Design Optimization of 3-DOF Redundant Planar Parallel Kinematic Mechanism Based Finishing Cut Stage for Improving Surface Roughness of FDM 3D Printed Sculptures

Abstract

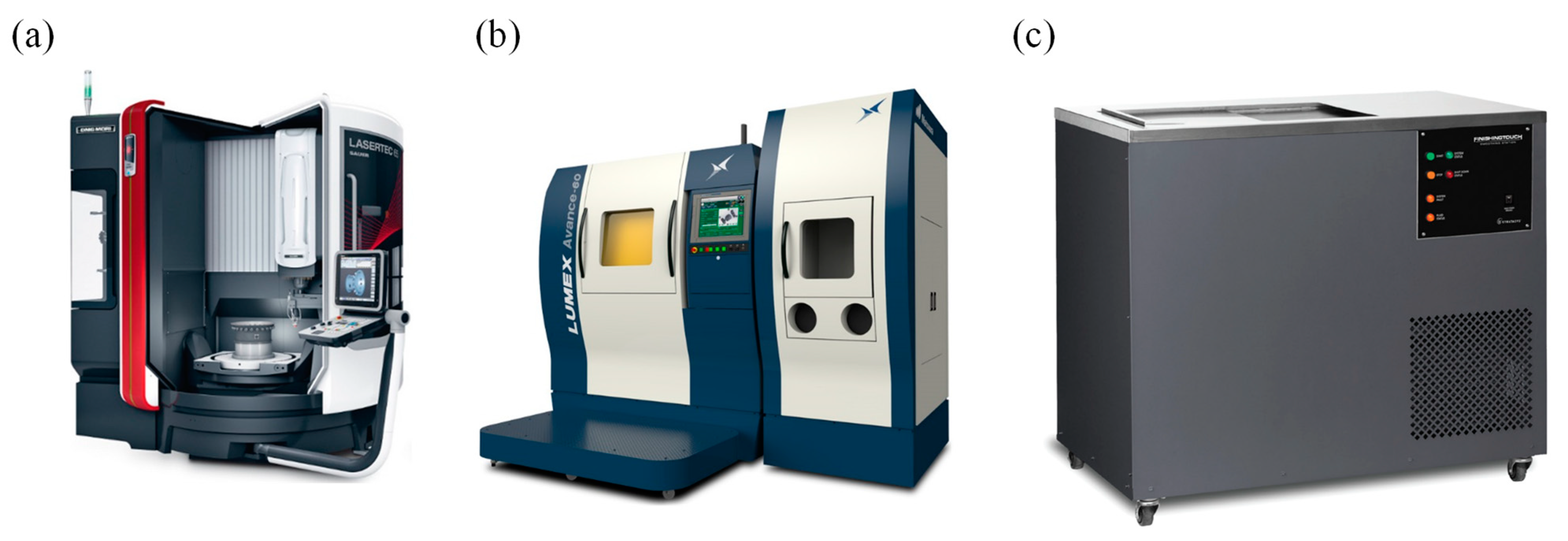

1. Introduction

2. Kinematic Analysis of Hybrid “Serial–Parallel” 3-DOF Parallel Kinematic Mechanism

2.1. Structure of 3-DOF Planar PKM

2.2. Kinematic Analysis

2.2.1. Inverse Kinematic

2.2.2. Forward Kinematic

2.3. Jacobian Analysis

2.3.1. Constrained Jacobian

2.3.2. Forward Jacobian

3. Workspace Analysis

3.1. Workspace Shape and Condition of Initial Design

3.2. Workspace Optimization

3.2.1. Definition of Objective Function

3.2.2. Optimization Result

| Algorithm 1. Optimization algorithm based on genetic algorithm |

| While function value Do { 1. Set the design parameters and position of the end effector for orientation of the end-effector() = −10:1:10 (1) Calculate the workspace by weighted grid (2) Sum the length of links () (3) Calculate the value of objective function end 2. Find the minimum value of objective function } |

3.3. Singularity Analysis

3.3.1. Isotropy and Manipulability

3.3.2. Analysis Results According to the Combination of Active Joints

4. Kinematic Stiffness Analysis

4.1. Kinematic Stiffness Modeling for Nonredundant Case

4.2. Kinematic Stiffness Modeling for 1-DOF Redundancy Case

4.3. Displacement Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Aslani, K.-E.; Chaidas, D.; Kechagias, J.; Kyratsis, P.; Salonitis, K. Quality Performance Evaluation of Thin Walled PLA 3D Printed Parts Using the Taguchi Method and Grey Relational Analysis. J. Manuf. Mater. Process. 2020, 4, 47. [Google Scholar] [CrossRef]

- Aslani, K.E.; Kitsakis, K.; Kechagias, J.D.; Vaxevanidis, N.M.; Manolakos, D.E. On the application of grey Taguchi method for benchmarking the dimensional accuracy of the PLA fused filament fabrication process. SN Appl. Sci. 2020, 2, 1016. [Google Scholar] [CrossRef]

- Chen, S.L.; Chang, T.H.; Inasaki, I.; Liu, Y.-C. Post-Processor Development of a Hybrid TRR-XY Parallel Kinematic Machine Tool. Int. J. Adv. Manuf. Technol. 2002, 20, 259–269. [Google Scholar] [CrossRef]

- Liang, Q.; Zhang, D.; Coppola, G.; Mao, J.; Sun, W.; Wang, Y.; Ge, Y. Design and Analysis of a Sensor System for Cutting Force Measurement in Machining Processes. Sensors 2016, 16, 70. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.; Yu, J.; Lee, D. Calibration of In-Plane Center Alignment Errors in the Installation of a Circular Slide with Machine-Vision Sensor and a Reflective Marker. Sensors 2020, 20, 5916. [Google Scholar] [CrossRef]

- Pateloup, S.; Chanal, H.; Duc, E. Geometric and Kinematic Modelling of a New Parallel Kinematic Machine Tool: The Tripteor X7 Designed by PCI. Adv. Mater. Res. 2010, 112, 159–169. [Google Scholar] [CrossRef]

- Gao, F.; Liu, X.J.; Chen, X. The relationships between the shapes of the workspaces and the link lengths of 3-DOF symmetrical planar parallel manipulators. Mech. Mach. Theory 2001, 36, 205–220. [Google Scholar] [CrossRef]

- Glozman, D.; Shoham, M. Novel 6-DOF parallel manipulator with large workspace. Robotica 2009, 27, 891–895. [Google Scholar] [CrossRef]

- Li, H.; Gosselin, C.M.; Richard, M.J. Determination of maximal singularity-free zones in the workspace of planar three-degree-of-freedom parallel mechanisms. Mech. Mach. Theory 2006, 41, 1157–1167. [Google Scholar] [CrossRef]

- Masouleh, M.T.; Gosselin, C. Determination of singularity-free zones in the workspace of planar 3-PRR parallel mechanisms. J. Mech. Des. 2007, 129, 649–652. [Google Scholar] [CrossRef]

- Abbasnejad, G.; Daniali, H.M.; Kazemi, S.M. A new approach to determine the maximal singularity-free zone of 3-RPR planar parallel manipulator. Robotica 2012, 30, 1005–1012. [Google Scholar] [CrossRef]

- Cha, S.H.; Lasky, T.A.; Velinsky, S.A. Singularity avoidance for the 3-RRR mechanism using kinematic redundancy. In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Rome, Italy, 10–14 April 2007. [Google Scholar]

- Kotlarski, J.; Abdellatif, H.; Ortmaier, T.; Heimann, B. Enlarging the useable workspace of planar parallel robots using mechanisms of variable geometry. In Proceedings of the 2009 ASME/IFToMM International Conference on Reconfigurable Mechanisms and Robots, London, UK, 22–24 June 2009. [Google Scholar]

- Wang, G.; Wang, Y.; Zhao, J.; Chen, G. Process optimization of the serial-parallel hybrid polishing machine tool based on artificial neural network and genetic algorithm. J. Intell. Manuf. 2012, 23, 365–374. [Google Scholar] [CrossRef]

- Wang, M.; Liu, H.; Huang, T.; Chetwynd, D.G. Compliance analysis of a 3-SPR parallel mechanism with consideration of gravity. Mech. Mach. Theory 2015, 84, 99–112. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, J.; Zhang, L.; Li, D.; Li, R. A novel surface self-adapting parallel machine tool for blade machining. In Proceedings of the 2009 International Conference on Mechatronics and Automation, Changchun, China, 9–12 August 2009. [Google Scholar]

- Zhang, H.; Fang, H.; Fang, Y.; Jiang, B. Workspace analysis of a hybrid kinematic machine tool with high rotational applications. Math. Probl. Eng. 2018, 2018, 2607497. [Google Scholar] [CrossRef]

- Kanaan, D.; Wenger, P.; Chablat, D. Kinematic analysis of a serial–parallel machine tool: The VERNE machine. Mech. Mach. Theory 2009, 44, 487–498. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Wang, L.; Li, T.; You, Z. Study on the stiffness of a 5-DOF hybrid machine tool with actuation redundancy. Mech. Mach. Theory 2009, 44, 289–305. [Google Scholar] [CrossRef]

- Xu, P.; Cheung, C.-F.; Li, B.; Ho, L.-T.; Zhang, J.-F. Kinematics analysis of a hybrid manipulator for computer controlled ultra-precision freeform polishing. Rob. Coput. Integr. Manuf. 2017, 44, 44–56. [Google Scholar] [CrossRef]

- Wang, Z.; Ji, S.; Sun, J.; Wan, Y.; Yuan, Q.; Zheng, L. A methodology for determining the maximal regular-shaped dexterous workspace of the PMs. In Proceedings of the 2007 International Conference on Mechatronics and Automation, Harbin, China, 5–8 August 2007. [Google Scholar]

- Lee, D.H.; Kim, J.W.; Seo, T.W. Optimal design of 6-DOF eclipse mechanism based on task-oriented workspace. Robotica 2012, 30, 1041–1048. [Google Scholar] [CrossRef][Green Version]

- Liu, X.J.; Wang, J.; Oh, K.K.; Kim, J. A taking the approach to the design of a DELTA robot with a desired workspace. J. Intell. Rob. Syst. 2004, 39, 209–225. [Google Scholar] [CrossRef]

- Lou, Y.; Liu, G.; Chen, N.; Li, Z. Optimal design of parallel manipulators for maximum effective regular workspace. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems; Institute of Electrical and Electronics Engineers (IEEE), Edmonton, AB, Canada, 2–6 August 2005. [Google Scholar]

- Saglia, J.A.; Dai, J.S.; Caldwell, D.G. Geometry and kinematic analysis of a redundantly actuated parallel mechanism that eliminates singularities and improves dexterity. J. Mech. Des. 2008, 130, 124501. [Google Scholar] [CrossRef]

- Saafi, H.; Laribi, M.A.; Zeghloul, S. Redundantly actuated 3-RRR spherical parallel manipulator used as a haptic device: Improving dexterity and eliminating singularity. Robotica 2015, 33, 1113–1130. [Google Scholar] [CrossRef]

- Huang, T.; Li, M.; Li, Z.; Chetwynd, D.; Whitehouse, D. Optimal kinematic design of 2-DOF parallel manipulators with well-shaped workspace bounded by a specified conditioning index. IEEE Trans. Robot. Autom. 2004, 20, 538–543. [Google Scholar] [CrossRef]

- Lara-Molina, F.A.; Rosario, J.M.; Dumur, D. Multi-objective design of parallel manipulator using global indices. Open Mech. Eng. J. 2010, 4, 37–47. [Google Scholar] [CrossRef][Green Version]

- Huang, M.Z.; Thebert, J.L. A study of workspace and singularity characteristics for design of 3-DOF planar parallel robots. Int. J. Adv. Manuf. Technol. 2010, 51, 789–797. [Google Scholar] [CrossRef]

- Huang, T.; Li, M.; Zhao, X.M.; Mei, J.P.; Chetwynd, D.G.; Hu, S.J. Conceptual design and dimensional synthesis for a 3-DOF module of the TriVariant-a novel 5-DOF reconfigurable hybrid robot. IEEE Trans. Robot. 2005, 21, 449–456. [Google Scholar] [CrossRef]

- Laribi, M.A.; Romdhane, L.; Zeghloul, S. Analysis and dimensional synthesis of the DELTA robot for a prescribed workspace. Mech. Mach. Theory 2007, 42, 859–870. [Google Scholar] [CrossRef]

- Yu, Y.; Li, J.; Li, Y.; Li, S.; Li, H.; Wang, W. Comparative Investigation of Phenomenological Modeling for Hysteresis Responses of Magnetorheological Elastomer Devices. Int. J. Mol. Sci. 2019, 20, 3216. [Google Scholar] [CrossRef] [PubMed]

| Design Parameters | L11 | L12 | L21 | L22 | L31 | A | B |

|---|---|---|---|---|---|---|---|

| Initial value 1 | 0.10 m | 35° | –35° | ||||

| Initial value 2 | 0.11 m | ||||||

| Initial value 3 | 0.12 m | ||||||

| Initial value 4 | 0.13 m | ||||||

| Number of Variables | 7(L11, L12, L21, L22, L31, A, B) |

| Lower bound | 0.04 0.04 0.04 0.04 0.04 20 −20] |

| Upper bound | [0.24 0.24 0.24 0.24 0.24 60 −60] |

| Population type | Double vector |

| Population size | 200 |

| Creation function | Constraint dependent |

| Fitness scaling | Proportional |

| Selection | Uniform |

| Mutation | Adaptive feasible |

| Crossover | Scattered |

| Stopping criteria | Function tolerance: 1 × 10−4 |

| Design Parameters | [m] | [m] | [m] | [m] | [m] | [°] | [°] |

|---|---|---|---|---|---|---|---|

| Initial variables | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 40 | −40 |

| Optimized variables | 0.1092 | 0.1431 | 0.0697 | 0.1995 | 0.1624 | 29.49 | −38.26 |

| Set 1 | Configuration | Set 2 | Configuration |

|---|---|---|---|

| Combination between joints on arc-shaped frame | Combination according to the serial chain structure | ||

| Actuate Set | Nonredundant | Redundant | |||

|---|---|---|---|---|---|

| q1 − q2 − q4 | q1 − q2 − q4 − q7 | ||||

| Index | Isotropy | Manipulability | Isotropy | Manipulability | |

| Angle of end effector | –30° | 0.0045 ± 0.0024 | 0.7473 ± 4.1905 | 0.0619 ± 0.0080 | 0.0446 ± 0.0081 |

| 0° | 0.0050 ± 0.0028 | 1.7840 ± 35.6422 | 0.0632 ± 0.0062 | 0.0475 ± 0.0069 | |

| 30° | 0.0053 ± 0.0034 | 0.9262 ± 5.4762 | 0.0635 ± 0.0066 | 0.0474 ± 0.0081 | |

| Tool Angle | Driving Method | Stiffness | Displacement Amount [] | Torque Norm [Nm] | Actuator Torque [Nm] | Torque Norm at Global Maxima [Nm] | |||

|---|---|---|---|---|---|---|---|---|---|

| Magnitude | Isotropy | ||||||||

| −30° | Nonredundant | 2.76 × 1010 | 5.50 × 10−2 | 78.0 | 1.169 | –1.090 | –0.421 | - | 1.169 |

| 1-redundant | 4.21 × 1010 | 3.13 × 10−2 | 46.1 | 0.920 | –0.562 | –0.552 | 0.474 | 0.926 | |

| 0° | Nonredundant | 3.17 × 1010 | 6.86 × 10−2 | 70.9 | 1.037 | –0.959 | –0.393 | - | 1.037 |

| 1-redundant | 5.32 × 1010 | 5.86 × 10−2 | 40.2 | 0.822 | –0.477 | –0.556 | –0.373 | 0.834 | |

| 30° | Nonredundant | 3.20 × 1010 | 4.72 × 10−4 | 101.9 | 1.289 | –1.280 | 0.128 | - | 1.289 |

| 1-redundant | 5.97 × 1010 | 4.14 × 10−4 | 33.2 | 0.739 | –0.473 | –0.472 | –0.316 | 0.739 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, M.; Jeong, H.; Lee, D. Design Optimization of 3-DOF Redundant Planar Parallel Kinematic Mechanism Based Finishing Cut Stage for Improving Surface Roughness of FDM 3D Printed Sculptures. Mathematics 2021, 9, 961. https://doi.org/10.3390/math9090961

Lee M, Jeong H, Lee D. Design Optimization of 3-DOF Redundant Planar Parallel Kinematic Mechanism Based Finishing Cut Stage for Improving Surface Roughness of FDM 3D Printed Sculptures. Mathematics. 2021; 9(9):961. https://doi.org/10.3390/math9090961

Chicago/Turabian StyleLee, Minbok, Hyungjin Jeong, and Donghun Lee. 2021. "Design Optimization of 3-DOF Redundant Planar Parallel Kinematic Mechanism Based Finishing Cut Stage for Improving Surface Roughness of FDM 3D Printed Sculptures" Mathematics 9, no. 9: 961. https://doi.org/10.3390/math9090961

APA StyleLee, M., Jeong, H., & Lee, D. (2021). Design Optimization of 3-DOF Redundant Planar Parallel Kinematic Mechanism Based Finishing Cut Stage for Improving Surface Roughness of FDM 3D Printed Sculptures. Mathematics, 9(9), 961. https://doi.org/10.3390/math9090961