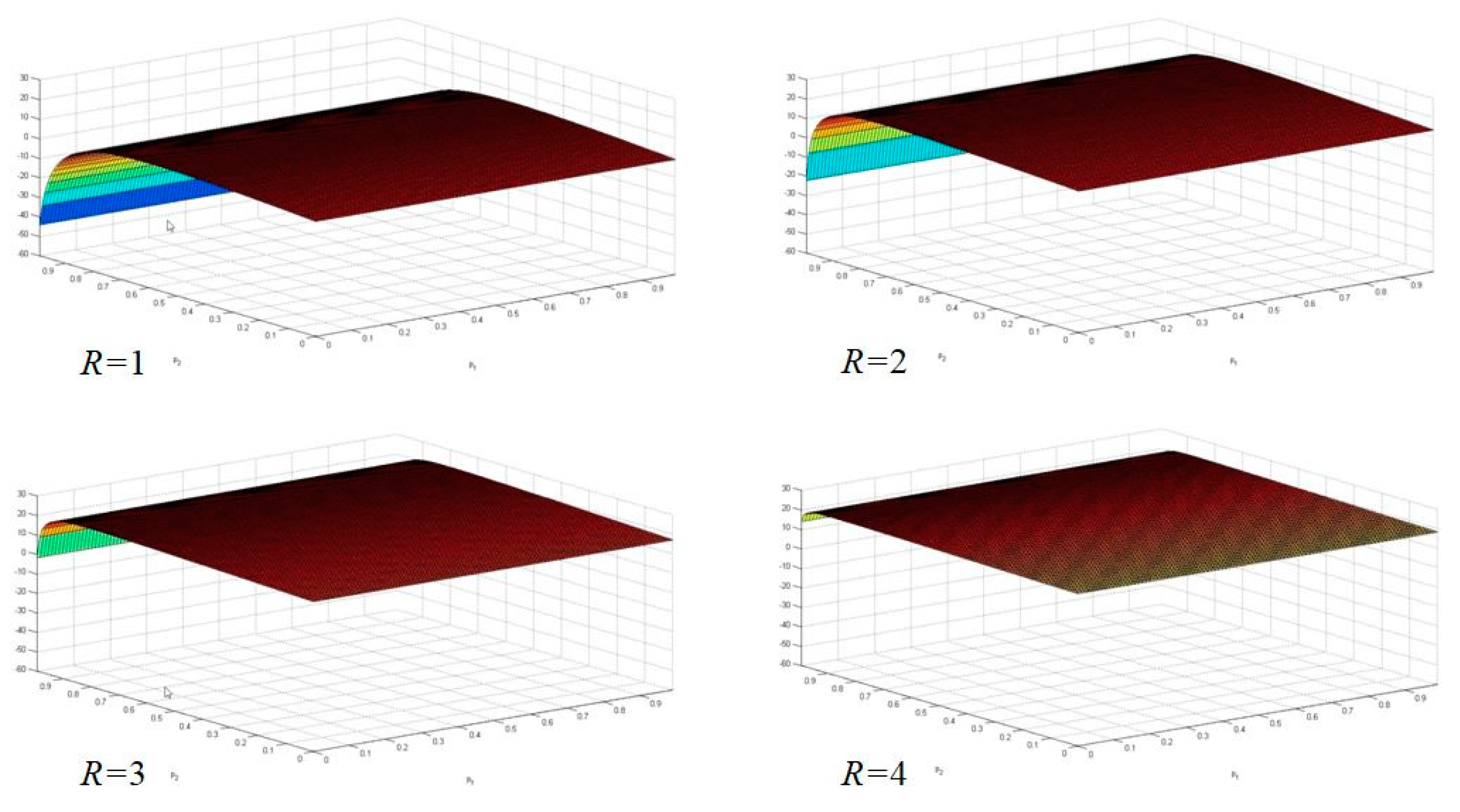

6.3.2. The Generalized Erlang Distribution Case

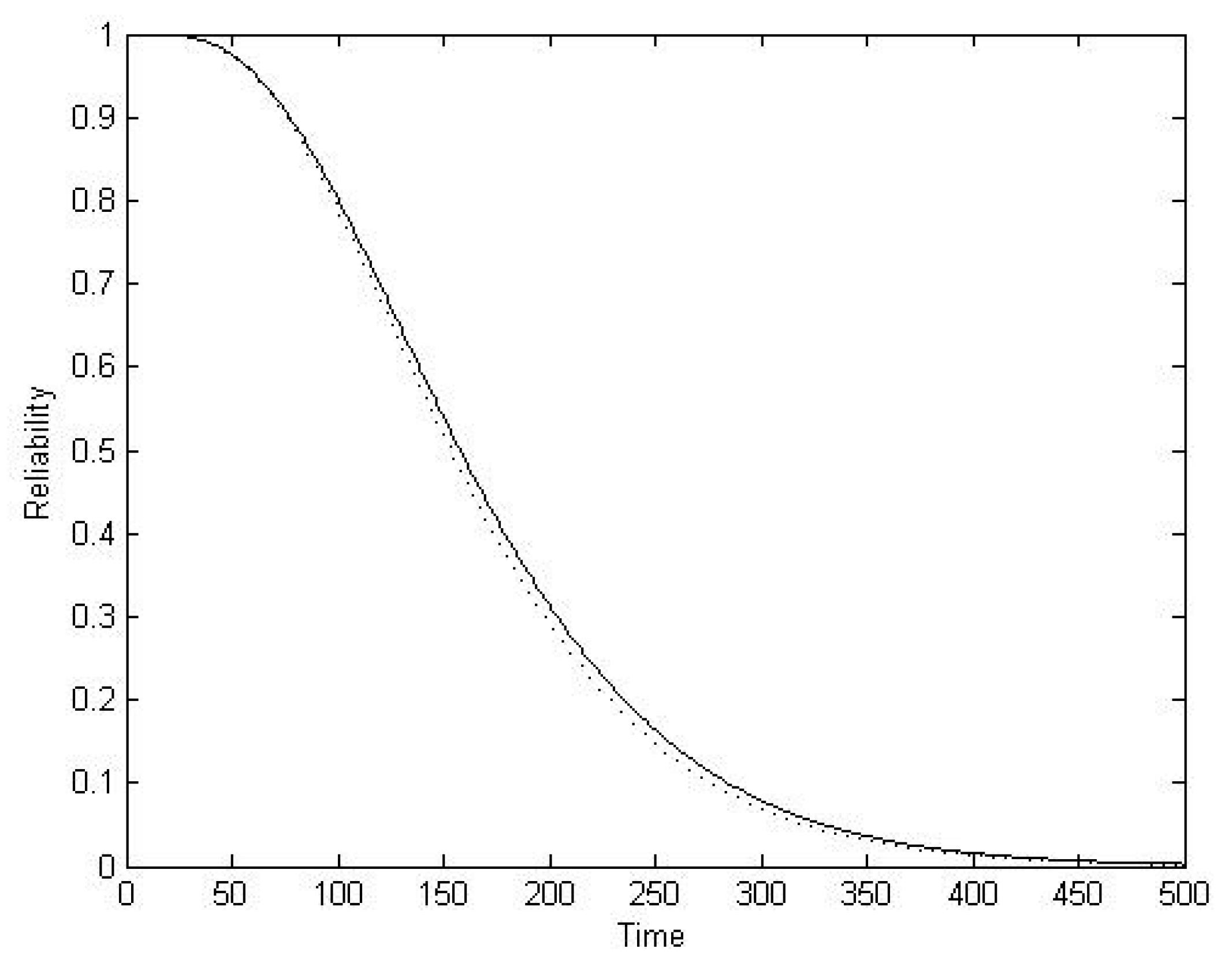

6.4. The Optimum System with the Generalized Erlang Distribution

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Transition Probability Matrix Blocks for the Online Unit Depending on Type of Event

Appendix B

Appendix B.1. Matrices for the Markovian Arrival Process Depending on the Type of Event

Appendix B.2. The Matrix DO

- For k = 1,…, R−1

- For k = R,…, n

Appendix B.3. The Matrix DD

- For k = R, …, n

- For r = N, …, k

Appendix B.4. The Matrix DAD and DBD

- For k = R, …, n

- For r = N−1, …, k−1

Appendix B.5. The Matrix DC

- For k = 2, …, R−1 and k ≠ R ≥ 3

- For k = R ≥ 2

- For k = R+1, …, n with R ≤ n−1

- For r = 0,…, k−1, ,;For r = 1,…, k−1;For r = 2,…, k−1,

Appendix B.6. The Matrix DCD

- For k = R

- The matrix blocks for the case k = R areFor r = 1,…, k−1

- For k = R+1, …, n and R ≤ n−1

- For r = N−1, …, k−1

Appendix B.7. The Matrix DNS

- If R = 1with .

- If R > 1with .

Appendix C

- For r = 0, …, k−R and k ≥ R

- For r = 1,…, k−R−1 and k ≥ R+2;.

- For r = 0, …, k−R−1 and k ≥ R+1

- If R = 1,

References

- Levitin, G.; Xing, L.; Dai, Y. Optimal sequencing of warm standby elements. Comput. Ind. Eng. 2013, 65, 570–576. [Google Scholar] [CrossRef]

- Zhai, Q.; Peng, R.; Xing, L.; Yang, J. Reliability of demand-based warm standby systems subject to fault level coverage. Appl. Stoch. Model. Bus. Ind. 2015, 31, 380–393. [Google Scholar] [CrossRef]

- Cha, J.H.; Finkelstein, M.; Levitin, G. On preventive maintenance of systems with lifetimes dependent on a random shock process. Reliab. Eng. Syst. Saf. 2017, 168, 90–97. [Google Scholar] [CrossRef]

- Levitin, G.; Finkelstein, M.; Dai, Y. Redundancy optimization for series-parallel phased mission systems exposed to random shocks. Reliab. Eng. Syst. Saf. 2017, 167, 554–560. [Google Scholar] [CrossRef]

- Osaki, S.; Asakura, T. A two-unit standby redundant system with repair and preventive maintenance. J. Appl. Probab. 1970, 7, 641–648. [Google Scholar] [CrossRef]

- Nakagawa, T. Maintenance Theory of Reliability; Springer Series in Reliability Engineering; Springer: London, UK, 2005. [Google Scholar] [CrossRef]

- Finkelstein, M.; Cha, J.H.; Levitin, G. A hybrid preventive maintenance model for systems with partially observable degradation. IMA J. Manag. Math. 2020, 31, 345–365. [Google Scholar] [CrossRef]

- Levitin, G.; Xing, L.; Xiang, Y. Optimizing preventive replacement schedule in standby systems with time consuming task transfers. Reliab. Eng. Syst. Saf. 2021, 205, 107227. [Google Scholar] [CrossRef]

- Yang, L.; Ma, X.; Peng, R.; Zhai, Q.; Zhao, Y. A preventive maintenance policy based on dependent two-stage deterioration and external shocks. Reliab. Eng. Syst. Saf. 2017, 160, 201–211. [Google Scholar] [CrossRef]

- Murchland, J.D. Fundamental Concepts and Relations for Reliability Analysis of Multi-State Systems. 1975. Available online: https://inis.iaea.org/search/search.aspx?orig_q=RN:8291134 (accessed on 19 April 2021).

- Levitin, G.; Lisnianski, A. Multi-state system reliability analysis and optimization (universal generating function and genetic algorithm approach). In Handbook of Reliability Engineering; Springer: London, UK, 2003; pp. 61–90. [Google Scholar] [CrossRef]

- Lisnianski, A.; Frenkel, I.; Ding, Y. Multi-State System Reliability Analysis and Optimization for Engineers and Industrial Managers; Springer: London, UK, 2010. [Google Scholar] [CrossRef]

- Neuts, M.F. Matrix-Geometric Solutions in Stochastic Models: An Algorithmic Approach; Dover Publications: Mineola, NY, USA, 1981; p. 332. [Google Scholar]

- Neuts, M.F. A versatile Markovian point process. J. Appl. Probab. 1979, 16, 764–779. [Google Scholar] [CrossRef]

- Artalejo, J.R.; Antonio, G.-C. Markovian arrivals in stochastic modelling: A survey and some new results (invited article with discussion: Rafael Pérez-Ocón, Miklos Telek and Yiqiang Q. Zhao). SORT-Statistics Oper. Res. Trans. 2011, 34. Available online: https://www.raco.cat/index.php/SORT/article/view/217210 (accessed on 19 April 2021).

- He, Q.-M. Fundamentals of Matrix-Analytic Methods; Springer: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Peng, R.; Xiao, H.; Liu, H. Reliability of multi-state systems with a performance sharing group of limited size. Reliab. Eng. Syst. Saf. 2017, 166, 164–170. [Google Scholar] [CrossRef]

- Yu, J.; Zheng, S.; Pham, H.; Chen, T. Reliability modeling of multi-state degraded repairable systems and its applications to automotive systems. Qual. Reliab. Eng. Int. 2018, 34, 459–474. [Google Scholar] [CrossRef]

- Ruiz-Castro, J.E.; Dawabsha, M. A discrete MMAP for analysing the behaviour of a multi-state complex dynamic system subject to multiple events. Discret. Event Dyn. Syst. Theory Appl. 2019, 29, 1–29. [Google Scholar] [CrossRef]

- Ruiz-Castro, J.E. Markov counting and reward processes for analysing the performance of a complex system subject to random inspections. Reliab. Eng. Syst. Saf. 2016, 145, 155–168. [Google Scholar] [CrossRef]

- Ruiz-Castro, J.E. A complex multi-state k-out-of-n: G system with preventive maintenance and loss of units. Reliab. Eng. Syst. Saf. 2020, 197, 106797. [Google Scholar] [CrossRef]

- Ruiz-Castro, J.E.; Dawabsha, M.; Alonso, F.J. Discrete-time Markovian arrival processes to model multi-state complex systems with loss of units and an indeterminate variable number of repairpersons. Reliab. Eng. Syst. Saf. 2018, 174, 114–127. [Google Scholar] [CrossRef]

- Ruiz-Castro, J.E.; Dawabsha, M. A multi-state warm standby system with preventive maintenance, loss of units and an indeterminate multiple number of repairpersons. Comput. Ind. Eng. 2020, 142, 106348. [Google Scholar] [CrossRef]

- Doshi, B.T. Queueing systems with vacations? A survey. Queueing Syst. 1986, 1, 29–66. [Google Scholar] [CrossRef]

- Ke, J.-C.; Wang, K.-H. Vacation policies for machine repair problem with two type spares. Appl. Math. Model. 2007, 31, 880–894. [Google Scholar] [CrossRef]

- Zaiming, L.; Renbin, L. Reliability Analysis of the Repair Facility for an n-Unit Series Repairable System with an Unreliable Repair Facility and Finite Vacations. In Proceedings of the 2010 3rd International Conference on Information Management, Innovation Management and Industrial Engineering, Kunming, China, 26–28 November 2010; IEEE: New York, NY, USA, 2010; pp. 443–448. [Google Scholar] [CrossRef]

- Wu, Q.; Wu, S. Reliability analysis of two-unit cold standby repairable systems under Poisson shocks. Appl. Math. Comput. 2011, 218, 171–182. [Google Scholar] [CrossRef] [Green Version]

- Shrivastava, R.; Kumar Mishra, A. Analysis of Queuing Model for Machine Repairing System with Bernoulli Vacation Schedule. Int. J. Math. Trends Technol. 2014, 10, 85–92. [Google Scholar] [CrossRef] [Green Version]

- Jain, M.; Meena, R.K. Fault tolerant system with imperfect coverage, reboot and server vacation. J. Ind. Eng. Int. 2017, 13, 171–180. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Wu, W.; Tang, Y. Analysis of an k-out-of-n:G system with repairman’s single vacation and shut off rule. Oper. Res. Perspect. 2017, 4, 29–38. [Google Scholar] [CrossRef]

- Ruiz-Castro, J.E. A Complex Multi-State System with Vacations in the Repair. J. Math. Stat. 2019, 15, 225–232. [Google Scholar] [CrossRef]

| Transient Regime (up to Time ν) | Stationary Regime | |

|---|---|---|

| Availability | ||

| Mean time in | ||

| Mean time in | ||

| Mean operational time |

| Without inspection | 0.3043 | 0.2411 | 0.2306 | 0.2240 |

| With inspection | 0.3057 | 0.2410 | 0.2299 | 0.2234 |

| Υnv | Υv | Υw | Υi | Λrep | Λmi | ΛNS | Φ | A |

|---|---|---|---|---|---|---|---|---|

| 0.6806 (0.6826) | 0.3194 (0.3174) | 0.3139 (0.3187) | 0.3667 (0.3639) | 0.0409 (0.0432) | 0.0049 | 0.0058 (0.0059) | 22.4364 (21.2077) | 0.8772 (0.8752) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz-Castro, J.E. Optimizing a Multi-State Cold-Standby System with Multiple Vacations in the Repair and Loss of Units. Mathematics 2021, 9, 913. https://doi.org/10.3390/math9080913

Ruiz-Castro JE. Optimizing a Multi-State Cold-Standby System with Multiple Vacations in the Repair and Loss of Units. Mathematics. 2021; 9(8):913. https://doi.org/10.3390/math9080913

Chicago/Turabian StyleRuiz-Castro, Juan Eloy. 2021. "Optimizing a Multi-State Cold-Standby System with Multiple Vacations in the Repair and Loss of Units" Mathematics 9, no. 8: 913. https://doi.org/10.3390/math9080913