Performance Improvement of a Negative-Pressurized Isolation Room for Infection Control

Abstract

:1. Introduction

2. Negative-Pressurized Isolation Room

2.1. System Description

2.2. CFD Simulation and Improvement Strategy

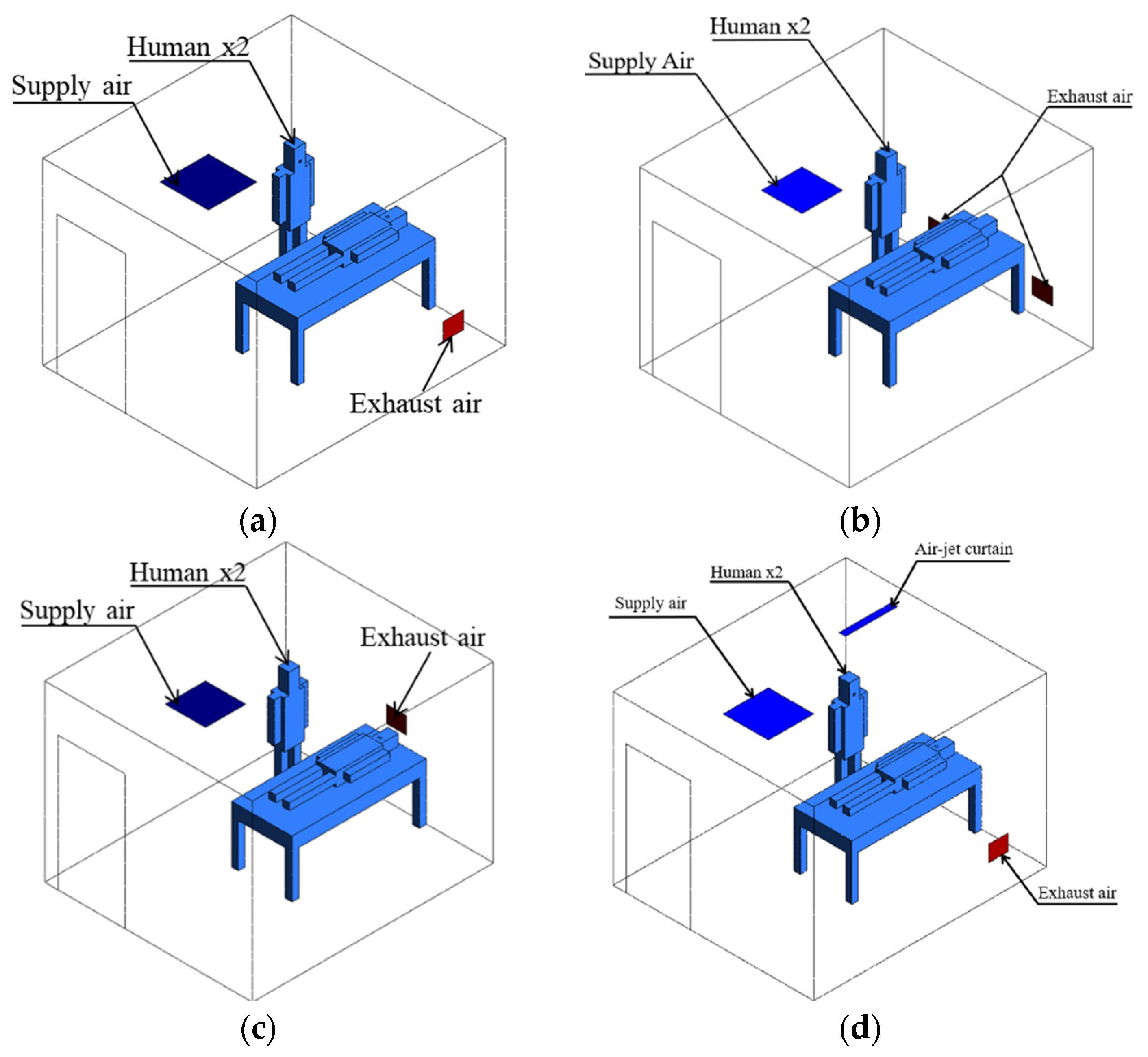

- Case 1: Ceiling supply air passes across the patient, and right wall-mounted exhaust air grilles are located about 40 mm above the floor. This is the base existing model for the negative-pressurized isolation model (Figure 2a).

- Case 2: Two wall-mounted exhaust air grilles are located beside the patient’s head at 25 mm above the floor (Figure 2b).

- Case 3: Wall-mounted exhaust air grilles are located behind the patient’s head at 1000 mm above the floor (Figure 2c).

- Case 4: Case 1 with an additional ceiling-mounted air-jet curtain, which is placed between the patient’s bed and the medical staff (Figure 2d).

2.3. Boundary Conditions and Initial Conditions

2.4. Grid Independence Test

3. Results and Discussion

3.1. Arrangement of Exhaust Air Grilles

3.2. Air-Jet Curtain

3.3. Cough Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Van Doremalen, N.; Bushmaker, T.; Morris, D.H. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N. Engl. J. Med. 2020, 382, 1564–1567. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ning, Z.; Chen, Y. Aerodynamic analysis of SARS-CoV-2 in two Wuhan hospitals. Nature 2020, 582, 557–560. [Google Scholar] [CrossRef]

- Scientific Brief: SARS-CoV-2 Transmission. Available online: https://www.cdc.gov/coronavirus/2019-ncov/science/science-briefs/sars-cov-2-transmission.html (accessed on 7 May 2021).

- Induri, S.N.R.; Chun, Y.C.; Chun, J.C.; Fleisher, K.E.; Glickman, R.S.; Xu, F.; Ioannidou, E.; Li, X.; Saxena, D. Protective measures against COVID-19: Dental practice and infection control. Healthcare 2021, 9, 679. [Google Scholar] [CrossRef] [PubMed]

- Kalliomäki, P.; Hagström, K.; Itkonen, H.; Grönvall, I.; Koskela, H. Effectiveness of directional airflow in reducing containment failures in hospital isolation rooms generated by door opening. Build. Environ. 2019, 158, 83–93. [Google Scholar] [CrossRef]

- ANSI/ASHRAE/ASHE Standard-170. Ventilation of Health Care Facilities; American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2017. [Google Scholar]

- Centers for Disease Control and Prevention (CDC). Guidelines for Preventing the Transmission of Mycobacterium Tuberculosis in Health-Care Settings; Department of Health and Human Services: Atlanta, GA, USA, 2005. [Google Scholar]

- Institute of Occupational Safety and Health (IOSH). Recommended Guidelines of Isolation Ward for SARS Patients; Institute of Occupational Safety and Health: Taipei, Taiwan, 2003. [Google Scholar]

- Wang, C.H.; Kuo, N.W. Post-occupancy evaluation of negative-pressure isolation rooms: Using the balanced scorecard framework. J. Archit. Plan. Res. 2009, 26, 1–13. [Google Scholar]

- Li, Y.; Leung, G.M.; Tang, J.W. Role of ventilation in airborne transmission of infectious agents in the built environment—A multidisciplinary systematic review. Indoor Air 2007, 17, 2–18. [Google Scholar] [CrossRef] [PubMed]

- Borro, L.; Mazzei, L.; Raponi, M.; Piscitelli, P.; Miani, A.; Secinaro, A. The role of air conditioning in the diffusion of SARS-CoV-2 in indoor environments: A First computational fluid dynamic model, based on investigations performed at the Vatican State Children’s hospital. Environ. Res. 2021, 193, 110343. [Google Scholar] [CrossRef] [PubMed]

- Kao, P.H.; Yang, R.J. Virus diffusion in isolation rooms. J. Hosp. Infect. 2005, 62, 338–345. [Google Scholar] [CrossRef]

- Cho, J.K. Investigation on the contaminant distribution with improved ventilation system in hospital isolation rooms: Effect of supply and exhaust air diffuser configurations. Appl. Therm. Eng. 2019, 148, 208–218. [Google Scholar] [CrossRef]

- Khankari, K. Airflow path matters: Patient room HVAC. ASHRAE J. 2016, 58, 16–26. [Google Scholar]

- Wang, F.J.; Huang, J.S. Performance improvement analysis for a negative-pressurized biosafety level laboratory. In Proceedings of the 4th International Conference on Building Energy, Environment, Melbourne, Australia, 5–9 February 2018. [Google Scholar]

- Huang, J.M.; Tsao, S.M. The Influence of air motion on bacteria removal in negative pressure isolation rooms. HVAC&R Res. 2005, 11, 563–585. [Google Scholar]

- Pereira, M.L.; Tribess, A. A review of air distribution patterns in surgery rooms under infection control focus. Appl. Therm. Eng. 2005, 4, 113–121. [Google Scholar] [CrossRef]

- Cao, G.; Liu, S.; Boor, B.; Novoselac, A. Dynamic interaction of a downward plane jet and a cough jet with respect to particle transmission: An analytical and experimental study. J. Occup. Environ. Hyg. 2017, 14, 620–633. [Google Scholar] [CrossRef]

- Wang, H.; Qian, H.; Zhou, R.; Zheng, X. A novel circulated air curtain system to confine the transmission of exhaled contaminants: A numerical and experimental investigation. Build. Simul. 2020, 13, 1425–1437. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.; Qian, H.; Ma, J.; Zhou, R.; Zheng, X. Using air curtains to reduce short-range infection risk in consulting ward: A numerical investigation. Build. Simul. 2021, 14, 325–335. [Google Scholar] [CrossRef]

- ANSYS. Ansys Fluent, Workbench 2020 R2. Available online: https://www.scribd.com/document/478910198/ANSYS-Fluent-Tutorial-Guide-2020-R2-pdf (accessed on 6 March 2021).

- Siobal, M.S. Monitoring exhaled carbon dioxide. Respir. Care 2016, 61, 1397–1416. [Google Scholar] [CrossRef] [Green Version]

- Spagnoli, G.; Tranfo, G.; Moccaldi, R. Air Quality in Operating Theatres: The Occupational Point of View; Maroni, M., Ed.; Springer: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Schell, M.; Hinthout, D. Demand control ventilation using CO2. ASHRAE J. 2001, 43, 18–29. [Google Scholar]

- Shih, Y.C.; Chiu, C.C.; Wang, O. Dynamic airflow simulation within an isolation room. Build. Environ. 2007, 42, 3194–3209. [Google Scholar] [CrossRef]

- Memarzadeh, F. Improved strategy to control aerosol-transmitted infections in a hospital suite. ASHRAE Trans. 2011, 117, 1–11. [Google Scholar]

- Pantelic, J. Designing for airborne infection control. ASHRAE J. 2019, 61, 64–65. [Google Scholar]

- Zhang, Y.; Feng, G.; Kang, Z.; Bi, Y.; Cai, Y. Numerical simulation of coughed droplets in conference room. Procedia Eng. 2017, 205, 302–308. [Google Scholar] [CrossRef]

- Wei, J.; Li, Y. Human cough as a two-stage jet and its role in particle transport. PLoS ONE 2017, 12, e0169235. [Google Scholar]

- VanSciver, M.; Miller, S.; Hertzberg, J. Particle image velocimetry of human cough. Aerosol. Sci. Technol. 2011, 45, 415–422. [Google Scholar] [CrossRef]

| Parameters | Supply Air | Exhaust Air | Exhaled Air by Patient |

|---|---|---|---|

| Velocity (m/s) | 0.3 | - | 0.18 |

| Temperature (°C) | 22 | 24 | 37 |

| CO2 Concentration (ppm) | 400 | - | 38,000 |

| Pressure (Pa) | - | −15 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Chaerasari, C.; Rakshit, D.; Permana, I.; Kusnandar. Performance Improvement of a Negative-Pressurized Isolation Room for Infection Control. Healthcare 2021, 9, 1081. https://doi.org/10.3390/healthcare9081081

Wang F, Chaerasari C, Rakshit D, Permana I, Kusnandar. Performance Improvement of a Negative-Pressurized Isolation Room for Infection Control. Healthcare. 2021; 9(8):1081. https://doi.org/10.3390/healthcare9081081

Chicago/Turabian StyleWang, Fujen, Citra Chaerasari, Dibakar Rakshit, Indra Permana, and Kusnandar. 2021. "Performance Improvement of a Negative-Pressurized Isolation Room for Infection Control" Healthcare 9, no. 8: 1081. https://doi.org/10.3390/healthcare9081081

APA StyleWang, F., Chaerasari, C., Rakshit, D., Permana, I., & Kusnandar. (2021). Performance Improvement of a Negative-Pressurized Isolation Room for Infection Control. Healthcare, 9(8), 1081. https://doi.org/10.3390/healthcare9081081